Fabricated steel structure tower crane foundation bearing platform

A technology for tower crane foundation and steel structure, applied in basic structure engineering, construction and other directions, can solve the problems of waste of concrete materials, long construction and maintenance time, environmental protection and other problems, and achieve the effect of saving construction costs, reducing prices, and ensuring construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

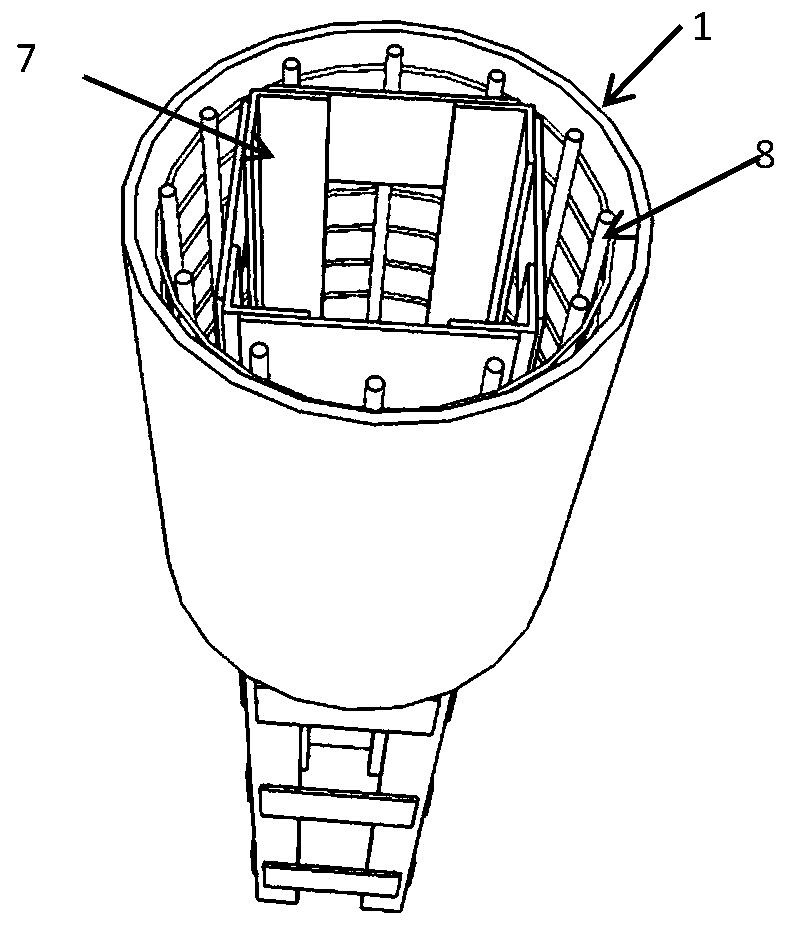

[0029] like figure 1 and figure 2 As shown, the present invention provides an assembled steel structure tower crane foundation cap, the tower crane foundation cap includes four round steel pipes 1, an arc-shaped channel-shaped steel composite steel member 2 directly fixedly connected with the round steel pipes 1, and several adjustment dimensions H-shaped steel component 3, a box-shaped steel component 4, several U-shaped buckles 6, and several steel components with holes 9;

[0030] like image 3 As shown, the round steel pipe 1 is inserted outside the lattice column 7 of the lower foundation, and the lattice column 7 is located in the middle of the round steel pipe; A plurality of circular reinforcement cages 8 of circular stirrups, the diameter of the circular reinforcement cage 8 is smaller than the diameter of the circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com