Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "No twisting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

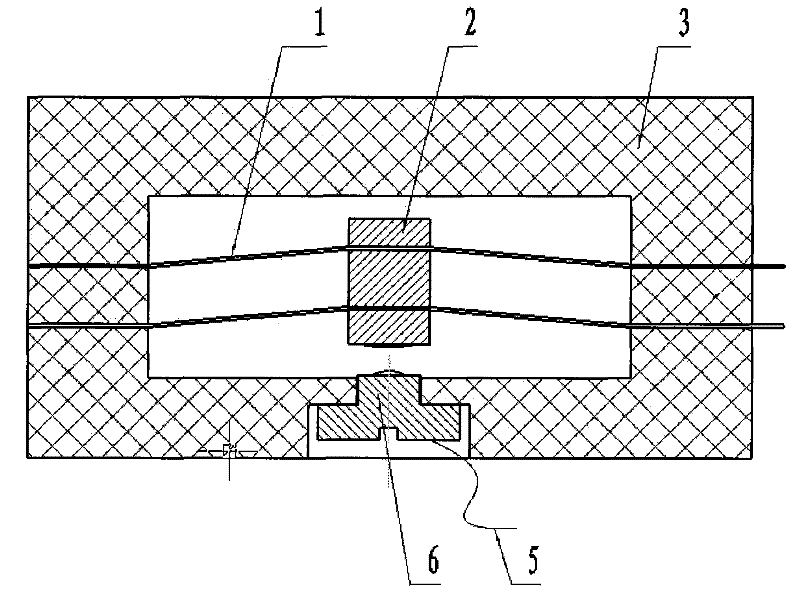

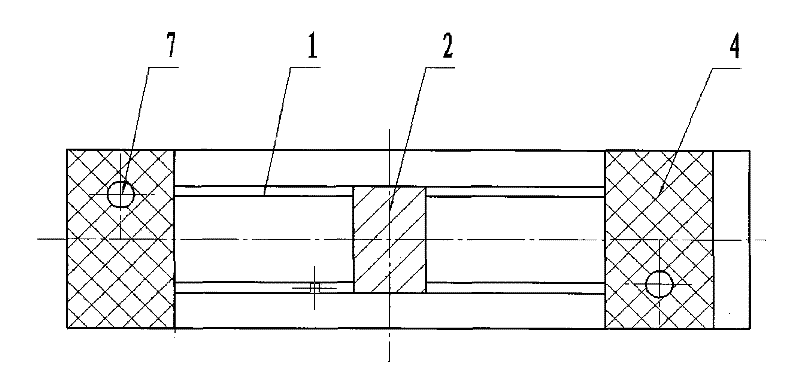

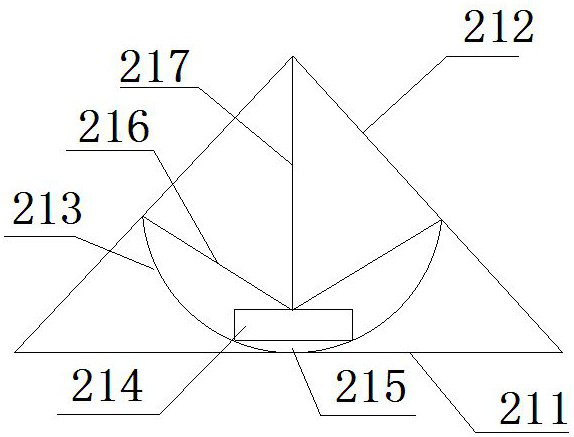

Flexion type acceleration switch

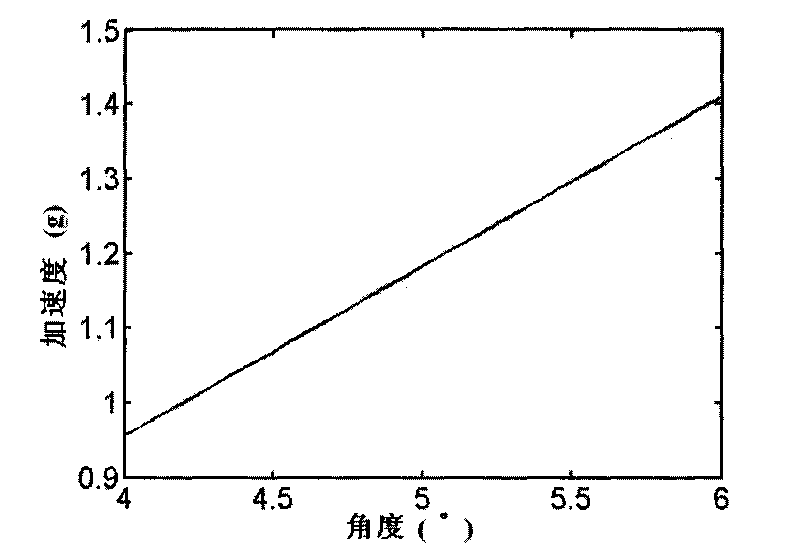

InactiveCN101752141ANo twistingSignificant switching threshold characteristicsElectric switchesInterference resistanceAngle alpha

The invention relates to a flexion type acceleration switch. In the switch, a tilted support beam, a mass block and a height adjustable contact component in a group are arranged in an insulation encapsulated shell of the switch, wherein the tilted support beam is of a double layer structure; two ends of the support beam are fixed at two sides of the shell; the double layer tilted support beam supports the mass block in a certain angle alpha to ensure that the mass block is balanced and suspended in an inner cavity of the insulation encapsulated shell; a contact is arranged on the bottom of the mass block; the height adjustable contact is arranged on the insulation encapsulated shell right under the mass block, and remains a certain distance from the mass block; when the double-layered tilted support beam is bent under the action of exterior threshold inertia force, the mass block moves along the exterior acceleration velocity to ensure that elastic contact is formed between the contact on the mass block and the height adjustable contact, and extrudes the contact to form stable contact by means of flexion elastic force. The acceleration switch is characterized by simple structure, adjustable threshold value and strong interference resistance.

Owner:XIDIAN UNIV +2

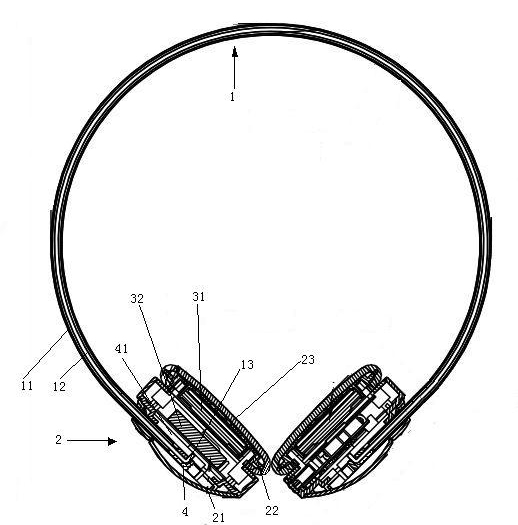

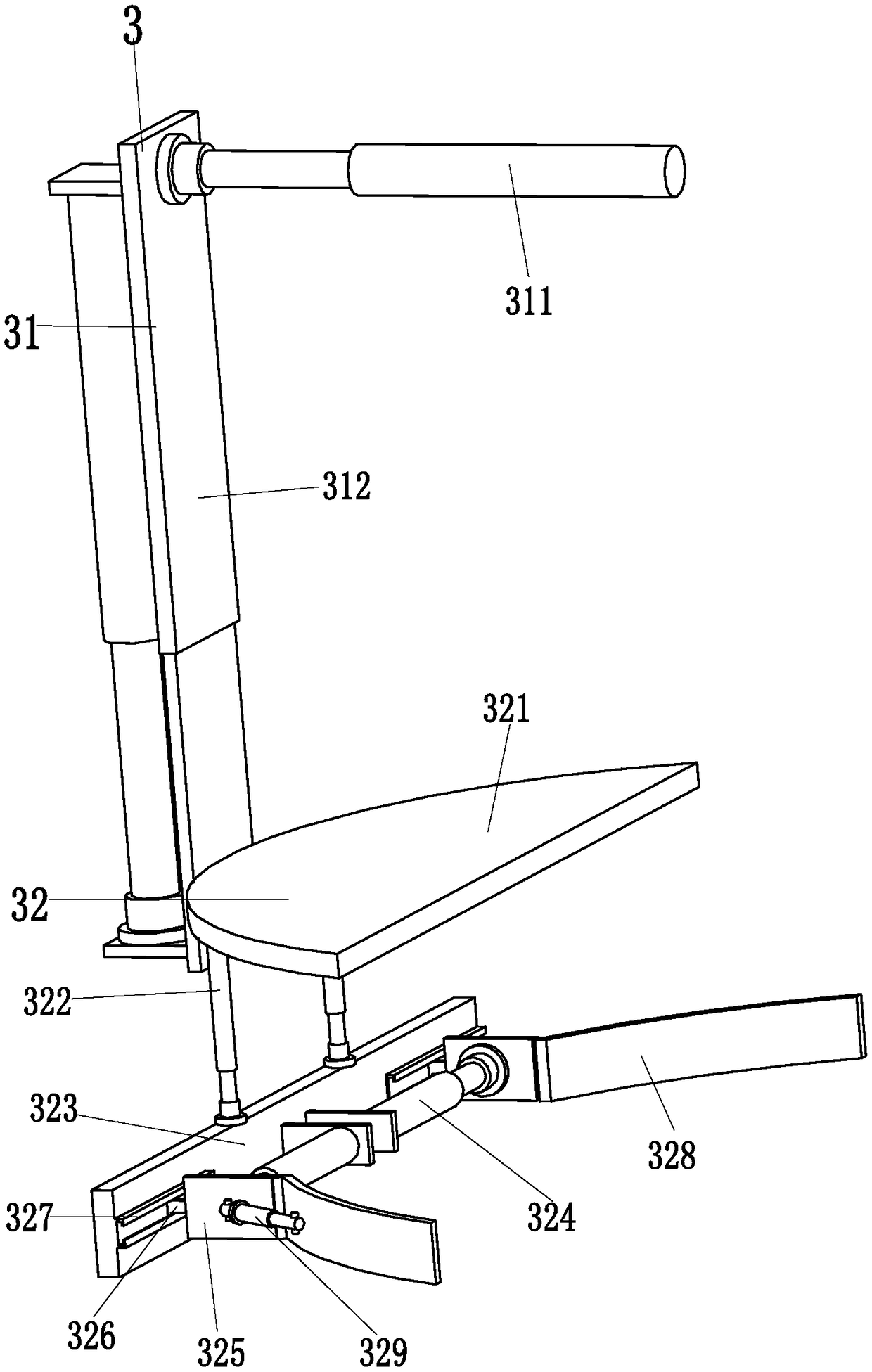

Headset with earflaps capable of rotating and extending relative to head band

The invention relates to a headset with a head band suspended on the head, in particular to a headset with earflaps capable of rotating and translating relative to the head band. The headset with the earflaps capable of rotating and translating relative to the head band comprises the head band and a pair of the earflaps arranged on the left and right ends of the head band, wherein audio circuit boards and loudspeakers are arranged inside the earflaps; the head band is an opened hoop with elasticity; the left end and the right end of the head band are respectively inserted into the pair of the earflaps; rotating and translating structures which enable the earflaps to do rotating and translating motions relative to the head band are arranged between the end parts of the earflaps and the earflaps; and the rotating and translating structures are positioned inside the earflaps. The headset with the earflaps capable of rotating and translating relative to the head band, provided by the invention has the advantages of concise appearance structure, good generality and comfortableness and long service life and solves the problems that the traditional headset can not combine the generality and the comfortableness and movably connected parts are easy to seize to affect the service life of the headset as adjustment structures for adjusting the position of the earflaps are positioned outside the earflaps.

Owner:浙江魔杰电子股份有限公司

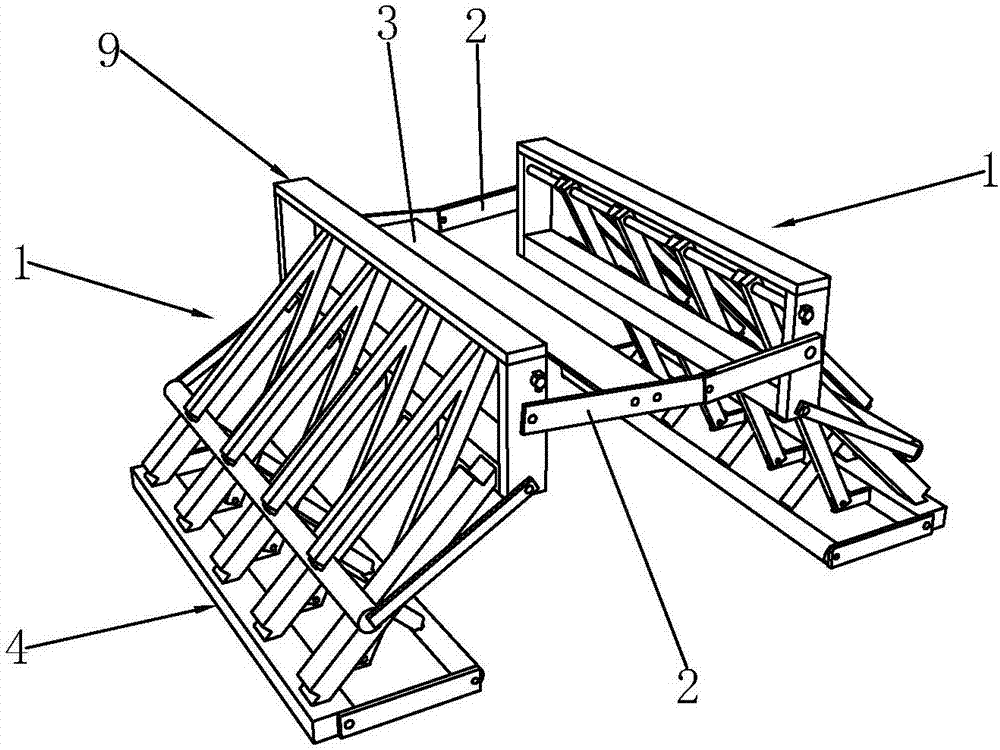

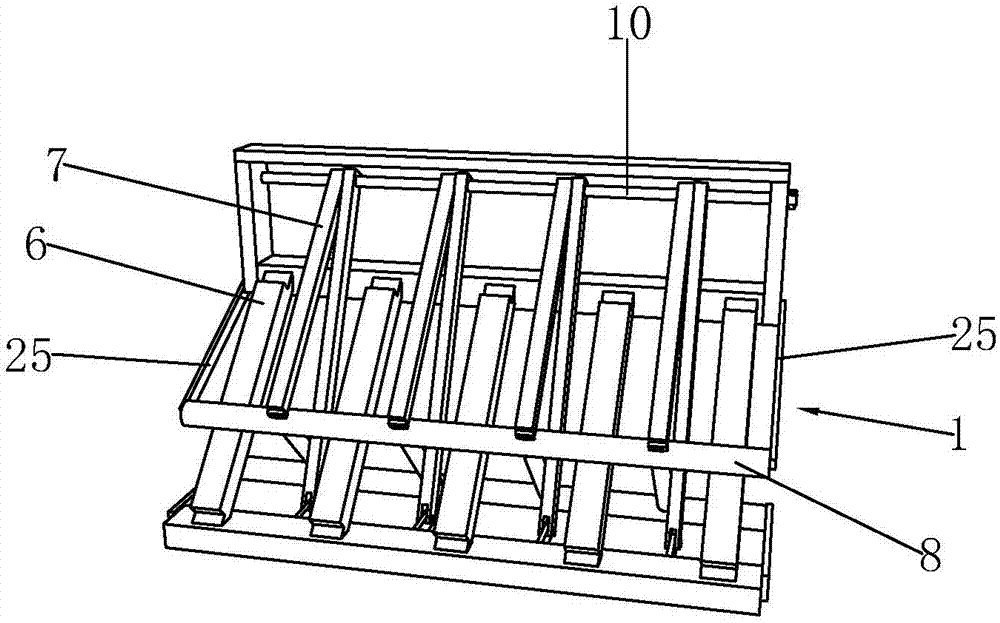

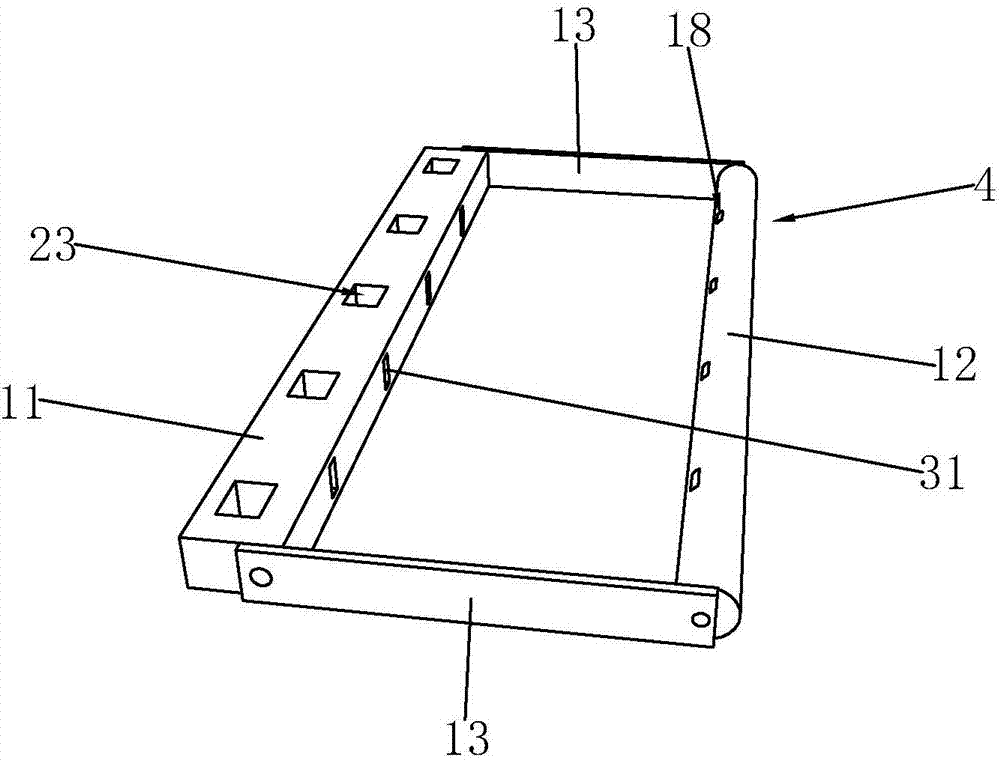

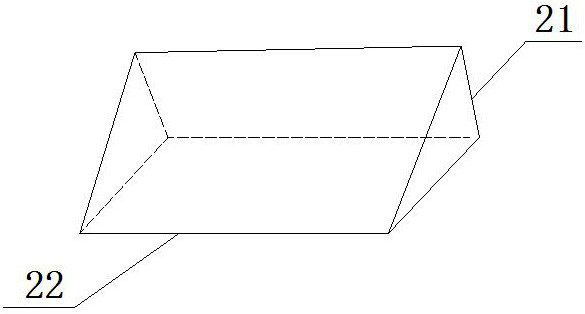

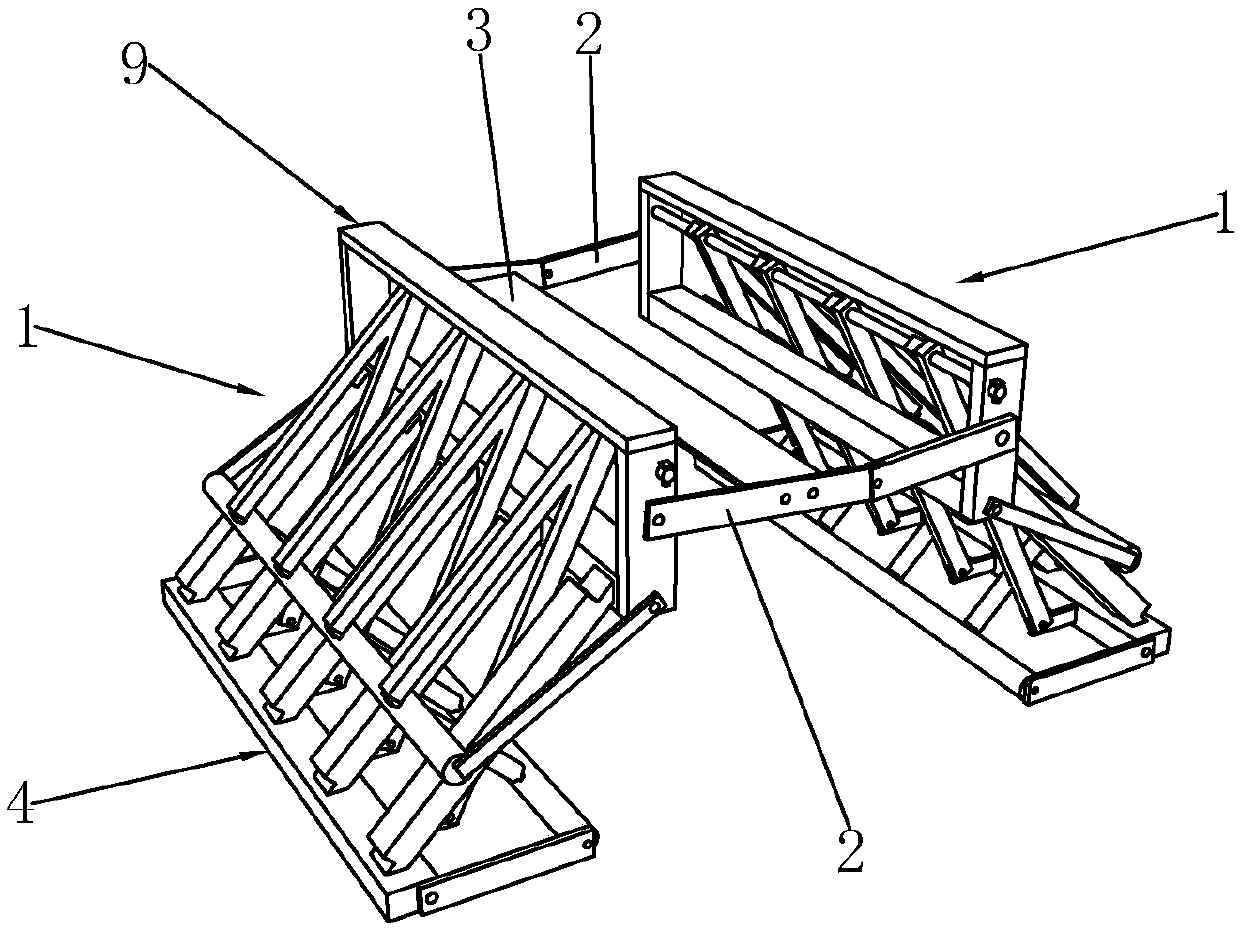

Support scaffold for ancient building gallery bridge and construction method of support scaffold

