Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Edge loading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

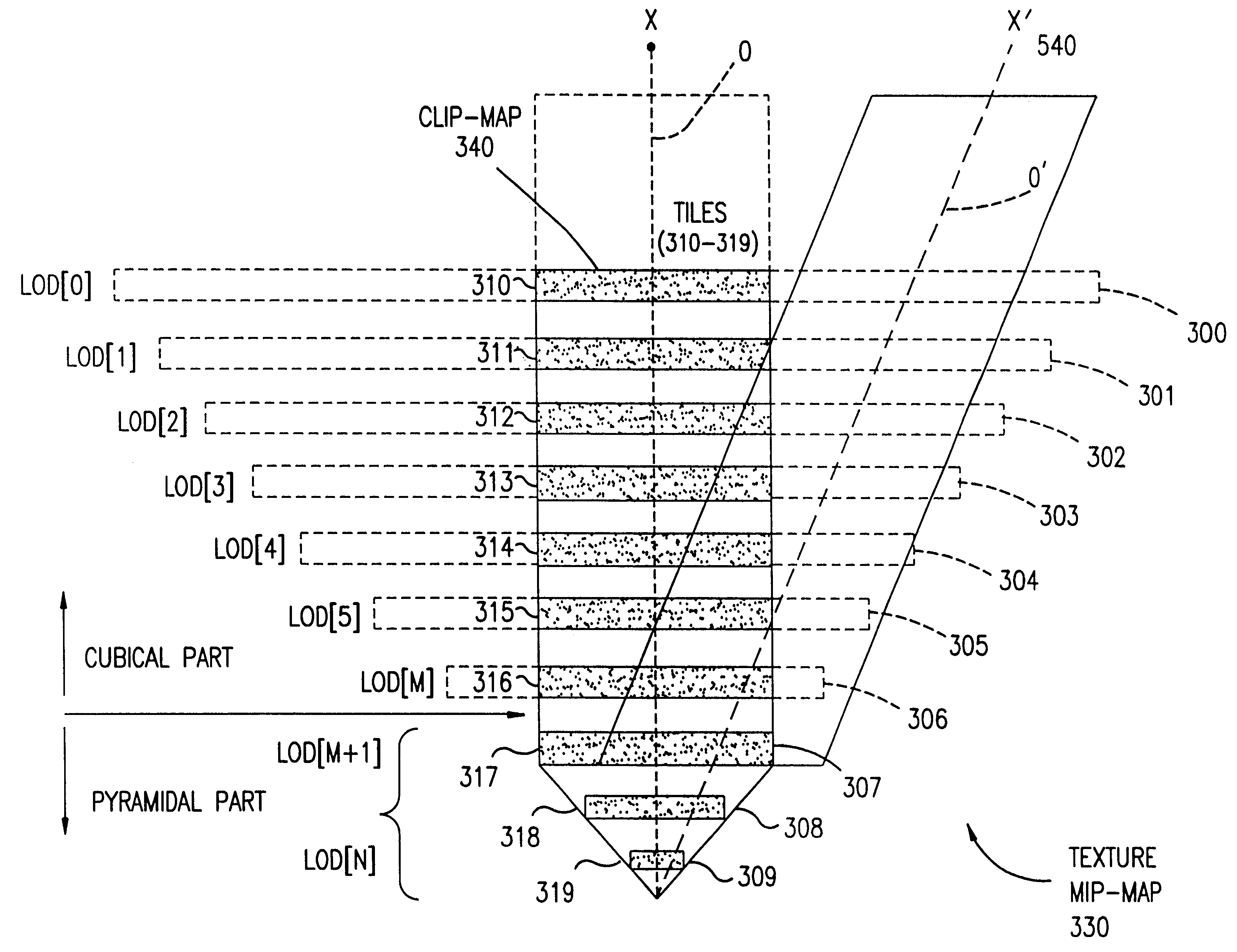

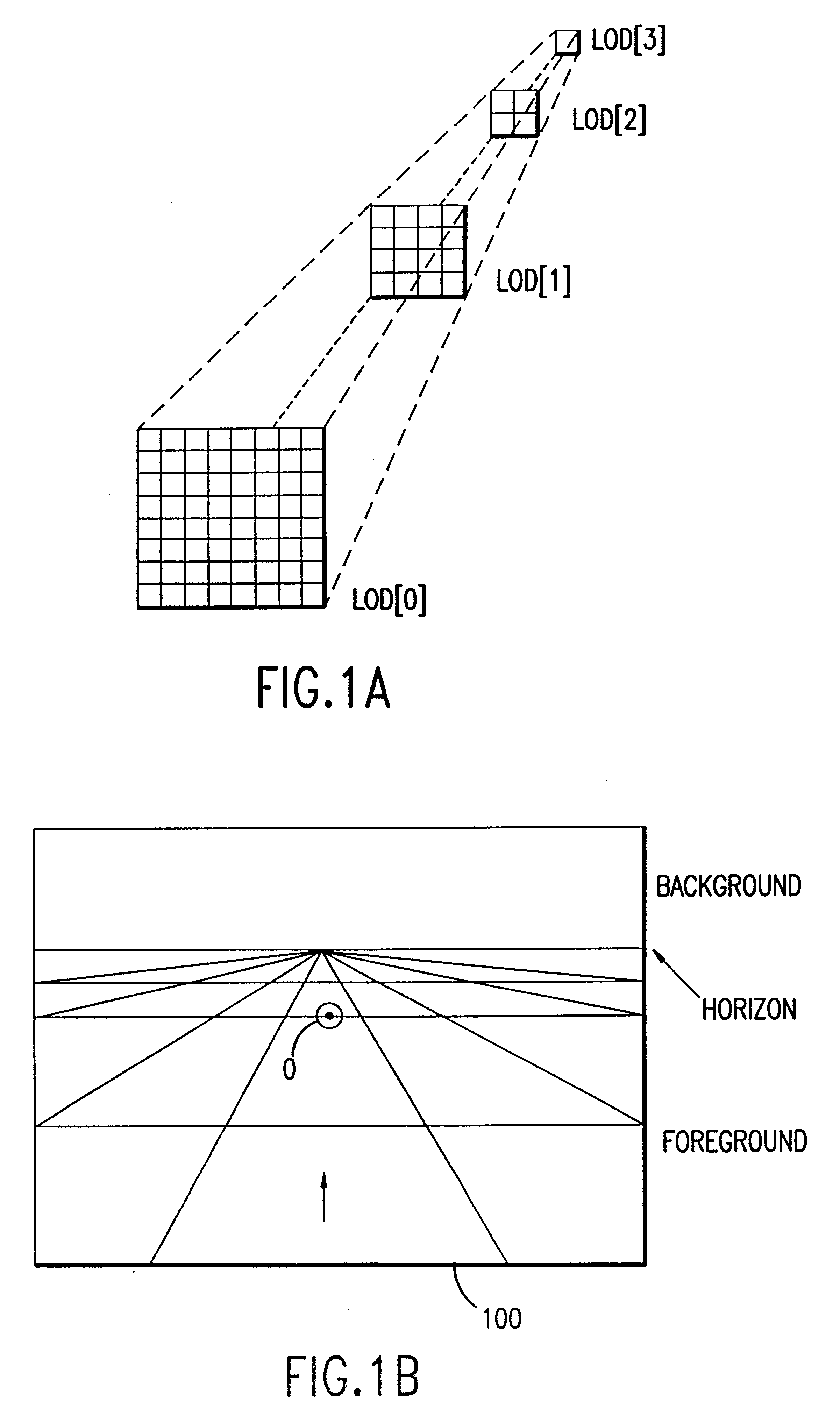

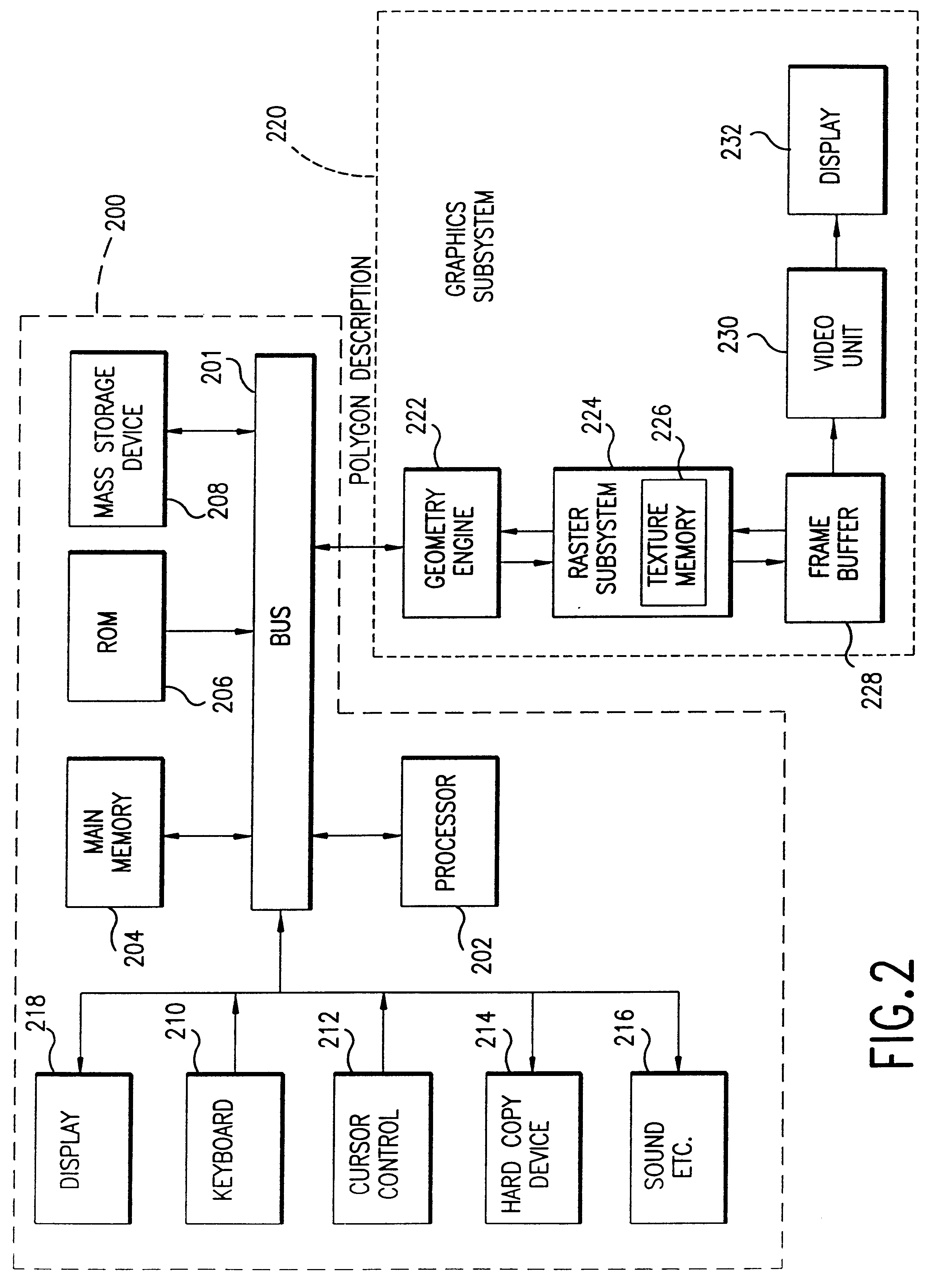

Method and system for providing texture using a selected portion of a texture map

InactiveUS6417860B1Cathode-ray tube indicatorsFilling planer surface with attributesTerrainMass storage

An apparatus and method for quickly and efficiently providing texel data relevant for displaying a textured-image. A large amount of texture source data, such as photographic terrain texture, is stored as a two-dimensional or three-dimensional texture MIP-map on one or more mass storage devices. Only a relatively small clip-map representing selected portions of the complete texture MIP-map is loaded into faster, more expensive memory. These selected texture MIP-map portions forming the clip-map consist of tiles which contain those texel values at each respective level of detail that are most likely to be mapped to pixels being rendered for display based upon the viewer's eyepoint and field of view. To efficiently update the clip-map in real-time, texel data is loaded and discarded from the edges of tiles. Attempts to access a texel lying outside of a particular clip-map tile are accommodated by utilizing a substitute texel value obtained from the next coarser resolution clip-map tile which encompasses the sought texel.

