Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95 results about "Acetal copolymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acetal is a thermoplastic polymer that is used for the production of many products due to its high strength and low friction. Acetal polymer is made as either a homopolymer or a copolymer. The name acetal is the common name used for polyoxymethylene (POM).

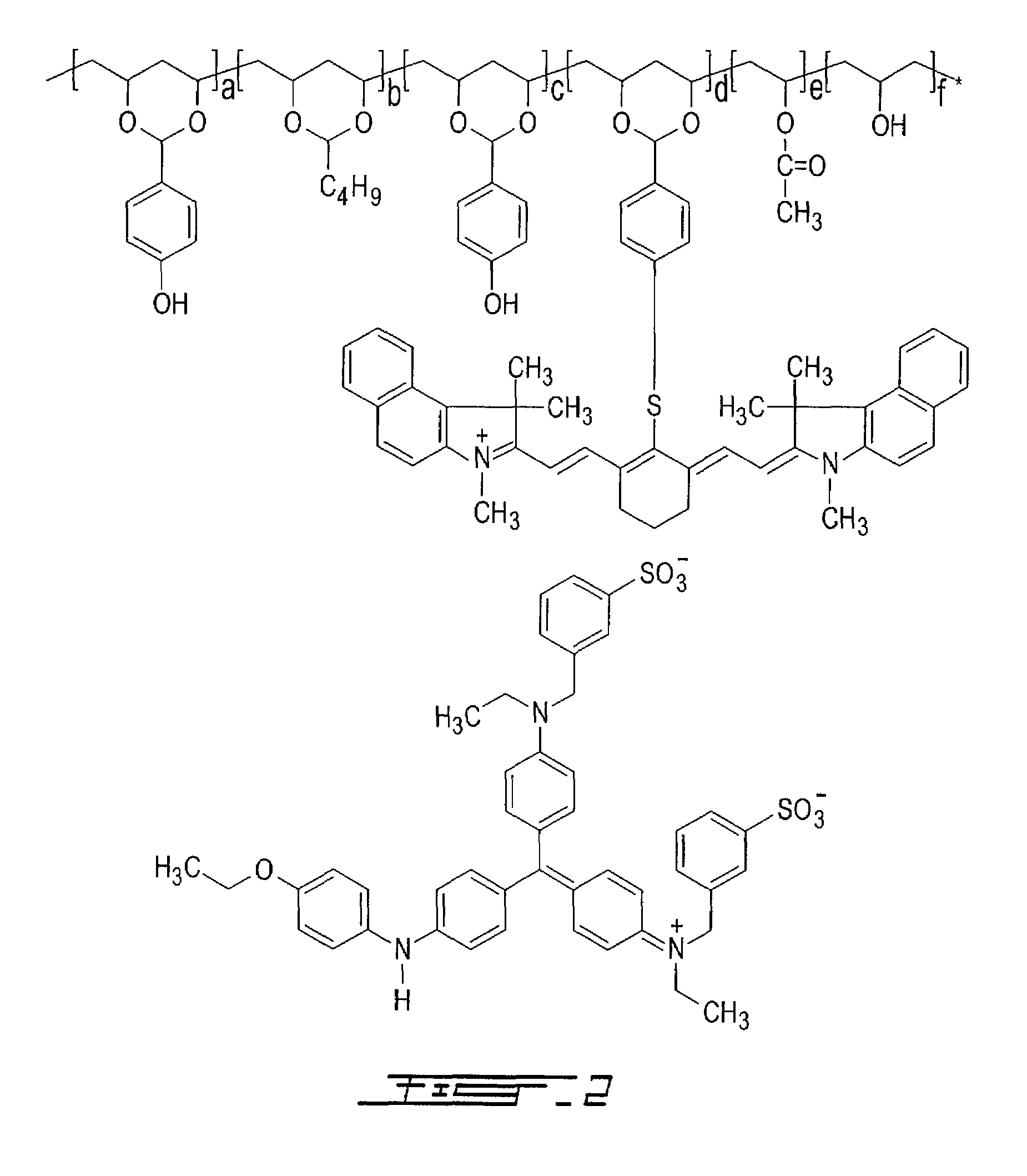

