Composition design method of recycled ogfc mixture

A design method and technology of mixed materials, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of not being able to restore and regenerate old materials, the potential value of unused old materials, etc., and achieve cost reduction , Improve the water damage resistance, the effect of simple composition design method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

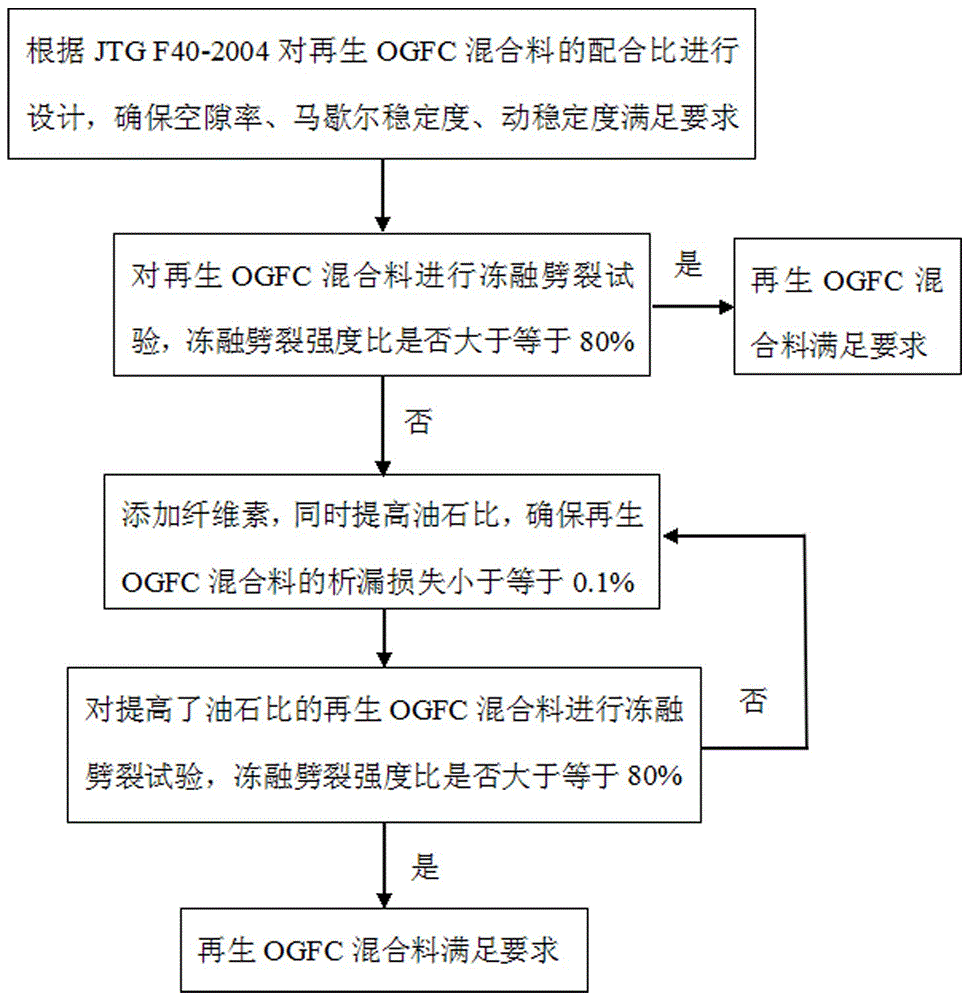

[0032] Take the composition design method of recycled OGFC-13 mixture as an example.