Owner:MICROSOFT TECH LICENSING LLC

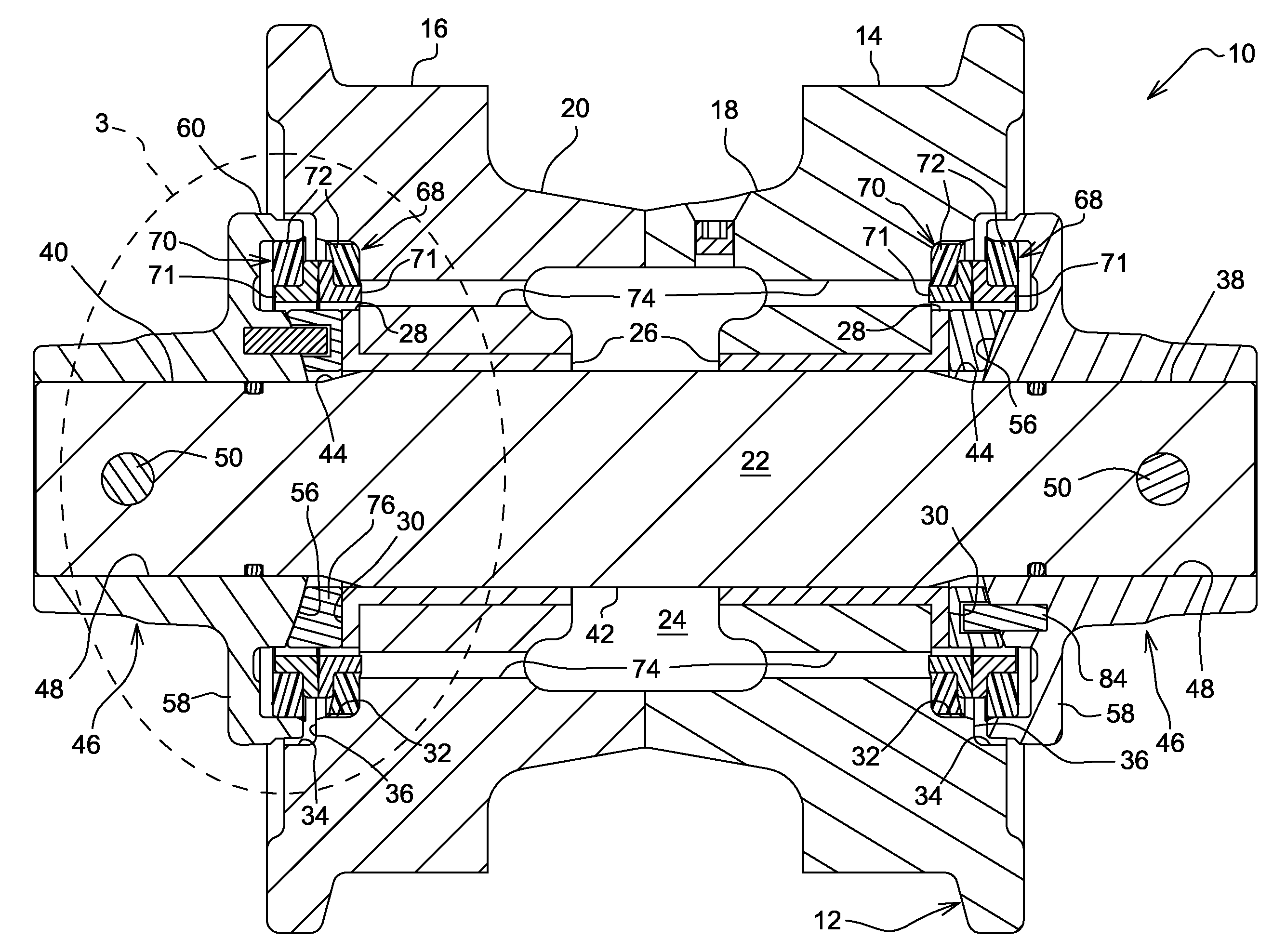

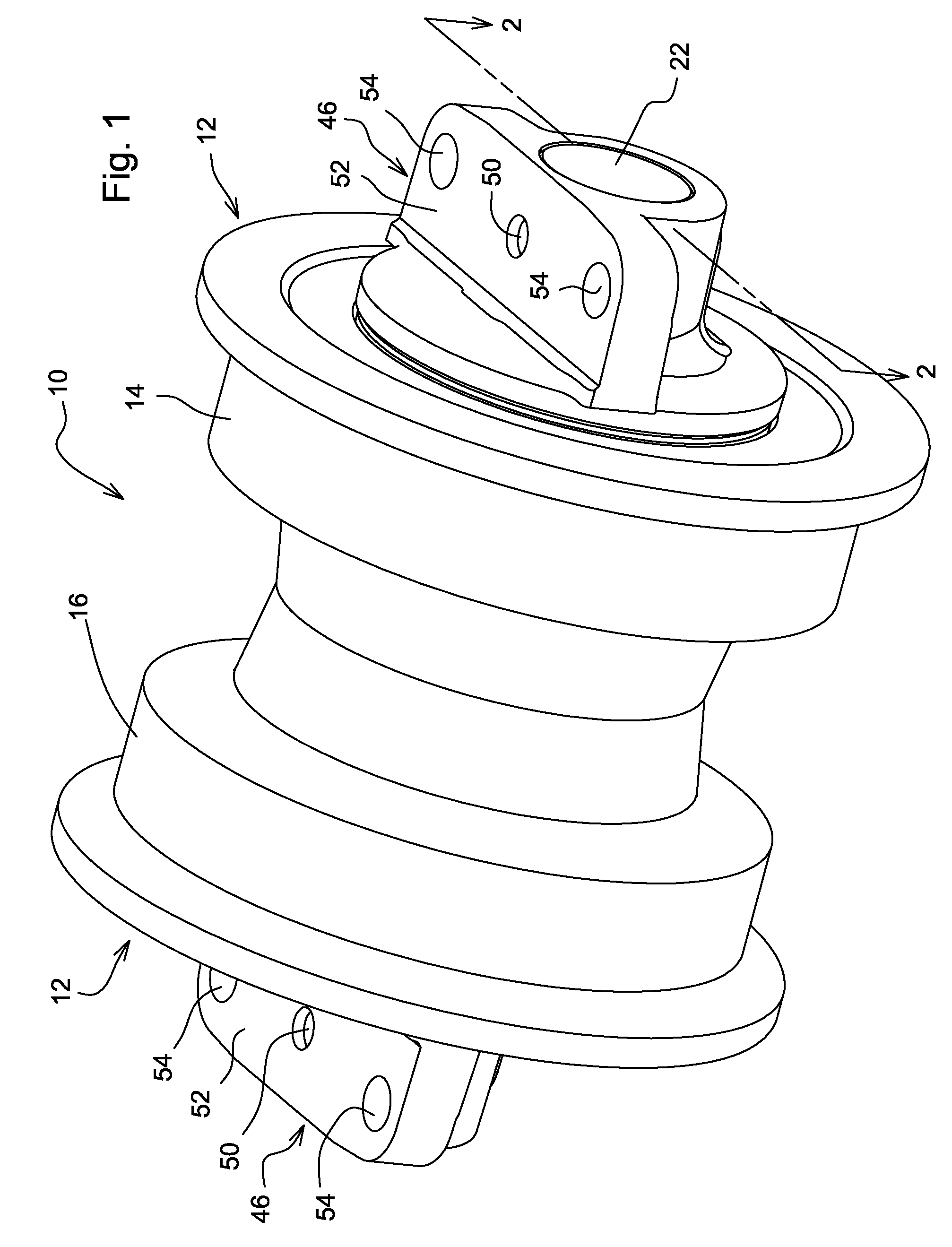

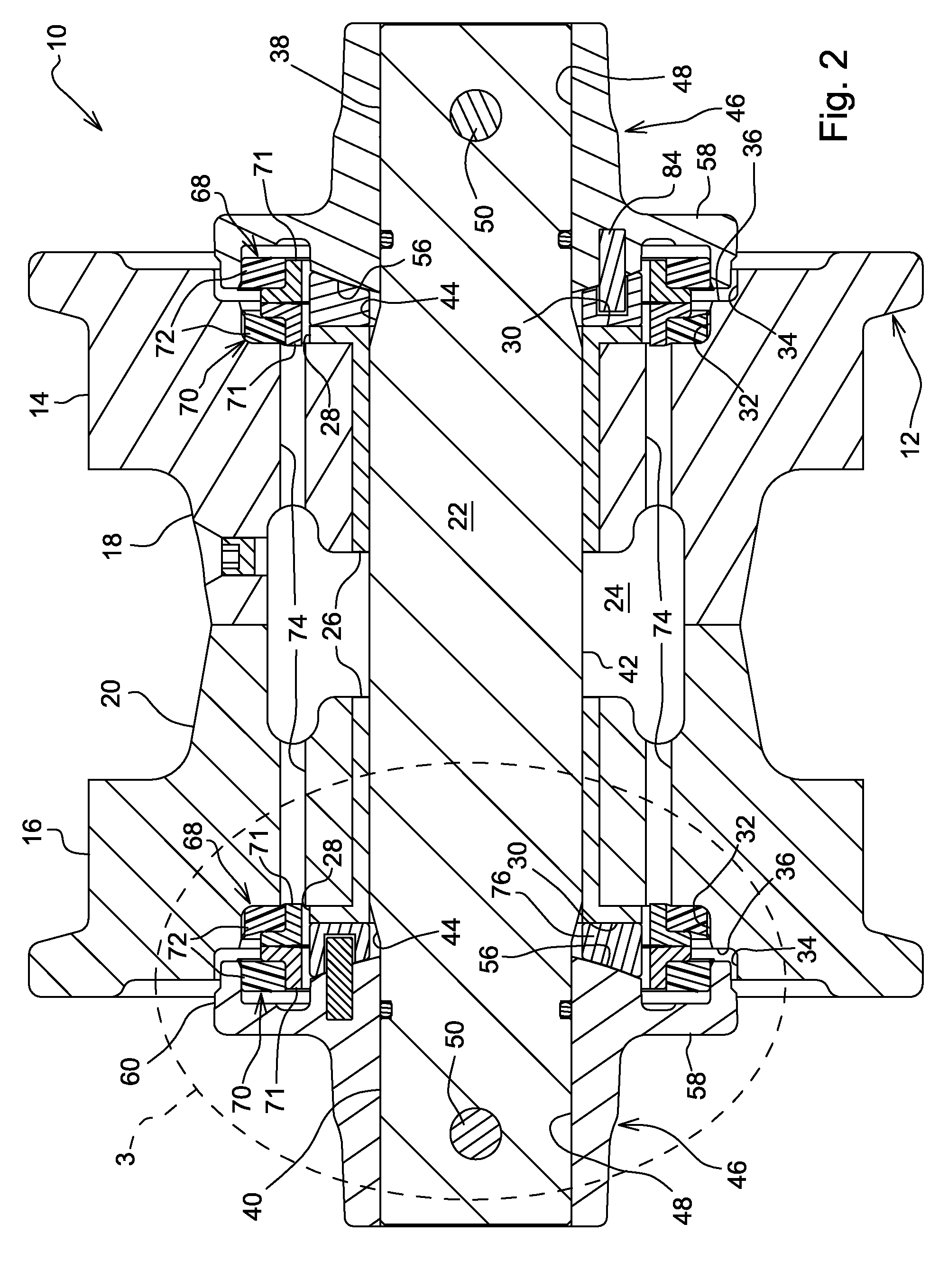

Crawler Track Roller With Internal Spherical Spacers

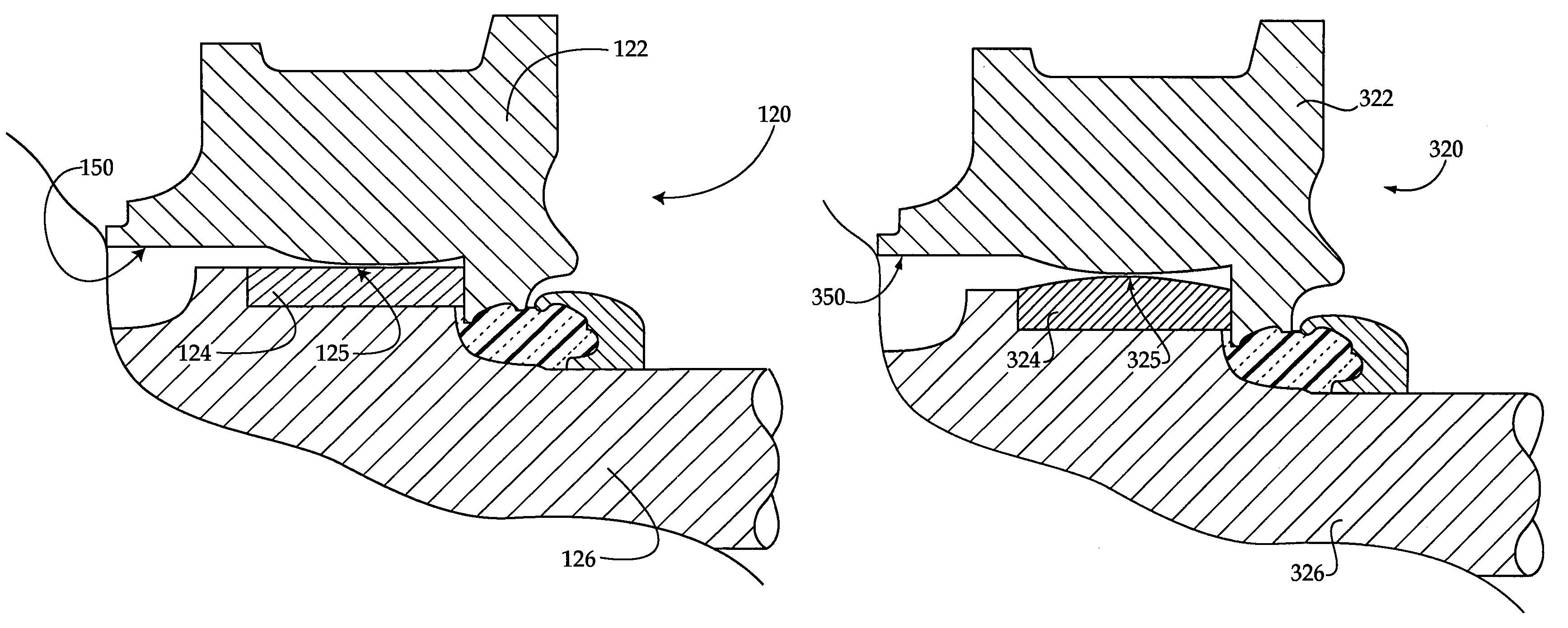

A roller for supporting an endless track of a track laying tractor is mounted for rotation about a shaft or axle fixed between transversely spaced, parallel rails of a track support frame. The roller is constructed of mirror image halves having axially inner ends welded together, with a pair of thrust bushings being received on the shaft and respectively disposed in supporting relationship the roller halves. Each thrust bushing includes an axially outer end defined by an annular flange having an axially outwardly facing flat bearing surface. A pair of mounting brackets are respectively received on, and fixed to opposite ends of the shaft and fixed to the pair of rails of the support frame. Non-uniform edge loading of the bushings due to minor shaft deformations due to flexure of the track support frame rails is minimized by providing axially inwardly facing ends of the brackets with spherically contoured surfaces, and by locating an annular spacer between each bracket and bushing flat bearing surface, the annular spacer having outer and inner axially facing surfaces respectively shaped complimentary to the spherical contoured surface of the bracket and the flat bearing surface of the bushing

Owner:DEERE & CO

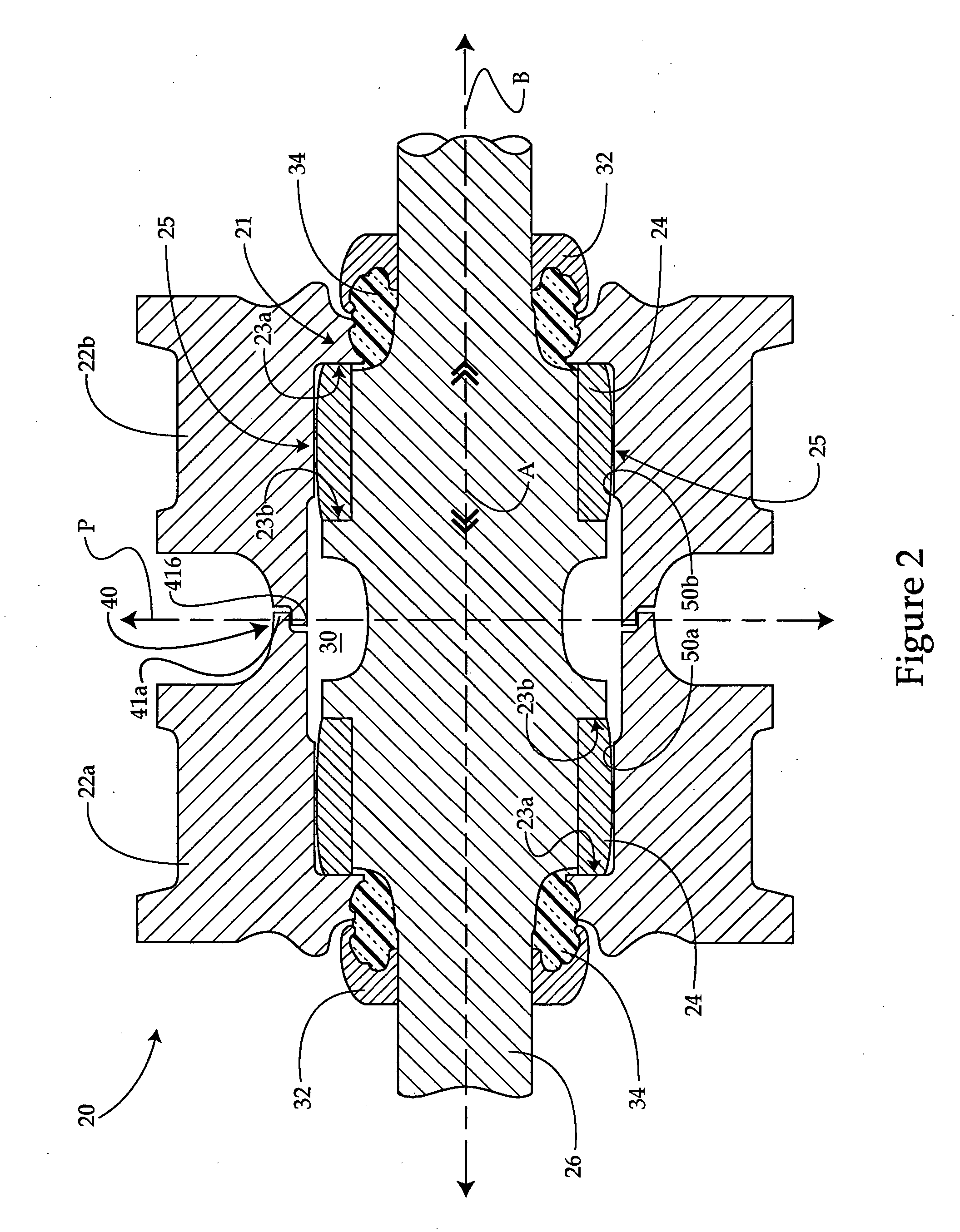

Joint assembly to resist galling

Joint assemblies are useful for connecting one structure to another structure. When the various structures deflect or bend, edge loading occurs therebetween. The subject joint assembly includes a pin positioned between a first and second structure. An insert is free floating positioned around the pin for contacting either of the first or second structures. A crown shaped surface is utilized on the insert at a substantially central location therealong. The crown shaped surface directs forces to the center of the insert to reduce edge loading.