ActiveCN107044088AImprove stabilitySimple structureBridge erection/assemblyArchitectural engineeringLoad capacity

The invention discloses a support scaffold for an ancient building gallery bridge and a construction method of the support scaffold. The support scaffold comprises support base frames, support connecting rods and a reinforcing plate, the reinforcing plate is arranged between the support connecting rods, and the support connecting rods are arranged between the support base frames; and each support base comprises a base, first arch ribs, second arch ribs, third arch ribs, a beam frame, a support transverse frame and a support rod, the first arch ribs are arranged between the base and the beam frame, the second arch ribs are arranged between the base and the support transverse frame, the third arch ribs are arranged between the beam frame and the support rod, and the support rod penetrates through the support transverse frame. The construction method comprises the following steps of (a) clearing a workyard; (b) constructing a frame; (c) assembling the support base frames; (d) reinforcing; and (e) monitoring. According to the support scaffold for the ancient building gallery bridge and the construction method of the support scaffold, connecting of the support scaffold is flexible, disassembling and assembling are convenient, repairing is convenient, the anti-load capacity is high, the steadiness and the endurance are achieved, the construction method is simple, the construction period is short, the construction quality is easy to control, transportation of materials is convenient, and the construction cost is low.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

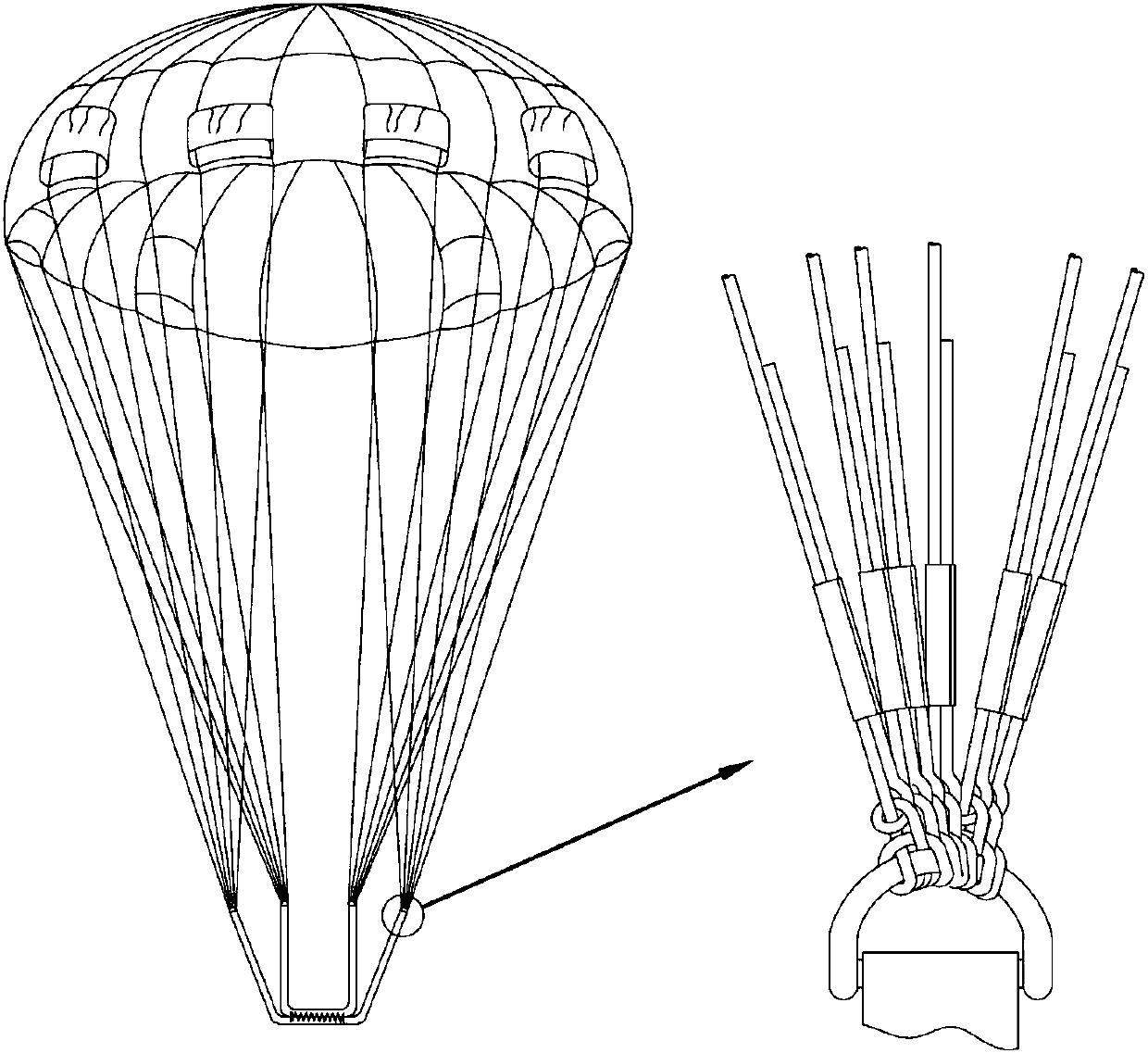

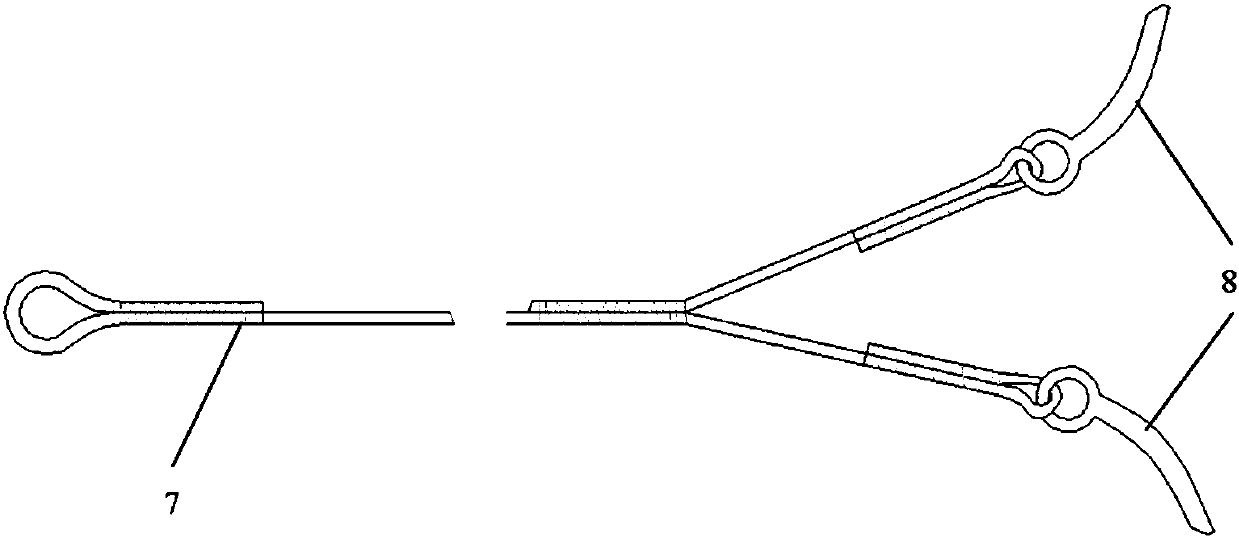

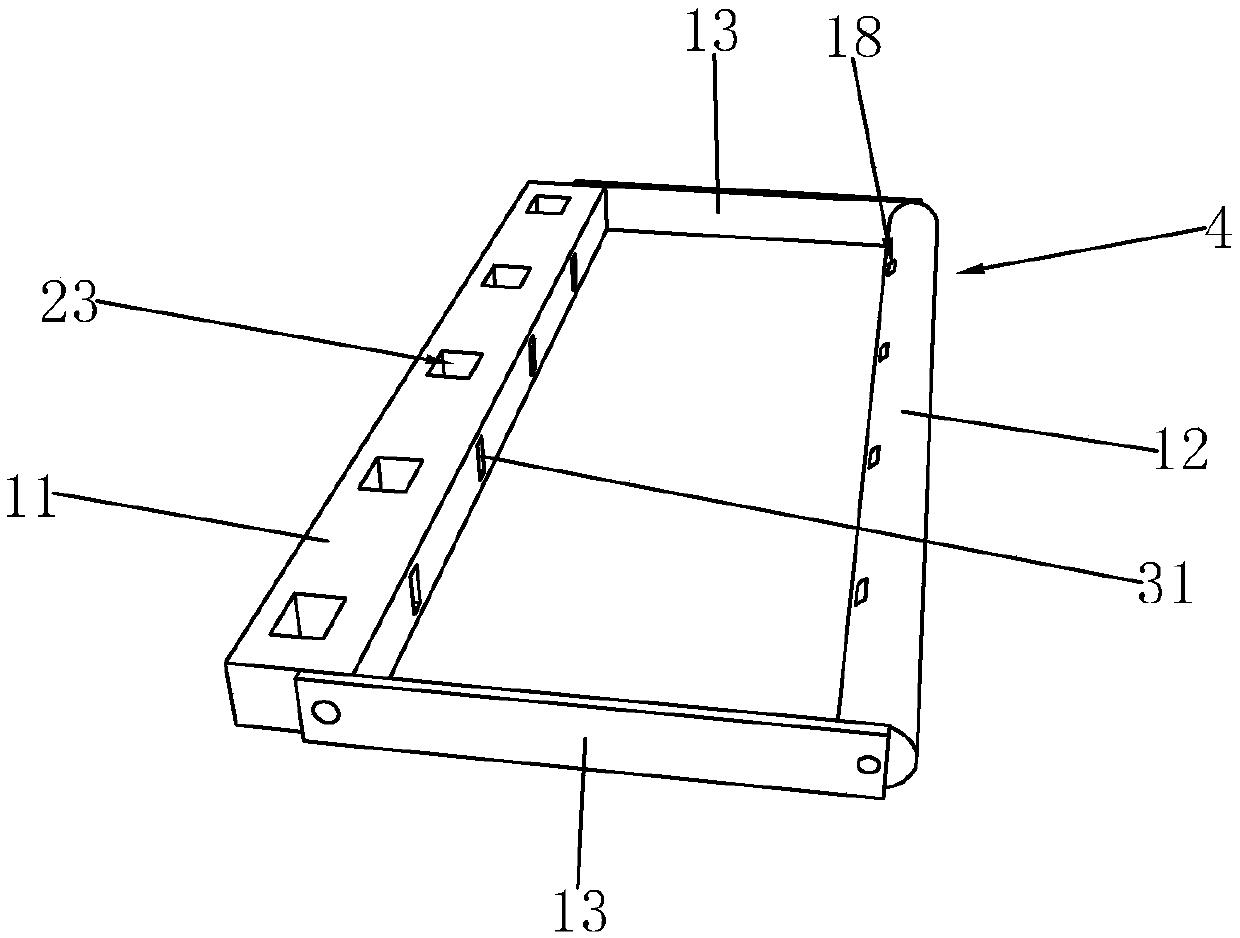

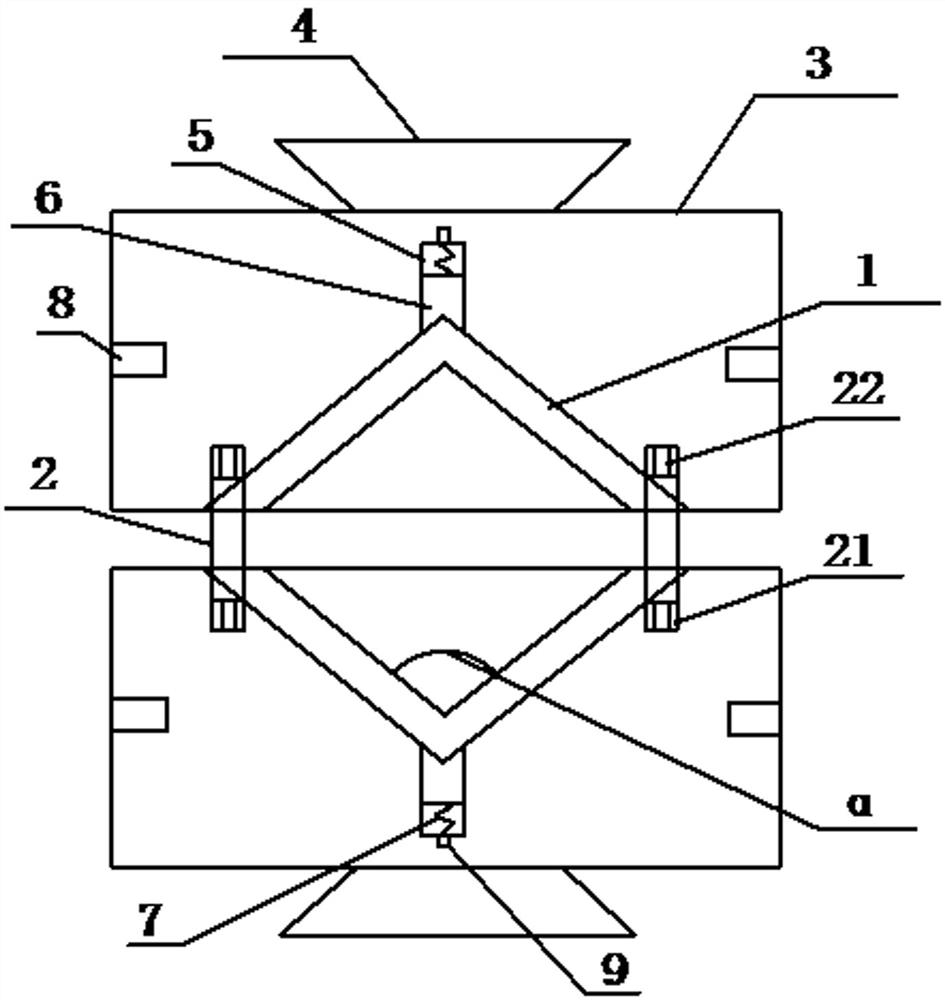

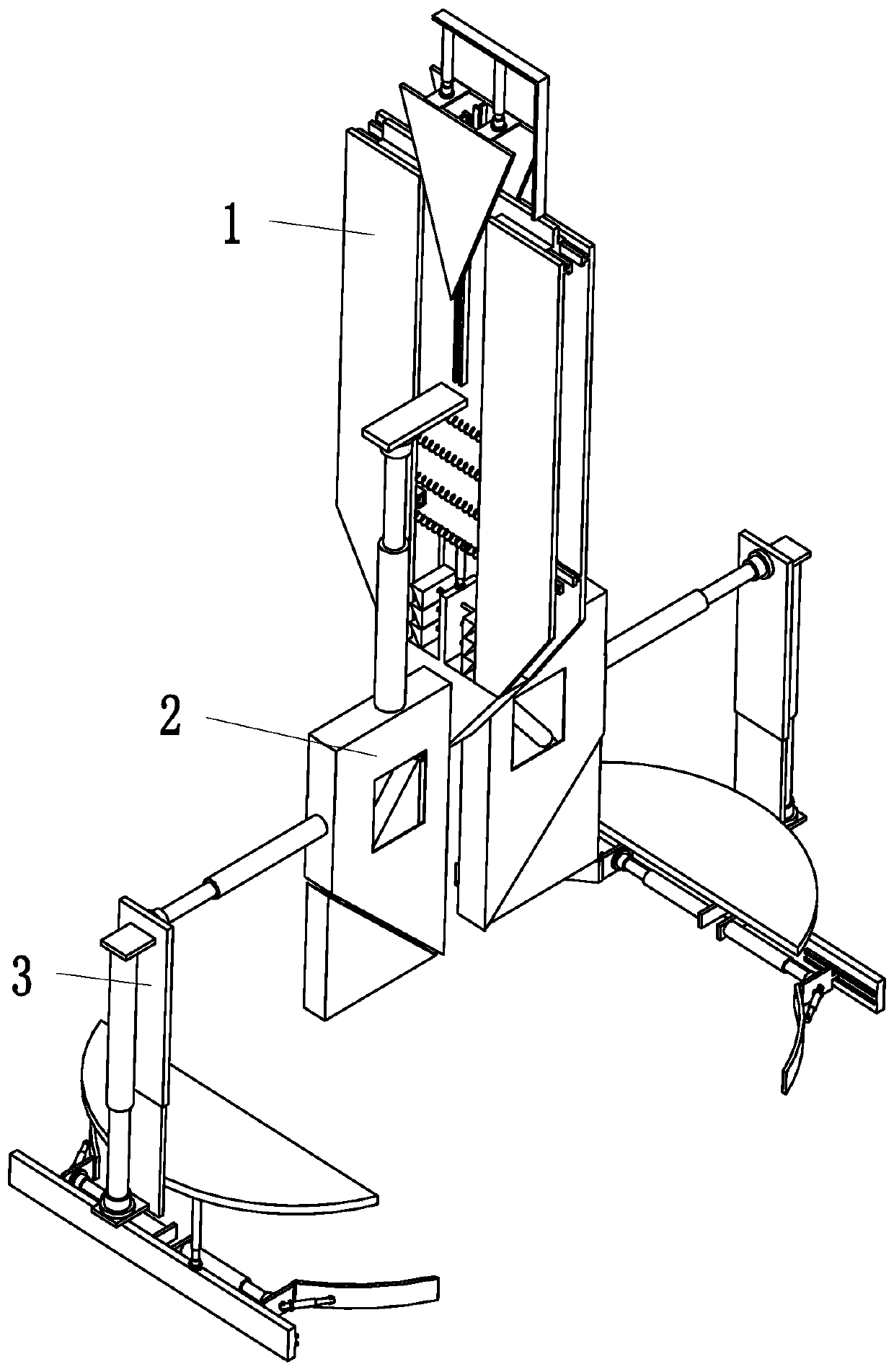

Seat recycling system for ejection tests

ActiveCN108033035ADoes not affect eccentricityRequirements that do not affect the ejection procedureAircraft ejection meansFinal product manufactureHuman bodyEngineering

