Cold-mix semi-flexible composite pavement material and preparation method thereof

A composite pavement, semi-flexible technology, applied in the field of modern pavement engineering construction, can solve the problems of plate cracking, insufficient rigidity, short service life, etc., and achieve the effects of good low temperature deformation capacity, simple construction process and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

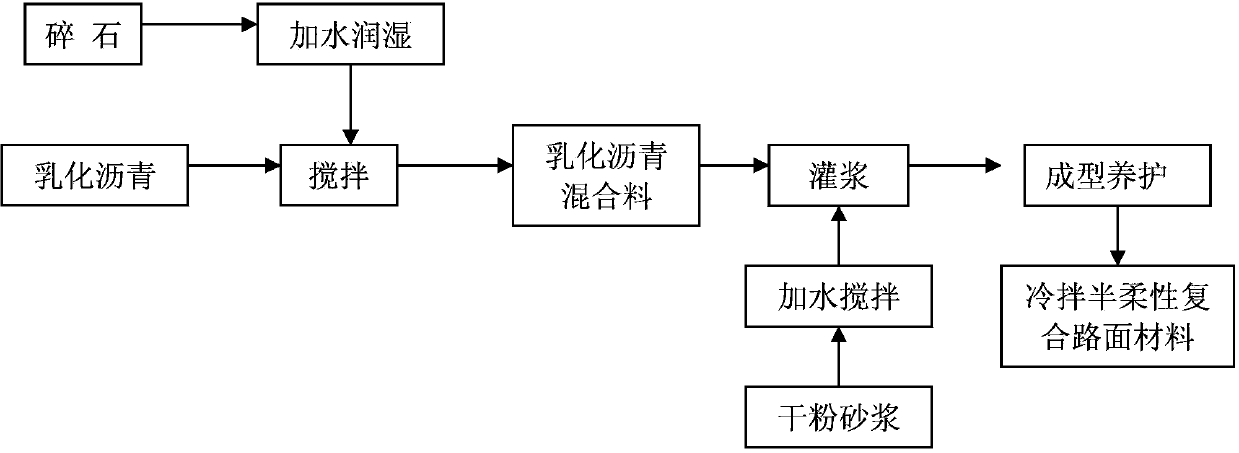

Method used

Image

Examples

Embodiment 1

[0030] Moisten 90% of the crushed stone with 1% of water by mass, add 6% of emulsified asphalt and mix well, and finally add 3% of mineral powder and fully mix to form emulsified asphalt Mixture;

[0031] The cement mortar used for grouting is mixed with dry powder mortar and water. Add water accounting for 19% of the mass percentage of cement mortar into the mixing pot of the cement mortar mixer, stir at a low speed, and then add dry powder cement mortar accounting for 81% of the cement mortar mass. Add it to the mixing pot, after the water and the dry cement mortar are evenly mixed, stir at high speed for 240 seconds;

[0032] The composition and mass ratio of dry powder mortar are: cement 46.5%, superfine quartz sand 25%, fly ash 10%, metakaolin 12%, expansion agent 6%, early strength agent 0.3%, dry powder superplasticizer 0.2%;

[0033] Pour the prepared cement mortar into the surface of the mixture, and rely on the self-weight and super fluidity of the cement mortar to ...

Embodiment 2

[0041] Moisten 90% of the crushed stone with 1.5% of water by mass, add 5% of emulsified asphalt and mix well, and finally add 3.5% of mineral powder and fully mix to form emulsified asphalt Mixture;

[0042] The cement mortar used for grouting is made by mixing dry powder mortar with water. Add water accounting for 20% of the mass percentage of cement mortar into the mixing pot of the cement mortar mixer, stir at a low speed, and then add dry powder cement mortar accounting for 80% of the mass percentage of cement mortar Add it to the mixing pot, after the water and the dry cement mortar are evenly mixed, stir at high speed for 300 seconds;

[0043] The composition and mass ratio of dry powder mortar are: cement 46.5%, superfine quartz sand 25%, fly ash 10%, metakaolin 12%, expansion agent 6%, early strength agent 0.3%, dry powder superplasticizer 0.2%;

[0044] The surface of the prepared cement mortar emulsified asphalt mixture, relying on the self-weight of the cement mor...

Embodiment 3

[0052] Moisten 90% of the crushed stone with 1.5% of water by mass, add 5.5% of emulsified asphalt and mix well, and finally add 4% of mineral powder and fully mix to form emulsified asphalt Mixture;

[0053] The cement mortar used for grouting is made by mixing dry powder mortar with water. Add water accounting for 20% of the mass percentage of cement mortar into the mixing pot of the cement mortar mixer, stir at a low speed, and then add dry powder cement mortar accounting for 80% of the mass percentage of cement mortar Add it to the mixing pot, after the water and the dry powder cement mortar are evenly mixed, stir at high speed for 360 seconds;

[0054]The composition and mass ratio of dry powder mortar are: cement 46.5%, superfine quartz sand 25%, fly ash 10%, metakaolin 12%, expansion agent 6%, early strength agent 0.3%, dry powder superplasticizer 0.2%;

[0055] The surface of the prepared cement mortar emulsified asphalt mixture, relying on the self-weight of the ceme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com