Owner:CATERPILLAR INC

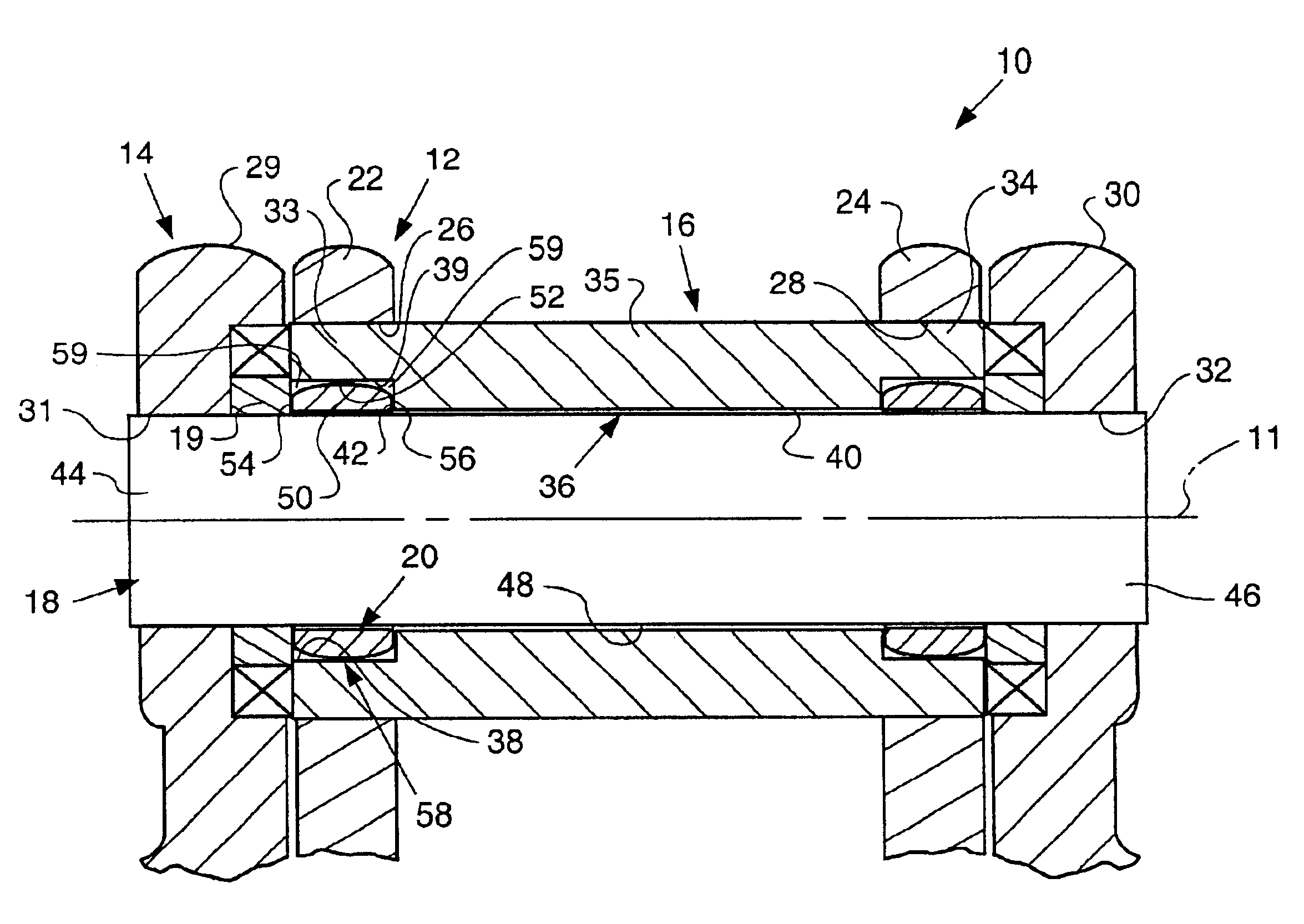

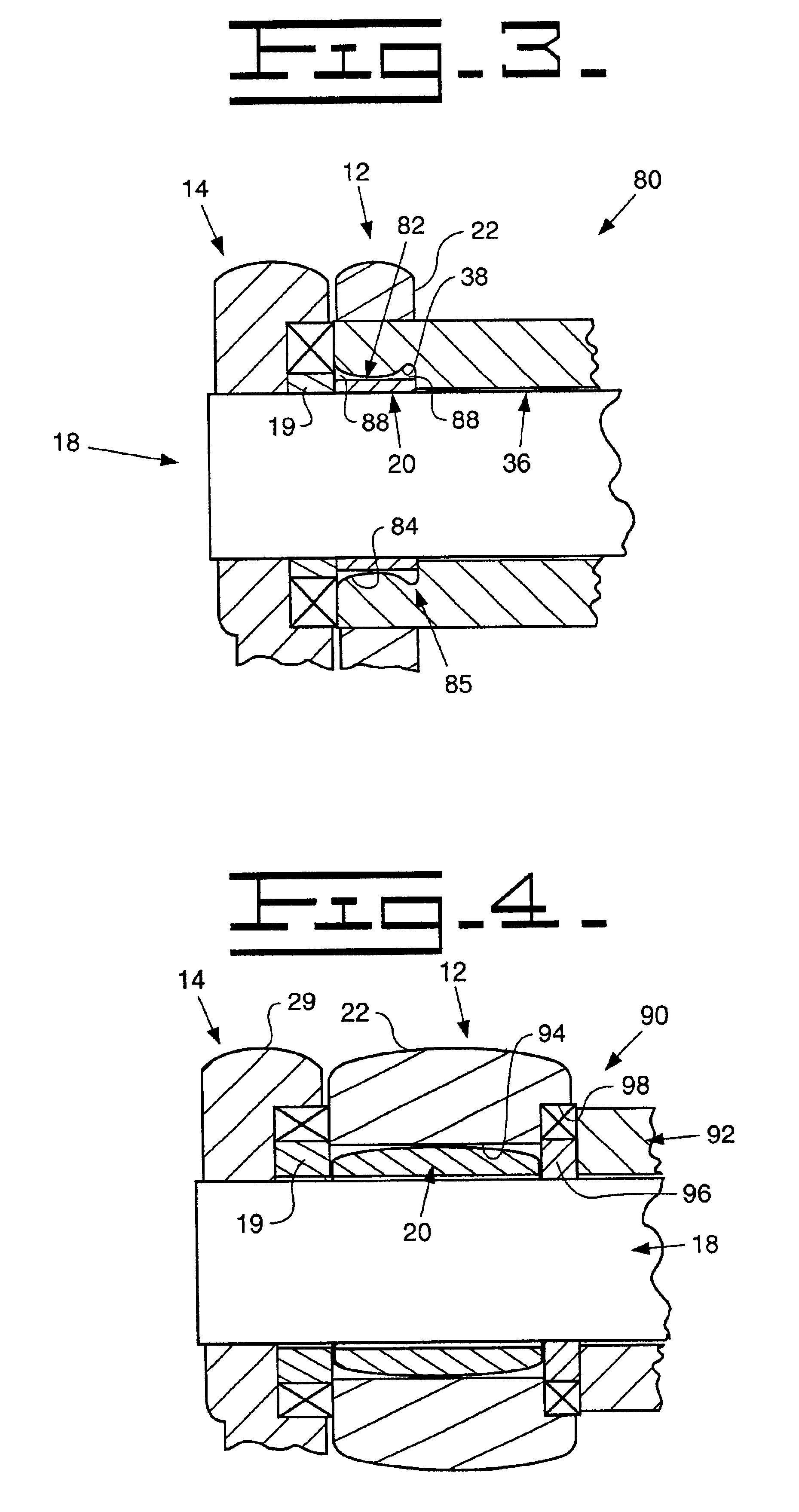

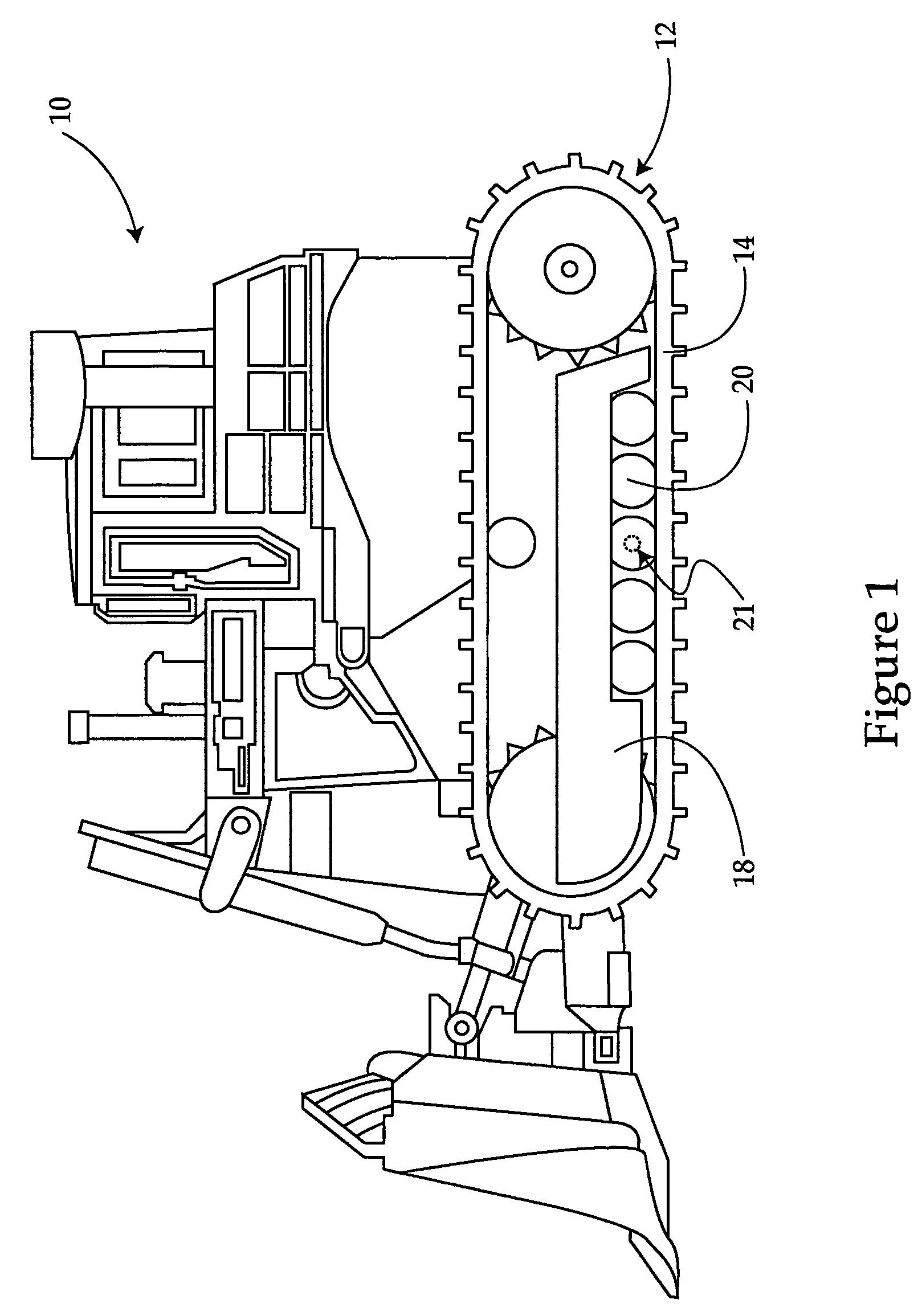

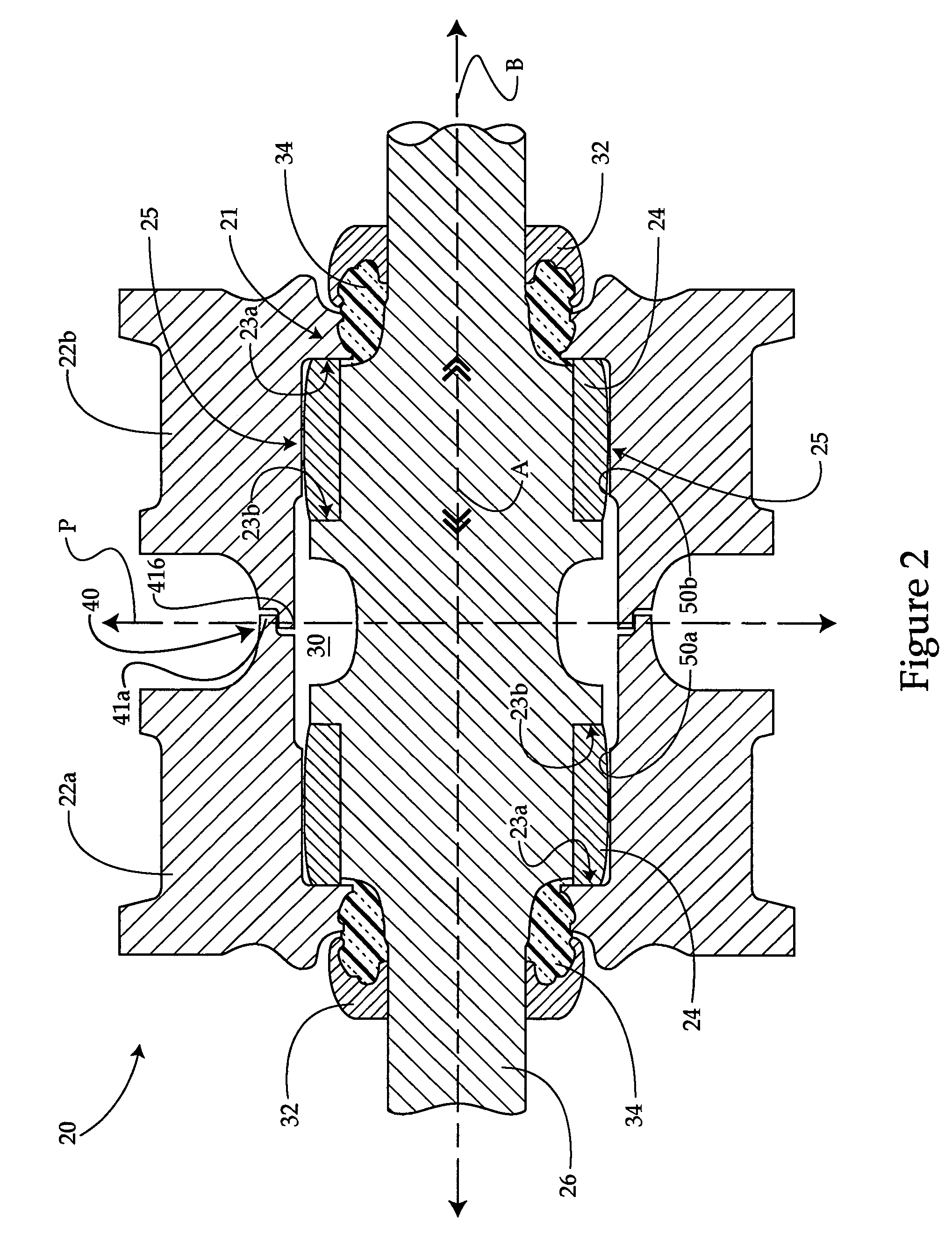

Machine track roller assembly

A track-type work machine is provided, including a roller frame and a track extending about the roller frame. A track roller is mounted along the roller frame and rotatable against the track. The track roller is rotatably supported by a bearing that includes a shaft extending in the track roller and at least one sleeve rotatable about the shaft. At least one of the sleeve and the track roller include a load transmitting crown. A method is further provided of reducing edge loading of a track roller bearing, by transmitting selected loads on the bearing toward a center thereof at least in part by crowning a rotatable sleeve of the bearing.

Owner:CATERPILLAR INC

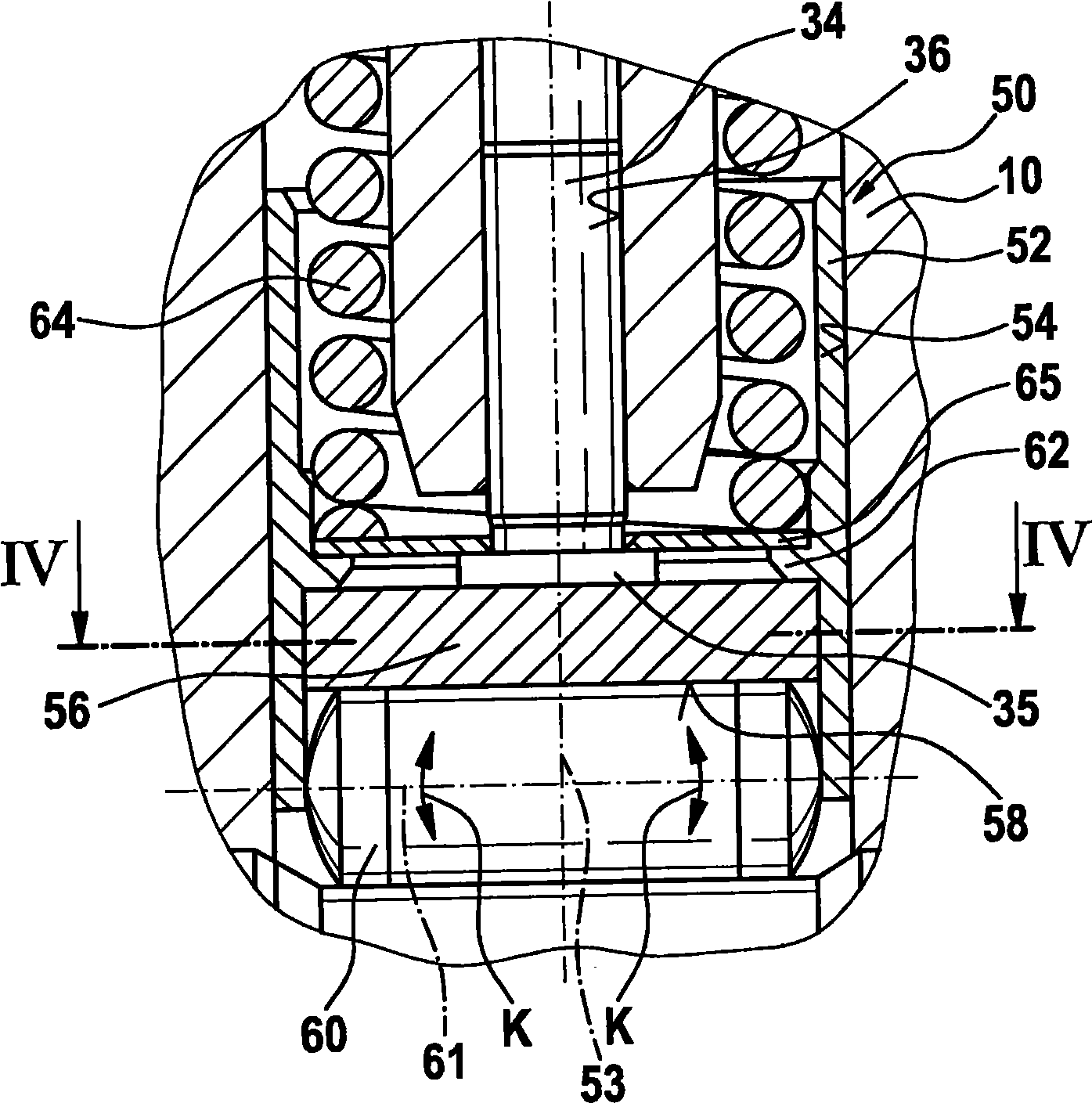

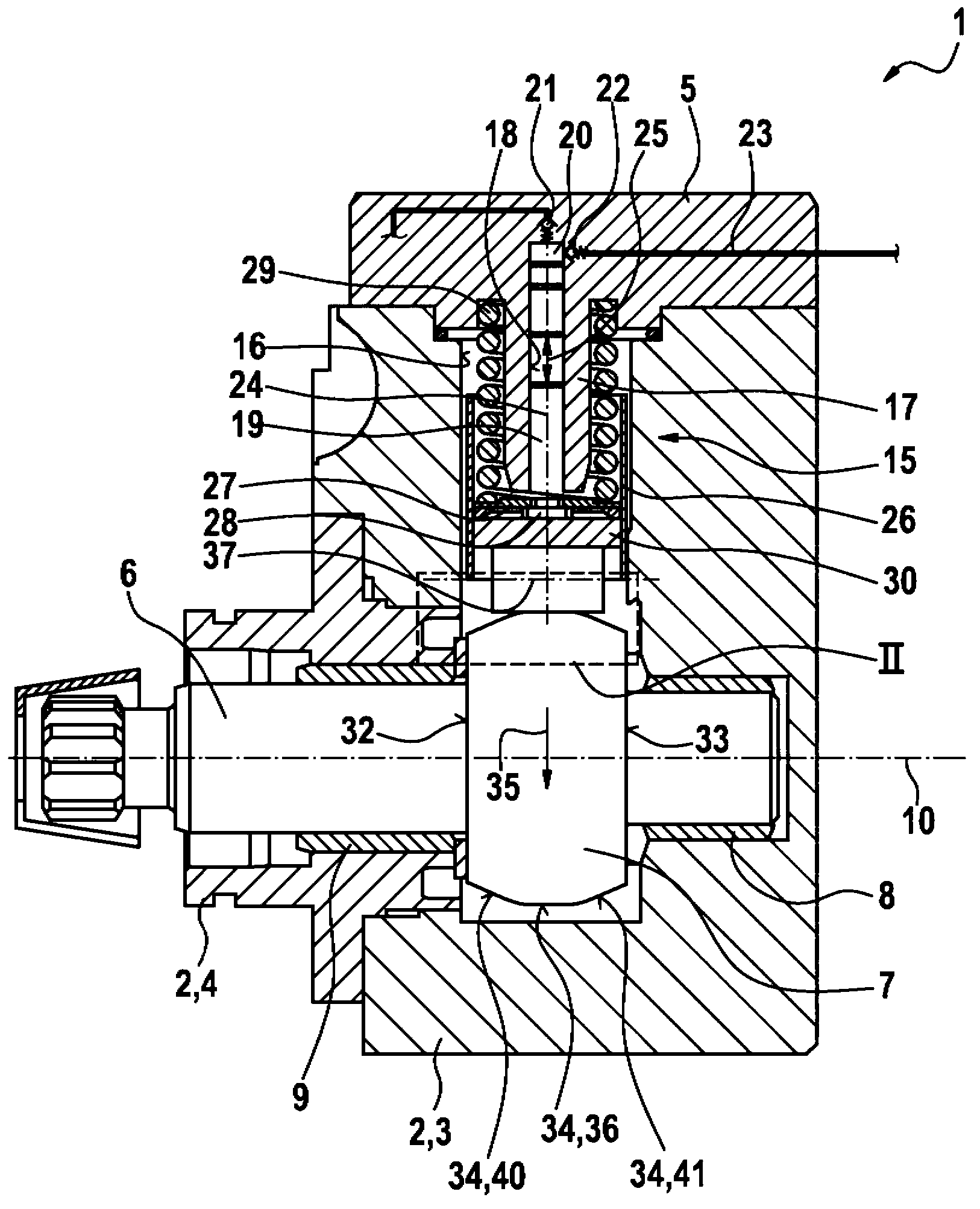

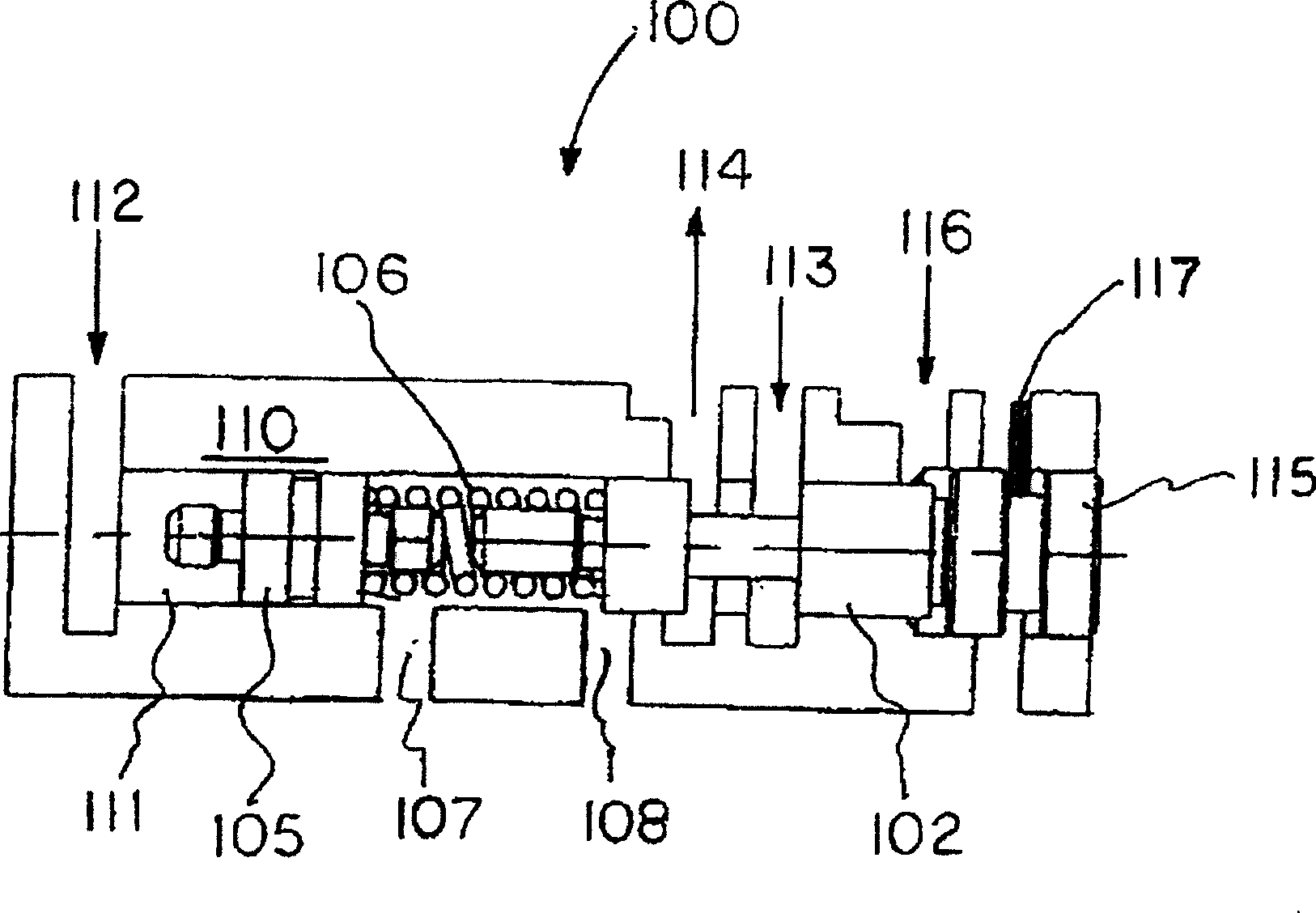

Tappet assembly for a high-pressure pump and high-pressure pump comprising at least one tappet assembly

The invention relates to a tappet assembly for a high-pressure pump, especially for the prose of fuel supply, and to a high-pressure pump including such a tappet assembly. The tappet assembly has a hollow cylindrical tappet base into which a roller support is inserted in the direction of the longitudinal axis of the tappet base. A roller is rotatably received in the roller support. The roller support is arranged at a right angle to the rotational axis of the roller with little or no play in the tappet base and in the direction of the rotational axis of the roller with larger play than at a right angle to the rotational axis of the roller in the tappet base. As a result, the roller support can perform a limited tilting motion in the tappet base, thereby allowing the rotational axis of the roller to be aligned in relation to the rotational axis of a driving shaft driving the tappet assembly in a lifting motion and avoiding edge loading of the roller on a cam or avoiding the need for eccentrics on the driving shaft.

