Cylindrical roller bearing and bearing device for transmission

A cylindrical roller and bearing technology, which is applied in the field of cylindrical roller bearings and bearing devices for transmissions, can solve problems such as limitations and larger sizes, and achieve the effects of suppressing burnout, suppressing edge loads, and realizing miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

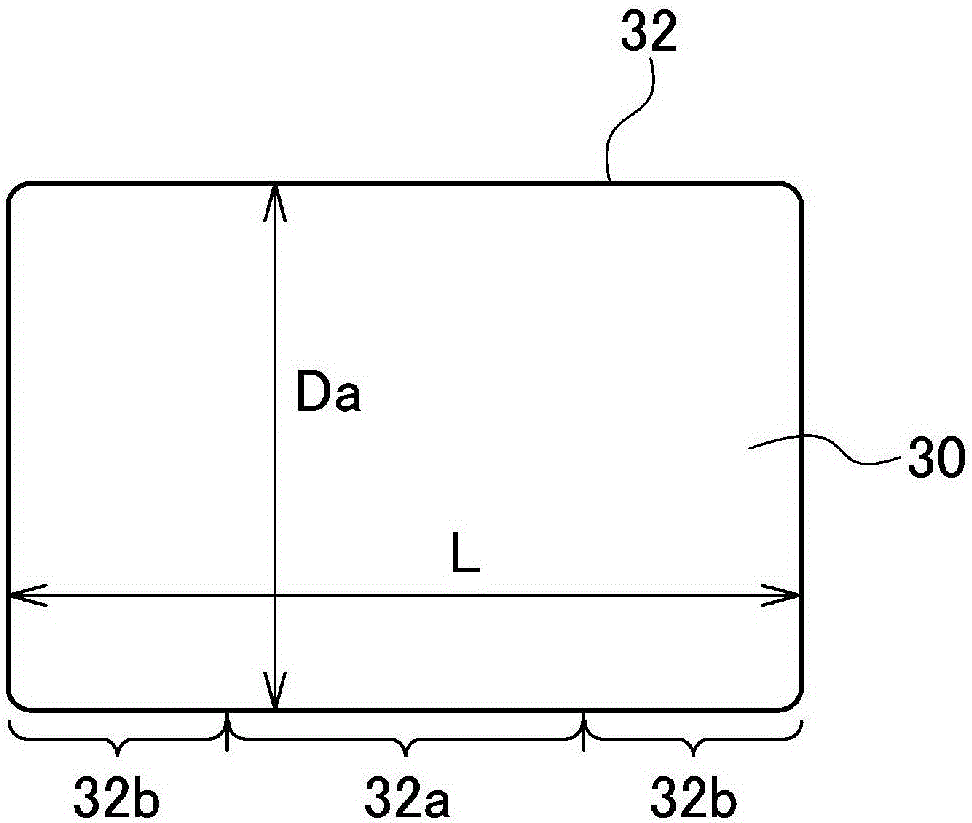

[0081] Here, with regard to the cylindrical roller bearing 1 of the present embodiment, verification experiments were performed while changing the shape of the rolling surface 32 of the cylindrical roller 30 to confirm the effect thereof. In addition, the verification experiment was performed under the following conditions, and the target lifetime was 120 Hrs.

[0082] Verify experimental conditions

[0083] Load: 0.4C (C: basic rated dynamic load)

[0084] Speed: 3000rpm

[0085] Lubrication conditions: ATF, 120°C, oil bath

[0086] Foreign matter: 0.05g / L: (Foreign matter size: 10-50μm, iron)

[0087] Tilt: 0rad (no tilt), 3 / 1000rad (with tilt)

[0088] [Table 1]

[0089]

[0090] Table 1 shows the experimental results in the case of using the cylindrical roller 30 in which the rolling surface 32 was crowned with a single arc. It can be confirmed from Table 1 that if the radius of curvature is 300 to 700 mm, the target life can be achieved even if there is a relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com