Self-inflow type semi-flexible composite pavement and construction method thereof

A composite pavement, semi-flexible technology, applied to cohesive pavement paved on site, roads, roads, etc., can solve the problems of low compressive strength of pavement, affecting the skeleton of asphalt mixture, long maintenance time, etc., and achieve long service life of pavement , less maintenance cost, avoid early cracking and later shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Preparation of asphalt mixture

[0040] Performance indicators of asphalt: softening point > 75, penetration 45-70, flash point > 230, film aging mass loss < 1%;

[0041] Mineral powder: It is obtained by grinding hydrophobic stones such as strong basic rocks in limestone or magmatic rocks;

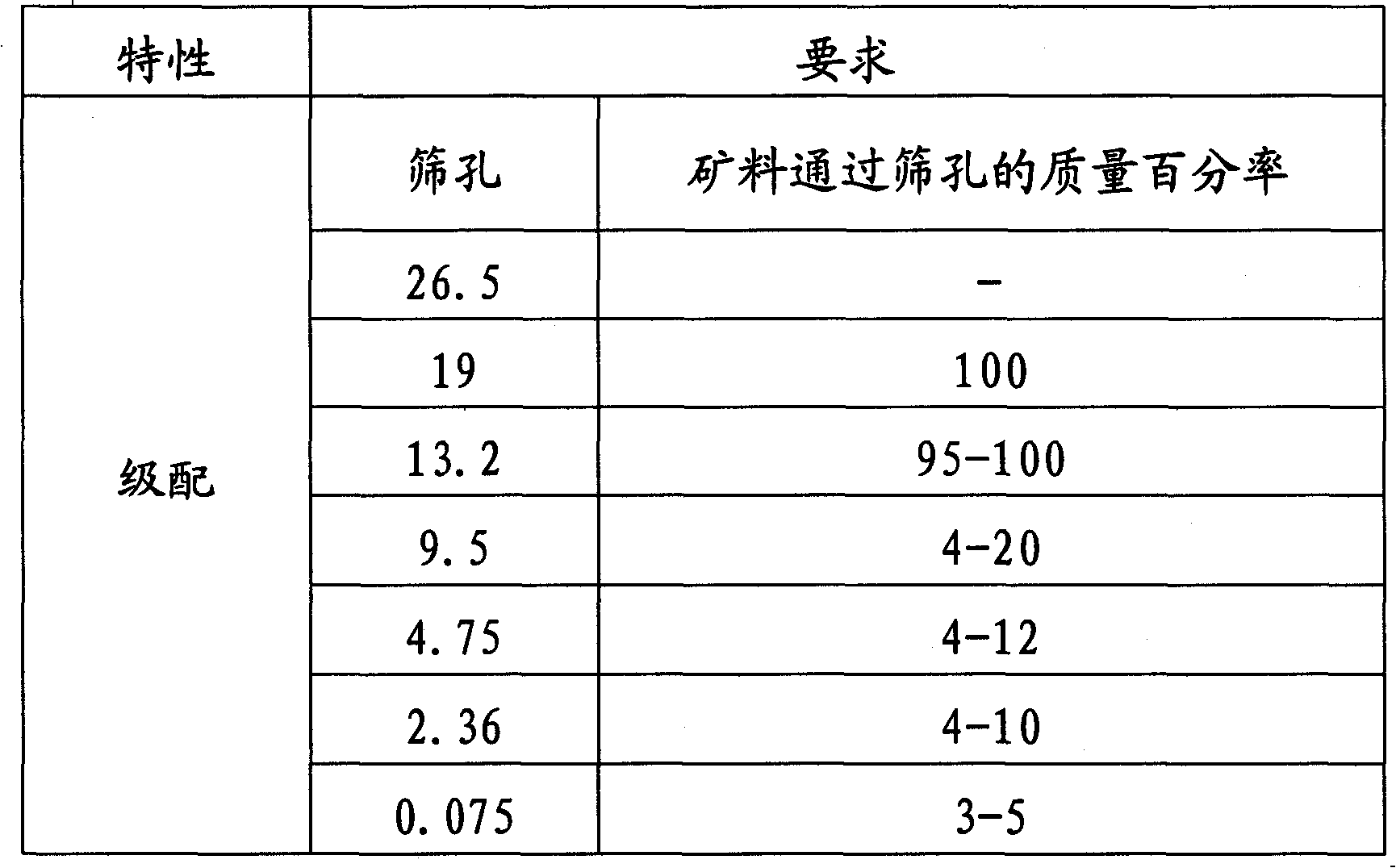

[0042] Mineral material: use granite or basalt, the maximum diameter is 26.5mm, and the design range of mineral material gradation is shown in Table 1;

[0043] Table 1

[0044]

[0045] The performance index of mineral material: wear value40BPN, firmness<12%.

[0046] The weight ratio of asphalt, mineral powder and mineral aggregate is designed to be 3:4:93.

[0047] Mix and stir the asphalt, mineral powder and mineral material in the above ratio at 160°C to obtain asphalt mixture.