Owner:ROBERT BOSCH GMBH

Tappet assembly for a high-pressure pump and high-pressure pump comprising at least one tappet assembly

InactiveCN101523044AIncrease the gapReduce gapCam-followersFuel injecting pumpsRotational axisDrive shaft

The invention relates to a tappet assembly for a high-pressure pump, especially for the purpose of fuel supply, and to a high-pressure pump comprising said tappet assembly. The tappet assembly has a hollow cylindrical tappet base (52) into which a roller support (56) is inserted in the direction of the longitudinal axis (53) of the tappet base (52), a roller (60) being rotatably received in the roller support (56). The roller support (56) is arranged at a right angle to the rotational axis (61) of the roller (60) with little or no play in the tappet base (52) and in the direction of the rotational axis (61) of the roller (60) with larger play than at a right angle to the rotational axis (61) of the roller (60) in the tappet base (52). As a result, the roller support (56) can perform a limited tilting motion in the tappet base (52), thereby allowing the rotational axis (61) of the roller (60) to be aligned in relation to the rotational axis (13) of a driving shaft (12) driving the tappet assembly (50) in a lifting motion and avoiding edge loading of the roller (60) on a cam (26) or avoiding the need for eccentrics on the driving shaft (12).

Owner:ROBERT BOSCH GMBH

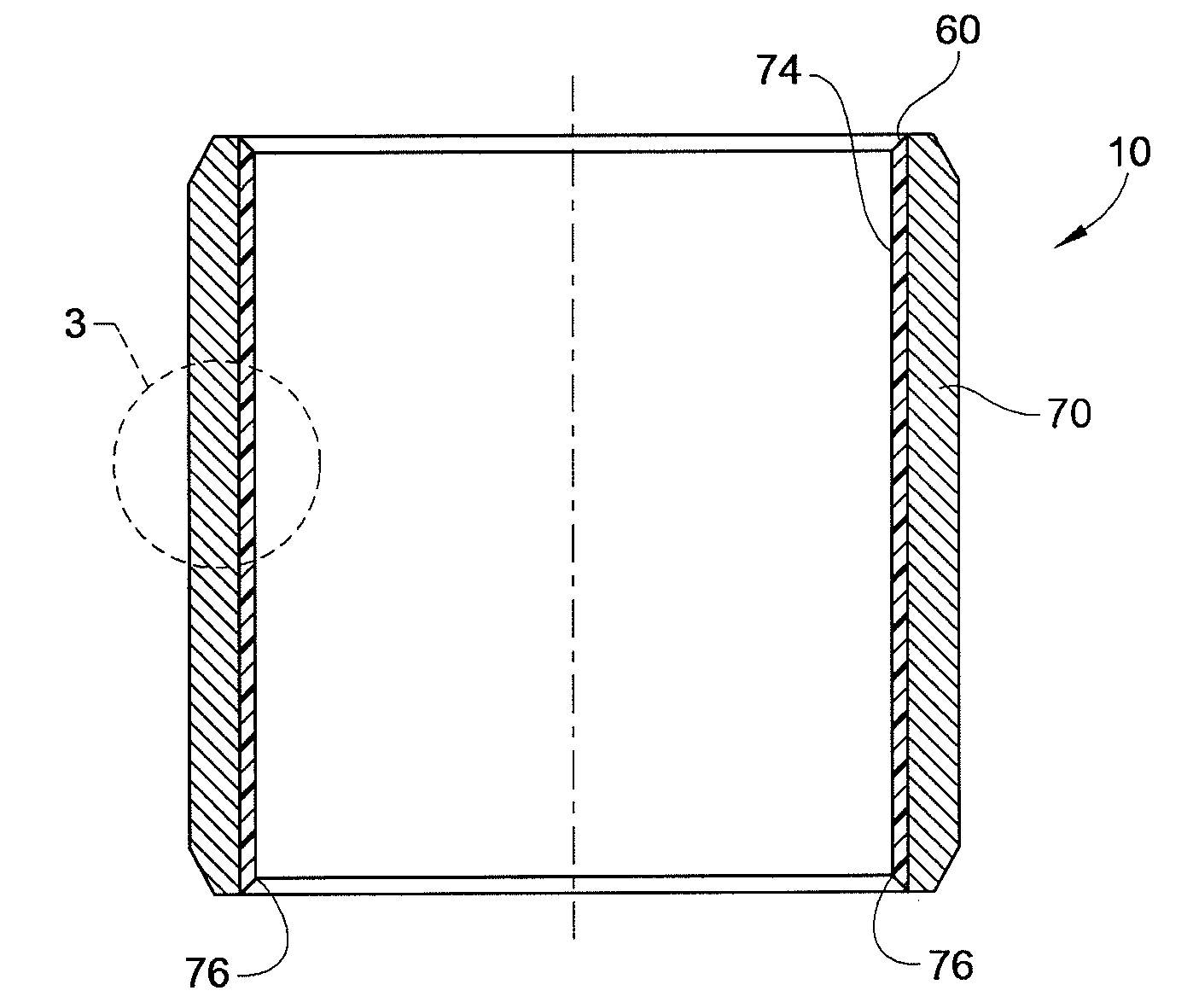

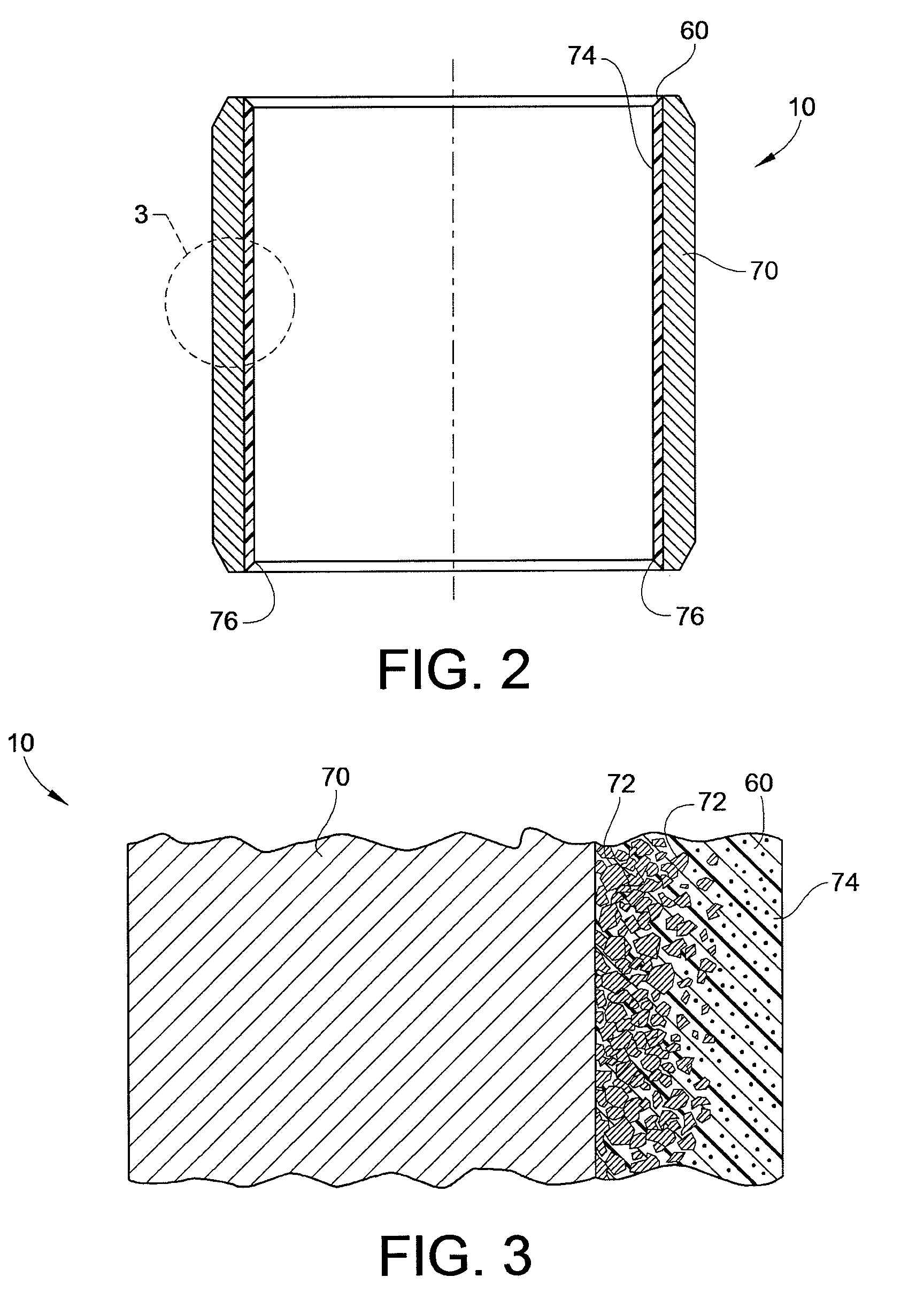

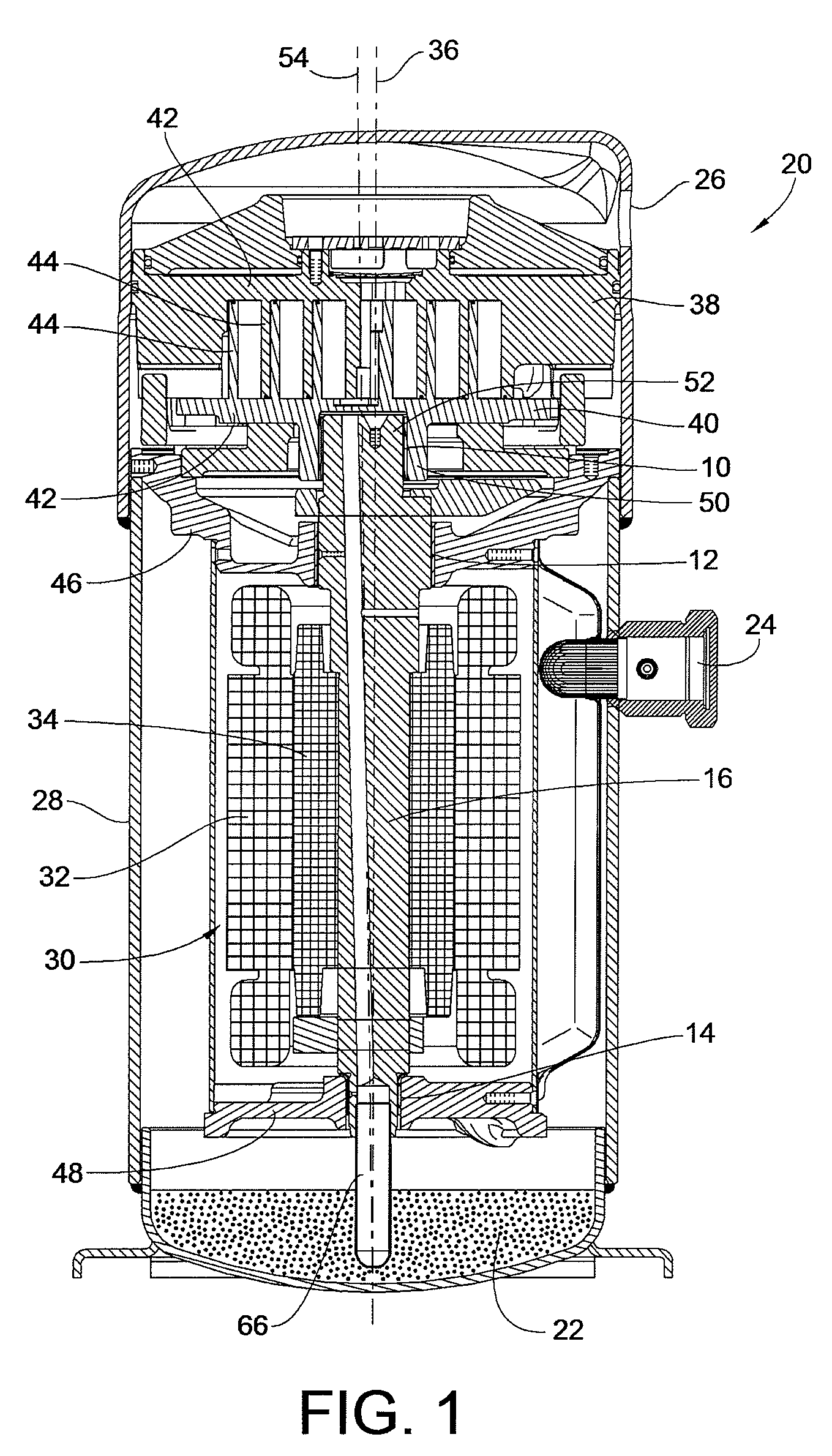

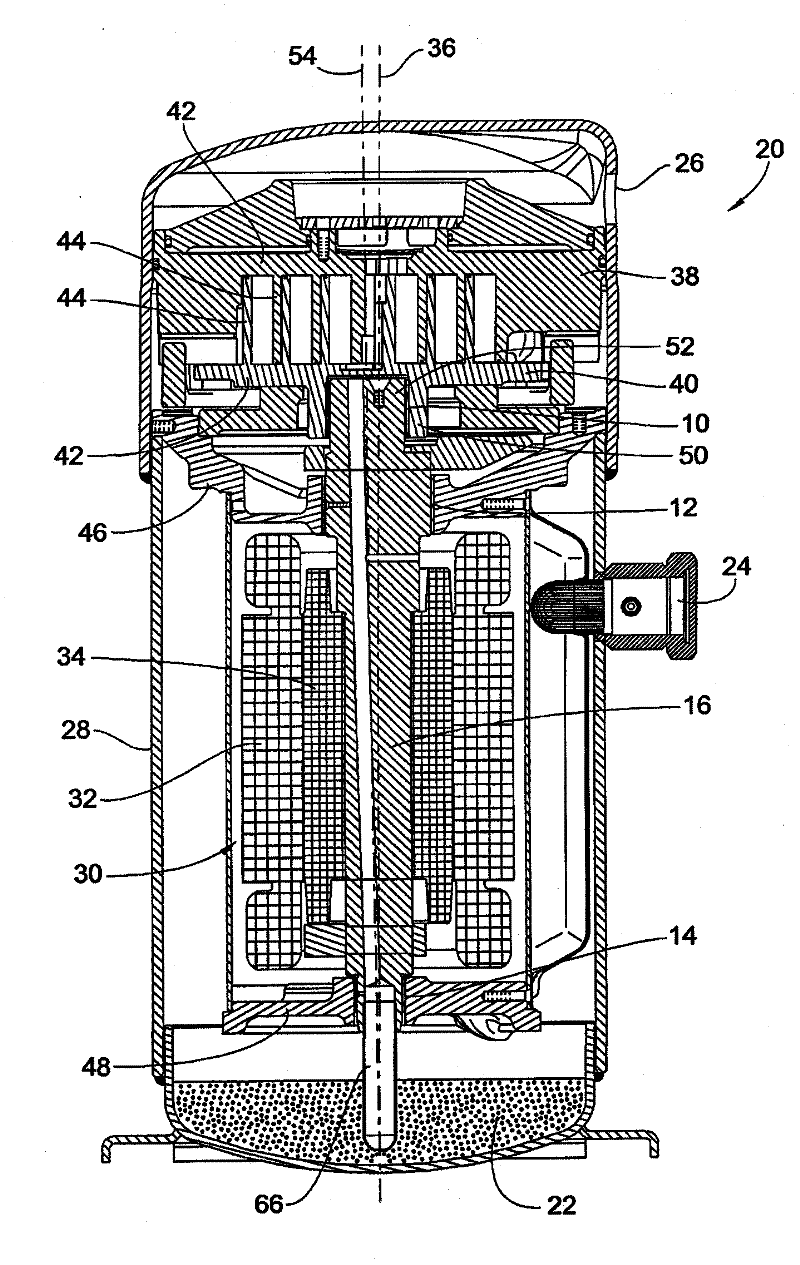

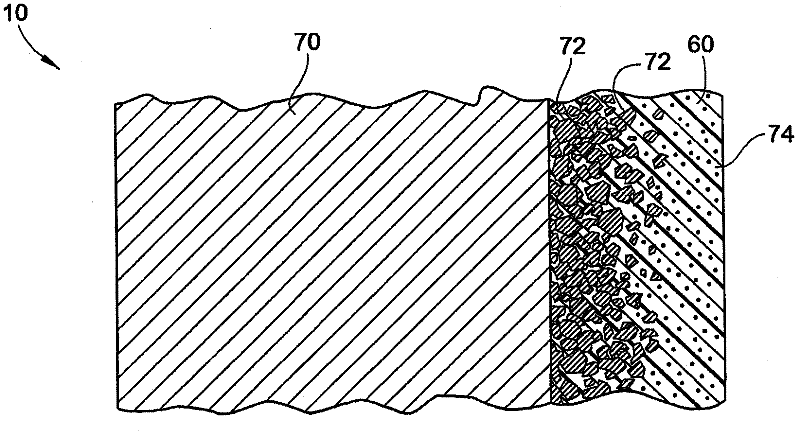

Shaft Bearings, Compressor with Same, and Methods

InactiveUS20100239447A1Easy to compressRotary combination bearingsEngine of arcuate-engagement typeDrive shaftEdge loading

A bearing material composition that lines a support includes a combination of a thermoplastic conforming material and abrasive particles which provide a combined effect for remedying the effects due to edge loading that may be caused by misalignment between the bearing and a shaft to which a portion is rotatably mounted. The conforming material may be PTFE such that it does not have a memory and is subject to cold flow and creep. As a result, misalignment problems and edge loading are remedied by the combination of abrasive removal of metal material from the drive shaft at the location of edge loading and creep of the conforming material at the location of edge loading which may provide an overall greater bearing interface surface.

Owner:BITZER KUEHLMASCHINENBAU GMBH

High efficiency production of nanofibrillated cellulose

ActiveUS9988762B2Energy required to produceImprove propertiesPulp properties modificationPaper/cardboardFiberCellulose

A scalable, energy efficient process for preparing cellulose nanofibers employs treating the cellulosic material with a first mechanical refiner with plates having a configuration of blades separated by grooves, and subsequently treating the material with a second mechanical refiner with plates having a configuration of blades separated by grooves different than the first refiner. The plate configurations and treatment operations are selected such that the first refiner produces a first specific edge loading (SEL) that is greater than the SEL of the second refiner, by as much as 2-50 fold. An exemplary high first SEL may be in the range of 1.5 to 8 J / m. Paper products made with about 2% to about 30% cellulose nanofibers having a length from about 0.2 mm to about 0.5 mm, preferably from 0.2 mm to about 0.4 mm have improved properties.