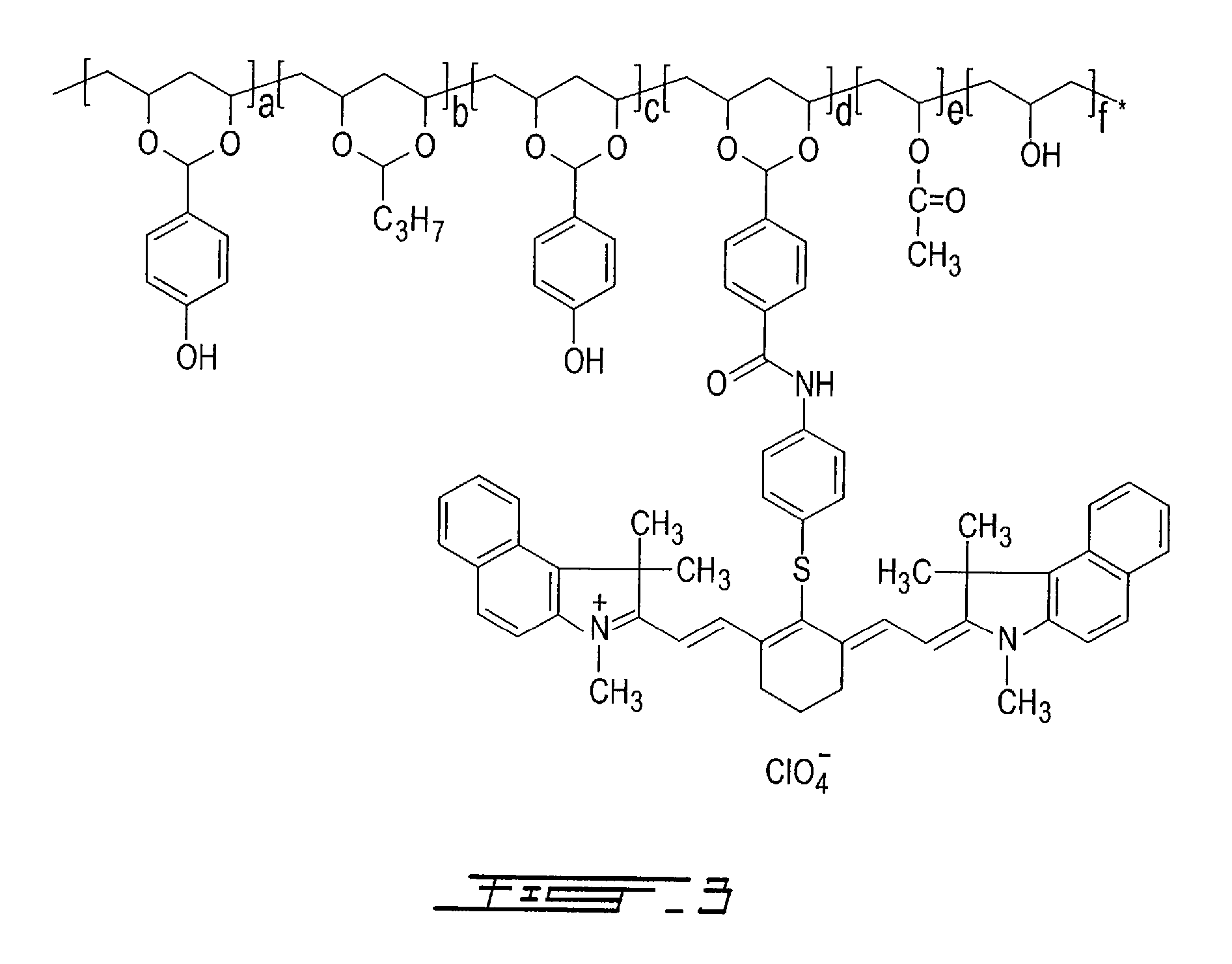

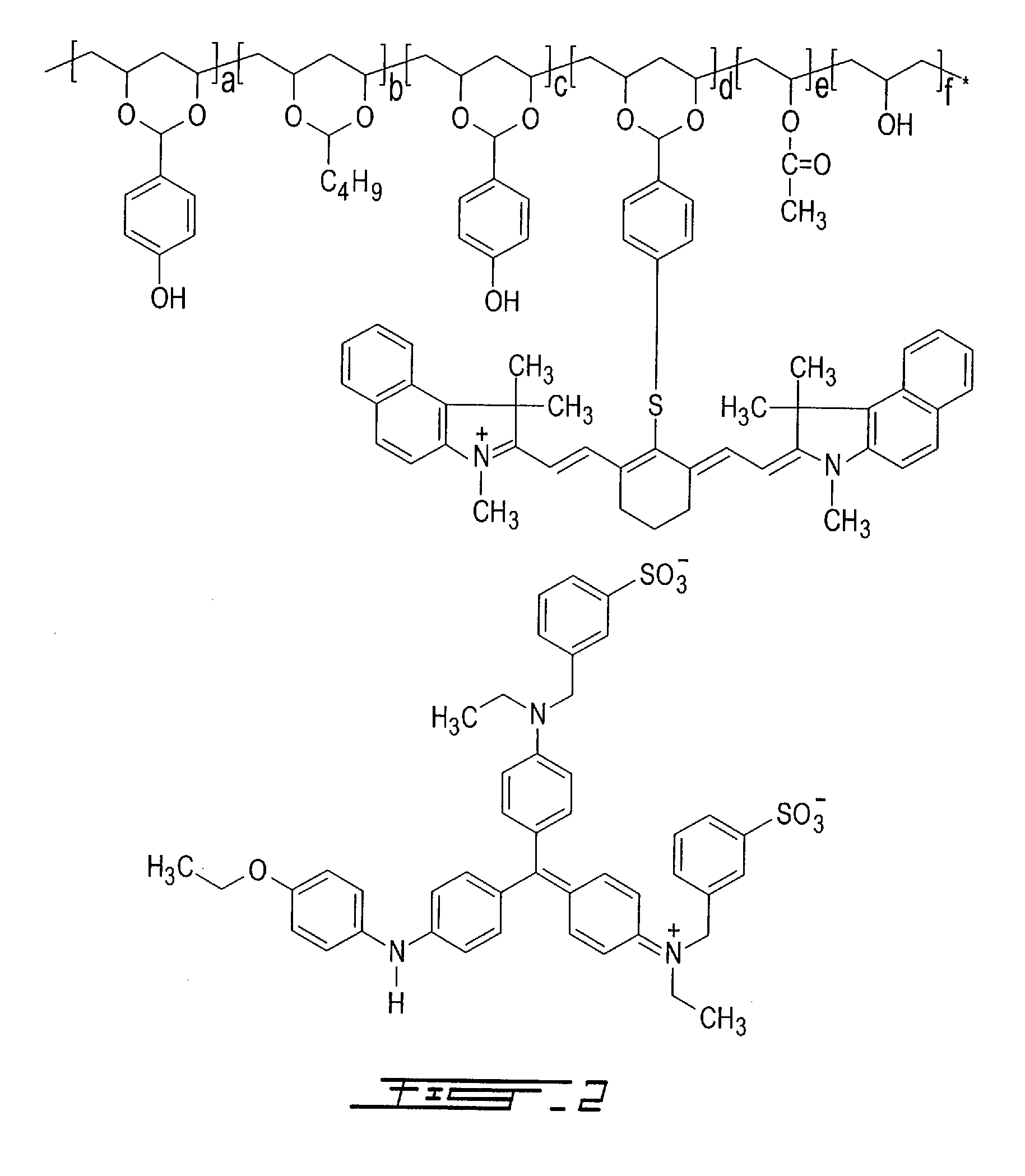

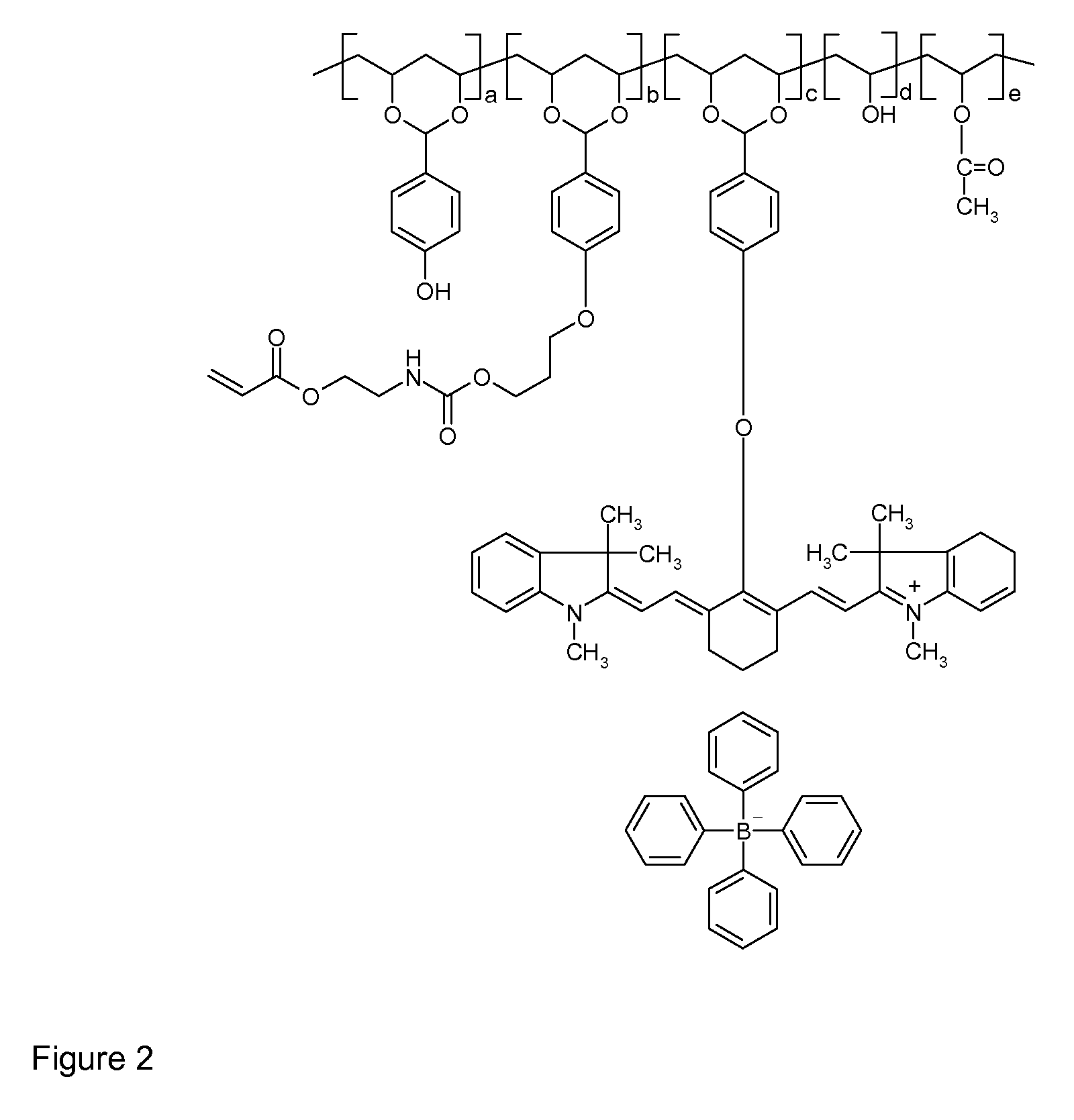

Materials for lithographic plates coatings, lithographic plates and coatings containing same, methods of preparation and use

InactiveUS20070269739A1Extended shelf lifeEasy to processOrganic compound preparationPhotosensitive materialsAcetal copolymerPlanographic printing

This invention relates to iodonium salts, acetal copolymers and polymer binders comprising functional groups capable of undergoing cationic or radical polymerization, their method of preparation and their use in the preparation of coating solutions and coatings. This invention also relates to coatings containing the iodonium salts, acetal copolymers and / or polymer binders and to negative working lithographic printing plates comprising these coatings.