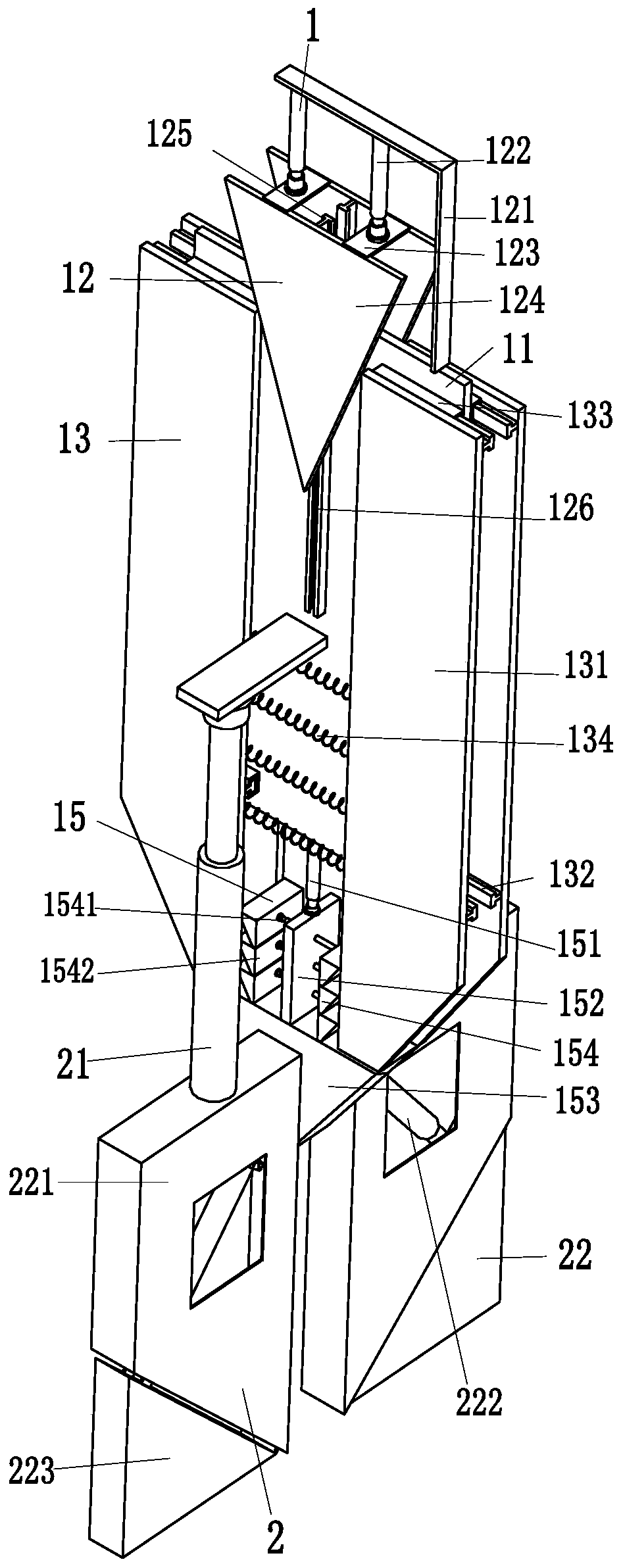

The invention discloses a seat recycling system for ejection tests. The seat recycling system for the ejection test comprises a recycling parachute (1), a hanging device (2), a life-saving box cover (27) in a seat bucket, a parachute sleeve and a packaging rope (26), wherein the hanging device (2) is installed on a seat, the parachute sleeve is sewn on packaging cloth on the inner side of the life-saving box cover and used for packaging the recycling parachute (1), the packaging rope (26) seals the packaging cloth of the life-saving box cover to realize the packaging of the recycling parachute(1) and connected to the bottom plate of the seat bucket, and the two ends of the parachute rope of the recycling parachute (1) extend from the rears of the left and right sides of the life-saving box cover (27) and are connected with the top end of the hanging device (2). According to the invention, the recycling parachute is installed in the space on the inner side of the seat chair and under the human body, so that the eccentricity of the seat cannot be influenced, and the test state and the actual use state can be highly fitted. The system can be used by matching with various situations of ejection tests, especially high-speed ejection tests, the state of the seat after ejection tests is basically complete, and the recovery success rate of the seat is high.

Owner:AEROSPACE LIFE SUPPORT IND LTD

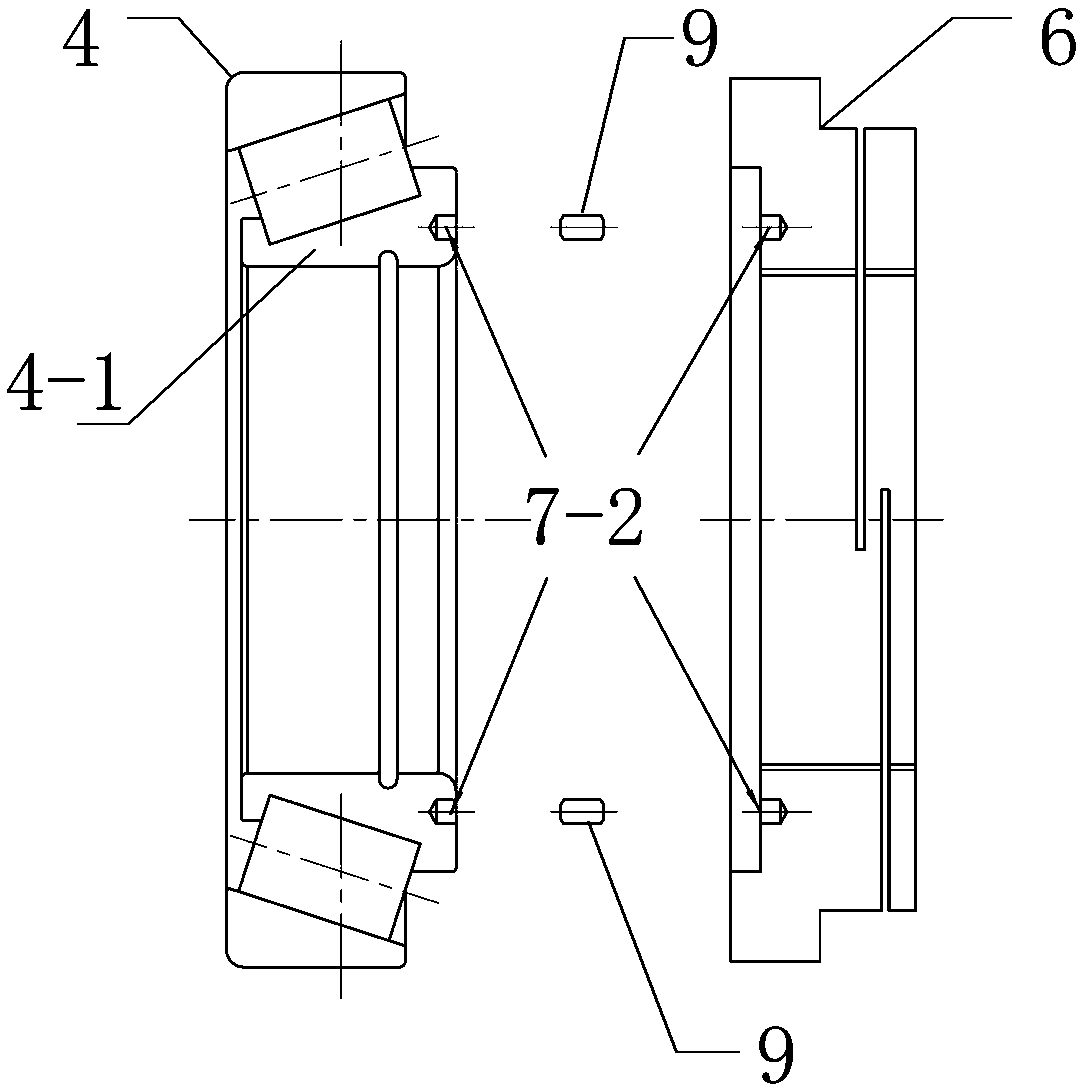

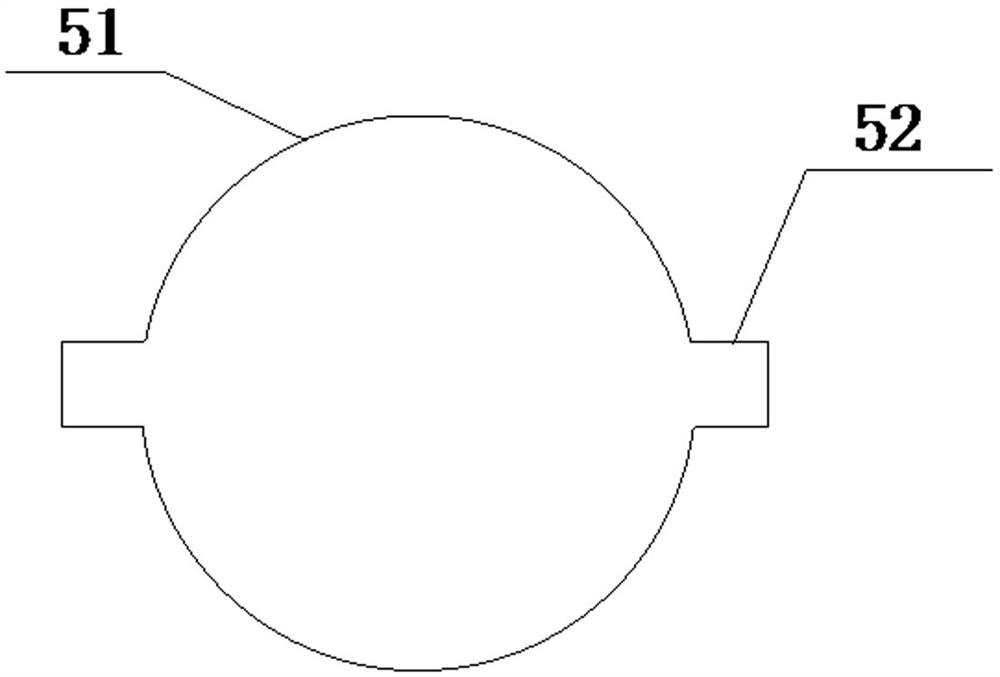

Inner ring stop mechanism of wheel hub bearing

PendingCN110594302AEasy to installEasy to disassemble and maintainHubsBearing unit rigid supportEngineeringMechanical engineering

The invention discloses an inner ring stop mechanism of a wheel hub bearing. The inner ring stop mechanism includes a shaft head with a limiting stepped surface and a wheel hub with a limiting steppedsurface. The wheel hub sleeves the shaft head through a wheel hub inner bearing and a wheel hub outer bearing arranged in an inner cavity of the wheel hub, and the wheel hub inner bearing is abuttedagainst the limiting stepped surface of the shaft head for limiting through a bearing race. The wheel hub outer bearing is locked and fixed by a locking nut, the bearing race and the shaft head are ininterference fit connection, an inner ring of the wheel hub inner bearing and an inner ring of the wheel hub outer bearing are in clearance fit connection with the shaft head, the inner ring of the wheel hub inner bearing and the bearing race limit the circumferential rotation of the wheel hub inner bearing relative to the shaft head through a circumferential limiting structure between the binding surfaces of the inner ring of the wheel hub inner bearing and the bearing race, and the inner ring of the wheel hub outer bearing and the locking nut limit the circumferential rotation of the wheelhub outer bearing relative to the shaft head through a circumferential limiting structure between the binding surfaces of the inner ring of the wheel hub outer bearing and the locking nut. The problems that the wheel hub bearings are difficulty in assembling and maintaining, the inner rings of the hub bearings are in clearance fit, clearance of the maintenance-free wheel hub bearings are unable tobe adjusted, and the requirement of the machining precision of parts is high are solved.