Owner:UNIVERSITY OF MAINE

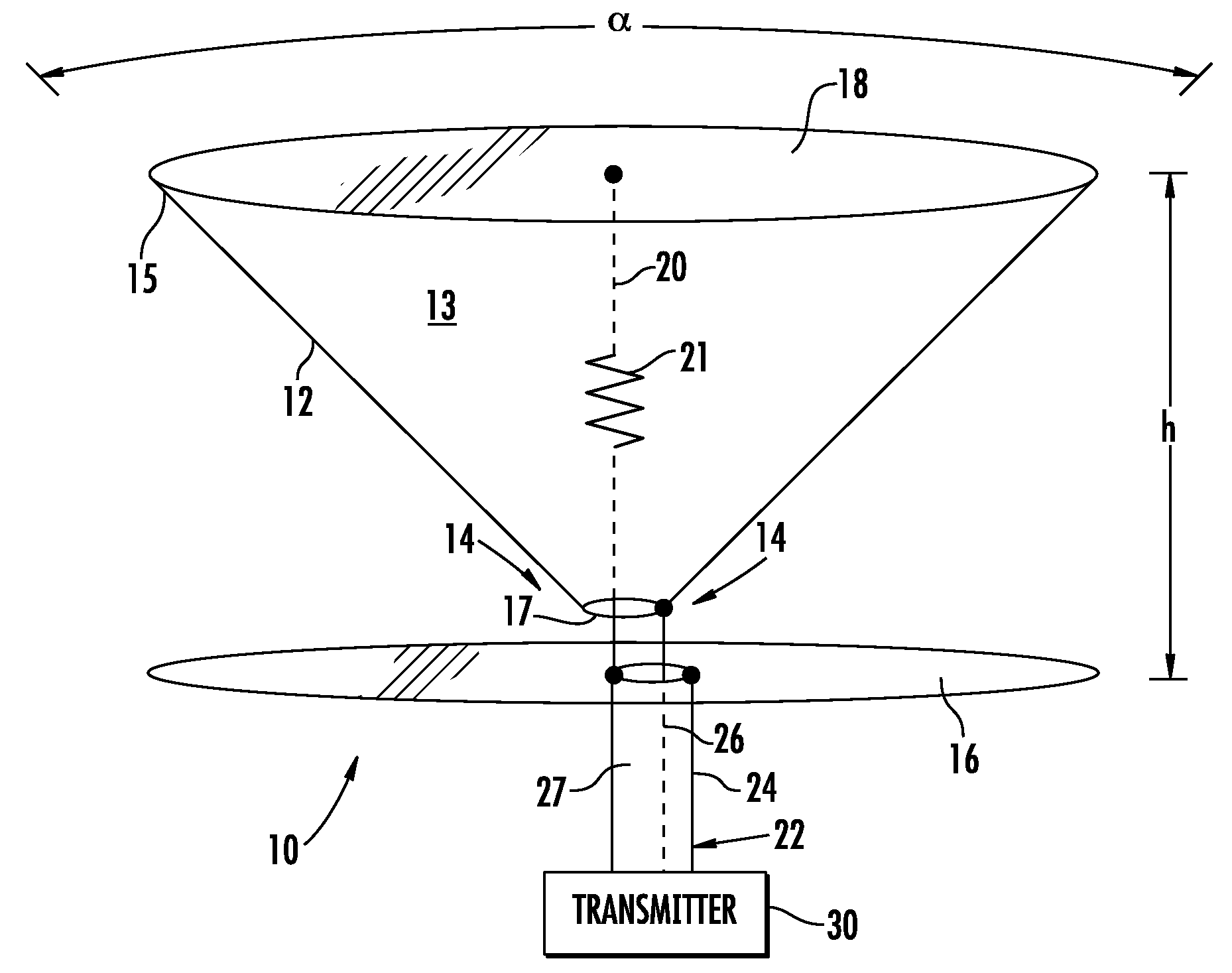

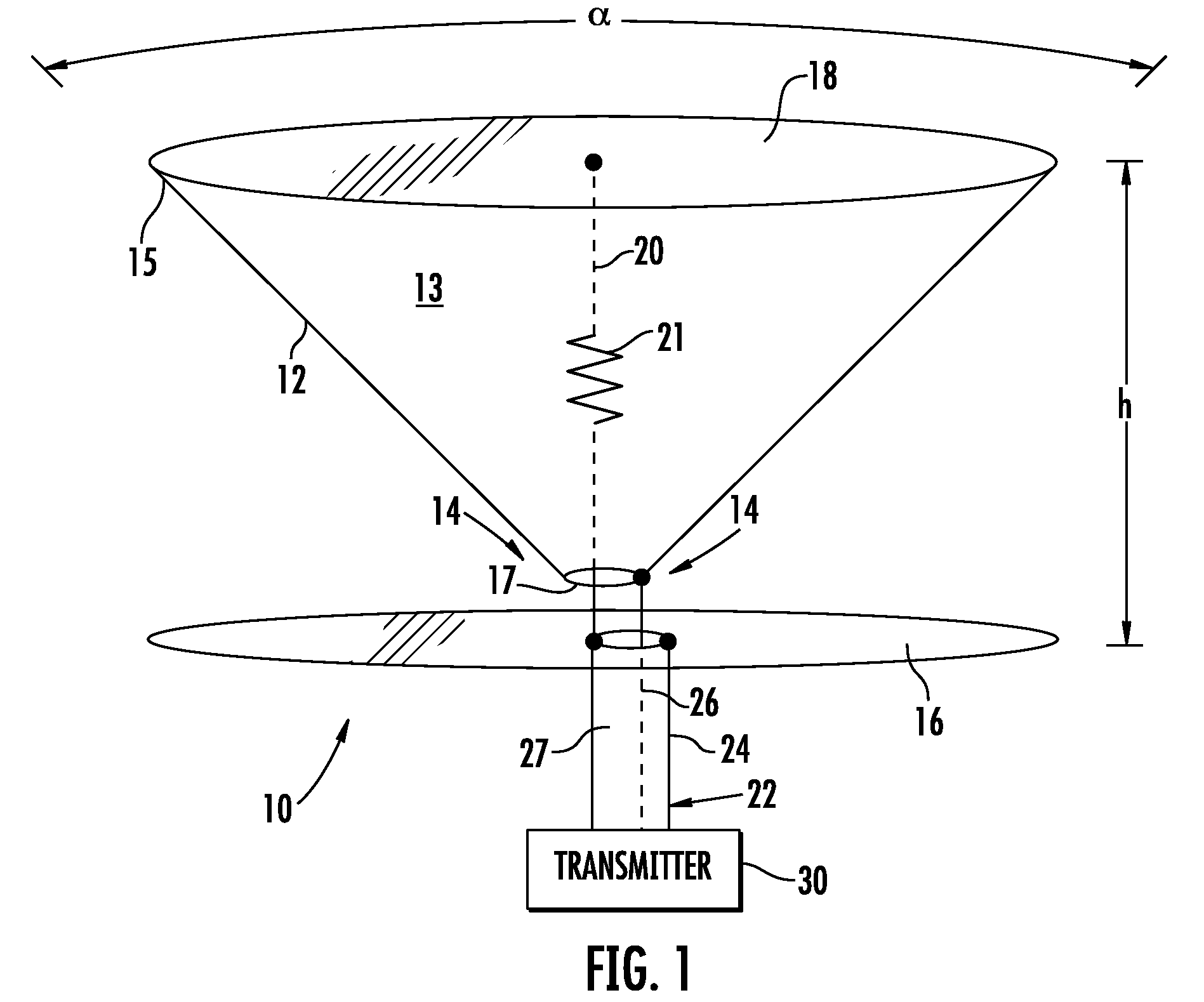

Folded conical antenna and associated methods

InactiveUS20090289865A1Reduce gainIncrease available bandwidthElongated active element feedAntenna feed intermediatesElectrical conductorEdge loading

The conical monopole antenna includes a conical antenna element having an apex and a base, a conductive base member coupled across the base of the conical antenna element and a ground plane antenna element, e.g. a disc antenna element, adjacent the apex of the conical antenna element. A fold conductor is coupled between the conductive base member and the ground plane antenna element. The fold conductor may include at least one impedance element, such as a resistive element or inductive element. An antenna feed structure is coupled to the ground plane and conical antenna elements. The antenna may have reduced gain above a cutoff frequency being traded for low VSWR below the cutoff frequency to get increased usable bandwidth. The folded resistive termination is preferential to driving point attenuation and edge loading, and the conical monopole antenna provides low VSWR at most radio frequencies.

Owner:HARRIS CORP

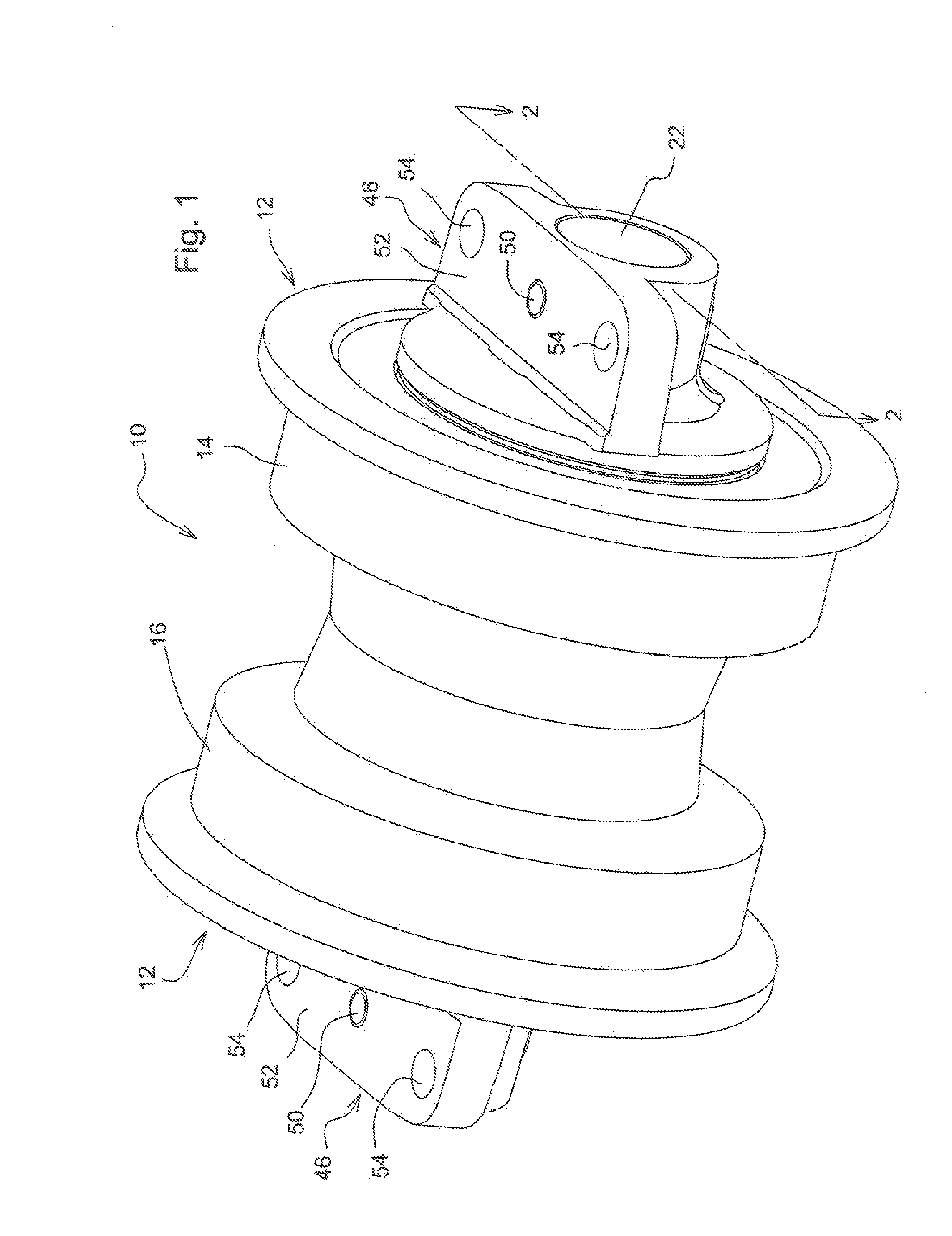

Crawler track roller with internal spherical spacers

An endless track support roller is mounted for rotation about a shaft adapted for being fixed between parallel rails of a track support frame. The roller comprises mirror image halves, with a pair of thrust bushings being received on the shaft and respectively disposed in supporting relationship to the roller halves. Each thrust bushing includes an axially outwardly facing thrust face. Mounting brackets fixed to opposite ends of the shaft are adapted to be fixed to the pair of frame rails. Non-uniform edge loading of the bushings resulting from shaft deformations caused by flexure of the frame rails is minimized by providing axially inwardly facing ends of the brackets with spherically contoured surfaces, and by locating an annular spacer between each bracket and bushing thrust face, the annular spacer having outer and inner axially facing surfaces respectively shaped complimentary to the spherically contoured bracket surface and to the bushing thrust face.

Owner:DEERE & CO

Folded conical antenna and associated methods

InactiveUS7973731B2Reduce gainIncrease available bandwidthElongated active element feedAntenna feed intermediatesElectrical conductorEdge loading

Owner:HARRIS CORP

System, method and apparatus for spring-energized dynamic sealing assembly

InactiveCN102667268AIncrease loadEnhancing reverse axis motionEngine sealsPiston ringsElastomerMetal strips

A seal assembly is disclosed. The seal comprises a metal spring bonded to an elastomer body that is coupled to a polymer ring. The spring may comprise a cantilevered, overlapped metal strip. The elastomer and polymer mechanically interlock with radial members. The elastomer has contacting surfaces configured in outward extending radii to enhance forward edge loading and oil removal from the dynamic surface. In hydraulic service, the seal prevents the egress of hydraulic fluid and ingress of foreign particles.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

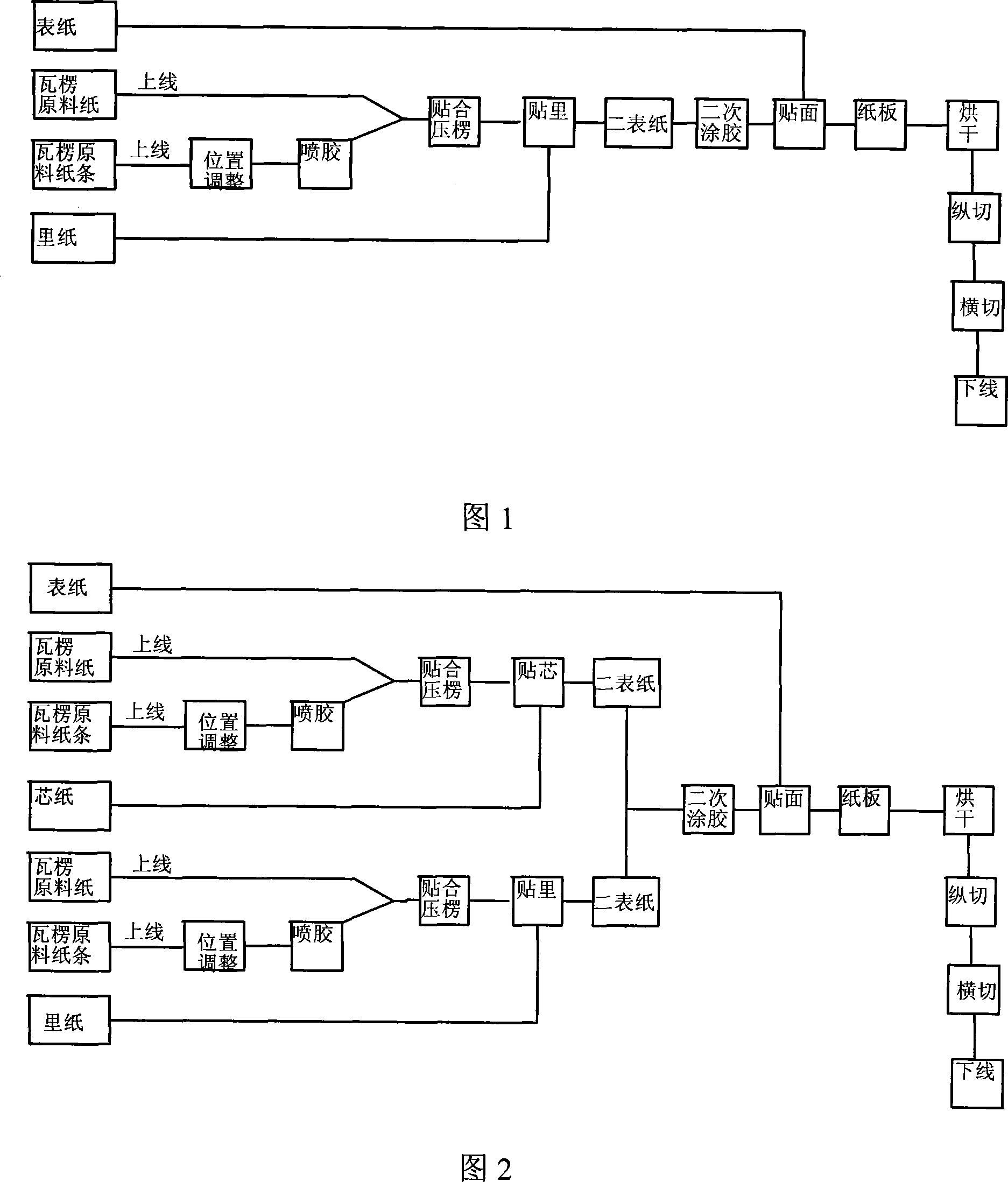

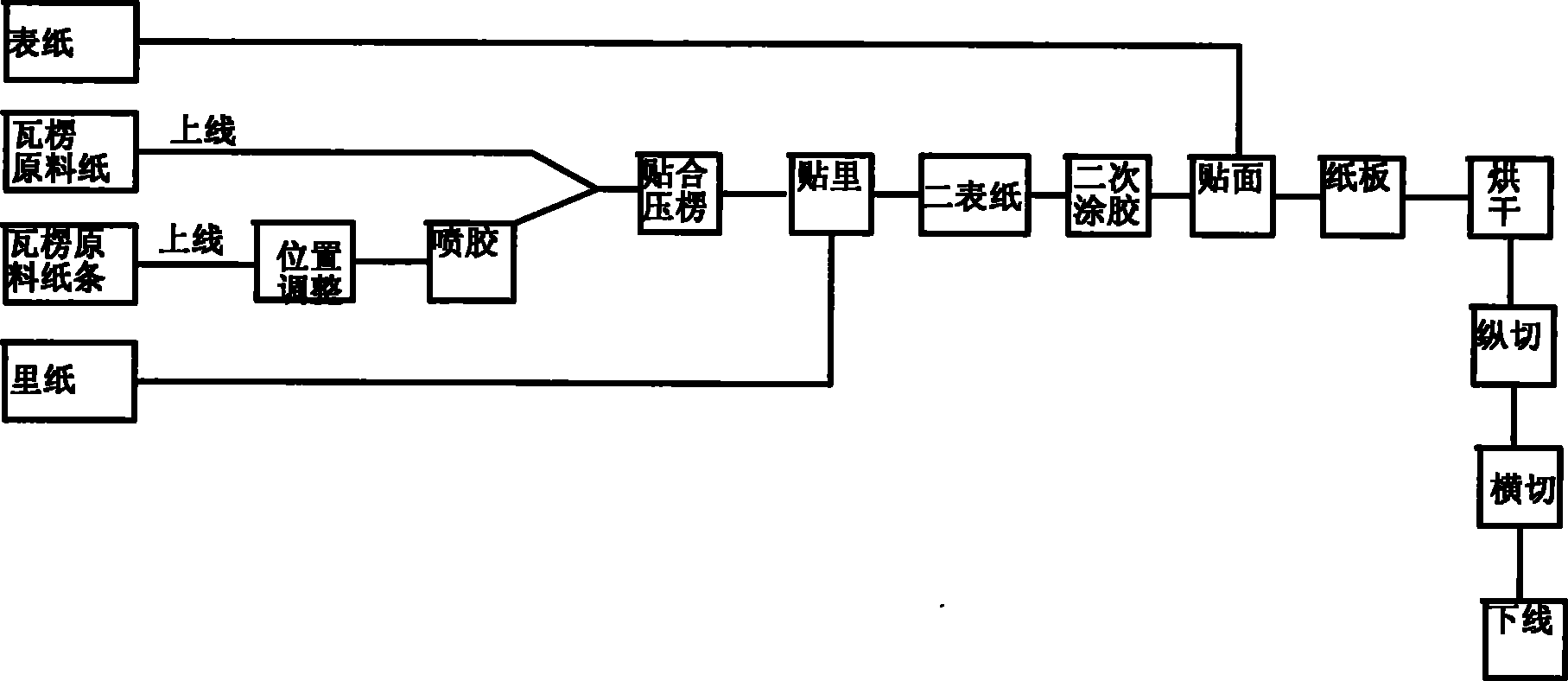

Technique for processing high bearing corrugated board

InactiveCN101130287AImprovement of quality indicators such as pressureImprove pressure bearing capacityMechanical working/deformationCardboardEdge loading

The invention relates to a producing process for corrugated board, especially a producing process for high-loading corrugated board. A producing process that low-weight corrugated stock paper is used to produce high-loading corrugated board is provided. The process comprises feeding at least a corrugated stock paper, feeding an internal stock, corresponding to number of corrugated stock paper, feeding at least a corrugated stock paper strip with the same width of box height, adjusting and determining the position of corrugated stock paper strip to corrugated stock paper, spraying glue for each corrugated stock paper strip, preparing two-surface paper by sticking and pressing of corrugated stock paper and corrugated stock paper strip and sticking internal surface, coating glue for two-surface paper in second time, preparing paper board by sticking surface, drying, cutting in vertical direction, cutting in horizontal direction and finishing product. Because several layer of corrugated paper is added at the height position of paper box the problem that the cost of package box is against various loading quality indexes of paper box is solved. Stock is saved and cost is decreased. Various physical indexes such as loading, ring loading and edge loading so on is improved and the demand for product packaging is satisfied at a larger extent.

