Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

761 results about "Gray level image" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Color invariant image fusion of visible and thermal infrared video

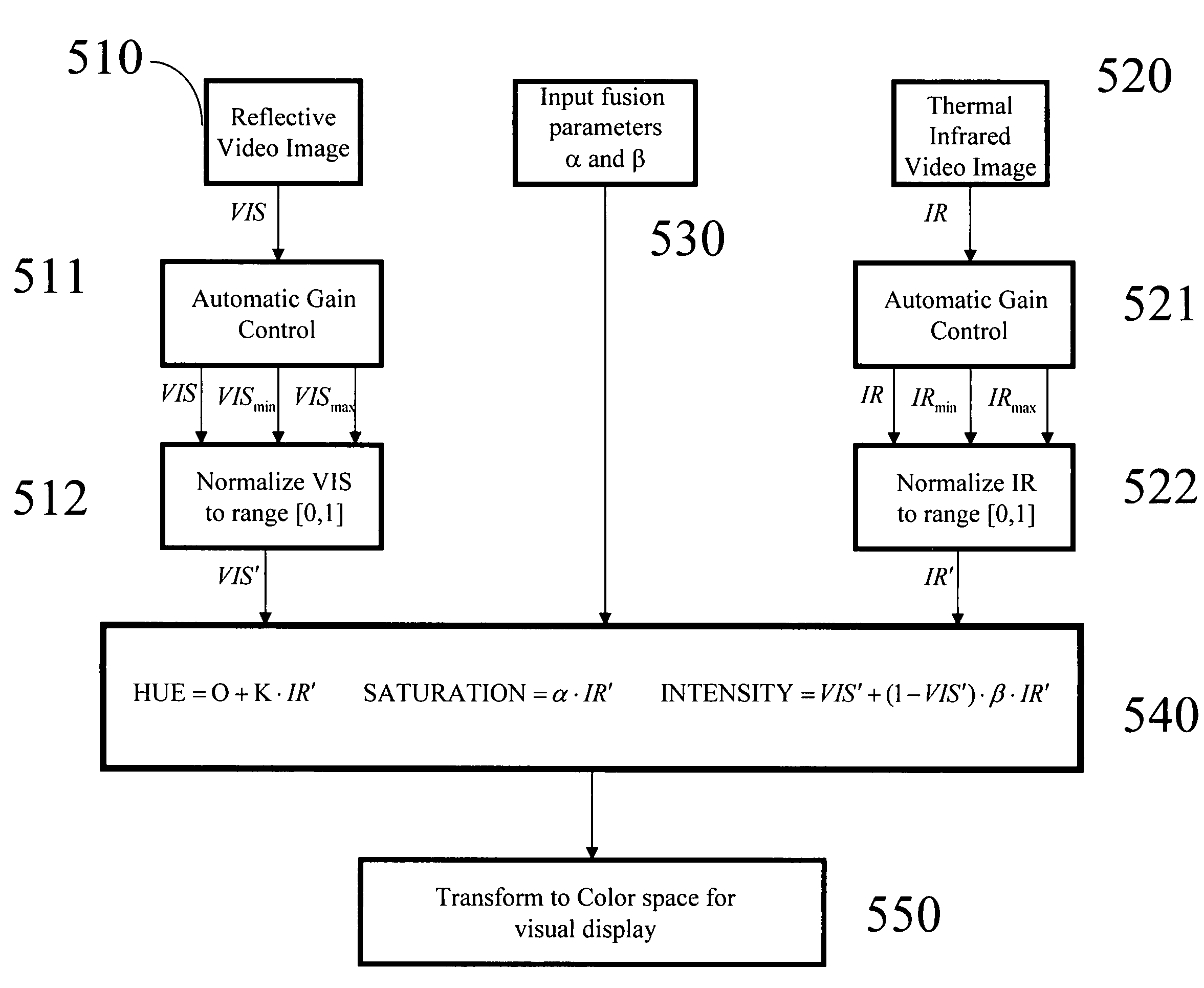

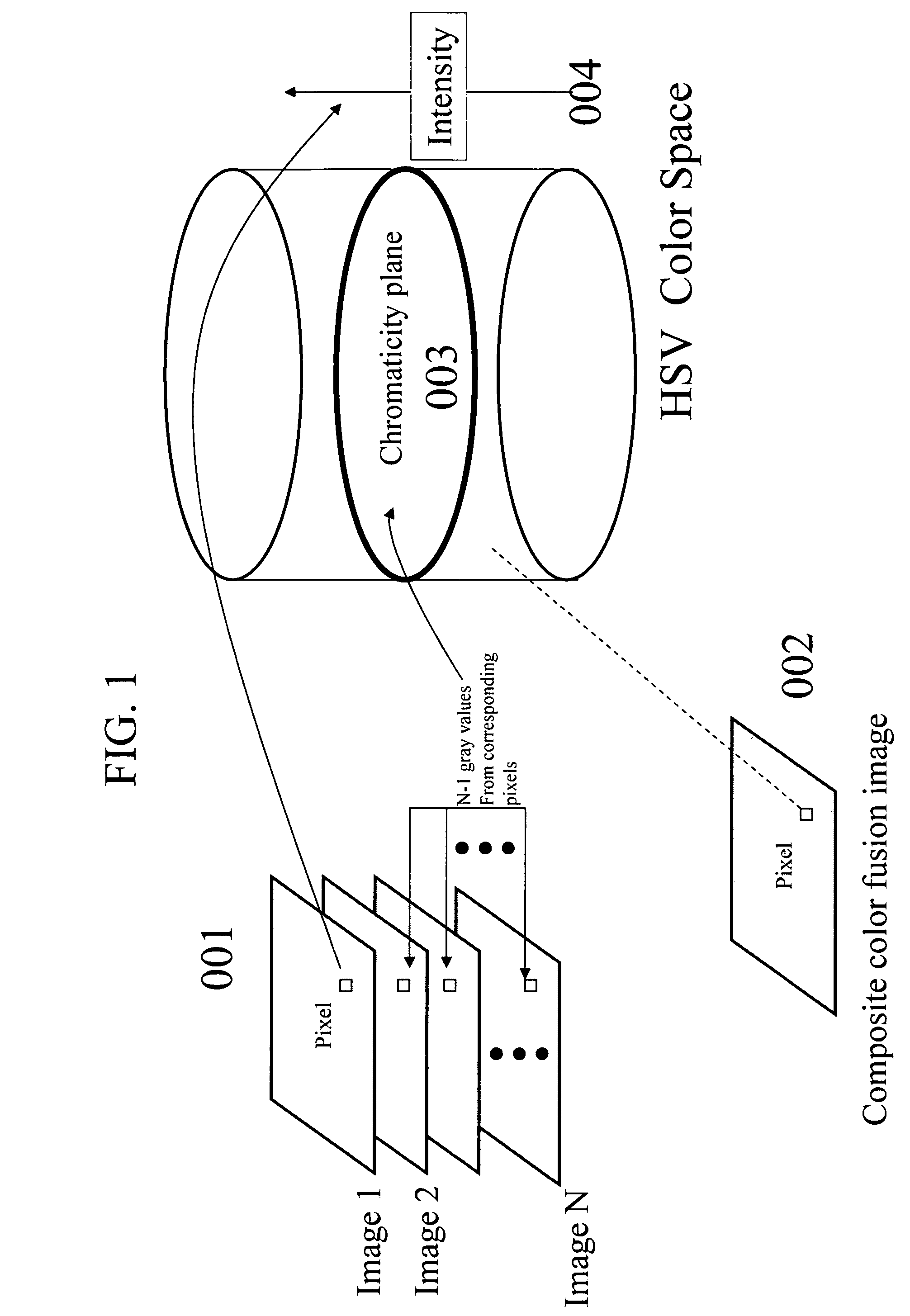

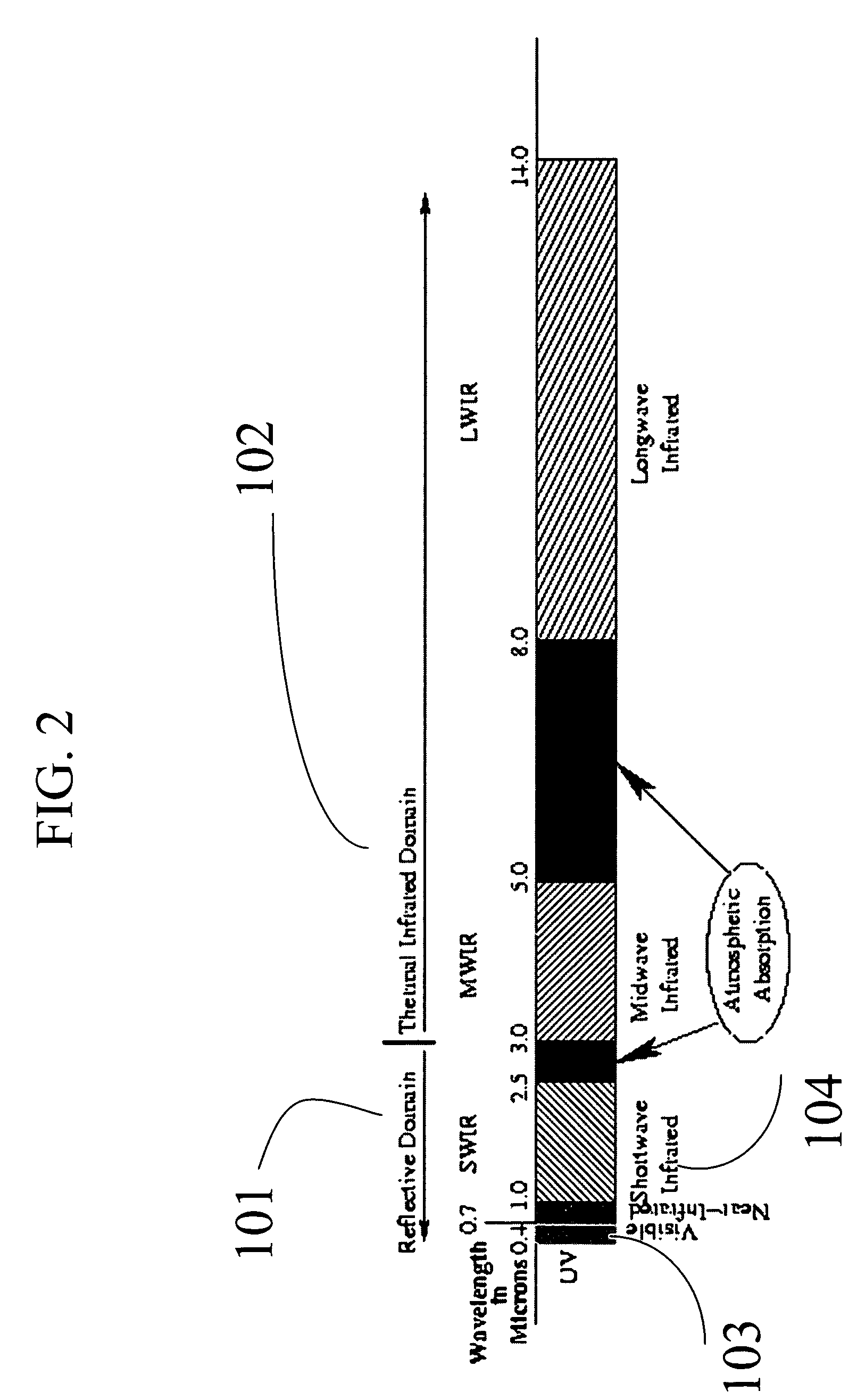

A methodology for forming a composite color image fusion from a set of N gray level images takes advantage of the natural decomposition of color spaces into 2-D chromaticity planes and 1-D intensity. This is applied to the color fusion of thermal infrared and reflective domain (e.g., visible) images whereby chromaticity representation of this fusion is invariant to changes in reflective illumination.

Owner:EQUINOX CORP

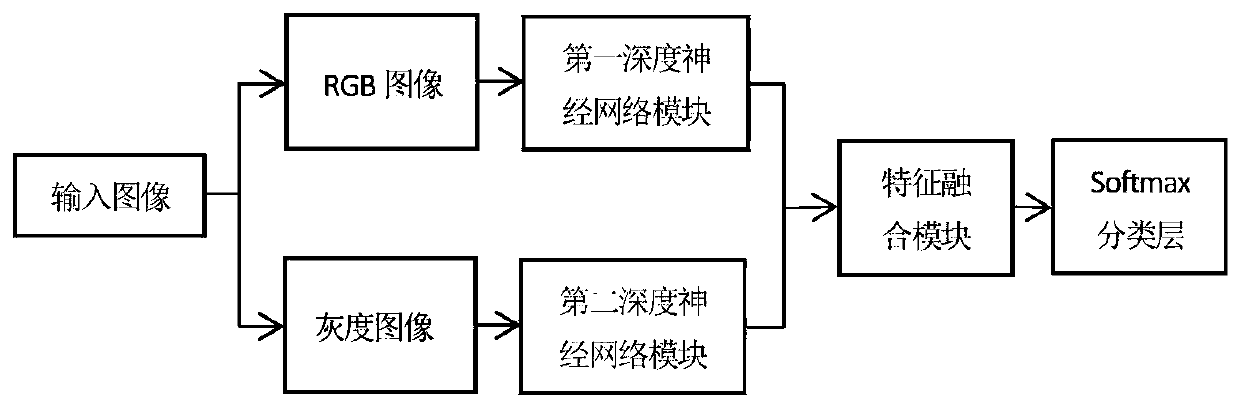

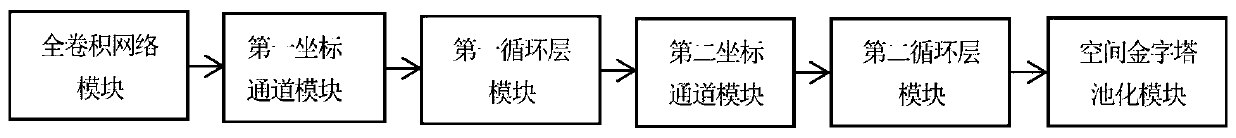

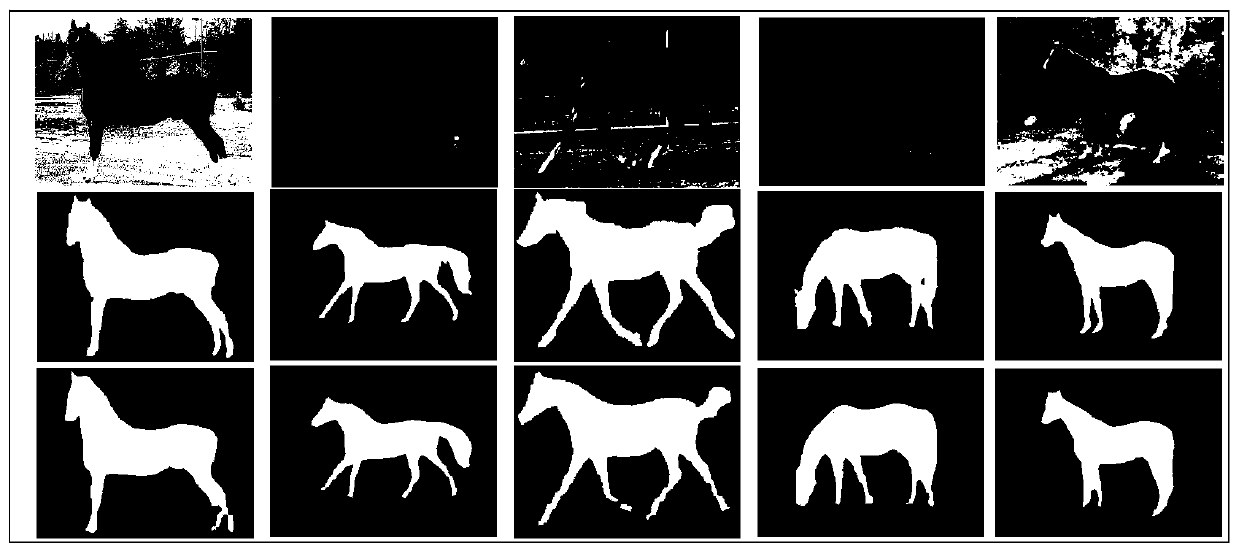

An image semantic segmentation method based on deep learning

ActiveCN109711413ARich coordinate featuresImprove generalization abilityInternal combustion piston enginesCharacter and pattern recognitionData setRgb image

The invention discloses an image semantic segmentation method based on deep learning. The method comprises four parts of data set processing, deep semantic segmentation network construction, deep semantic segmentation network training and parameter learning, and semantic segmentation on a test image. The RGB image and the gray level image of the input image are used as the input of the network model, the edge information of the gray level image is fully utilized, and the richness degree of input characteristics is effectively increased; a convolutional neural network and a bidirectional threshold recursion unit are combined, and more context dependency relationships and global feature information are captured on the basis of learning image local features; coordinate information is added tothe feature map through the first coordinate channel module and the second coordinate channel module, the coordinate features of the model are enriched, the generalization ability of the model is improved, and a semantic segmentation result with high resolution and accurate boundary is generated.

Owner:SHAANXI NORMAL UNIV

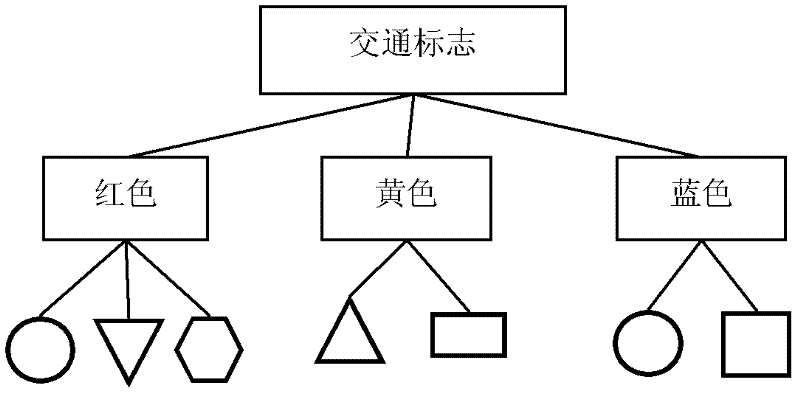

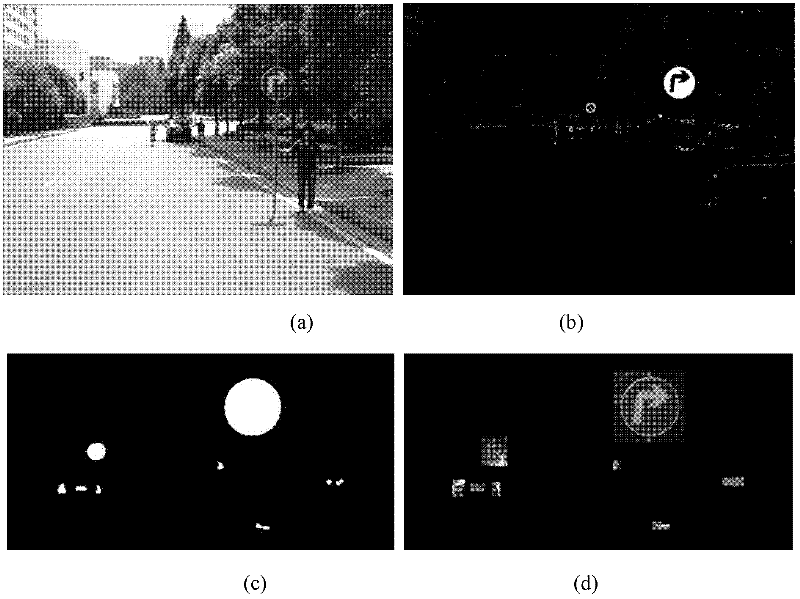

Method for recognizing road traffic sign for unmanned vehicle

InactiveCN102542260AFast extractionFast matchingDetection of traffic movementCharacter and pattern recognitionClassification methodsNear neighbor

The invention discloses a method for recognizing a road traffic sign for an unmanned vehicle, comprising the following steps of: (1) changing the RGB (Red, Green and Blue) pixel value of an image to strengthen a traffic sign feature color region, and cutting the image by using a threshold; (2) carrying out edge detection and connection on a gray level image to reconstruct an interested region; (3) extracting a labeled graph of the interested region as a shape feature of the interested region, classifying the shape of the region by using a nearest neighbor classification method, and removing a non-traffic sign region; and (4) graying and normalizing the image of the interested region of the traffic sign, carrying out dual-tree complex wavelet transform on the image to form a feature vector of the image, reducing the dimension of the feature vector by using a two-dimension independent component analysis method, and sending the feature vector into a support vector machine of a radial basis function to judge the type of the traffic sign of the interested region. By using the method, various types of traffic signs in a running environment of the unmanned vehicle can be stably and efficiently detected and recognized.