Owner:彭绍文

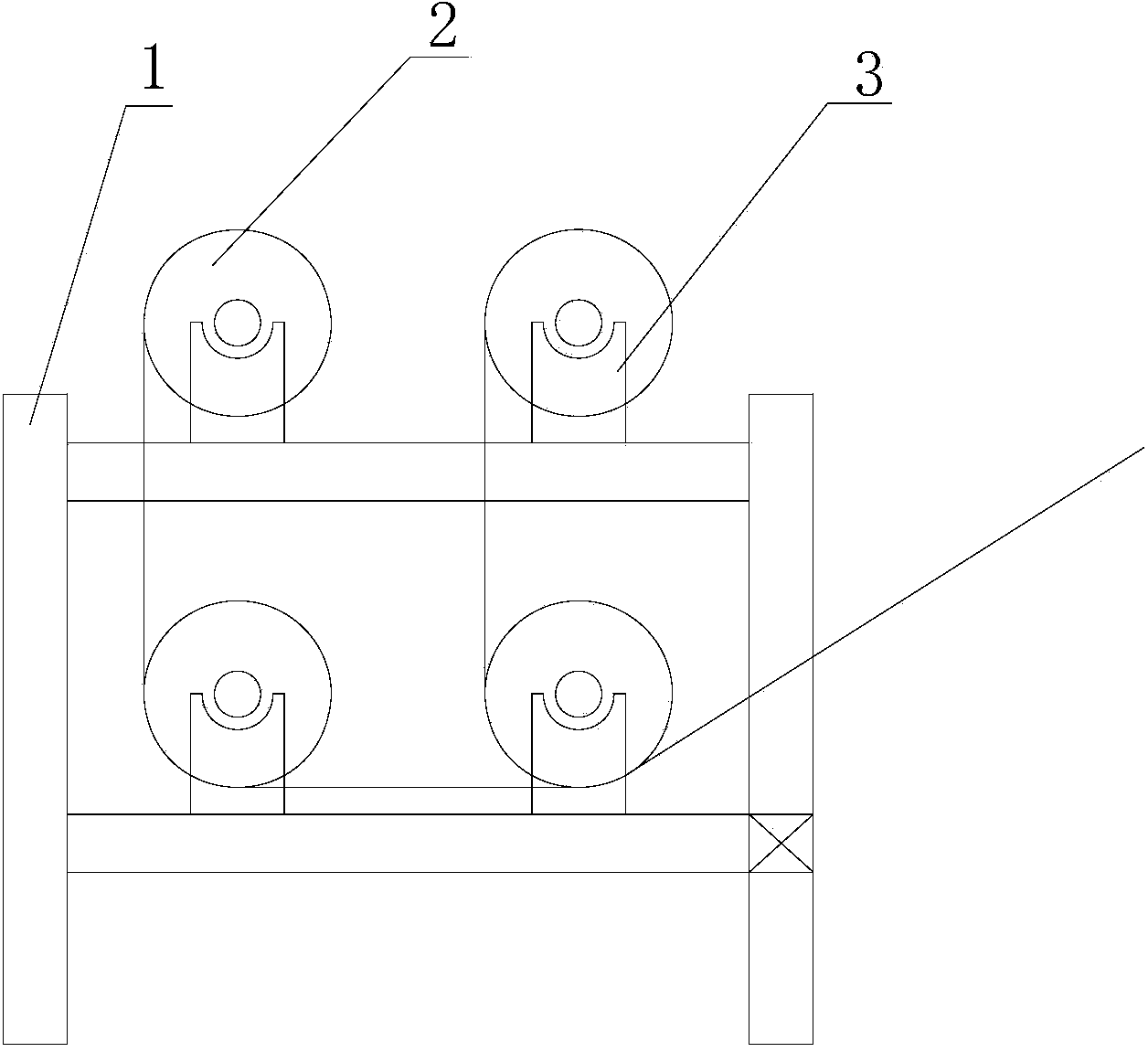

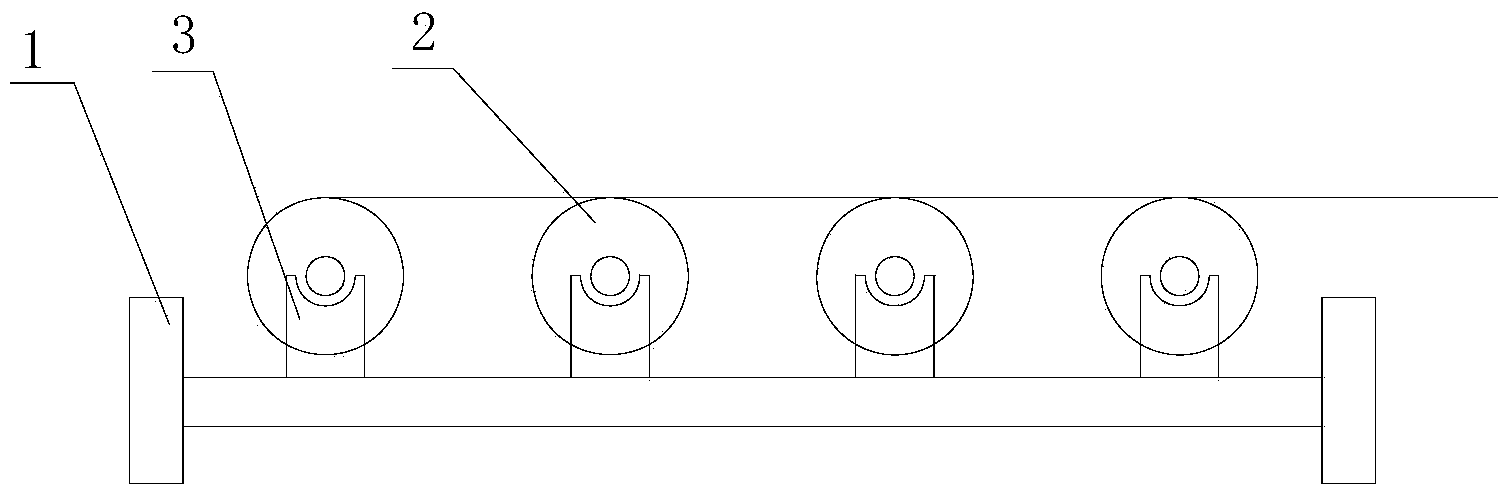

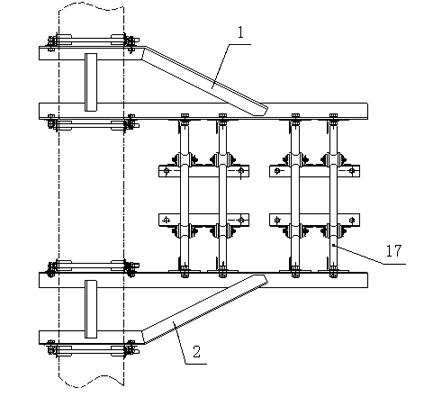

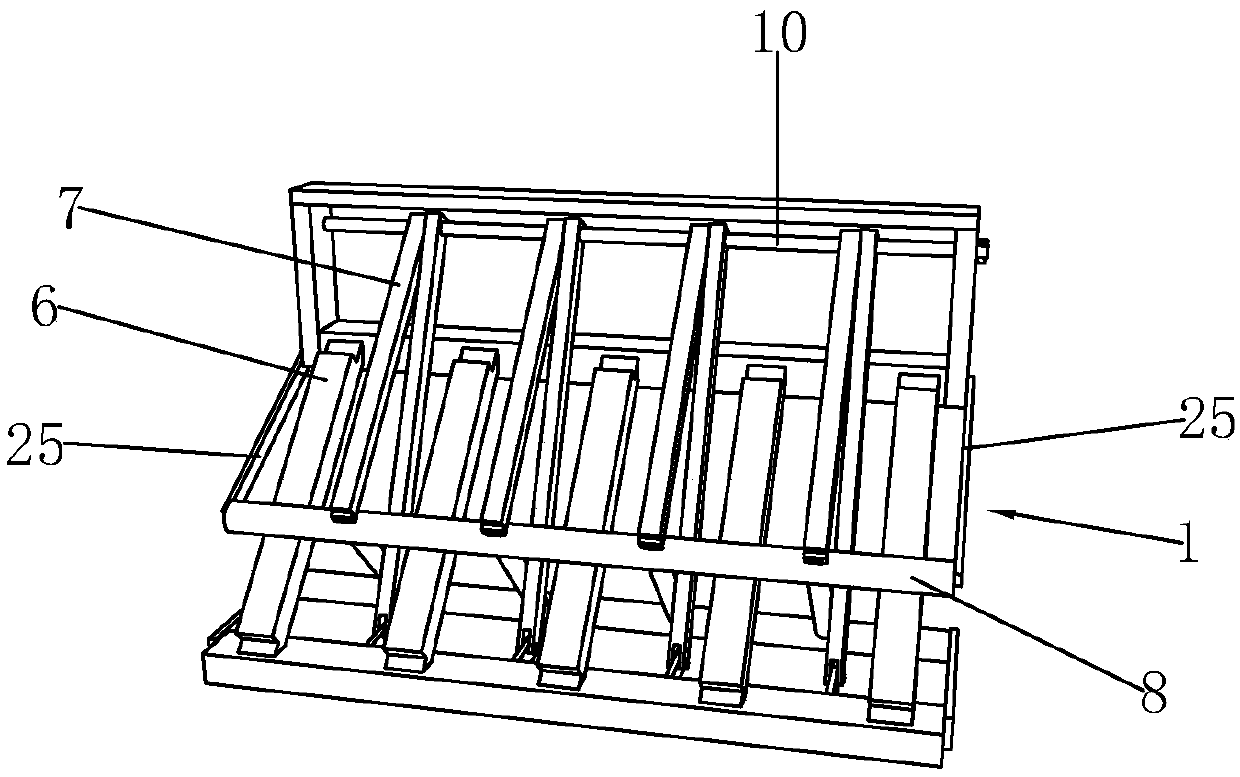

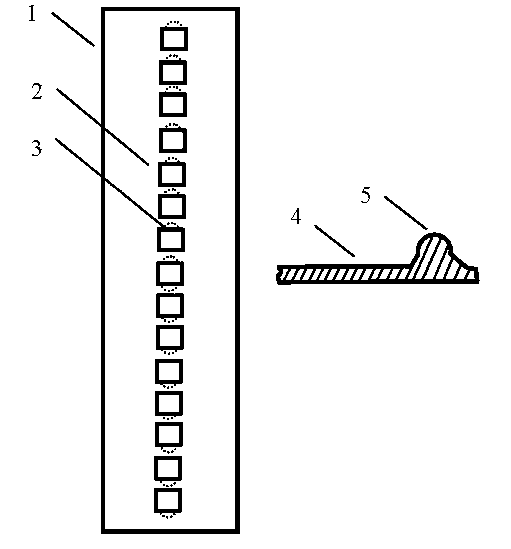

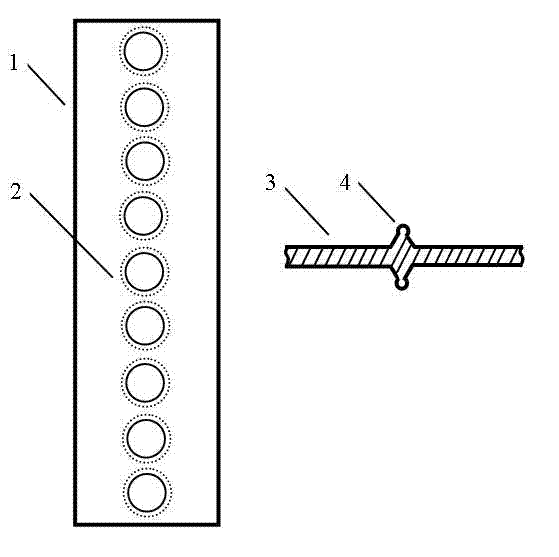

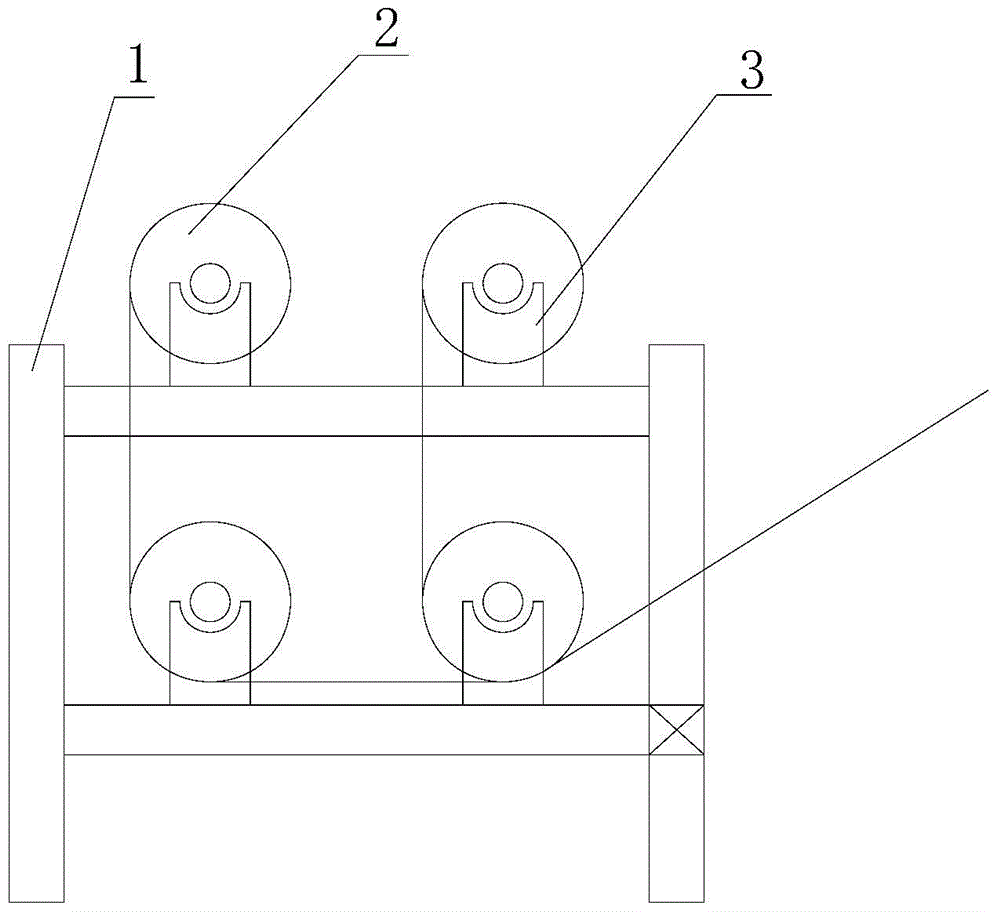

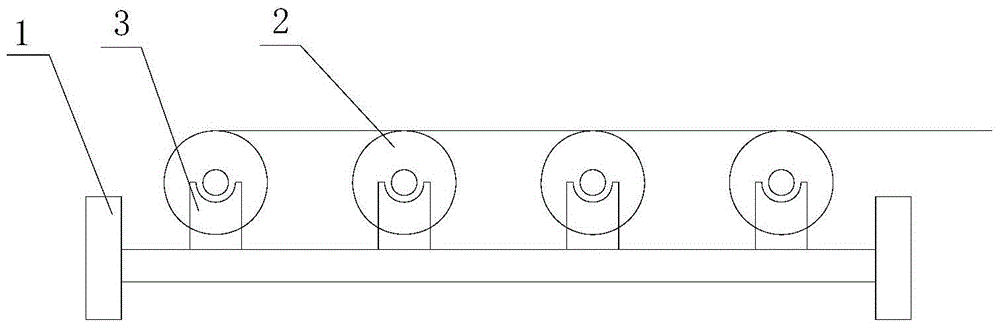

Slasher creel

The invention provides a slasher creel. According to the technical scheme, the slasher creel comprises a base and a plurality of pairs of rack bodies which are mounted on the base and are used for supporting warp beams. The pairs of rack bodies are arranged in the same plane in parallel, and the heights of the pairs of rack bodies are the same. According to the slasher creel, the rack bodies which are used for supporting the warp beams are arranged in the same plane in parallel, the heights of the rack bodies are the same, the distances between the warp beams can be effectively shortened compared with a traditional beam creel of an up-down layer structure in the first map, and warps can be effectively prevented from being twisted together. Through verification of experiments, under the condition that the wraps are wet (is not dried after dewatering), the condition of warp twisting does not happen, the drying step which has to be executed after warp dyeing is omitted, and production efficiency is improved. The slasher creel has the advantages that the distances of the warp beams can be effectively shortened, the warps can not be twisted together without being dried, the drying step is omitted, and the production efficiency is improved.

