Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109 results about "Compound pendulum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compound pendulum. Any swinging rigid body free to rotate about a fixed horizontal axis is called a compound pendulum or physical pendulum. The appropriate equivalent length for calculating the period of any such pendulum is the distance from the pivot to the center of oscillation.

Combined twistless compound pendulum

The invention relates to a compound swing bar without twist. The rocker is made to be one left and one right structure, of which, the midpoint of one edge on two sides of semi-cylindrical concave is opened and combined with pin. The prism on the top of support is made to be the bended supporting awl to form a point contact between the hollow of the top of midpoint on rocker and the peak of bended supporting awl to make the rocker hang in a vertical state, thereby eliminating twisting, saving time, reducing the measure error and cost.

Owner:SICHUAN UNIV

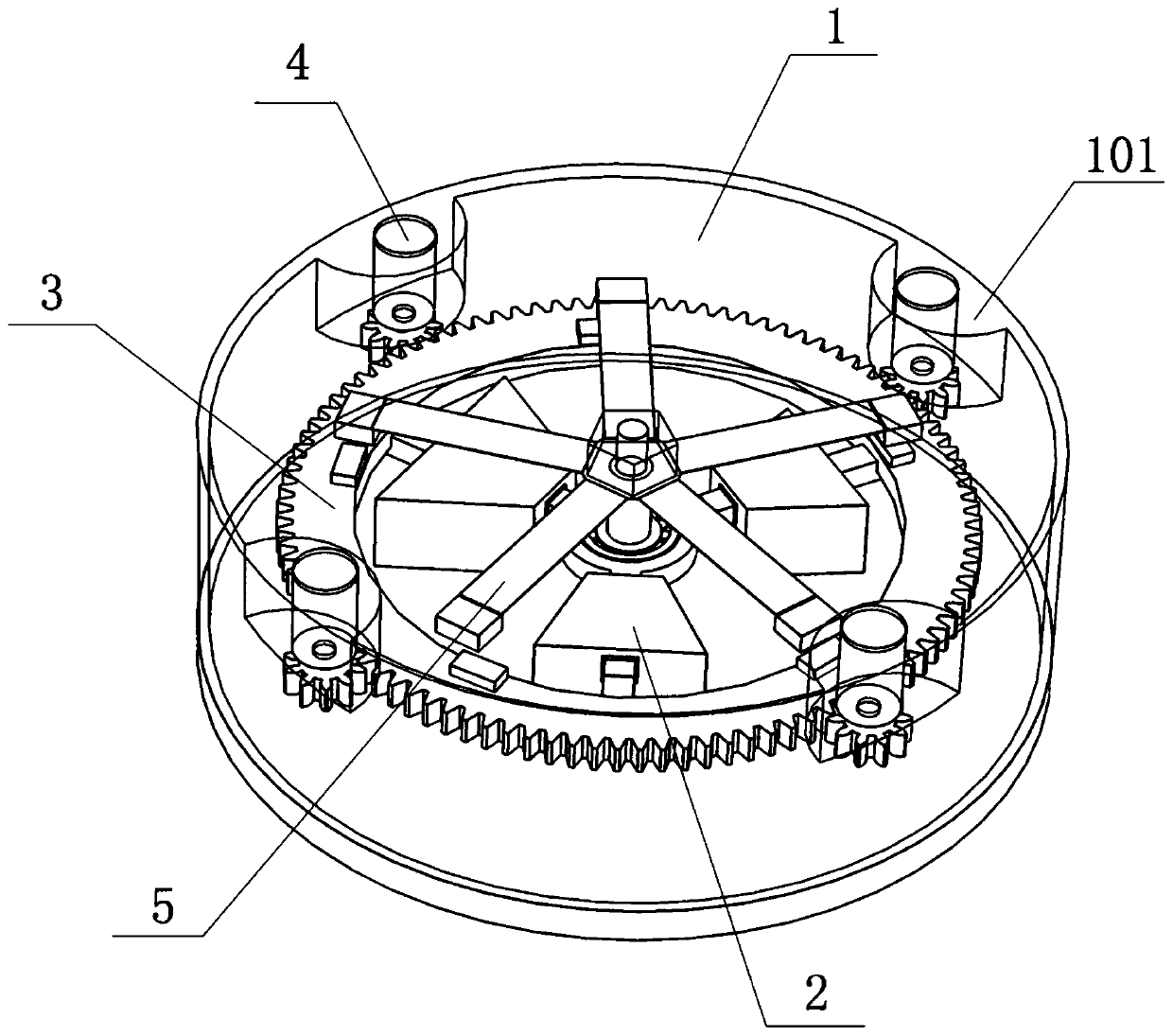

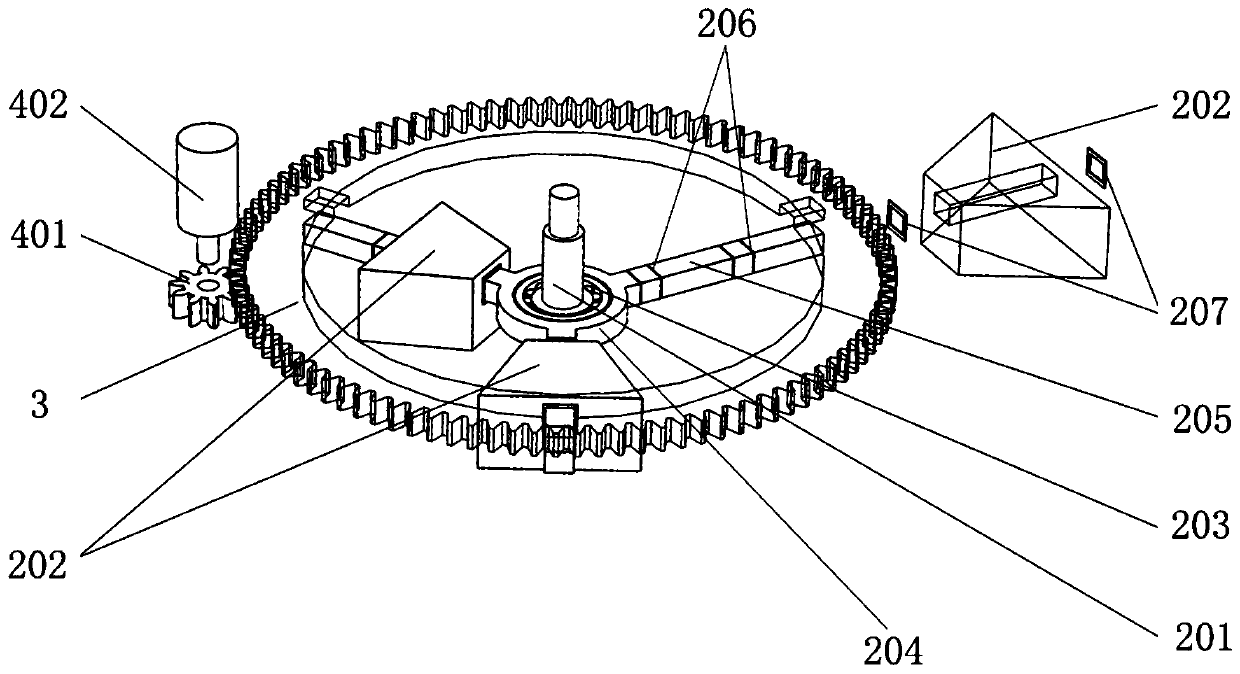

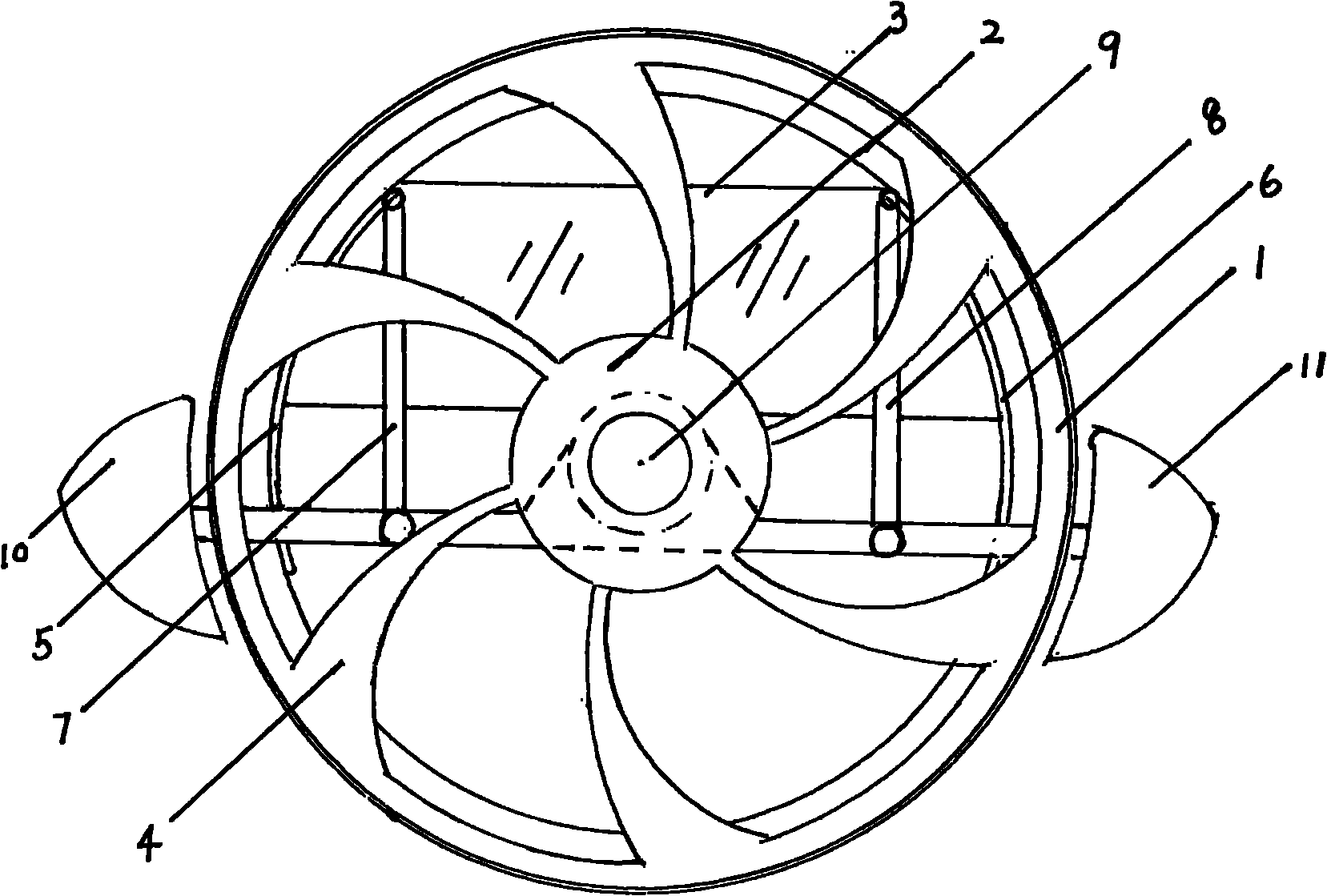

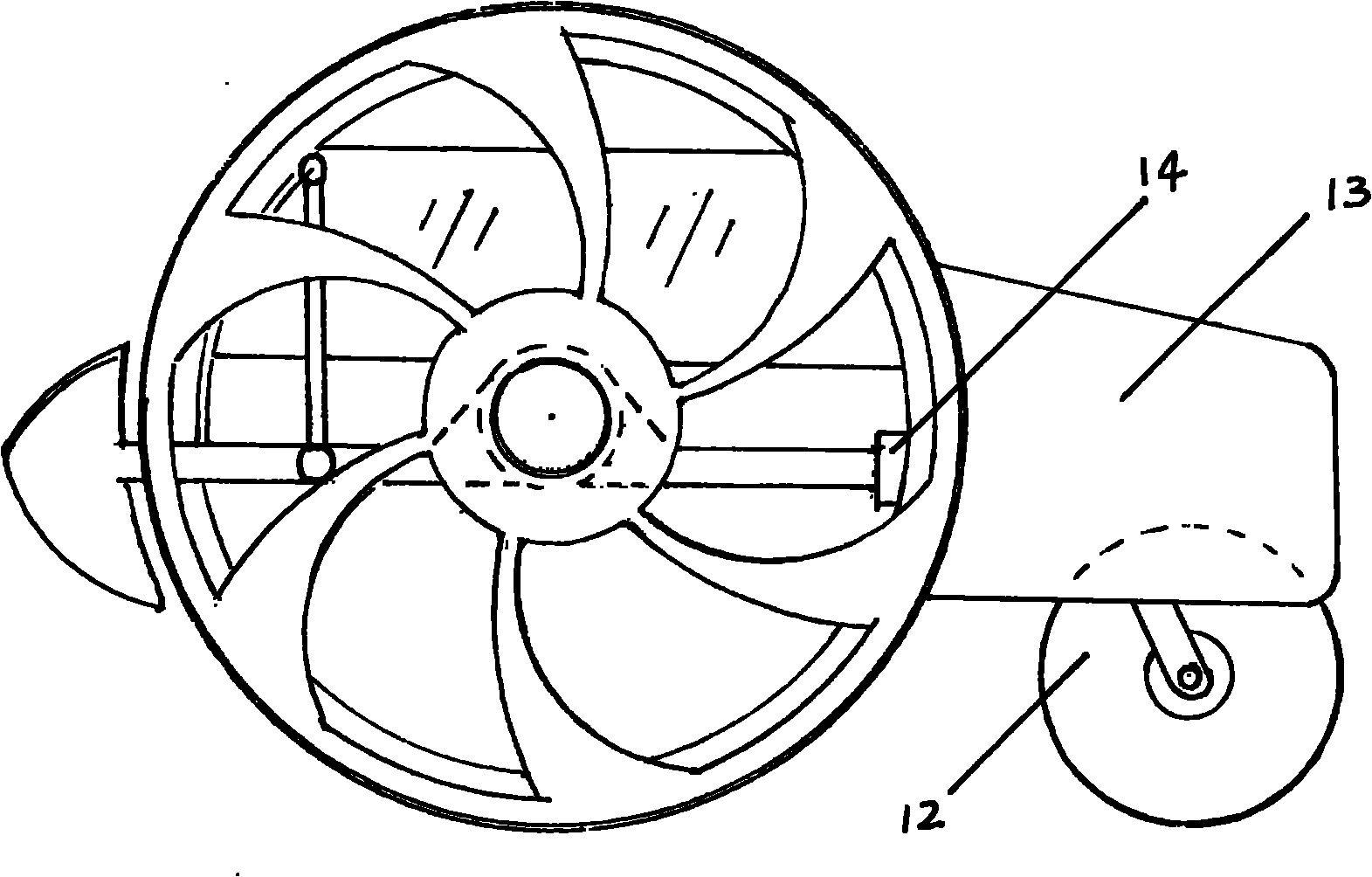

Compound pendulum frequency upconversion type wave energy collecting device

PendingCN110594077AWide spectrum coverageImprove energy capture efficiencyPiezoelectric/electrostriction/magnetostriction machinesEngine fuctionsElectromagnetic generatorFrequency spectrum

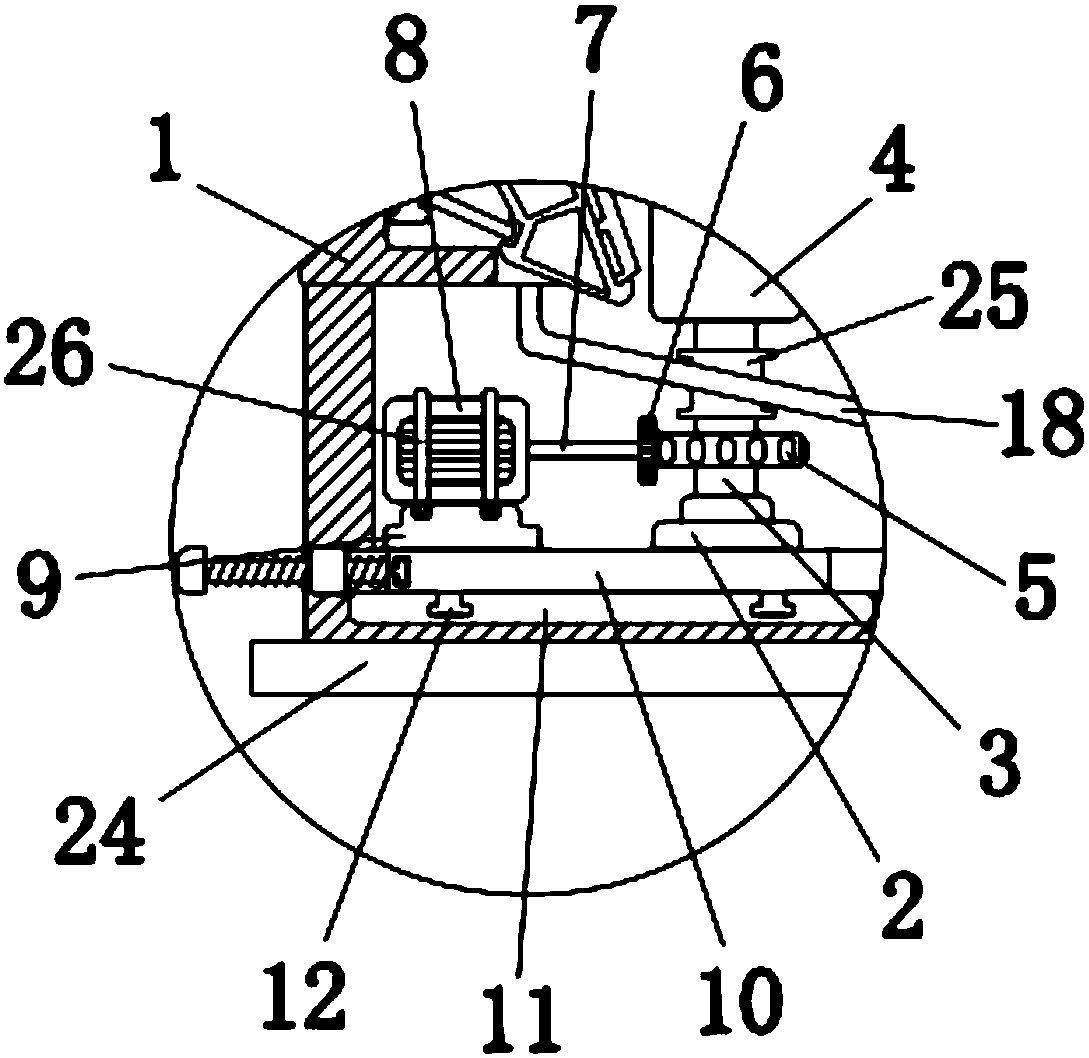

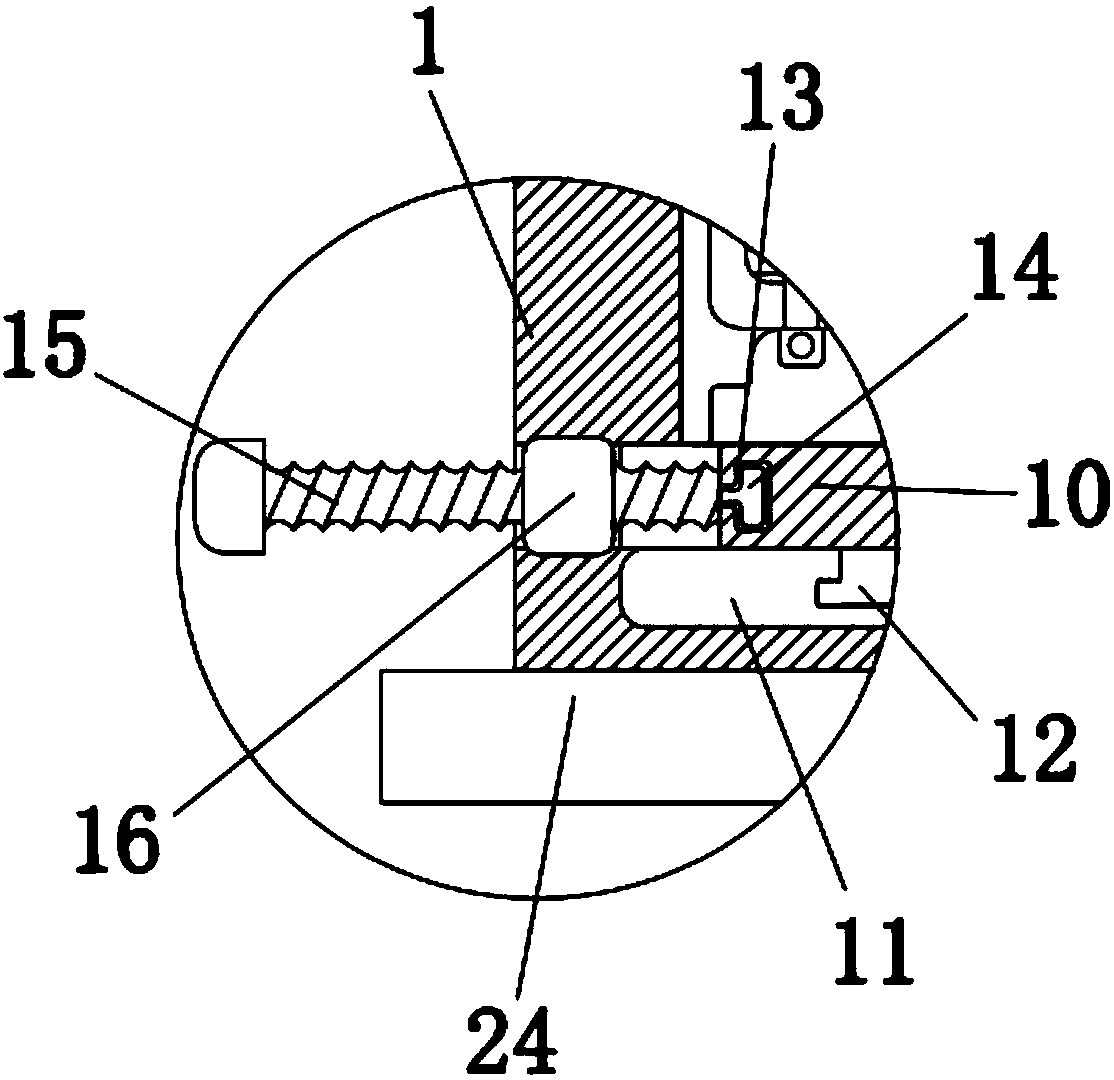

The invention discloses a compound pendulum frequency upconversion type wave energy collecting device. The compound pendulum frequency upconversion type wave energy collecting device comprises a shell, a compound pendulum mechanism, a driving gear, an electromagnetic power generating mechanism and a piezoelectric power generating mechanism. The shell floats on the water surface and swings along with waving, the compound pendulum mechanism is rotationally arranged in the shell and rotates along with swinging of the shell, and driving gear is rotationally arranged in the shell, and the driving gear and the compound pendulum mechanism rotate synchronously. The electromagnetic power generating mechanism is arranged in the shell and used for being in engaged transmission with the driving gear to be driven by the driving gear to generate power through electromagnetic induction. The piezoelectric power generating mechanism is arranged in the shell and located above the end face of the drivinggear and is used for generating deformation to generate power through a piezoelectric effect when the driving gear rotates. Thus, when the shell non-directionally swings along with waving, the compound pendulum mechanism generates non-directional rotation and adapts to dynamic changes of water surface wave energy, and high energy harvesting efficiency is achieved. Meanwhile, the electromagnetic power generating mechanism and the piezoelectric power generating mechanism carry out energy conversion through two different electromechanical coupling energy exchange mechanisms, the spectrum coverage range on wave energy is wide, high adaptability is achieved, and the conversion efficiency is high.