Owner:AMERICAN DYE SOURCE

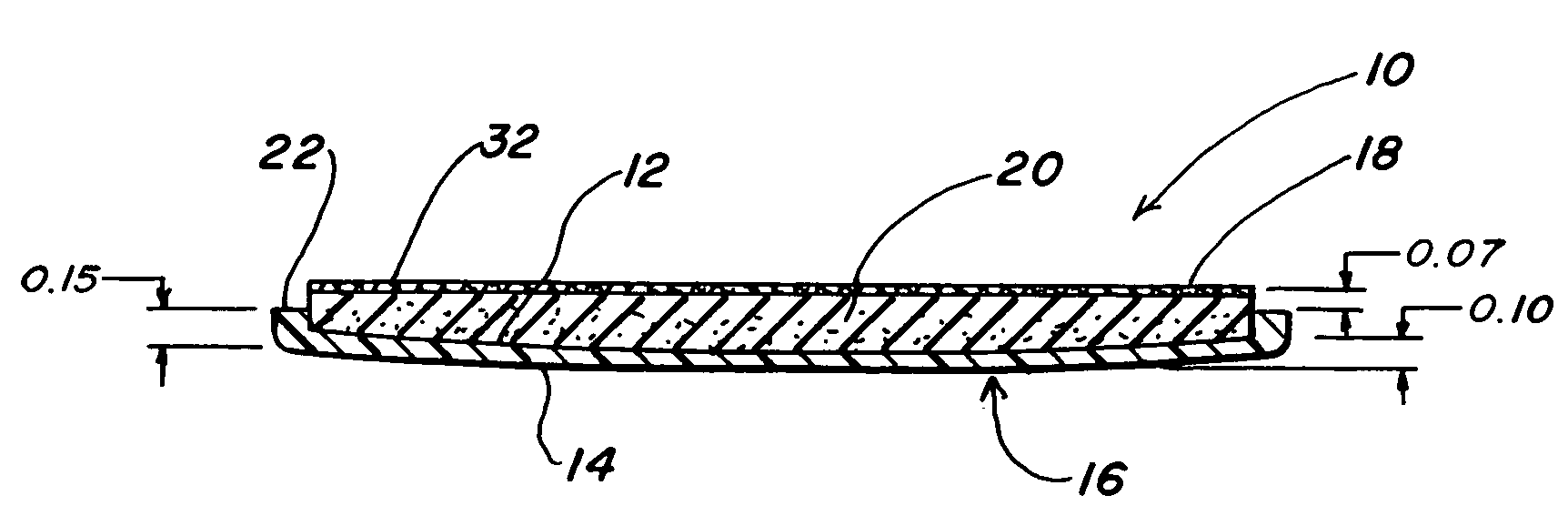

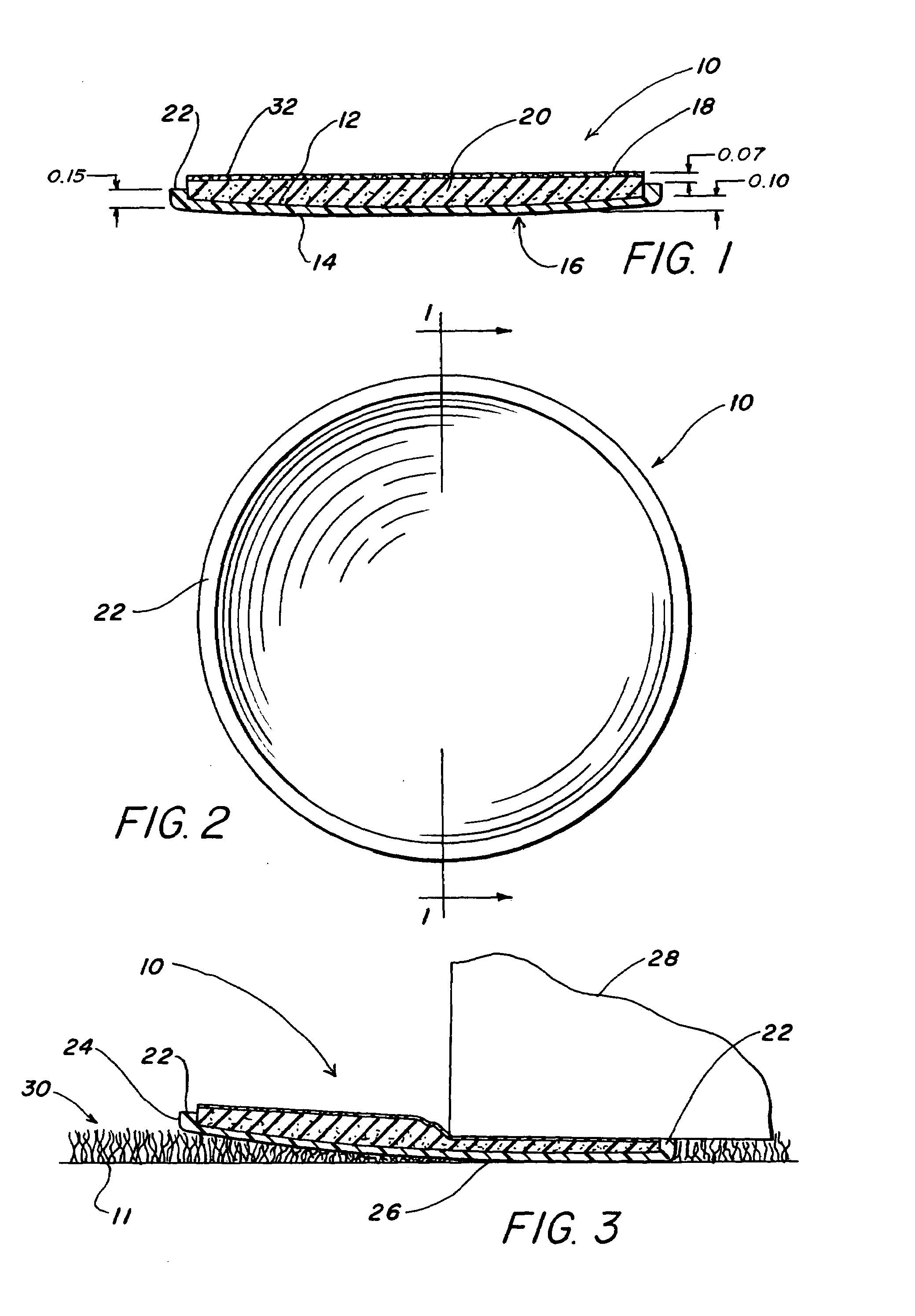

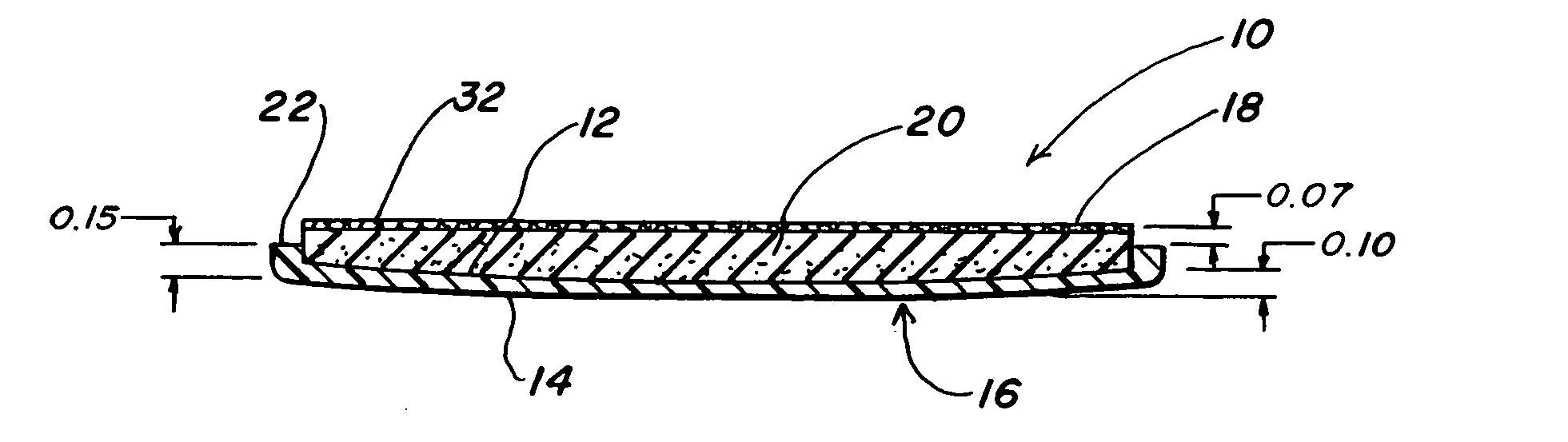

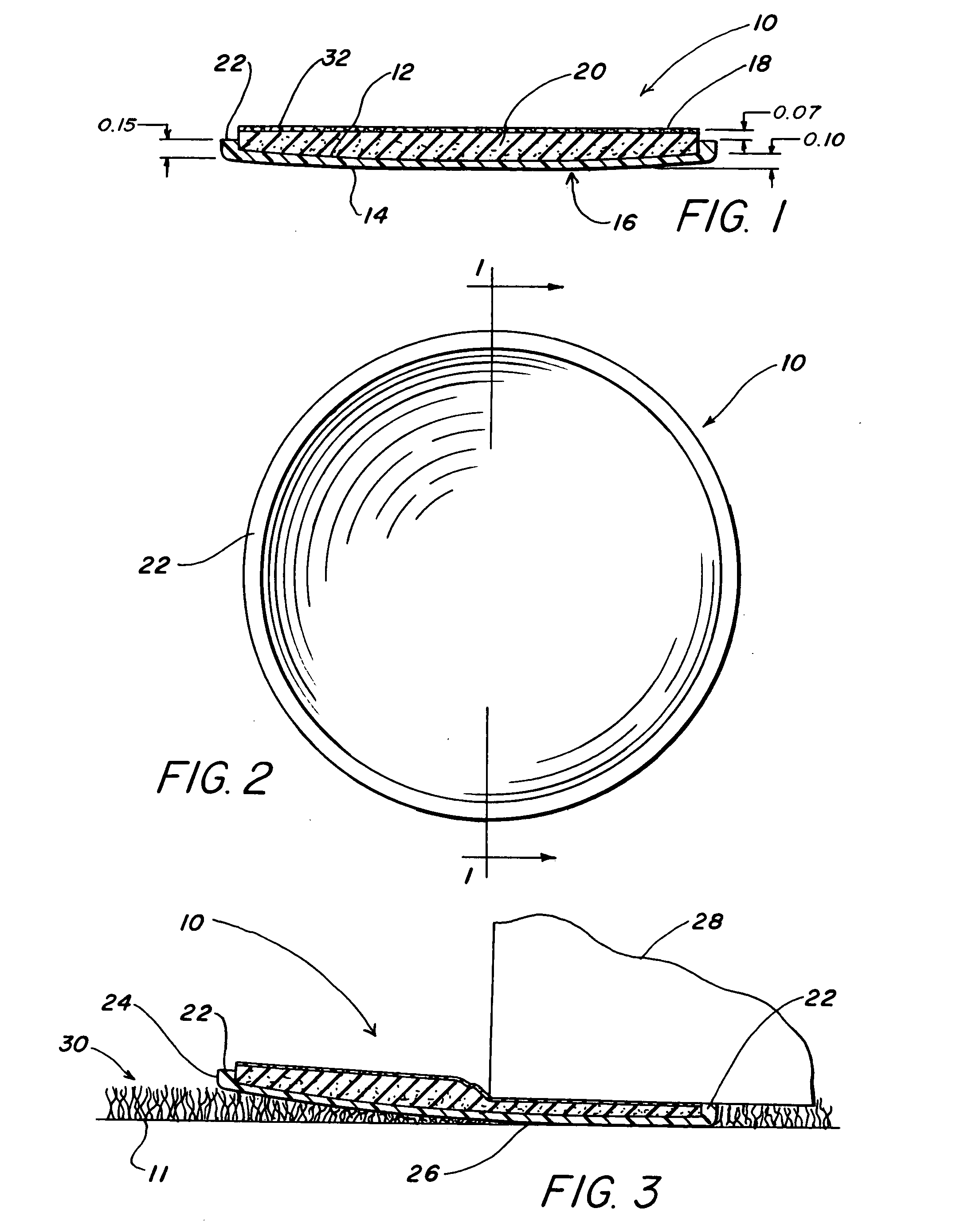

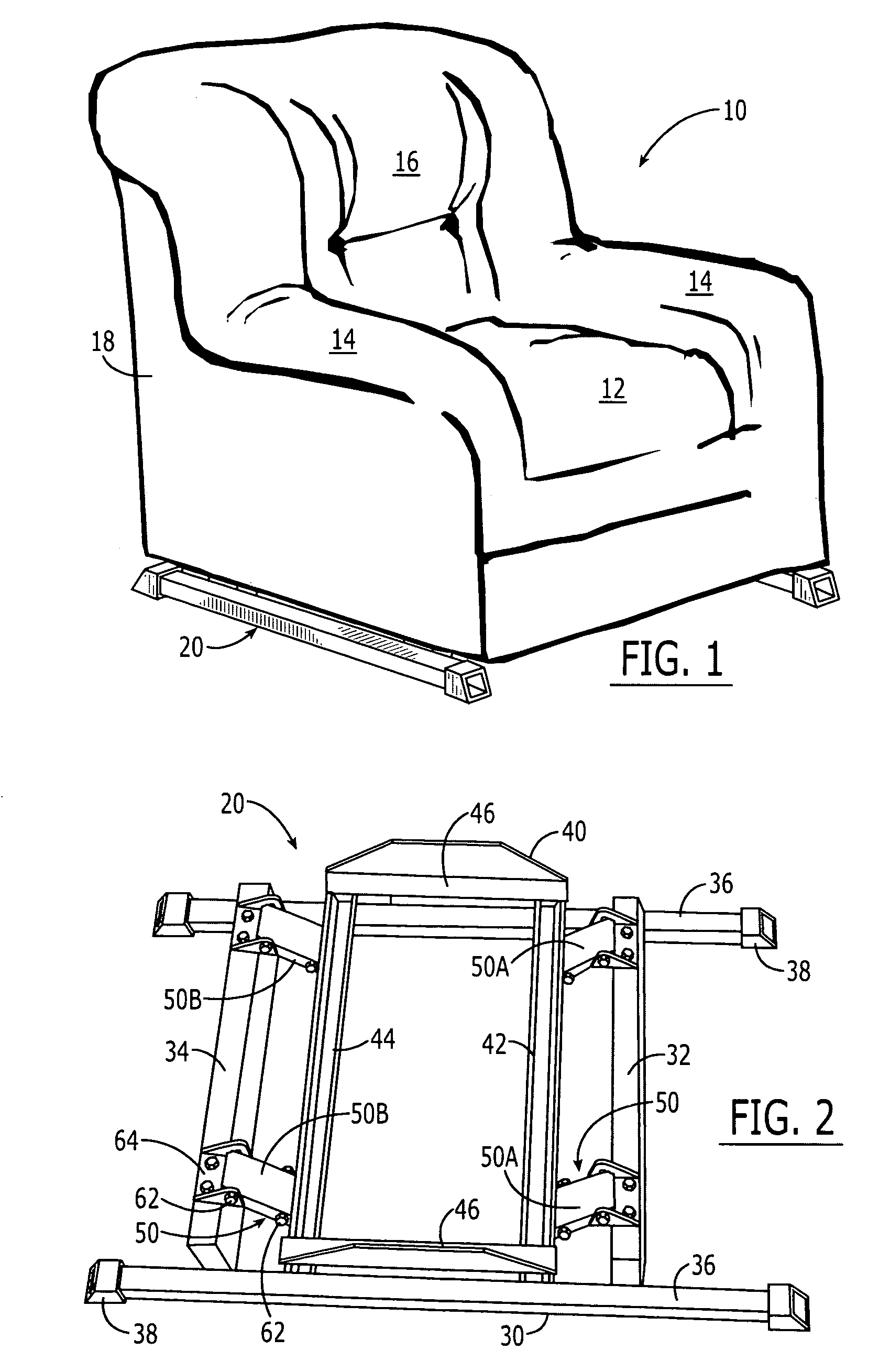

Heavy duty molded equipment slide

A slide formed from an upwardly cupped plate made of an acetal copolymer matrix into which a lubricant is incorporated with slidability and load baring capability making it suitable for use in moving furniture or other heavy objects across a floor. A non-slip pad formed of a synthetic plastic material is seated in a recess formed in an upper face of the plate. The plate is shaped such that when it is partially inserted under a heavy object, a forward edge of a lower face of the plate rises above the floor such that the slide will pass over obstacles.

