Cold mix asphalt and its preparation method, as well as the mixture containing the asphalt and its application

A technology for asphalt mixture and cold mix asphalt, which is used in building thermal insulation materials, building components, buildings, etc., can solve the problems of short service life, tire wear, and high driving noise, and achieves improved demulsification speed and bonding strength. degree, good emulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

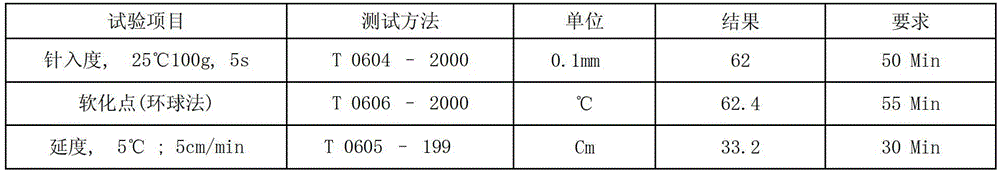

[0077] The raw materials used in the emulsified asphalt provided by this implementation are as follows: 90# heavy traffic asphalt (61 parts), furfural extraction oil (1.5 parts), SBS 4301 (3.2 parts), elemental sulfur (0.04 parts), modified paraffin ( 1.0 parts); for the production of asphalt raw materials for emulsification; cationic surfactant is tall oil imidazoline (1.0 parts), stabilizer is 1,3-β-glucan (0.04 parts); active anti-stripping agent Octadecylaminoethylpiperazine (0.2 parts) and 38 parts of water are used to prepare soap.

[0078] Heat the heavy traffic asphalt to 175 degrees Celsius, and add the required compatible additive furfural to extract oil and polymer 43011SBS at one time by weight percentage. Pass the mixture through a colloid mill at 4000RPM to speed up production. The milled mixture was continued to fully swell the SBS modified substance for 4 hours under the condition of stirring. Add the required elemental sulfur and continue to react for 3 hour...

Embodiment 3

[0105] The raw materials used in the emulsified asphalt provided by this implementation are as follows: 90# heavy traffic asphalt (64 parts), furfural extraction oil (2.4 parts), SBS 4303 (3.8 parts), elemental sulfur (0.1 part); lignin imidazoline (1.2 parts), the active anti-stripping agent is histamine phosphate (0.3 parts), the stabilizer is hydroxyethyl cellulose ether (number average molecular weight: 250000) (0.06 parts), and 35 parts of water are used to prepare soap.

[0106] Heat the heavy traffic asphalt to 180 degrees Celsius, and add the required compatible additive furfural to extract oil and polymer 4303SBS at one time by weight percentage. Pass the mixture through a colloid mill at 4000RPM to speed up production. The milled mixture was continued to fully swell the SBS modified substance for 4 hours under the condition of stirring. Add the required elemental sulfur and continue to react for 4 hours. Thereby, the required raw material asphalt is obtained, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com