Owner:CENT SOUTH UNIV

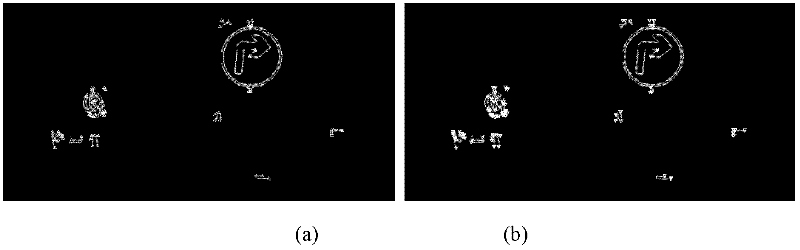

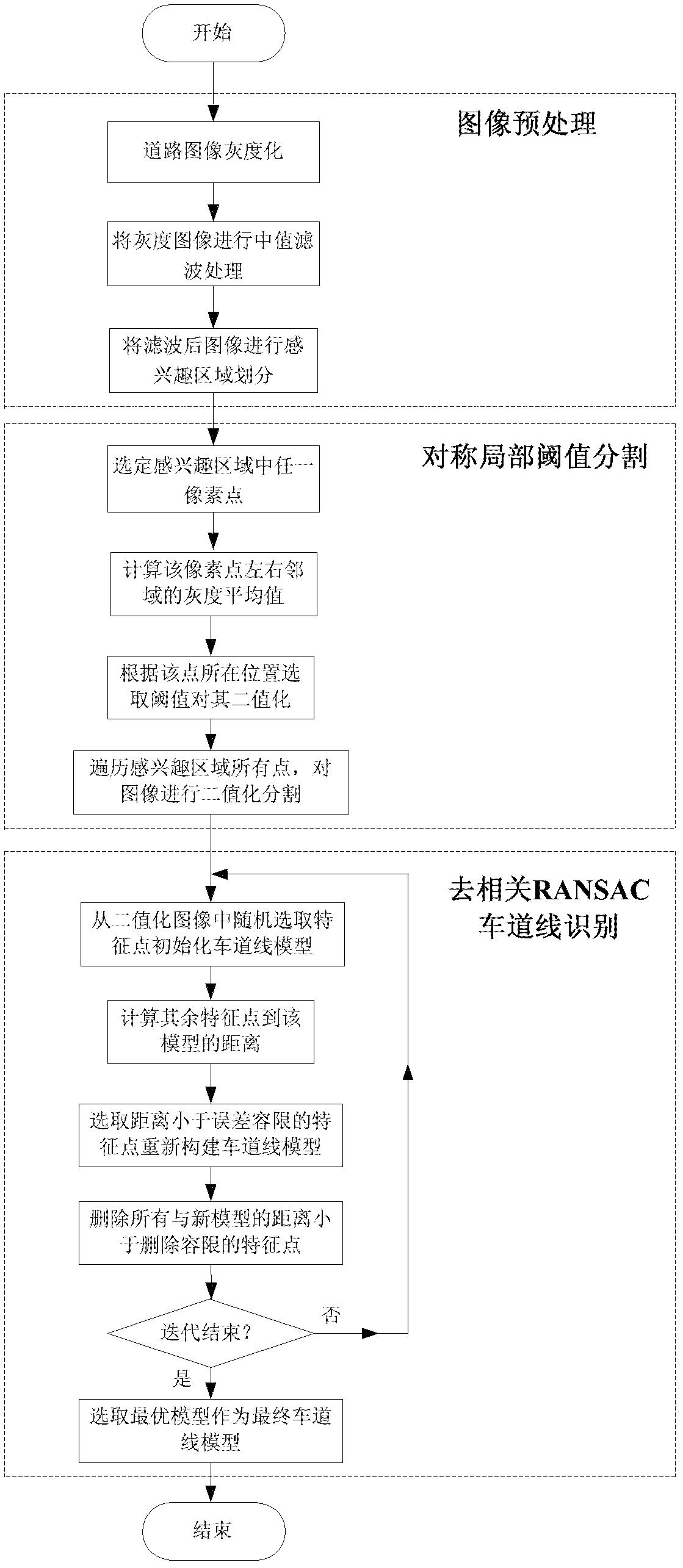

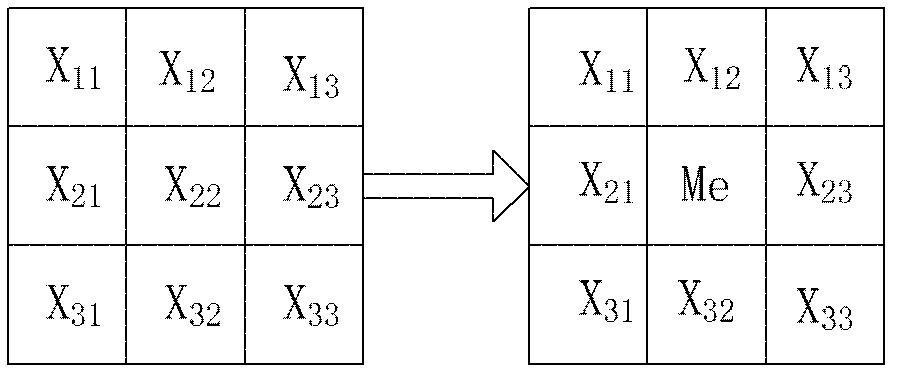

Method for extracting and recognizing lane line features of complex road conditions

InactiveCN102592114AEfficient identificationReduce correlationCharacter and pattern recognitionFeature extractionGray level

The invention relates to a method for detecting lane lines of complex road conditions, which includes: firstly converting colored road images into gray level images and performing median filtering, then performing area of interest division on the filtered images, performing binaryzation processing on road images in the area of interest by using a symmetrical local threshold dividing method so as to extract lane line feature information, and finally performing parallel recognition respectively on a left lane line and a right lane line by adopting a decorrelation random sample consensus algorithm (RANSAC) method based on extracted lane line feature point distribution law. Compared with a traditional RANSAC method, the method for detecting lane lines of complex road conditions greatly improves instantaneity, remarkably strengths robustness and can fast and effectively detect lane lines in terms of complex road conditions caused by illumination changing, shadow shielding, lane line damaging, splotch covering and the like.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

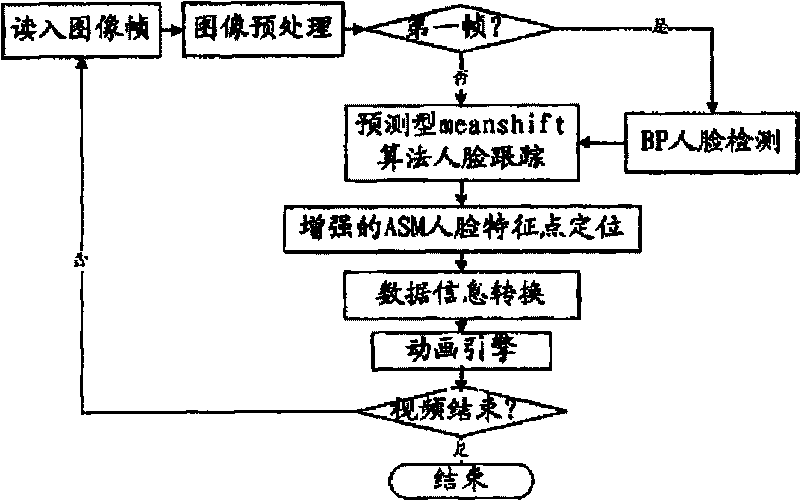

Video-based 3D human face expression cartoon driving method

InactiveCN101739712ASufficient prior knowledgeGood tracking resultCharacter and pattern recognition3D-image renderingFace detectionPattern recognition

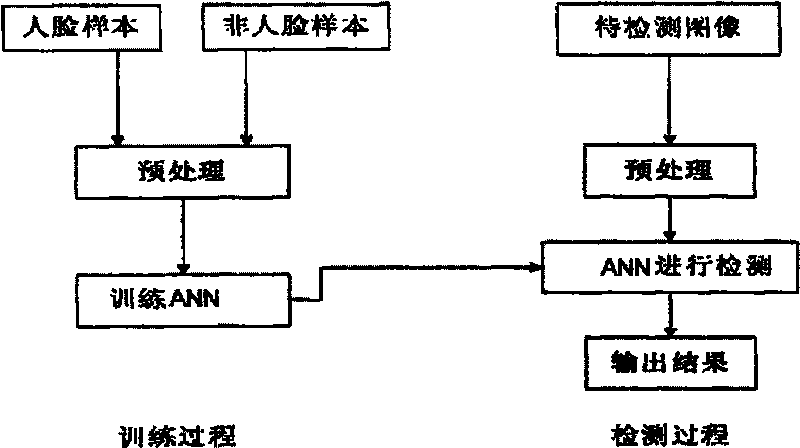

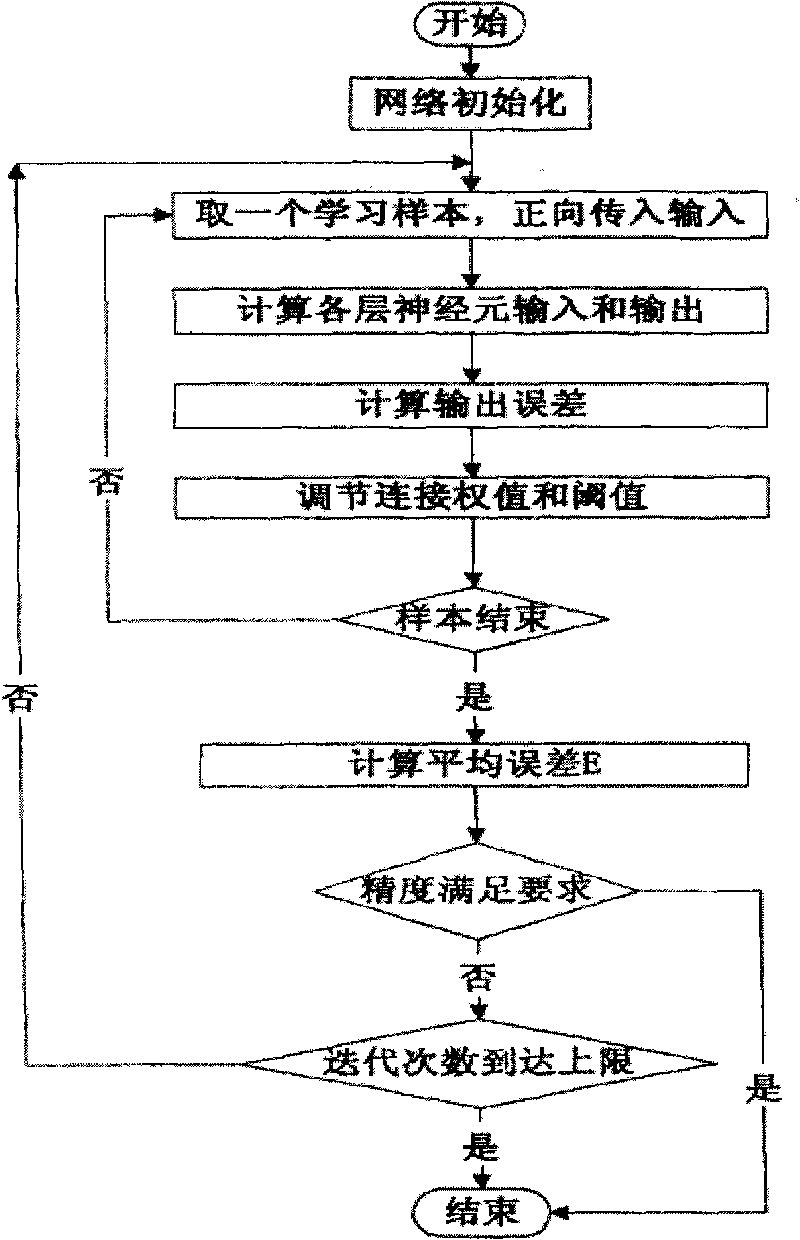

The invention discloses a video-based 3D human face expression cartoon driving method, which comprises the following steps: (1) image preprocessing, namely improving the image quality through light compensation, Gaussian smoothing and morphology operation of a gray level image; (2) BP human face detection, namely detecting a human face in a video through a BP neural network algorithm, and returning the size of the position of the human face for providing a smaller search range for human face characteristic point positioning of the next step to ensure instantaneity; (3) ASM human face characteristic point positioning and tracking, namely precisely extracting characteristic point information of human face shape, eyes, eyebrows, mouth and nose through an enhanced active shape model algorithm and a predicted meanshift algorithm, and returning the definite position; and (4) data information conversion, namely converting the data information acquired in the human face characteristic point positioning and tracking step to acquire the motion information of the human face. The method can overcome the defects in the prior art, and can achieve live human face cartoon driving effect.

Owner:SICHUAN UNIV

Vehicle license plate recognition method and system based on coarse positioning and fine positioning fusion

InactiveCN103870803AImprove accuracyThe result is accurateCharacter and pattern recognitionEngineeringRecognition system

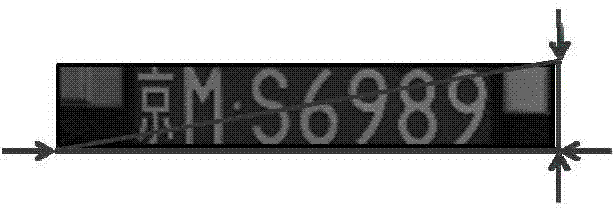

The embodiment of the invention provides a vehicle license plate recognition method and a vehicle license plate recognition system based on coarse positioning and fine positioning fusion. The method comprises the steps that a positive sample set and a negative sample set of a vehicle license plate image are collected, Haar-like characteristics of the positive sample set and the negative sample set are extracted to train a vehicle license plate classifier, and a vehicle license plate region in an image to be detected is subjected to coarse positioning by using the vehicle license plate classifier; the vehicle license plate region subjected to coarse positioning is converted into a gray level image, vertical and horizontal projection information is analyzed to determine the upper and lower boundaries and the left and right boundaries of a vehicle license plate, and a vehicle license plate region subjected to fine positioning is obtained; a vehicle license plate character set comprising predetermined vehicle license plate characters is collected, a tesseract engine is used for analyzing the character characteristics of the predetermined vehicle license plate characters in the vehicle license plate character set and training to obtain a vehicle license plate character repertoire, the vehicle license plate region subjected to the fine positioning is identified by the vehicle license plate character repertoire, and characters in the vehicle license plate region subjected to the fine positioning are determined. According to the vehicle license plate recognition method and the vehicle license plate recognition system based on coarse positioning and fine positioning fusion, the problem that the positioning precision of the vehicle license plate is subjected to interference due to complicated background is solved.

Owner:BEIJING UNIV OF POSTS & TELECOMM

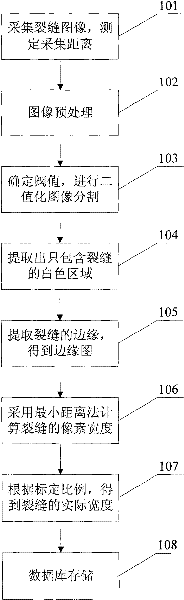

Tunnel lining crack width measuring method and device

The invention relates to a tunnel lining crack width measuring method, which comprises the follow steps of: (1) picking up crack images through a digital camera and measuring pickup distance through a laser distance measuring instrument; (2) selecting a region required to be measured on the picked images and converting selected region images into gray level images; (3) determining the threshold value of the gray level images selected in the second step, cutting binary image cutting, and obtaining a target region; (4) extracting a white region only comprising crack in the target region; (5) extracting the edge of the crack by a sub pixel method, and obtaining sub pixel level edge images; (6) circulating the pixel width of the crack by a minimum distance method; (7) circulating the actual width of the obtained crack according to the calibration proportion of the predetermined actual pixel size and the image pickup distance; and (8) storing the obtained actual width data into a crack data base. Compared with the prior art, the tunnel lining crack width measuring method has the advantages of low cost, high speed, convenience, high precision and the like.

Owner:TONGJI UNIV

Starting and unblock method decided by human face identification by utilizing mobile phone cam

InactiveCN101393598ACost unchangedImprove confidentialityCharacter and pattern recognitionRadio/inductive link selection arrangementsPattern recognitionFace detection

The invention discloses a method for determining whether to permit starting up and unlocking a mobile phone by identifying a human face by a mobile phone camera. The method makes use of a human face detection method based on a gray level image and comprises the following steps: firstly, establishing a standard human face identifying template (a face image template for a mobile phone user); secondly, taking a photograph of the face of an operator by the camera before starting up or unlocking the mobile phone so that mobile phone software can automatically perform a global search of the input image and calculate the related coefficient of different parts between the image and the standard human face identifying template; and thirdly, judging whether the image accords with a human face image in the template according to a preset threshold value. If the image accords with the human face image in the template, the mobile phone is started up or unlocked automatically, otherwise, the mobile phone prompts a user that the starting up or the unlocking is failed.

Owner:SHANGHAI SIMCOM LTD

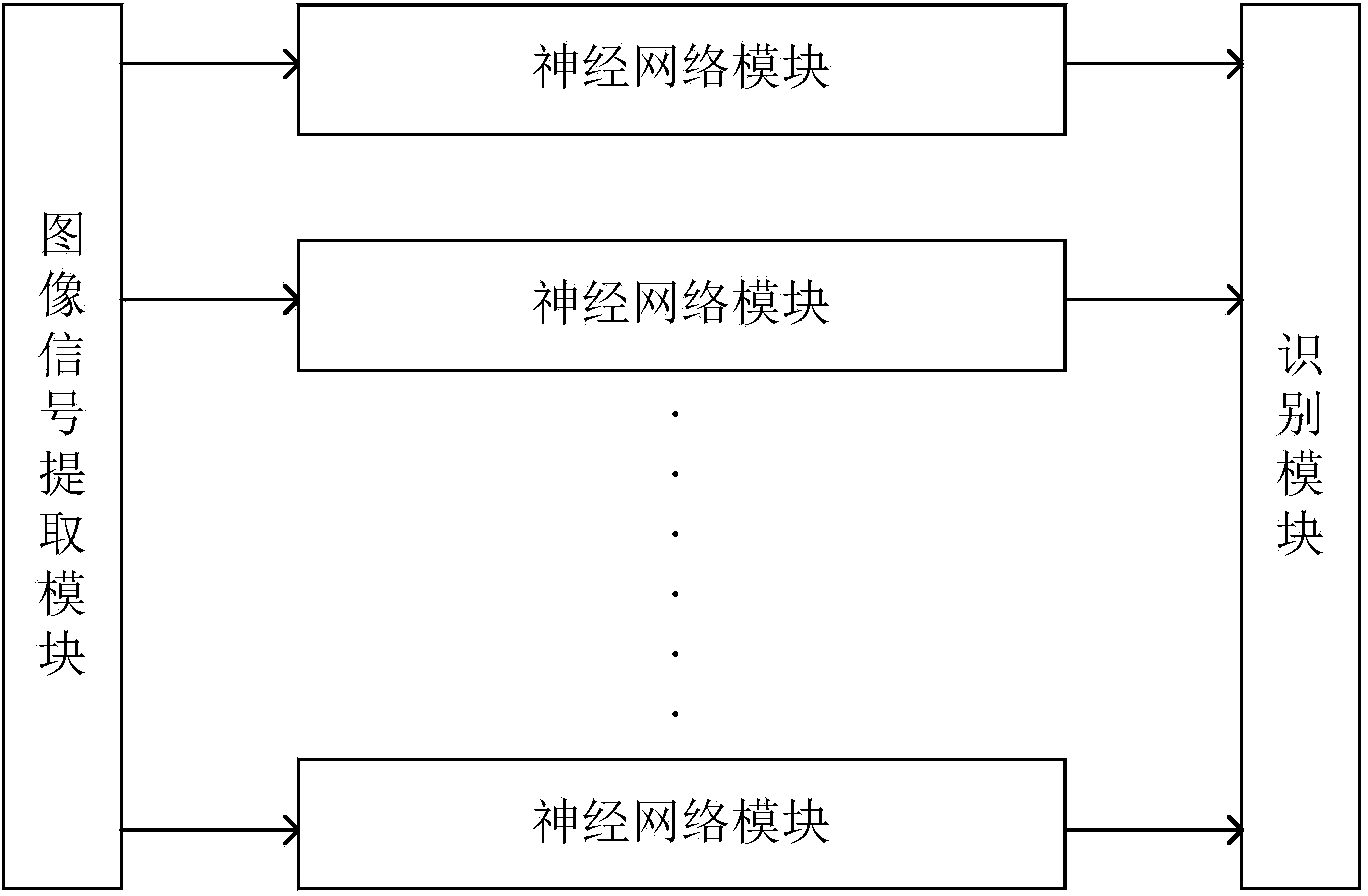

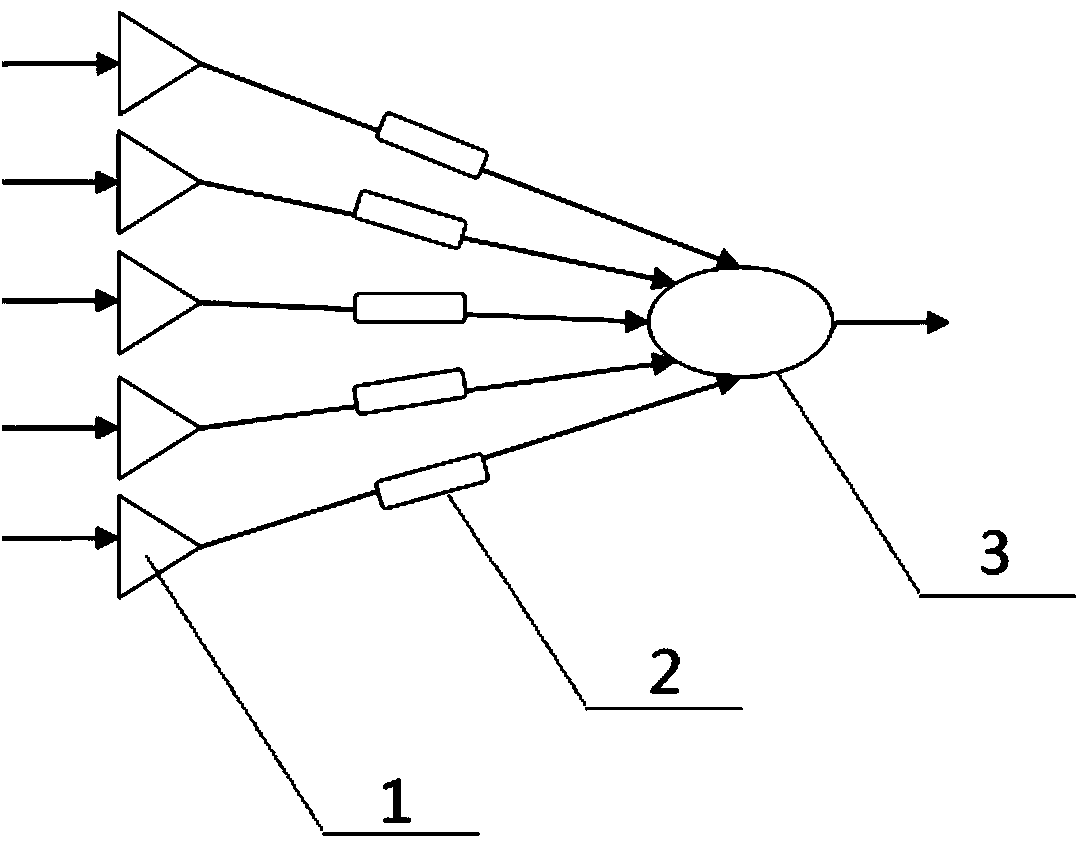

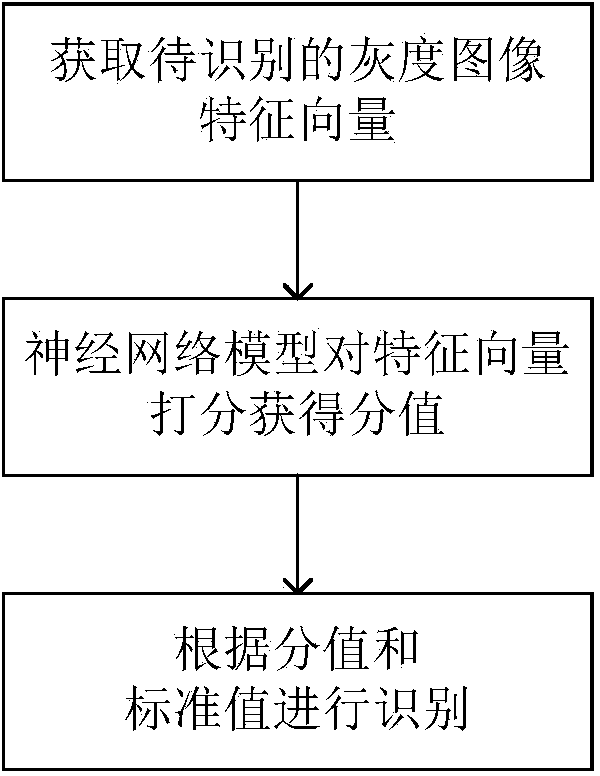

Memristor based image identification system and method

InactiveCN103810497AShorten the timeReduce energy consumptionCharacter and pattern recognitionFeature vectorTime complexity