Owner:JIANGSU PINYTEX TEXTILE DYEING & FINISHING

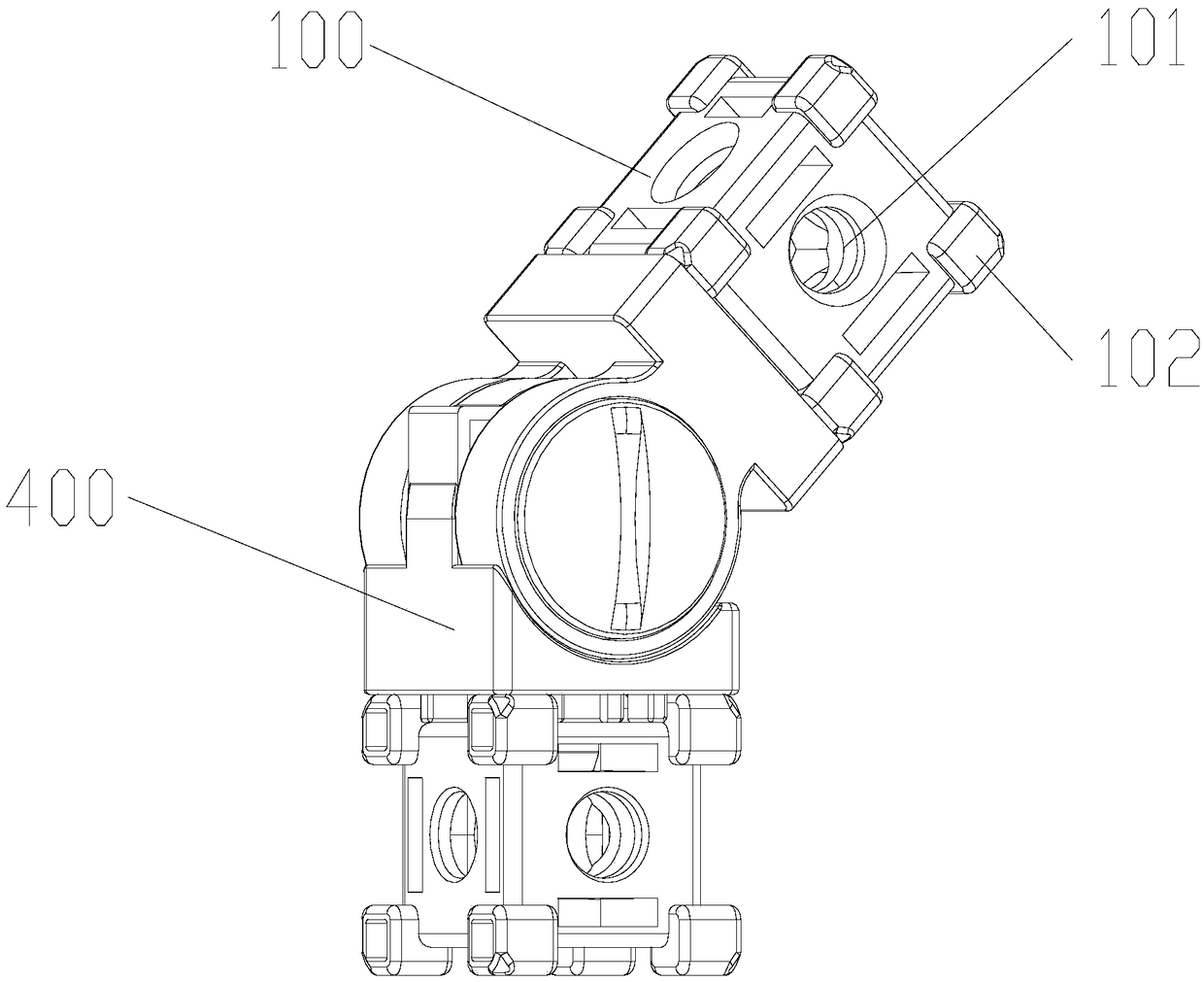

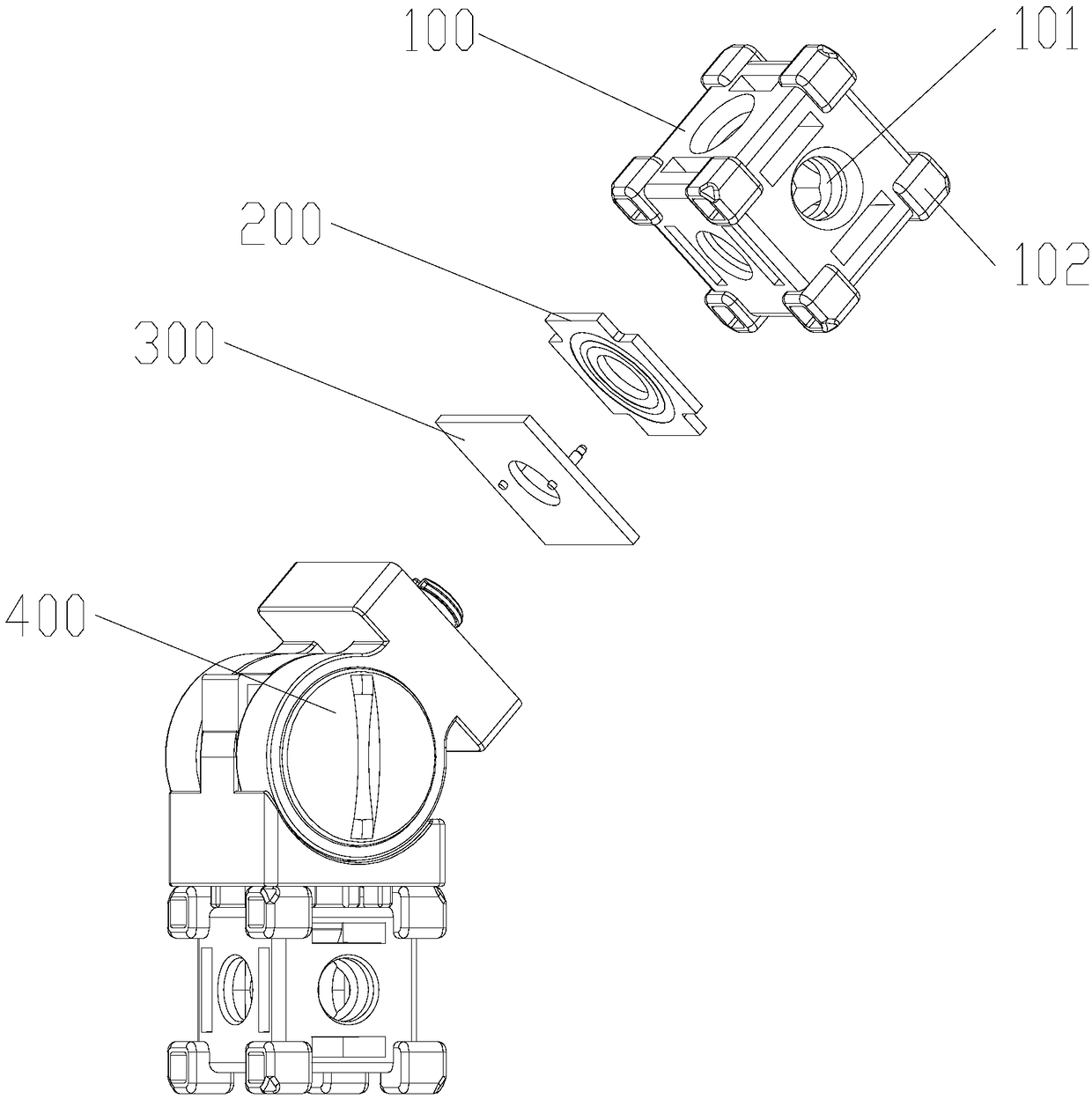

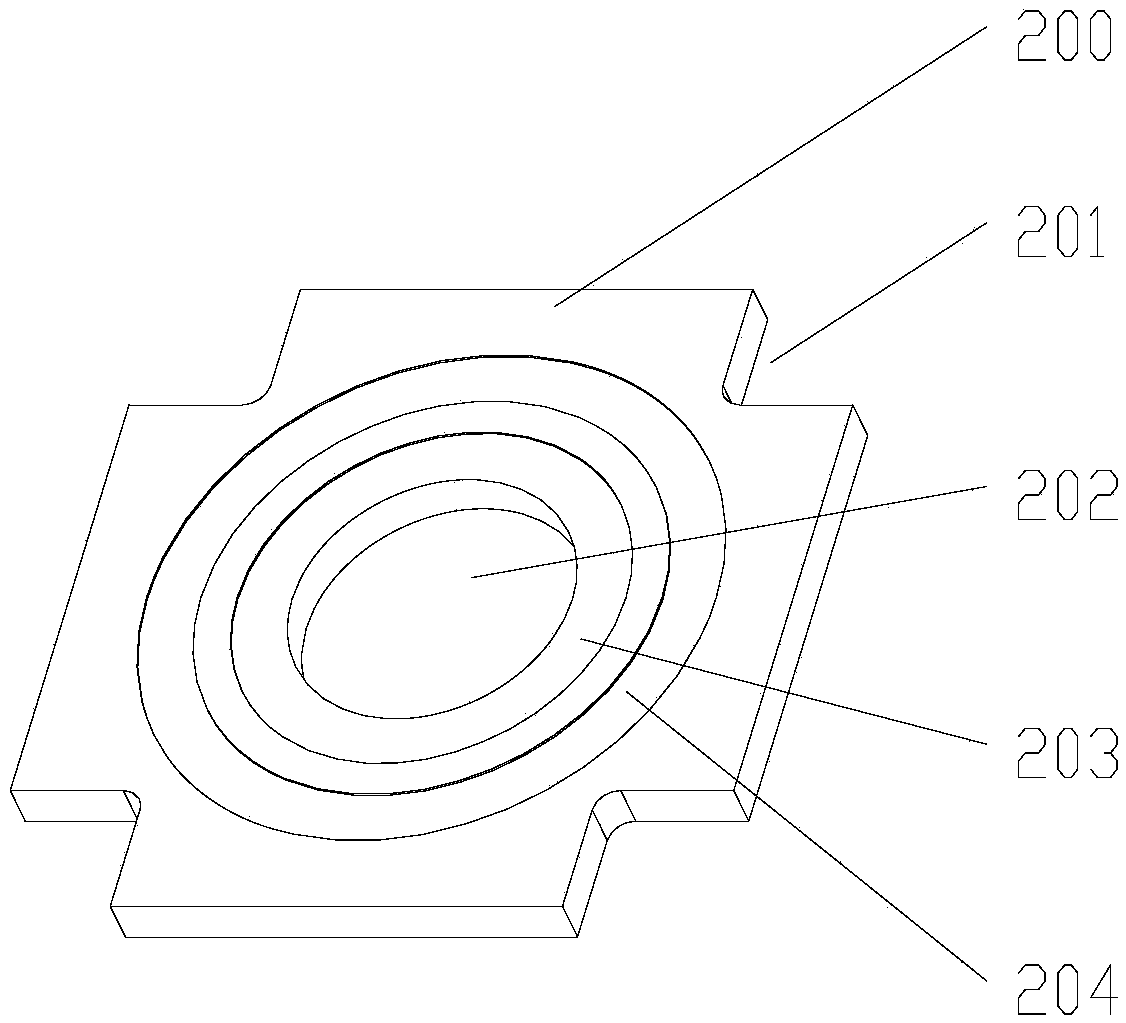

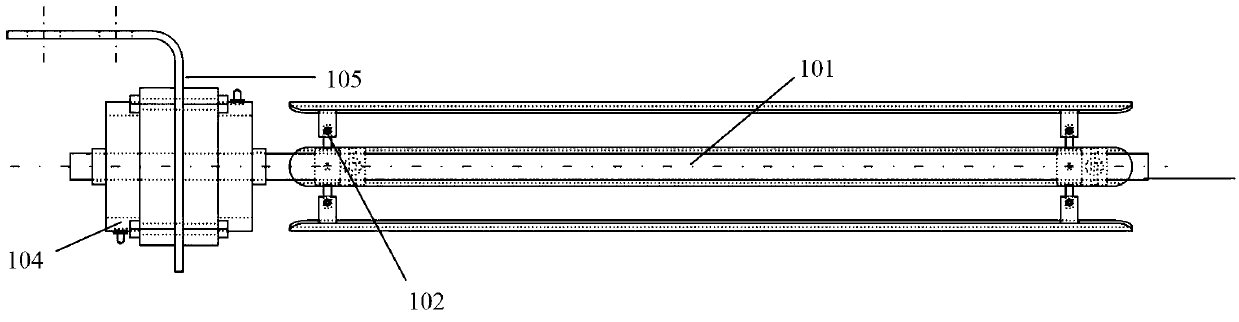

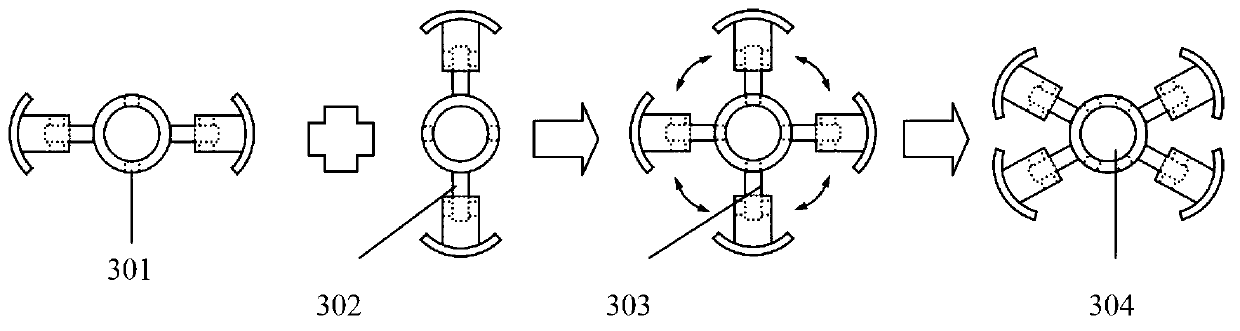

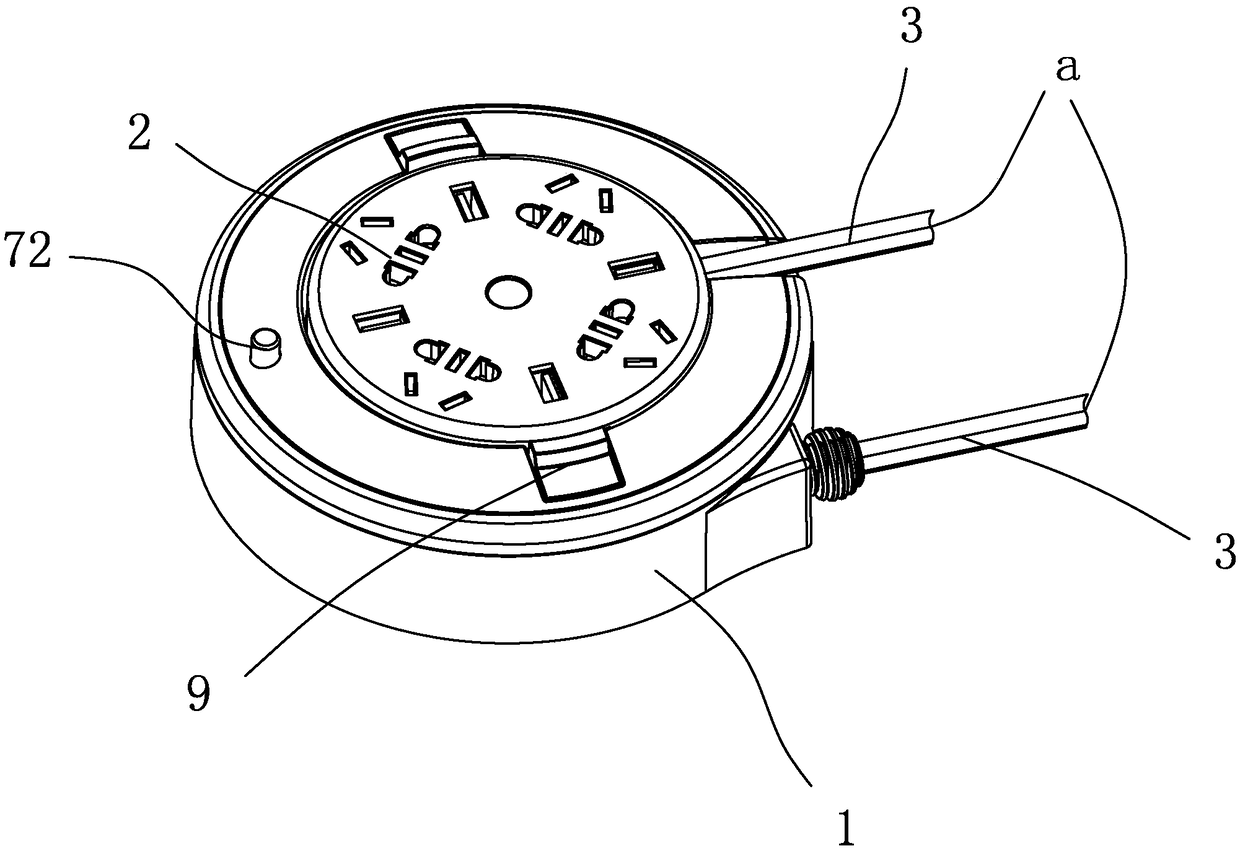

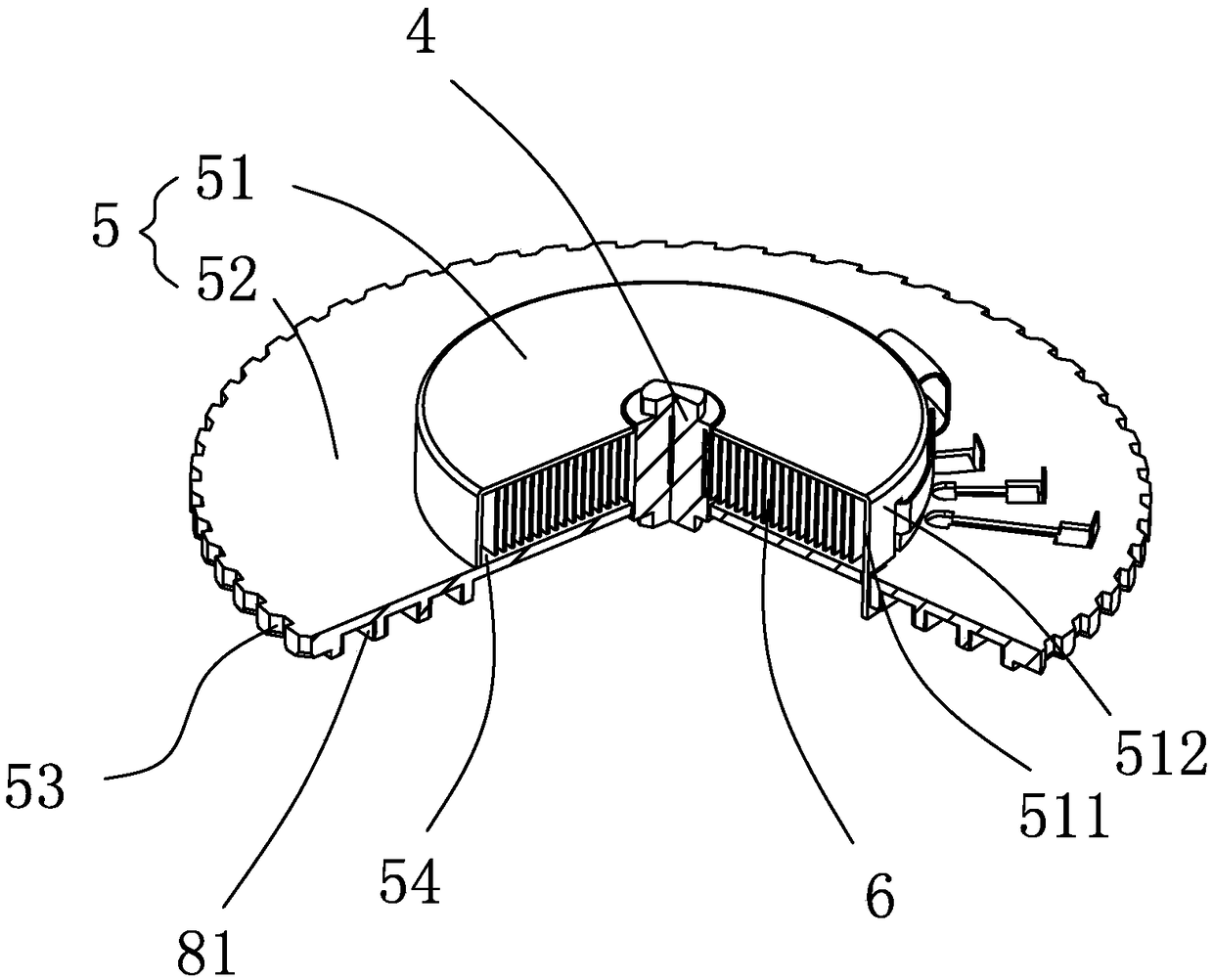

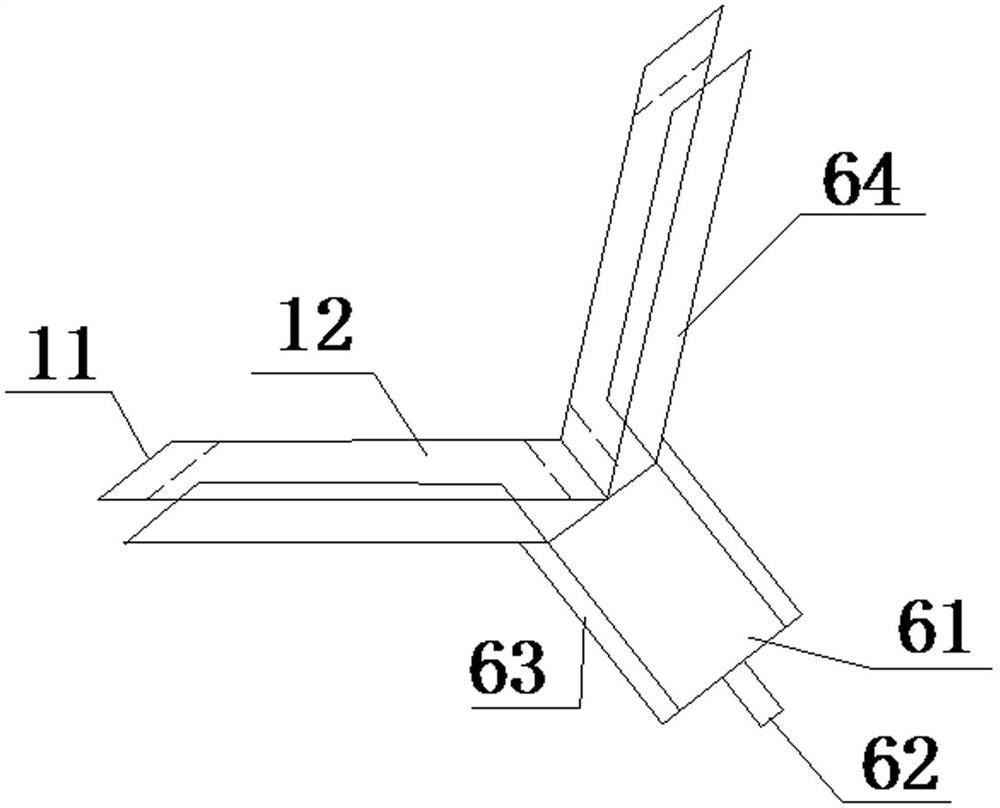

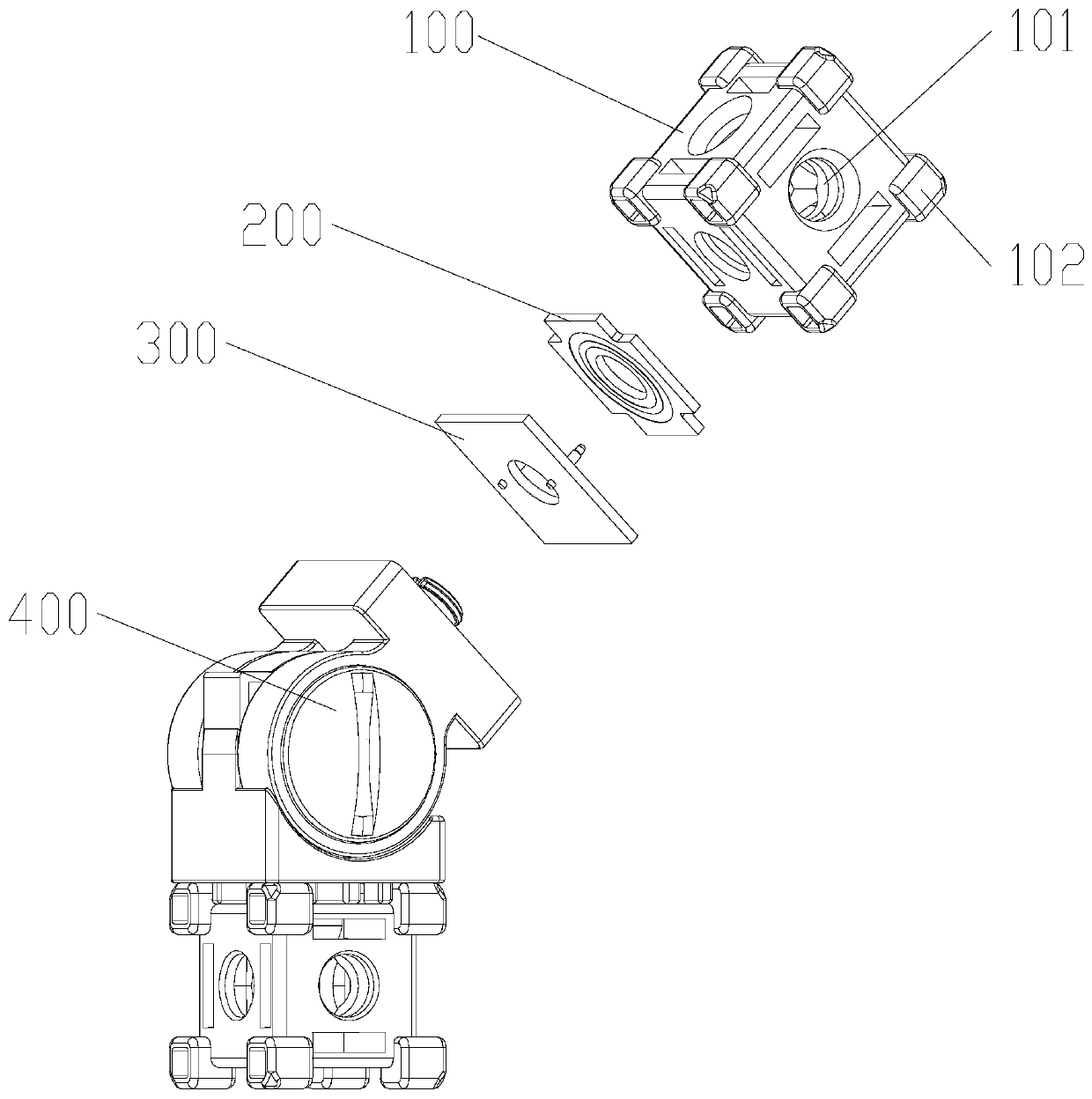

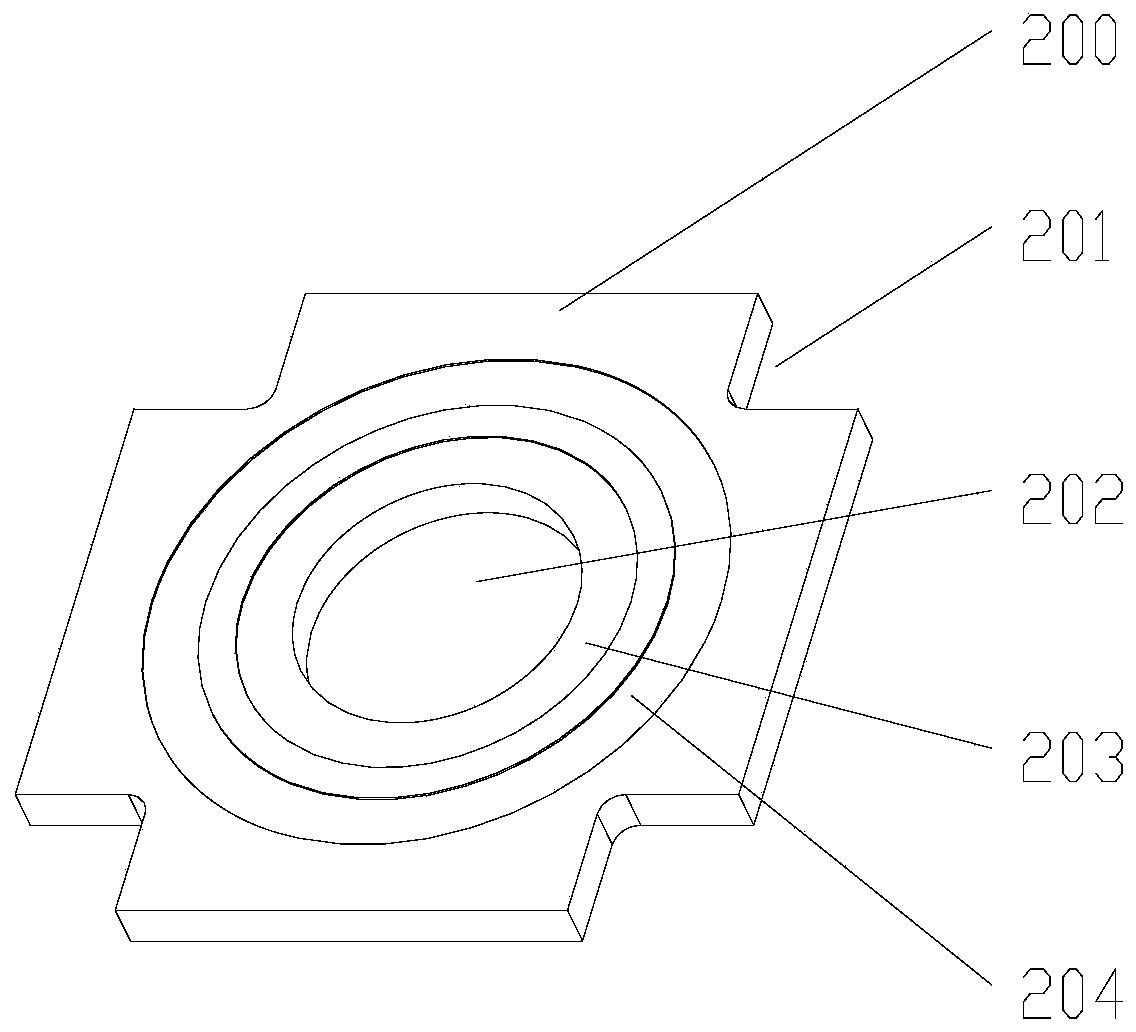

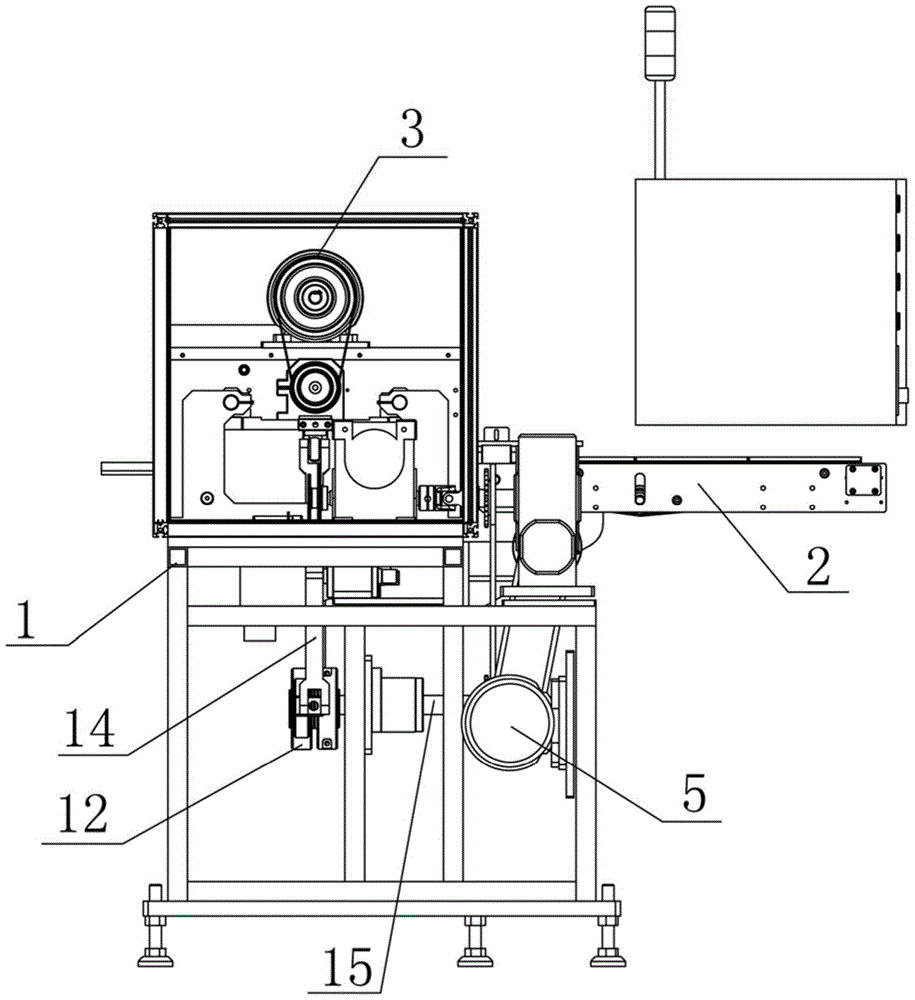

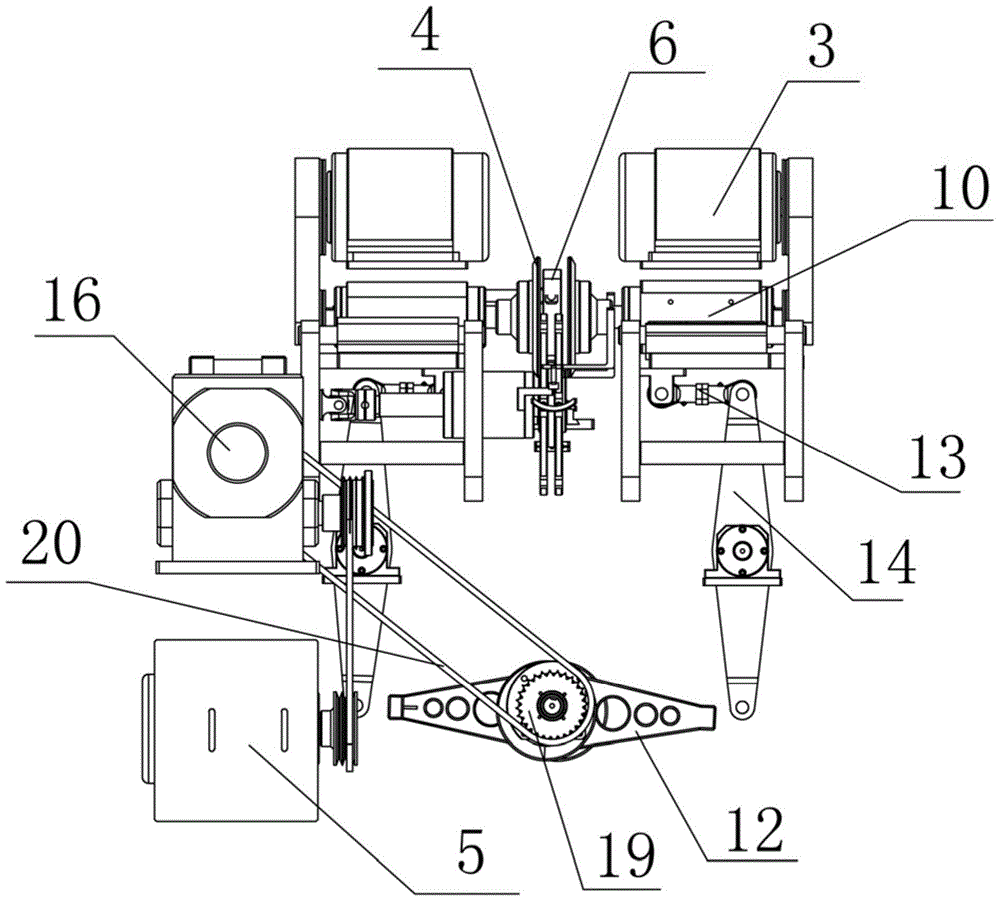

Assembled rotational conductive module

ActiveCN108767609AIncrease freedomEasy and convenient installationFlexible/turnable line connectorsConductive channelHinge angle

