Sulphoaluminate cement material with retarding effect

A technology of sulfoaluminate cement and setting retardation, applied in the field of cement materials, can solve the problems of limited source of retarder, high effect, toxic cost, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

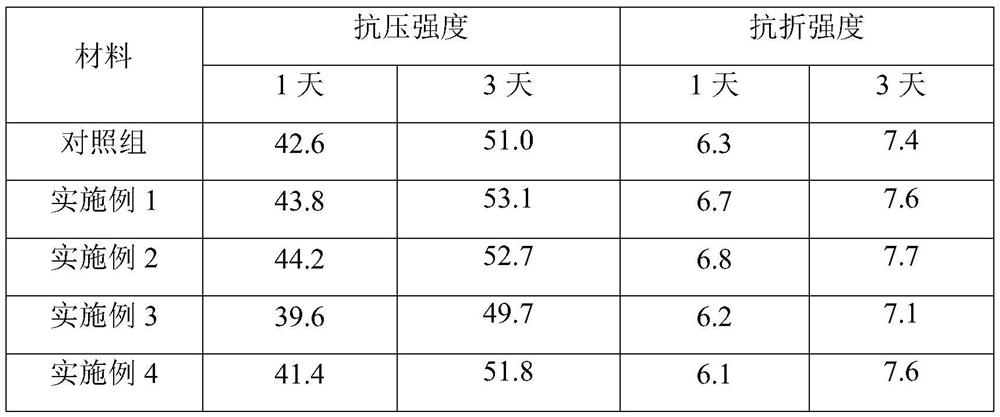

Examples

Embodiment 1

[0024] A sulphoaluminate cement material with retarding effect, the material is composed of the following components in parts by weight: 100 parts of sulphoaluminate cement, 7 parts of sodium chloride, 1.5 parts of montmorillonite, 5 parts of silica fume share.

[0025] Sulphoaluminate cement, sodium chloride, montmorillonite and silica fume are respectively weighed according to the above dosage ratio, and mixed evenly to obtain a sulphoaluminate cement material with retarding effect.

Embodiment 2

[0027] A sulphoaluminate cement material with retarding effect, the material is composed of the following components in parts by weight: 100 parts of sulphoaluminate cement, 4 parts of sodium chloride, 1 part of montmorillonite, 5 parts of silica fume share.

[0028] Sulphoaluminate cement, sodium chloride, montmorillonite and silica fume are respectively weighed according to the above dosage ratio, and mixed evenly to obtain a sulphoaluminate cement material with retarding effect.

Embodiment 3

[0030] A sulphoaluminate cement material with retarding effect, the material is composed of the following components in parts by weight: 100 parts of sulphoaluminate cement, 12 parts of sodium chloride, 2 parts of montmorillonite, 10 parts of silica fume share.

[0031] Sulphoaluminate cement, sodium chloride, montmorillonite and silica fume are respectively weighed according to the above dosage ratio, and mixed evenly to obtain a sulphoaluminate cement material with retarding effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com