The invention discloses a memristor based image identification system and method. The system comprises an image signal extracting module, a plurality of memristor based neural network modules, and an identification module, wherein an input end of the identification module is connected with an output end of each neural network module, and an input end of each neural network module is connected with an output end of the signal extracting module. The method includes the following steps that (1) a feature vector of a gray level image to be identified is acquired and input into the neural network modules; (2) each neural network module grades and identifies the feature vector according to an image model of each neural network module; (3) a difference value between a value of each neural network module and obtained standard values during training is calculated, and the classification of an image to be identified is judged according to the difference value. The memristor based image identification system has good expansibility, high integration density, and low power consumption; the method has low time complexity and high identification accuracy.

Owner:HUAZHONG UNIV OF SCI & TECH

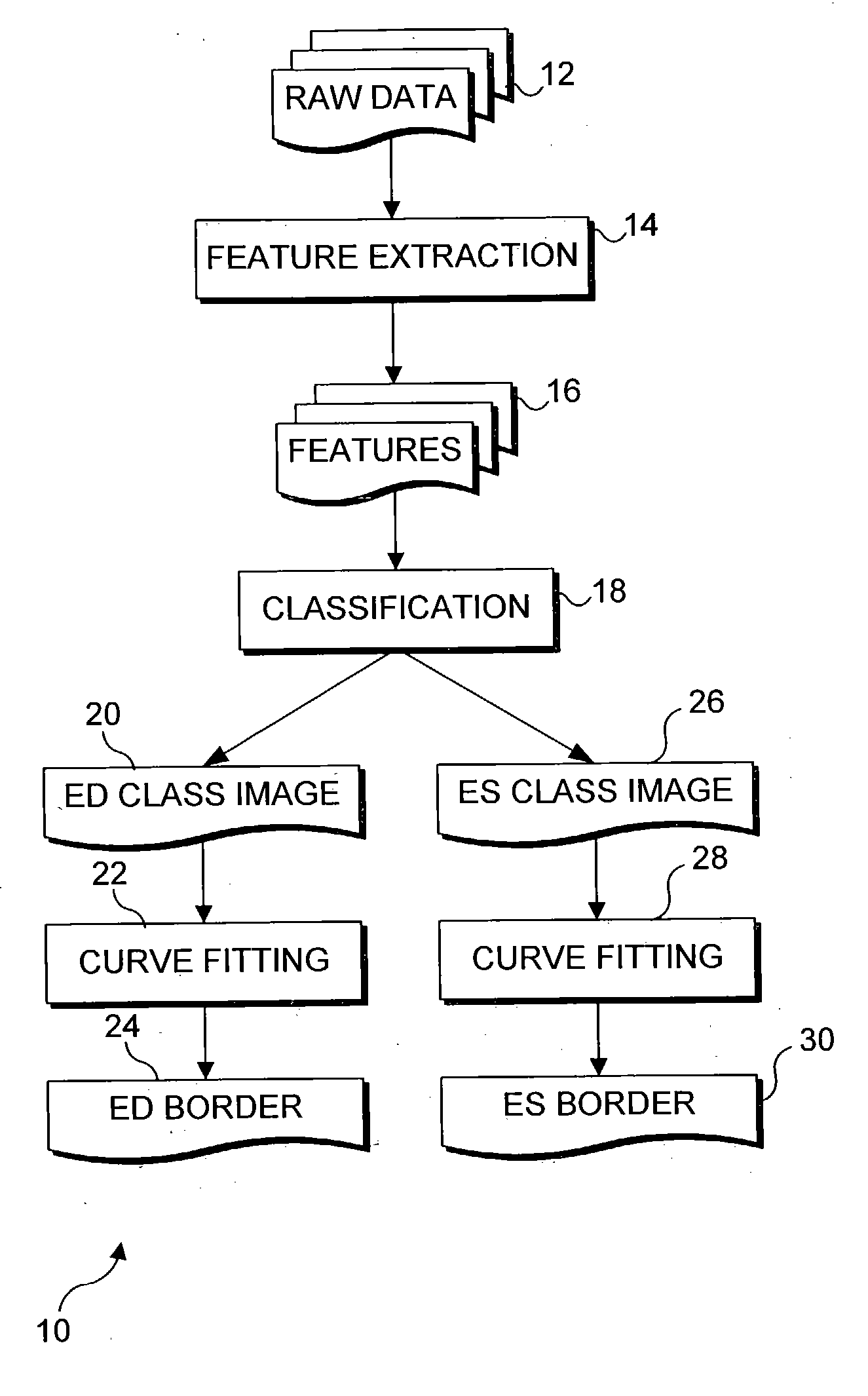

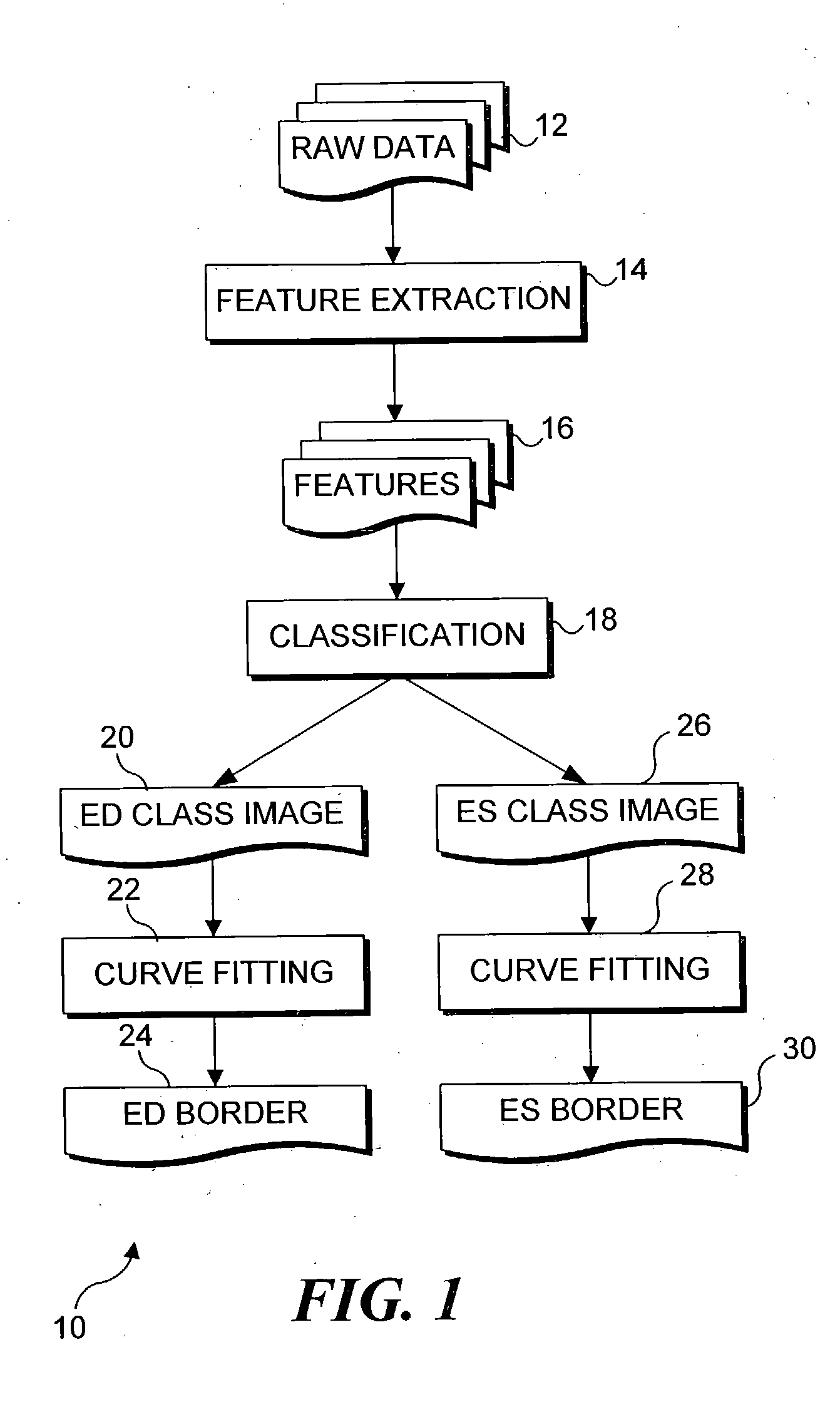

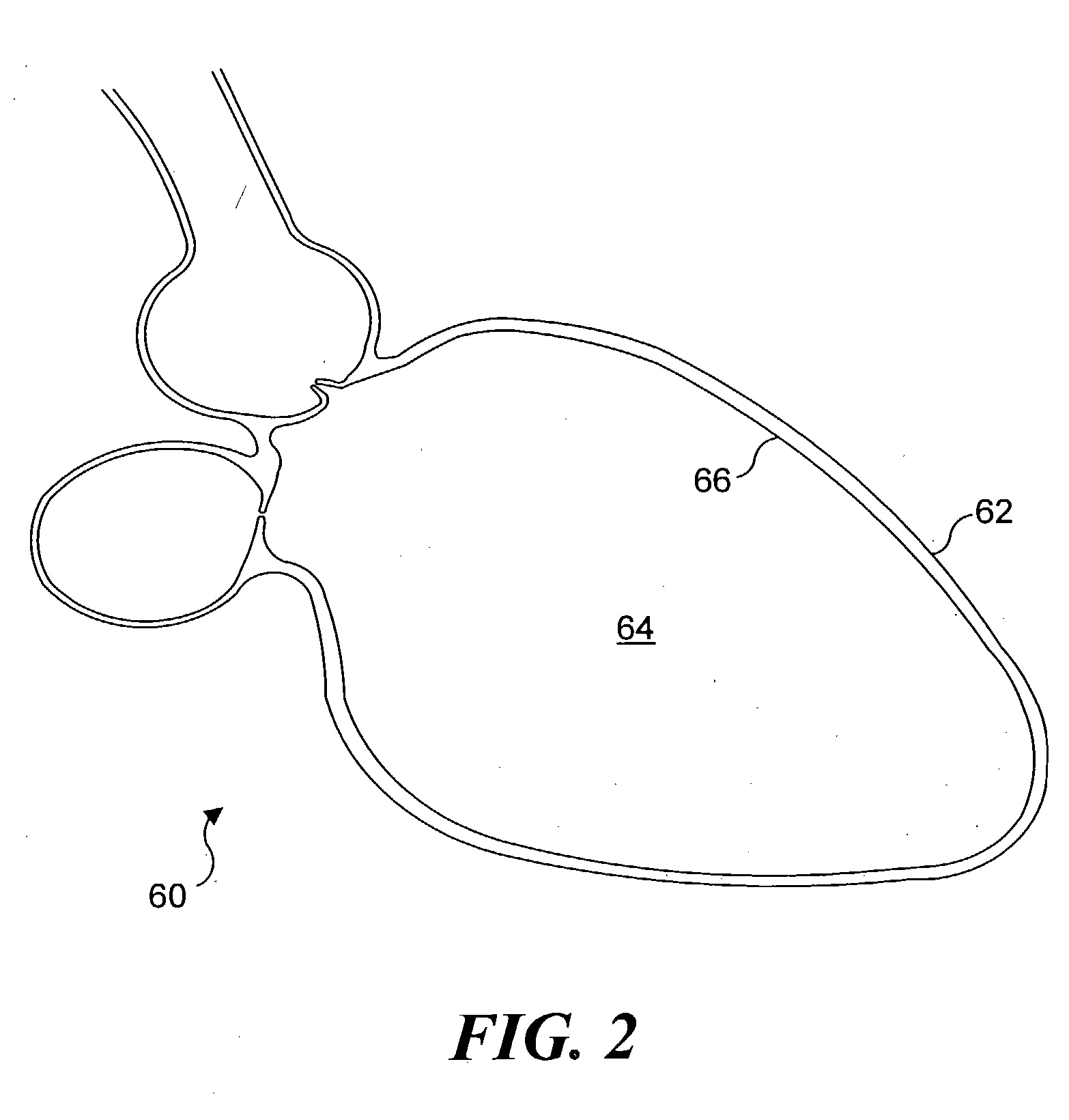

Segmentation of left ventriculograms using boosted decision trees

An automated method for determining the location of the left ventricle at user-selected end diastole (ED) and end systole (ES) frames in a contrast-enhanced left ventriculogram. Locations of a small number of anatomic landmarks are specified in the ED and ES frames. A set of feature images is computed from the raw ventriculogram gray-level images and the anatomic landmarks. Variations in image intensity caused by the imaging device used to produce the images are eliminated by de-flickering the image frames of interest. Boosted decision-tree classifiers, trained on manually segmented ventriculograms, are used to determine the pixels that are inside the ventricle in the ED and ES frames. Border pixels are then determined by applying dilation and erosion to the classifier output. Smooth curves are fit to the border pixels. Display of the resulting contours of each image frame enables a physician to more readily diagnose physiological defects of the heart.

Owner:UNIV OF WASHINGTON

Method and system for navicular identification

InactiveCN103514448ASolve the difficult problem of ship shape recognitionMeet the needs of fishery administrationImage analysisCharacter and pattern recognitionOn boardContour tracing

The invention relates to the technical field of navicular identification, in particular to a method and system for navicular identification based on interest target regions and SUSAN (Small Univalue Segment Assimilating Nucleus) edge detection. The navicular identification method comprises the following steps: S1, converting an image to be identified into a gray level image; S2, extracting an interest target region from the gray level image; S3, utilizing a SUSAN operator to perform edge detection on the interest target region to obtain edge information, and performing target contour tracing on the edge information to form an shape of the target to be identified; S4, obtaining shape context of the shape of the target to be identified; S5, matching the shape context of the shape of the target to be identified with shape context of the shape of a template, and determining whether the target to be identified is the navicular identification. The method solves the problems of identification of a navicular object on an ocean surface scene and difficulty in navicular identification for on-board cargo, and can be widely applied to monitoring of exploitation of marine resource, thereby satisfying the requirements of fishery administration.

Owner:北京国基科技股份有限公司

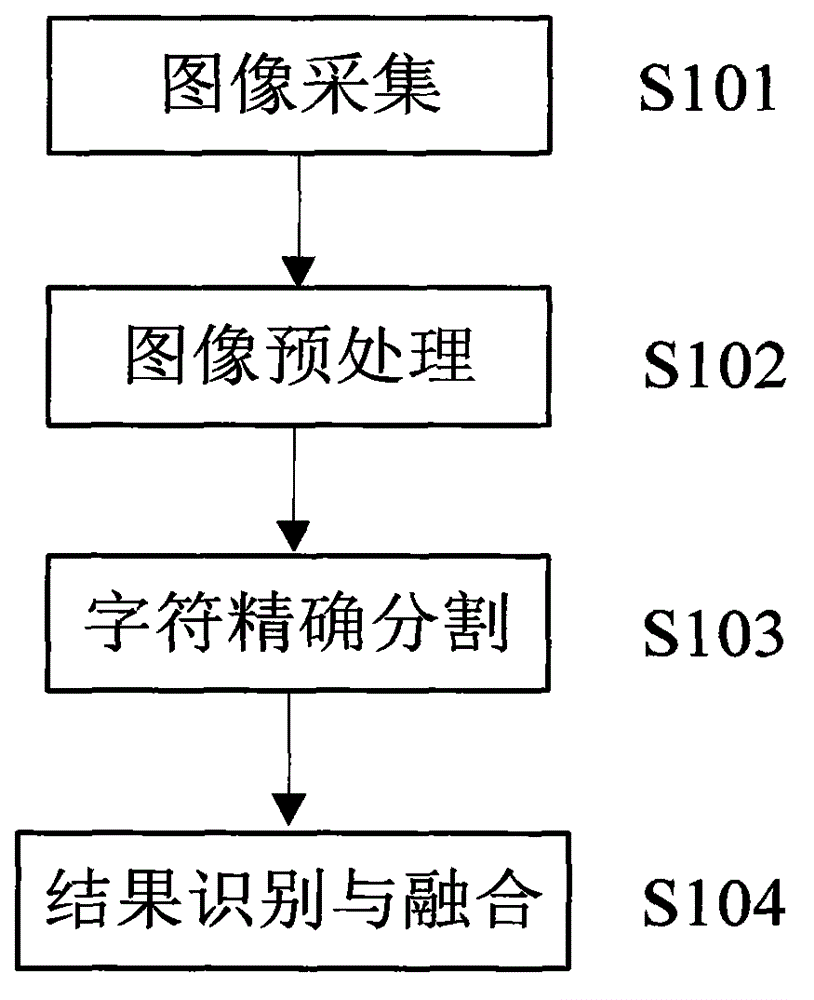

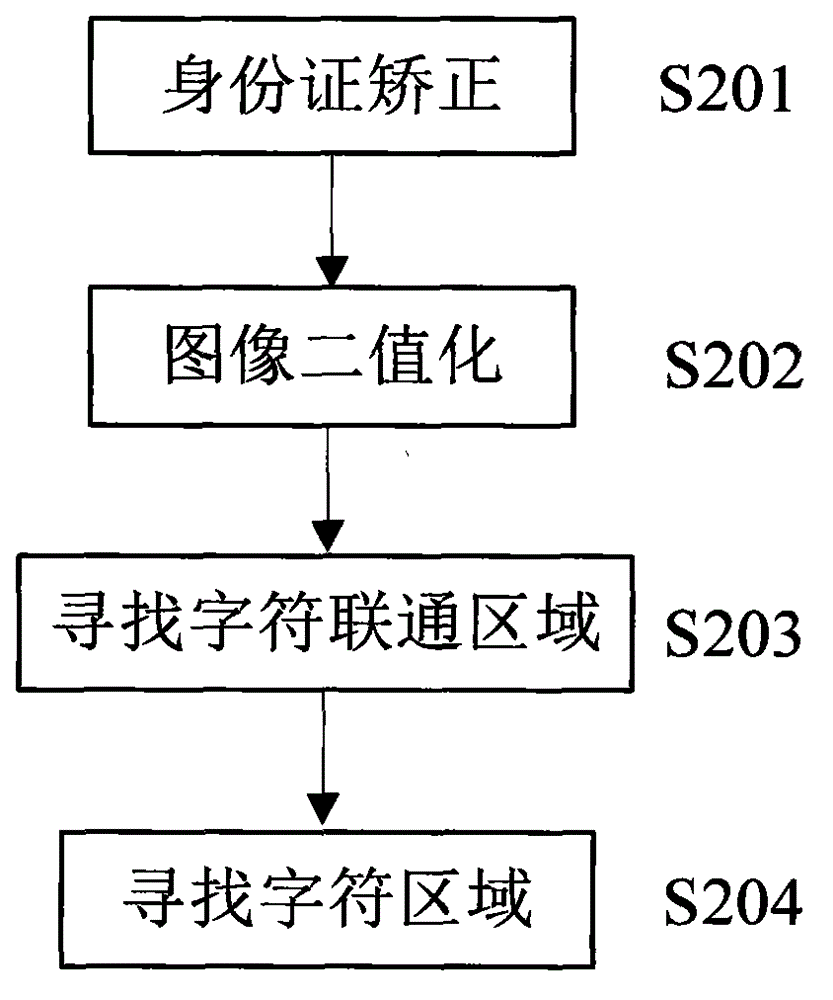

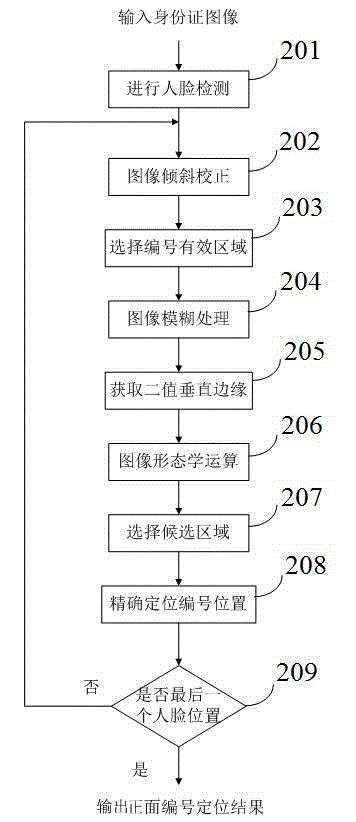

Identity card number recognition method and device based on natural scene

InactiveCN106156712ASolve the problem of low efficiency of manual entryCharacter and pattern recognitionImaging processingNoise removal

The invention discloses an identity card number recognition method and a device based on a natural scene. An identity card picture which is distinct and can enable the identity card number to be recognized by a human eye is acquired through a front-end hardware device, and the hardware device can be a mobile phone, a camera, a scanner and the like; and through technical means such as image processing and mode recognition, automatic extraction and recognition are carried out on the identity card number. The technical scheme is mainly as follows: the captured picture is firstly subjected to image pre-processing, wherein the pre-processing comprises noise removal, image gray level conversion, identity card boundary extraction, and image binarization; connection region searching is carried out on the binary image after pre-processing, and certain candidate regions with dense characters are determined to be the regions of the identity card number; local binarization processing is then carried out on each candidate region, the position of each character is acquired, and character segmentation on a gray level image is carried out; and finally, a deep learning method is used for recognizing each segmented character, discrimination is then carried out according to the arrangement sequence of the identity card number, the width and the height of each character and the character recognition confidence, and a character sequence with the highest confidence level is selected as the final recognition result and is outputted.