The invention discloses an assembled rotational conductive module and belongs to the technical field of modular products. The assembled rotational conductive module comprises a structure module, a first PCB, a second PCB and a hinge assembly, wherein a buckle is clamped into a buckle hole in an installation condition; the first PCB and the second PCB sleeve a guide post separately; a first conductive needle is propped against a first conductive channel; a second conductive needle is propped against a second conductive channel; the first PCB is clamped on the surface of the structure module; the second PCB is clamped into a clamping groove; and a wire is connected with an interface of the second PCB. When the structure module of the assembled rotational conductive module and the hinge assembly rotate relatively, the conductive needles can be always propped against the corresponding conductive channels, thereby achieving conductive transmission at an arbitrary angle. The conductive needles and the corresponding conductive channels are connected in a sliding manner, thereby overcoming the problems that an internal wire of a rotating shaft is wound and is easily broken in the prior art. The hinge assembly can rotate back and forth in a hinge plane, and furthermore, the structure module can freely rotate around the guide post, so that the assembled rotational conductive module is great in degree of freedom, and stable conduction can be achieved while multi-angle structure connection is achieved.

Owner:HUNAN YUEGANG MOOKRAY IND CO LTD

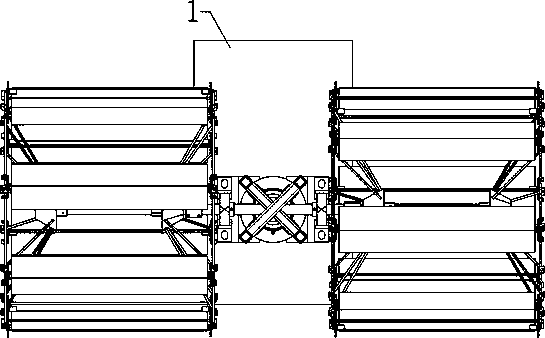

Yarn reversing device suitable for inner drawn bobbins

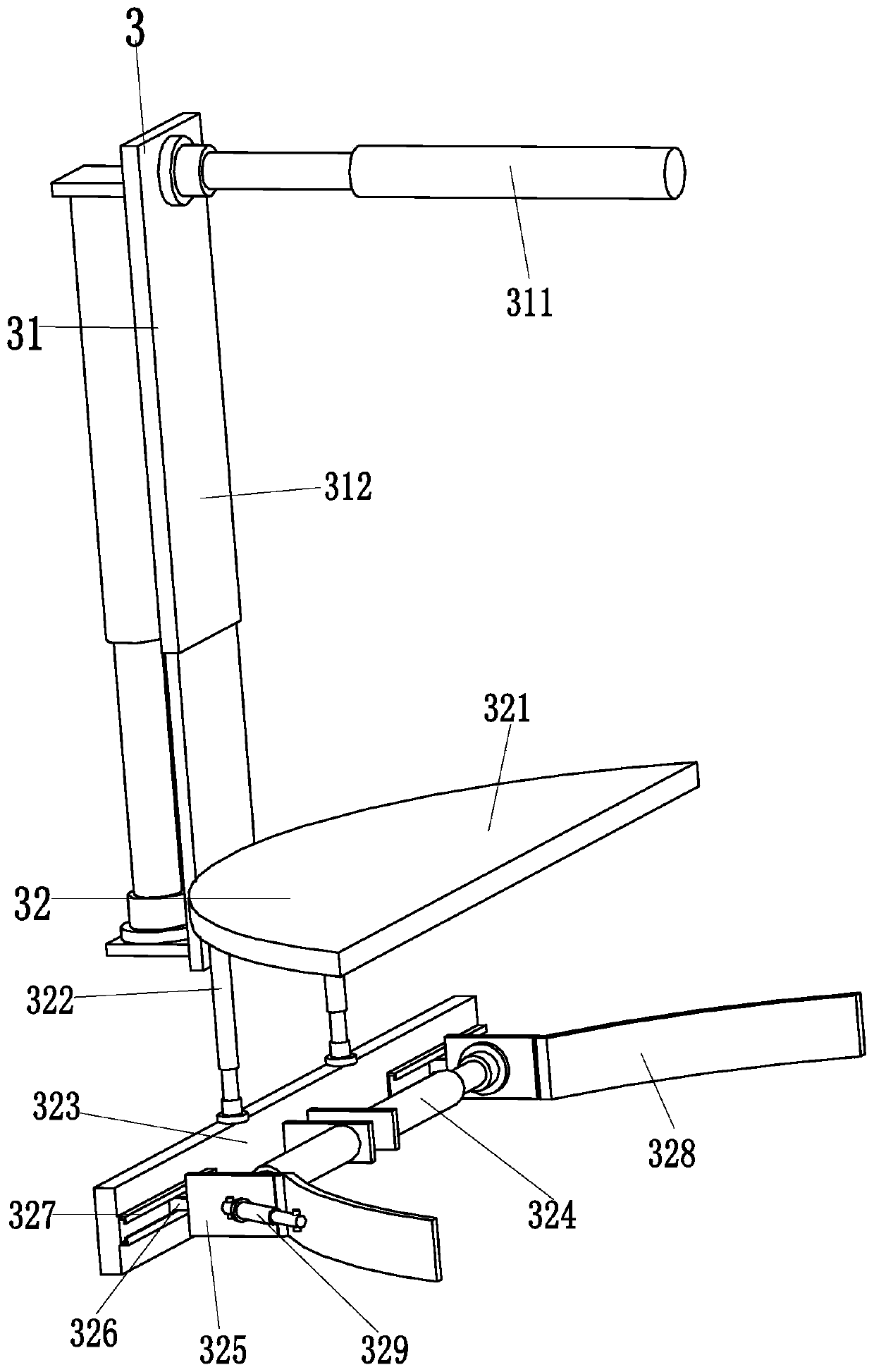

The invention discloses a yarn reversing device suitable for inner drawn bobbins. The device comprises a mounting support, two groups of inner supports, a main shaft and a bearing seat, wherein the mounting support provides mounting hole sites for components in the device; the inner supports clamp the bobbins in various shapes from the inner sides of the bobbins so as to ensure that the bobbins do not slide relatively in a rotating process of reverse winding; the two groups of inner supports are arranged on the main shaft which serves as a rotating shaft of the whole device; and the main shaft is installed and fixed on the bearing seat, so that friction produced in the rotating process of the main shaft is reduced, and the main shaft is connected with the mounting support together. By virtue of the device, the twisting phenomenon produced in the yarn reversing process of the inner drawn bobbins can be avoided, yarns can be uniformly guided away the bobbins without curling, and the quality of the yarns in the yarn reversing process is ensured.

Owner:SHANGHAI JINWEI HIGH PERFORMANCE FIBER

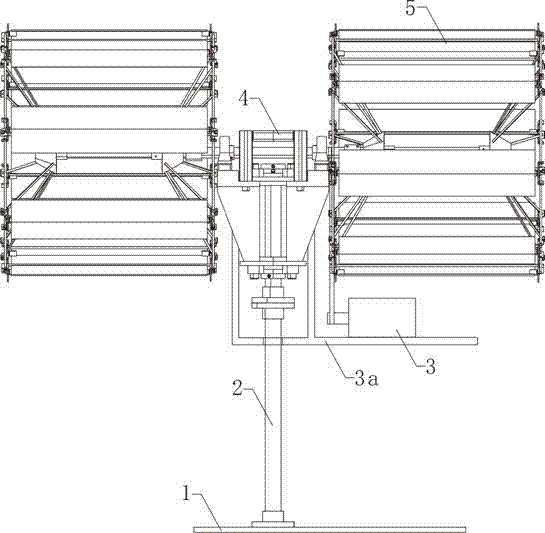

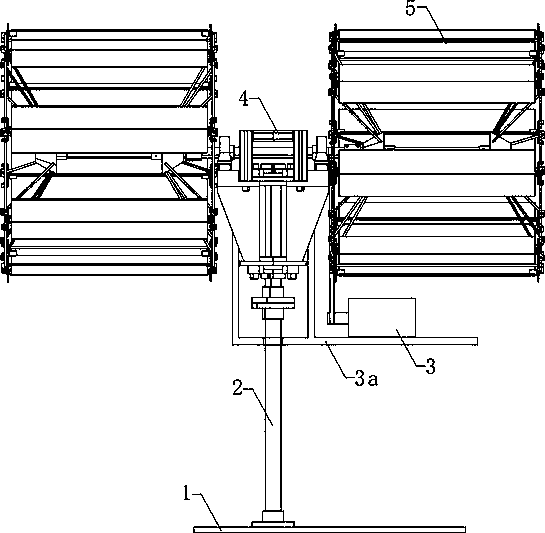

Rotary electric winding device for textiles

The invention discloses a rotary electric winding device for textiles. The winding device comprises a base, a supporting rod, a rotating motor, a roller supporting and rotating mechanism, winding roller mechanisms and a roller supporting and rotating spindle. By improving and providing the rotary electric winding device for textiles, the winding work can be automatically performed; and the winding speed is regulated by the rotating motor, so that the labor time of a worker is saved, and the economic benefits of textile enterprises are increased. When the rotary electric winding device is used, the rotating motor rotates to drive the roller supporting and rotating spindle to rotate by virtue of a chain, the roller supporting and rotating spindle drives the winding roller mechanisms at two sides to rotate, so that the normal winding work is realized; and the roller supporting and rotating mechanism can drive the winding roller mechanisms to realize horizontal rotation in the use process, so that the winding space and range are increased.

Owner:河北南冠科技有限公司

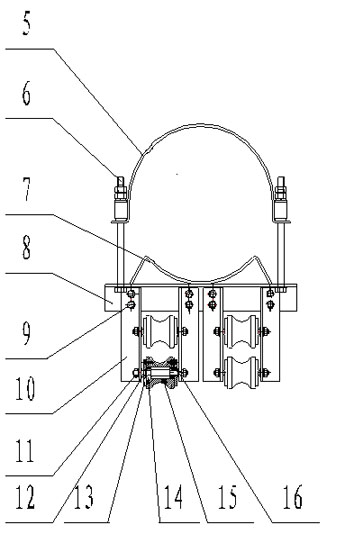

Design method of wind-proof anti-theft weight restraint bracket

InactiveCN101941388AGood fixed effectReduce frictional resistanceTrolley linesRope railwaysClassical mechanicsFrictional resistance

The invention relates to a weight restraint bracket, in particular to a design method of a wind-proof anti-theft weight restraint bracket. The invention is characterized in that the weight restraint bracket comprises guide pulleys, one end of a weight fixing frame is provided with an anchor ear of the weight fixing frame, the other end thereof is the body of the weight fixing frame, the M-shaped anchor ear is welded on the body of the weight fixing frame, and both ends of the anchor ear of the weight fixing frame are fixed at both ends of the body of the weight fixing frame by bolts; and two groups of parallel guide pulley angle cleats are vertically fixed on the body of the weight fixing frame by bolts, two parallel guide pulleys are vertically connected between the two parallel guide pulley angle cleats of each group, and a gap is formed between the two guide pulleys. The weight restraint bracket of the invention overcomes the problems of oscillation, impact, clamping stagnation, deflection and the like of the weight restraint bracket in a strong wind area, and simultaneously changes the sliding friction between the anchor ear of the weight and the restraint pipe into rolling friction, thereby reducing the friction resistance.

Owner:周建科

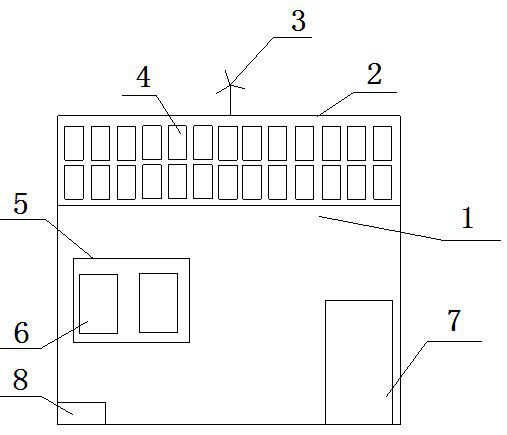

Fabricated green building structure

ActiveCN111794430APlay a supporting roleEnsure stabilityBuilding roofsRoof covering using slabs/sheetsSolar batteryMechanical engineering

The invention discloses a fabricated green building structure. The fabricated green building structure comprises a wall frame, a triangular prism roof is fixed to the top of the wall frame, a plurality of solar panels and a wind turbine generator are installed on the side of the triangular prism roof, and a window and a door are installed on the wall frame. The triangular prism roof comprises twoisosceles triangular frames with symmetrical arrangement, the isosceles triangular frames comprise bottom frames and two isosceles frames, the two isosceles frames are connected through semicircular elastic parts, side midpoints of outer arcs of the semicircular elastic parts and the bottom frames are connected in a pressed mode, and side midpoints of inner arcs of the semicircular elastic parts and connecting parts are connected in a pressed mode. Arc protrusions are arranged on the bottom surfaces of the connecting parts, the arc protrusions are connected with the side midpoints of the innerarcs of the semicircular elastic parts in a pressed mode, one ends of vertical rods are connected with vertexes of the isosceles triangular frames, and the other ends of the vertical rods are connected with the top surfaces of the connecting parts. One ends of inclined rods are connected with midpoints of the isosceles frames, and the other ends of the inclined rods are connected with the top surfaces of the connecting parts. The fabricated green building structure can overcome the deficiency of the prior art and meet the seismic requirements of a prefabricated green building.

Owner:中建五局华南建设有限公司

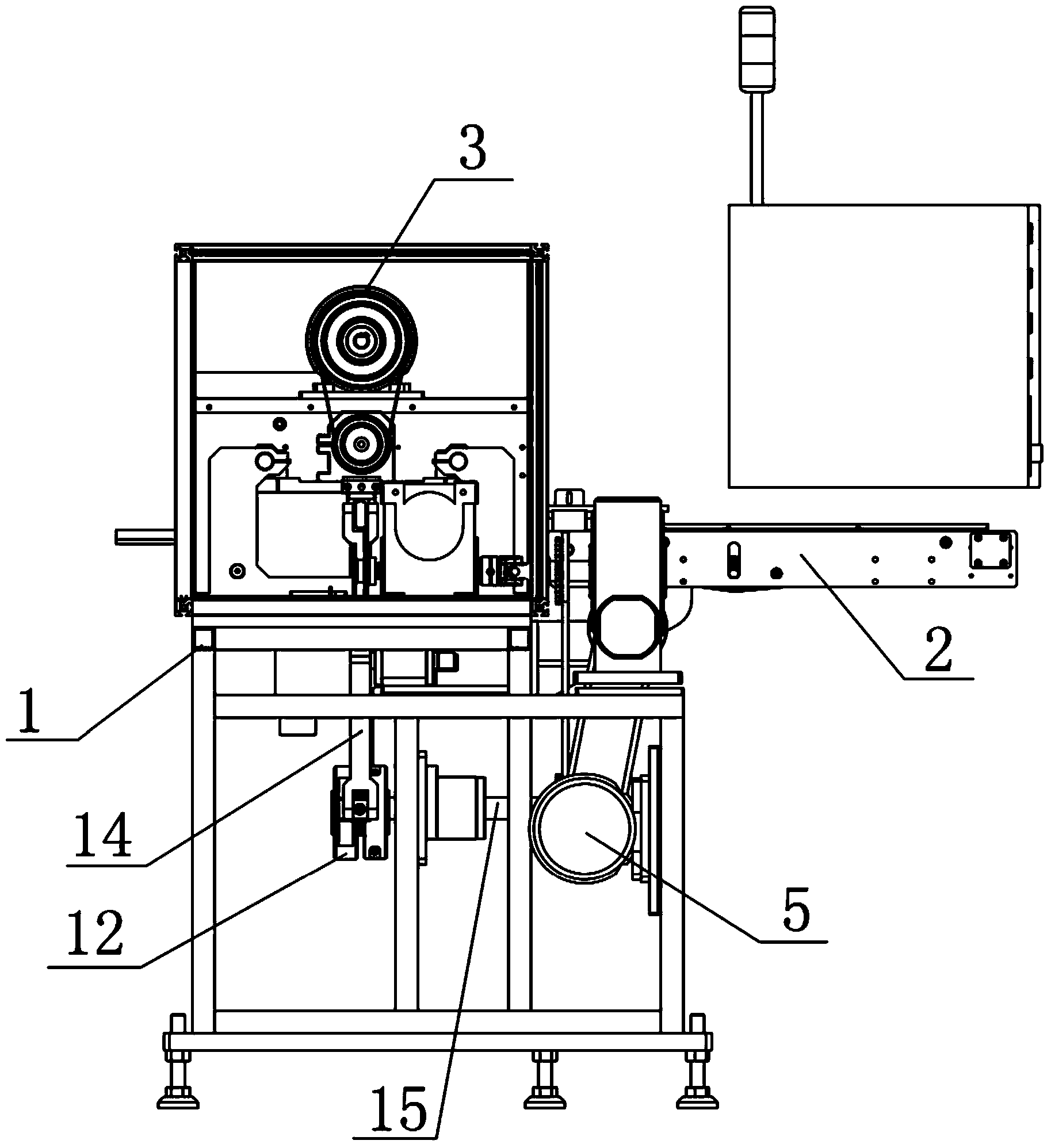

Chord grinding machine

The invention discloses a chord grinding machine. The chord grinding machine comprises a machine frame, a guide rail, two grinding wheels, a drive mechanism and a chuck, wherein the two grinding wheels are driven by a first motor, the drive mechanism is used for driving the two grinding wheels to horizontally move, the chuck is arranged on the machine frame through a rotary shaft and is driven by a servo motor to rotate, an annular groove is formed in the outer circumferential surface of the chuck, one or more working grooves penetrating through the two bottom faces of the chuck are formed in the edge of the chuck in the axial direction, the depth of the working grooves is smaller than that of the annular groove, the chuck is arranged between the two grinding wheels and is parallel with the two grinding wheels, the position where each grinding wheel is located on the machine frame is higher than the position where the chuck is located on the machine frame, the height of the bottommost end of each grinding wheel is smaller than that of the topmost end of the chuck, the guide rail is composed of a front guide rail section and a rear guide rail section, and the chuck is located between the front guide rail section and the rear guide rail section. The chord grinding machine has the advantages that in the process that the grinding wheels grind tile-shaped magnets, the positions of the tile-shaped magnets are fixed relatively, and the tile-shaped magnets will not twist in the grinding process, so that form and location tolerance is avoided.