Owner:丁乃今

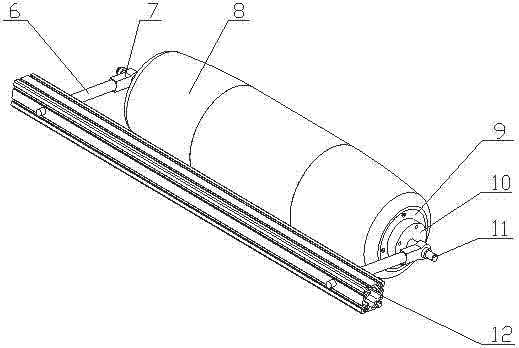

Mattress durability combined testing machine

InactiveCN103759958AHighlight substantiveConvenient and efficient implementation of comprehensive testingStructural/machines measurementCombined testClassical mechanics

The invention relates to a mattress durability combined testing machine which comprises a roller component, a frame component, an edge loading component, a center loading component and an air cylinder component. The roller component is arranged on an examine platform in the middle of the frame component, the air cylinder component is mounted inside the frame component on a side portion, the roller component is connected to the air cylinder component through a push plate on the air cylinder component, and the edge loading component and the center loading component are mounted on the frame component. The mattress durability combined testing machine is designed according a new testing standard, a clamp can be adjusted according to the size of a mattress to be tested, an integrated combined-type mattress testing machine rather than a separating-type mattress testing machine is adopted, the combined tests of durability of mattresses of different sizes can be achieved conveniently and effectively, multiple mattress tests can be completed easily and conveniently, and the reliability and stability of the tests are guaranteed.

Owner:SHANGHAI UNIV

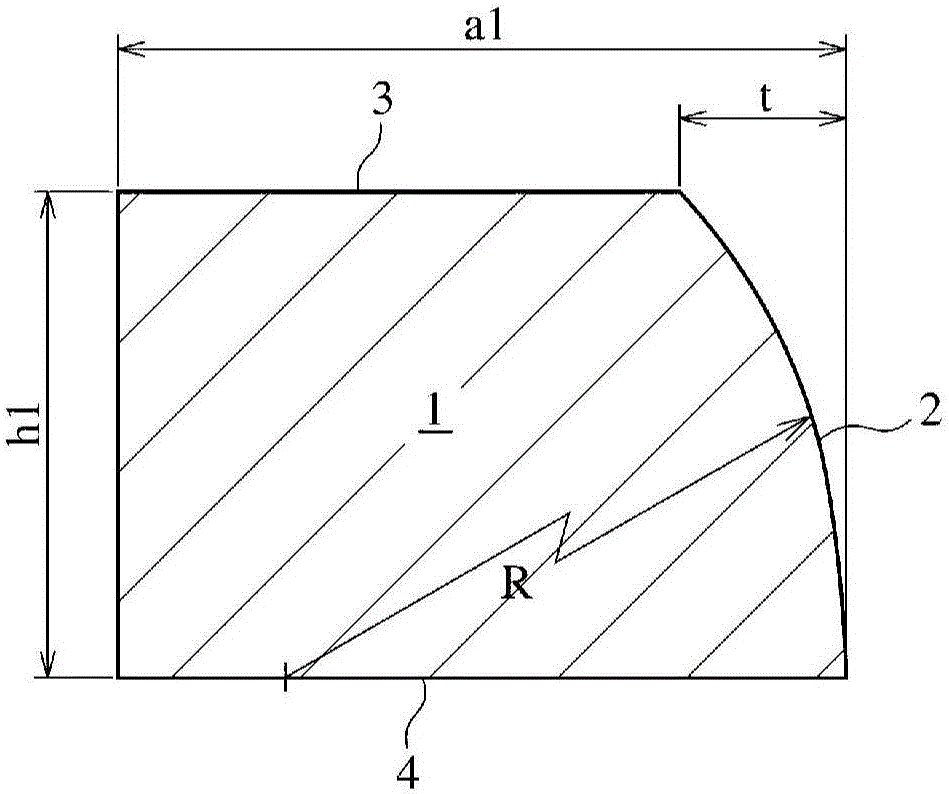

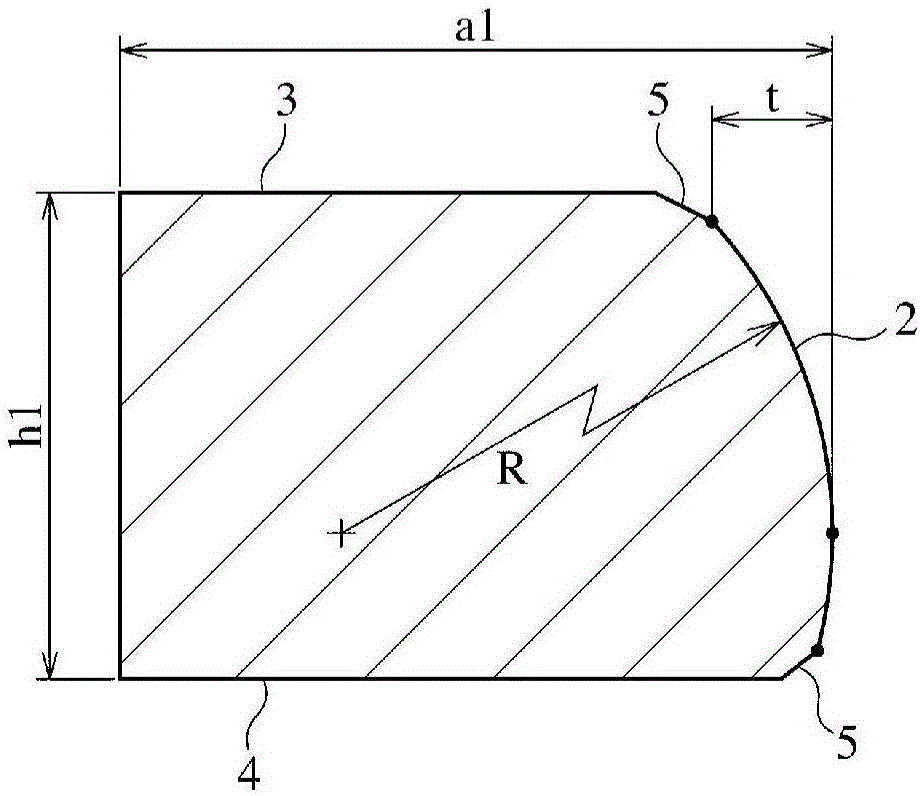

Piston ring

ActiveCN106662246AReduce contact (Hertz) stressReduce the amount of backlashPiston ringsMachines/enginesCombustion chamberPiston ring

The invention discloses a piston ring. In order to provide a piston ring that has excellent scuffing resistance and abrasion resistance, even when used in harsh environments wherein pressure and thermal load are increased, and in order to provide a piston ring that can also avoid edge loading, a first curved surface of an outer peripheral sliding surface according to the present invention protrudes to the outside in a cross-section that passes through the central axis of a piston ring and that is parallel to said central axis, and the radius of curvature of said first curved surface continuously increases or decreases from a crank chamber side to a combustion chamber side.

Owner:RIKEN CO LTD

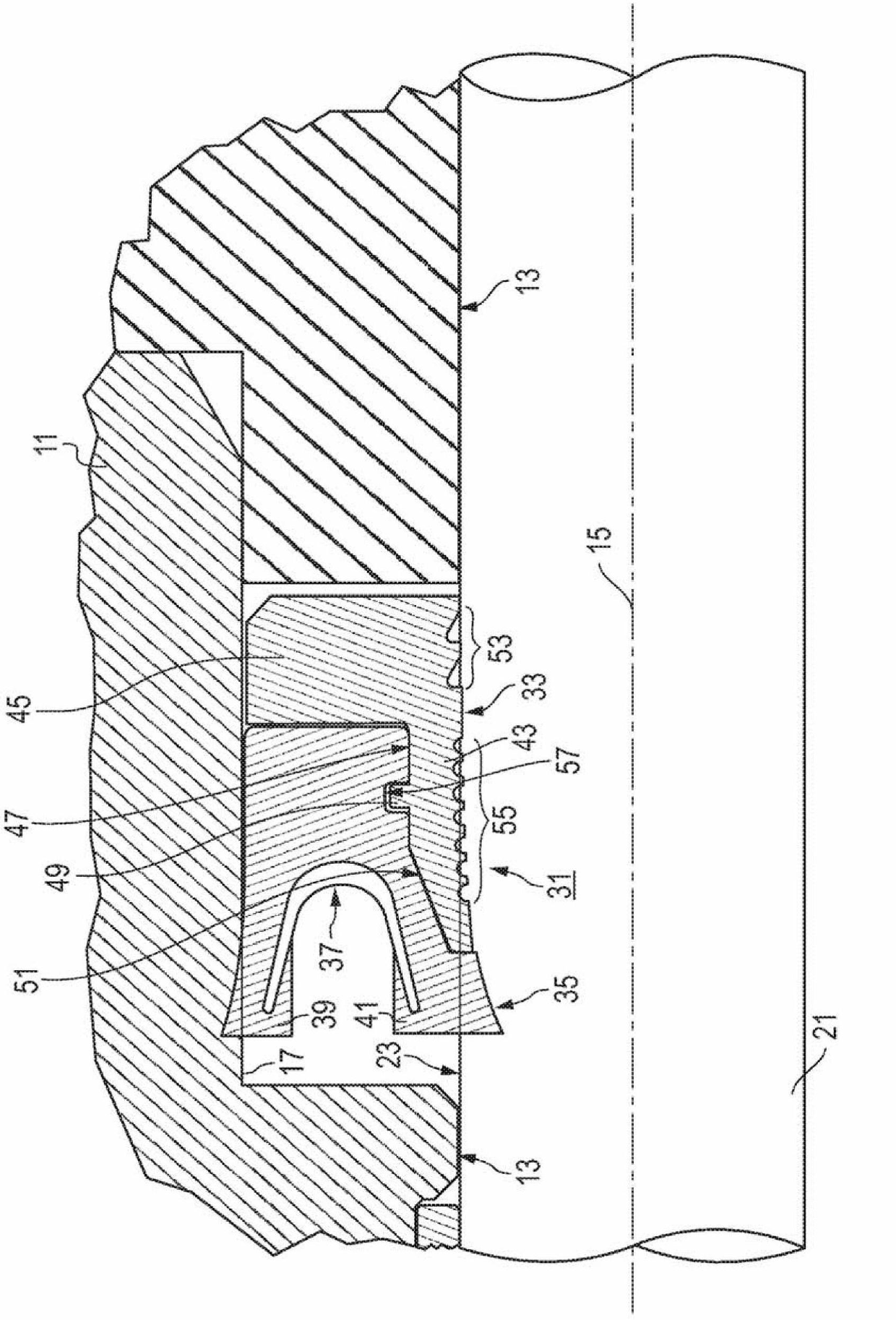

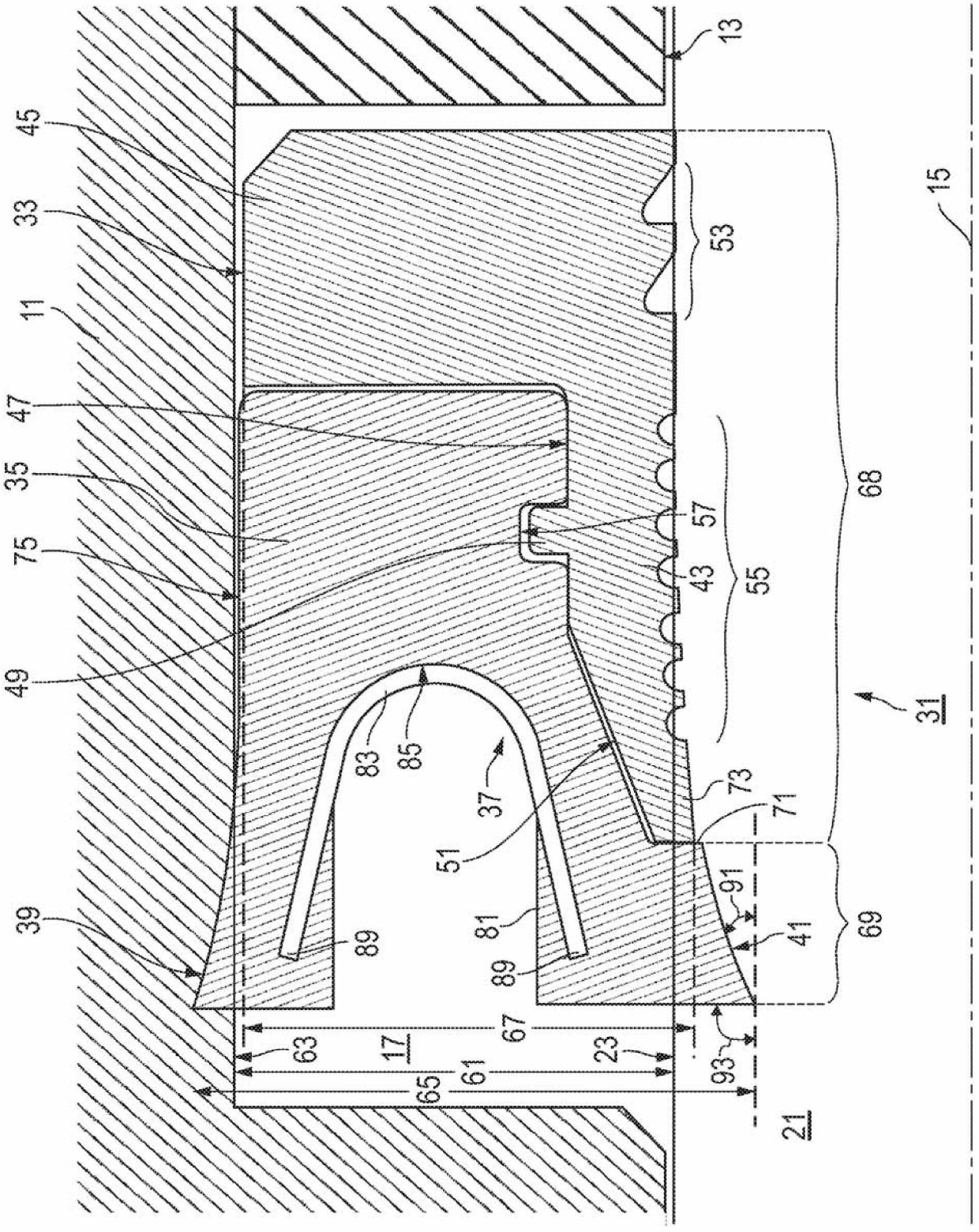

Work machine track roller assembly

ActiveUS20060181149A1Reducing edge loadingReduce side loadControlling membersRail-engaging wheelsEdge loadingEngineering

A track-type work machine is provided, including a roller frame and a track extending about the roller frame. A track roller is mounted along the roller frame and rotatable against the track. The track roller is rotatably supported by a bearing that includes a shaft extending in the track roller and at least one sleeve rotatable about the shaft. At least one of the sleeve and the track roller include a load transmitting crown. A method is further provided of reducing edge loading of a track roller bearing, by transmitting selected loads on the bearing toward a center thereof at least in part by crowning a rotatable sleeve of the bearing.

Owner:CATERPILLAR INC

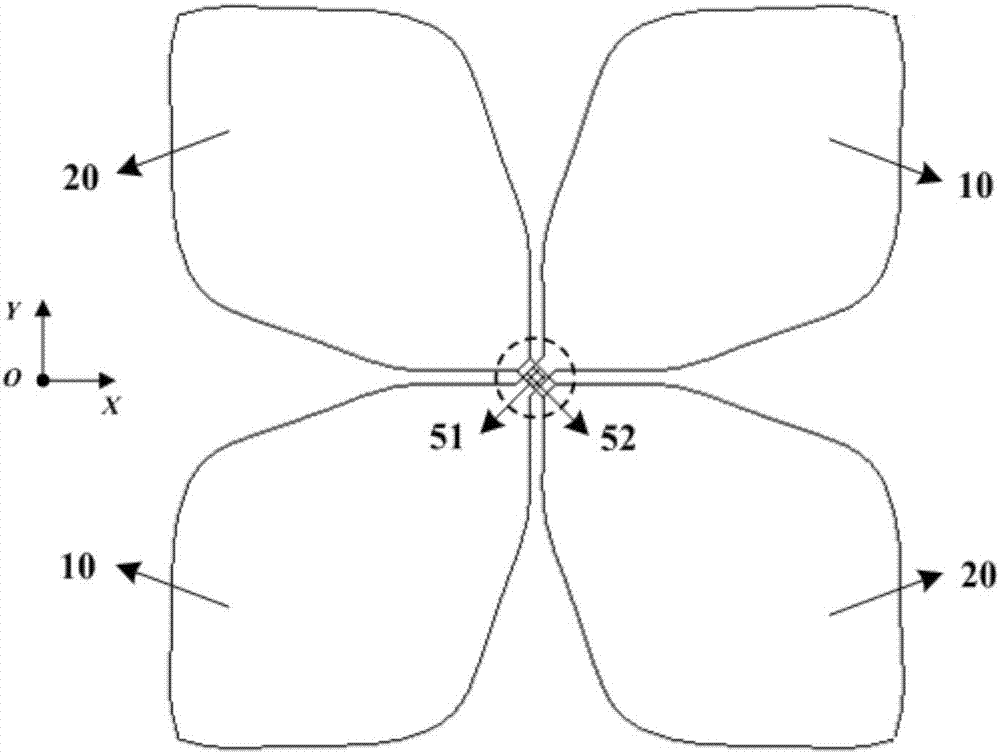

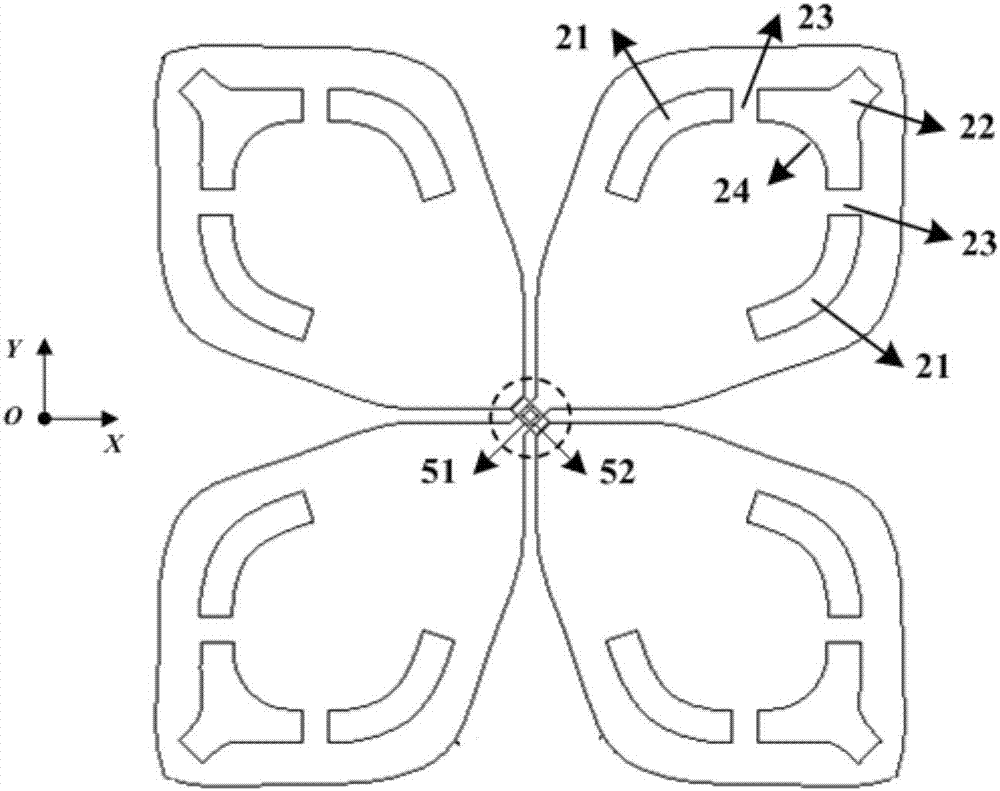

Low-profile double-frequency ultra-wideband antenna

ActiveCN107240769AImprove isolationHigh gainSimultaneous aerial operationsRadiating elements structural formsUltra-widebandCoaxial cable