Owner:信帧机器人技术(北京)有限公司

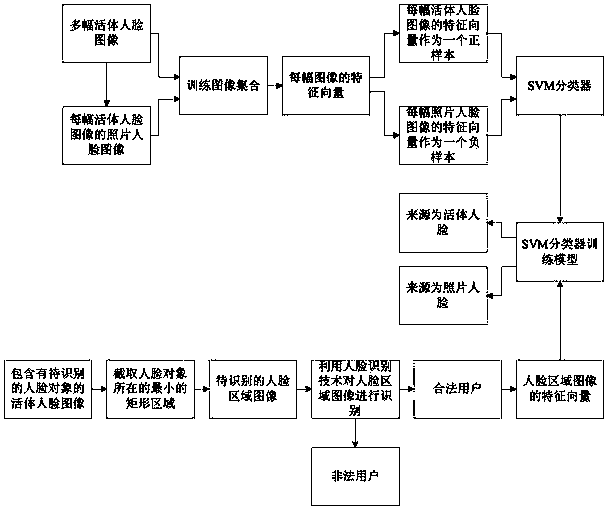

Living body human face identifying method

ActiveCN104766063AEliminate potential safety hazardsReduce the proportion of occupationCharacter and pattern recognitionGray level imageLiving body

The invention discloses a living body human face identifying method. The method is divided into a training stage and an identifying stage. In the training stage, multiple living body human face images and picture human face images are obtained, the feature vector of a gray level image of each living body human face image is extracted to serve as a positive sample, and the feature vector of a gray level image of the human face image of each picture is extracted to serve as a negative sample, all the positive samples and all the negative samples are input into an SVM classifier to be trained, and an SVM classifier training model is obtained; one frame human face image is obtained in the identifying stage, the human face identifying technology is used for identification, when an identification result shows that a user is legal, the living body detection technology is used for extracting the feature vectors, and the feature vectors are input into the SVM classifier training model to conduct living body detection. The living body human face identifying method has the advantages that the human face identifying technology is used for judging whether the human face is the human face of the legal user or not, the legal user then can judge whether the human face is a living body human face or a counterfeit picture human face through the living body detection technology if the user is legal, and therefore potential safety hazards caused by the picture human face are effectively eliminated.

Owner:NINGBO UNIV

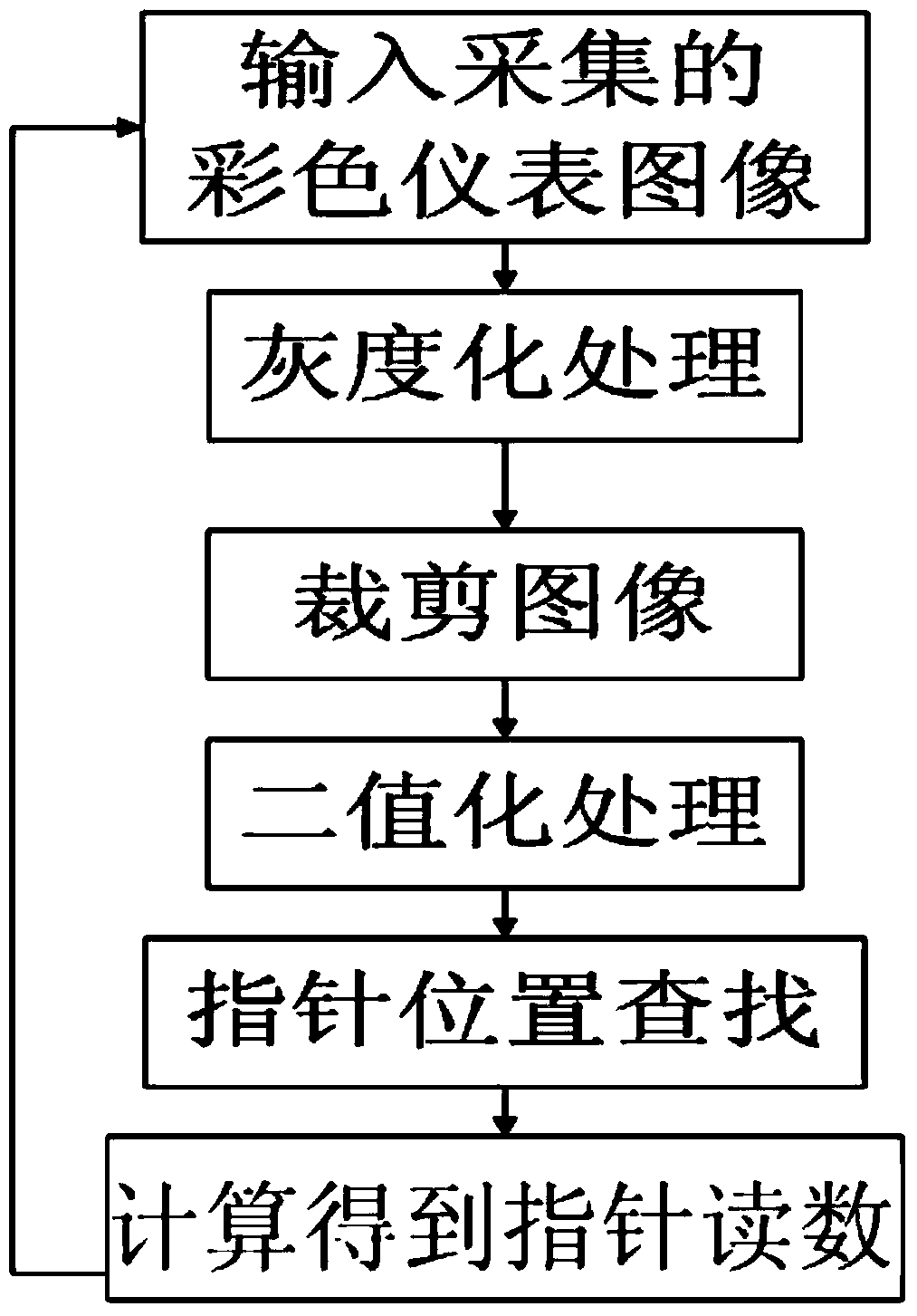

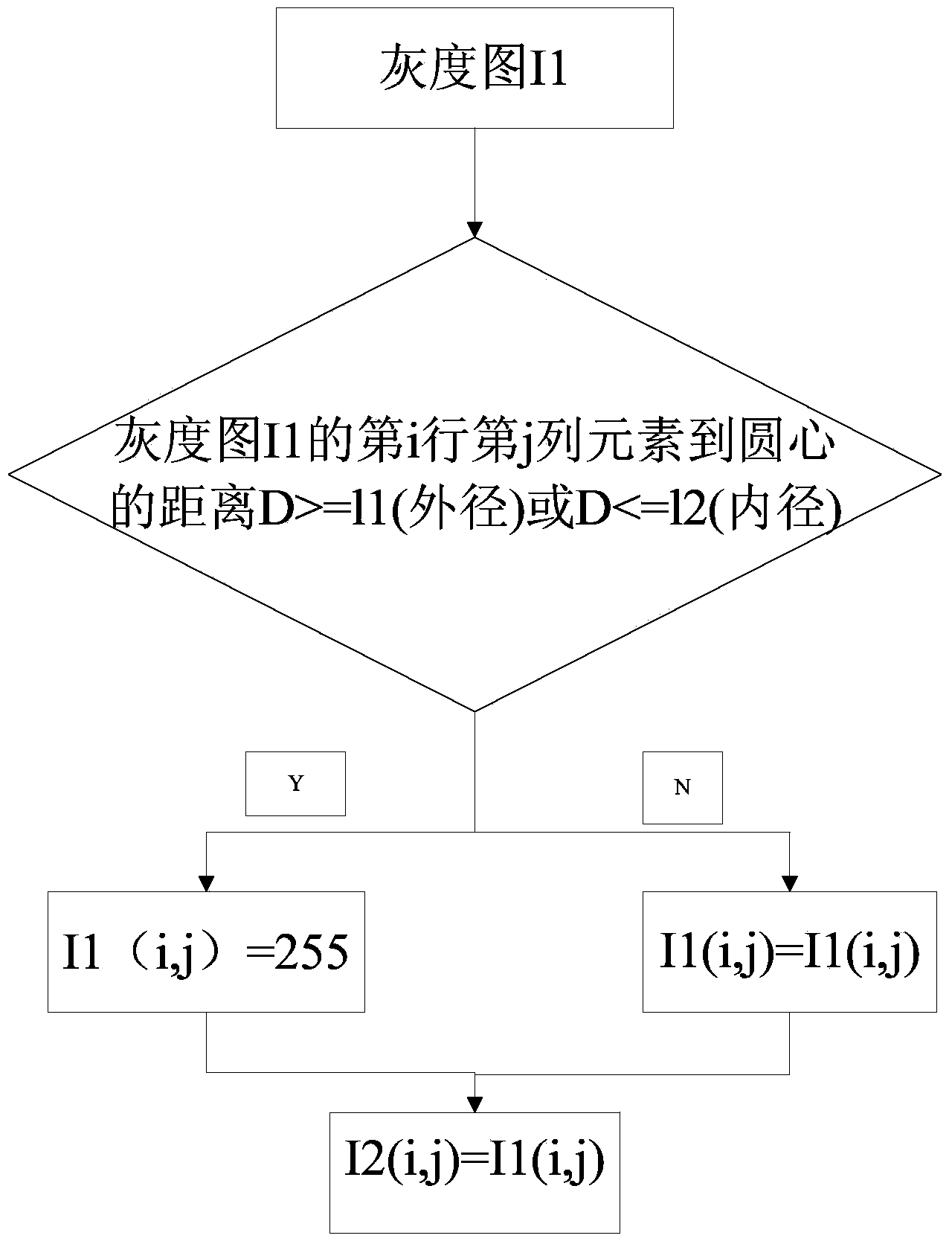

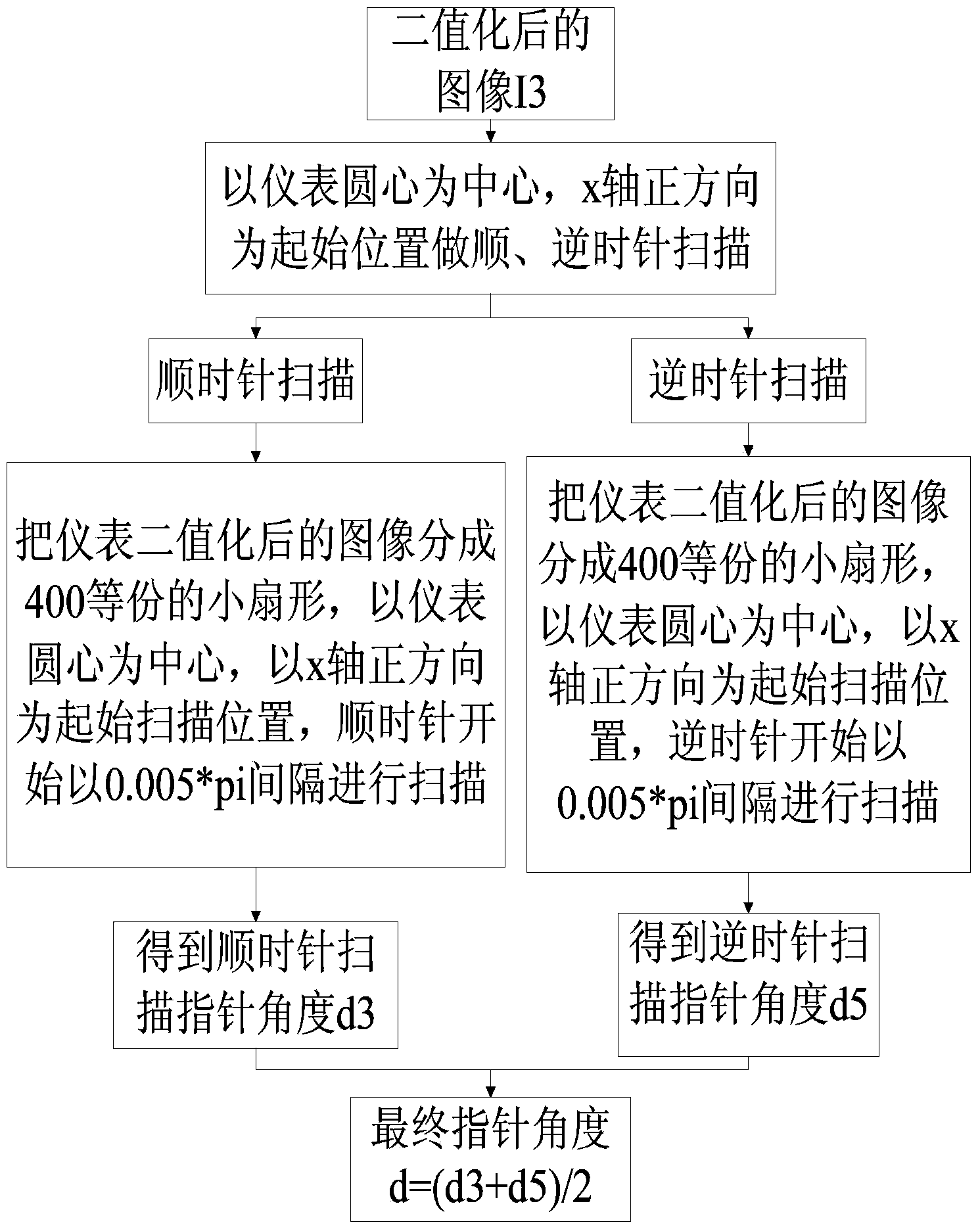

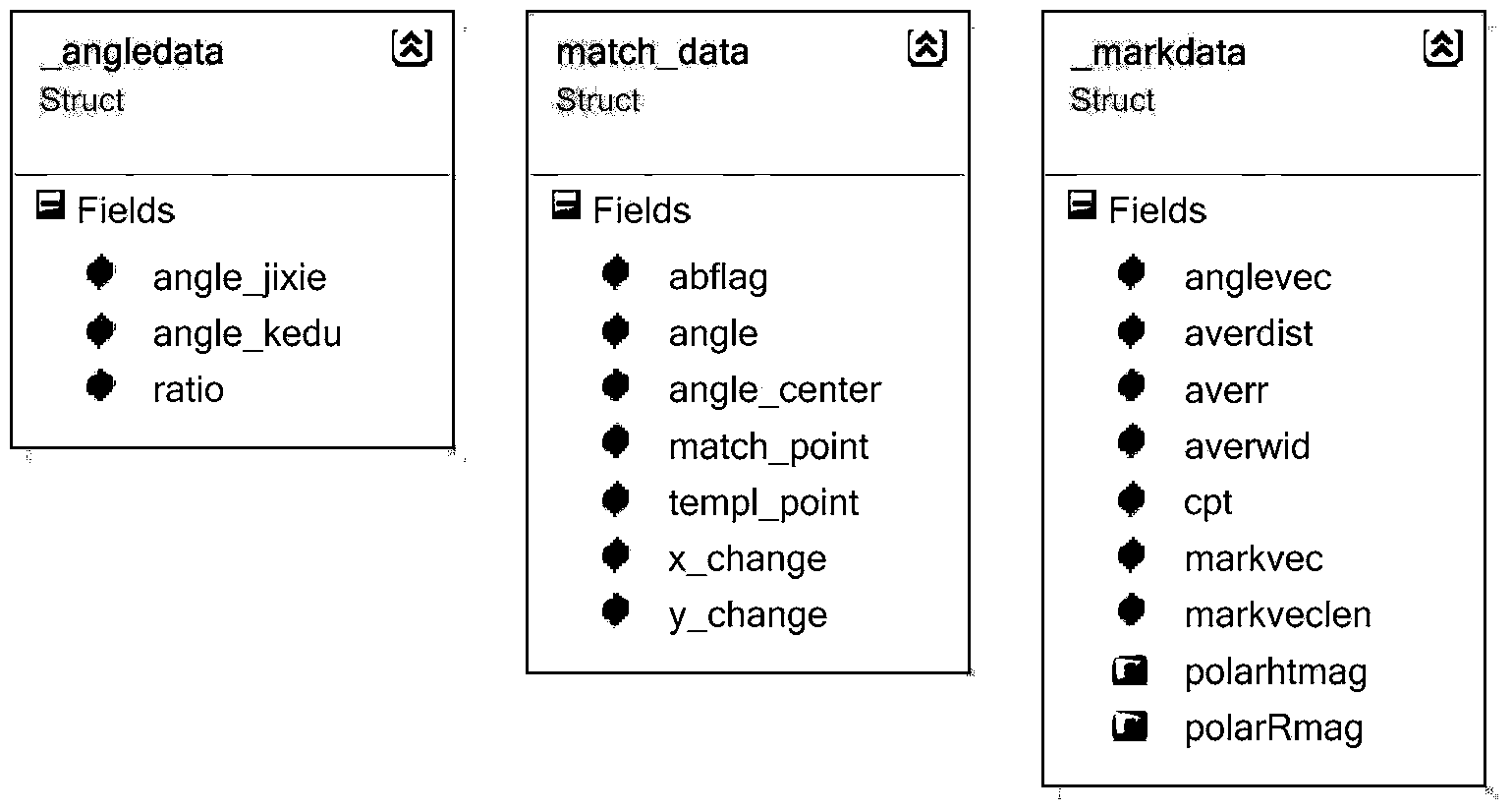

Detecting algorithm for identifying meter needle

ActiveCN103714329AOvercome the disadvantage of large errorHigh precisionCharacter and pattern recognitionColor imageLine fitting

