Double-cavity compound-pendulum jaw crusher for ore crushing

A jaw crusher and ore crushing technology, applied in the field of material grinding and ore crushing, can solve the problems of difficulty in designing and manufacturing a jaw crusher, increasing investment in civil engineering and equipment, and increasing operating costs. The effect of equipment maintenance, light weight and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

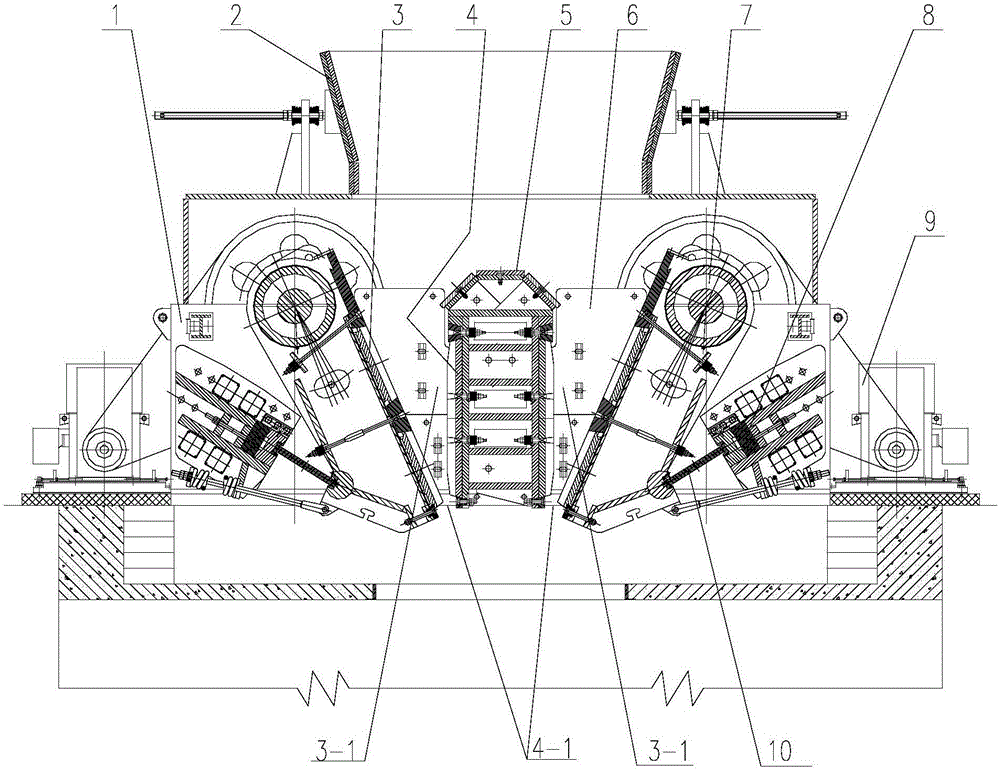

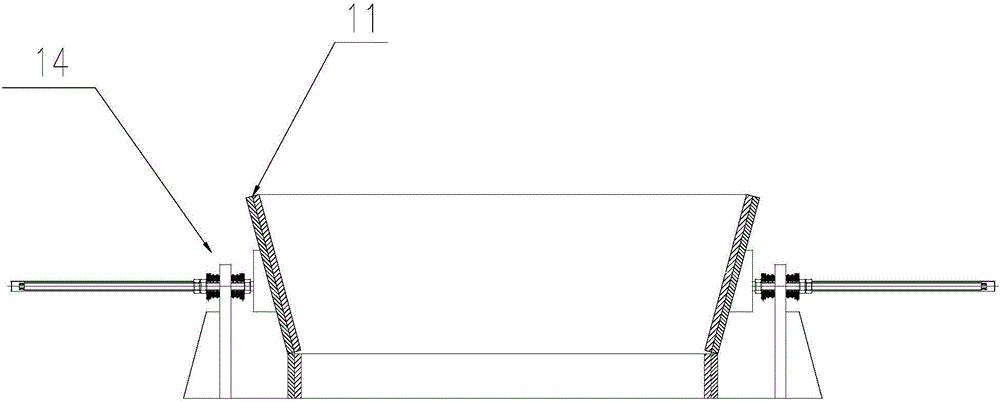

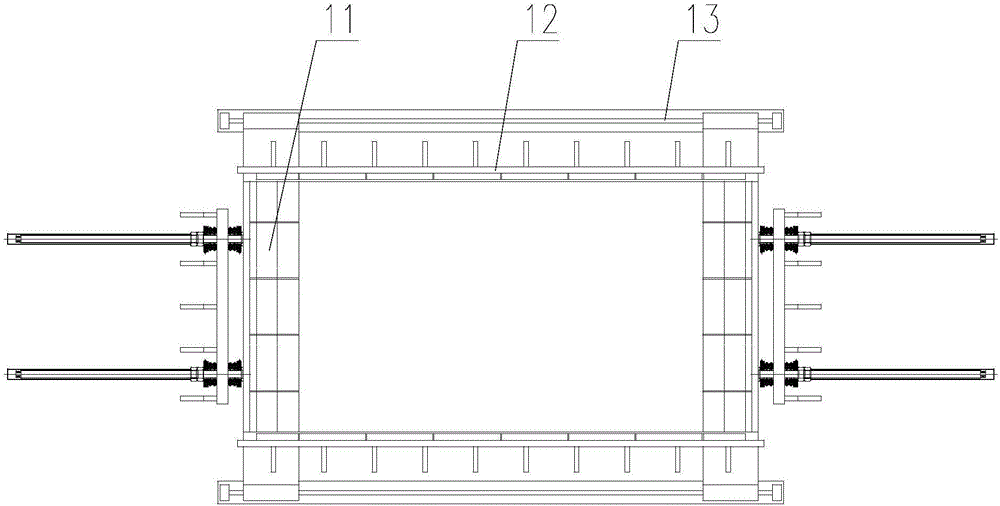

[0025] see Figure 1 to Figure 3 , a double-cavity compound pendulum jaw crusher for ore crushing, the frame 1 adopts an assembled structure, and an adjustable feeding hopper 2 is installed on one end of the frame; the bottom of the feeding hopper 2 is symmetrical Two independently driven movable jaws 3 are arranged, and the movable jaws 3 are connected to a motor drive device 9 that drives the two movable jaws 3 to perform compound pendulum motion independently; the fixed jaw 4 is in the middle of the two movable jaws, and the fixed jaw 4 is fixed On the frame 1; two independent crushing chambers 3-1 are formed between the above-mentioned two movable jaws 3 and the middle fixed jaw 4, and the two crushing chambers have independent discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com