Owner:SUZHOU UNIV

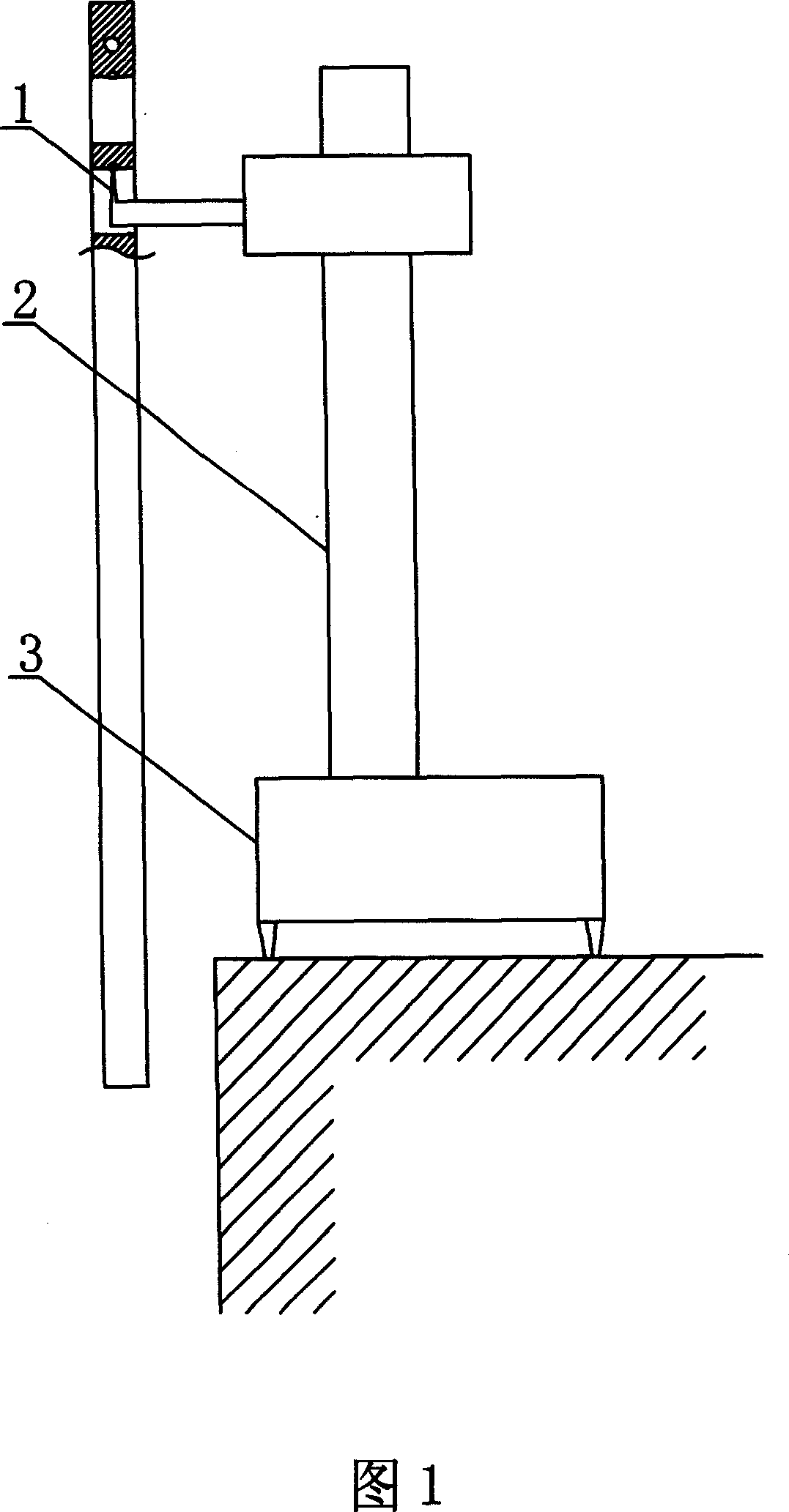

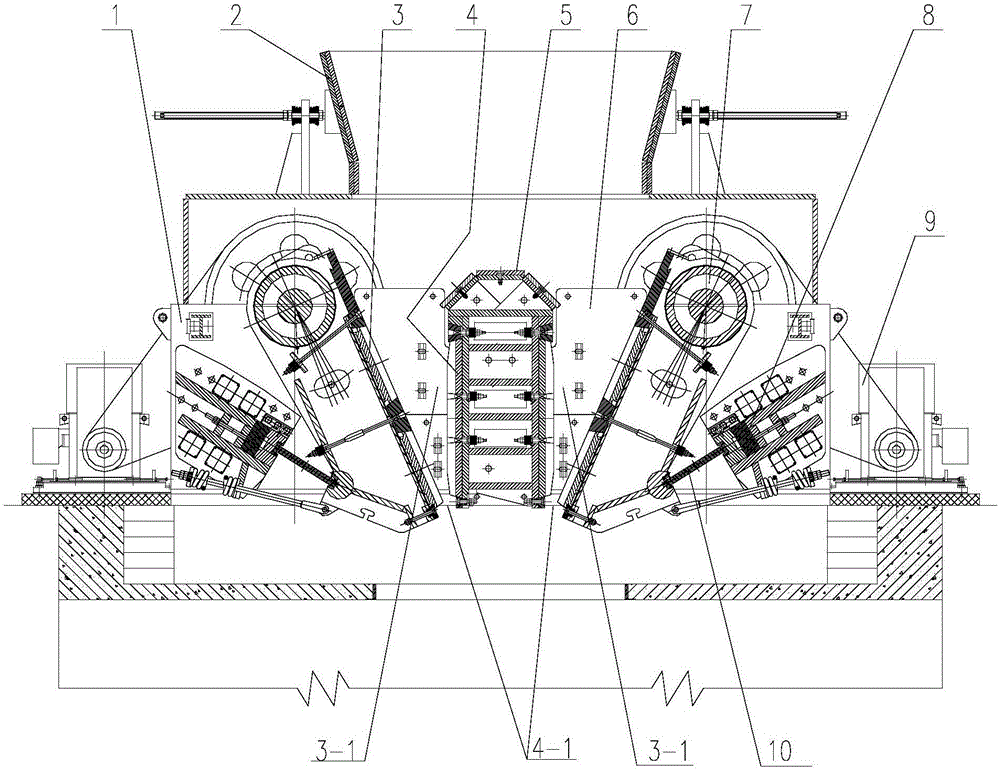

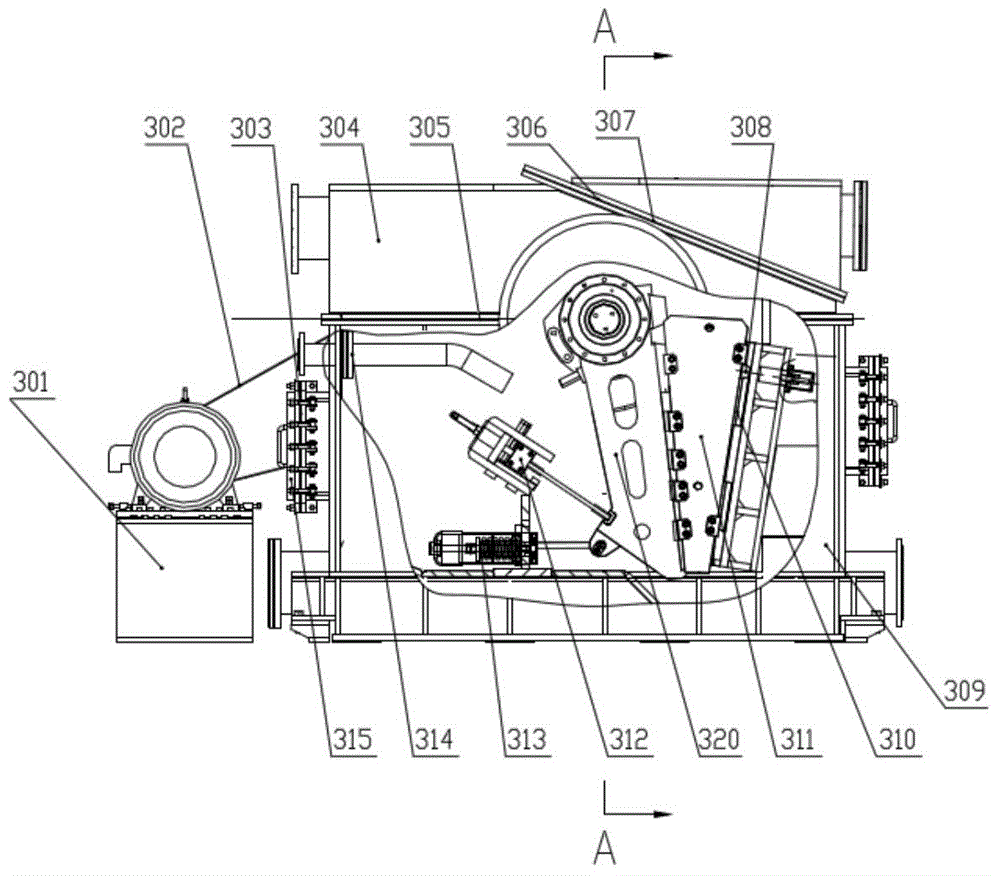

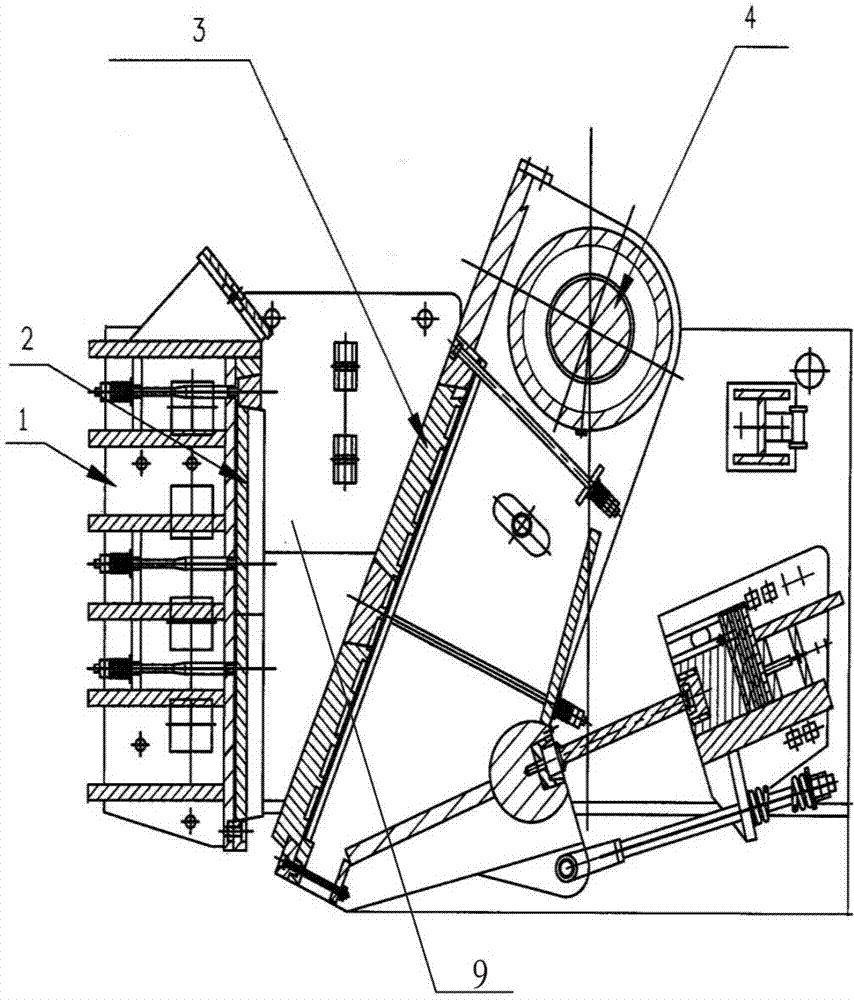

Double-cavity compound-pendulum jaw crusher for ore crushing

The invention relates to a double-cavity compound-pendulum jaw crusher for ore crushing. The double-cavity compound-pendulum jaw crusher is characterized by comprising a rack and an adjustable feeding hopper installed at the upper end of the rack, wherein the size and position of the feeding hopper are both adjustable; two independently-driven movable jaws are symmetrically arranged below the feeding hopper, and are connected with a motor drive device for driving the two movable jaws to carry out a compound-pendulum motion independently; a fixed jaw is arranged between the two movable jaws, and is fixed on the rack; two independent crushing cavities are formed between the two movable jaws and the middle fixed jaw; a discharge port is arranged below the fixed jaw; a material separation anvil for separating ores to the left crushing cavity and the right crushing cavity is installed on the symmetry axis of the two movable jaws at the top of the fixed jaw; the two movable jaws are connected with movable jaw adjustment mechanisms with the same structure respectively; and a detection door and an observation hole are further arranged in the rack. The double-cavity compound-pendulum jaw crusher disclosed by the invention has the advantages of being efficient, high in yield, easy to manufacture, high in applicability, flexible to operate, capable of guaranteeing a discharge granularity, and the like.