Owner:CHANGAN UNIV

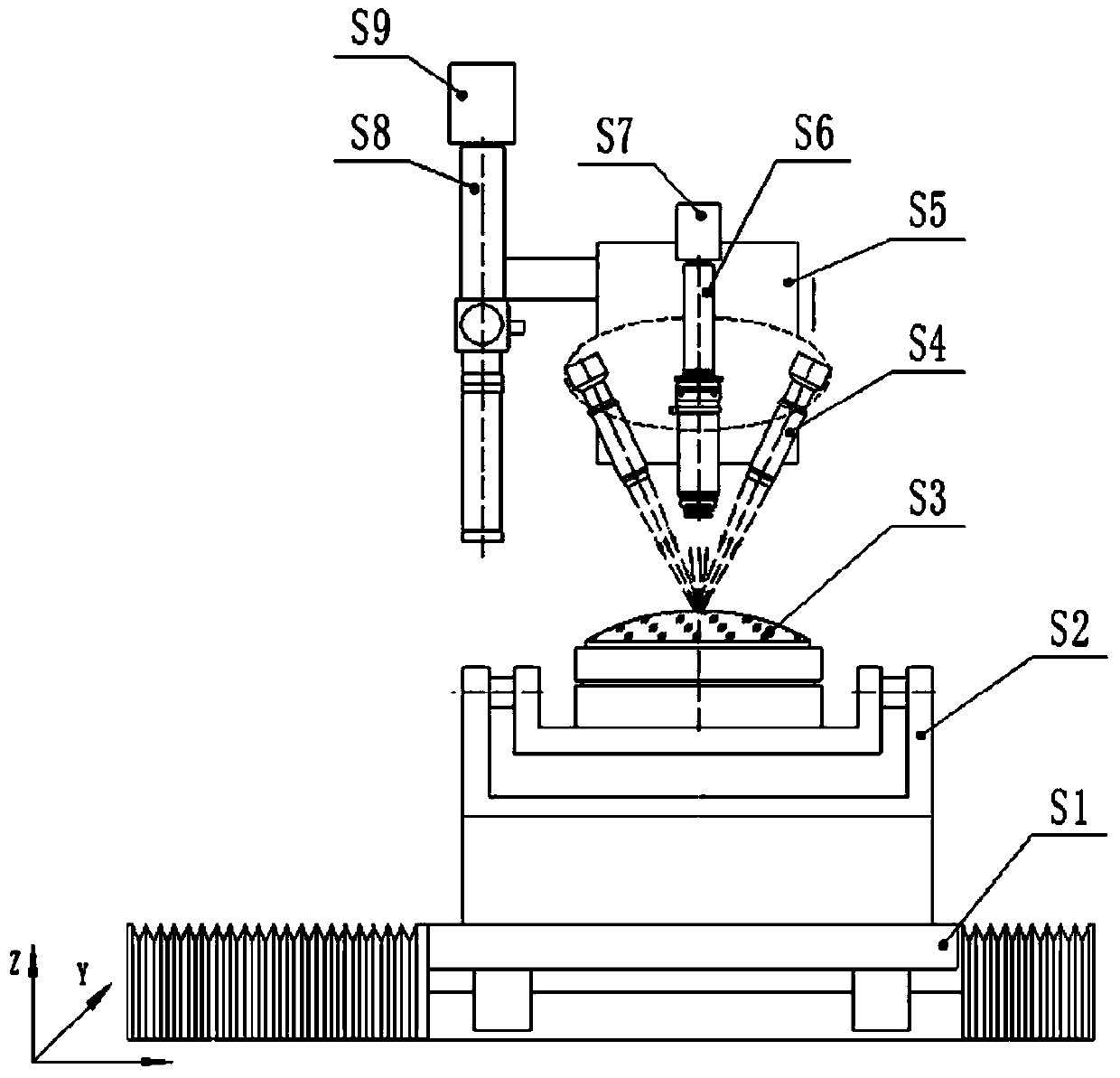

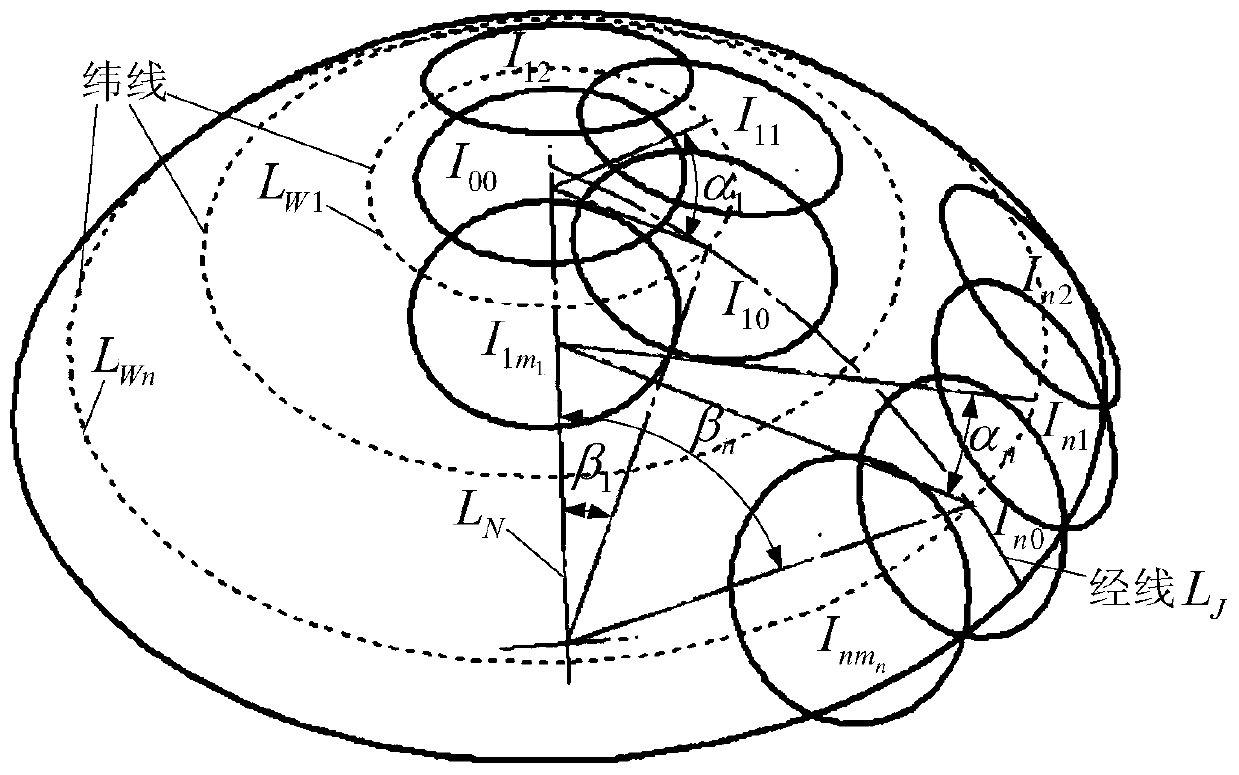

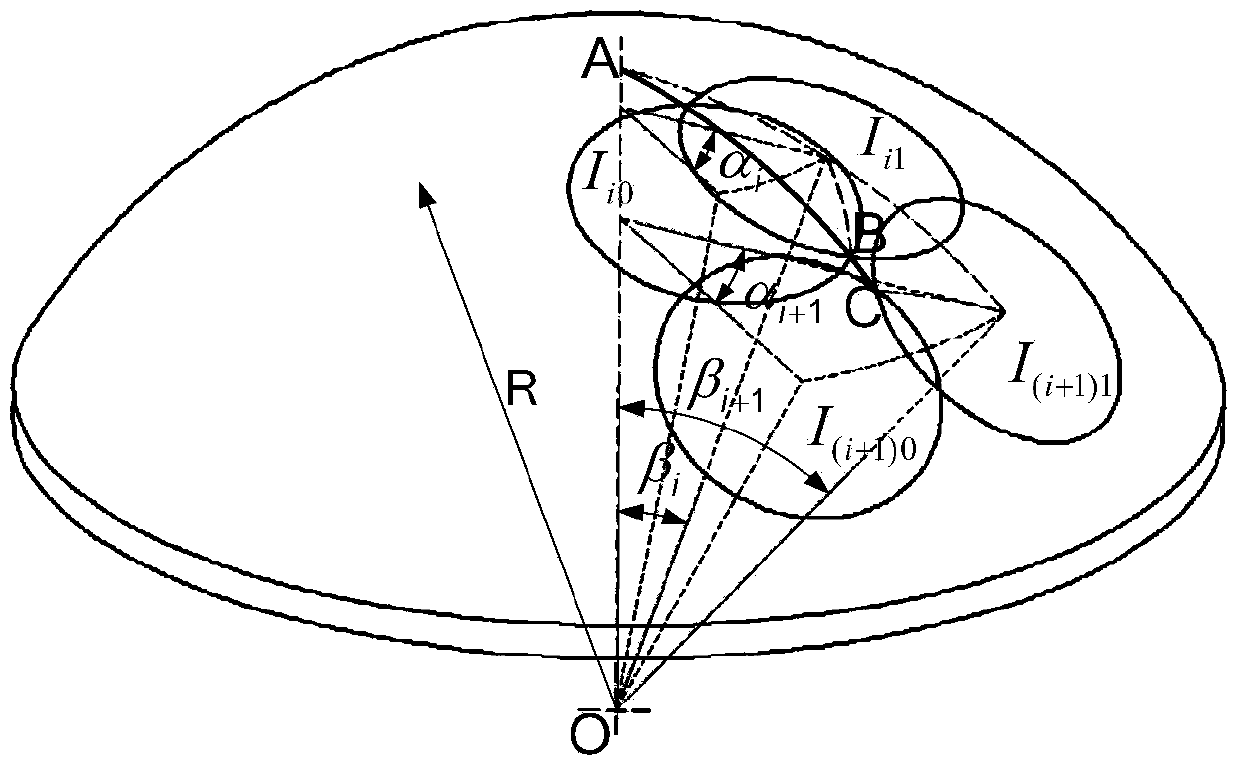

System and method for detecting surface defects of large-caliber spherical optical element

ActiveCN104215646ARealize automated quantitative detectionImprove detection efficiencyMaterial analysis by optical meansFeature extractionGray level

The invention discloses a system and method for detecting surface defects of a large-caliber spherical optical element. The system comprises an XY two-dimensional guide rail, a two-dimensional rotating system, a large-caliber spherical optical element, an annular illuminating light source, a Z-direction guide rail, a microscope, a CCD1, an optical auto-collimating centering instrument and a CCD2, wherein the large-caliber spherical optical element is fixedly arranged on the two-dimensional rotating system; the two-dimensional rotating system is arranged on the XY two-dimensional guide rail, so that multi-axis linkage of the large-caliber spherical optical element is realized; the CCD1 is connected to the microscope and is fixedly arranged on the annular illuminating light source; the annular illuminating light source and the optical auto-collimating centering instrument are fixedly arranged on the Z-direction guide rail and are in translational motion along with the Z-direction guide rail along the Z-axis direction; and the CCD2 is connected to the optical auto-collimating centering instrument. According to the invention, the subaperture sampling process of the surface defects of the large-caliber spherical optical element is realized, and full-caliber defect gray level images are subjected to digital feature extraction, so that automatic quantitative determination of the defects is realized.

Owner:ZHEJIANG UNIV

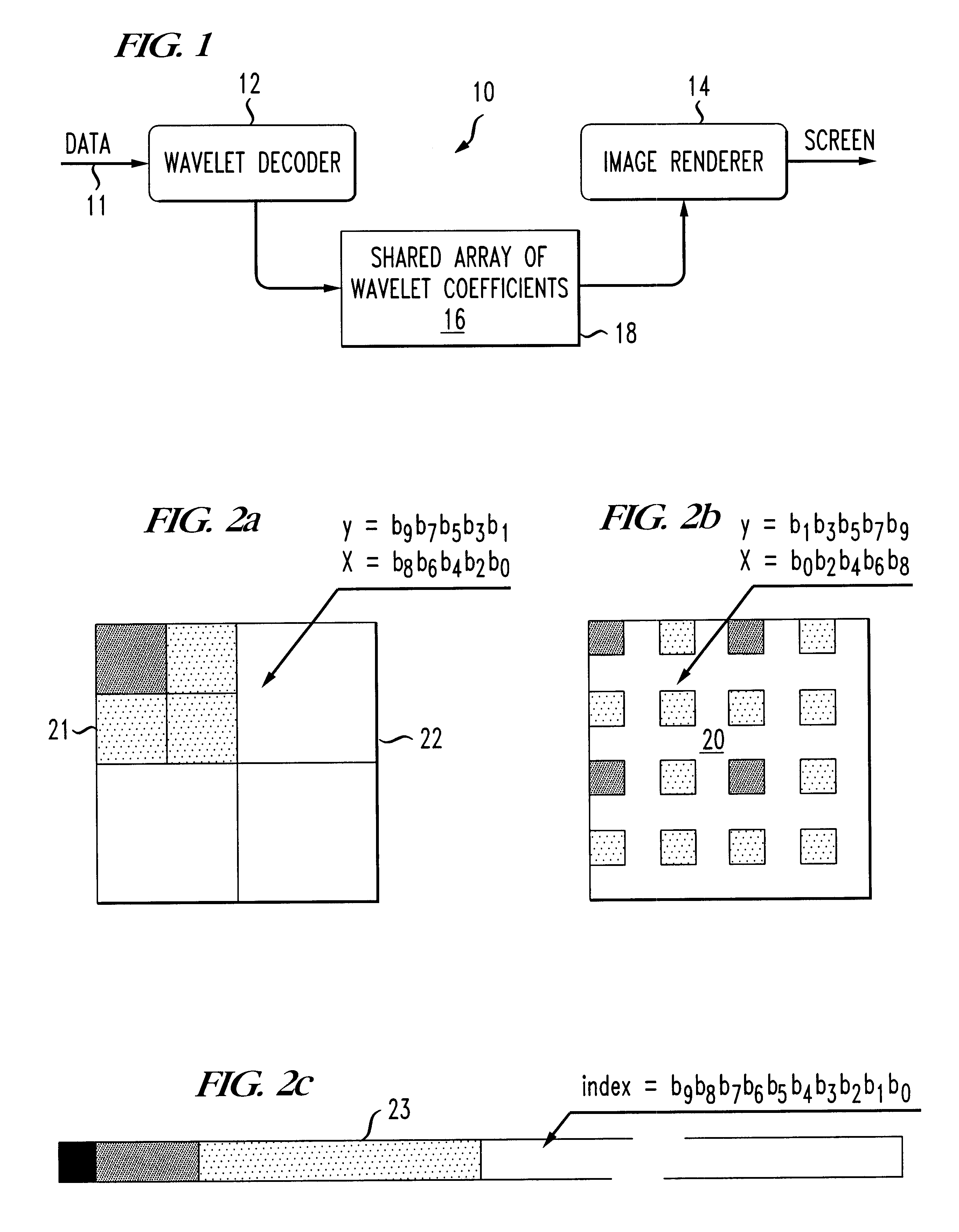

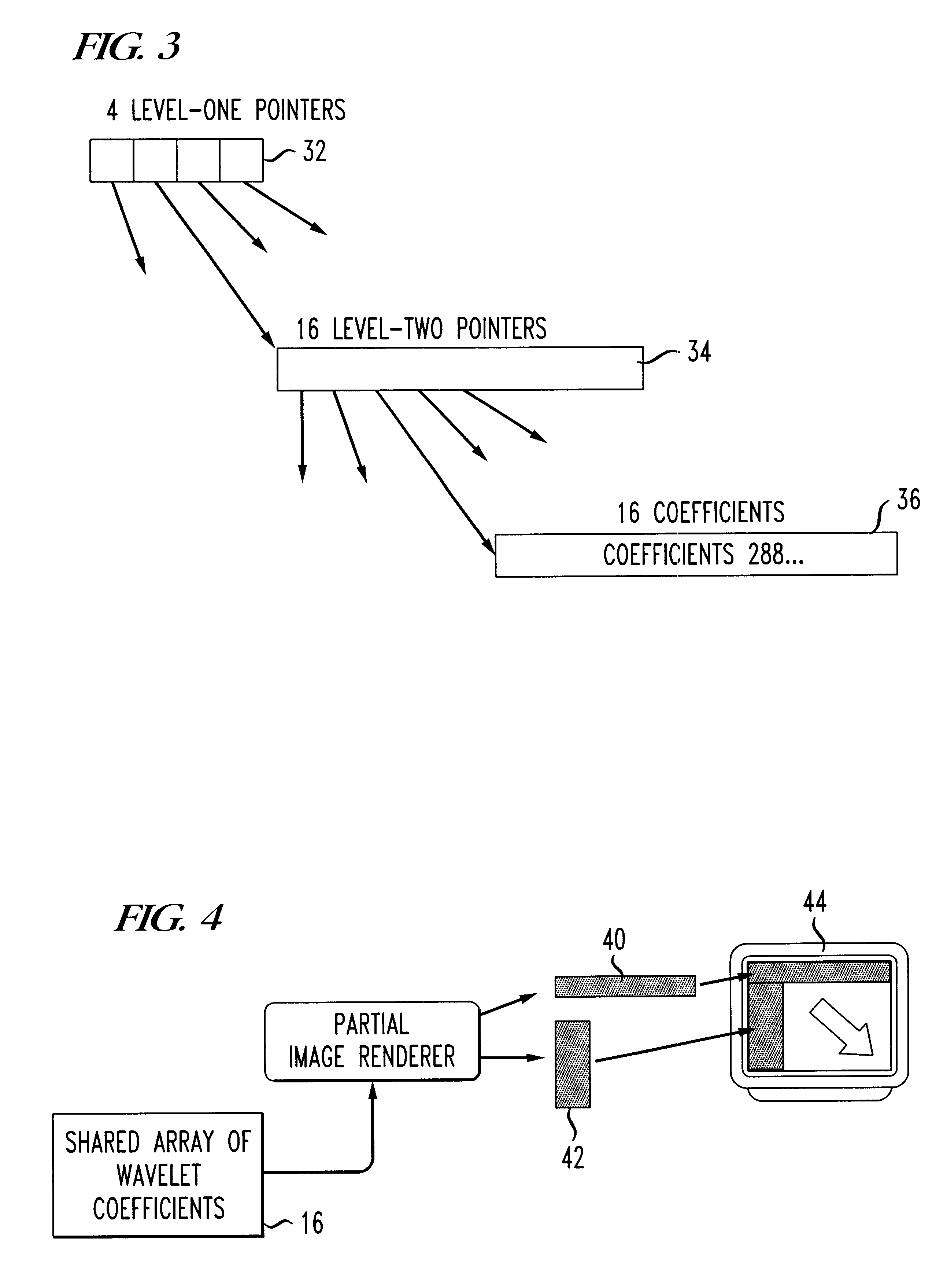

Progressive image decoder for wavelet encoded images in compressed files and method of operation

InactiveUS6587588B1Picture reproducers using cathode ray tubesPicture reproducers with optical-mechanical scanningArray data structureGray level

A progressive image display decoder and method of operation for wavelet encoded images achieves reduced memory storage requirements for wavelet transform coefficients and reduced execution time in displaying the image thereby overcoming the limitations of the prior art. Conveniently, a wavelet image format, typically DjVu IW44 facilitates progressive rendering and smooth scrolling of large color or gray level images with limited memory requirements. The progressive wavelet decoder is composed of two components. The first component decodes the incoming image data and updates an array of wavelet coefficients. The second component applies an inverse wavelet transform to the array of wavelet coefficients for the purpose of reconstructing the image. The operation of the first component (the decoder) is triggered by the incoming compressed image data. The received data is decoded and is used to apply updates to an array of wavelet coefficients. Each update improves the accuracy of the coefficients and therefore improves the fidelity of the reconstructed image. The coefficient array is composed of several two-dimensional arrays (one for each of the color components) having one entry corresponding to each 32x32 blocks in the image. Each entry contains 1024 wavelet coefficients organized as a sparse array with two levels of indirection. The operation of the second component (the renderer) is typically triggered when enough data has been received to display an updated version of the image, or when the user performs an action which requires displaying a new part of the image. In the latter case, the renderer only reconstructs the pixel values for the parts of the image, which are needed. A further reduction of the computation time is obtained by using "lifting" for implementing a fast inverse wavelet transform.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

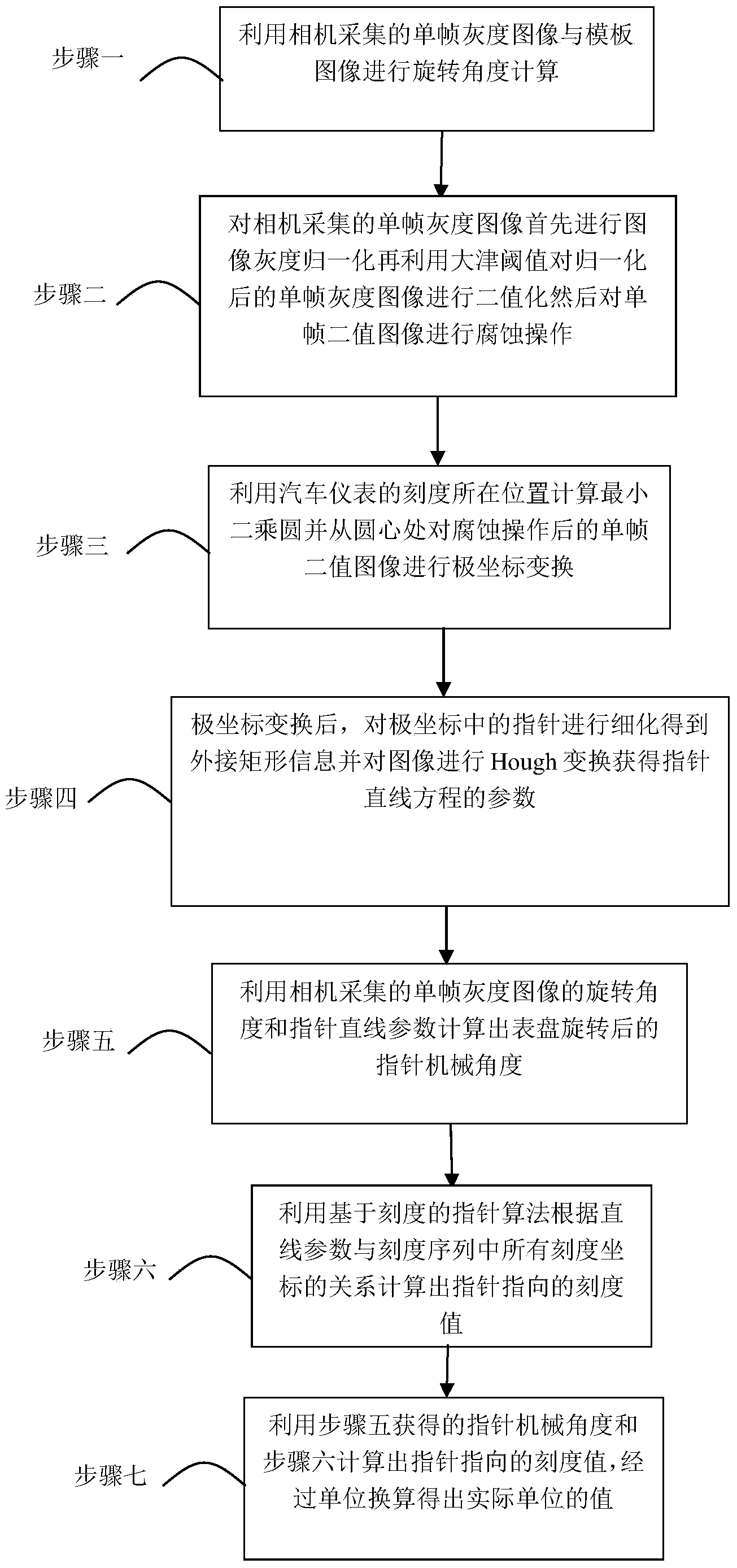

Method for detecting position of automobile meter needle based on mechanical angle and scale identification

The invention discloses a method for detecting the position of an automobile meter needle based on a mechanical angle and scale identification and relates to a needle position detection method. The method mainly solves the problems that a needle deforms when being detected in a small angle with a traditional method; dependency on the zero scale is high, so that the orderly scale sequence can not be obtained due to inaccuracy of scale distribution features; rotation errors generated when an instrument panel is assembled will not be detected with the traditional method. The method for detecting the position of the automobile meter needle based on the mechanical angle and the scale identification includes the following steps that firstly, the rotation angle of a single-frame gray level image is calculated; secondly, a single-frame binary image is normalized, binarized and then corroded; thirdly, polar coordinate conversion is carried out on the image; fourthly, parameters of a needle linear equation are obtained; fifthly, the mechanical angle of the needle is calculated; sixthly, the scale value pointed by the needle is calculated out; seventhly, the value of a practical unit is obtained. The method for detecting the position of the automobile meter needle based on the mechanical angle and the scale identification is applied to the needle position detection field.