Owner:SAFETY CRAFTED TOOL SOLUTIONS

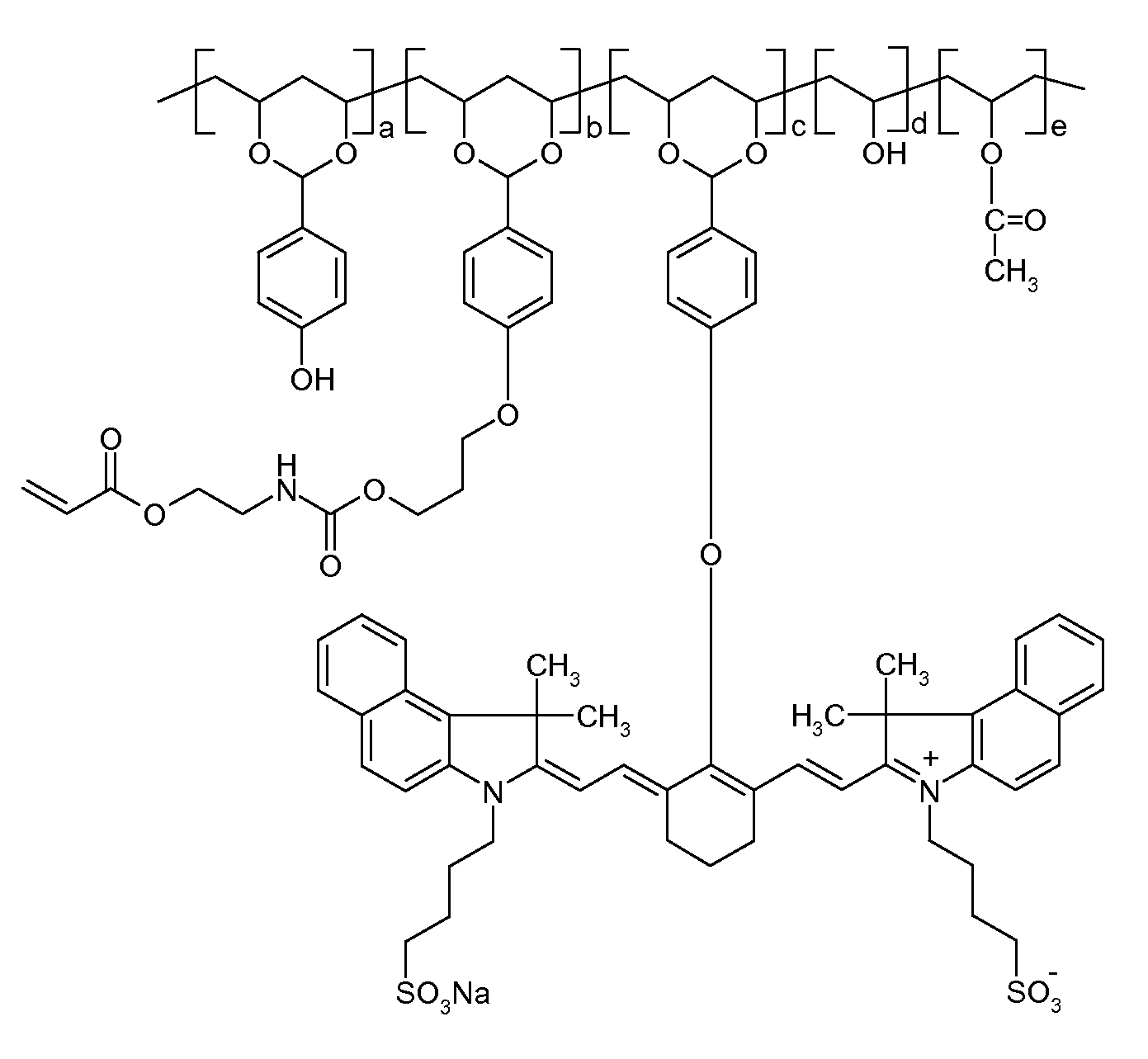

