Self-aligning roller bearing, bearing, and self-aligning roller bearing processing method

An automatic centering and roller technology, which is applied in the processing of bearings and rollers for bearings, and in the field of bearing rollers, can solve the problems of inability to provide high-precision products, processing rounded corners Rb, and changes in outer diameters to achieve reduction Effect of small rotational moment, suppression of edge load, and improvement of rotational accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below, based on Figure 1 to Figure 10 , to describe the embodiment of the present invention.

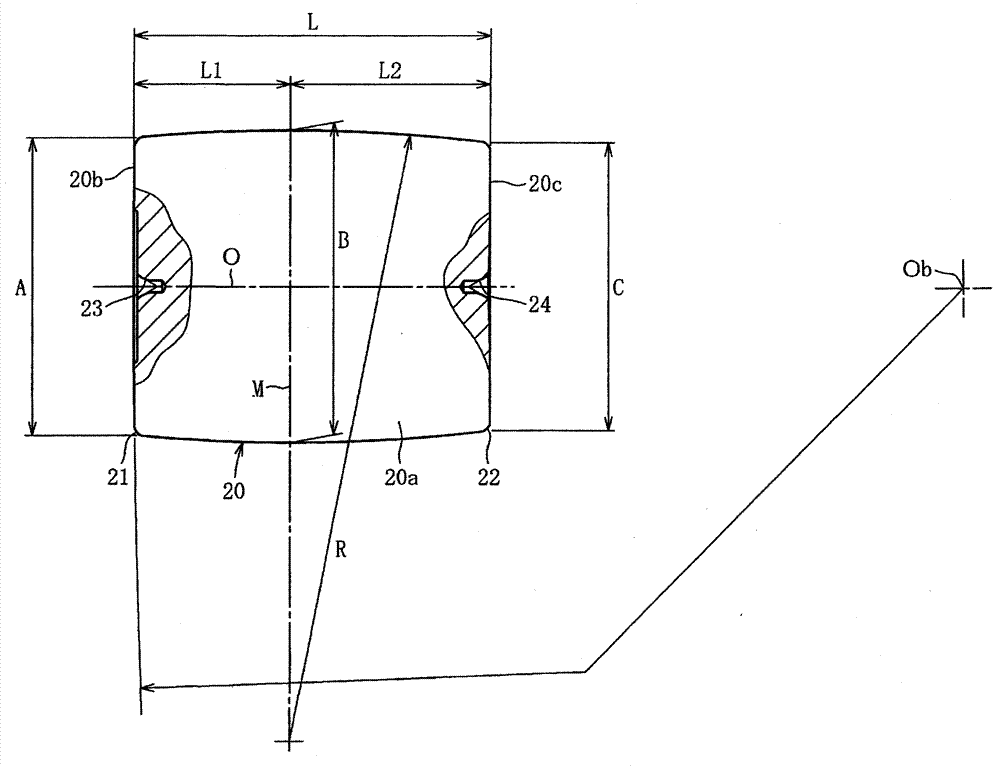

[0038] Figure 1 to Figure 3 The bearing roller of the present invention is shown, and the bearing roller 20 is a self-aligning roller. In self-aligning roller bearings, there are asymmetric roller bearings and symmetrical roller bearings according to the shape of the rollers. The asymmetrical roller bearing is a bearing using asymmetrical rollers in which the position of the largest diameter deviates from the center of the length. In symmetrical roller bearings, symmetrical rollers with the largest diameter at the center of the length are used.