Owner:SINOMA TECH & EQUIP GRP

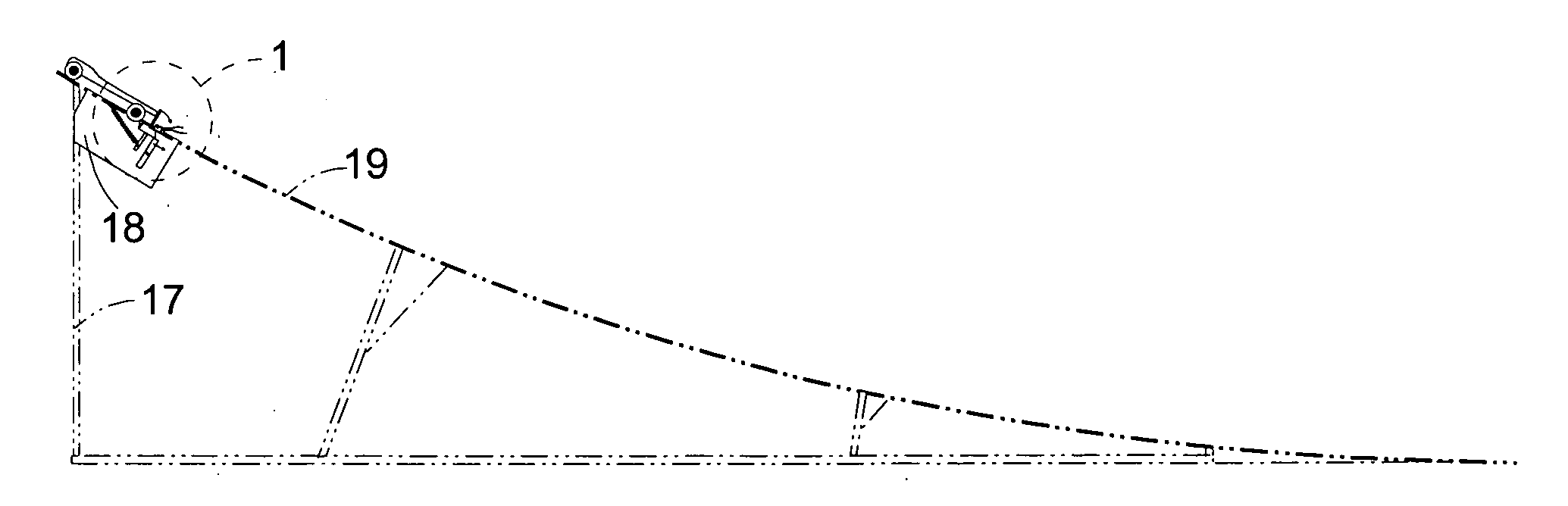

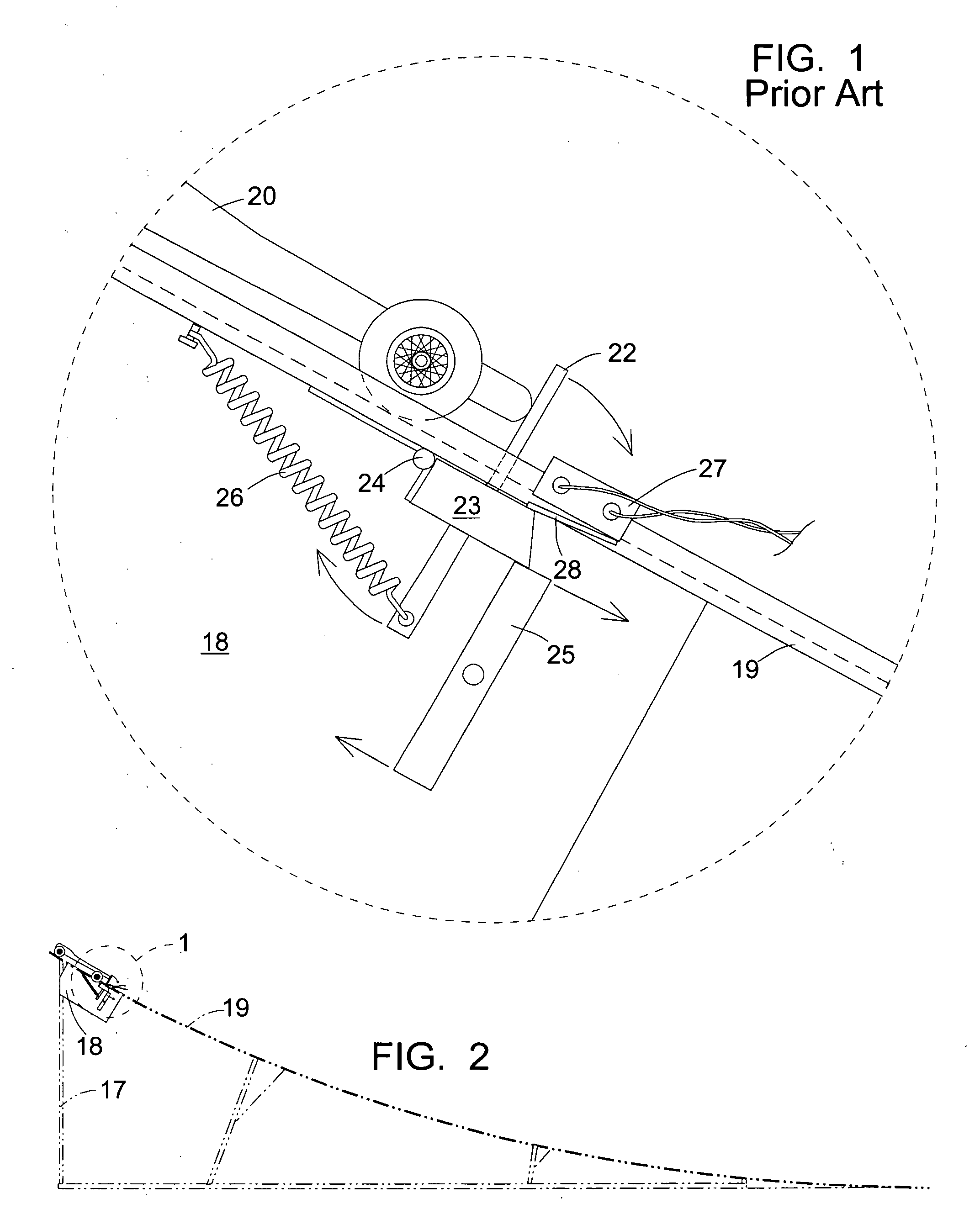

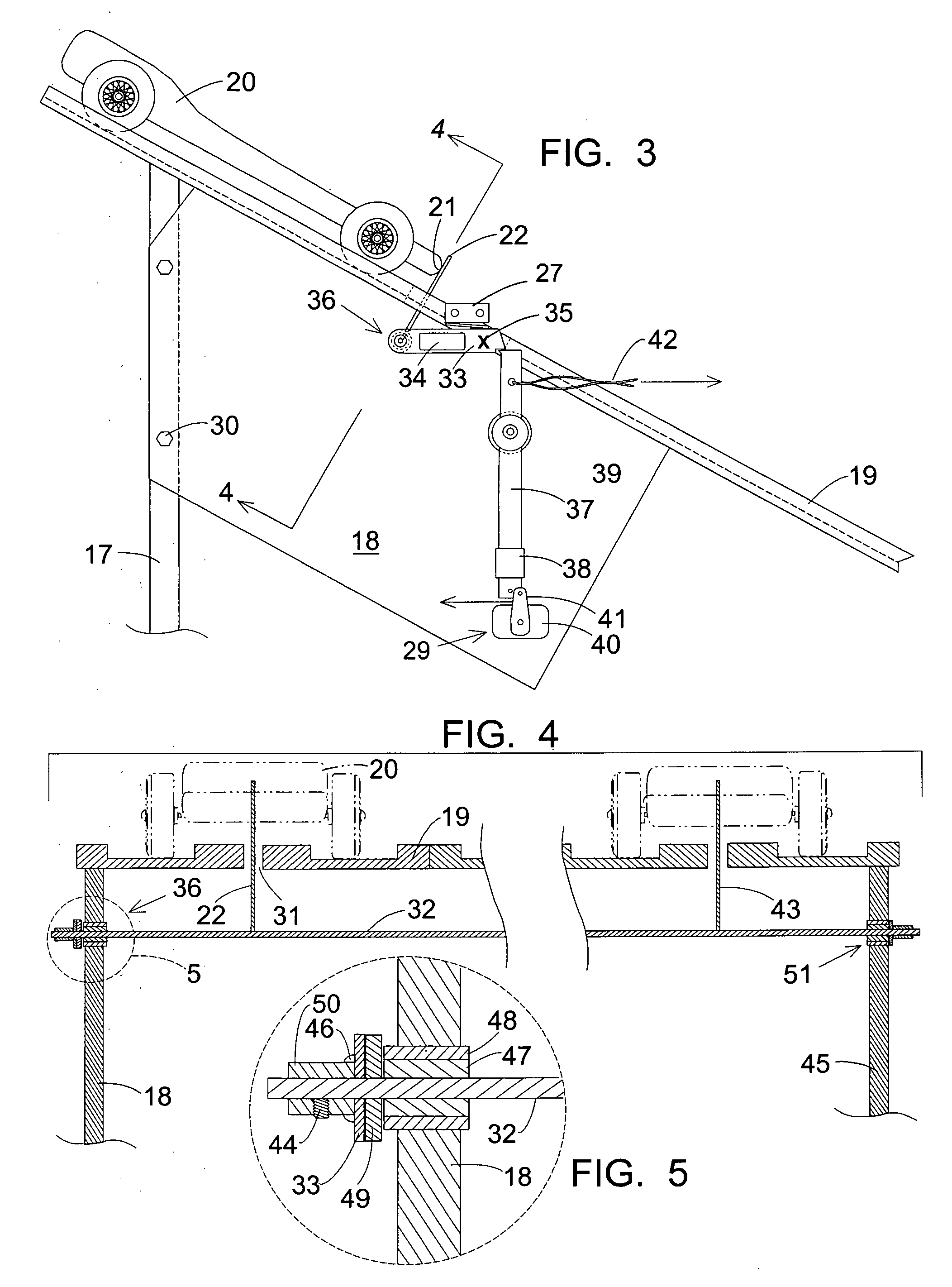

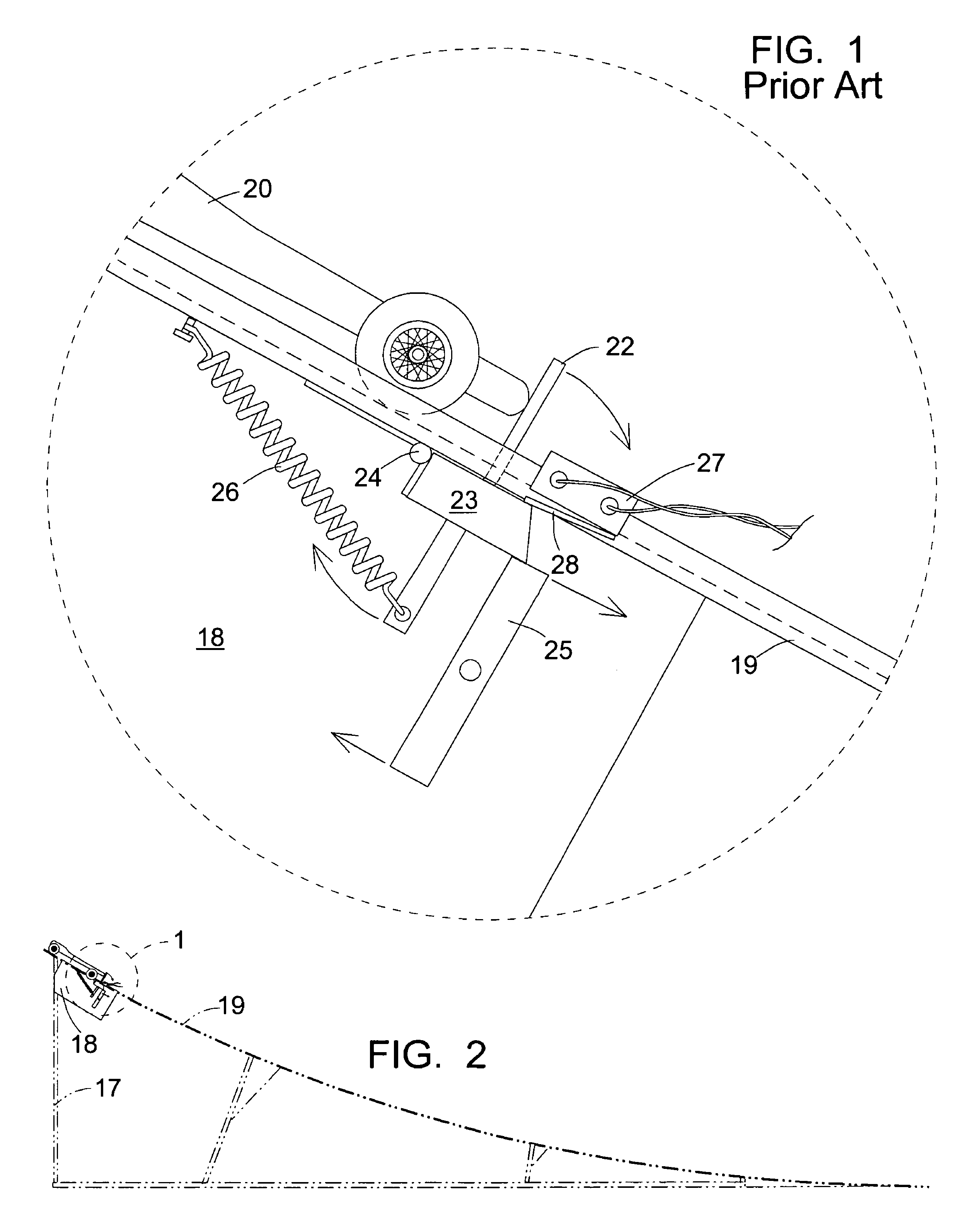

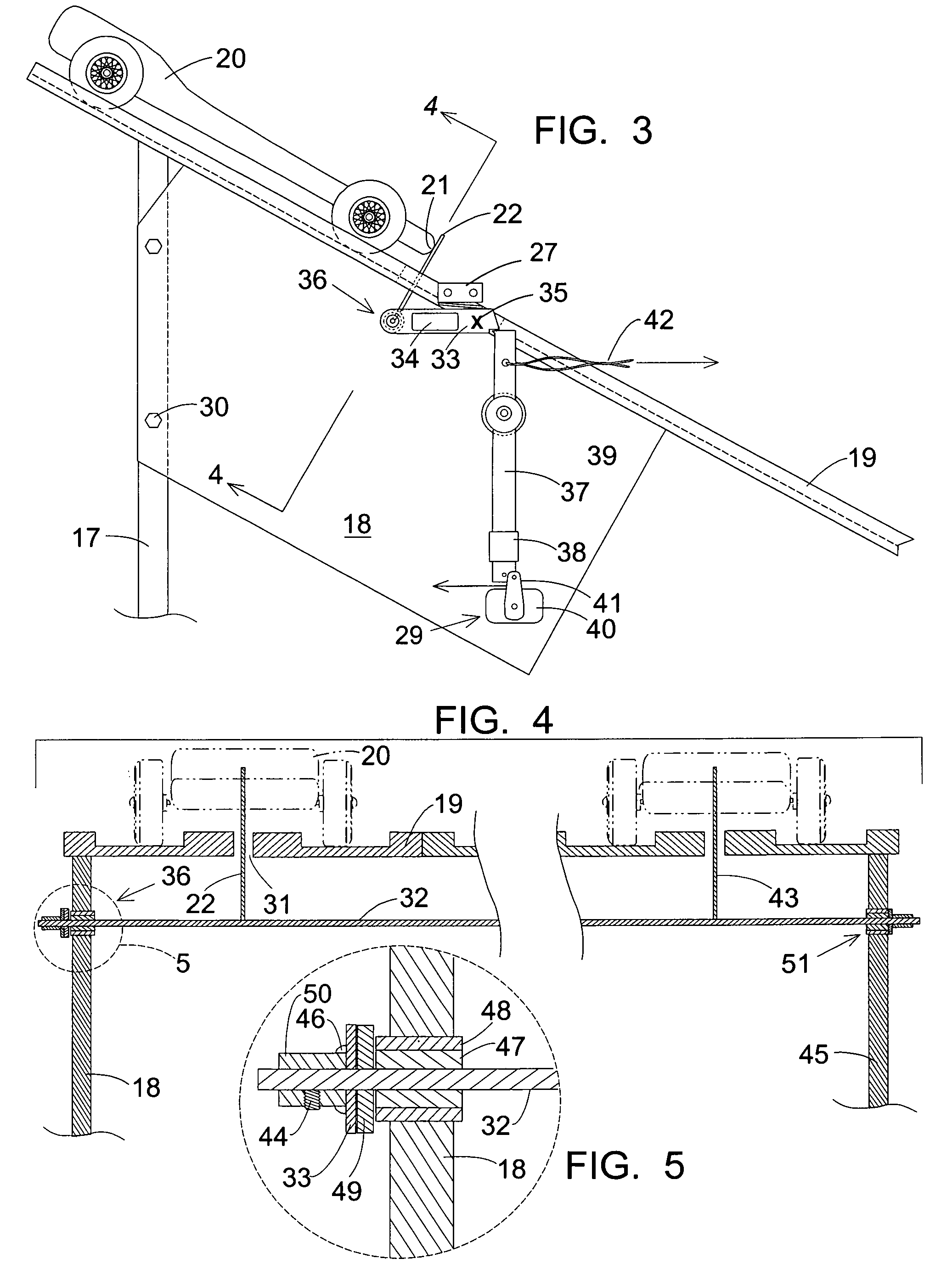

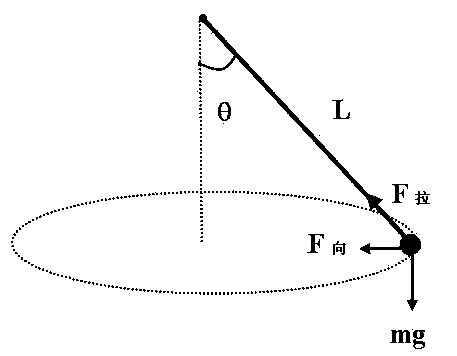

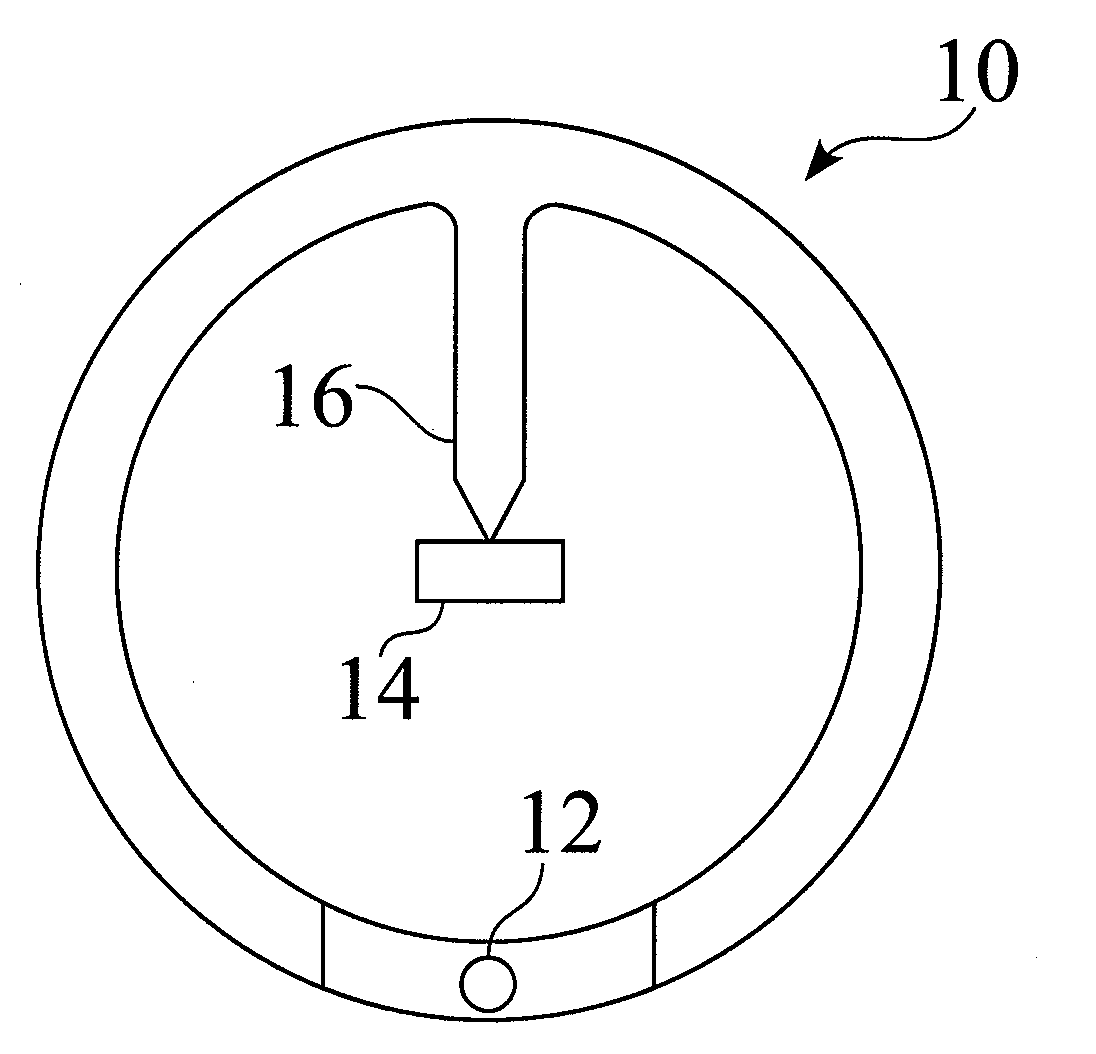

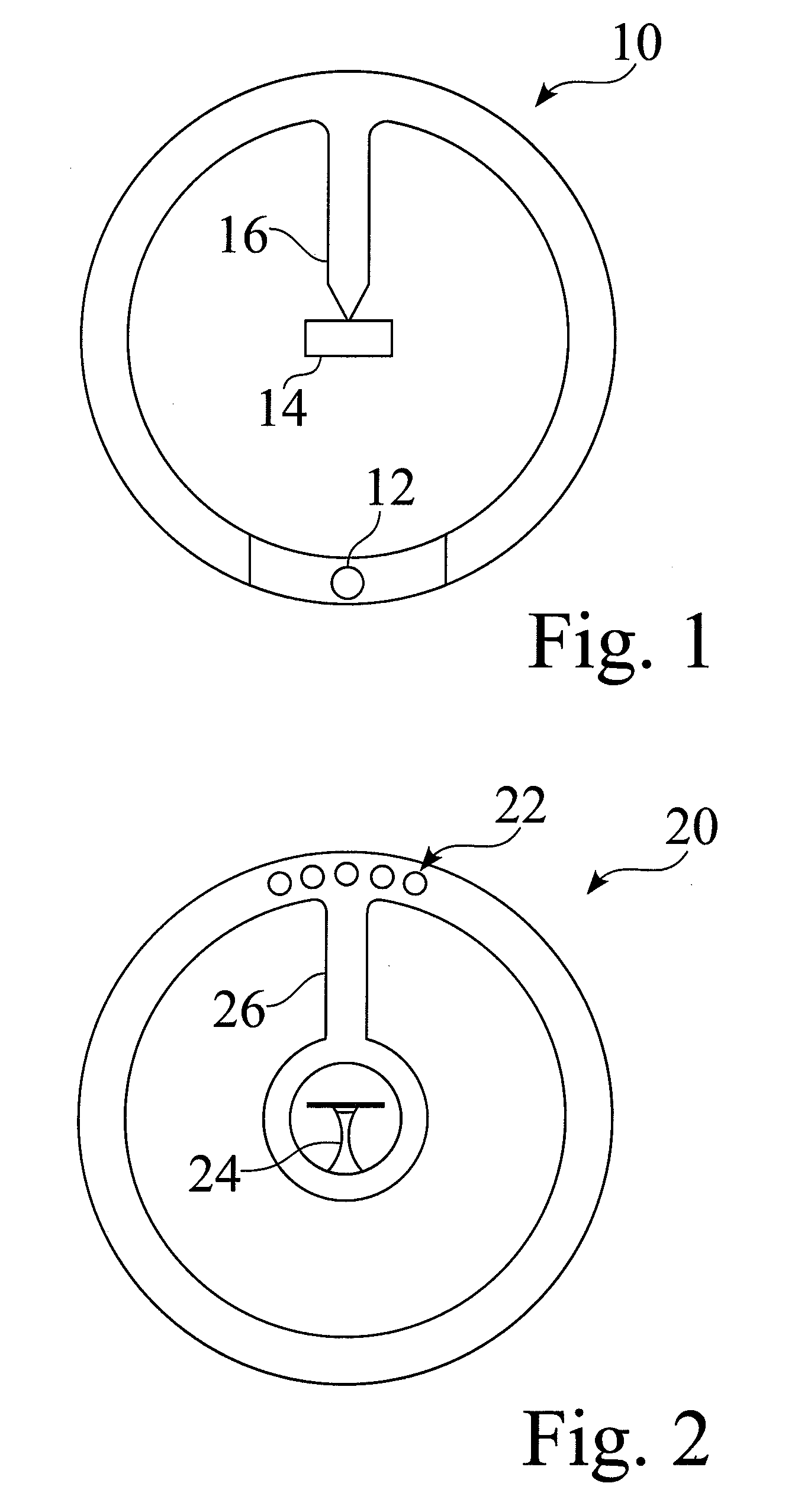

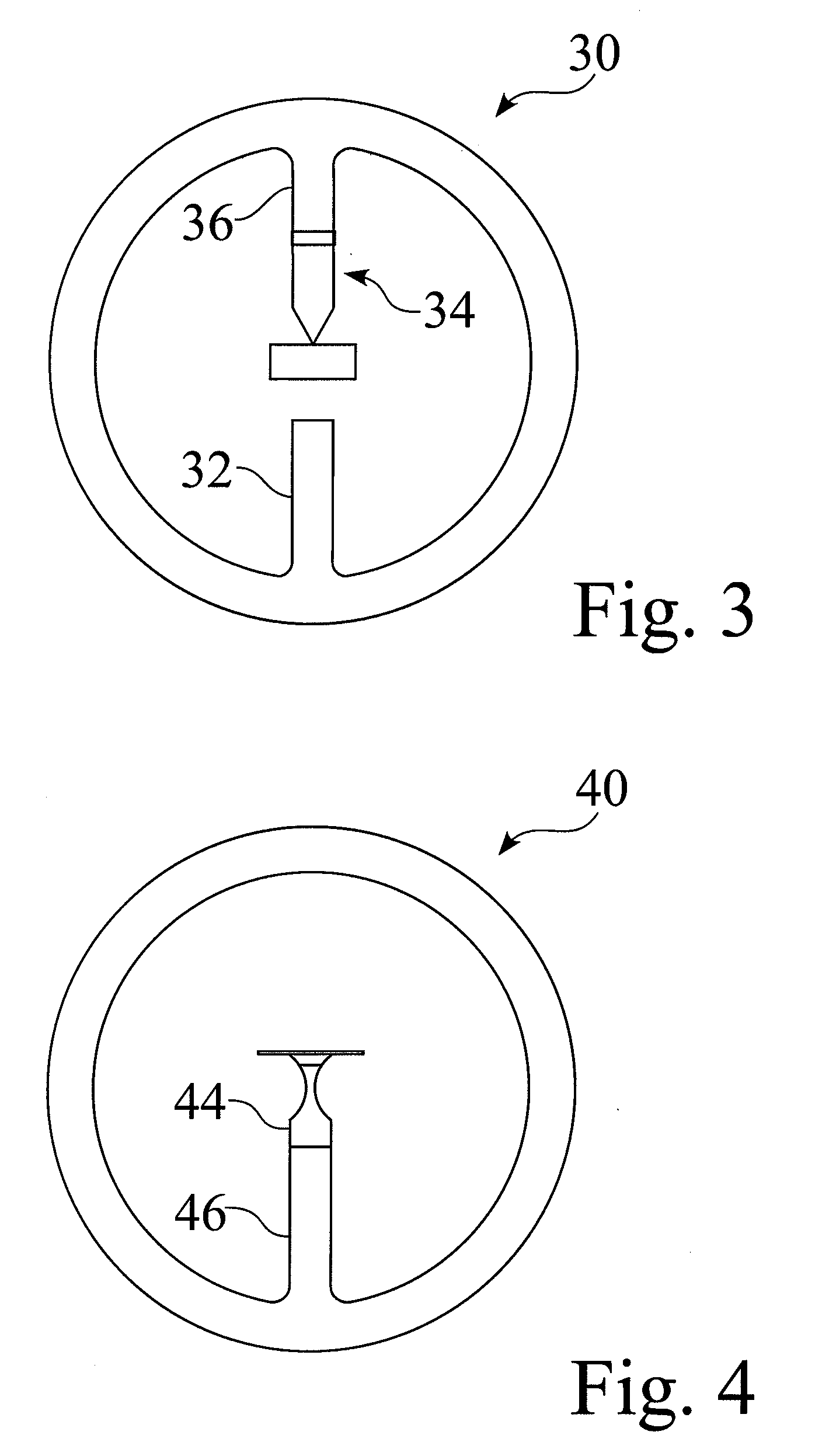

Start gate for gravity-driven cars

An improved start gate for gravity-driven cars which is itself a gravity-driven compound pendulum. The pendulum includes a horizontal drop member rigidly connected at one end to a start post support rod which in turn supports a plurality of start posts. A trigger lever, when moved either directly or remotely, allows the drop member to fall as in a compound pendulum thereby rotating the start posts and allowing the cars to start. The embodiment teaches that the subsequent initial start post acceleration is approximately twice the car acceleration. The equations of motion are solved showing that the start posts are guaranteed not to interfere with car motion. A major advantage over prior art spring-loaded start gates is that the gate “slap” from stopping overly-forceful spring motion and the associated track jarring and car jostling is eliminated, thereby contributing substantially to a more smooth and fair start.

Owner:JOBE JOHN DEWEY

Double-cavity compound pendulum jaw crusher

PendingCN108160161AImprove crushing qualityReduce distanceGrain treatmentsEngineeringCompound pendulum

The invention discloses a double-cavity compound pendulum jaw crusher comprising a main body. A base is mounted at the bottom end of the interior of the main body, a supporting rod is mounted at the top end of the base, and a roller is arranged on the outer wall of the supporting rod. A first gear is mounted on the outer wall of the bottom end of the supporting rod, a second gear is arranged on the left side of the first gear, and the second gear is connected with the first gear in an engaged mode. According to the double-cavity compound pendulum jaw crusher, through cooperation of the supporting rod and the roller, cooperation of the first gear and the second gear, and cooperation of a motor and a rotating rod, the roller rotates in the main body to enable raw materials on the two sides to be evenly scattered, and the main body is assisted to crush the raw materials while the roller rotates at a high speed; and through cooperation of a sliding groove and a sliding block and cooperation of a bolt and a nut, the distance between the supporting rod and the inner wall of the main body is adjusted, the raw materials are more finely crushed while the distance is shortened, the crushingquality of the crusher is improved, and the work efficiency is high.

Owner:湖州志平矿山机械制造厂

Start gate for gravity-driven cars

An improved start gate for gravity-driven cars which is itself a gravity-driven compound pendulum. The pendulum includes a horizontal drop member rigidly connected at one end to a start post support rod which in turn supports a plurality of start posts. A trigger lever, when moved either directly or remotely, allows the drop member to fall as in a compound pendulum thereby rotating the start posts and allowing the cars to start. The embodiment teaches that the subsequent initial start post acceleration is approximately twice the car acceleration. The equations of motion are solved showing that the start posts are guaranteed not to interfere with car motion. A major advantage over prior art spring-loaded start gates is that the gate “slap” from stopping overly-forceful spring motion and the associated track jarring and car jostling is eliminated, thereby contributing substantially to a more smooth and fair start.

