Open-graded lignin fiber asphalt mixture and preparation method thereof

A technology of lignin fiber and asphalt mixture, which is applied in the field of pavement paving materials, can solve the problem of the lack of promulgation of road performance requirements for open-graded fiber asphalt mixture, improve water stability and anti-rutting ability, reduce cost, performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

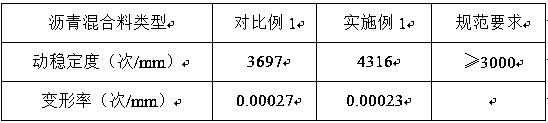

Embodiment 1

[0026] In this example, the aggregates are divided into three groups according to particle size: the first group of aggregates: 10-15mm (including 10mm and 15mm); the second group of aggregates: 5-10mm (including 5mm and excluding 10mm); Three sets of aggregates: ≤3 mm;

[0027] Raw materials: 9043g of aggregates (including 4069g of the first group of aggregates, 3436g of the second group of aggregates, and 1357g of the third group of aggregates), 180.9g of mineral powder (limestone with a particle size of 0.075mm or less), 399g of SBS modified asphalt, wood Vegetable fiber 9g.

[0028] The preparation method is as follows:

[0029] 1. Put 9043g of aggregate and 180.9g of ore powder in an oven at 175°C and heat and dry them to constant weight (generally not less than 6h);

[0030] 2. Heat the SBS modified asphalt in an oven to the mixing temperature of the asphalt mixture (175~185°C), and keep the temperature for later use;

[0031] 3. Preheat the indoor small mixing pot to...

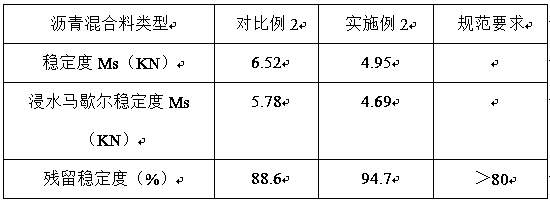

Embodiment 2

[0034] In this example, the aggregates are divided into three groups according to particle size: the first group of aggregates: 10-15mm (including 10mm and 15mm); the second group of aggregates: 5-10mm (including 5mm and excluding 10mm); Three sets of aggregates: ≤3 mm;

[0035] Raw materials: 5000g of aggregates (of which the mass of the first group of aggregates, the second group of aggregates, and the third group of aggregates are 2250g, 1900g, and 750g respectively), 100g of mineral powder (limestone with a particle size of 0.075mm or less), SBS modified 221g permanent asphalt, 5g lignin fiber.

[0036] The preparation method is as follows:

[0037] 1. Put the aggregate and mineral powder in an oven at 175°C and heat and dry them to constant weight (generally not less than 6 hours);

[0038] 2. Heat the SBS modified asphalt in an oven to the mixing temperature of the asphalt mixture, and keep the temperature for later use;

[0039] 3. Preheat the indoor small mixing pot...

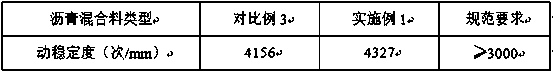

Embodiment 3

[0041] Embodiment 3 fiber comparison test

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com