[0048] 2. Preparation of road mortar

[0049]The raw material composition and weight ratio of mortar are shown in Table 2

[0050] Table 2

[0051] Element

weight ratio

...

Embodiment 2

[0064] 1. Preparation of asphalt mixture

[0065] Performance indicators of asphalt: softening point > 75, penetration 45-70, flash point > 230, film aging mass loss < 1%;

[0066] Mineral powder: It is obtained by grinding hydrophobic stones such as strong basic rocks in limestone or magmatic rocks;

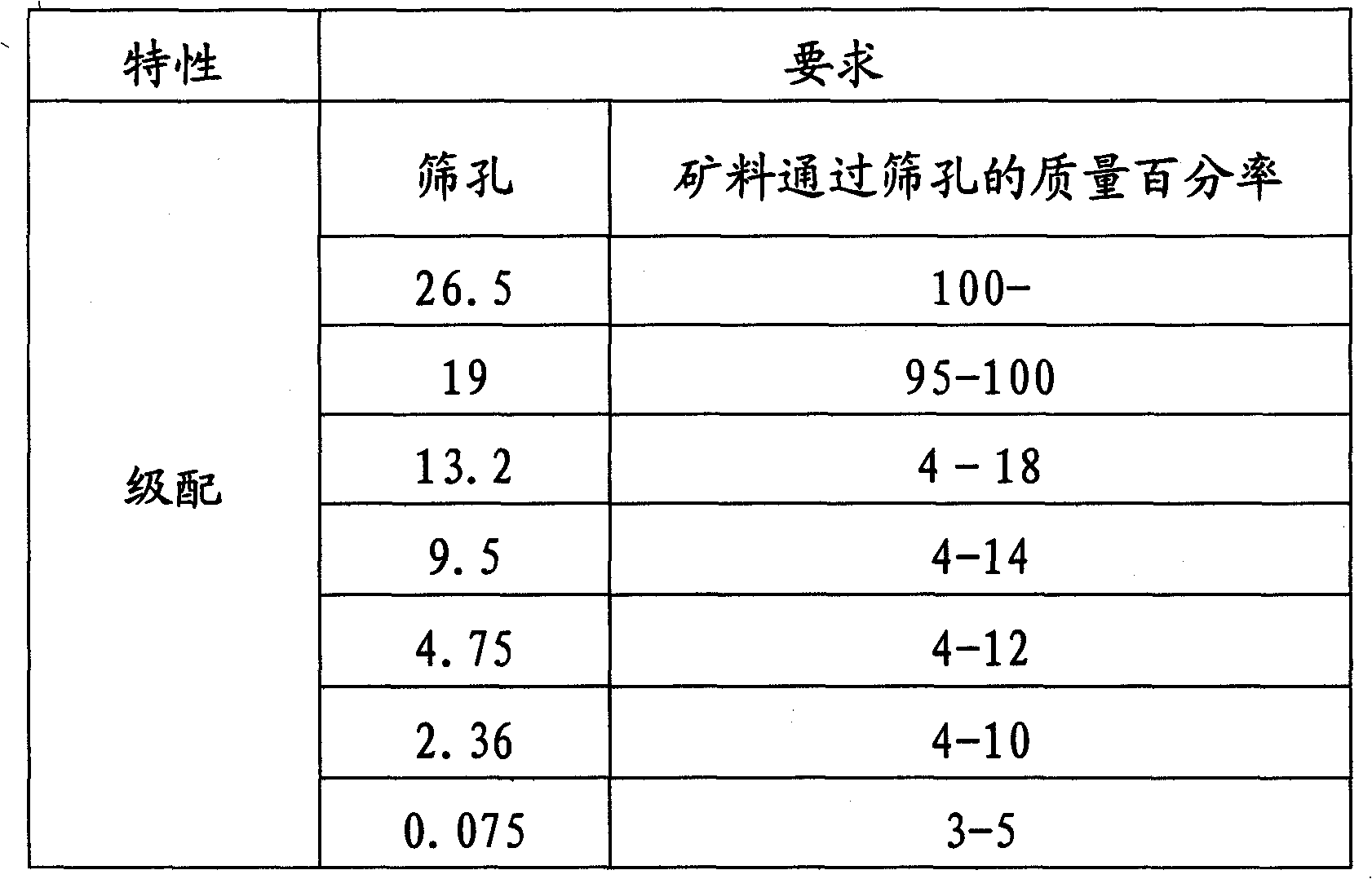

[0067] Mineral material: use granite or basalt, the maximum diameter is 26.5mm, and the design range of mineral material gradation is shown in Table 4;

[0068] Table 4

[0069]

[0070] The performance index of mineral material: wear value40BPN, firmness<12%.

[0071] The weight ratio of asphalt, mineral powder and mineral aggregate is designed to be 4:4:92.

[0072] Mix and stir the asphalt, mineral powder and mineral material in the above ratio at 170°C to obtain asphalt mixture.