Owner:德昌电机(南京)有限公司

Non-shaking compound pendulum starting device

InactiveCN101644784ANo twistingImprove accuracyEducational modelsGravitational wave measurementEngineeringScrew thread

The invention relates to an experimental instrument, in particular to a non-shaking compound pendulum starting device. The non-shaking compound pendulum starting device comprises a knob, a fixing clip, a slide way upper clip, a chock block, a slide way lower clip, a bracket, a handle, a rotating wheel, a rotating handle, a slide strip, a chock strip and snap rings. The upper end of the bracket isprovided with the fixing clip with the side face in an F shape. The right end of the slide strip is provided with the horizontal chock strip which is vertical to the slide strip and has a rectangularsection. A part of the rotating handle positioned between the slide way upper clip and the slide way lower clip is provided with screw threads. The outer end of the rotating handle and the rotating wheel are coaxial and are formed into a whole, and the edge of the rotating wheel is provided with the handle integrated with the rotating wheel into a whole. In the invention, a swing rod can be ensured not to twist in the process of swinging, the experimental error caused by tremor is avoided, and the accuracy of the experimental results is enhanced.

Owner:启东兴源生态有机肥料有限公司

A rotary electric winding device for textile

The invention discloses a rotary electric winding device for textiles. The winding device comprises a base, a supporting rod, a rotating motor, a roller supporting and rotating mechanism, winding roller mechanisms and a roller supporting and rotating spindle. By improving and providing the rotary electric winding device for textiles, the winding work can be automatically performed; and the winding speed is regulated by the rotating motor, so that the labor time of a worker is saved, and the economic benefits of textile enterprises are increased. When the rotary electric winding device is used, the rotating motor rotates to drive the roller supporting and rotating spindle to rotate by virtue of a chain, the roller supporting and rotating spindle drives the winding roller mechanisms at two sides to rotate, so that the normal winding work is realized; and the roller supporting and rotating mechanism can drive the winding roller mechanisms to realize horizontal rotation in the use process, so that the winding space and range are increased.

Owner:河北南冠科技有限公司

A kind of supporting arch used for ancient building covered bridge and its construction method

ActiveCN107044088BSimple structureFlexible connectionBridge erection/assemblyArchitectural engineeringEngineering

The invention discloses a support scaffold for an ancient building gallery bridge and a construction method of the support scaffold. The support scaffold comprises support base frames, support connecting rods and a reinforcing plate, the reinforcing plate is arranged between the support connecting rods, and the support connecting rods are arranged between the support base frames; and each support base comprises a base, first arch ribs, second arch ribs, third arch ribs, a beam frame, a support transverse frame and a support rod, the first arch ribs are arranged between the base and the beam frame, the second arch ribs are arranged between the base and the support transverse frame, the third arch ribs are arranged between the beam frame and the support rod, and the support rod penetrates through the support transverse frame. The construction method comprises the following steps of (a) clearing a workyard; (b) constructing a frame; (c) assembling the support base frames; (d) reinforcing; and (e) monitoring. According to the support scaffold for the ancient building gallery bridge and the construction method of the support scaffold, connecting of the support scaffold is flexible, disassembling and assembling are convenient, repairing is convenient, the anti-load capacity is high, the steadiness and the endurance are achieved, the construction method is simple, the construction period is short, the construction quality is easy to control, transportation of materials is convenient, and the construction cost is low.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

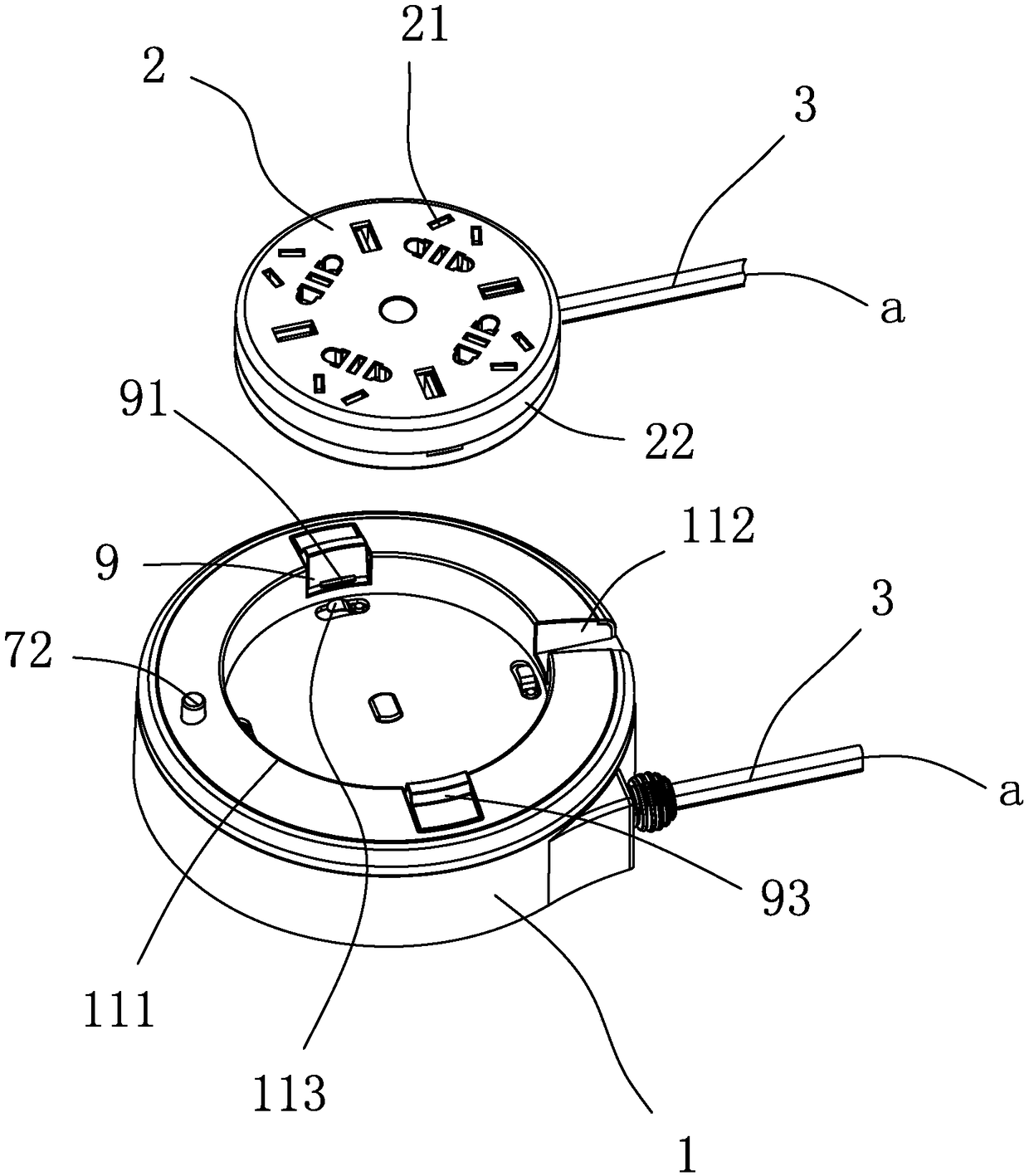

Wall socket

PendingCN109088284AEasy to locate and installInstallation positioningTwo-part coupling devicesCoupling parts mountingCoil springEngineering

A wall socket including a base, a socket head and a wire, the socket head is detachably connected with the base, one end of the wire is electrically connected with the socket head, the other end of the conductor is arranged in the base, a socket is arranged on the socket head, the base comprises an inner cavity, the inner cavity is provided with a shaft and a rotating member rotatably arranged onthe shaft, the other end of the conductor is fixed and wound on the rotating member, a guide hole is arranged on the base, a coil spring is arranged between the rotating member and the shaft for returning the rotating member after rotating, ratchet teeth are uniformly arranged in the circumferential direction of the rotating member, a pawl elastically pressed on the ratchet teeth and an operationbutton for controlling the pawl to be away from the ratchet teeth are arranged on the base, and the pawl can prevent the rotating member from returning when the ratchet teeth are in conflict with eachother. As the wall socket of the invention can position the wire at any retract position when the socket head is taken out for use, the structure is simple, the problem of wire winding and knotting is not liable to occur, and the use is more convenient.

Owner:WENZHOU BODEN ELECTRIC APPLIANCE

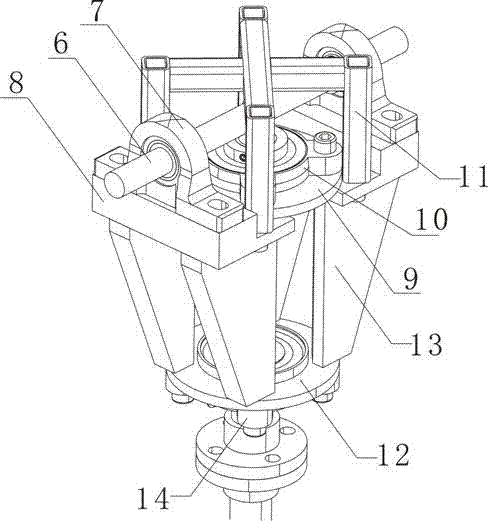

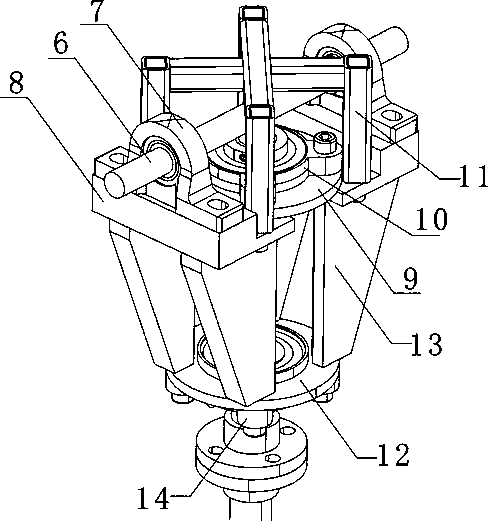

Intelligent assembling robot of power distribution cabinet

The invention relates to an intelligent assembling robot of a power distribution cabinet. The intelligent assembling robot comprises a switching device, two linear groove devices and two screw head limiting devices, wherein the middle of the switching device is provided with the two linear groove devices, the two linear groove devices are symmetrically arranged, and one screw head limiting deviceis installed at the outer end of each linear groove device correspondingly. According to the robot, the problems that when a screw is installed on the power distribution cabinet, a corresponding screwdriver needs to be used for working; when the screw is installed, the screw is required to be held by a person, and then the screw is installed by means of a tool, due to the fact that the screw is small, the screw can fall off during manual installation, and the screw is prone to be twisted in an inclined manner; and when a cross slot screw and a linear groove are installed, the person needs to tighten the cross slot screw and the linear groove by means of the corresponding tool, a large number of tools enable the person to be inconvenient to carry, the process is long in consumed time, laborintensity is high, efficiency is low and the like are solved, so that the function of carrying out multi-azimuth limiting on the cross slot screw and the linear groove screw can be realized.

Owner:中通服节能技术服务有限公司

A prefabricated green building structure

ActiveCN111794430BPlay a supporting roleEnsure stabilityBuilding roofsRoof covering using slabs/sheetsSolar batteryMechanical engineering

The invention discloses an assembled green building structure, which comprises a wall frame, a triangular prism roof is fixed on the top of the wall frame, a number of solar panels and a wind turbine are installed on the side of the triangular prism roof, and windows and wind turbines are installed on the wall frame. The door, the triangular prism roof includes two symmetrically arranged isosceles triangular frames, the isosceles triangular frame includes a bottom frame and two isosceles frames, the two isosceles frames are connected by a semicircular elastic piece, and the semicircular elastic piece The midpoint of the outer arc side is crimped with the bottom frame, and the midpoint of the inner arc side of the semicircular elastic part is crimped with the connector. Midpoint crimping, one end of the vertical rod is connected to the apex of the isosceles triangle frame, the other end of the vertical rod is connected to the top surface of the connector, one end of the oblique rod is connected to the midpoint of the isosceles frame, and the other end of the oblique rod is connected to the top surface of the connector. The invention can improve the deficiencies of the prior art, and meets the anti-seismic requirements of the prefabricated green building.

Owner:中建五局华南建设有限公司

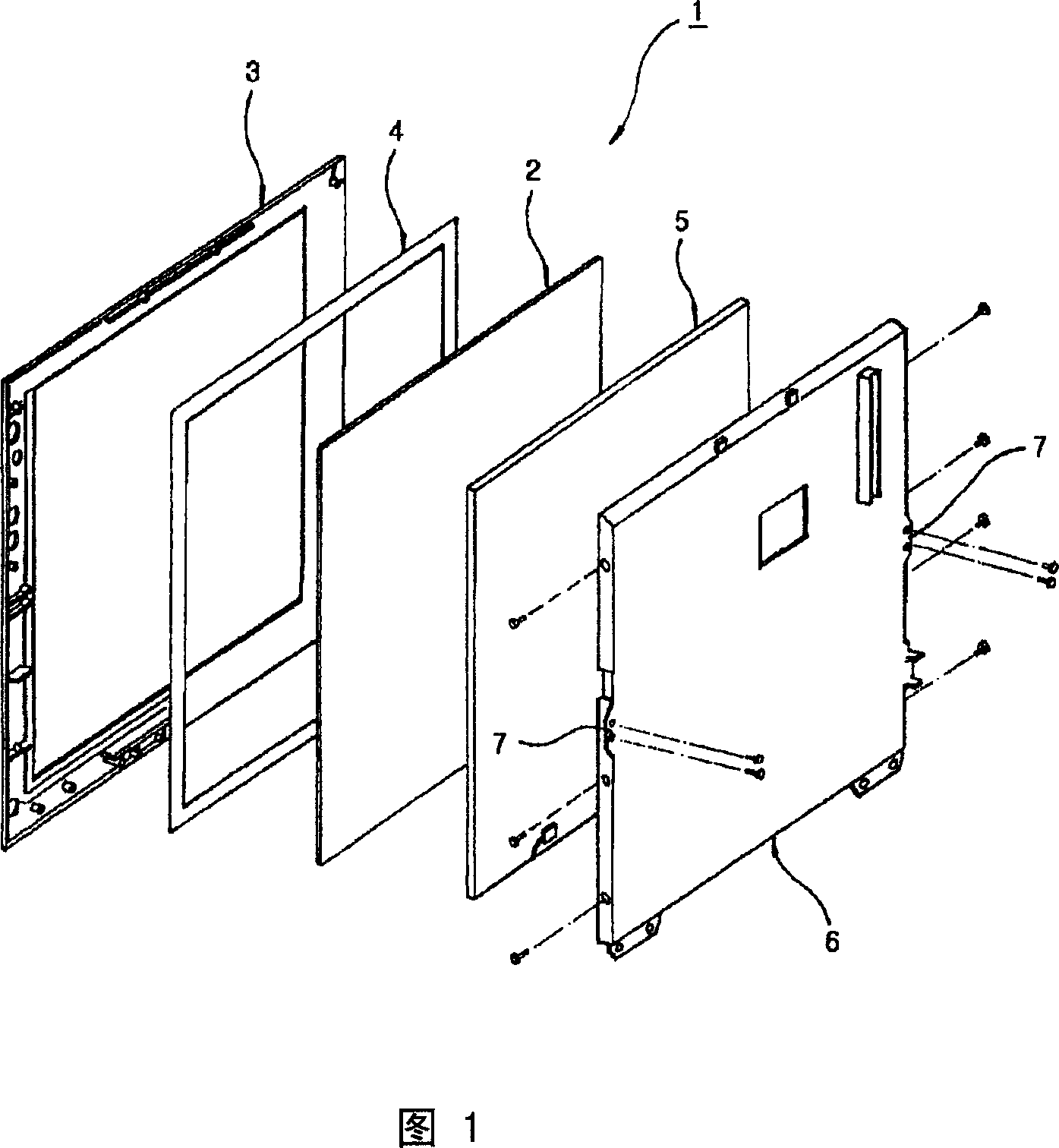

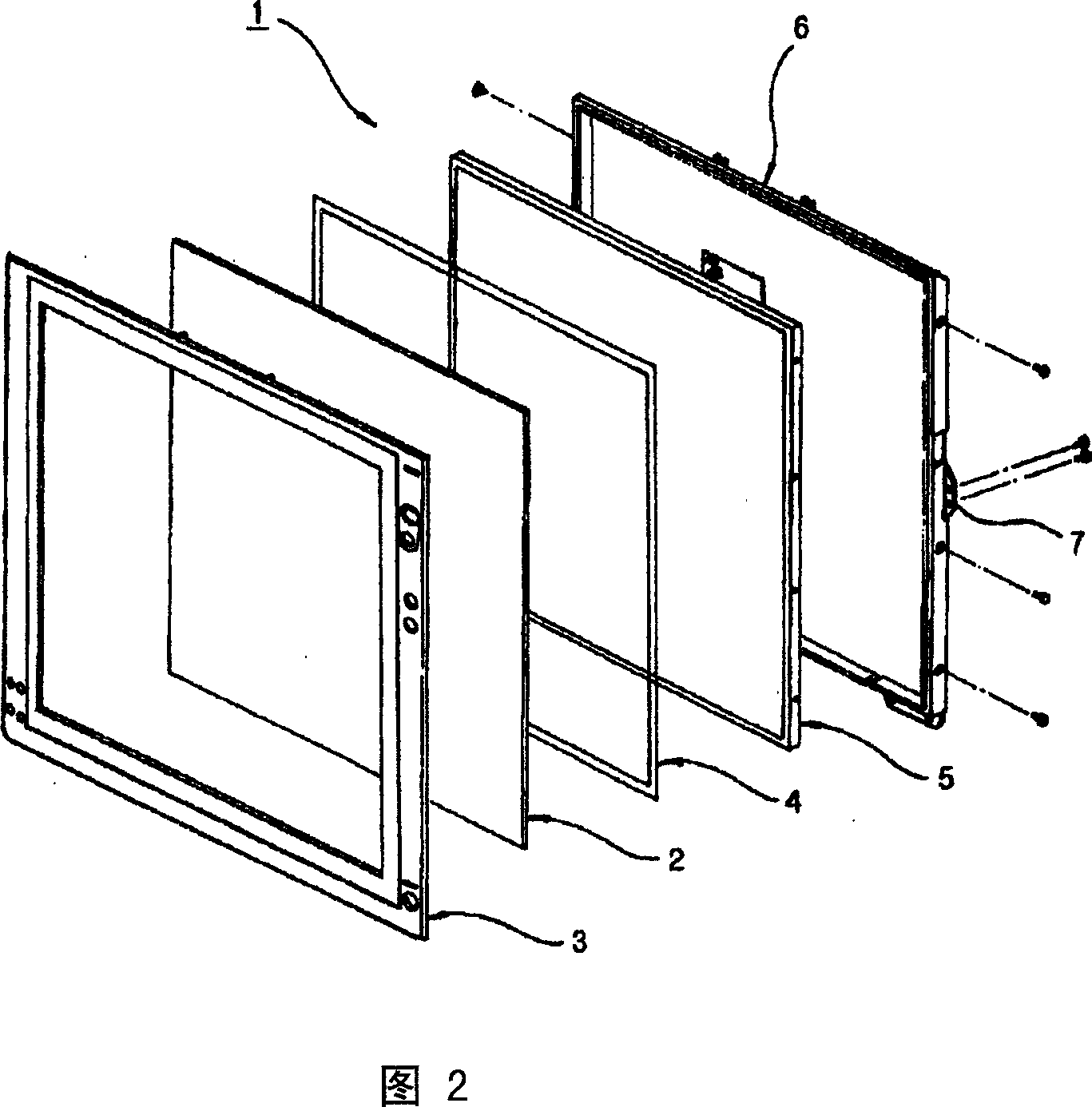

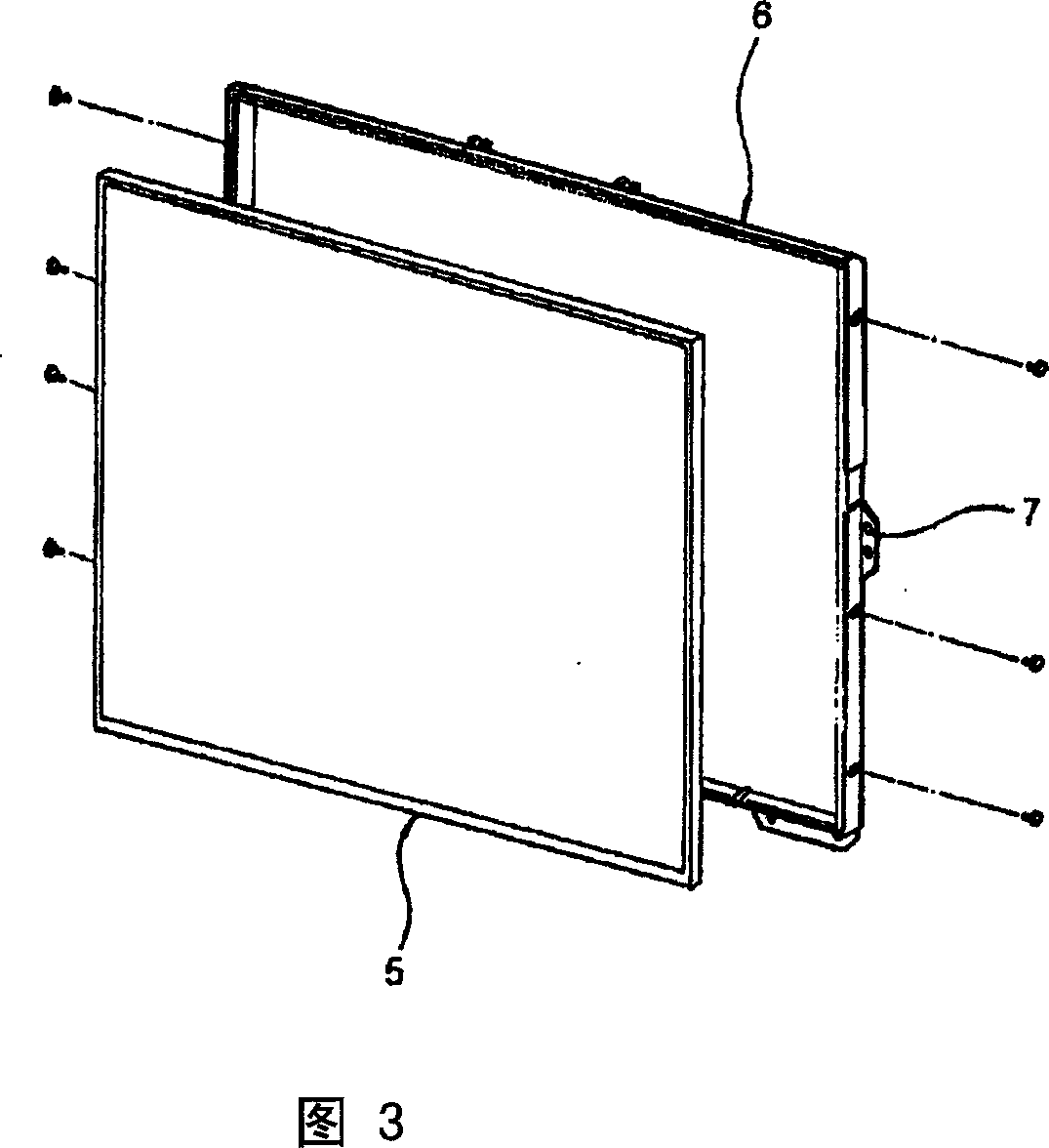

Touch screen fastening device for liquid crystal display device

This invention is about a touch screen equipped between the back and the white machine shell of the LCD module of the liquid crystal display, and the touch screen fixing device of the liquid crystal display that won't diverge the appointed position after longtime use and can keep it steady. Its characteristic is that it's composed of following structures. A fixing end organ is equipped in all the upper and nether circumjacent parts inside the front machine shell to contain all the upper and nether ending parts of the back machine shell accreting the touch screen. A hooking link organ is equipped to make the touch screen unswerving from the fixed end organ in all the upper and nether circumjacent parts of the back machine shell corresponding to the fixed end organ. To make it have a certain flexibility and be nipped in the fixed end organ of the front machine shell, the above-mentioned hooking link organ of the back machine shell is made of flexible materials.