Owner:HARBIN INST OF TECH

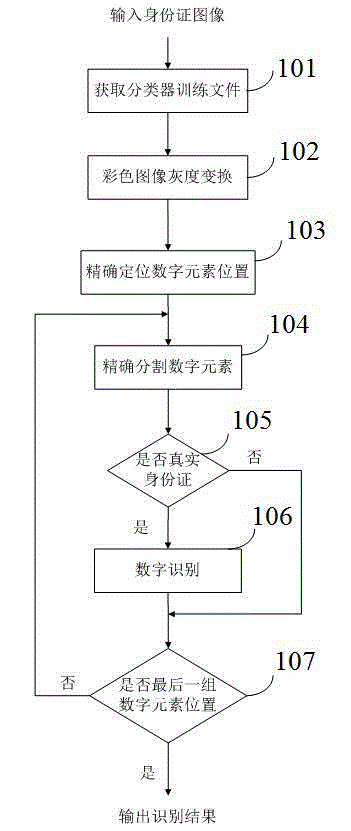

Digit recognition method for identification cards

InactiveCN104680161AImprove recognition accuracyLow costCharacter and pattern recognitionColor imagePattern recognition

The invention provides a digit recognition method for identification cards. The digit recognition method comprises the following steps: acquiring a classifier training file; transforming a color image to be identified into a gray level image; accurately positioning digit element positions of each identification card; accurately segmenting digit characters of each identification card; verifying whether a candidate region is a real digit region of each identification card; carrying out digit recognition on the basis of a nearest neighbor algorithm; judging whether the current digit element is the last group of digit element. According to the digit recognition method provided by the invention, positioning, segmentation and identification of digits on the identification cards are carried out by adopting an image processing technology; the recognition precision is relatively high, no special equipment is needed and the cost is low; the digit recognition method has strong applicability to various environments and can be used for reading information of multiple identification cards simultaneously.

Owner:ANHUI TSINGLINK INFORMATION TECH

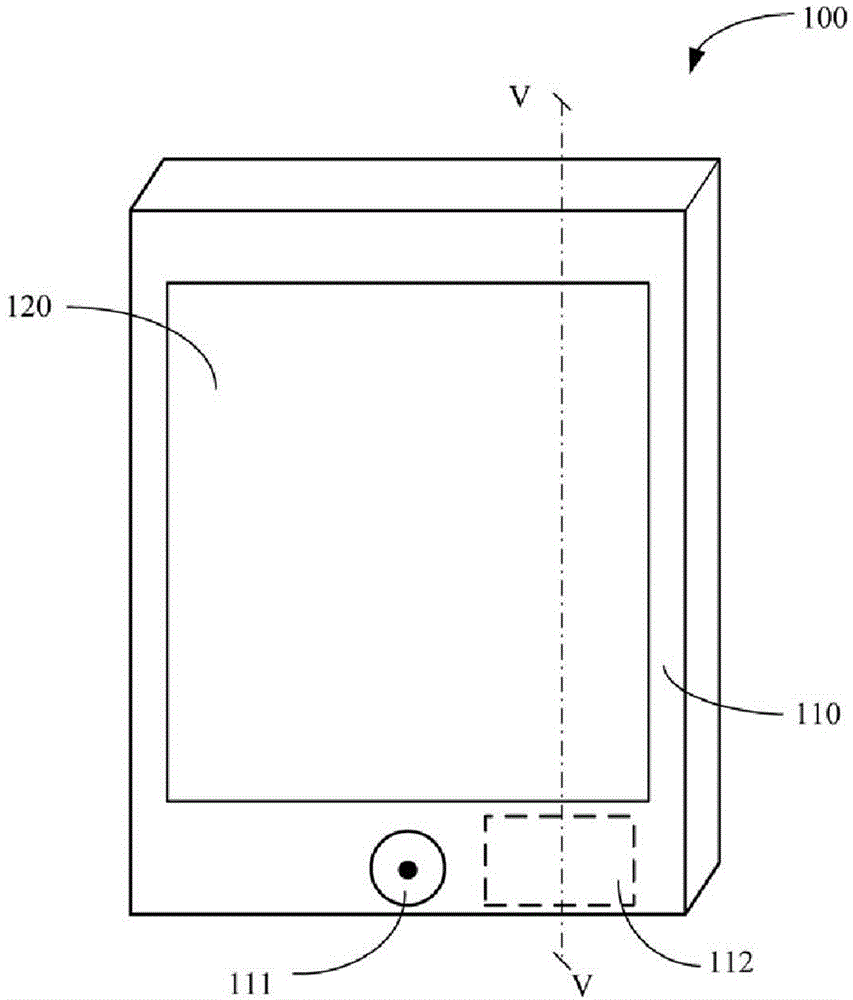

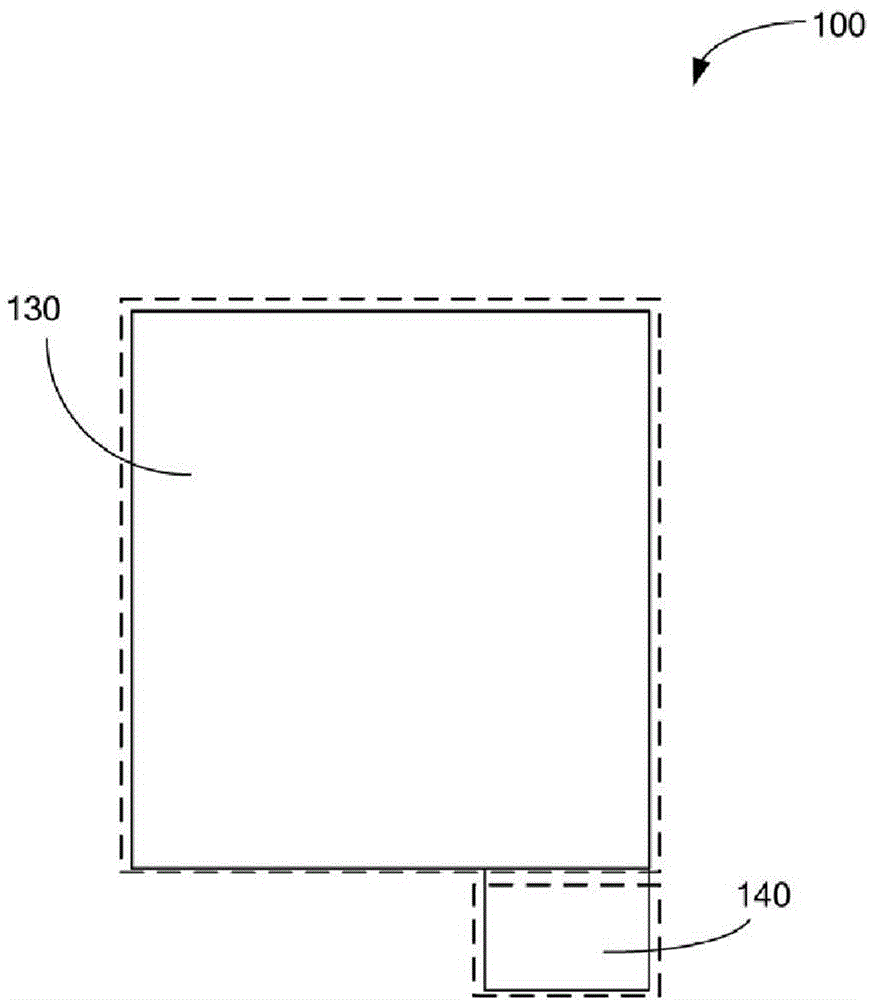

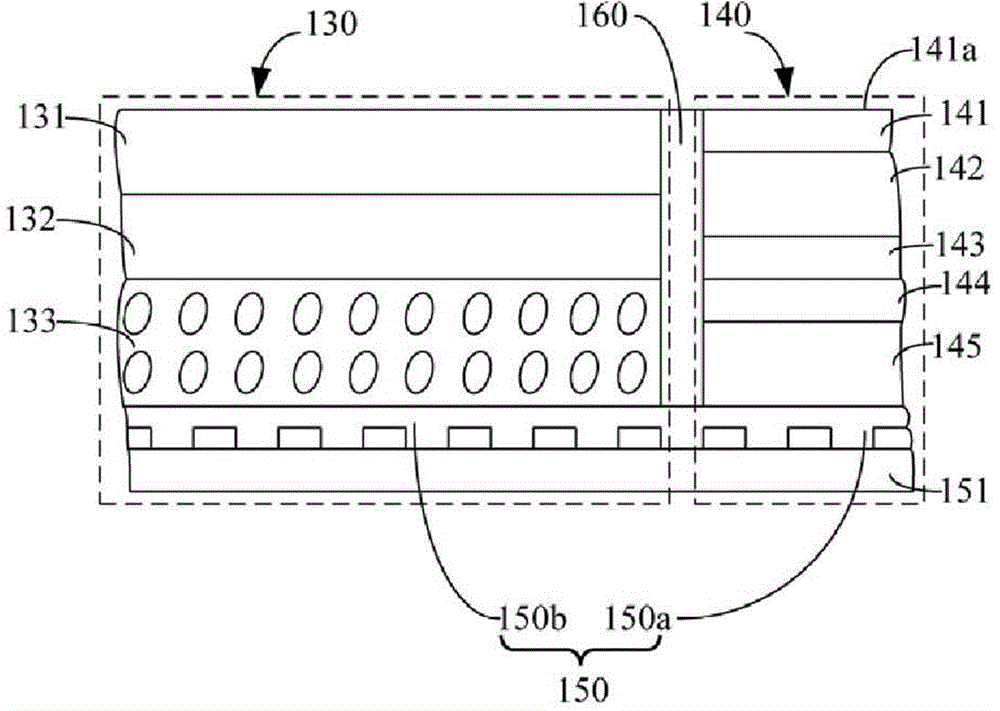

Electronic device

ActiveCN104424420AEasy to manufactureHighly integratedCharacter and pattern recognitionDigital data authenticationTransistor arrayContact layer

The invention provides an electronic device. The electronic device comprises a base plate, a display die set and a fingerprint recognizing die set, wherein the display die set and the fingerprint recognizing die set are arranged on the base plate; the fingerprint recognizing die set comprises a touch layer, a signal sending layer, a signal receiving layer and a first thin-film transistor array which are sequentially overlapped and arranged; the signal sending layer is used for continuously sending an ultrasonic signal to the contact layer and the signal receiving layer; the touch layer is used for reflecting the ultrasonic signal according to the sensed fingerprint; the signal receiving layer is used for receiving the ultrasonic signal and converting the received ultrasonic signal into an electric signal to transmit to the first thin-film transistor array; the first thin-film transistor array is used for acquiring a fingerprint gray level image according to the electric signal from the receiving layer; the display die set comprises a second thin-film transistor array which drives the display die set to display the image; the first thin-film transistor array and the second thin-film transistor array are formed on the base plate together.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

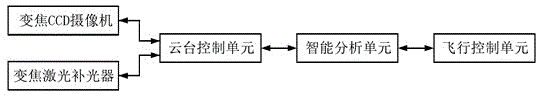

Unmanned aerial vehicle target tracking method and system

PendingCN104811667AExtended TrackingImplement trackingTelevision system detailsImage analysisFly controlUncrewed vehicle

The invention discloses an unmanned aerial vehicle target tracking method and system. The method includes that an image capture unit comprises a zooming CCD camera and a zooming laser light supplement device, and the zooming laser light supplement device is used for supplementing light for the monitored region of the zooming CCD camera to allow the zooming CCD camera to acquire sharp images of the monitored region; a pan tilt control unit controls the pan tilt in horizontal and vertical directions and the focal distance of the zooming CCD camera to allow a tracked target to be in the center of the vision of the zooming CCD camera constantly; an intelligent analysis unit adopts the method of extracting a moving target from the gray level image sequence and detects the moving target from the images; after extraction and positioning of the moving target, a flying control unit feeds the moving state of the target back to an unmanned aerial vehicle, and the unmanned aerial vehicle flies to track the ground dynamic target automatically. The method has the advantages that the visual distance is long, and the unmanned aerial vehicle is capable of tracking a moving target in a completely dark environment.

Owner:SHENZHEN PROTRULY ELECTRONICS CO LTD

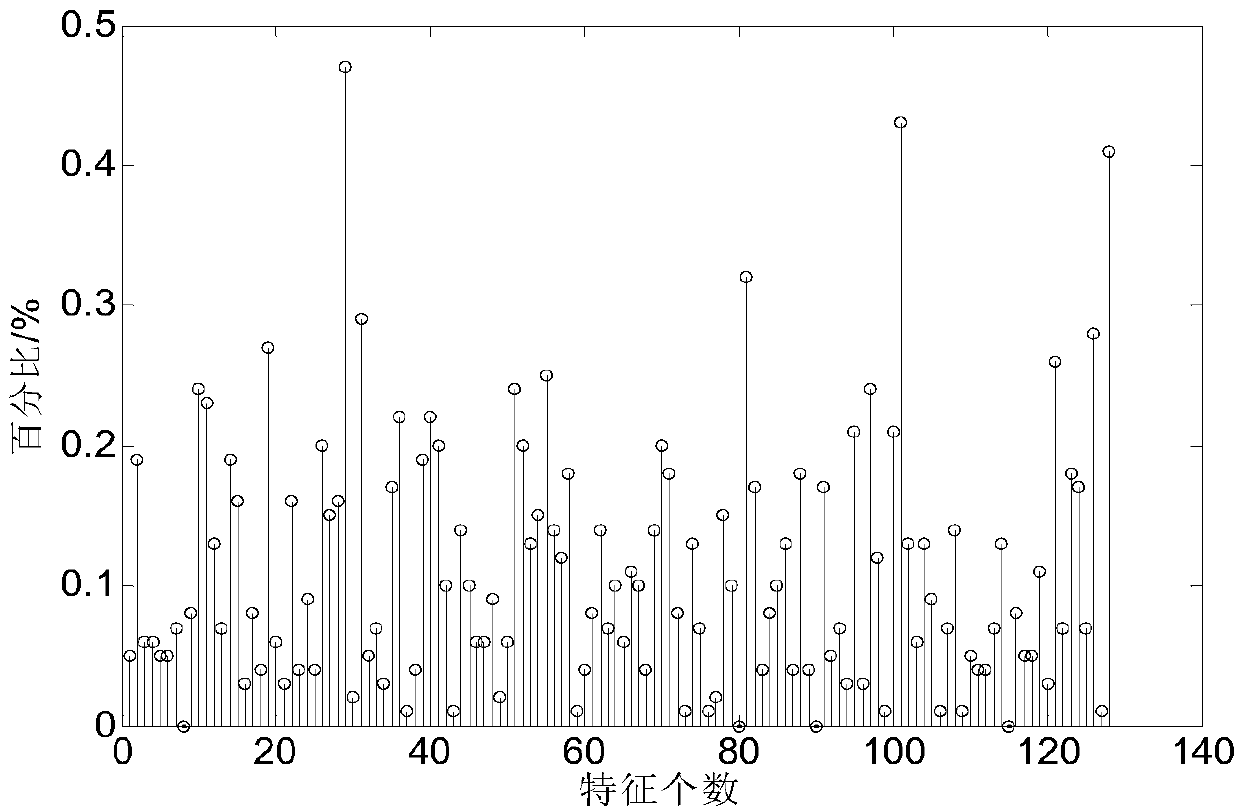

Hyperspectral image wave band selection method based on quantum-behaved particle swarm optimization algorithm

ActiveCN103714354AImprove search abilityImprove performanceCharacter and pattern recognitionBiological modelsGlobal optimalSpectral image

The invention discloses a hyperspectral image wave band selection method based on the quantum-behaved particle swarm optimization algorithm to mainly solve the problems that in the prior art, searching capacity is low and classification accuracy is not high. The hyperspectral image wave band selection method includes the steps of firstly, inputting hyperspectral gray level images, and setting up a training set through samples with labels; secondly, initiating position vectors, code vectors, fitness values and local optimal information of particles and global optimal information of population; thirdly, renewing the position vectors and the code vectors of the particles; fourthly, calculating the fitness values of the particles according to the renewed code vectors; fifthly, renewing the local optimal information of the particles and the global optimal information of the population; sixthly, judging whether iteration is stopped or not, outputting the optimal wave bands corresponding to the global optimal information if the stopping conditions are satisfied, and executing the third step if the stopping conditions are not satisfied. By means of the hyperspectral image wave band selection method, effectiveness of wave band selection is improved, the optimal wave bands can be selected out as less as possible in a self-adaption mode on the premise that classification accuracy is ensured, and the hyperspectral image wave band selection method can be used for preprocessing the hyperspectral images before classification.

Owner:XIDIAN UNIV

Character two-dimensional bar code recognition method based on scanning gun

InactiveCN103593653AAchieving identifiabilityImplement decodingCharacter and pattern recognitionSensing by electromagnetic radiationSplit linesDot matrix

A character two-dimensional bar code recognition method based on a scanning gun includes the steps of obtaining a gray level image from the scanning gun, conducting positioning on a solid circle locator in the gray level image, extracting a character area through a distortion correction and bilinear interpolation method; conducting binarization processing and denoising on the character area, conducting transverse and longitudinal histogram normalization on the character area, then, conducting secondary smoothing, determining segment lines through crests and troughs, then conducting resegmentation on characters obtained through segmentation, accurately obtaining the character area, conducting normalization processing on the characters to form a 20*30 dot matrix, extracting character characteristics, and conducting recognition through characteristic matching. The character two-dimensional bar code recognition method is mainly characterized in that rapid recognition of a character two-dimensional bar code is achieved on the basis of the scanning gun and under limitation of limited internal storage and time.