The present invention provides a low-profile double-frequency ultra-wideband antenna, which comprises at least one double-frequency ultra-wideband vibrator unit. The double-frequency ultra-wideband vibrator unit comprises a pair of ultra-wideband vibrators printed on a dielectric substrate and arranged in an orthogonal manner. The two arms of each ultra-wideband vibrator are of a fat-block shape, and the two arms of each ultra-wideband vibrator are provided with arc grooves at the ends along the edges at two sides. The end of each ultra-wideband vibrator is loaded with a section of arc branch knot along the outer edges of the vibrator arms. The centrally intersecting part is provided with a feeding point connected coaxial cable or a balancing device. According to the invention, through the adoption of a thick highly-dielectric-constant dielectric substrate and the use of the manner of opening grooves on the vibrator surface and the loading of open circuit branch knot at the end, it is possible to provide for a micro base station of mobile communications a low-profile double-frequency ultra-wideband antenna featuring a low profile, a small size, the realization of MIMO, high separation and a high gain. The method is also innovative in idea, clear in principle, suitable for use and easy for implementation. With a low cost, the antenna can be produced in batches, and it can best replace a traditional Small Cell antenna. In addition, for the design and improvement in a traditional wideband intersecting vibrator antenna, the invention can also apply effectively.

Owner:TONGYU COMM INC

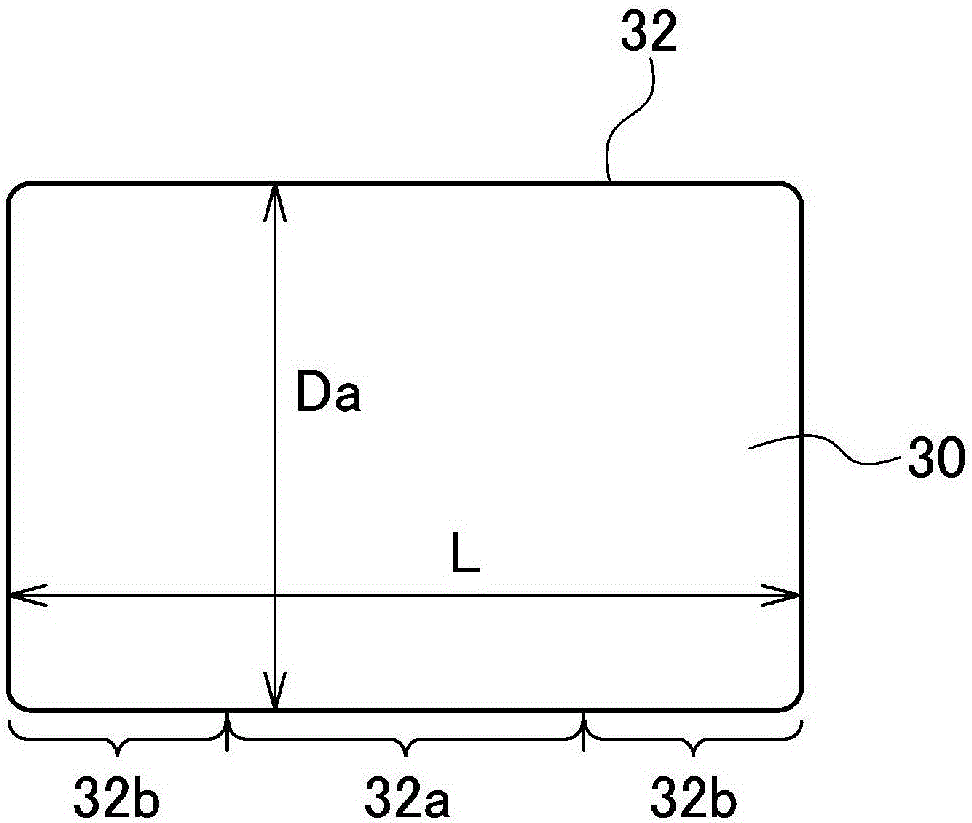

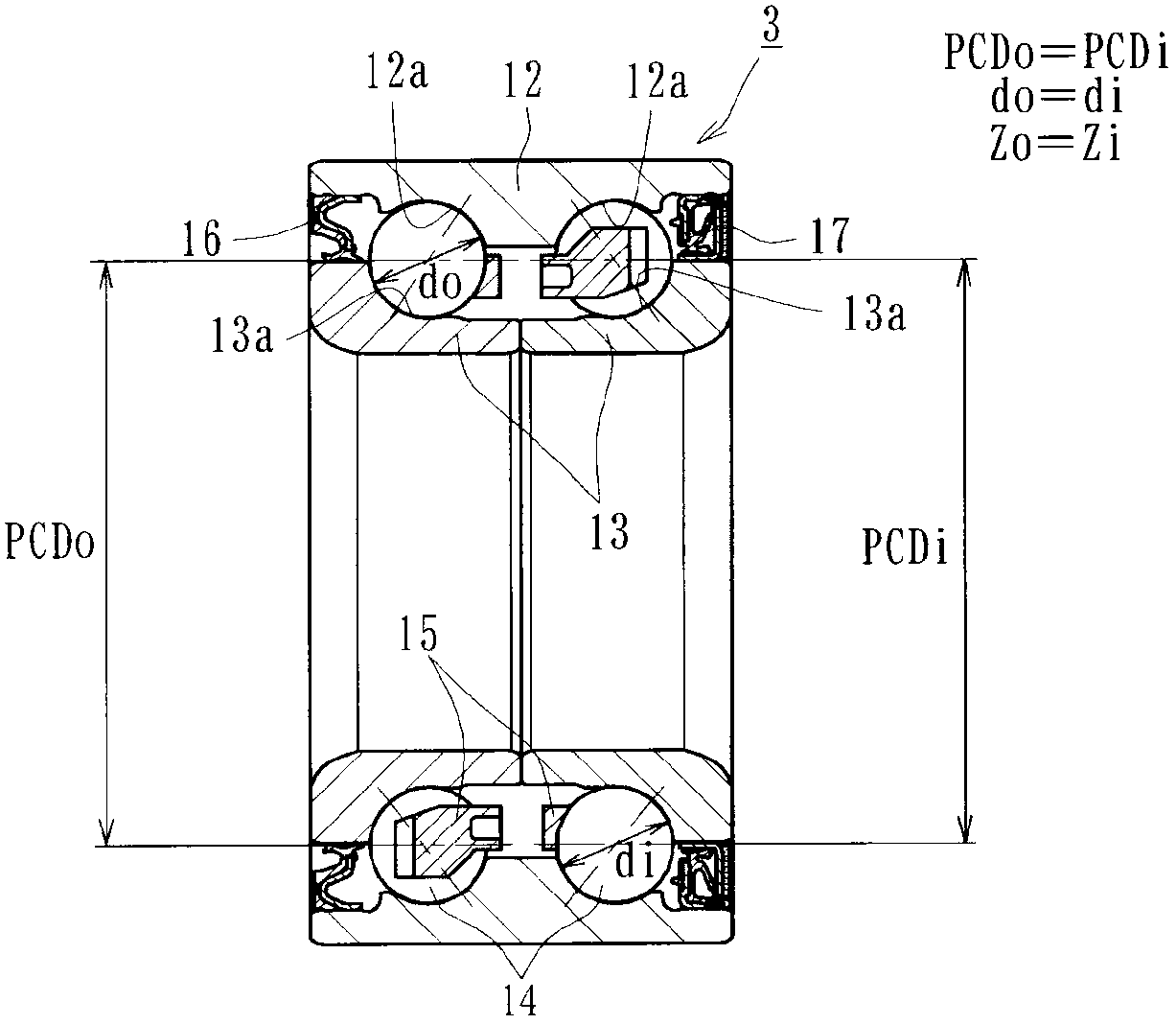

Cylindrical roller bearing and bearing device for transmission

InactiveCN105992882ASuppresses edge loadsInhibit burning lossRoller bearingsShaftsEdge loadingEngineering

A cylindrical roller bearing (1) is provided with an outer race (10), an inner race (20), and a plurality of cylindrical rollers (30). The outer race (10) has on the inner peripheral surface thereof an outer-race raceway surface (11) and a pair of outer-race flanges (12) provided on both axial-direction sides of the outer-race raceway (11). The inner race (20) has on the outer peripheral surface thereof an inner-race raceway (21) and an inner race flange (22) provided on one axial-direction side of the inner-race raceway (21). The cylindrical rollers (30) are arranged between the outer-race raceway (11) and the inner-race raceway (21). The radial-direction height (A) of the outer-race flanges (12) is greater than the radial-direction height (B) of the inner-race flange (22). The radial-direction gap (C) between the outer-race flanges (12) and the inner-race flange (22) is set to 2 mm or less. Consequently, the incidence of edge loading due to a thrust load is minimized and the state of lubrication inside the bearing is improved, which makes it possible to markedly reduce the size of a highly durable cylindrical roller bearing and transmission.

Owner:NSK LTD

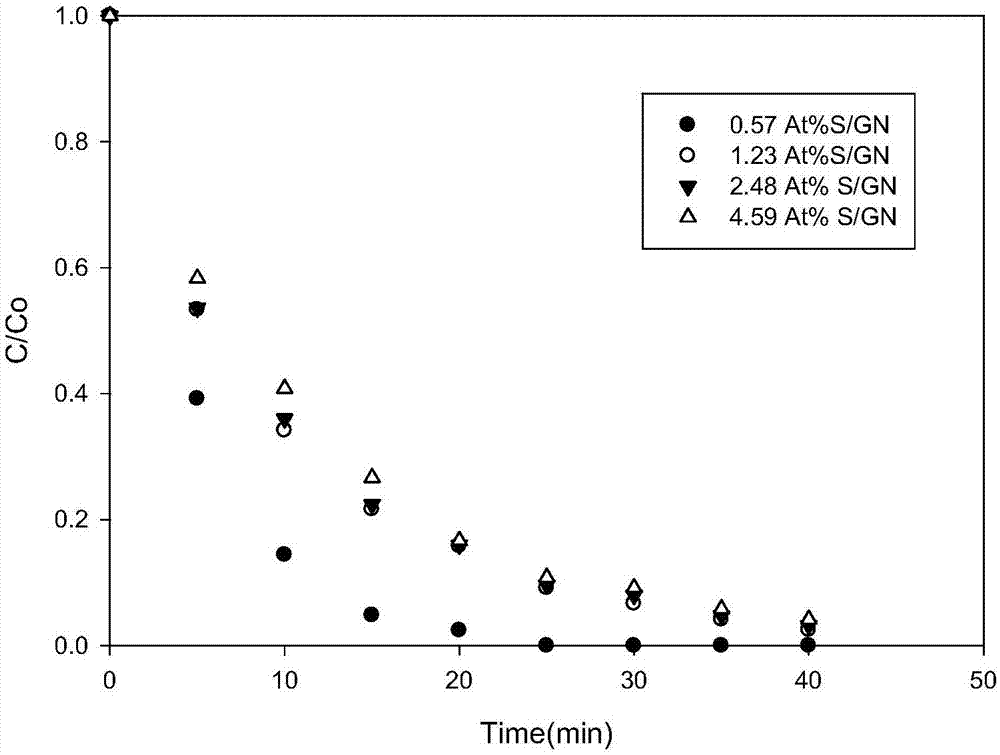

Sulfur-doped graphene catalytic material and preparation method thereof

ActiveCN107973289ASimple manufacturing methodPreparation raw materials are cheap and easy to obtainOrganic-compounds/hydrides/coordination-complexes catalystsGrapheneDoped grapheneEdge loading

The invention discloses a sulfur-doped graphene catalytic material and a preparation method thereof. The material is prepared by a hydrothermal synthesis method from the following raw materials in percentage by mass: graphite powder 0.20-0.85wt%, sodium nitrate 0.30-0.60 wt%, potassium permanganate 1.50-2.60 wt%, concentrated sulfuric acid 14.00-18.50 wt%, persulfate 0.01-0.07 wt%, hydrogen peroxide 24.00-30.00 wt %, and the balance of water, wherein sulfur atoms are loaded in a single form of edge loading into a graphene structure composed of six-membered carbon rings. The material of the invention can meet multi-directional requirements of materials in terms of economic cost and mechanism research, and has broad prospects both in scientific research and in catalytic industry applications.

Owner:HUAQIAO UNIVERSITY

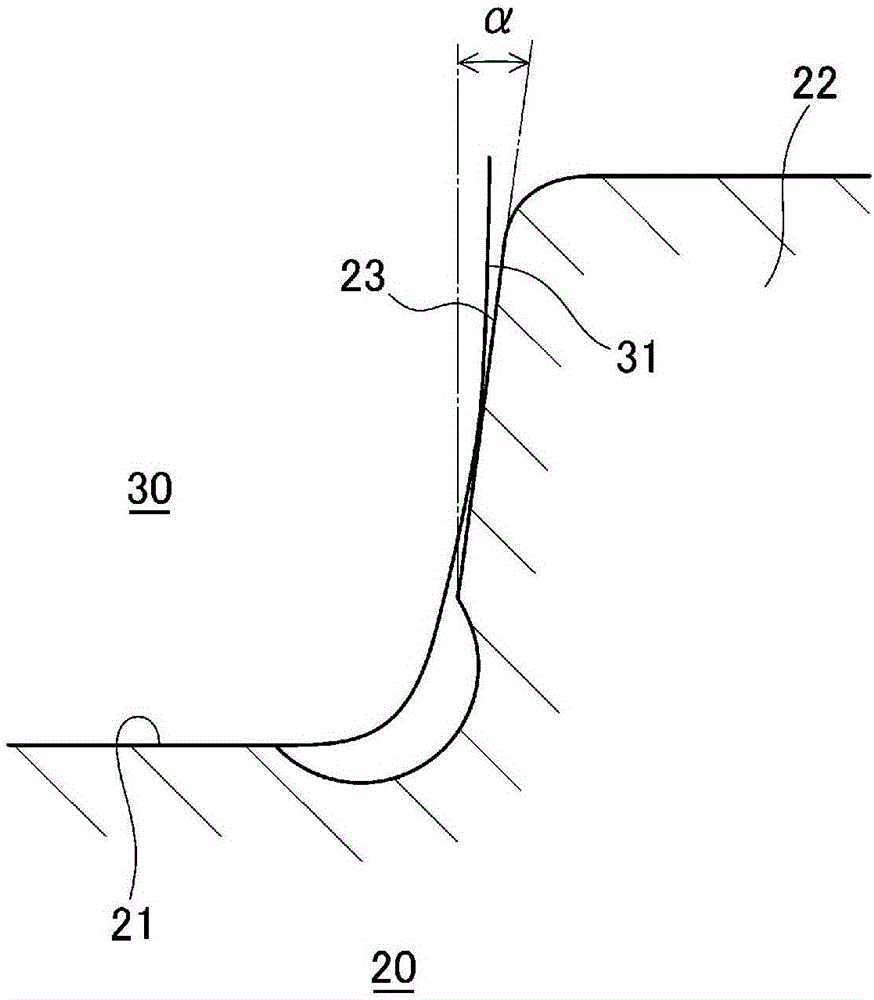

Support bearing, in particular running roller

ActiveCN105378311AEliminate edge loadsEvenly distributedRoller bearingsShaftsCylindrical bendingEdge loading

The invention relates to a support bearing, for example for straighteners, having an outer ring (2, 24, 41), having an inner ring (7, 23, 31, 40) and rolling bodies (1) which can roll between the outer ring (2, 24, 41) and the inner ring (7, 23, 31, 40) on raceways, wherein a bending moment prevails between the rings (2, 24, 41, 7, 23, 31, 40) as a result of a load with a fixed direction of action. With the aim of compensating for the bending moment, it is proposed to provide an outer raceway of the inner ring (7, 23, 31) and / or an inner raceway of the outer ring with a profiling with a variable diameter in the axial width, wherein the profiling is adapted or approximated to a non-cylindrical bending line caused by the bending moment in the rolling contact, and the bending line is defined by a line, on which bending forces which are transmitted from the inner ring (7, 23, 3) to the rolling bodies (1) and are caused by the bending moment lie substantially perpendicularly. As a result, in particular, the disadvantageous edge loading in a given load direction is suppressed, with the result that more rolling bodies (1) can transmit load between the rings (2, 24, 41, 7, 23, 31, 40) at the same time.