Owner:JOBE JOHN DEWEY

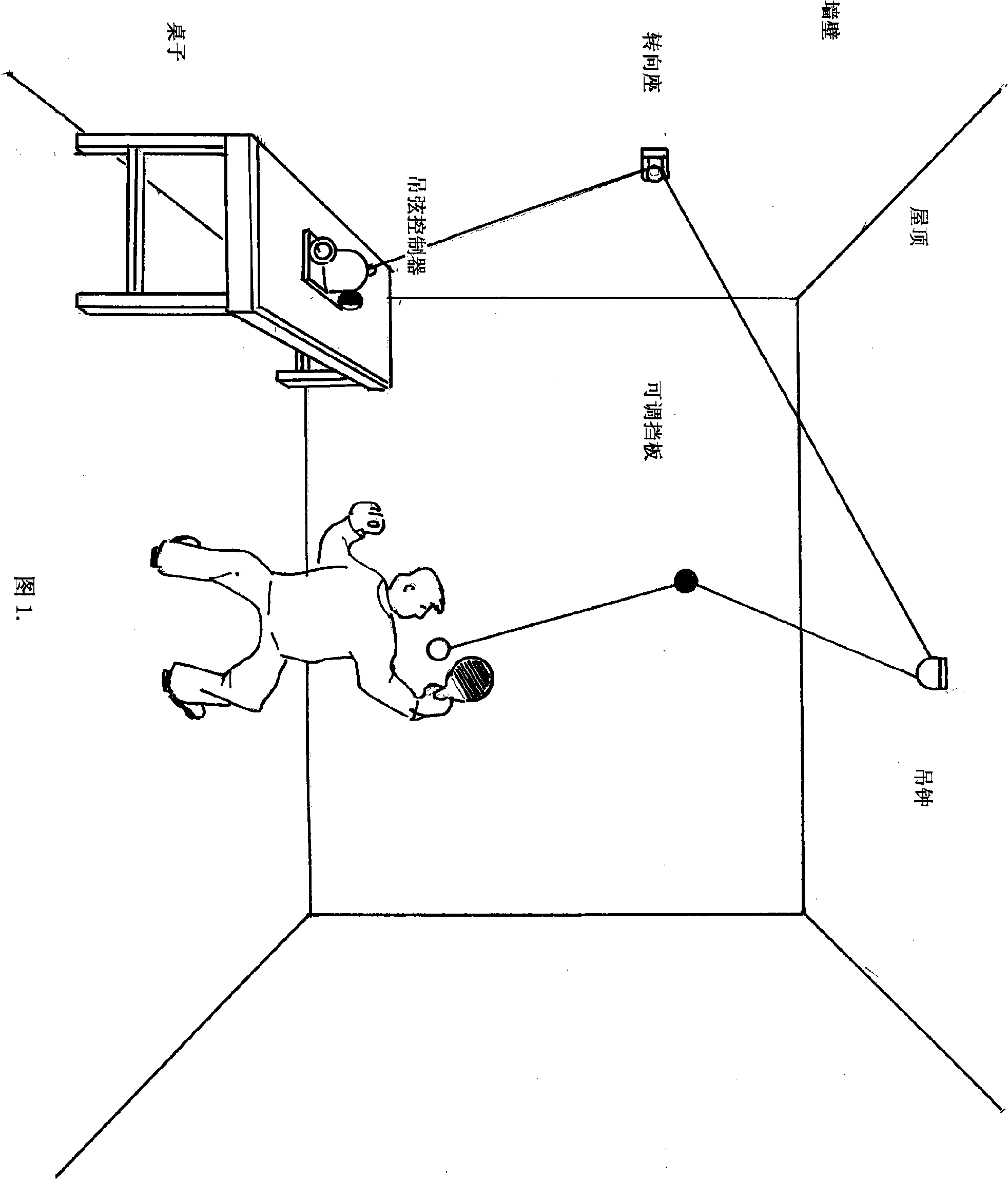

Simulation ball

InactiveCN101357264APrevention of myopiaIncreased systolic functionSport apparatusTraining - actionGeneral family

A simulative magic ball is a simulative batting device for training actions and skills of a plurality of competitive balls with simulative batting method for the first time. The simulative magic ball belongs to the field of family physical exercise or game toys. A plurality of ball exercises can be enjoyed in an ordinary home. The simulative batting method is easily mastered and the skills of the competitive balls are quickly improved. The simulative magic ball can strengthen the body, train strong basic skills, and provide great joys. Taking simulative table tennis as example, specific skills such as push and block, cut, lift, drive, sidespin, loop drive, and the like, can be practiced. The simulative magic ball can be used for training badminton, foot shuttlecock skills, etc. The device can be extended to play skill games, the batting difficulty and entertainment fun can be increased by a compound pendulum and a conical pendulum. In the simulative batting and games, physical knowledge is combined. Teenagers can deeply understand and research into the corresponding physical phenomena, get relieved from muscle and bone, prevent from short sight, and release pressure. The simulative magic ball has the advantages of physical training, physics learning and eyes exercise, and is applied to family sports and student exercise.

