Ultrahigh-viscosity porous antiskid asphalt drainage surface layer

An ultra-high viscosity and ultra-high technology, applied in the field of traffic engineering, can solve the problems of poor anti-fatigue performance and high cost, and achieve the effects of excellent anti-fatigue performance, increased service life, and improved anti-fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

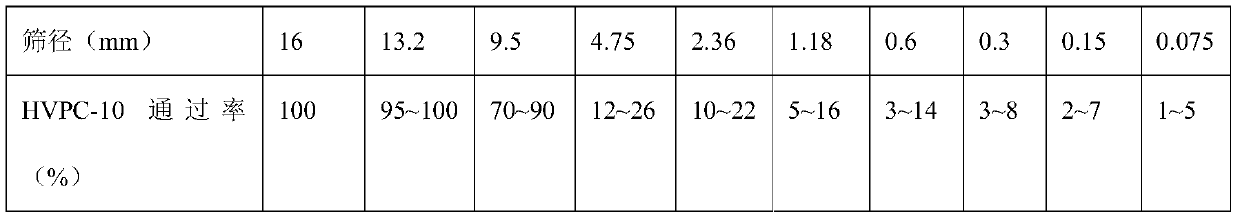

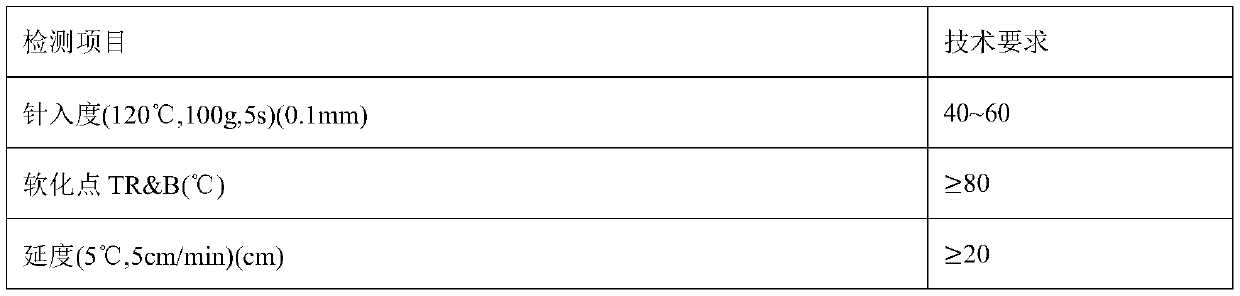

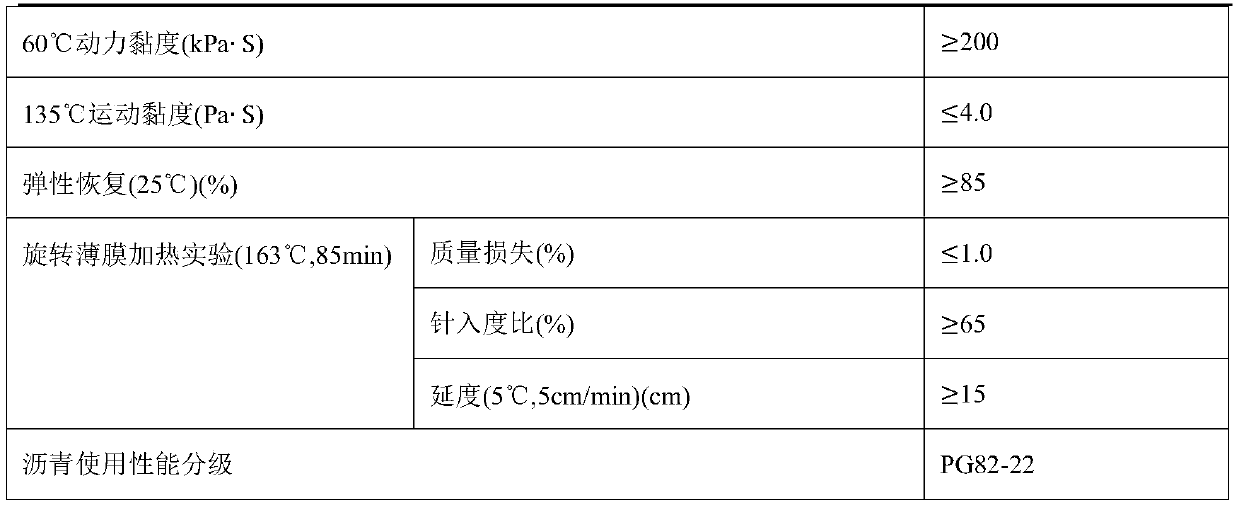

[0046] Performance of ultra-high viscosity asphalt binder:

[0047]

[0048] Use third-grade aggregate and mineral powder (≤0.075mm), control the passing rate of the key sieve hole 2.36mm, and choose three groups of gradations of 11.7%, 15.2%, and 17.4% as the initial gradation.

[0049] According to the optimal asphalt dosage of 7-7.5%, by the relationship

[0050] Asphalt dosage = asphalt ratio / (1+ asphalt ratio)

[0051] The mass percentage of asphalt and aggregate is in the range of 7.5-8%.

[0052] Therefore, in this embodiment, the asphalt ratio of 7.5% is selected as the asphalt ratio of the preliminary gradation. The Marshall specimens were compacted 50 times on each side, and the volumetric method was used to measure the bulk density of the asphalt mixture. The Marshall test results are shown in the table below.

[0053]

[0054]

[0055] With 14% as the target void ratio, the following gradation is selected as the design gradation:

[0056] M...

Embodiment 2

[0064] The properties of ultra-high viscosity asphalt binder are the same as in Example 1.

[0065] Three grades of aggregate and mineral powder are used to control the passing rate of the key sieve hole of 2.36mm, and three groups of gradations are selected as the initial gradation of 13.2%, 16.9%, and 19.4%.

[0066] Same as in Example 1, the asphalt ratio of 7.5% is used as the ratio of asphalt in the initial gradation. The Marshall specimens were compacted 50 times on each side, and the volumetric method was used to measure the bulk density of the asphalt mixture. The Marshall test results are shown in the table below.

[0067]

[0068] With 14% as the target void ratio, the following gradation is selected as the design gradation:

[0069]

[0070] Get Marshall test piece and carry out performance test with embodiment 1, the result is as follows:

[0071]

[0072]

[0073] Drainage performance: Same as Example 1, evaluate the drainage performance of ultra-hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com