Technique for processing high bearing corrugated board

A corrugated cardboard and production process technology, applied in the direction of mechanical processing/deformation, can solve the problems of high product cost and poor quality of packaging cartons, achieve quality and cost assurance, improve pressure bearing capacity, and save raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

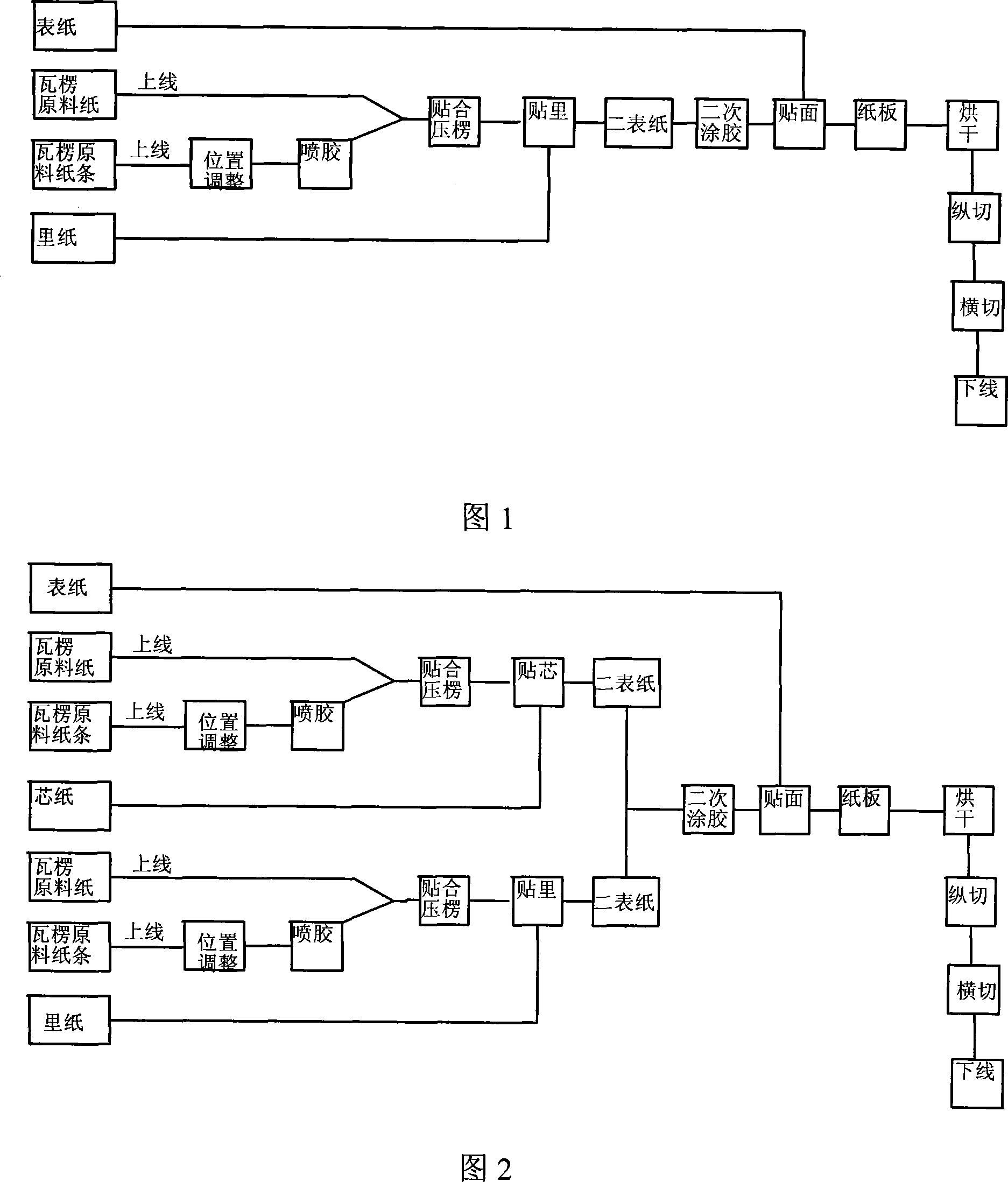

[0023] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0024] As shown in Figure 1, a three-layer cardboard production process for high-pressure corrugated cardboard includes the following steps: putting a roll of corrugated raw material paper on the line, and a layer of lining material on the line; putting a roll of corrugated raw material paper with the same width as the box height line; adjust and determine the position of the corrugated raw paper relative to the corrugated raw paper so that it is at the position of the height and width of the carton box, and spray the corrugated raw paper; the corrugated raw paper and the corrugated raw paper are laminated and pressed And paste inside to make the second surface paper; at this time, the second surface paper is changed from the old product's two-layer paper structure of one layer of corrugated pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com