Owner:刘培林

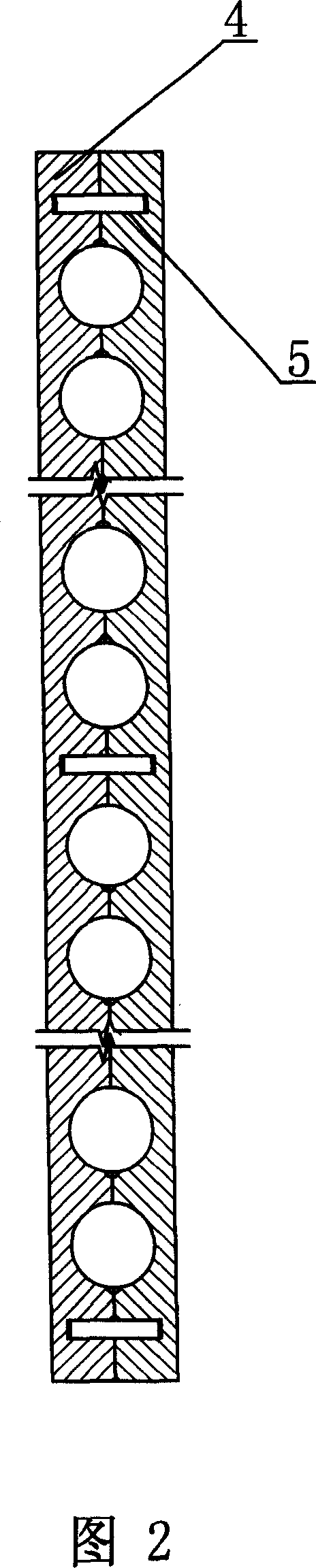

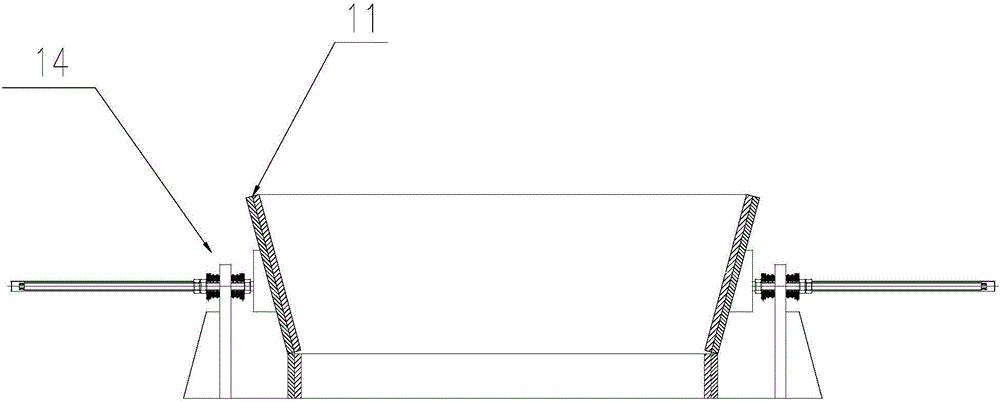

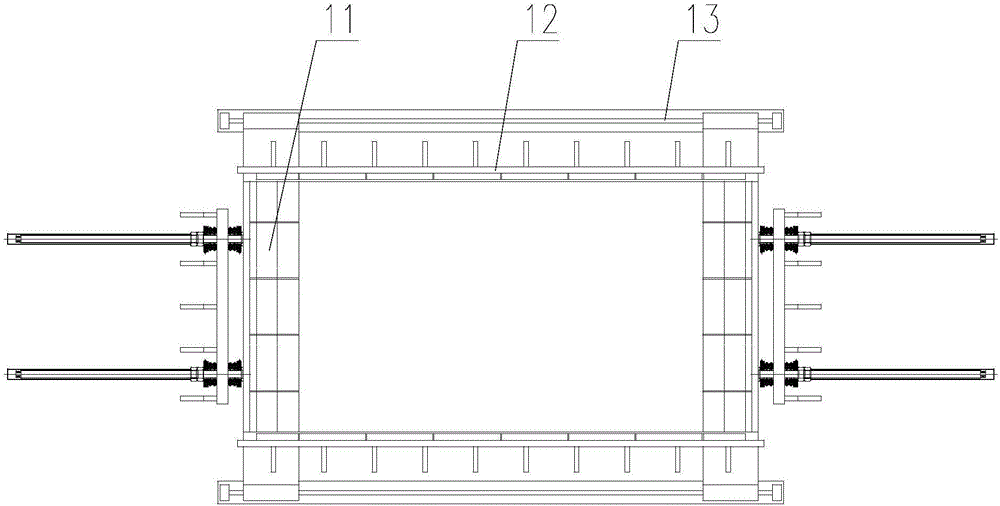

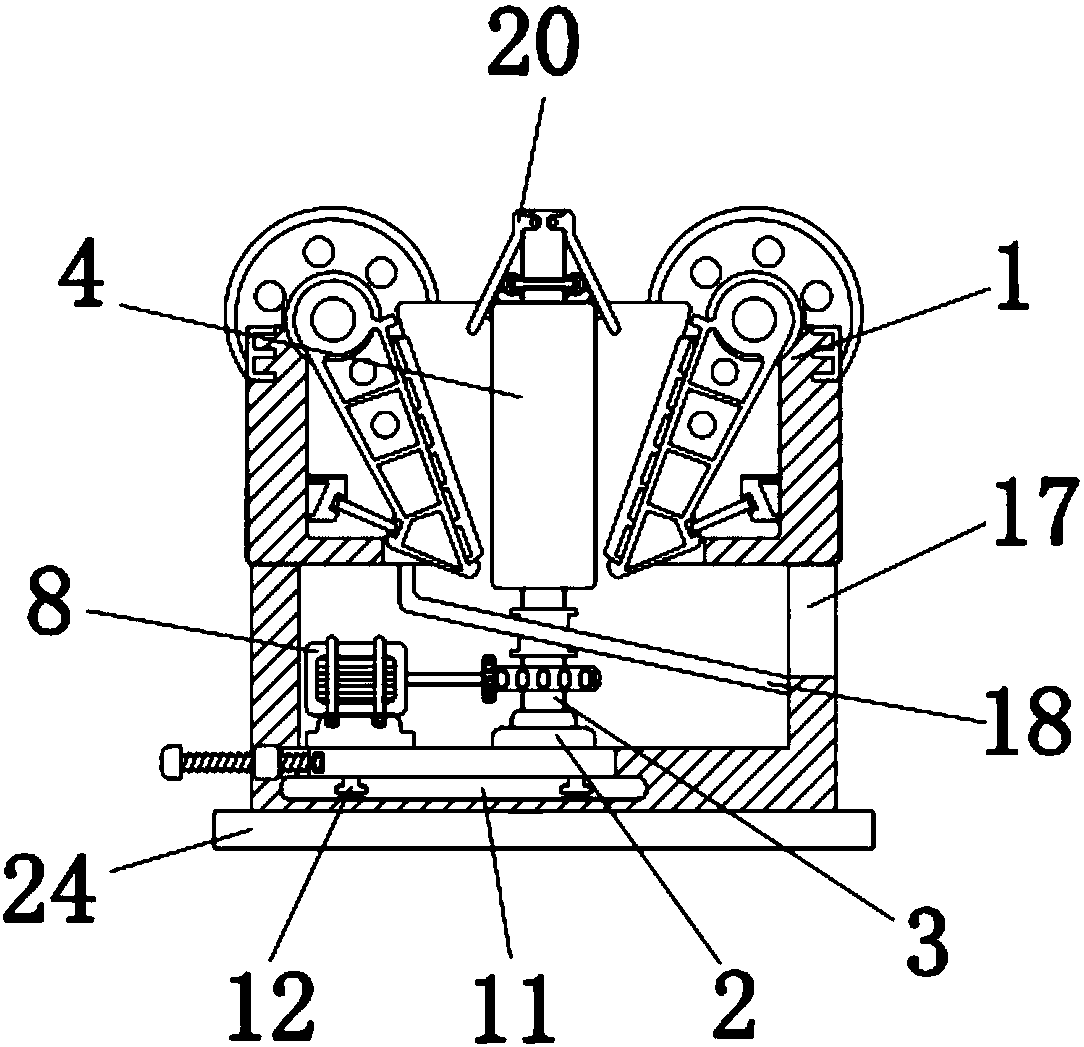

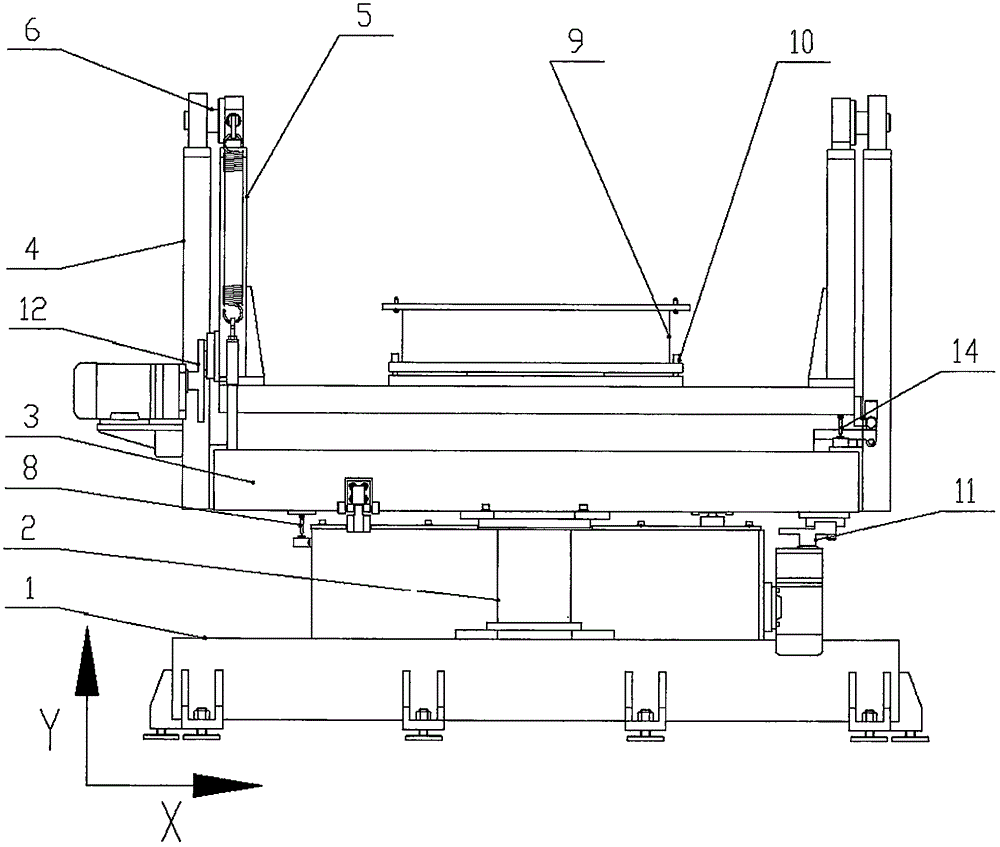

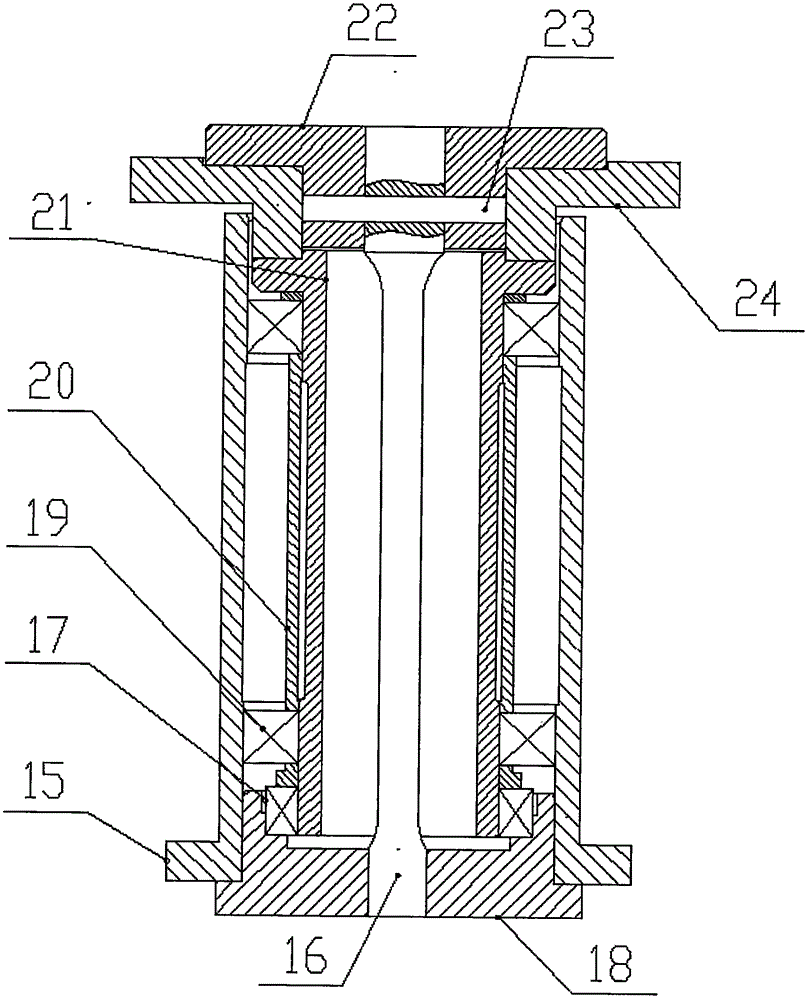

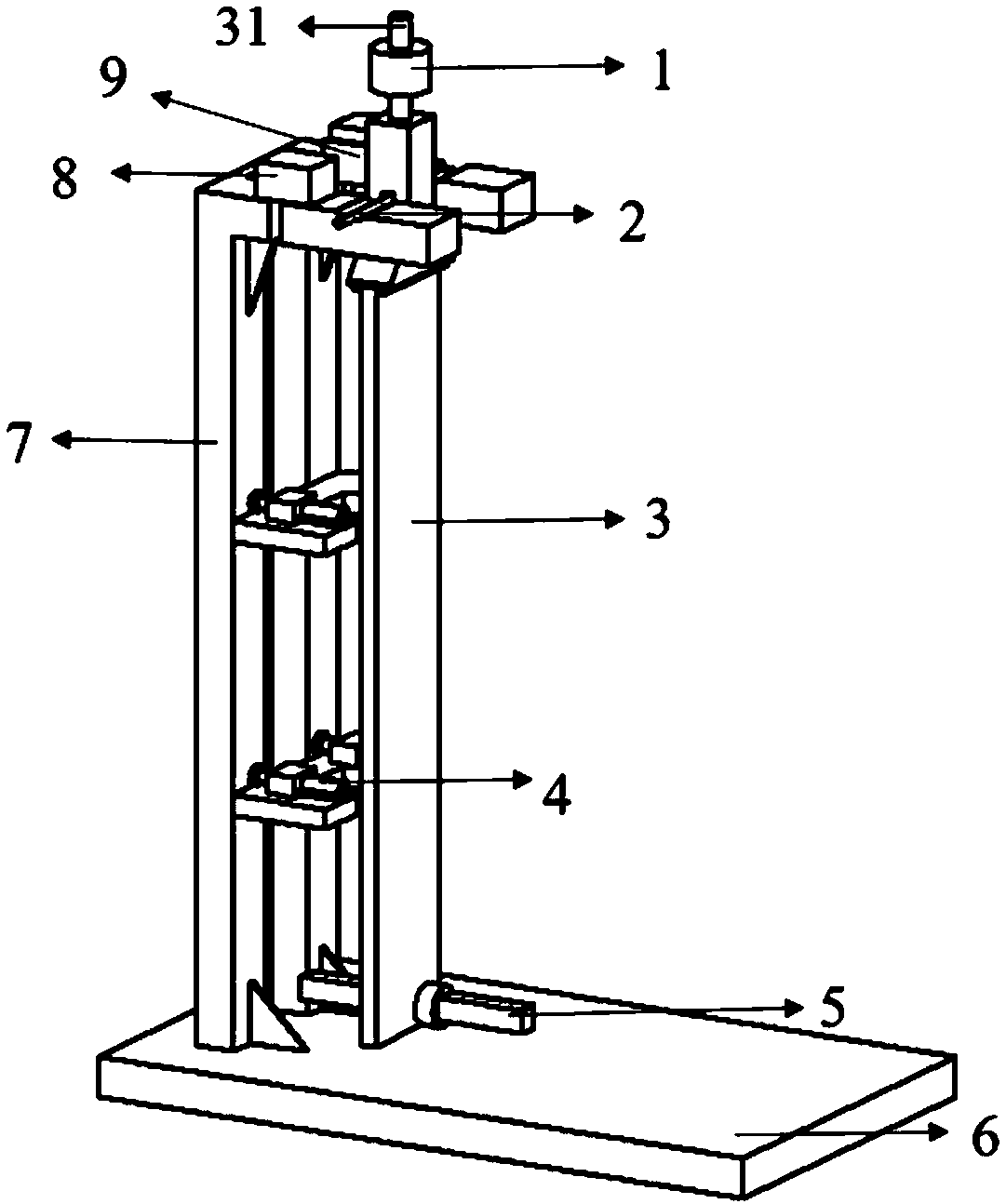

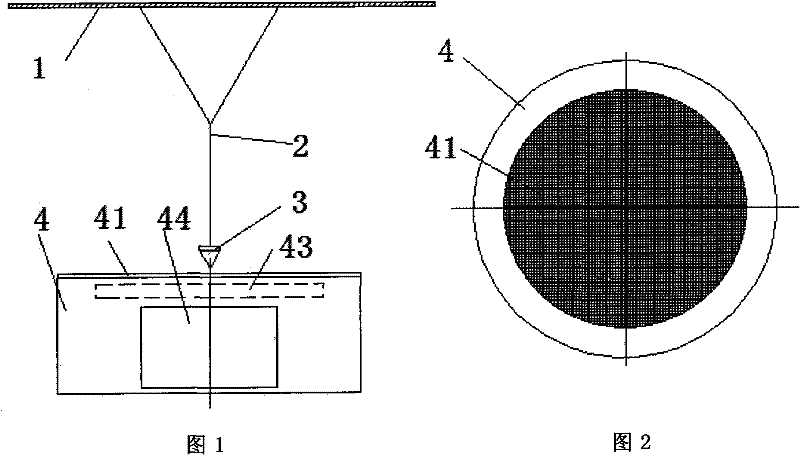

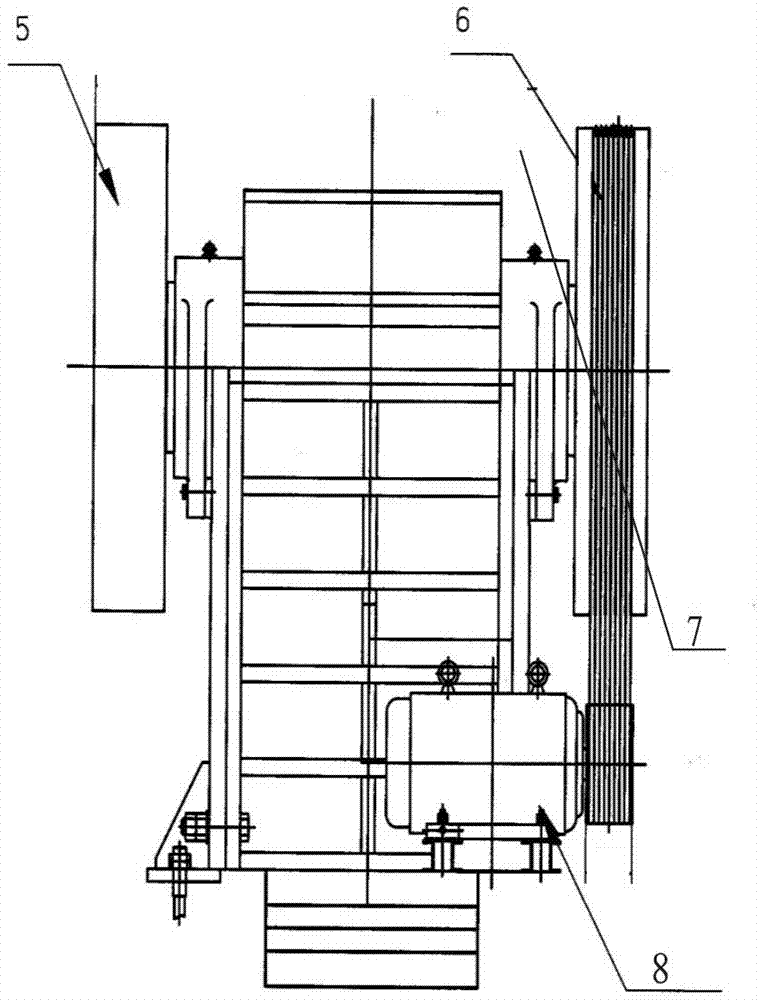

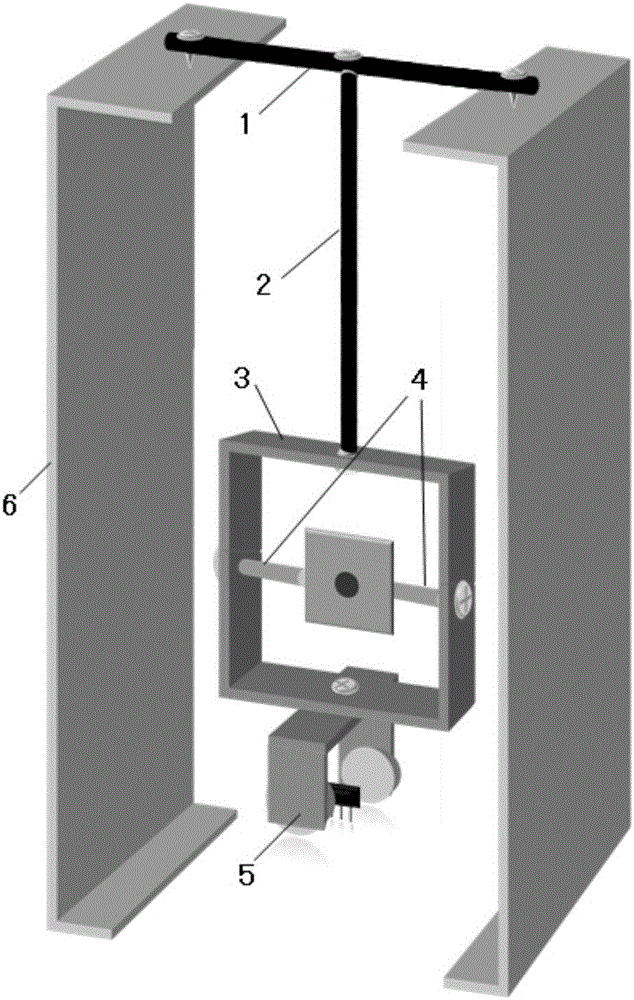

Device and method for measuring rotational inertia of satellite

The invention discloses a device and method for measuring rotational inertia of a satellite based on a torsional pendulum method and a compound pendulum method in principle and relates to the technical field of rotational inertia measuring.The device comprises a machine body, a rotary pre-twisting mechanism mounted on the top of the machine body and a workbench mounted on the top of the rotary pre-twisting mechanism.The rotary pre-twisting mechanism comprises a twisted bar, wherein the bottom end of the twisted bar is fixed to the machine body, and the top end of the twisted bar is fixed to the workbench. Fixed supporting frames are mounted on the workbench. Swing mechanisms are rotationally mounted on the fixed supporting frames through rotary shaft assemblies. A rotatable supporting rotation device is mounted on the swing mechanism.After the satellite is mounted on the supporting rotation device, the workbench and the swing mechanisms do Y-direction reciprocating swing periodic motion under the action of restoring force of the twisted bar, the swing mechanisms do X / Z-direction reciprocating swing periodic motion under the action of elastic restoring force of a tension spring and gravity of itself, the rotational inertia of the satellite in three directions can be calculated by measuring the swing periods in the Y-direction and the X / Z-direction, and measurement is convenient and fast.

Owner:西安百纳电子科技有限公司

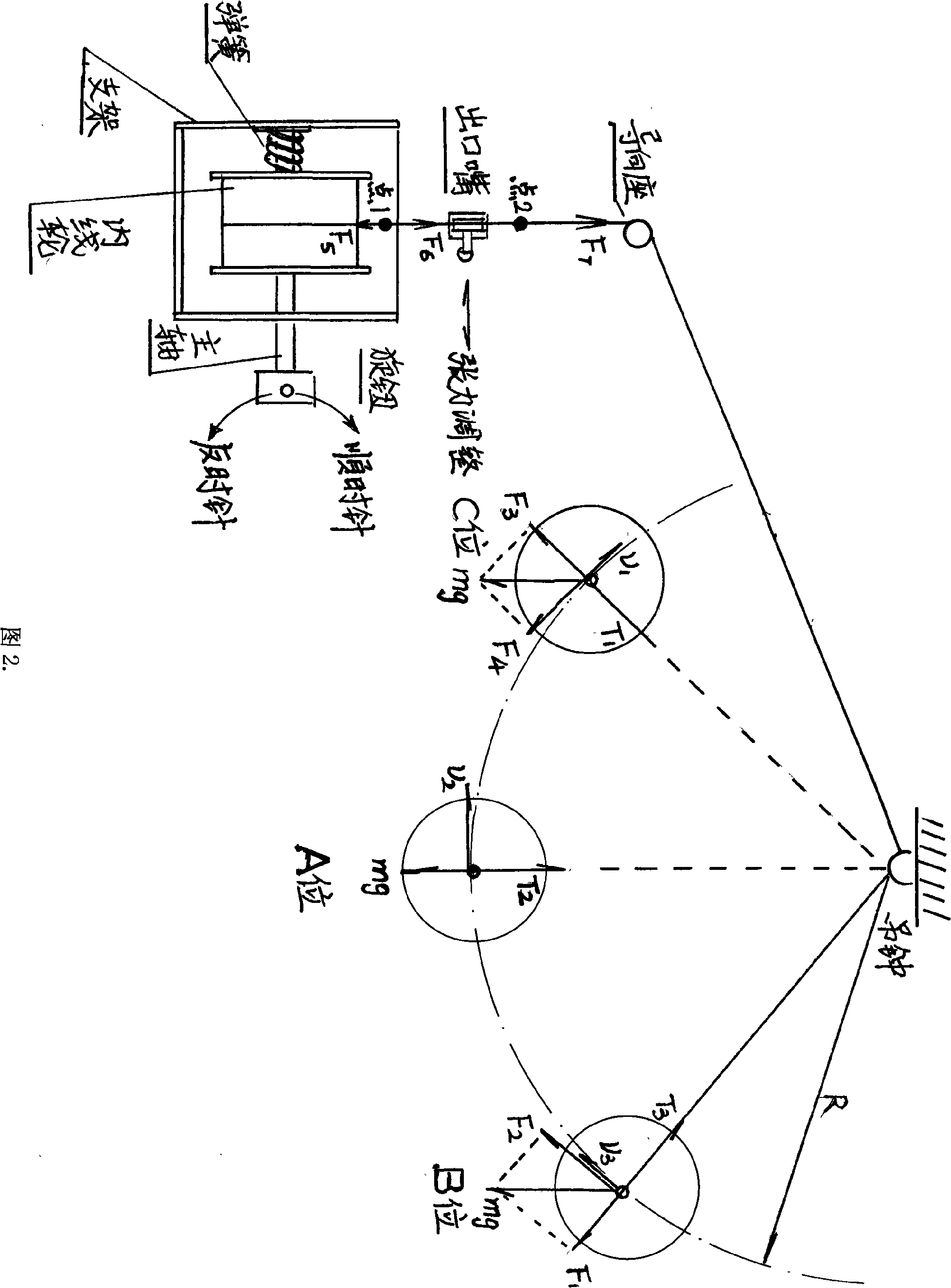

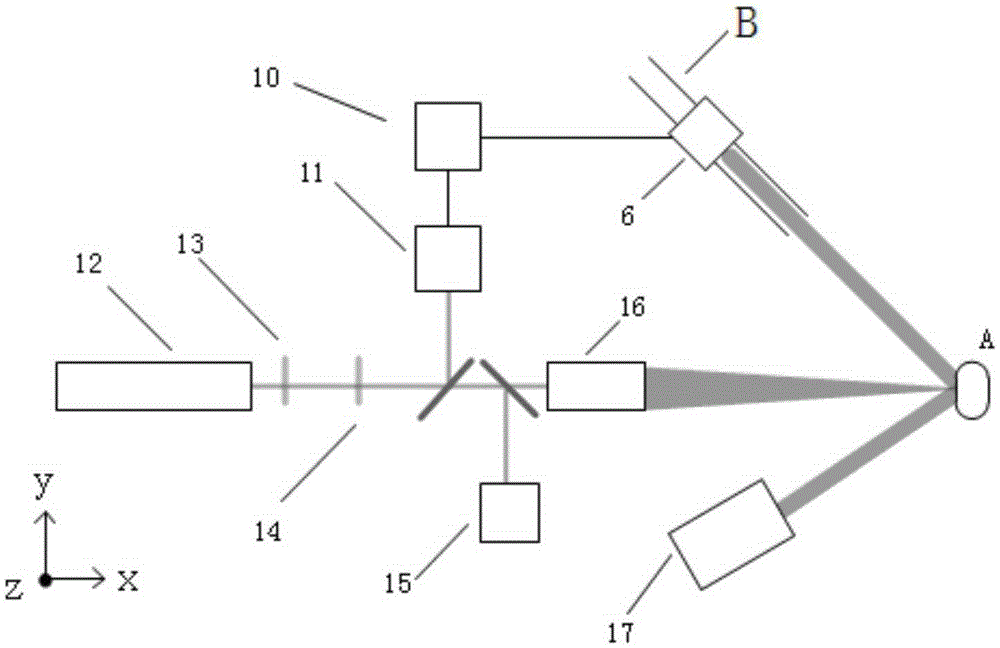

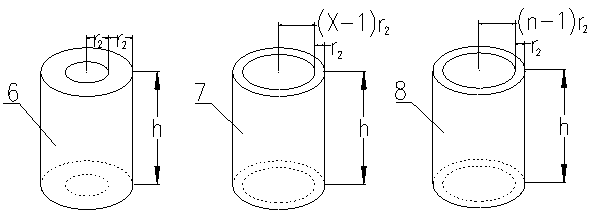

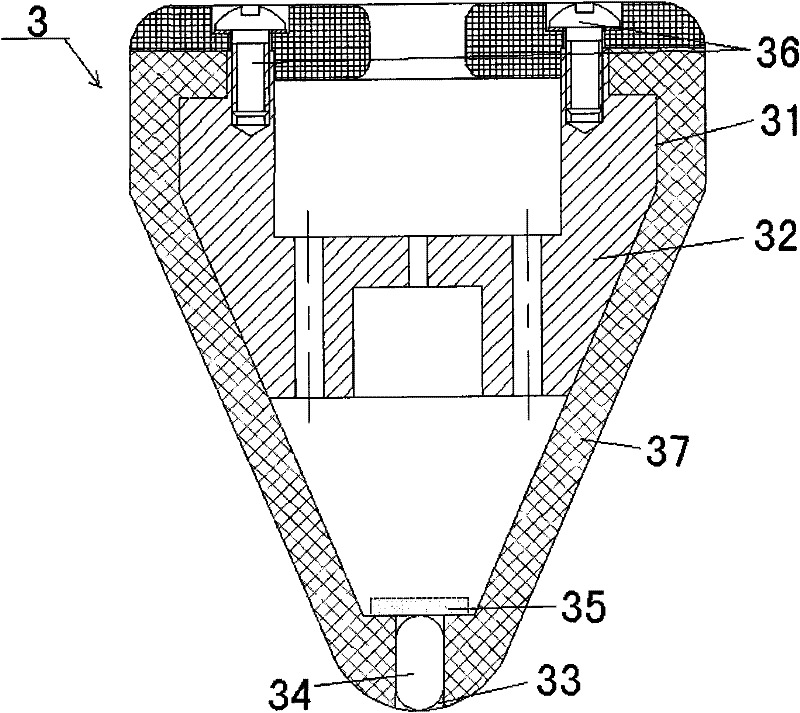

Test system of impulse coupling efficiency of target under the action of laser

ActiveCN105352639AIncrease and decrease distanceReduce distanceWork measurementTorque measurementEnergy regulationEngineering

The present invention provides a test system of an impulse coupling efficiency of a target under the action of a laser. The test system provided by the invention comprises: a compound pendulum device configured to dispose the target, a movable ruler device configured to detect the maximum swinging angle of the compound pendulum, a detection light source, an oscilloscope, a laser energy regulation unit and an energy meter. The compound pendulum device is composed of the compound pendulum and a compound pendulum support; and the movable ruler device is composed of a GHz photoelectric sensor, a one-dimensional translation stage and a horizontal slide rail. The impulse of a tested target is obtained under the laser irradiation through adoption of a photoelectric sensing unit and is configured to push the compound pendulum to reach the maximum swinging angle, the original impulse of the compound pendulum under the laser irradiation is obtained through adoption of the law of energy conservation, and the changing curve of the impulse coupling coefficient of the target is obtained through the dimensionless method of the impulse coupling efficiency when the laser single pulse energy is changed. The test system of an impulse coupling efficiency of a target under the action of a laser is applicable to the test of the impulse coupling efficiency of a target under the action of the laser in the target friction-free suspended state, and the precision measurement with a GHz dynamic response, a wide measurement range, a big swinging angle and high sensitivity is realized.

Owner:NANJING UNIV OF SCI & TECH

Gravity compound pendulum-based ultra-high precision micro force measuring device and measuring method

ActiveCN108981974ADoes not add massIncreased sensitivityForce measurement using counterbalancing forcesMeasurement deviceDifferential measurement

The invention discloses a gravity compound pendulum-based micro force measuring device and a measuring method. In the device, a rotating shaft passes through the gravity compound pendulum and is put on a support, the compound pendulum swings an angle under effects of micro-thrust, low friction exists between the shaft and the pendulum, and thus, the micro-thrust can be sensed; the horizontal microdisplacement of the compound pendulum is measured through micro-distance sensors which are arranged in a vertical differential mode, the swinging angle is indirectly measured, and further through a moment balance relationship, the size of the micro-thrust is inversely deduced. The measuring principle and the method are simple and feasible and can reach the precision of a micro newton level; a clump weight arranged at the top end of the gravity compound pendulum can move vertically, the gravity center and the inertia of the compound pendulum are adjusted, the micro-thrust sensitivity is increased, and the influences of external vibration are reduced; the horizontal displacement of the compound pendulum is measured in a differential mode, and errors brought by environment vibration, toolingand measuring devices can be eliminated; electromagnetic damping can reduce oscillation of the compound pendulum, and influences of a disturbance torque are reduced; and besides, calibration on the micro-thrust can be directly completed through a weight calibration mode, and the operation is simple and convenient.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

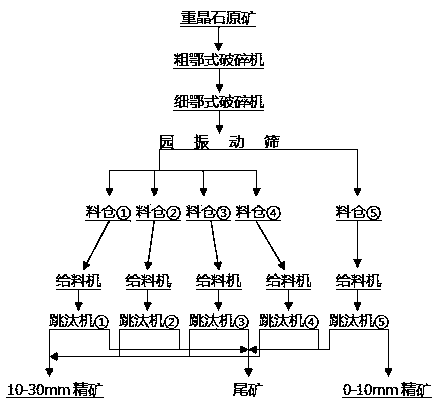

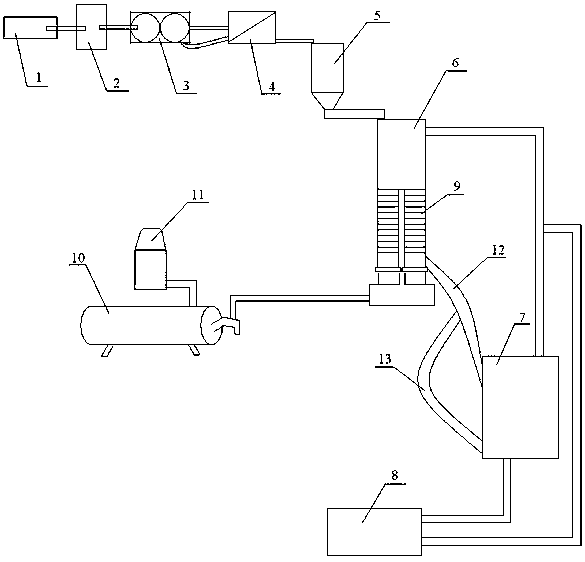

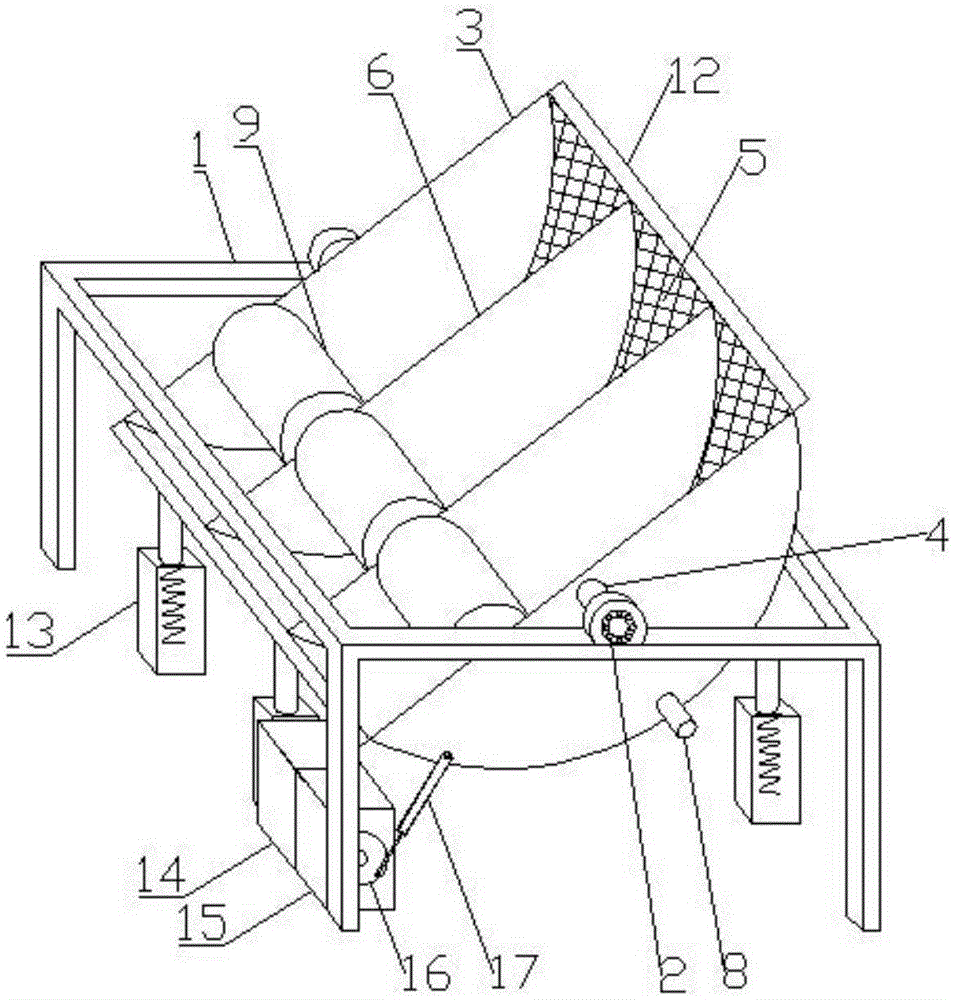

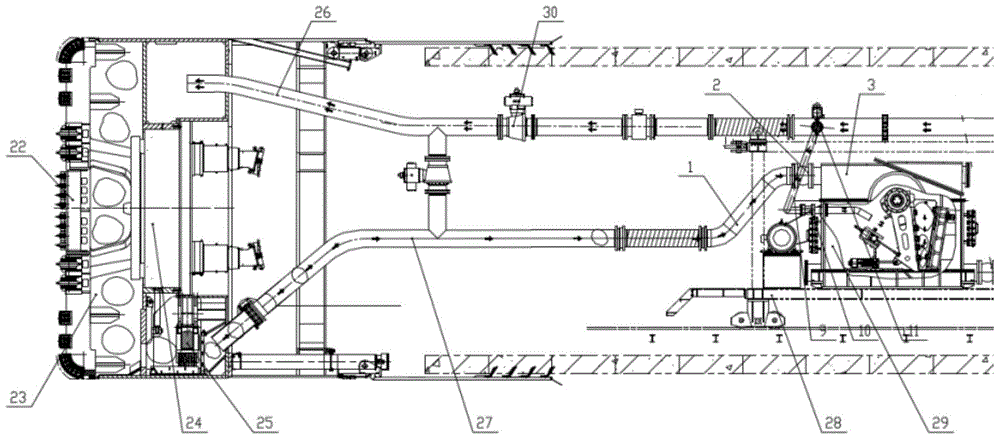

Processing system for separating barite from tailings and method of processing system

PendingCN107694743APrevent proliferationAvoid pollutionSolid separationGrain treatmentsWater flowEngineering

The invention relates to a processing system for separating barite from tailings. The processing system comprises a PE compound pendulum jaw crusher I, a PE compound pendulum jaw crusher, a twin-roller machine and a vibrating screen, wherein the PE compound pendulum jaw crusher I, the PE compound pendulum jaw crusher, the twin-roller machine and the vibrating screen are connected. The vibrating screen is provided with a raw ore particle discharging port with the particle diameter equal to or greater than 3mm and a raw ore particle discharging port with the particle diameter smaller than 3mm. The raw ore particle discharging port with the particle diameter equal to or greater than 3mm is connected with the twin-roller machine, and the raw ore particle discharging port with the particle diameter smaller than 3mm is connected with a stock bin. A feeder is arranged at the bottom of the stock bin, and a washbox is connected to the tail end of the feeder. A water sprayer is arranged above the washbox, one side of the washbox is connected with a settling pond and a purification pond, and a water segregation sieve provided with two water segregators I is arranged at the bottom of the washbox. The water segregators I are connected with a drying machine provided with a water segregator II. A cyclone dust collector is arranged at the top of the drying machine. A dry concentrate discharging port is formed in the bottom of the drying machine. A main water trough provided with a water flow regulation plate and a branched water trough provided with an overflow regulation plate are arranged on one side of the water segregation sieve. A powdery concentrate settling pond is arranged at the bottom of the branched water trough and connected with a sand suction pump. The settling pond is connected with the purification pond. The invention further discloses a processing method of the system. By adoption of the processing system for separating barite from tailings and the processing method of the processing system, pollution is small, and the purity of obtained concentrate is high.