Owner:ZHEJIANG UNIV OF TECH

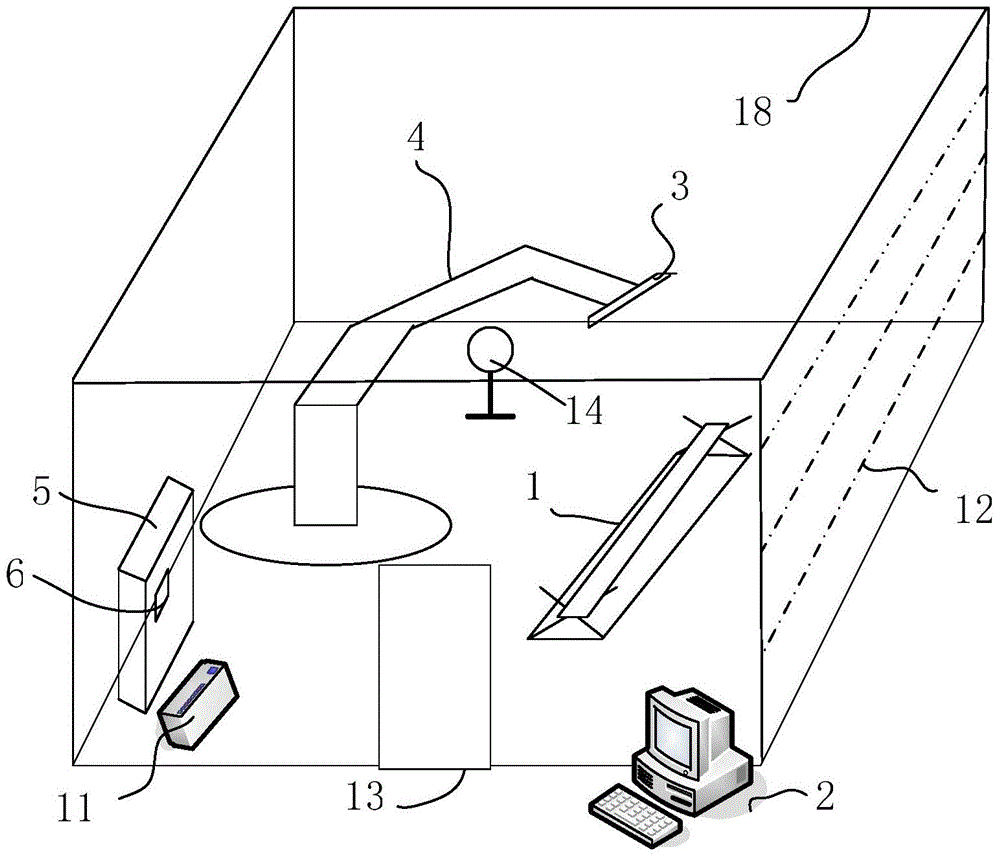

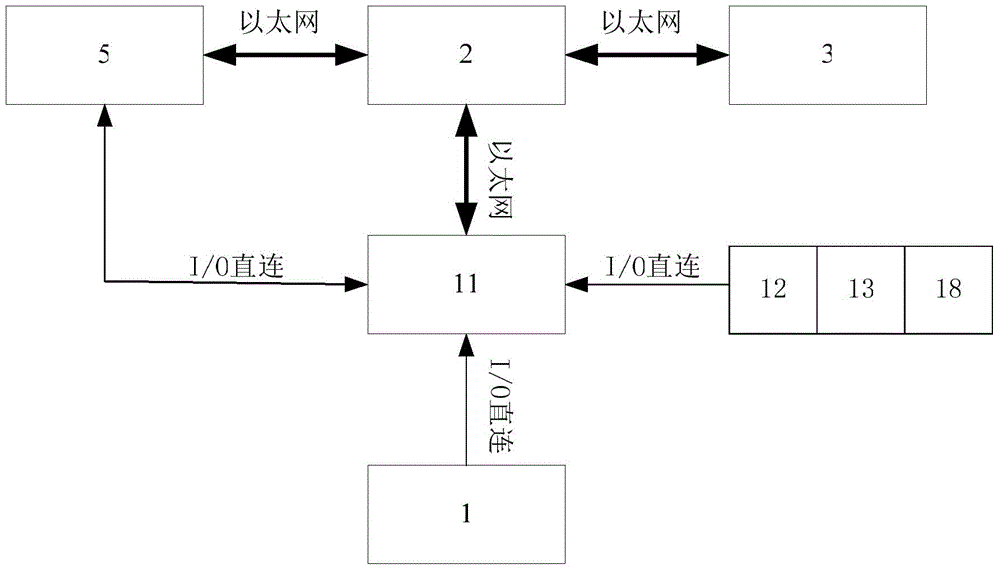

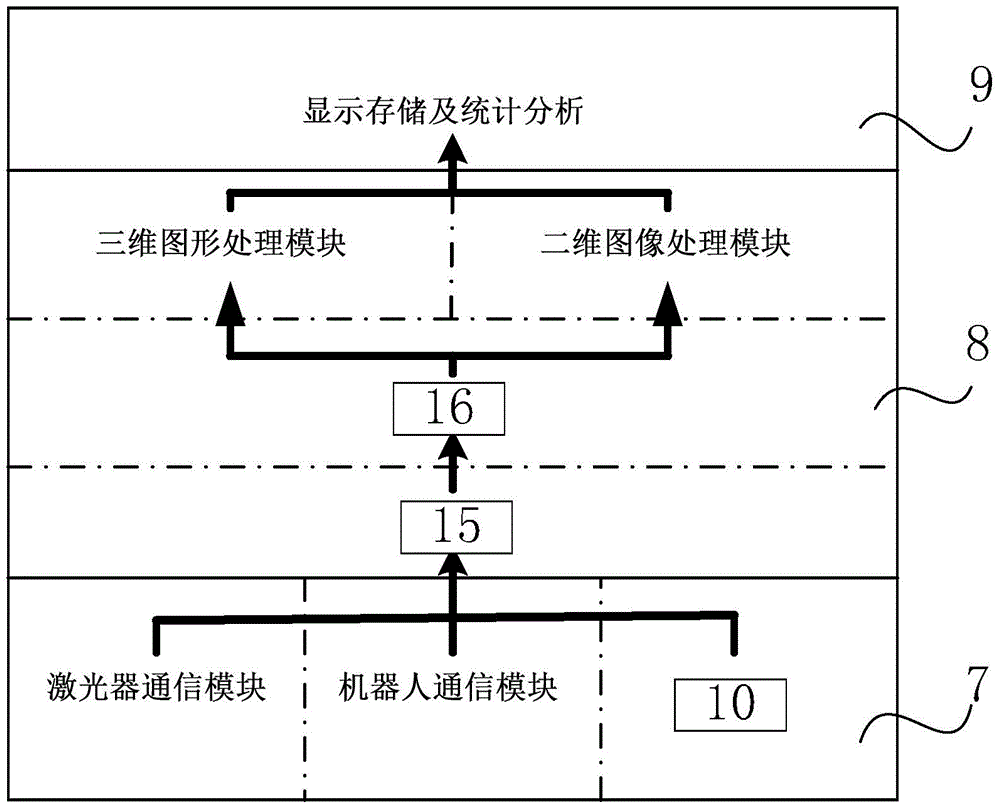

Robot workpiece assembly and form and location tolerance detection system and method based on face laser sensor

InactiveCN105333819AEasy to detectFacilitate information managementUsing optical meansEngineeringLaser sensor

The invention relates to a robot workpiece assembly and form and location tolerance detection system and method based on face laser sensor, and the system is characterized in that the system comprises a positioning assembly; the periphery of the positioning assembly is provided with the face laser sensor, robot equipment, and an industrial control computer, wherein the face laser sensor, the robot equipment and the industrial control computer communicate with each other. The system depends on a robot which is provided with the face laser sensor, so as to carry out the detection of wrong and leaked assembly of workpieces and the detection of the form and location tolerance of the workpieces. The face laser sensor can obtain the characteristics of three-dimensional data gray level image data of the surface of a detected part at a time under the condition that the robot is stationary, and enables the system to be higher in precision. Moreover, compared with a conventional binocular vision detection mode, the system does not need the assistance from external equipment, also does not need an additional marking point, is easy to implement, and is low in cost.

Owner:SUZHOU BEISHUO INSPECTION TECH CO LTD

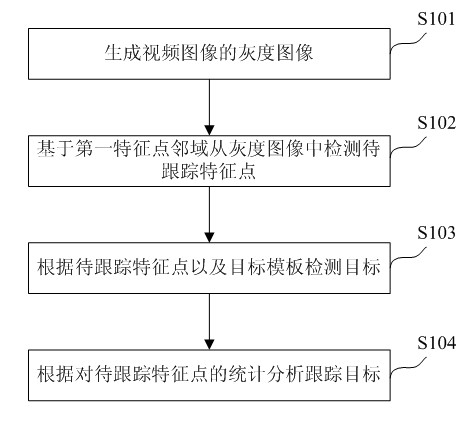

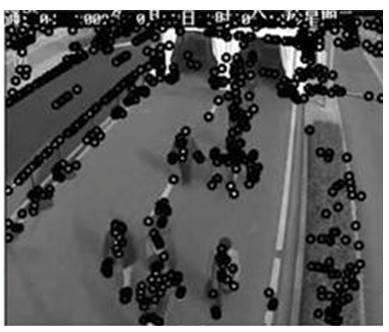

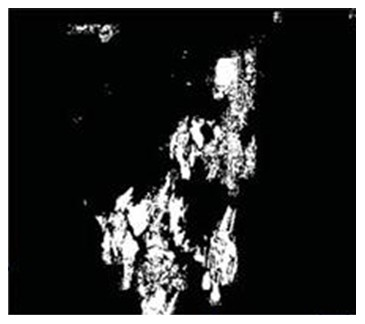

Target tracking method and system based on video image

ActiveCN102385690AEffective trackingAvoid being mistrackedCharacter and pattern recognitionPattern recognitionComputer graphics (images)

The invention discloses a target tracking method and a system based on video image, which belongs to the technical field of pattern recognition. The method comprises the following the steps: generating a gray level image of the video image, detecting characteristic points to be tracked in the gray level image based on a first characteristic point neighbourhood, detecting targets according to the characteristic points to be tracked and a stored target template, and analyzing the tracked target according to the statistic of the characteristic points to be tracked. In the invention, the characteristic points to be tracked of the pedestrian target are detected and tracked, and the moving synchronism of the pedestrian target and the corresponding characteristic points to be tracked is utilized, so that effective tracking of the pedestrian target can be realized, and the real-time performance and robustness of the tracking can be improved. Simultaneously, the characteristic points to be tracked are voted, so that the characteristic points can be prevented from being tracked by mistaken, and the leaked tracking of the pedestrian target can be avoided.

Owner:北京汉王智远科技有限公司

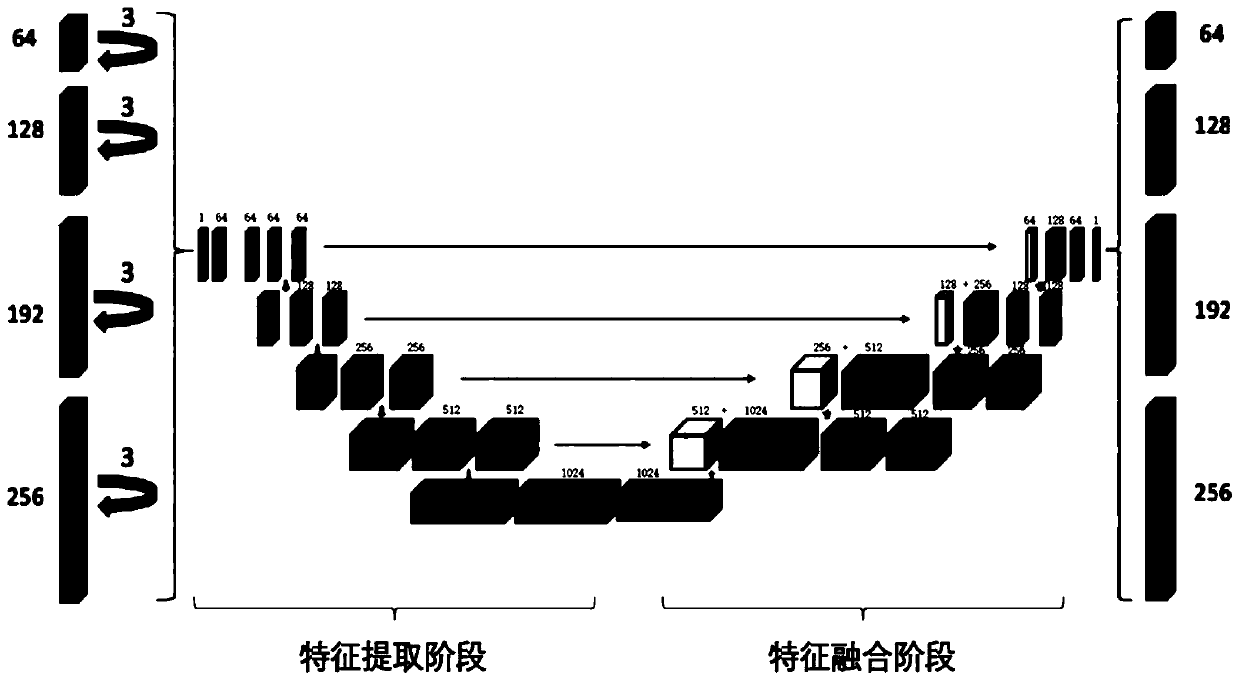

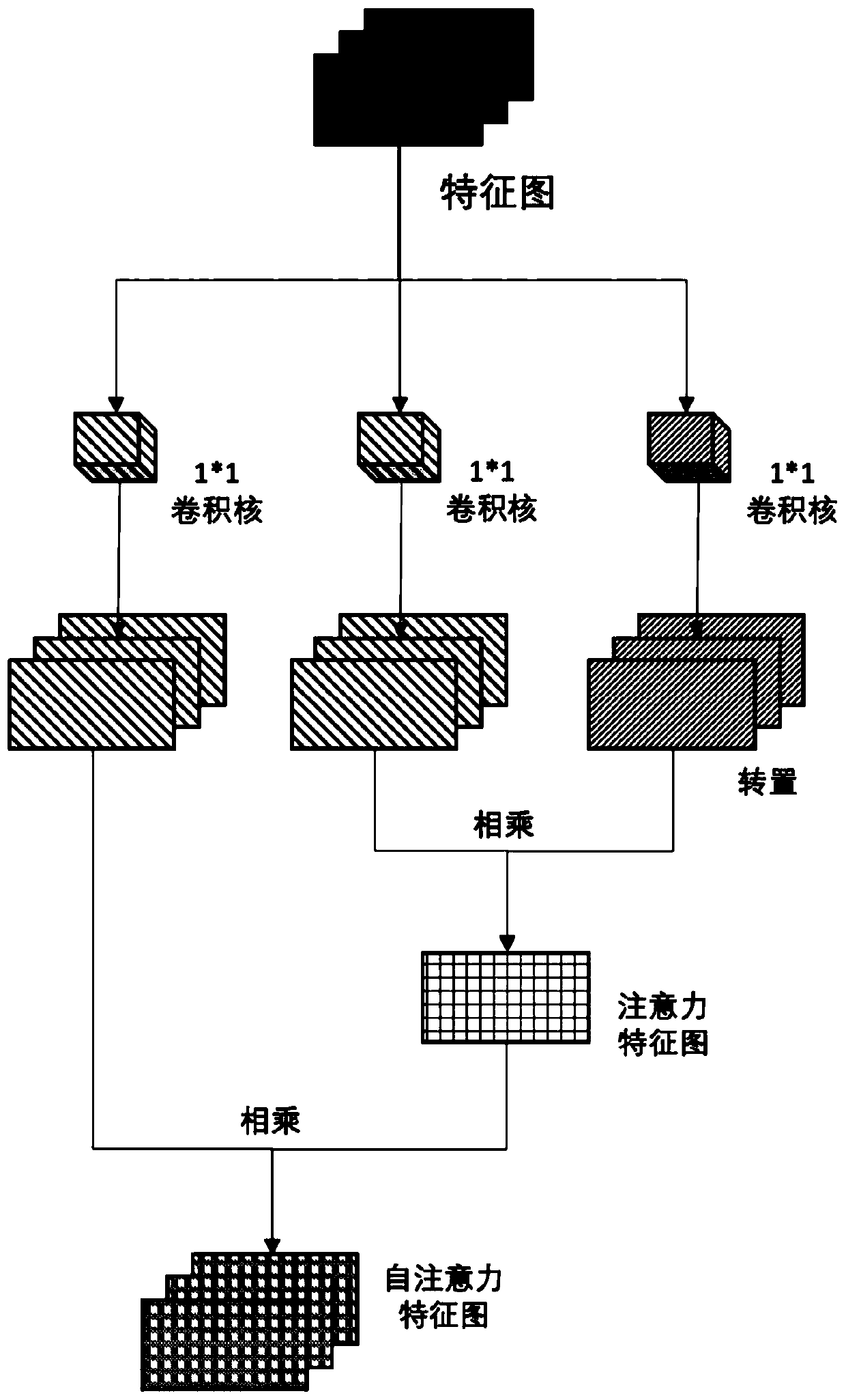

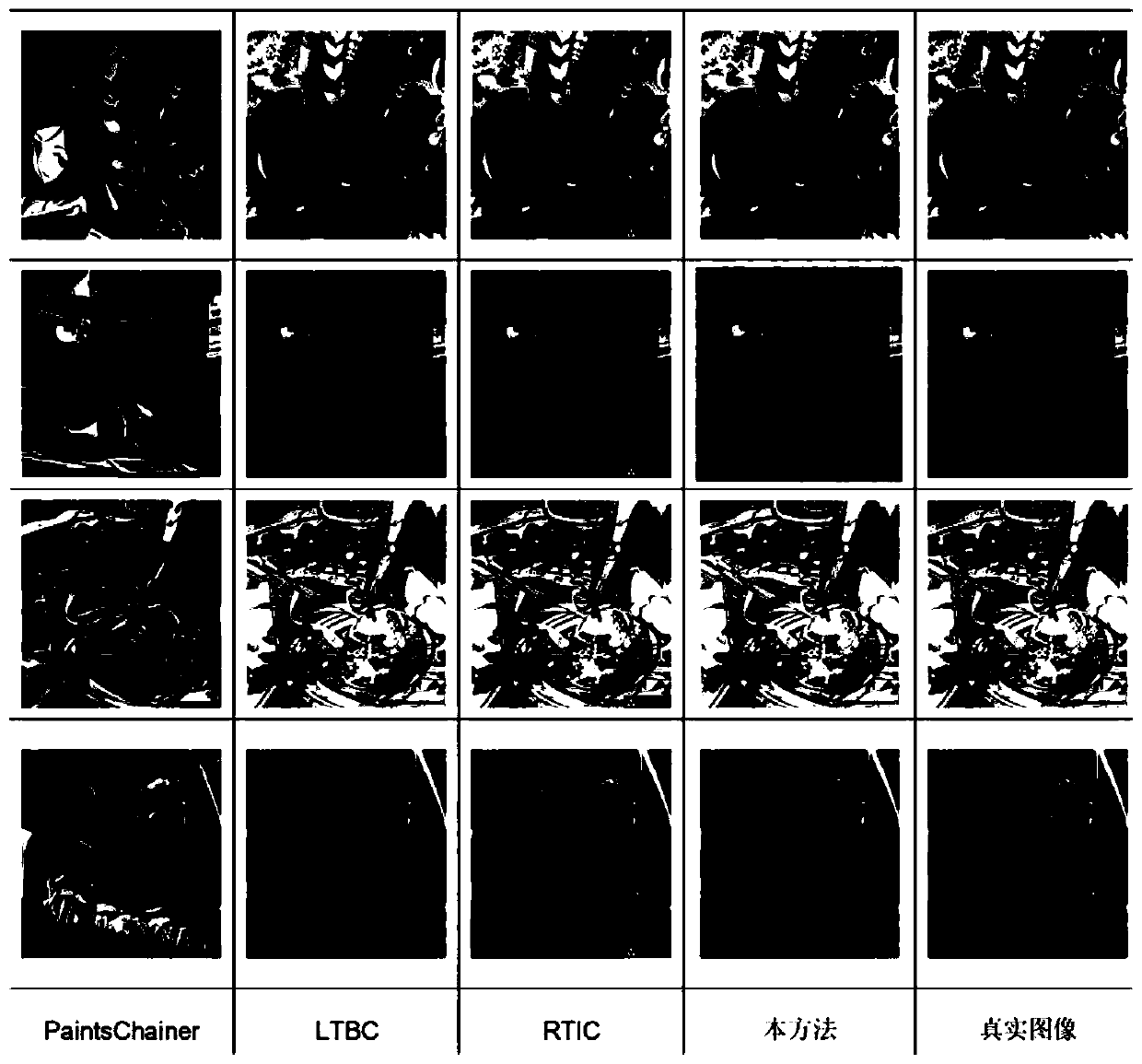

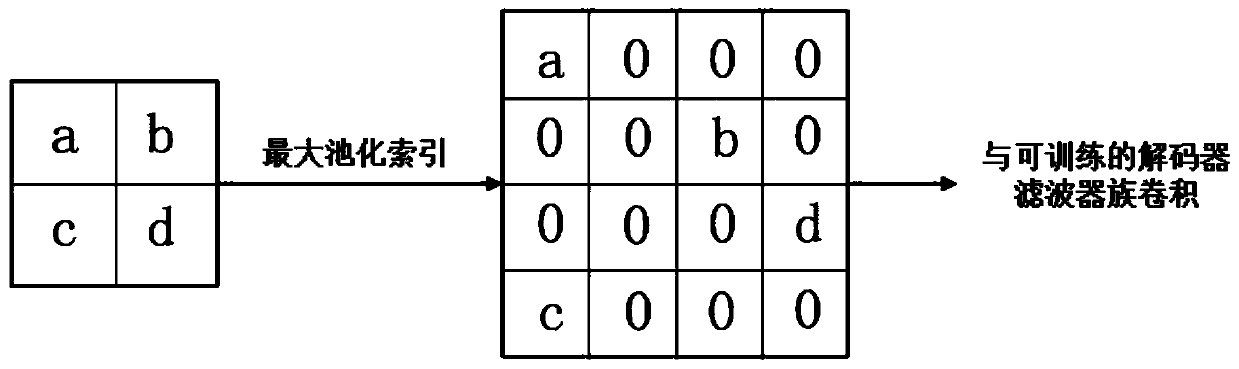

An image coloring method based on a self-attention generative adversarial network

ActiveCN109712203AHigh-resolutionGood coloring effectImage analysisGeometric image transformationColor imageTraining period

The invention discloses an image coloring method based on a self-attention generative adversarial network. The method comprises the following steps: step 1, training a grayscale image coloring model;2, inputting the gray level images in the training data set into an adversarial network to execute a feature extraction stage, a feature fusion stage, a deconvolution calculation stage and a self-attention learning stage to reconstruct corresponding color images; step 3, comparing the color image reconstructed after the self-attention learning with the corresponding original color image, and calculating a penalty function shown in the specification; and step 4, calculating a penalty function according to the formula shown in the specification, 4, taking the loss function as the optimization loss of the GAN on the basis of the formula shown in the specification, wherein the formula shown in the specification is shown in the specification; and step 5, dividing the training process into a plurality of preset sub-training periods, and sequentially training the sub-training periods by adopting a step-by-step growth strategy to obtain the generator network. According to the method, the colorimage conforming to human subjective visual preferences is reconstructed from a black-white or gray level image by adopting an adversarial generation network, so that the color image is more realistic.

