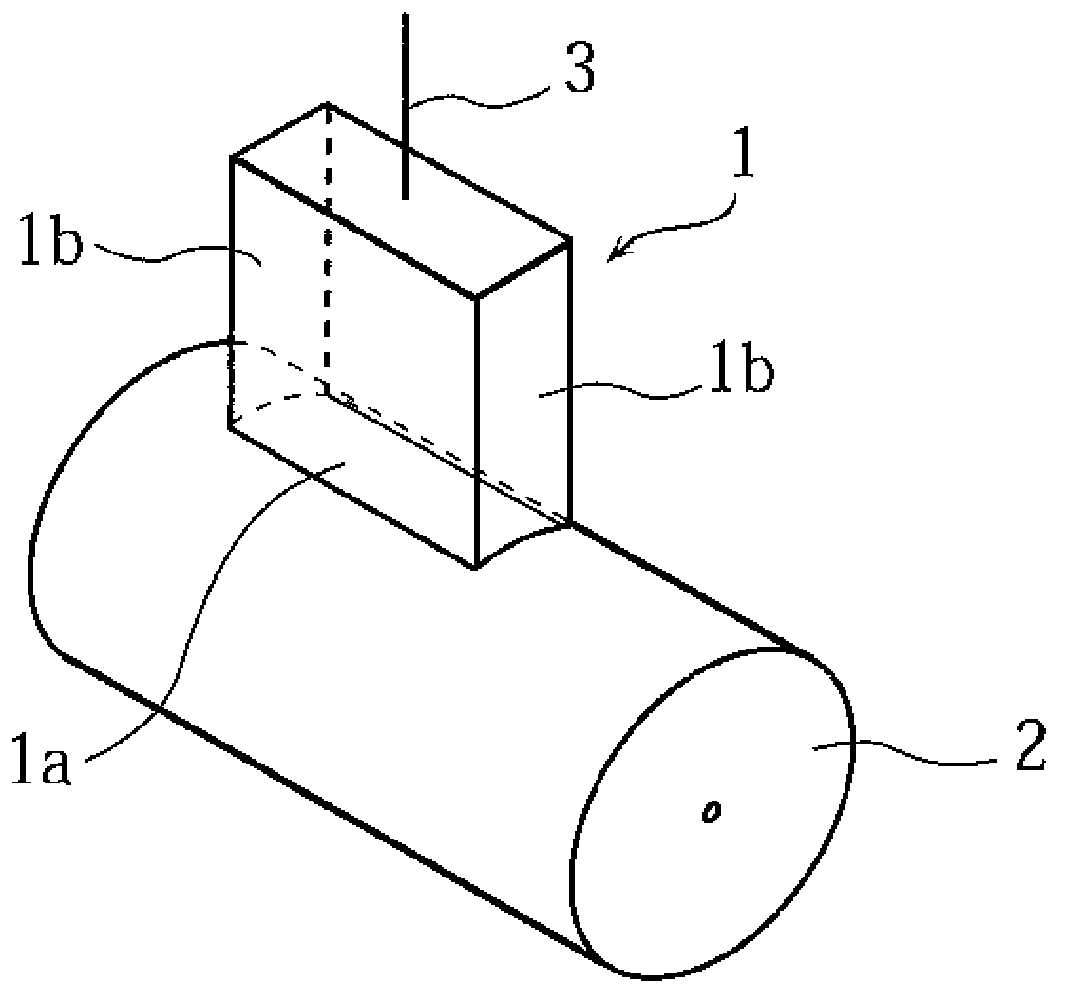

Carbon brush

A carbon brush and brush technology, which is applied in current collectors, electrical components, electromechanical devices, etc., can solve problems such as engine efficiency reduction, and achieve the effect of suppressing efficiency reduction, realizing EMI performance, and realizing long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] First, after blending 77% by mass of artificial graphite powder (average particle diameter: 20 μm) as an aggregate and 23% by mass of epoxy resin (thermosetting resin) as a binder, non-preheated Shaped mesophase carbon powder (average particle size 20μm, refer to figure 2 ). It should be noted that the mesophase carbon powder used was obtained by heat-treating coal tar pitch, solidifying, pulverizing, infusible, and adjusting the particle size. At this time, the ratio of the mesophase carbon powder to the total amount of the artificial graphite powder and the epoxy resin was 1% by mass. Then, kneading was carried out at room temperature for a predetermined time (60 minutes) so that the artificial graphite powder, the resin, and the mesophase carbon powder were uniformly mixed.

[0072] Next, this kneaded product was pulverized to an average particle diameter of 80 μm or less to prepare a molding powder for brush molding. Using a cold press, at 1 ton / cm 2 After the ...

Embodiment 2

[0075] Use approximately spherical mesophase carbon powder (average particle size 25 μm, refer to image 3 ) instead of the amorphous mesophase carbon powder, a carbon brush was produced in the same manner as in Example 1 above.

[0076] Hereinafter, the carbon brush produced in this way is called this invention brush A2.

Embodiment 3

[0078] The approximately spherical mesophase carbon powder used in the above-mentioned Example 2 was preheated at 600° C. for 5 hours (average particle size: 26 μm, Figure 4 Reference) was used instead of the amorphous mesophase carbon powder, and a carbon brush was produced in the same manner as in Example 1 above.

[0079] Hereinafter, the carbon brush produced in this way is called this invention brush A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com