Owner:文县白杨林矿业有限公司

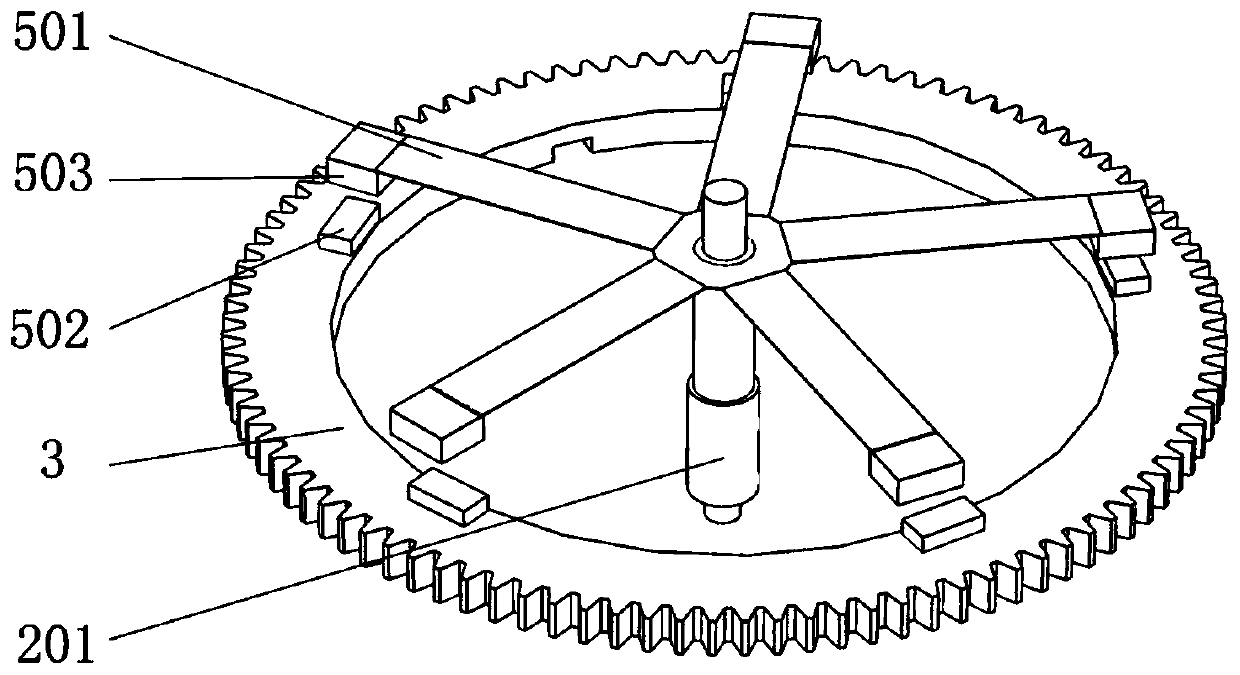

Self-locking tree rest

InactiveCN107360938AAutomatically adapts to diameter changesRealize deadlockBrake typesCultivating equipmentsGear wheelEngineering

Owner:漳州市云融企业管理有限公司

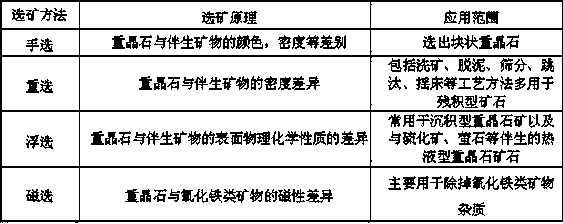

Compound pendulum type roller mill

ActiveCN105413816AIncrease contact areaImprove grinding efficiencyGrain treatmentsCurvilinear motionForce balance

The invention discloses a compound pendulum type roller mill which is capable of increasing the grinding area and improving grinding efficiency, high in efficiency and low in consumption. The compound pendulum type roller mill comprises a swinging box, wherein a bottom plate of the swinging box is in an arc shape, and the swinging box is equally divided into two parts at bearing central shafts at the two ends so that the swinging box tends to be in a two-force balance state in the moving process. The swinging box is hinged to the two ends of a support through the bearing central shafts. Spring boosters are mounted on the ground and located on the two sides of the swing of the swinging box. The spring boosters and a driving device jointly drive the swinging box to conduct compound pendulum motion under resultant force. The driving device is a crank and rocker mechanism. A box body is divided into two or more working bins by partition plates. Each partition plate is provided with material fineness control and material passing holes. A grinding medium roll is placed in each bin and conducts curvilinear motion to grind and impact ore to be thin and broken.

Owner:JIANPING WANSHOU JINYU IRON CONCENTRATOR

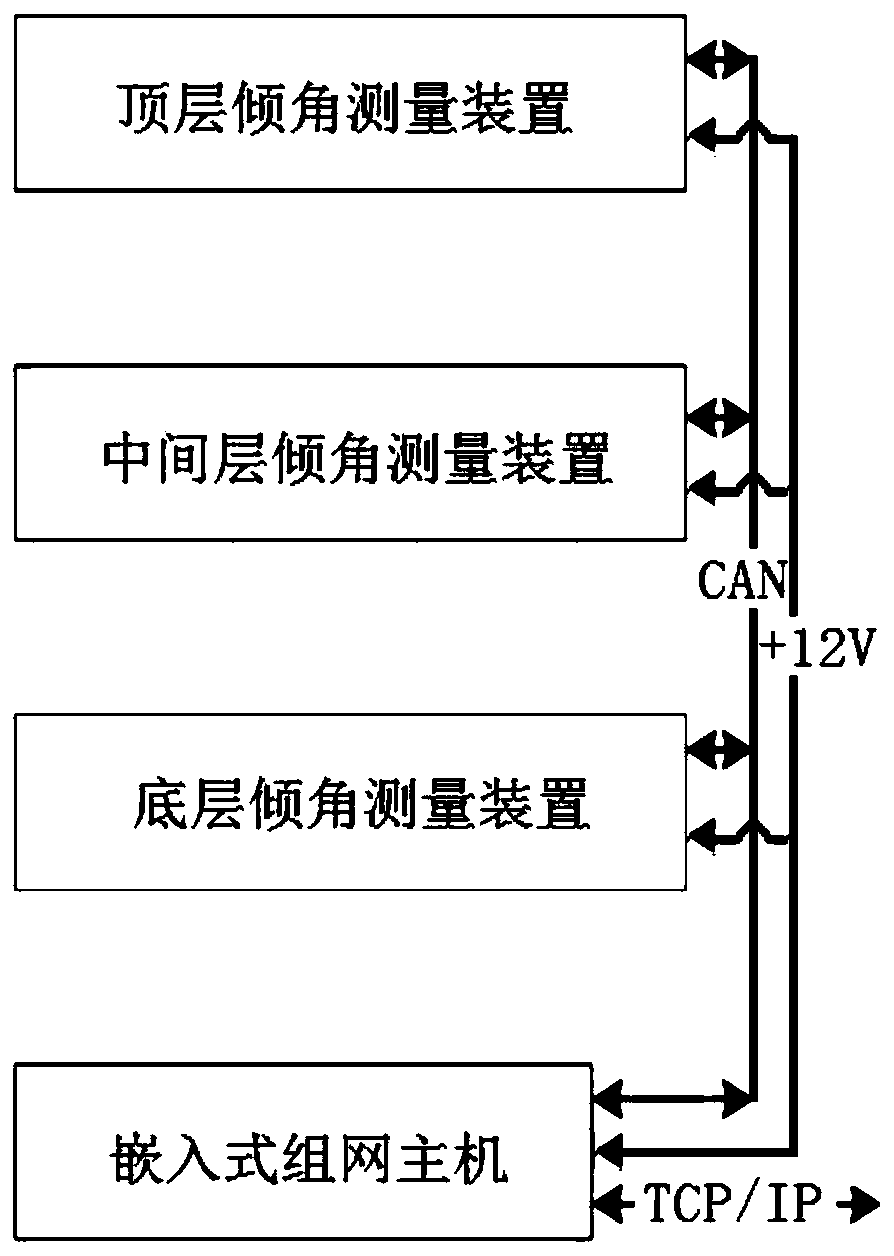

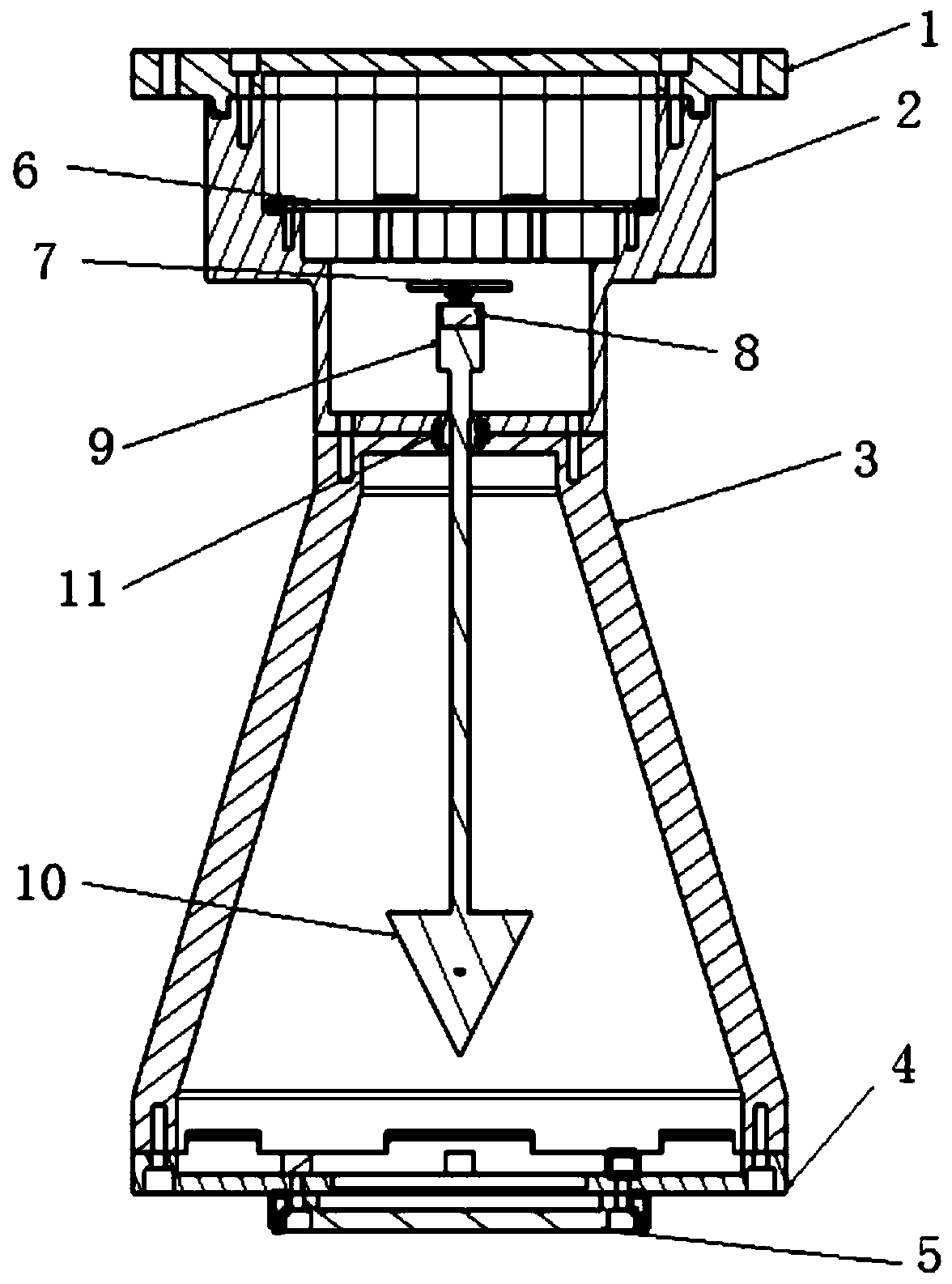

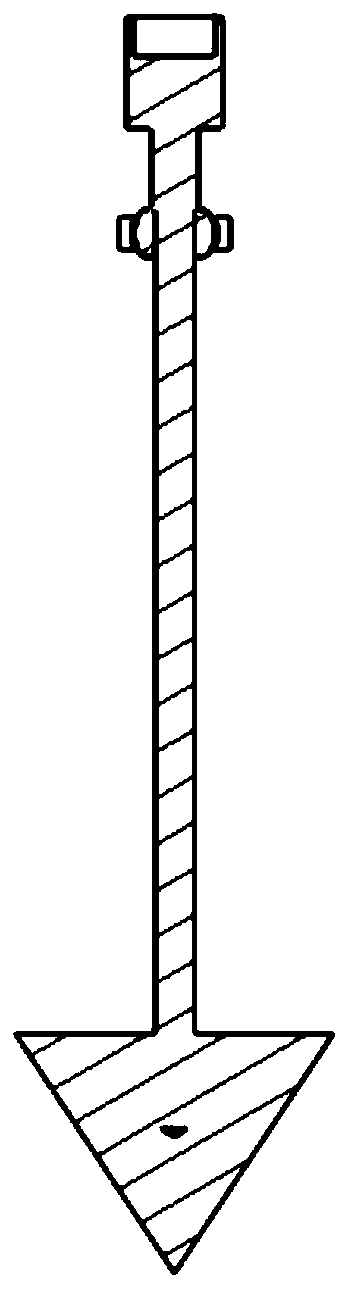

System for measuring inclination angle of wind power tower based on three-dimensional Hall sensor

The invention discloses a system for measuring an inclination angle of a wind power tower based on a three-dimensional Hall sensor. The system comprises an inclination angle measuring device and an embedded host, the inclination angle measuring device is arranged in a tower drum; the inclination angle measuring device comprises a three-dimensional Hall sensor, a microprocessor, a magnetic isolation CAN transceiver, a system basic sheet and a swing rod mechanism. A magnet is mounted on the swing rod mechanism; the three-dimensional Hall sensor is located above the magnet and is in non-contact magnetic field space crosslinking, the swing rod mechanism drives the magnet to rotate in the circumferential direction along with swinging of the tower drum and is used for adjusting proper sensitivity and damping characteristics, and the microprocessor completes tower drum inclination angle data measurement by reading internal data of the three-dimensional Hall sensor and conducting algorithm processing. Through the unique compound pendulum design of the three-dimensional Hall sensor and the swing rod mechanism, equal-angle transmission of external inclination angle signals of the system is completed, the data accuracy is high, and the repeatability is high.

Owner:赤峰华源新力科技有限公司

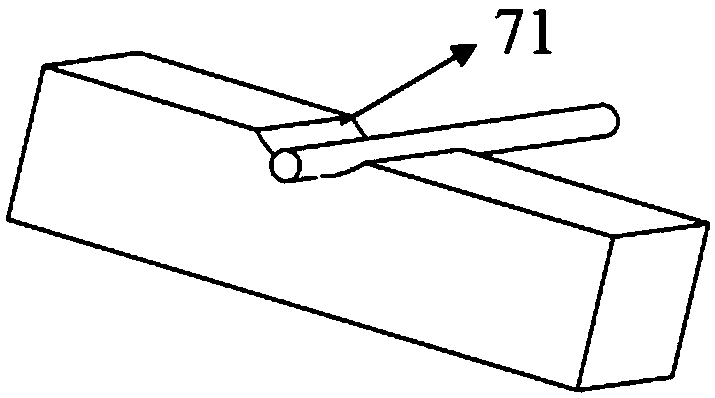

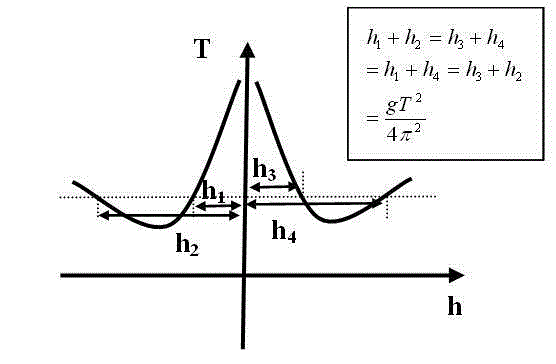

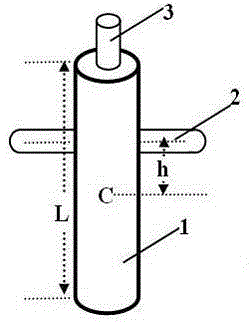

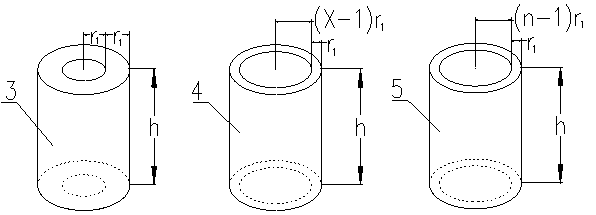

Method for measuring gravity acceleration by sleeving cylinder to increase compound pendulum length

InactiveCN103985290AReduce the impactIncrease the lengthEducational modelsGravitational wave measurementMeasurement deviceExperimental methods

The invention provides a method for measuring the gravity acceleration by sleeving a cylinder to increase the compound pendulum length, and relates to the field of physical experiment devices and experimental methods. The method is designed to overcome the defect that the measurement process and the data processing process are complex and high in time consumption and to reduce deviation introduced by calculation. According to the technical scheme, a cylindrical hanging rod is fixed to a thin rod, the central axis of the thin rod and the central axis of the hanging rod are perpendicular and intersect, the two ends of the hanging rod are placed in a pair of grooves, the central axis of the hanging rod is horizontal after the two ends of the hanging rod are placed in the grooves, and the thin rod can swing around the central axis of the hanging rod in a reciprocating mode; the distance h between the mass center C of the thin rod and the central axis of the hanging rod is larger than 0.30 time of the length L of the thin rod and smaller than 0.35 time of the length L of the thin rod; a sleeve rod is fixed to the upper end of the thin rod and shares the same central axis with the thin rod, the cylinder, the sleeve rod and the thin rod are made of the same material, the periphery of the cross section of the cylinder and the periphery of the cross section of the thin rod are the same in shape and equal in size, and the gap between the cylinder and the sleeve rod is too small and can be omitted. The method has the advantages that a measurement device and the measurement process are simple and clear, and data processing is easy and rapid.

Owner:SICHUAN UNIV

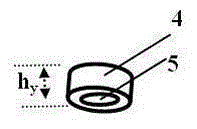

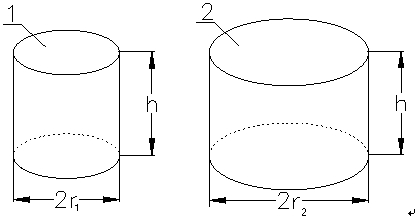

Method for measuring gravitational acceleration by utilizing increase of radius of pendulum bob

InactiveCN107490806AReduce human errorAvoid the problem of not being able to accurately find data points with the same periodEducational modelsGravitational wave measurementExperimental methodsGravitational force

The invention provides a method for measuring the gravitational acceleration by utilizing increase of the radius of a pendulum bob. According to the method, a calculation formula of the gravitational acceleration g is obtained by analyzing the swinging period of a compound pendulum system consisting of a swinging rod and cylindrical weights, researching the change of the swinging period of the compound pendulum system when the radiuses of the cylindrical weights with the radiuses of r2 and r1 are gradually increased by step lengths of r2 and r1 and comparing the influences on the swinging period caused by different step lengths. Compared with the current experimental methods widely adopted, the method provided by the invention has the advantages that from the experimental principle, the equivalent pendulum length can be obtained without depending on changing the position of the compound pendulum system from a mass center to a suspension point, and the value of the gravitational acceleration obtained by the slope of a fitting line is realized by analyzing the influence of the step lengths in radius change of the pendulum bob on the swinging period, so that the complex and tedious data processing work is reduced, the data processing speed is increased, the data processing error is reduced; and the method adopts a simple and definite principle and is convenient to understand and is suitable for being operated by students.

Owner:QIQIHAR UNIVERSITY

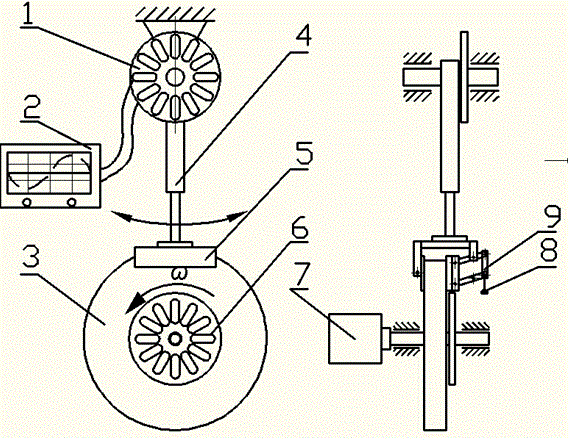

Pendular component vibration demonstration instrument

InactiveCN104537931AChange natural frequencyEnabling Quantitative ResearchSubsonic/sonic/ultrasonic wave measurementEducational modelsResearch modelEngineering

Provided is a pendular component vibration demonstration instrument. A compound pendulum mechanism is of a structure hinged to a spindle and is provided with a friction plate; a friction mechanism comprises a friction wheel, the structure that the compound pendulum mechanism is driven by the rotating friction wheel to swing through friction force generated by the friction wheel and a neighboring friction plate is formed the compound pendulum mechanism is provided with a pressure adjustment mechanism, the moving end of the pressure adjustment mechanism is connected with the friction plate and used for adjusting pressure of the friction plate on the friction wheel, the compound pendulum mechanism is connected with a tilt angle frequency sensor, and the tilt angle frequency sensor is used for detecting tilt angles or the frequency of the compound pendulum mechanism. The pendular component vibration demonstration instrument has the advantage that for a self-induced vibration demonstration and research model, the quantitative research of a self-induced vibration mechanism is achieved by changing rotating speed, the coefficient of friction (change friction plates of different materials and add lubricant oil), and the intrinsic frequency pendulum mechanism is changed.