[0073] 2. Preparation of road mortar

[0074] The raw material composition and weight ratio of mortar are shown in Table 5

[0075] table 5

[0076] Element

weight ratio

...

Embodiment 3

[0091] 1. Preparation of asphalt mixture

[0092] The gradation of asphalt, mineral powder, mineral aggregate and mineral aggregate is identical with embodiment 1;

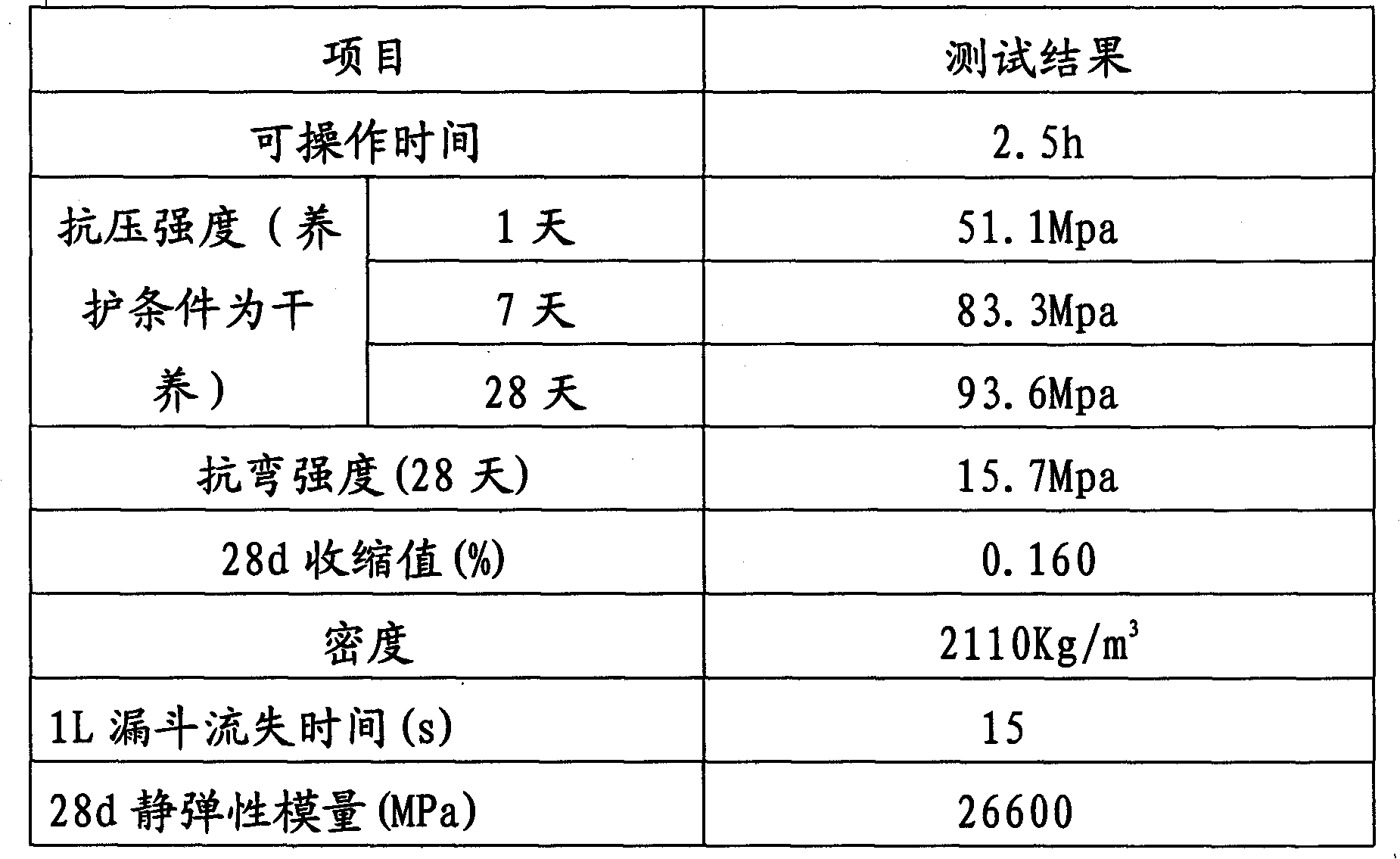

[0093] 2. Preparation of road mortar

[0094] The raw material composition and weight ratio of mortar are shown in Table 7

[0095] Table 7

[0096] Element

weight ratio

cement

45%

sand

32.5%

Vinyl acetate and ethylene copolymers

2.5%

Metakaolin with particle size <2μm

15%

Polyether, polyalcohol shrinkage reducer

4%

Sulfonated melamine formaldehyde resin and polycarboxylate ether mixture

0.5%

(weight ratio 3.2:6.8)

0.5%

[0097] Mix the components in the above proportions, add 22% of the total amount of water in the mortar, and use a continuous mixer to stir on site to obtain road mortar. The road mortar has reached final setting after 7.5 hours of curing. The performance test resu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com