[0033] 1. Performance test of raw materials

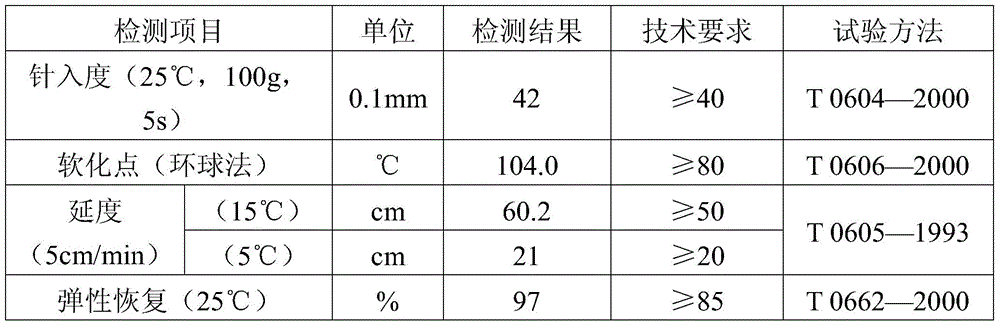

[0034] Basalt and machine-made sand are used as aggregate, high-viscosity modified asphalt is used as cementing material, lignin fiber is used as cellulose, and lime powder is used as mineral powder. The performance test results of high-viscosity modified asphalt are shown in Table 1, and the test results of lignin fiber performance are shown in Table 2.

[0035] The aging degree of OGFC-13 old material is 5 years, which contains mineral material and high-viscosity asphalt. The gradation and asphalt ratio of OGFC-13 old material are measured. The synthetic gradation is shown in Table 3, and the asphalt ratio is 4.5%.

[0036] Table 1: Performance test results of high viscosity modified asphalt

[0037]

[0038]

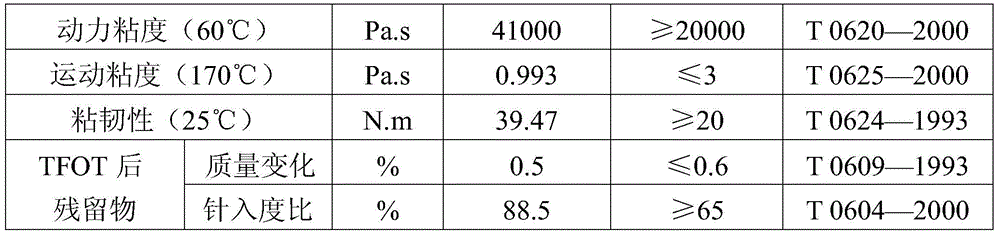

[0039] Table 2: Test results of lignin fiber properties

[0040] index

unit

test results

skills requirement...

Embodiment 2

[0057] Take the composition design method of recycled OGFC-13 mixture as an example.

[0058] 1. Performance test of raw materials

[0059] Andesite and machine-made sand are used as aggregates, high-viscosity modified asphalt is used as cementing material, lignin fiber and mineral fiber are used as cellulose, and lime powder and slaked lime are used as mineral powder. The properties of high-viscosity modified asphalt, lignin fiber, and mineral fiber were tested according to the industry testing standards of our country, and the test results were all in line with the corresponding regulations in the specifications of our country.

[0060] The aging degree of OGFC-13 old material is 5 years, which contains mineral materials and high-viscosity asphalt. The gradation and asphalt ratio of OGFC-13 old material are measured. The synthetic gradation is shown in Table 3, and the asphalt ratio is 4.5%.

[0061] 2. Composition design of recycled OGFC-13 mixture

[0062] Such as figur...

Embodiment 3

[0071] Take the composition design method of recycled OGFC-20 mixture as an example.

[0072] 1. Performance test of raw materials

[0073] Basalt and machine-made sand are used as aggregate, high-viscosity modified asphalt is used as cementing material, lignin fiber is used as cellulose, and slaked lime is used as mineral powder. The properties of high-viscosity modified asphalt and lignin fiber were tested according to the industry testing standards of our country, and the test results were all in line with the corresponding regulations in our country's specifications.

[0074] The aging degree of OGFC-20 old material is 7 years, which contains mineral material and high-viscosity asphalt. The gradation and asphalt ratio of OGFC-20 old material are measured, and the asphalt ratio is 4.0%.

[0075] 2. Composition design of recycled OGFC-20 mixture

[0076] Such as figure 1 Shown, a kind of composition design method of the regenerated OGFC-20 mixture based on fiber modificat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| freeze-thaw splitting strength ratio | aaaaa | aaaaa |

| freeze-thaw splitting strength ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com