Owner:南京乐汉东智能设备有限公司 +1

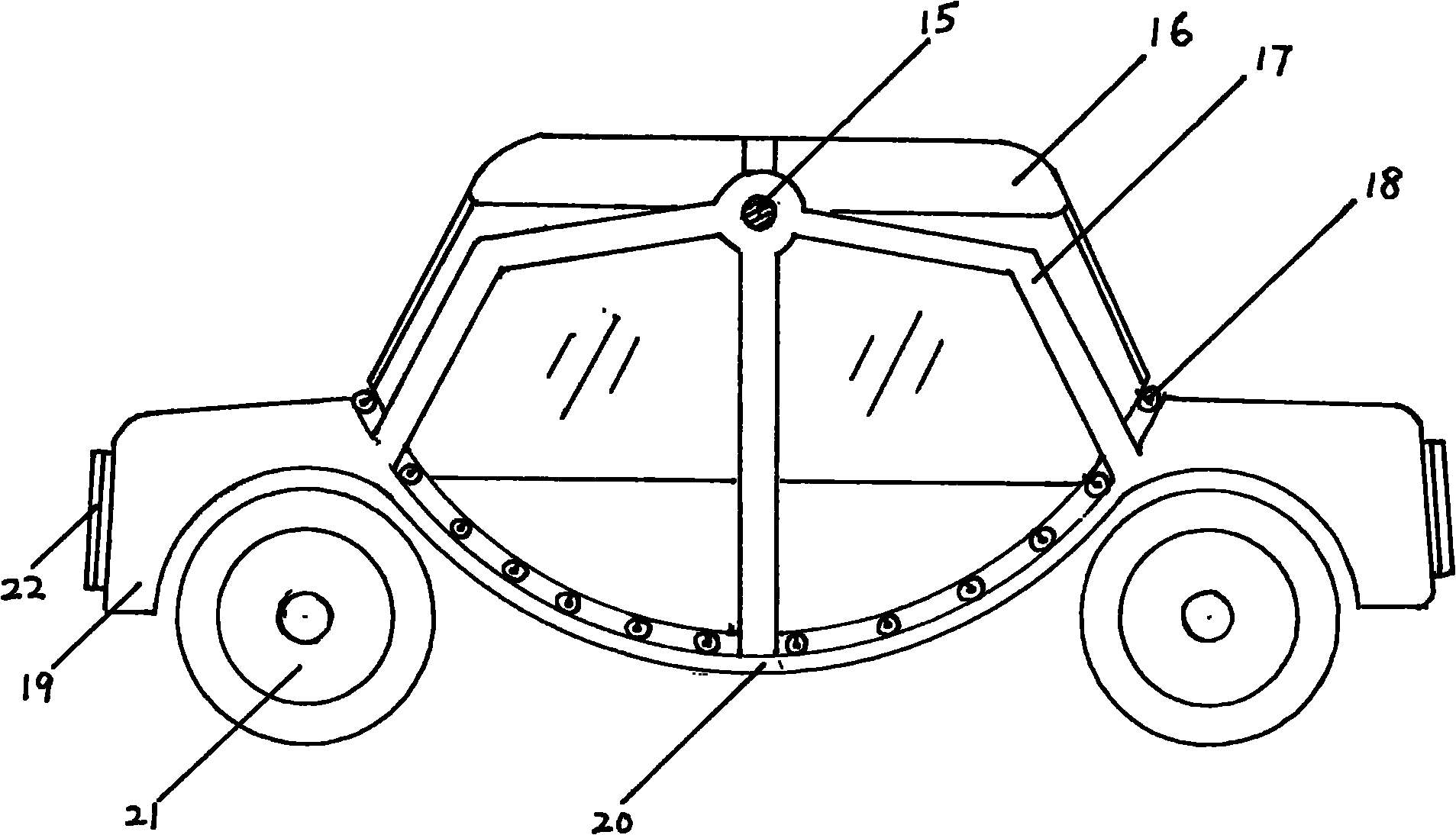

Compound pendulum type safe vehicle

InactiveCN102079335AReduce destructive energyReduce damageVehicle body-frame connectionsIn vehicleEngineering

A multi-type compound pendulum type safe vehicle can effectively ensure the safety of the in-vehicle personnel in high-speed impact or emergency brake, and can greatly reduce the damage degree of the vehicle body and the object being impacted. A whole compartment of the compound pendulum type safe vehicle is suspended in a high-position horizontal shaft and becomes a compound pendulum type movable structure. In impact or emergency brake, the compartment automatically swings upwards or rotates around the shaft thereby greatly reducing the frontward impact force. Because the compartment body does not impact an obstacle and can automatically buffer when the vehicle accelerates vigorously or suddenly stops, the safety of the in-vehicle personnel is ensured. The types of the vehicles can be divided into a two-wheel type, a three-wheel type, a four-wheel type, a multiple-wheel type, a crawler type and an amphibiousness type, thereby forming a series of compound pedulum type safe vehicles.

Owner:谭春阳

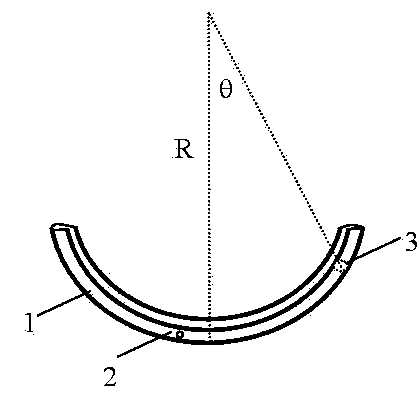

Method for measuring gravitational acceleration through rolling of small ball

InactiveCN104021709AExpand your mindEasy to measureEducational modelsEngineeringLight-emitting diode

The invention discloses a method for measuring the gravitational acceleration through rolling of a small ball and relates to the field of physical parameter measurement, in particular to the field of gravitational acceleration measurement. The method for measuring the gravitational acceleration through rolling of the small ball aims to overcome the shortages that a simple pendulum cannot effectively constraint a pendulum ball and conic pendulum overlaying is prone to occurrence. According to the technical scheme, the method comprises the steps that the small ball rolls down from the upper portion of one side of a circular-arc groove with the curvature radius being R and conducts reciprocated swing under mutual conversion of potential energy and kinetic energy; a pair of light holes are formed in the side faces of the circular-arc groove, a light-emitting diode and a receiving diode of a photogate are arranged in the light holes, and the swing period T of the small ball is measured by the photogate, wherein the gravitational acceleration g=(2pi / T)*2*1.4R. The method has the advantages that the small ball is limited by the circular-arc groove and conic pendulum overlaying like that of the simple pendulum is avoided; the method for measuring the gravitational acceleration expands thoughts of students; compared with a method for measuring the gravitational acceleration through a compound pendulum, the measurement process and the data processing process are as simple as those of a method for measuring the gravitational acceleration through the simple pendulum.

Owner:SICHUAN UNIV

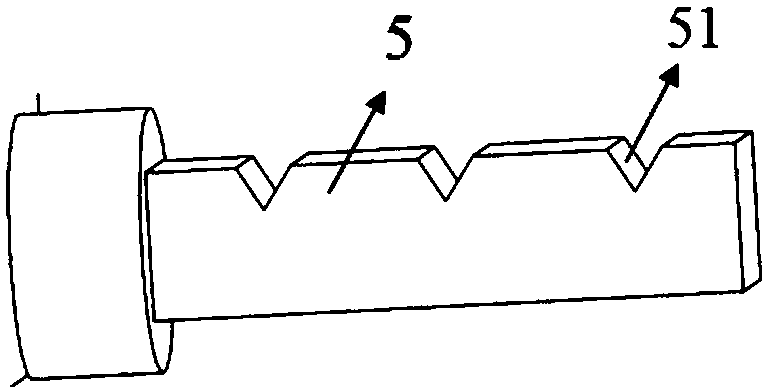

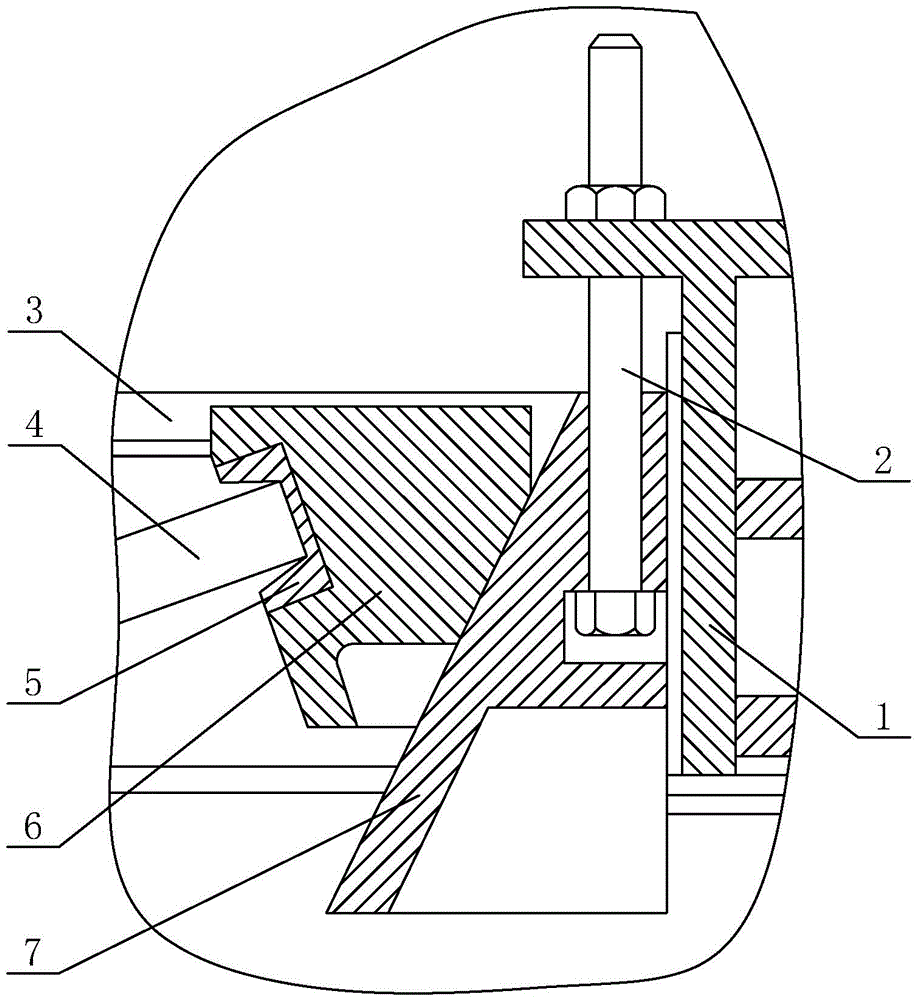

Discharge port adjustment device for compound pendulum jaw crusher

The invention discloses a discharge port adjustment device for a compound pendulum jaw crusher. The discharge port adjustment device comprises a supporting frame, a frame and a ribbed slab for mounting of a movable jaw, wherein the supporting frame is fixedly arranged on the frame and connected with a wedge through a height adjustment device, and an adjustment block matching with the wedge is arranged at the slope side of the wedge and arranged on the frame in a way of sliding along the horizontal direction; the non-slope side of the adjustment block is connected with the ribbed slab, an iron liner is fixedly arranged between the ribbed slab and the adjustment block. The discharge port adjustment device for a compound pendulum jaw crusher has the characteristics of reasonable design, simple and compact structure, convenience in operation, convenience in maintenance, wide application range, long service life, simple production technology, low production cost and convenience in popularization and use.

Owner:XIAN ZHIYUE ELECTROMECHANICAL TECH

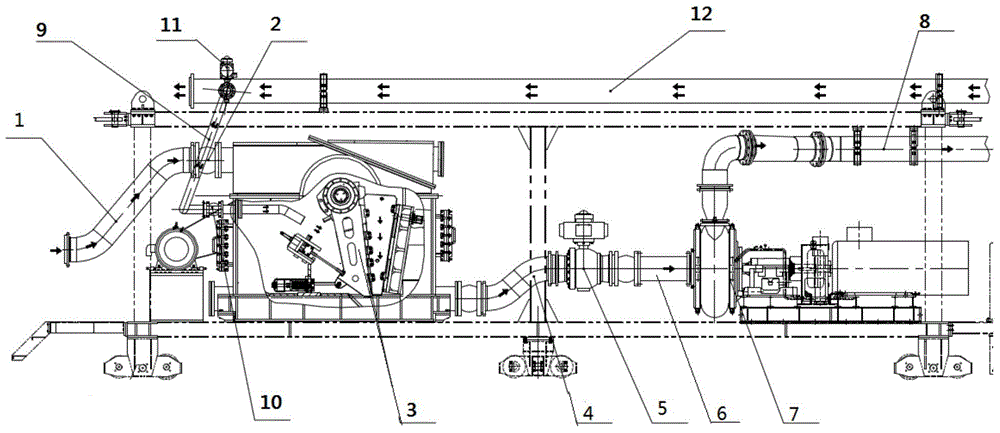

Slurry pipeline crusher used in shield machine

The invention provides a slurry pipeline crusher used in a shield machine. The slurry pipeline crusher is a closed slurry fluid jaw crusher with the inside having a sealed pressure reaching above 0.5MPa, and the slurry pipeline crusher comprises a frame, a movable jaw assembly, sealing gaskets, a fixed jaw plate positioned in the frame, and a motor driving assembly and a belt positioned outside the frame, wherein the frame, the movable jaw assembly and the sealing gaskets form an internal sealing space; the motor driving assembly and the belt are used for driving the movable jaw assembly to carry out compound pendulum extruding motion relative to the fixed jaw plate in order to extrude and crush bones between the movable jaw assembly and the fixed jaw plate; and the movable jaw assembly comprises an eccentric shaft arranged on the frame and a movable jaw plate positioned in the frame, and a rotation seal is formed between the movable jaw assembly and the frame. The slurry pipeline crusher has strong crushing ability and good maintainability, and can provide high-pressure crushing sealing environment.

Owner:CHINA RAILWAY CONSTR HEAVY IND

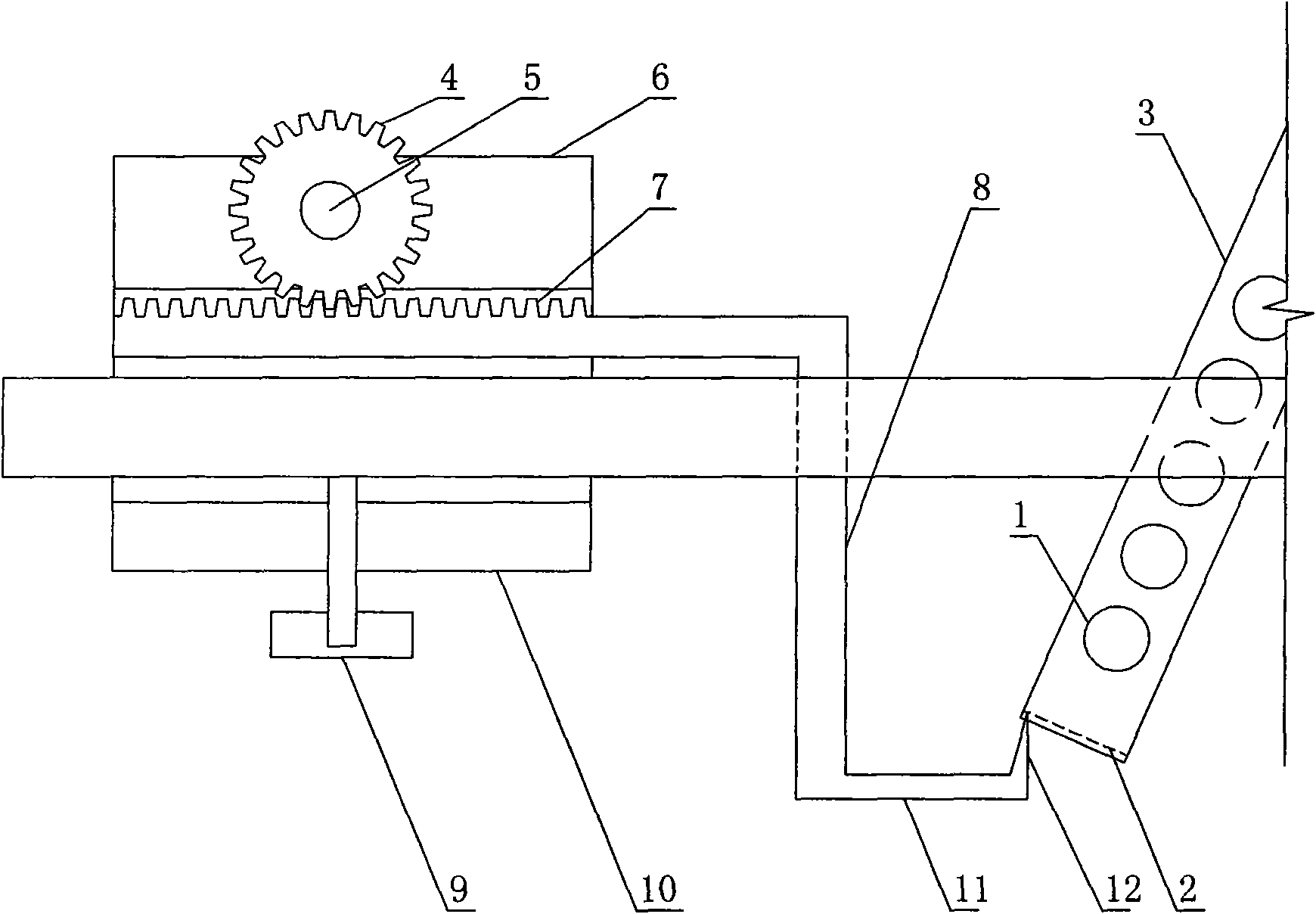

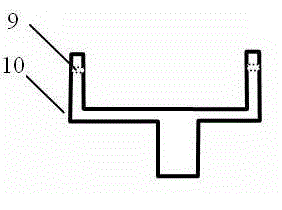

Balance swing rod and starting drive thereof

InactiveCN101655565ANo shakingNo twistingEducational modelsGravitational wave measurementGear wheelEngineering

The invention relates to an experimental apparatus, particularly to a balance swing rod and a starting device thereof. A compound pendulum swing rod without initial shaking is composed of a swing rodhole, a balance groove and a rod body; the starting device is composed of a gear, a rotating shaft, a gear carrier, a tooth bar, a drop arm, a knob, a table edge card, a transverse arm and a positioning hook; the lower end of the rod body is provided with the balance groove with a V-shaped cross section; the gear is sleeved on the rotating shaft and generates a running fit with the rotating shaft;the upper surface of the table edge card between two gear carriers is provided with the tooth bar which generates a running fit with the table edge card; the teeth of the tooth bar are upwards and engage with the teeth of the rotating shaft; one end of the tooth bar is provided with the L-shaped hook which is composed of the drop arm, the transverse arm and the positioning hook; and the sharp endof the positioning hook is of a triangular pyramid shape. The experimental apparatus prevents the experiment error caused by hand shaking and increase the accuracy of experiment result.

Owner:NINGBO YINZHOU YUNFAN ENG CONSULTING

Observation device of simple pendulum movement and record method of simple pendulum movement track

ActiveCN102236992ASolve the problem that it is difficult to make a larger circleNo offset distortionEducational modelsEngineeringCompound pendulum

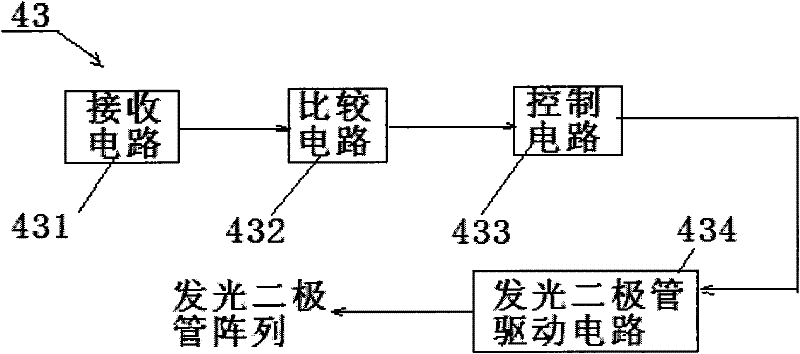

The invention discloses an observation device of simple pendulum movement and a record method of a simple pendulum movement track. The observation device comprises a cross rod, a rope, a pendulum bob and an observation platform, wherein one end of the rope is tied to the cross rod, and the other end of the rope is connected with the pendulum bob; the pendulum bob is suspended above the observation platform; the pendulum bob is internally provided with an emitter; and the observation platform is internally provided with a receiving controller, and the top surface of the observation platform is provided with a display screen which is electrically connected with the output end of the receiving controller. The movement track of a periodic pendulum is recorded through an electronic induction technology, an observer is led to understand the basic law of the pendulum through analysis on a track image, and simultaneously the characteristics of various pendulums such as Foucault pendulum, compound pendulum, torsional pendulum and the like and applications of the pendulums in production and life are further learnt.

Owner:SHANGHAI SCI & TECH MUSEUM

Tree supporting frame capable of changing support force

InactiveCN107372003AAutomatically adapts to diameter changesRealize deadlockWatering devicesRenewable energy machinesGear wheelSelf locking

The invention discloses a tree supporting frame capable of changing the support force. The tree supporting frame comprises a fixed base, support rods and an elastic bandage; the fixed base is provided with self-locking units, the support rods are connected with the self-locking units, and each self-locking unit comprises a gear, a gear lock and a gear holder, wherein the gear lock comprises a lock piece, a compound pendulum and a suspension frame which are arranged on the gear holder; a groove is formed in the portion, located below the corresponding compound pendulum, of each gear holder, each groove is internally provided with a mode adjusting device which comprises a spring, a compound pendulum adjusting block and a pulling part, each compound pendulum is located under the corresponding compound pendulum, a notch is formed in each compound pendulum adjusting block, and each mode adjusting device is used for achieving switching of the self-locking unit between an automatic locking mode and an active locking mode; the fixed base is formed by splicing four splicing pieces. Accordingly, in the using process, diameter variations of trees can be adapted automatically according to growth of the trees, and meanwhile the reinforcing function can be achieved for the trees.

