Yarn reversing device suitable for inner drawn bobbins

A yarn bobbin and yarn rewinding technology, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material processing, etc., can solve the problems of fiber damage and affecting yarn performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment, the technical solution of the present invention is described in detail:

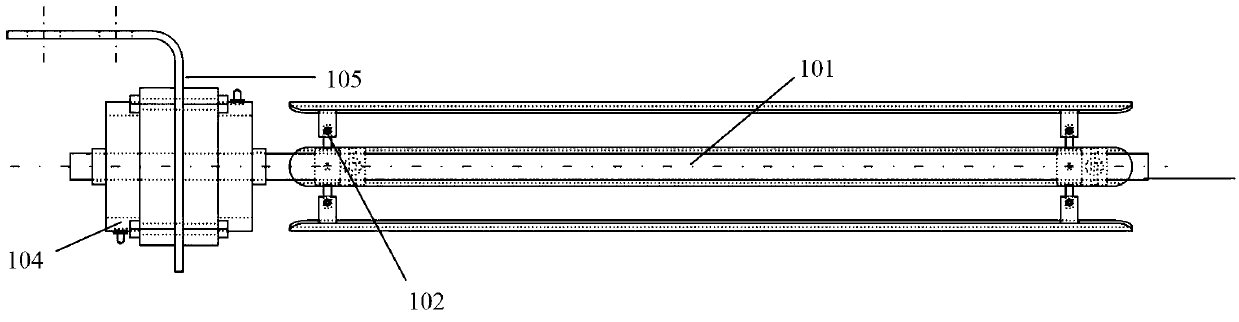

[0021] refer to figure 1 , The yarn rewinding device suitable for the inner-drawn yarn bobbin disclosed in the present invention mainly includes an arc-shaped support rod 101 , a rotating support 102 , a main shaft 103 , a bearing seat 104 , and a mounting support 105 .

[0022] figure 2 It is a side view of the disclosed yarn rewinding device.

[0023] refer to figure 2 , the mounting support 105 provides mounting holes for each component in the device. The side of the mounting support 105 is in an inverted L shape. For connection, the side of the mounting support 105 is provided with four mounting holes, which provide mounting holes for the bearing blocks 104 on the left and right sides.

[0024] The bearing seat 104 is used to install and fix the main shaft 103 to reduce the friction generated during the rotation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com