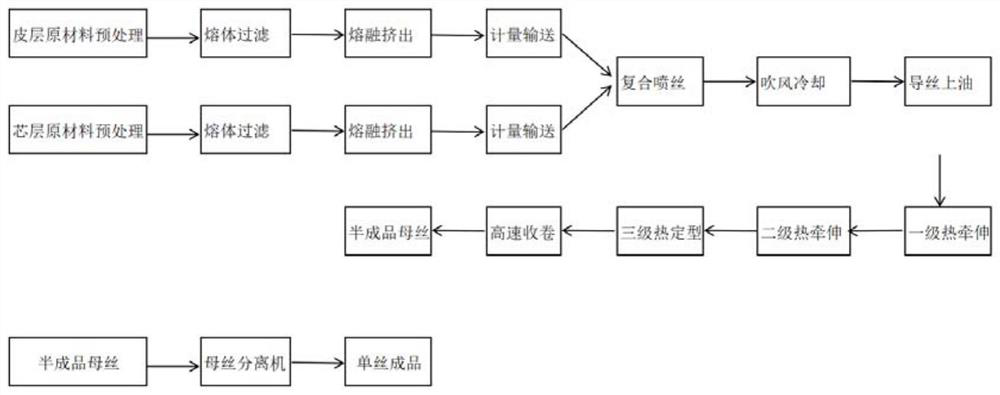

Production process of skin-core type polyester monofilament by separating mother yarn

A production process, sheath-core type technology, applied in the field of production process of sheath-core type polyester monofilament through mother wire, can solve the problems of uneven product quality, low output, high technical difficulty, etc. Effects of twisting process, increase in output, and reduction in production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 50KG of conventional polyester chips are pre-crystallized and dried to obtain dry polyester chips A. The pre-crystallization temperature of the conventional polyester chips is 170°C, the drying temperature is 170°C, and the drying time is 8 hours. The polyester Dry slice A has a moisture content of 0.002%;

[0024] Drum drying or continuous drying of 50 kg of low-melting point polyester chips to obtain low-melting point polyester chips B, the melting point of the low-melting point polyester chips B is 178°C, the drying temperature is 130°C, and the drying time is For 12 hours, the vacuum degree of drum drying is ≤-0.093Mpa, so that the moisture content of the low-melting point polyester chip B is ≤0.0045%. After the polyester dry chips A and the low-melting point polyester chips B are metered by the spinning metering pump, they are extruded into their respective screw extruders with a weight ratio of 35:65, and then enter the composite box for spinning .

[0025] One-...

Embodiment 2

[0030] 50KG of conventional polyester chips are pre-crystallized and dried to obtain dry polyester chips A. The pre-crystallization temperature of the conventional polyester chips is 170°C, the drying temperature is 170°C, and the drying time is 8 hours. The polyester Dry slice A has a moisture content of 0.002%;

[0031] Drum drying or continuous drying of 50 kg of low-melting polyester chips to obtain dry low-melting polyester chips B. The melting point of the low-melting polyester chips B is 178°C, the drying temperature is 130°C, and the drying time is For 12 hours, the drum drying vacuum degree is ≤-0.093Mpa, so that the moisture content of the low-melting point polyester chip B is ≤0.0045%.

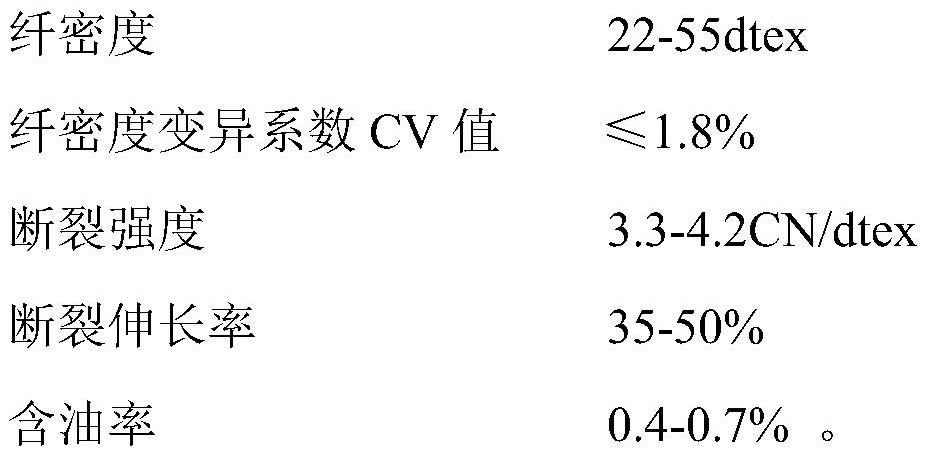

[0032] The polyester dry chip A and the low-melting point polyester chip B are measured by a spinning metering pump, and the weight ratio is 35:65. After mixing and compounding, the two-step method DT drawing is used to obtain The mother wire method includes: the number of spinnere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com