Owner:福建帝视信息科技有限公司

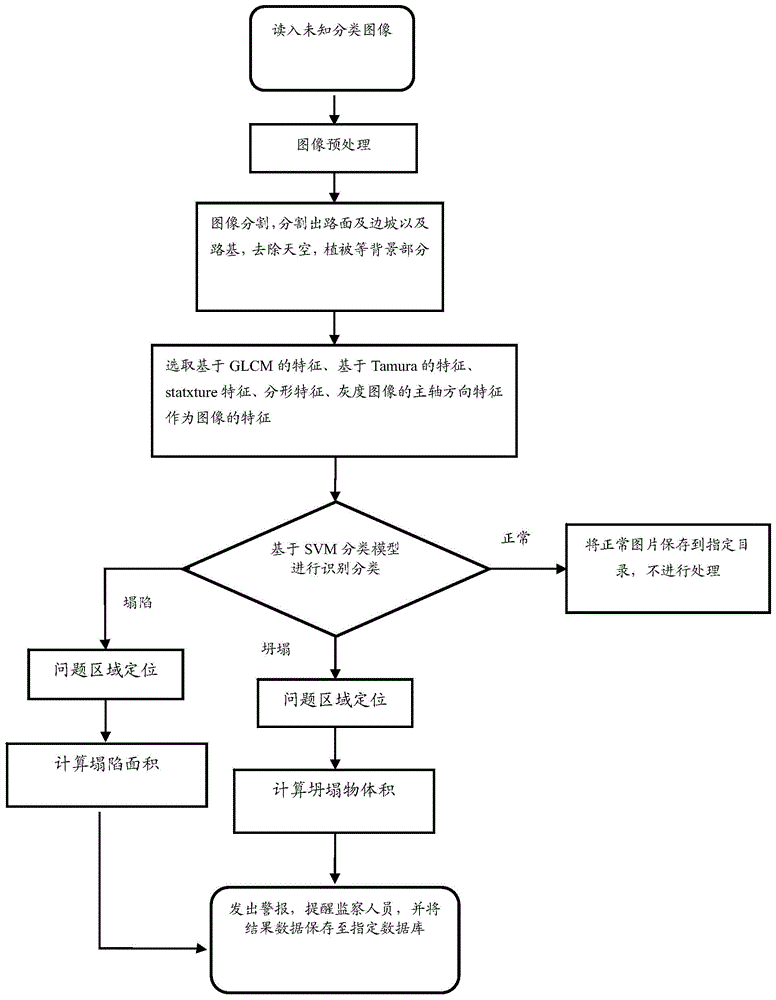

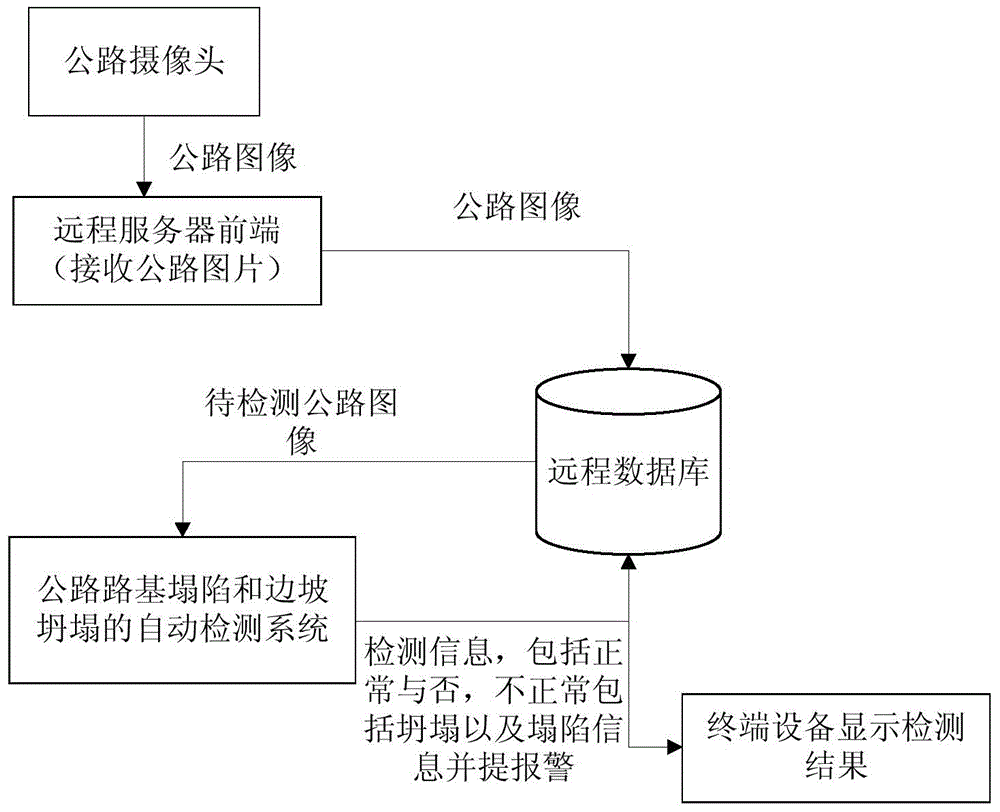

Method and system for automatically detecting roadbed collapse and side slope collapse of road

ActiveCN104134080AImprove efficiencyAccurate detectionCharacter and pattern recognitionFeature extractionRoad surface

The invention provides a method and system for automatically detecting road roadbed collapse and side slope collapse. The method includes the following steps: reading a road image; dividing the road image to obtain a road face image, a side slope image and a roadbed image; conducting characteristic extraction to select GLCM-based characteristics, the Tamura-based characteristics, the statxture characteristics, the fractal characteristics, the gray level image main axis direction characteristics and the image space characteristics to serve as the characteristics of the road face image, the side slope image and the roadbed image; conducting identification and classification on the images obtained after characteristic extraction, positioning problematic areas, and calculating parameter indexes including collapse areas and collapsed body deposit capacity. By means of the method and system, the road roadbed collapse and the side slope collapse can be automatically detected according to colorful images of the road, efficiency is high, and detection is accurate.

Owner:CHONGQING UNIV

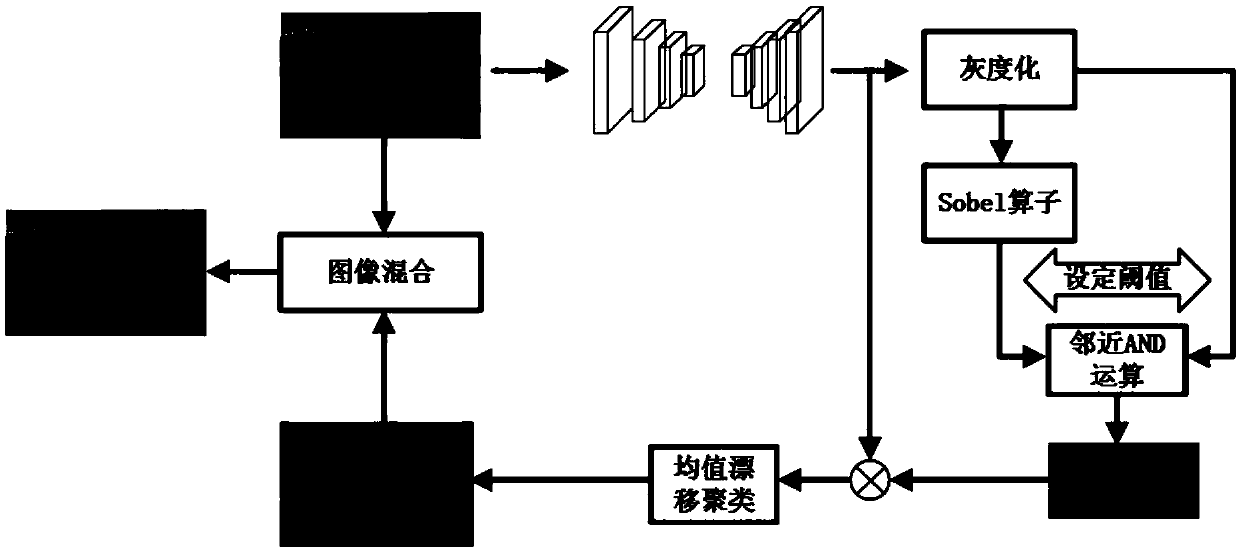

A lane line detection method based on a deep segmentation network

ActiveCN109635744AResolve detectionImprove robustnessCharacter and pattern recognitionNeural architecturesAlgorithmRoad condition

The invention discloses a lane line detection method based on a deep segmentation network. The method comprises the steps of 1, obtaining a normalized original image set and a lane line instance segmentation gray level image set; 2, constructing a multi-layer depth segmentation network, and training to obtain an optimal multi-layer depth segmentation network; 3, obtaining a lane line binary imageand a background binary image; 4, obtaining a feature map of the to-be-predicted road image; 5, obtaining a feature map of the to-be-predicted road image; 6, obtaining a lane line instance segmented image; And 7, obtaining a detection result map of the lane line. The method can effectively solve the problem of lane line change, can be suitable for lane line detection under various complex road conditions, and improves the robustness and real-time performance of detection.

Owner:安徽科大擎天科技有限公司

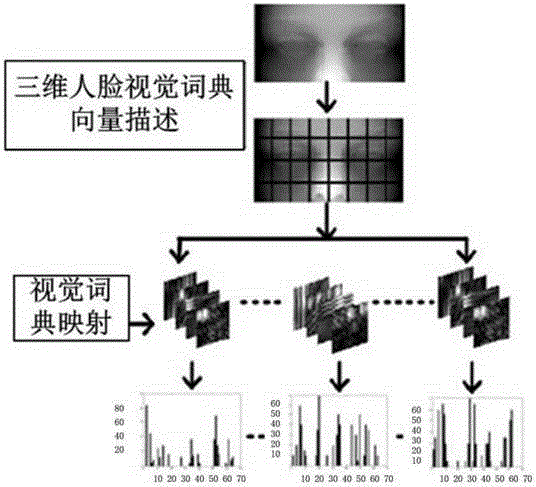

Multi-modal face recognition device and method based on multi-layer fusion of gray level and depth information

InactiveCN104598878AImprove performanceCharacter and pattern recognitionPattern recognitionGray level

The invention discloses a multi-modal face recognition device and method based on multi-layer fusion of gray level and depth information. The method mainly comprises the steps of recognizing the gray level information of a human face; recognizing the depth information of the human face; normalizing the gray level information and the depth information of the human face, based on normalized matching scores, obtaining multi-modal fused matching scores through fusion strategies to achieve multi-modal face recognition. According to the multi-modal face recognition device and method based on multi-layer fusion of gray level and depth information, a multi-modal system collects two-dimensional gray level information and three-dimensional depth information, makes use of the advantages of the two-dimensional gray level information and the three-dimensional depth information, and through the fusion strategies, overcomes certain inherent shortcomings of a single-modal system such as illumination of gray level images and expressions of depth images, thereby greatly enhancing the performance and achieve accurate and rapid face recognition.

Owner:SHENZHEN WEITESHI TECH

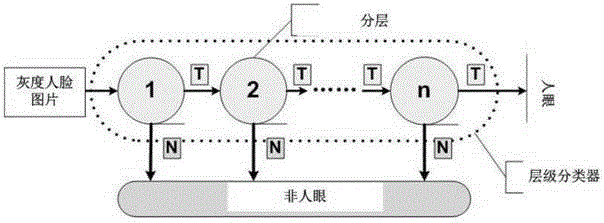

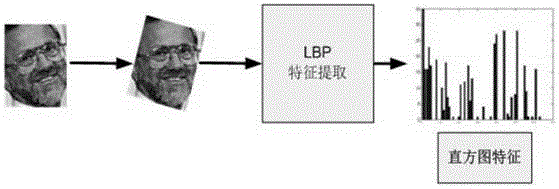

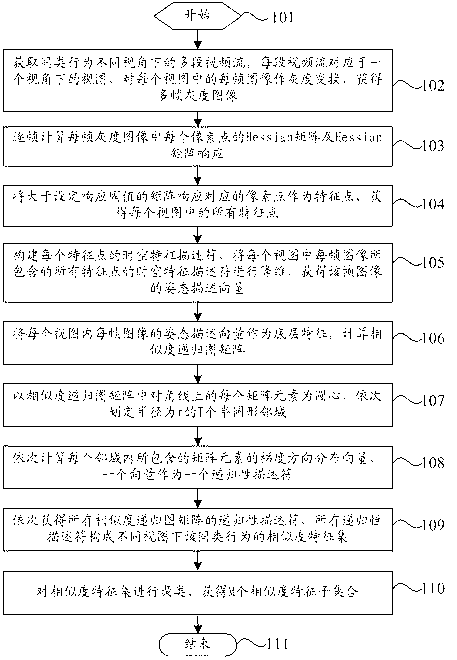

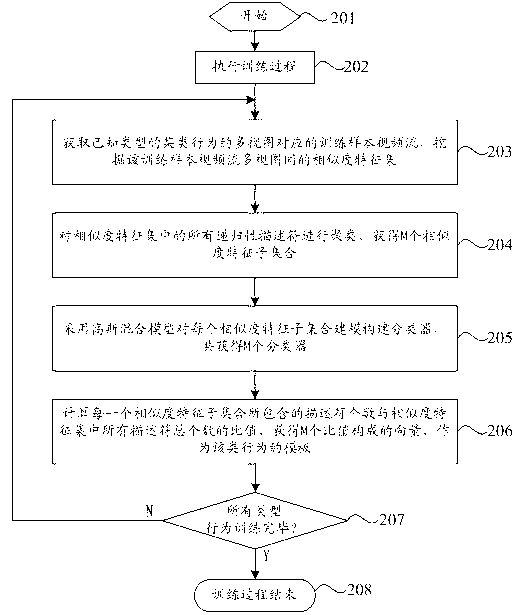

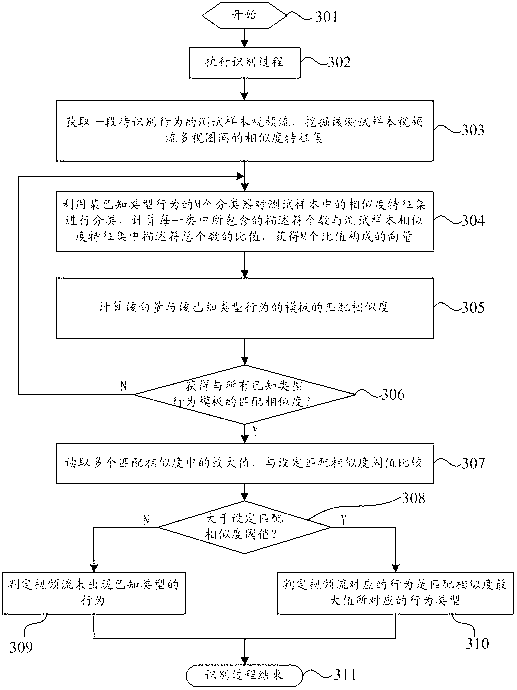

Similarity mining method of similar behaviors between multiple views and behavior recognition method

InactiveCN103310233AResolve interferenceResolution cycleCharacter and pattern recognitionDimensionality reductionEuclidean vector

The invention discloses a similarity mining method of similar behaviors between multiple views and a behavior recognition method. The behavior recognition method is based on the similarity mining method. The similarity mining method comprises calculating a Hessian matrix response of every pixel in every frame of gray images of video streaming of different views of the similar behaviors frame by frame; determining feature points according to the matrix responses; building space-time feature descriptors of the feature points and obtaining posture description vectors after dimensionality reduction; calculating a similarity recurrence plot matrix with the posture description vectors as low-level features; and obtaining recursiveness descriptors according to the recurrence plot matrix and clustering the recursiveness descriptors. According to the similarity mining method of the similar behaviors between the multiple views and the behavior recognition method, posture modeling is achieved through a space-time feature point method and recursive similarity between the multiple views is mined through a recurrence plot, so that the problem that background segmentation dependency is easy to cause distortion of human body postures is solved and the accuracy of similarity mining and the robustness of behavior recognition are improved.

Owner:苏州机目科技有限公司

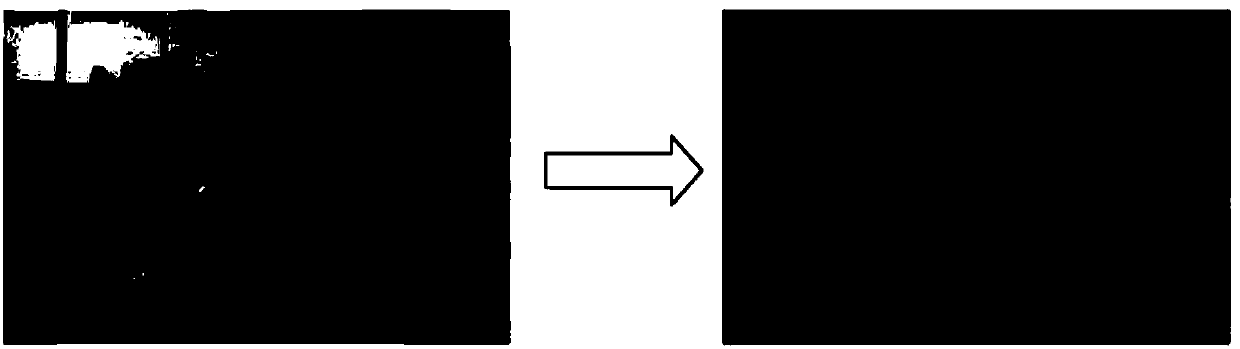

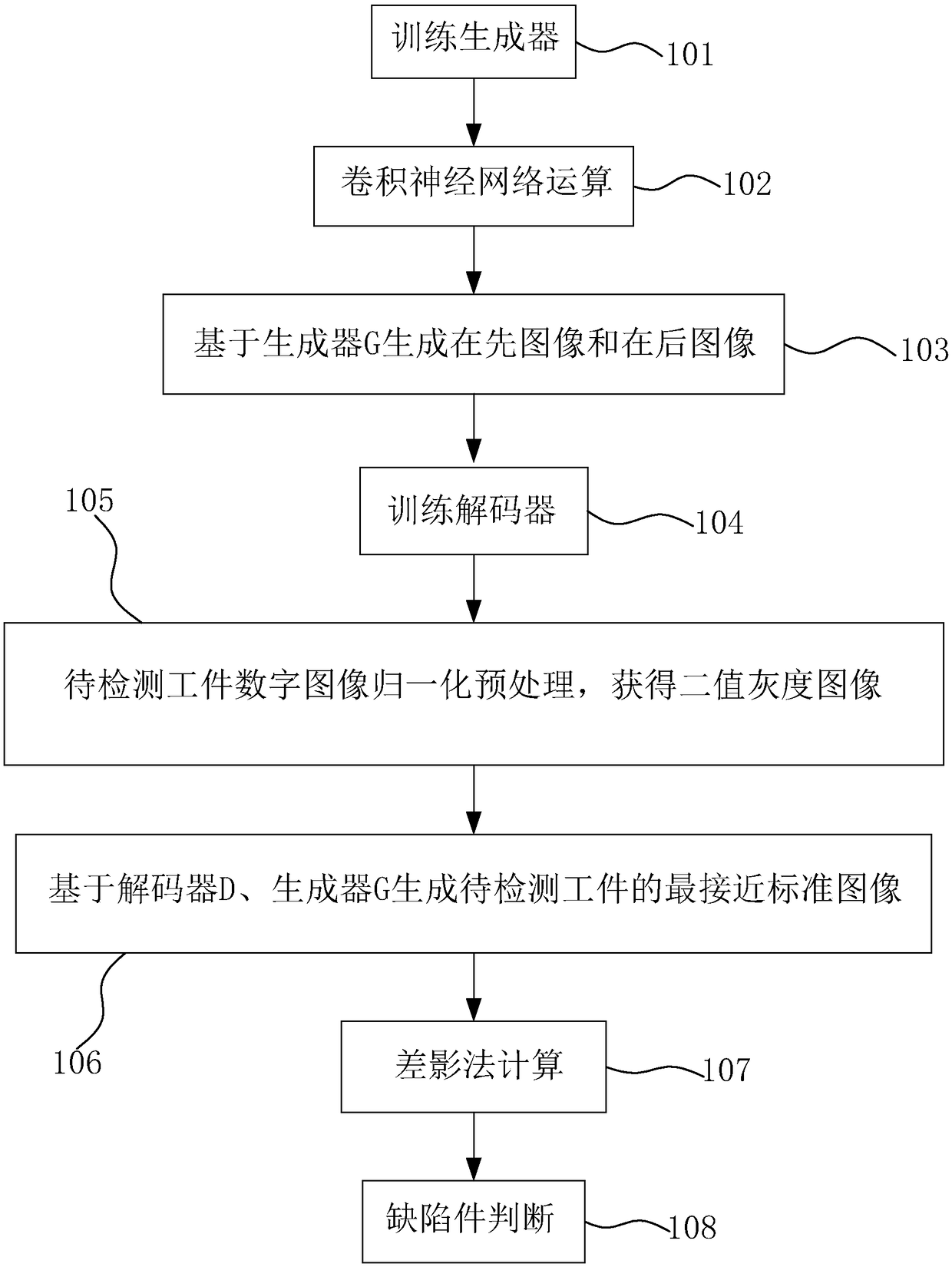

Visual defect detection equipment and detection method thereof

ActiveCN108734690AImprove portabilityImprove general performanceImage enhancementImage analysisGenerative adversarial networkDigital image

The invention relates to and provides visual defect detection equipment and a detection method thereof. The detection method comprises the following steps: acquiring the distribution probability of astandard component digital image by a generative adversarial network, and performing training to obtain a generator G capable of mapping a hidden space vector to the standard component digital image;performing training again to obtain a decoder D capable of realizing mapping from the digital image to the hidden space vector; lastly, inputting a binary gray level image of a detected workpiece obtained by preprocessing into the decoder D and the generator G in sequence to obtain a proximate standard image proximate to the detected workpiece; acquiring a differential value between the binary gray image of the detected workpiece and the proximate standard image by using a difference image method; and comparing the difference value with a threshold value to judge whether the detected workpieceis defective or not. The detection method has the advantages of high portability, high universality, short trial and error time and high detection accuracy.

Owner:SUZHOU HANTE VISUAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com