Owner:SCHAEFFLER TECH AG & CO KG

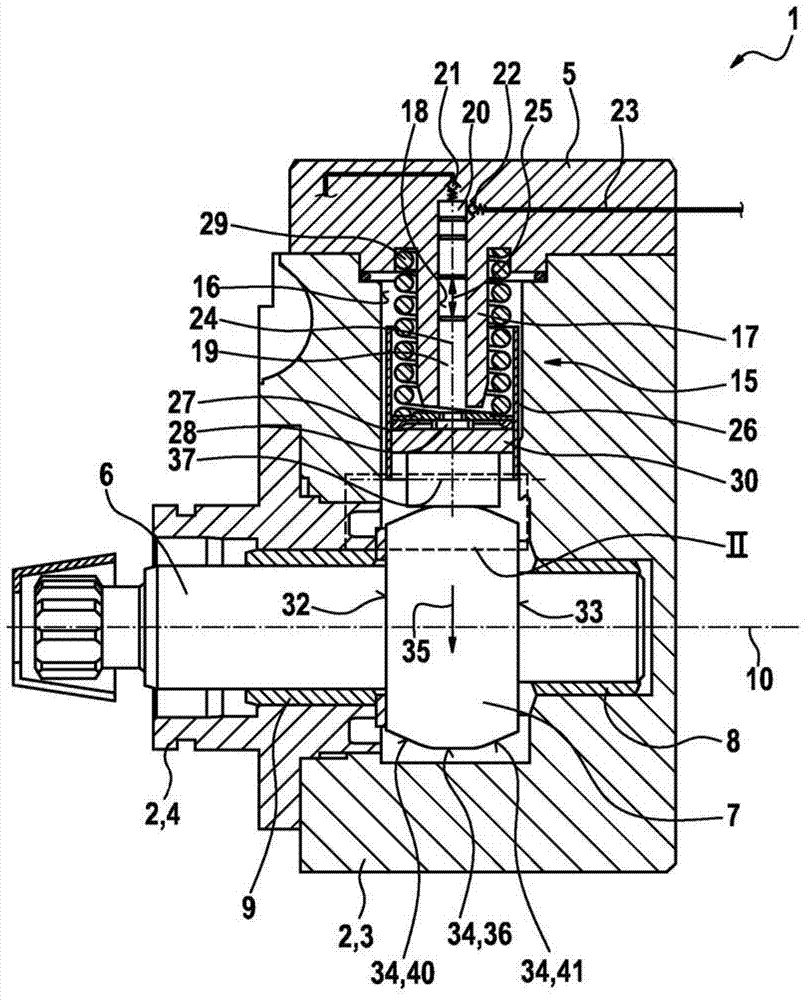

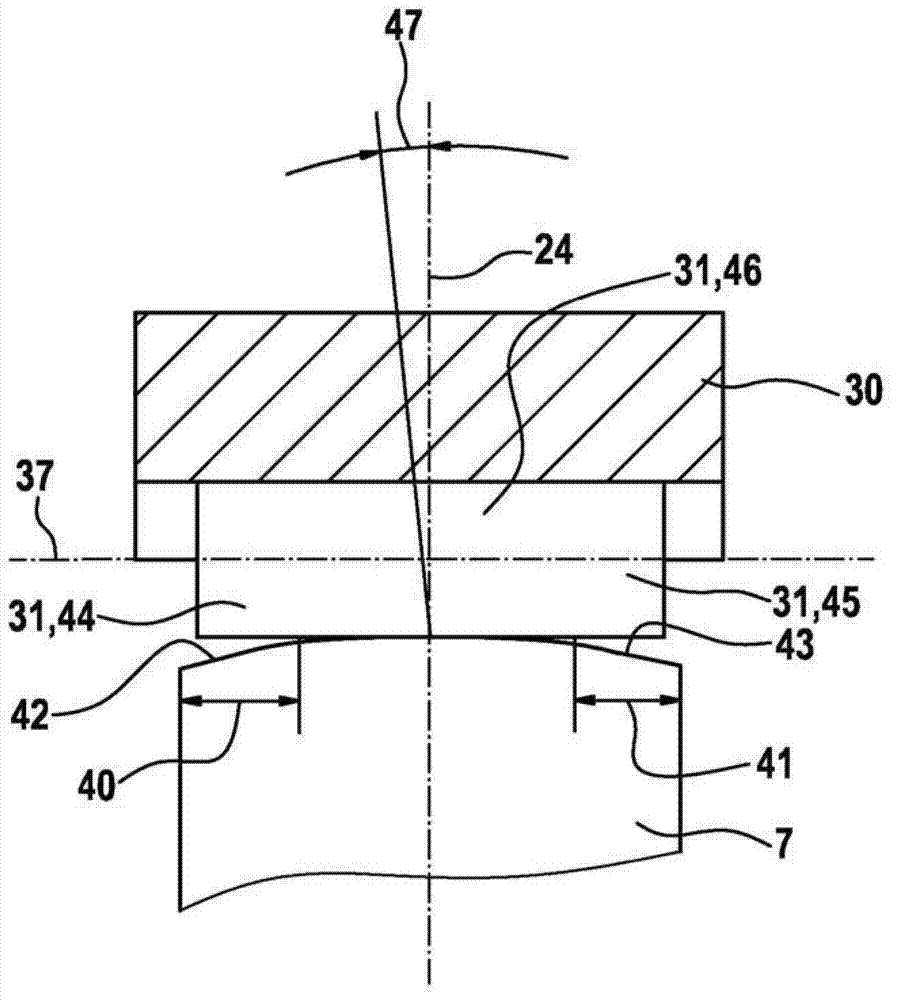

High-pressure pump

ActiveCN102939456AImproved scrolling characteristicsFavorable rolling characteristicsFuel injecting pumpsPiston pumpsCombustionDrive shaft

The invention relates to a high-pressure pump (1), which is used in particular as a radial or in-line piston pump for fuel injection systems of air-compressing, auto-igniting internal combustion engines, comprising a pump assembly (5) and a drive shaft (6), which comprises a cam (7) associated with the pump assembly (15). The pump assembly (15) has a roller shoe (30) and a roller (31) mounted in the roller shoe (30). The roller (31) rolls on a running face (34) of the cam (7). To this end, the cam (7) has eased areas (40, 41) on the running face (34) thereof. The eased areas (40, 41) ensure advantageous guidance of the roller (31) on the running face (34). The eased areas (40, 41) are needed in order to avoid edge loading. The fact that the eased areas are located on the camshaft and not on the roller (31) means that the hydrodynamics between the roller (31) and the roller shoe (30) can be perfected.

Owner:ROBERT BOSCH GMBH

Technique for processing high bearing corrugated board

InactiveCN101130287BImprovement of quality indicators such as pressureImprove pressure bearing capacityMechanical working/deformationCardboardEdge loading

The invention relates to a producing process for corrugated board, especially a producing process for high-loading corrugated board. A producing process that low-weight corrugated stock paper is used to produce high-loading corrugated board is provided. The process comprises feeding at least a corrugated stock paper, feeding an internal stock, corresponding to number of corrugated stock paper, feeding at least a corrugated stock paper strip with the same width of box height, adjusting and determining the position of corrugated stock paper strip to corrugated stock paper, spraying glue for each corrugated stock paper strip, preparing two-surface paper by sticking and pressing of corrugated stock paper and corrugated stock paper strip and sticking internal surface, coating glue for two-surface paper in second time, preparing paper board by sticking surface, drying, cutting in vertical direction, cutting in horizontal direction and finishing product. Because several layer of corrugated paper is added at the height position of paper box the problem that the cost of package box is against various loading quality indexes of paper box is solved. Stock is saved and cost is decreased. Various physical indexes such as loading, ring loading and edge loading so on is improved and the demand for product packaging is satisfied at a larger extent.

Owner:丁乃今

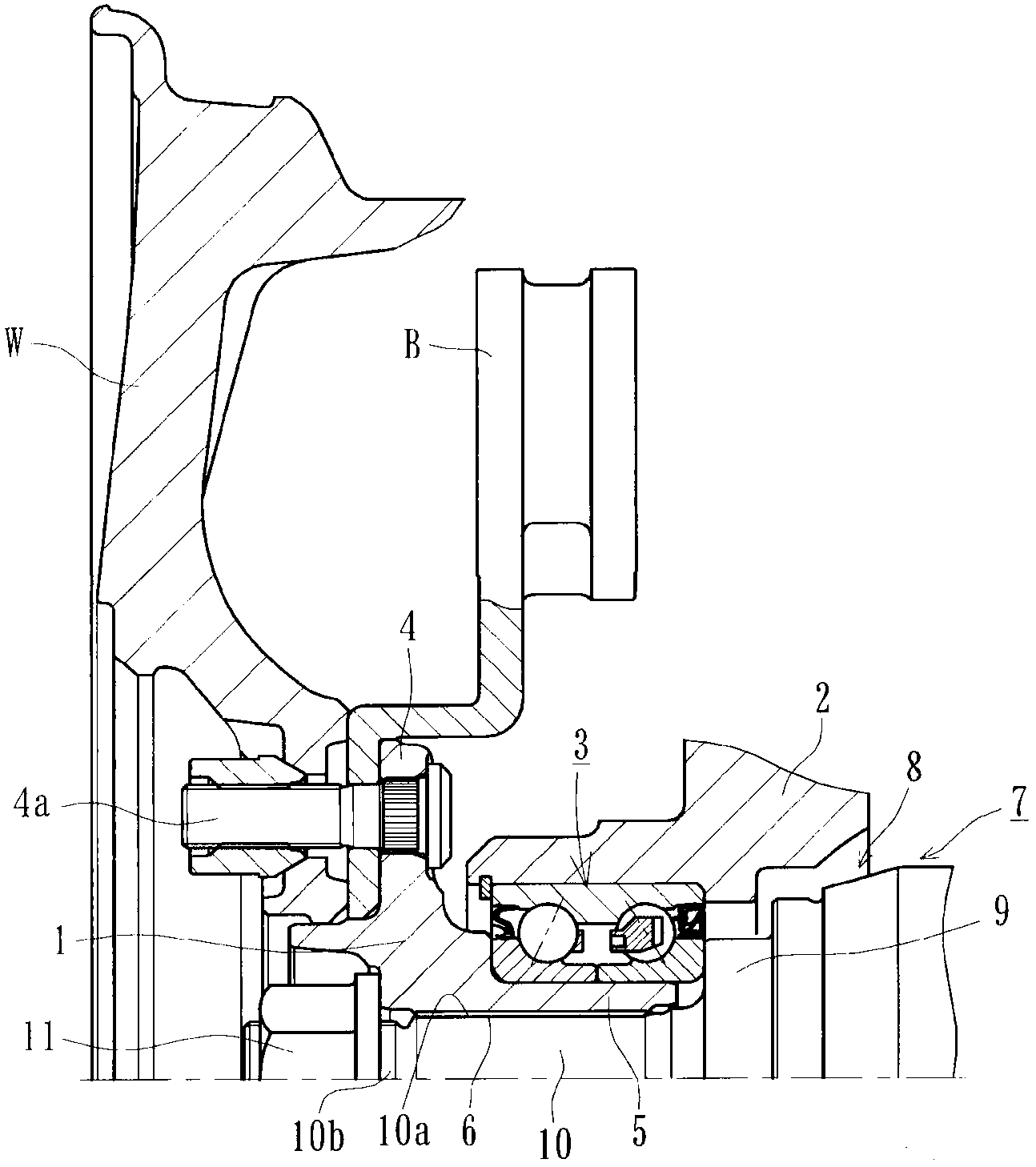

Vehicle wheel bearing device

ActiveCN102939470AImprove noise characteristicsExtend your lifeShaftsBall bearingsBall bearingEllipse

Disclosed is a vehicle wheel bearing device that prevents edge loading of the osculating ellipse of a ball, and that increases service life and acoustic characteristics. In the vehicle wheel bearing device, which is configured from a double-row angular ball bearing, the shoulder height of shoulders (18) of an outer member (12) is set in the range of 0.35-0.50 times the ball diameter in the double-row of balls (14); the corners (19) of the shoulders (18) are each configured from a flank (19a) that is a straight line that is tangential to an outer rolling surface (12a), and a chamfered section (19b) that is rounded in an arc having a predetermined curvature radius (r); by means of a formed grindstone that shapes the double-row of outer rolling surfaces (12a), the corners (19) are formed at that same time, and are formed smoothly and continuously from each outer rolling surface (12a); and the length (h) in the radial direction of the flank (19a) is set to be at least 0.2 mm.

Owner:NTN CORP

Shaft bearings, compressor with same, and methods

InactiveUS8167597B2Easy to compressRotary combination bearingsEngine of arcuate-engagement typeDrive shaftEdge loading

A bearing material composition that lines a support includes a combination of a thermoplastic conforming material and abrasive particles which provide a combined effect for remedying the effects due to edge loading that may be caused by misalignment between the bearing and a shaft to which a portion is rotatably mounted. The conforming material may be PTFE such that it does not have a memory and is subject to cold flow and creep. As a result, misalignment problems and edge loading are remedied by the combination of abrasive removal of metal material from the drive shaft at the location of edge loading and creep of the conforming material at the location of edge loading which may provide an overall greater bearing interface surface.

Owner:BITZER KUEHLMASCHINENBAU GMBH

Shaft bearings, compressor with same, and methods

A bearing material composition that lines a support includes a combination of a thermoplastic conforming material and abrasive particles which provide a combined effect for remedying the effects due to edge loading that may be caused by misalignment between the bearing and a shaft to which a portion is rotatably mounted. The conforming material may be PTFE such that it does not have a memory and is subject to cold flow and creep. As a result, misalignment problems and edge loading are remedied by the combination of abrasive removal of metal material from the drive shaft at the location of edge loading and creep of the conforming material at the location of edge loading which may provide an overall greater bearing interface surface.

Owner:BITZER KUEHLMASCHINENBAU GMBH

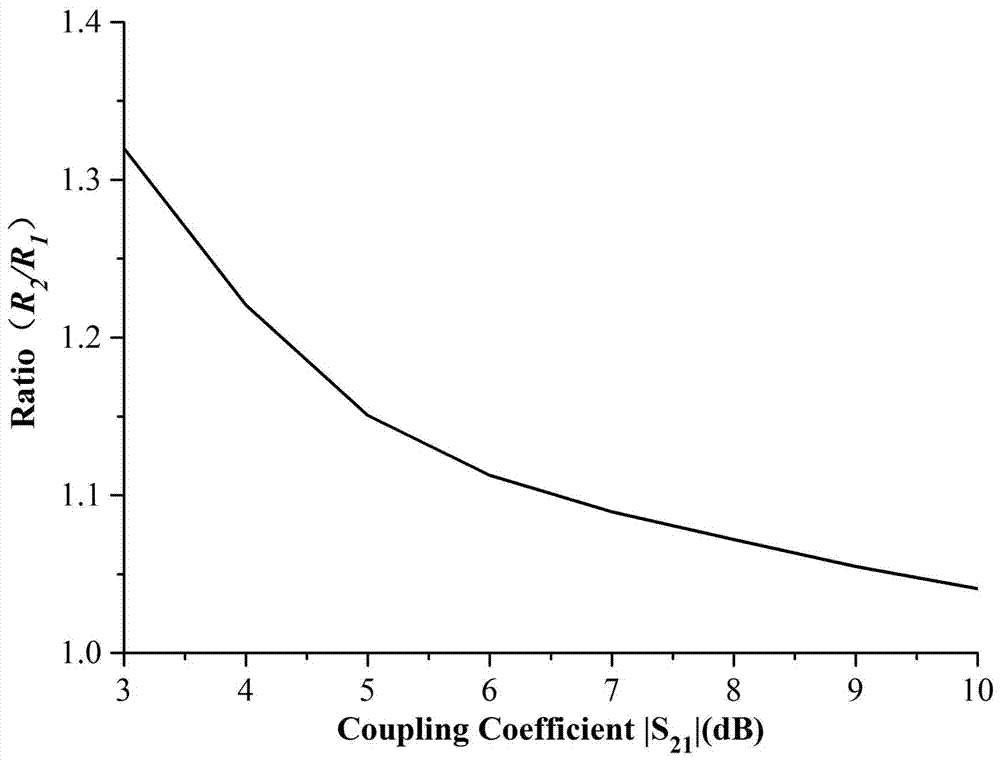

Millimeter wave quadrature coupler with arbitrary coupling factor and its design method

ActiveCN104795617BStable phase differenceSimplify the design processCoupling devicesModem deviceEdge loading

The invention discloses a millimeter-wave orthocoupler based on chip units and with arbitrary coupling factors and a design method thereof. The millimeter-wave orthocoupler comprises four 90-degree sector microstrip chip units linked with one another, four port lines, a plurality of metalized vias distributed in the edges of the chip units, a dielectric substrate and a metal ground. Four 90-degree sector microstrip chip units with the edges loaded of metalized vias, four pore lines, the dielectric substrates and the metal ground are used to form the dielectric integrated waveguide coupler based on the chip units; opposite sectors of the 90-degee sector microstrip chip units are equal in radius, adjacent sectors are unequal in radius, the different radius ratios lead to different coupling factors; the positions of the port lines 90 degrees spaced along the centers of the chip units are used to implement the phase orthogonal function of the orthocoupler. The millimeter-wave orthocoupler is widely applicable to systems such as modems, power amplifiers, balance mixers, system power detection, and amplitude control circuits of multi-beam antenna arrays.

Owner:SYSU CMU SHUNDE INT JOINT RES INST

Torque converter clutch regulating valve assembly and method of increasing hydraulic pressure using the same

InactiveCN100489352CIncrease influenceIncrease pressure flowFluid gearingsIsolation valveEdge loading

The invention discloses a torque converter clutch regulating valve assembly and a method for increasing hydraulic pressure by using the same. It consists of mainly two cooperating valves, a replacement modulating apply valve and a replacement isolation valve, in hydraulic communication with the main line pressure circuit and the torque converter clutch apply circuit. In one embodiment, the modulating action valve utilizes a modulating action valve sleeve which provides support for the modulating action valve to avoid edge loading. The improved control land on the modulating action valve has a reduced cross-sectional area to increase the effect of the pulse width modulated solenoid, which provides an output pressure in response to the solenoid coil in the pulse width modulated converter system. Applied duty cycle. In another embodiment, isolation valve sleeves are used when the isolation valve bore is so worn that it cannot be repaired by simply installing a replacement isolation valve.

Owner:SONNAX INDS

A mattress durability comprehensive testing machine

InactiveCN103759958BConvenience and Efficiency for Comprehensive Durability TestingConvenient and efficient implementation of comprehensive testingStructural/machines measurementCombined testClassical mechanics

The invention relates to a mattress durability comprehensive testing machine, comprising a roller part, a frame part, an edge loading part, a central loading part and a cylinder part; the roller part is placed on an inspection platform in the middle of the frame part, and the cylinder part The components are installed in the side frame components, the roller components are connected to the cylinder components through the push plates on the cylinder components, and the side loading components and the central loading components are installed on the frame components. The invention is designed according to the new detection standard, the fixture can be adjusted according to the size of the mattress to be tested, and the combined mattress testing machine is used as a whole instead of a separate mattress testing machine, which can conveniently and effectively realize mattresses of different sizes The comprehensive test of durability enables multiple mattress tests to be completed easily, ensuring the reliability and stability of the test.

Owner:SHANGHAI UNIV

A kind of synergistic moisturizing antifreeze coal dust inhibitor and preparation method thereof

The invention relates to a synergistic moisturizing and antifreezing coal dust inhibitor and a preparation method thereof; the technical problem to be solved is to provide a series of coal dust inhibitors with high-efficiency dampening and antifreezing functions by using compound synergistic technology; , film former, penetrating agent, humectant, coagulant, antifreeze and water. It can be prepared by mixing solutions with relevant concentrations, and can also be added while dissolving; its mass percentages are calcium chloride (33%) 22-52, ethylene glycol (10%) 4-16, glycerin (30) 0-8, CMC (2.5%) 1‑26, PVA (1%) 0‑26, PAM (1%) 0‑17, JFC (5%) 3‑19, magnesium chloride (30%) 0‑22. When in use, it can be sprayed directly on coal piles, coal transportation channels, etc. If it is sprayed with fine water mist, it is more conducive to wetting and penetration, and can reduce the amount of water used.

Owner:EASTERN GANSU UNIVERSITY +1

High-pressure pump

ActiveCN102939456BImproved scrolling characteristicsFavorable rolling characteristicsFuel injecting pumpsPiston pumpsCombustionDrive shaft

The invention relates to a high-pressure pump (1), which is used in particular as a radial or in-line piston pump for fuel injection systems of air-compressing, auto-igniting internal combustion engines, comprising a pump assembly (5) and a drive shaft (6), which comprises a cam (7) associated with the pump assembly (15). The pump assembly (15) has a roller shoe (30) and a roller (31) mounted in the roller shoe (30). The roller (31) rolls on a running face (34) of the cam (7). To this end, the cam (7) has eased areas (40, 41) on the running face (34) thereof. The eased areas (40, 41) ensure advantageous guidance of the roller (31) on the running face (34). The eased areas (40, 41) are needed in order to avoid edge loading. The fact that the eased areas are located on the camshaft and not on the roller (31) means that the hydrodynamics between the roller (31) and the roller shoe (30) can be perfected.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com