Gravity compound pendulum-based ultra-high precision micro force measuring device and measuring method

The technology of a measuring device and measuring method, which is applied in the field of ultra-high-precision micro-thrust measuring devices, can solve problems such as the influence of measuring accuracy, and achieve the effects of reducing vibration, simple structure of the measuring device, simple and easy-to-operate measuring principle and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

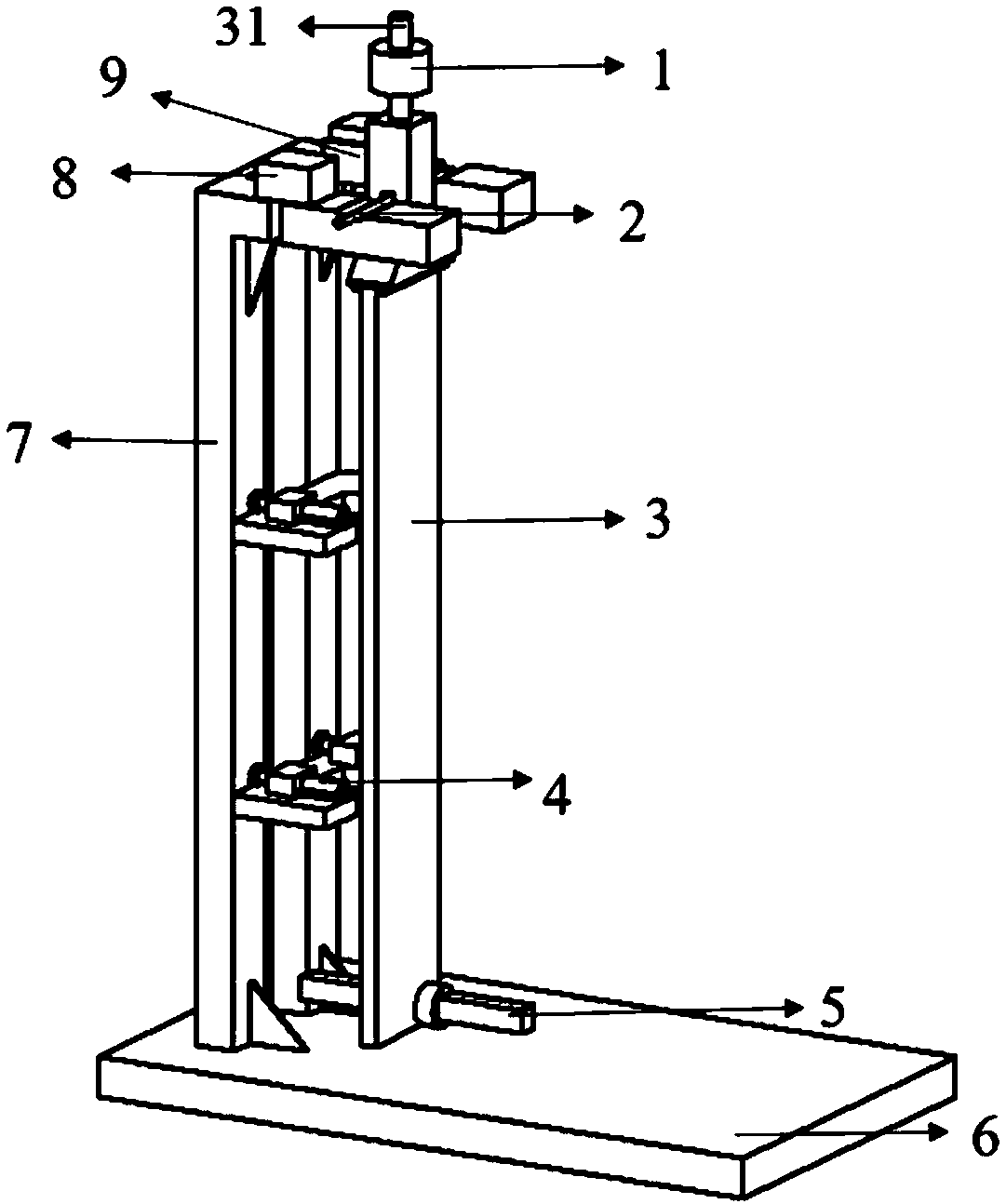

[0049] Such as figure 1 The shown micro-force measuring device based on the gravity compound pendulum, combined with figure 2 , the measuring device includes:

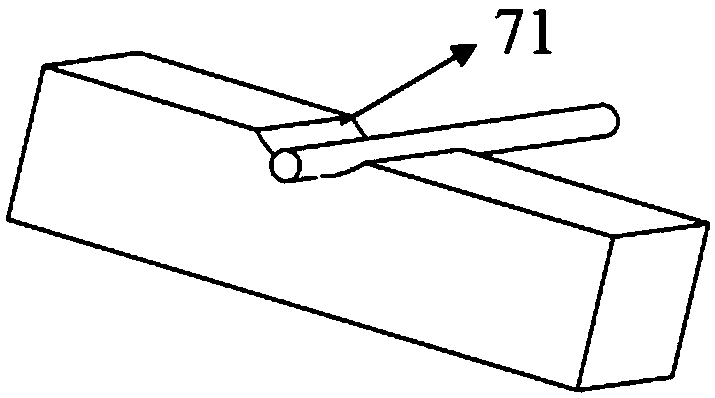

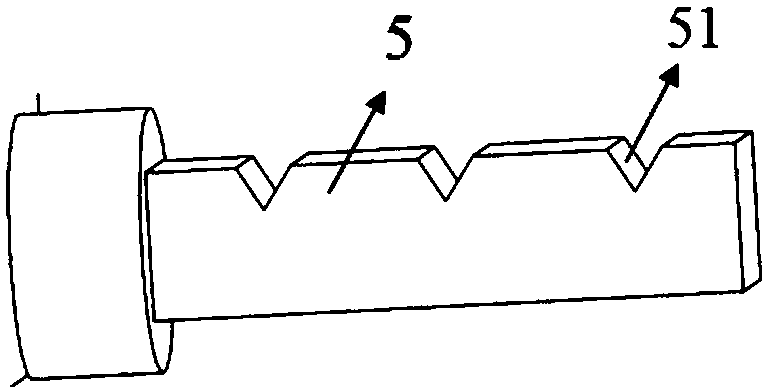

[0050]The base 6 placed horizontally, the support 7 perpendicular to the base 6 and fixedly connected thereto, the gravity compound pendulum 3, the center of mass of the gravity compound pendulum 3 passing through the compound pendulum 3 and the two ends resting on the rotating shaft support 71 at the top of the support 7 Revolving shaft 2, the two upper and lower differentials are arranged on the support 7 for measuring the horizontal swing displacement of the gravity compound pendulum 3. The macro measuring sensor 4, the counterweight 1 that can move up and down along the rod portion 31 at the top of the gravity compound pendulum 3, and the two respectively Corresponding to the calibration rod 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com