Owner:漳州市云融企业管理有限公司

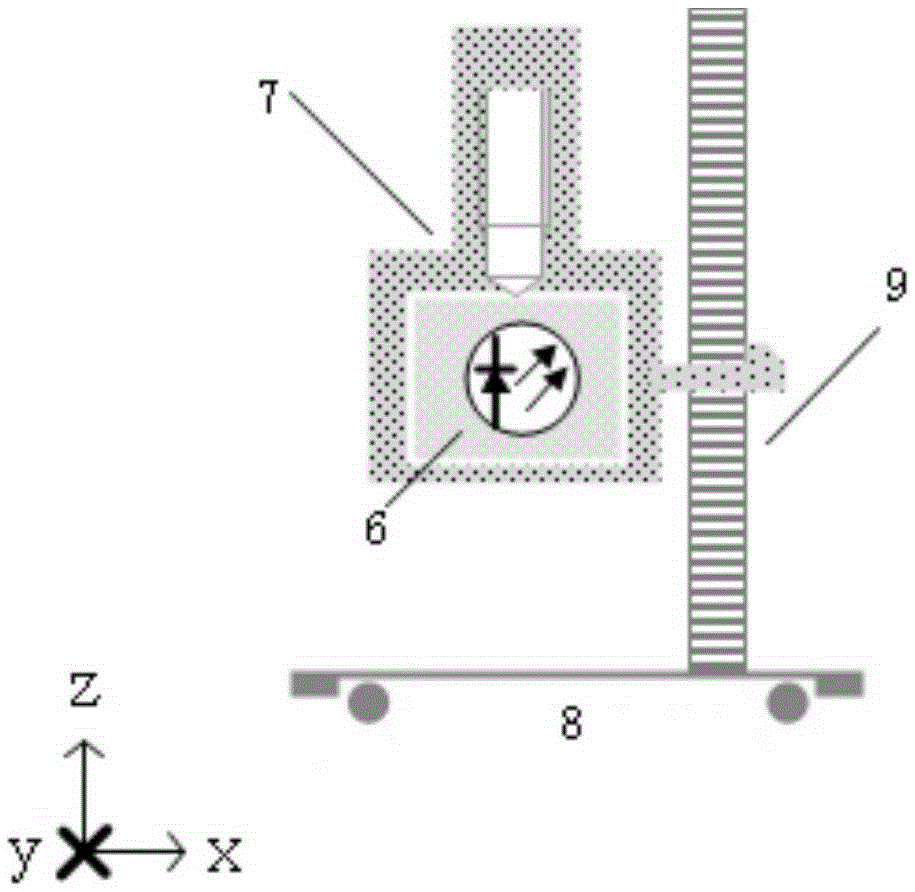

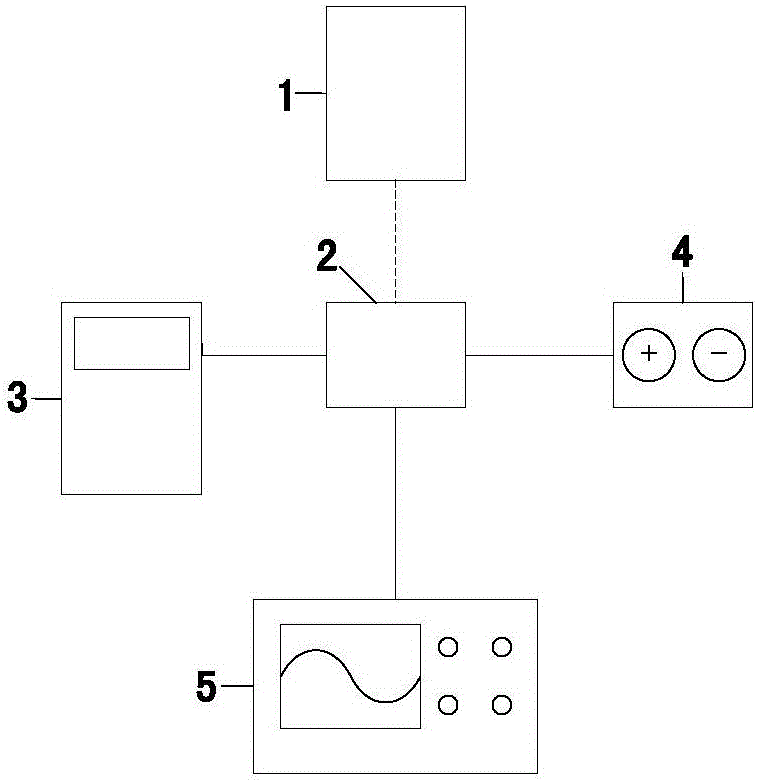

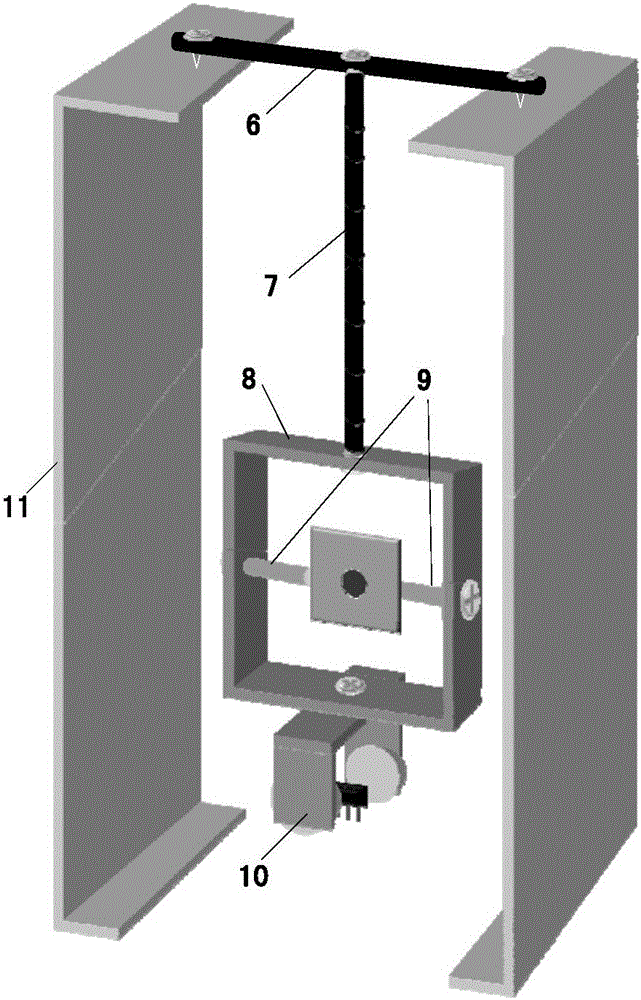

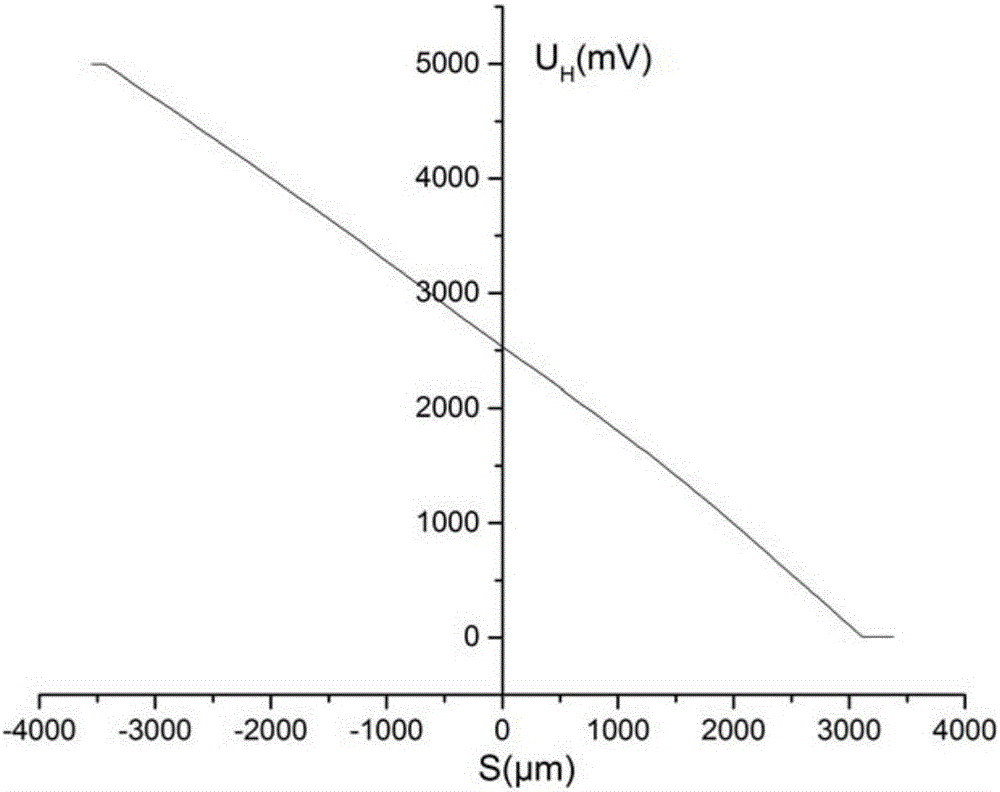

Dynamic measurement system and method of infinitesimal displacement caused by laser impulse coupling

ActiveCN105136009AAccurate displacementAccurate Transient MeasurementsUsing electrical meansCouplingSignal detector

The invention brings forward a dynamic measurement system and method of infinitesimal displacement caused by laser impulse coupling. The method comprises: according to a Hall electromagnetic effect principle, a linear hall sensor as a signal detector is used for measuring micron-grade infinitesimal displacement during the laser impulse coupling process based on combination with compound pendulum; the infinitesimal displacement of the compound pendulum is converted into an electric signal by the linear hall sensor and the signal is shown by an oscilloscope; data obtained by the oscilloscope are analyzed to obtain target material displacement caused by the laser impulse coupling as well as cycle information and then obtain information containing a target material speed and acceleration distribution and the like, thereby obtaining impulse coupling information of the target material. According to the invention, extraction of infinitesimal displacement, speed, and acceleration information of solid target material due to the impulse coupling can be realized. The method is simple and effective; the measurement system is compact and simple; and adaptability is high.

Owner:NANJING UNIV OF SCI & TECH

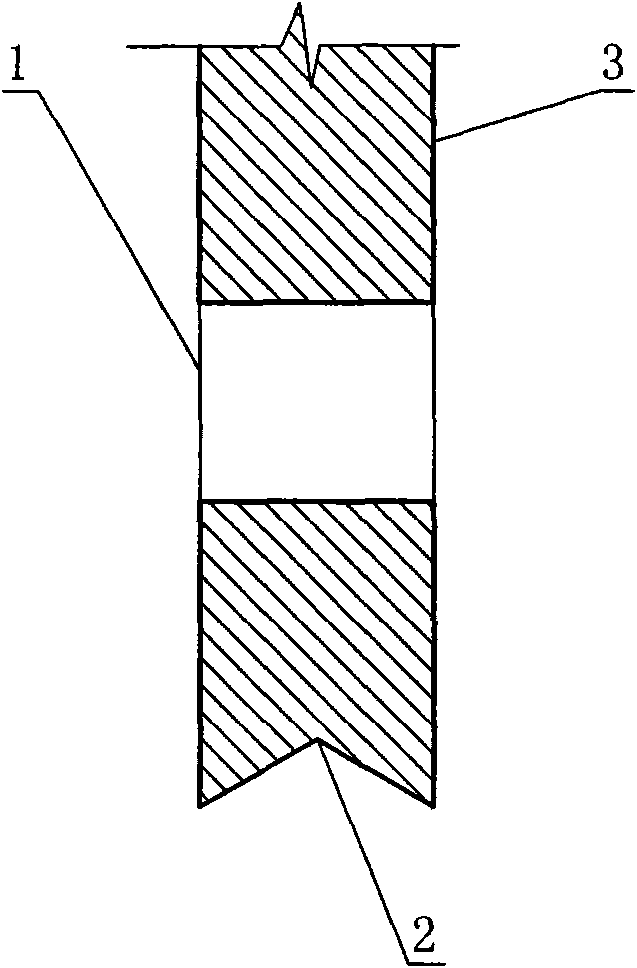

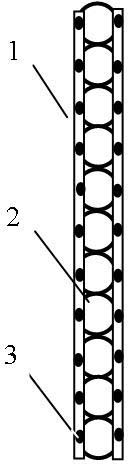

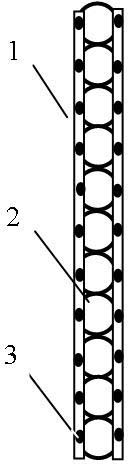

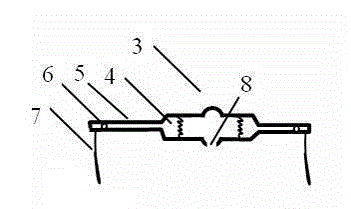

Wriggle-free compound pendulum consisting of metal ring and strip clamp slot

InactiveCN102645677APrevent twistingEnsure peaceful coexistenceGravitational wave measurementHardnessEngineering

A wriggle-free compound pendulum consisting of a metal ring and a strip clamp slot relates to the compound pendulum field and in particular relates to the manufacture of an oscillating bar of a wriggle-free compound pendulum used in an experiment for testing acceleration of gravity with the compound pendulum. Most of the oscillating bars of the compound pendulums and pendants are in line contact, thus twist easily occurs; and in a certain patent, blade contact is adopted, but the pendant and the oscillating bar are poor in durability. In order to overcome the defect that the common compound pendulum is easy to twist and blade contact causes damage easily, the oscillating bar of the compound pendulum is formed by connecting metal rings in the invention. Rings which have 10mm diameters and are made of stainless steel or high-hardness aluminum alloy are drawn close with the head and tail so as to form the oscillating bar of the compound pendulum; the two sides of the rings are clamped through clamp slots made of stainless steel or high-hardness aluminum alloy, and then the rings are fixed in the clamp slots through point welding; the pendent of the compound pendulum is a cylinder which has a 3mm diameter and is made of stainless steel or high-hardness aluminum alloy; the oscillating bar of the compound pendulum can be effectively avoided to twist through point welding; and point contact is adopted instead of blade contact, thus improving the durability of the oscillating bar and the pendent of the compound pendulum.

Owner:SICHUAN UNIV

Compound pendulum jaw breaker

The invention relates to the technical field of machinery. A compound pendulum jaw breaker consists of a rack, a fixed jaw plate, a movable jaw plate, an eccentric shaft, a flywheel, a belt wheel and an electric motor. The compound pendulum jaw breaker is characterized in that the fixed jaw plate is arranged on the rack; the movable jaw plate is matched with the fixed jaw plate; the movable jaw plate is provided with the eccentric shaft; a triangular belt is arranged to be connected with the eccentric shaft and the electric motor through the belt wheel and the flywheel. The compound pendulum jaw breaker has the beneficial effects of simple structure, convenience in use and good time-saving and labor-saving effects.

Owner:CHENGDU SHUANGLIU JINSHI MACHINERY

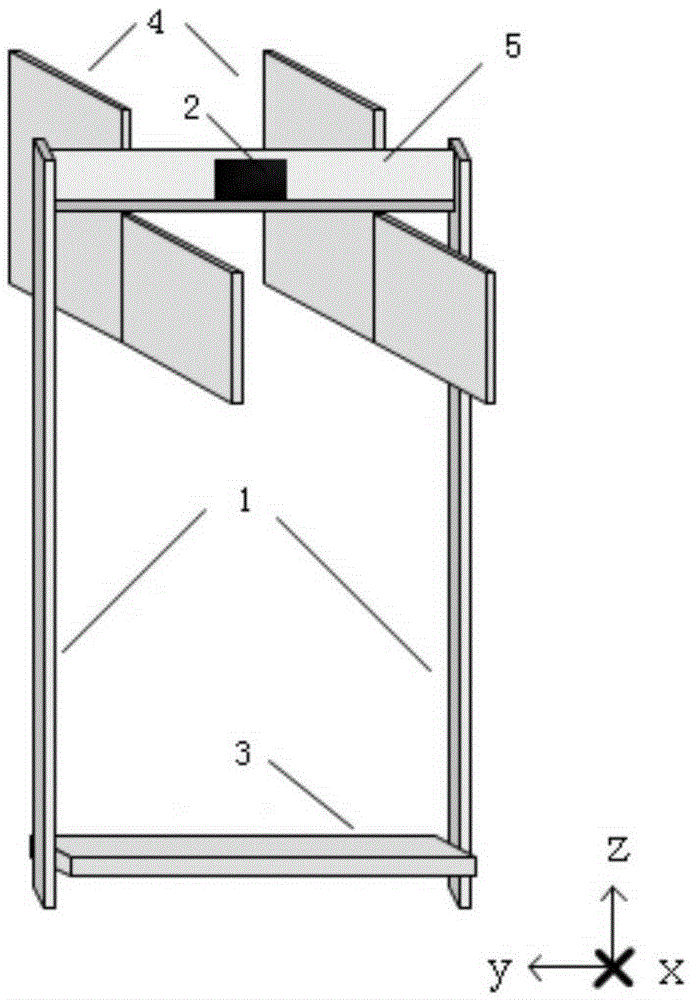

Compound pendulum apparatus for determining displacement in laser impulse coupling process

The invention provides a compound pendulum apparatus for determining displacement in a laser impulse coupling process. The compound pendulum apparatus comprises a pinpoint pendulum support point, an oscillating arm, a target material storage frame, an adjustable target material clamp, a right-angled arch magnetic storage structure and a compound pendulum oscillating frame and the like. By adopting an axial symmetric structure, all components of the compound pendulum apparatus are detachable and replaceable, and an oscillating point adopts a pinpoint support point way to reduce friction. The compound pendulum apparatus is convenient in disassembling, combining and component replacing and is used for determining infinitesimal displacement during the laser impulse coupling process.

Owner:NANJING UNIV OF SCI & TECH

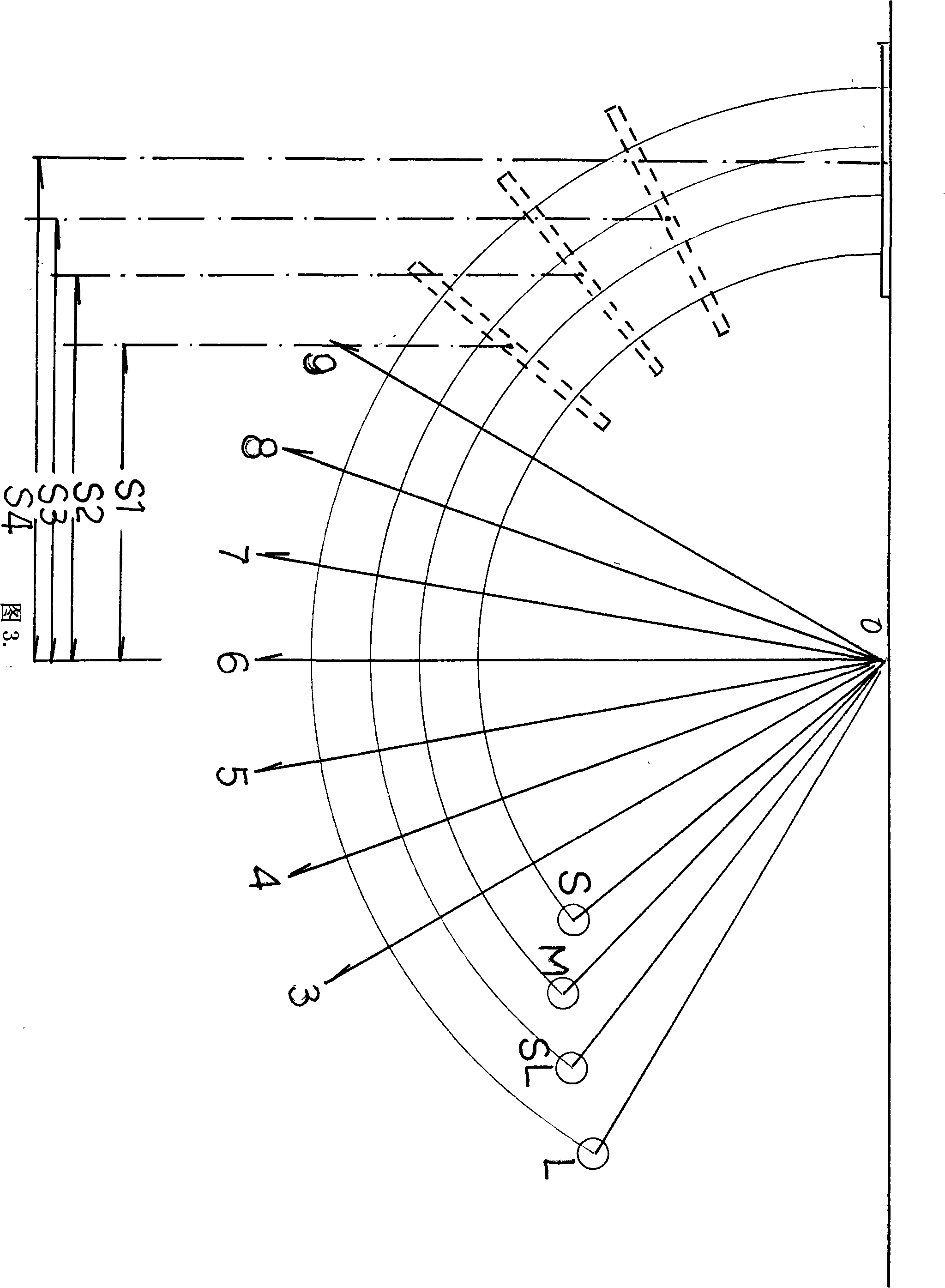

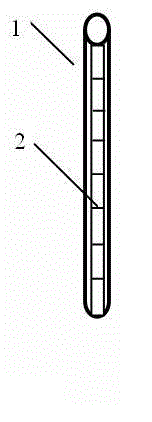

Clamped type compound pendulum with graduated scale

InactiveCN102723023AData processing is simpleImprove measurement efficiencyEducational modelsEngineeringData processing

The invention provides a clamped type compound pendulum with a graduated scale, which relates to the field of experiments of college physics, in particular to making of the compound pendulum with the graduated scale. A swinging rod of the compound pendulum in college physics lab is generally provided with a circular hole; and as too larger spaces are available between suspending points and periodic quantity is discrete, data processing of the compound pendulum experiment is substantially complicated. In order to overcome the complicatedness in data processing of compound pendulum, the graduated scale is additionally arranged on the swinging rod in the invention, and the swinging rod of the compound pendulum is fixed through clamping. The technical scheme is as follows: the swinging rod is a cylinder with diameter of 10 mm and length of 500-800 mm; one part is cut off from the cylinder to form a rectangular surface at the surface of the cylinder; the rectangular surface is 4 mm wide; the rectangle is marked to form a millimeter graduated scale; and the swinging rod is clamped by a fixture in which a number reading window is formed. The clamped type compound pendulum with the graduated scale, provided by the invention, has the advantages as follows: as no suspending hole is available on the swinging rod, the spaces between fixing points can be continuously changed, so that coordinates of the four suspending points with the same periods can be directly measured so as to simplify the data processing process.

Owner:SICHUAN UNIV

Enhanced compound pendulums and systems

ActiveUS20100128574A1Easy constructionGood compensationFrequency stabilisation mechanismEngineeringThermal expansion

Enhanced compound pendulums provide thermal compensation and / or barometric compensation, such as for a mechanical clock system. The enhanced compound pendulums are simple to construct, and can be more easily compensated than conventional, single-bob pendulums. The enhanced compound pendulums typically comprise material that is added above the point of rotation. Thermal expansion factors for components of the enhanced compound pendulums may preferably be chosen to provide thermal compensation to the first order. In some embodiments of enhanced compound pendulums, volume is added above the pivot to provide barometric compensation, such as by equalizing the moments above and below the pivot, or by providing geometric symmetry above and below the pivot, with a lower density above the pivot.

Owner:THE LONG NOW FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com