Owner:NANJING LG TONGCHUANG COLOR DISPLAYS SYST CO LTD

Method for planting fibrous root crops in inferior land

PendingCN113331012AImprove survival rateImprove qualityGrowth substratesFertilising methodsMedicinal herbsSoil science

The invention provides a method for planting fibrous root crops in the inferior land, and relates to the field of crop planting. The method for planting the fibrous root crops in the inferior land comprises the following steps: preparing crop base soil; carrying out seedling raising, filling grooves with the crop base soil, planting fibrous root system crops of grains, oil, cotton, vegetables and medicinal materials into the crop base soil, planting any two adjacent fibrous root system crops at intervals, laying drip irrigation pipes on the soil surface layer of the crop base soil for irrigation, and draining and recycling redundant accumulated water in the grooves after irrigation is completed. According to the method, the crops are directly planted in the planting area of the inferior land, new soil and the crops can be isolated from the external environment, the survival rate of the crops is increased, the influence of accumulated water on crop planting can be avoided, meanwhile, various wastes can be secondarily utilized to be used as fertilizers, and therefore, the method has high practical value and large-scale popularization and application are facilitated.

Owner:胡皓

Fabricated steel structure tower crane foundation bearing platform

PendingCN111321754ANo twistingThere is no need to consider issues such as deformationFoundation engineeringArchitectural engineeringTower crane

The invention discloses a fabricated steel structure tower crane foundation bearing platform. The fabricated steel structure tower crane foundation bearing platform comprises a plurality of sub-steelstructure bearing platforms, the sub-steel structure bearing platforms are connected through arc-shaped H-shaped composite steel members, a plurality of adjustable-size H-shaped steel members, cross-shaped H-shaped steel members and U-shaped buckles; the sub-steel structure bearing platforms comprise lattice columns of a lower foundation, reinforced cages, concrete and round steel pipes; the reinforced cages are arranged in the round steel pipes, the lattice columns of the lower foundation are arranged in the reinforced cages, and the concrete is poured between the round steel pipes and the lattice columns; and the outer sides of the round steel pipes are fixedly connected with the arc-shaped H-shaped composite steel members, the arc-shaped H-shaped composite steel members are connected with the adjustable-size H-shaped steel members through the U-shaped buckles, the adjustable-size H-shaped steel members are connected with one another through the U-shaped buckles, and the adjustable-size H-shaped steel members are connected with the cross-shaped H-shaped steel members through the U-shaped buckles. The force is reliable, and the installation and disassembly are convenient. The problems of long maintenance time for construction of a cast-in-situ concrete tower crane foundation bearing platform, waste of concrete materials and environmental protection are solved.

Owner:ZHEJIANG UNIV CITY COLLEGE

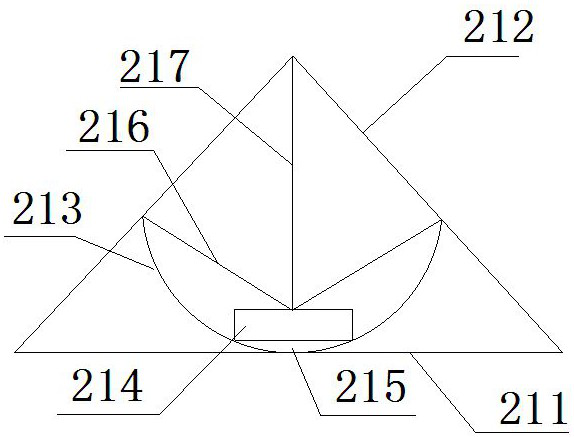

Twist-free compound pendulum in spherical surface touch

InactiveCN102663934BGuaranteed to be verticalReduce frictionEducational modelsEngineeringMechanical engineering

The invention discloses a twist-free compound pendulum in spherical surface touch, relating to the physics experiments of colleges, in particular to the fabrications of twist-free compound pendulums. According to the compound pendulum in the physics laboratory of college, generally, a swinging rod touches with a hanging rod through a wire, and the compound pendulum can be frequently twisted. There is a kind of compound pendulum that a knife edge is designed on the swinging rod of the compound pendulum for touch, but with poor durability. The technical scheme of the invention is as follows: hanging holes of the swinging rod are designed into square through holes, and concave hemispherical surfaces are formed on the sides of the square through holes far away from the center of mass; and a convex hemispherical surface is formed on the hanging rod, the hemispherical surface of the hanging rod is smaller than the hemispherical surface of the swinging rod in diameter, and a conical bracket is added between the hemispherical surface and the hanging rod, thereby ensuring that the two hemispherical surfaces can touch with each other, and further ensuring that the hanging rod can touch with the swinging rod in a spherical surface point contact mode. The twist-free compound pendulum in spherical surface touch disclosed by the invention has the following beneficial effect: the compound pendulum is low in friction, less in damage, high in durability, free of twist and less in experimental regulation due to the spherical surface touch.

Owner:SICHUAN UNIV

Improved V-shaped anvil

ActiveCN112808920AAvoid replacementShorten working timeForging/hammering/pressing machinesSuperalloyLever pressing

The invention discloses an improved V-shaped anvil. The improved V-shaped anvil comprises two V-shaped anvil bodies which are symmetrically arranged, a dovetail-shaped connecting block is fixed to the top face of a V-shaped anvil block, a second cylindrical groove is formed in the center of the bottom face of the V-shaped anvil block, one end of a first spring is connected with the top face of the second cylindrical groove, the other end of the first spring is connected with a pressing rod, a third cylindrical groove is formed in the top face of the second cylindrical groove, each V-shaped anvil body comprises two trapezoid prismatic table anvils, trapezoid prismatic table through grooves are formed in the top faces of the trapezoid prismatic table anvils, the pressing rod comprises a cylindrical rod, a cylindrical protrusion is fixed to the top face of the cylindrical rod and connected with the first spring in a sleeved mode, two trapezoid prismatic table side rods are symmetrically fixed to the edge of the side face of the cylindrical rod, elastic pieces are fixed to the side faces of the trapezoid prismatic table through grooves, the side faces of the trapezoid prismatic table side rods are connected with the elastic pieces in a pressing mode, and cross-shaped pressing rods are movably connected to the top faces of the trapezoid prismatic table side rods. According to the improved V-shaped anvil, defects in the prior art can be overcome, high-temperature alloy forging structure is obviously improved, and the working efficiency is improved.

Owner:AVIC SHANGDA METAL REGENERATION TECH

An assembled rotating conductive module

ActiveCN108767609BNo twistingRealize conductive transmissionFlexible/turnable line connectorsModular productComputer module

The invention discloses an assembled rotational conductive module and belongs to the technical field of modular products. The assembled rotational conductive module comprises a structure module, a first PCB, a second PCB and a hinge assembly, wherein a buckle is clamped into a buckle hole in an installation condition; the first PCB and the second PCB sleeve a guide post separately; a first conductive needle is propped against a first conductive channel; a second conductive needle is propped against a second conductive channel; the first PCB is clamped on the surface of the structure module; the second PCB is clamped into a clamping groove; and a wire is connected with an interface of the second PCB. When the structure module of the assembled rotational conductive module and the hinge assembly rotate relatively, the conductive needles can be always propped against the corresponding conductive channels, thereby achieving conductive transmission at an arbitrary angle. The conductive needles and the corresponding conductive channels are connected in a sliding manner, thereby overcoming the problems that an internal wire of a rotating shaft is wound and is easily broken in the prior art. The hinge assembly can rotate back and forth in a hinge plane, and furthermore, the structure module can freely rotate around the guide post, so that the assembled rotational conductive module is great in degree of freedom, and stable conduction can be achieved while multi-angle structure connection is achieved.

Owner:HUNAN YUEGANG MOOKRAY IND CO LTD

string length grinder

ActiveCN104108056BAvoid wear and tearImprove economyGrinding drivesGrinding feedersGrinding wheelMagnet

Owner:德昌电机(南京)有限公司

Twisting-preventive compound pendulum contacting by circular spherical grooved surface

InactiveCN102708735BGuaranteed to be verticalReduce frictionEducational modelsPhysical laboratoryEngineering

A twisting-preventive compound pendulum contacting by circular spherical grooved surface and relates to college physical test, in particular to manufacturing of a twisting-preventive pendulum. A pendulum rod in a physics lab is generally in linear contact with a hanging rod and always twists. A kind of a pendulum rod is in spot contact via a knife edge but is poor in durability. The technical scheme of the twisting-preventive compound pendulum includes that a circular hole is reserved on the pendulum rod, a circular groove is reserved at the center of the circular hole, the bottom of the cross section of the circular groove is semi-circular, a projection in the shape of a thin circular cake is formed on the hanging rod, the top of the cross section of the cake is semi-circularly formed, the diameter of the semicircular top of the hanging rod is smaller than that of the semicircular bottom of the groove of the hanging rod, so that two spherical surfaces are guaranteed to be in spot contact. The hanging rod in spherical contact is small in friction, low in abrasion and high in durability. Vertical state of the swing rod can be guaranteed and no twisting is caused due to the fact that the spherical contact is spot contact, test error is reduced, testing accuracy is increased, horizontal adjustment procedures of instruments are reduced and test speed is increased.

Owner:SICHUAN UNIV

A sizing beam creel

ActiveCN103924408BSmall spacingPrevent twistingTextile treatment carriersEngineeringMechanical engineering

Owner:JIANGSU PINYTEX TEXTILE DYEING & FINISHING

An intelligent assembly robot for power distribution cabinet

ActiveCN108637655BReduce labor intensityRealize the function of multi-directional limitMetal working apparatusElectric powerScrew head

Owner:中通服节能技术服务有限公司

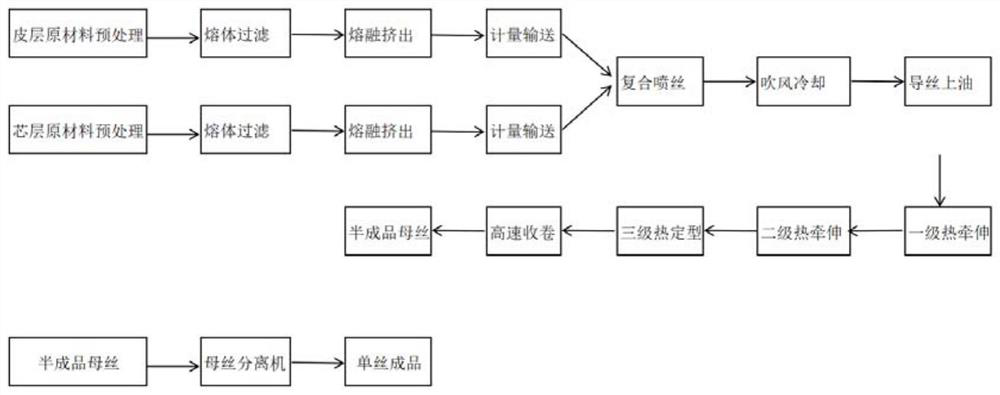

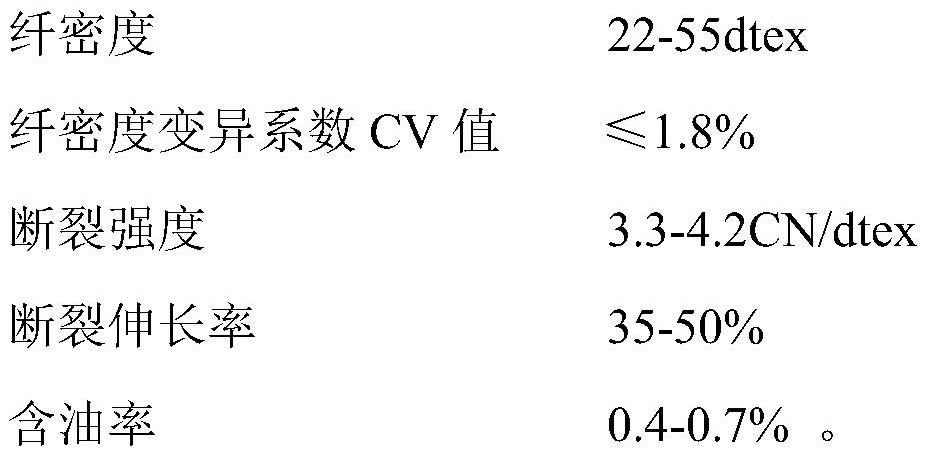

Production process of skin-core type polyester monofilament by separating mother yarn

PendingCN113981554AReduce manufacturing costNo hair problemArtificial thread manufacturing machinesSpinning head liquid feederPolyesterPolymer science

The invention discloses a production process of a skin-core polyester monofilament by separating a mother yarn. The production process comprises the following steps: drying, carrying out melt spinning, preparing the mother yarn, and preparing a monofilament; the drying step comprises the steps that conventional polyester chips are pre-crystallized and dried to obtain dry polyester chips A, the pre-crystallization temperature of the conventional polyester chips is 160-170 DEG C, the drying temperature of the conventional polyester chips is 150-170 DEG C, the drying time of the conventional polyester chips is 6-8 hours, and the moisture content of the dry polyester chips A is smaller than or equal to 0.003%; the low-melting-point polyester chips are subjected to one of rotary drum drying or continuous drying to obtain low-melting-point polyester dry chips B, the melting point of the low-melting-point polyester chips B is 110-230 DEG C, the drying temperature is 60-130 DEG C, the drying time is 8-30 hours, the rotary drum drying vacuum degree is smaller than or equal to -0.093 Mpa, and the water content of the low-melting-point polyester chips B is smaller than or equal to 0.0045%; the preparation process of the skin-core type polyester monofilament is high in production yield and uniform in evenness, and a user uses the skin-core fibers which do not need to be twisted.

Owner:苏州领纤新材料科技有限公司

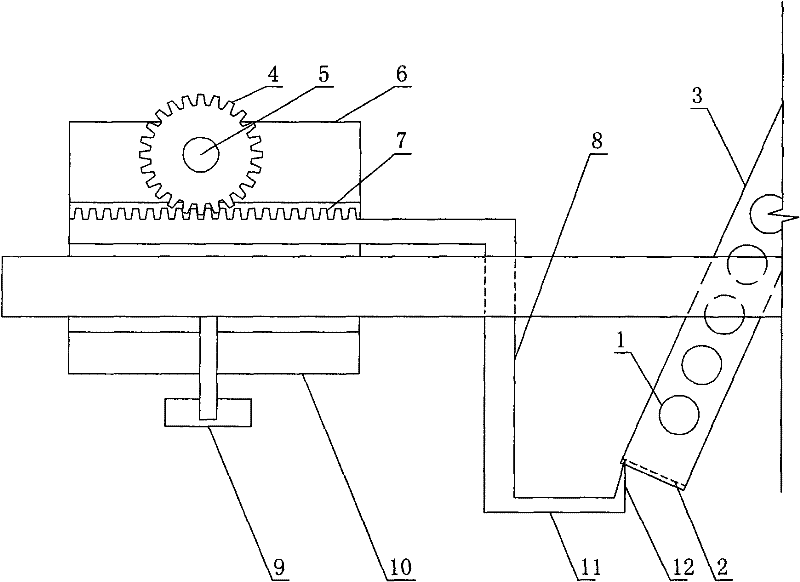

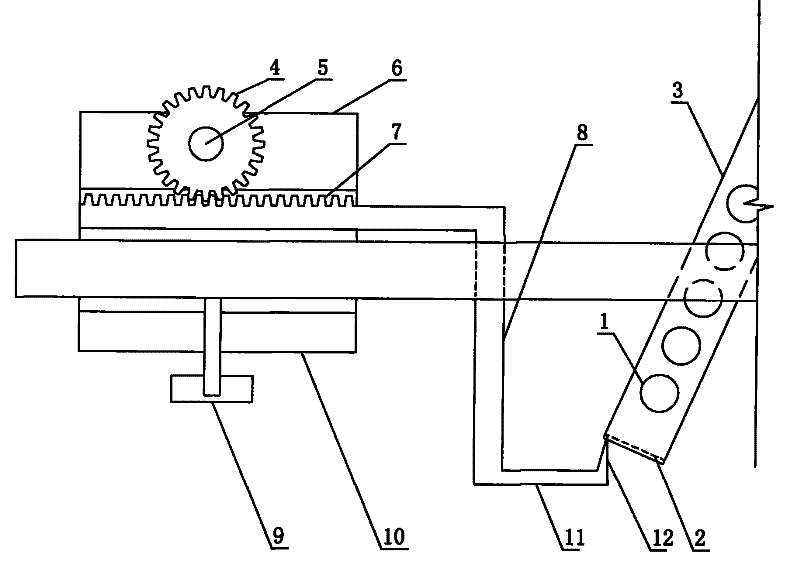

Balance swing rod and starting drive thereof

InactiveCN101655565BNo shakingNo twistingEducational modelsGravitational wave measurementEngineeringHand shaking

The invention relates to an experimental apparatus, particularly to a balance swing rod and a starting device thereof. A compound pendulum swing rod without initial shaking is composed of a swing rod hole, a balance groove and a rod body; the starting device is composed of a gear, a rotating shaft, a gear carrier, a tooth bar, a drop arm, a knob, a table edge card, a transverse arm and a positioning hook; the lower end of the rod body is provided with the balance groove with a V-shaped cross section; the gear is sleeved on the rotating shaft and generates a running fit with the rotating shaft; the upper surface of the table edge card between two gear carriers is provided with the tooth bar which generates a running fit with the table edge card; the teeth of the tooth bar are upwards and engage with the teeth of the rotating shaft; one end of the tooth bar is provided with the L-shaped hook which is composed of the drop arm, the transverse arm and the positioning hook; and the sharp end of the positioning hook is of a triangular pyramid shape. The experimental apparatus prevents the experiment error caused by hand shaking and increase the accuracy of experiment result.

Owner:NINGBO YINZHOU YUNFAN ENG CONSULTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com