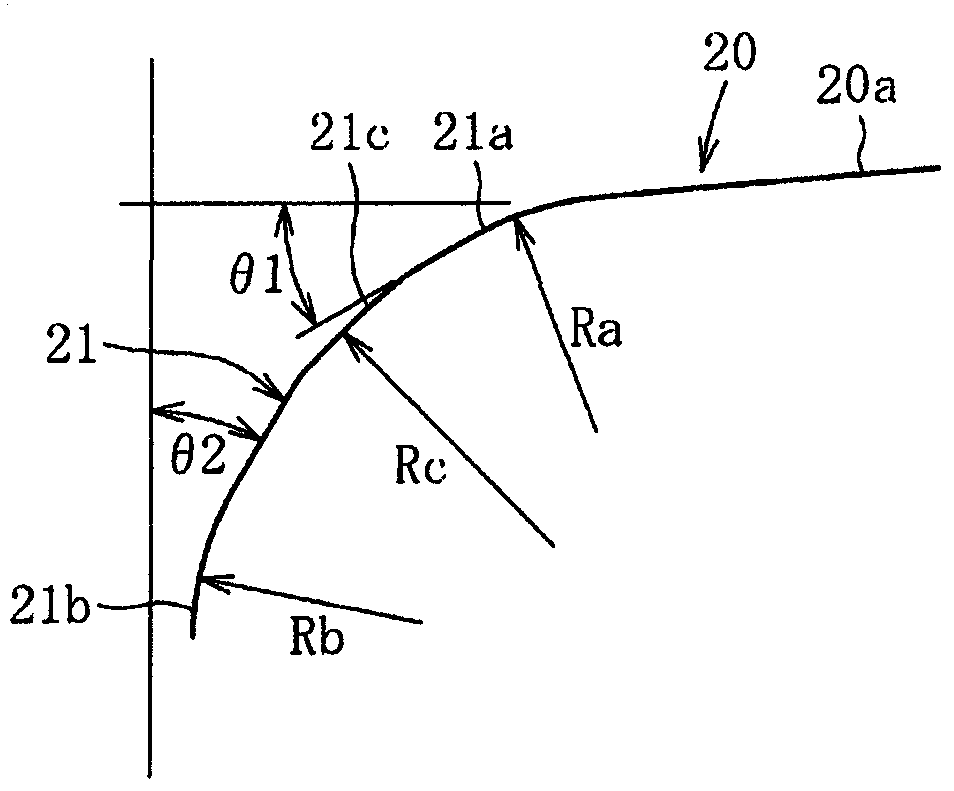

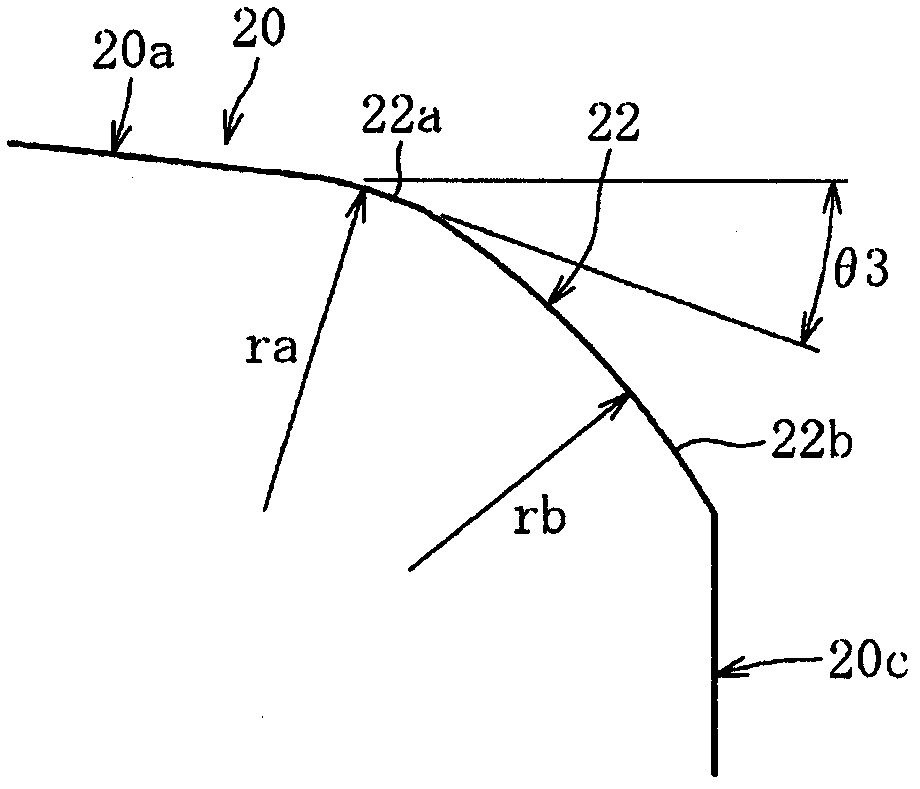

[0039] The roller 20 of this embodiment is an asymmetrical roller, and the maximum outer diameter part M of the outer diameter surface 20a deviates from the axial centerline. Further, the large end surface 20b is a spherical surface having a larger curvature than the outer diameter surface 20a, and the small end surface 20c is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com