Inner ring stop mechanism of wheel hub bearing

A technology of hub bearings and stop mechanisms, which is applied in the direction of hubs, bearing components, shafts and bearings, etc., which can solve the problems of maintenance-free hub bearings that cannot be adjusted, high machining accuracy requirements for hub parts, and difficulty in assembly and maintenance of hub bearings. , to achieve the effect of convenient adjustment of hub bearing clearance, efficient and economical processing, convenient and quick assembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings, but this embodiment should not be construed as limiting the present invention.

[0034] It should be noted that: the shaft head referred to in this application is also referred to as a half-shaft sleeve or a hub shaft tube, which is defined as a shaft head in the present invention.

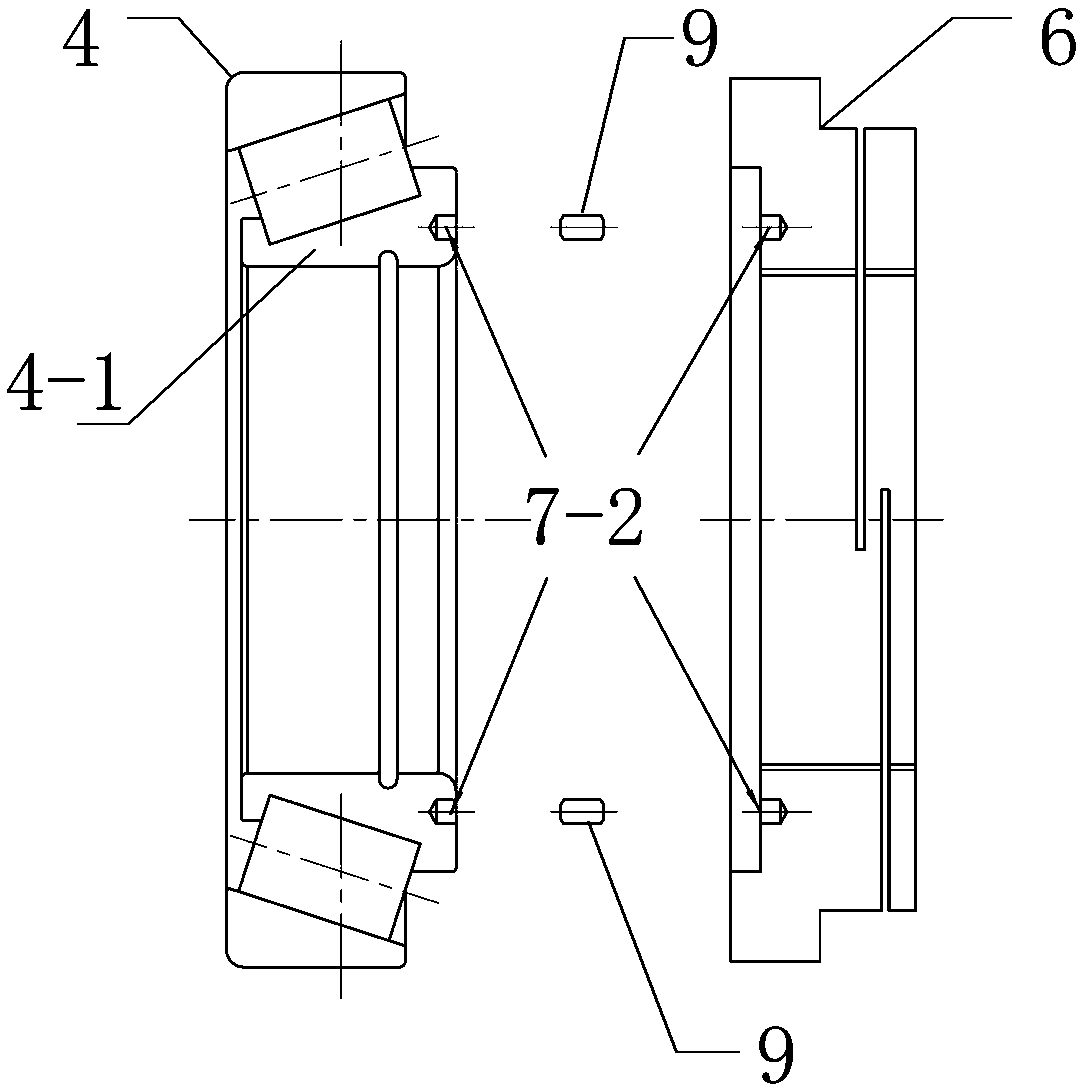

[0035] The present invention as Figure 1 to Figure 5 Shown:

[0036] A stopping mechanism for the inner ring of a wheel hub bearing, comprising a shaft head 1 with a limit step surface, and a wheel hub 2, the wheel hub 2 is set on the shaft head through the wheel hub inner bearing 3 and the wheel hub outer bearing 4 arranged in its inner cavity, wherein: The inner ring 3-1 of the hub inner bearing is limited by abutting against the limit step surface of the shaft head through the bearing race 5, and the bearing race includes a radial contact surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com