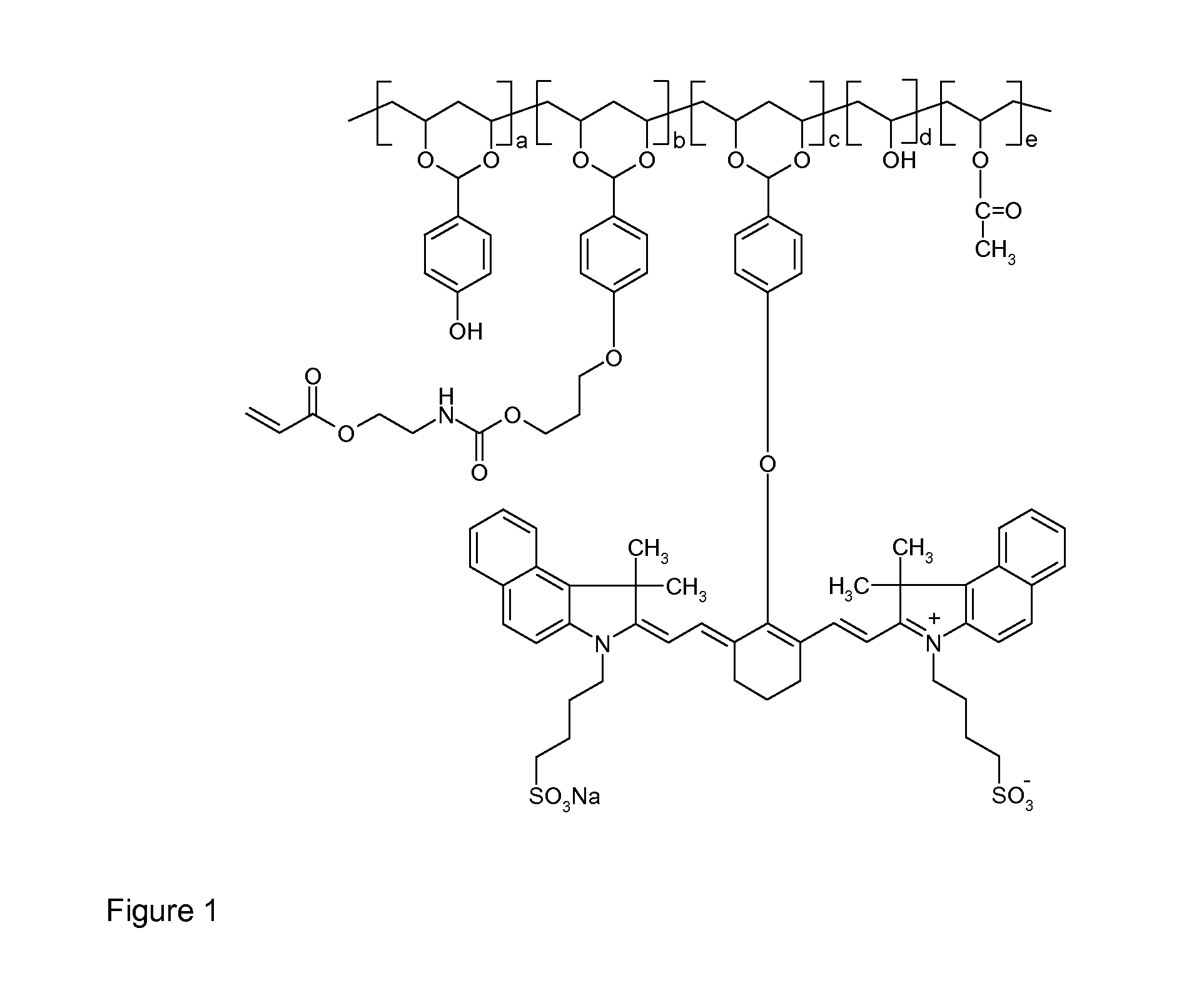

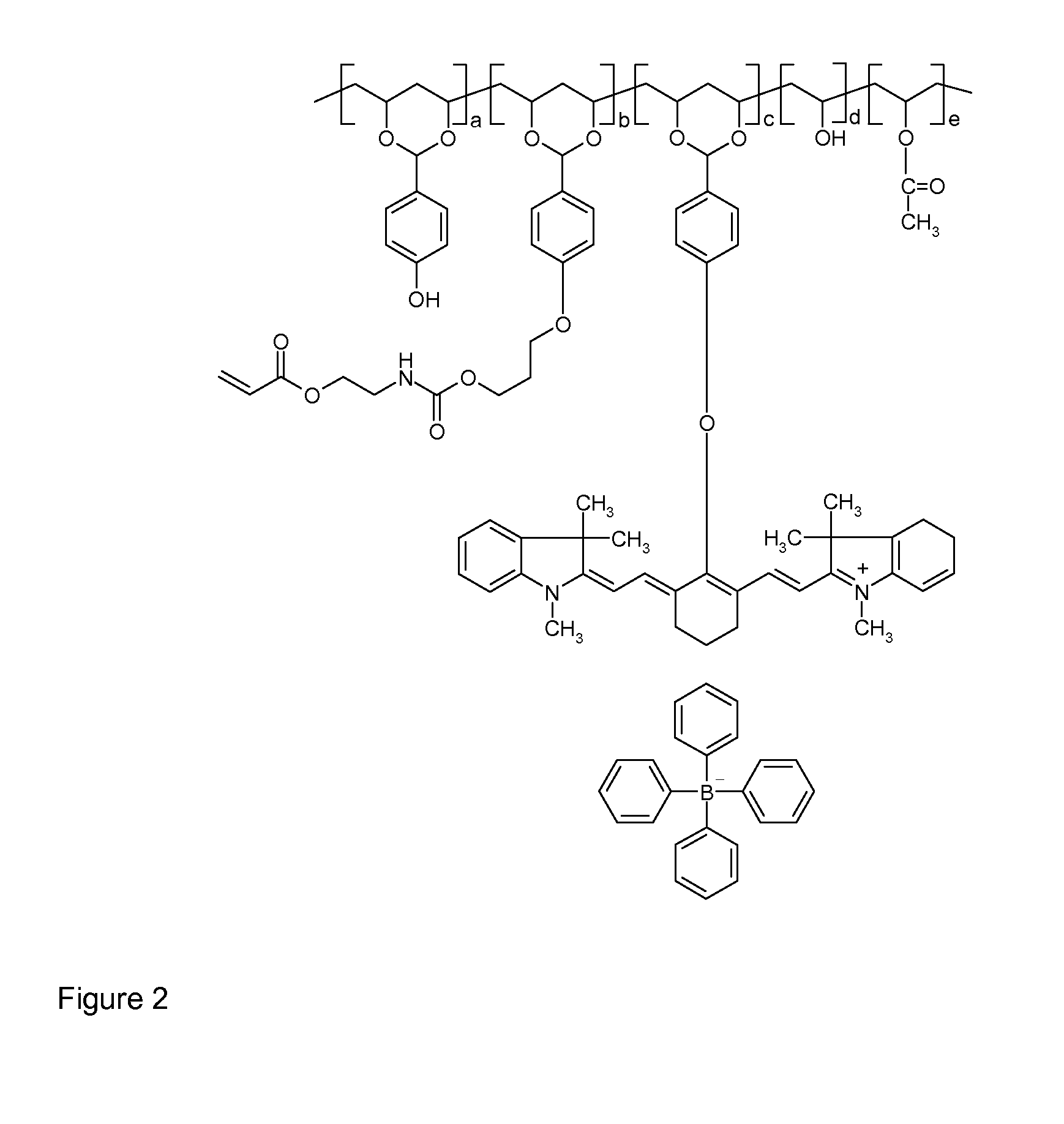

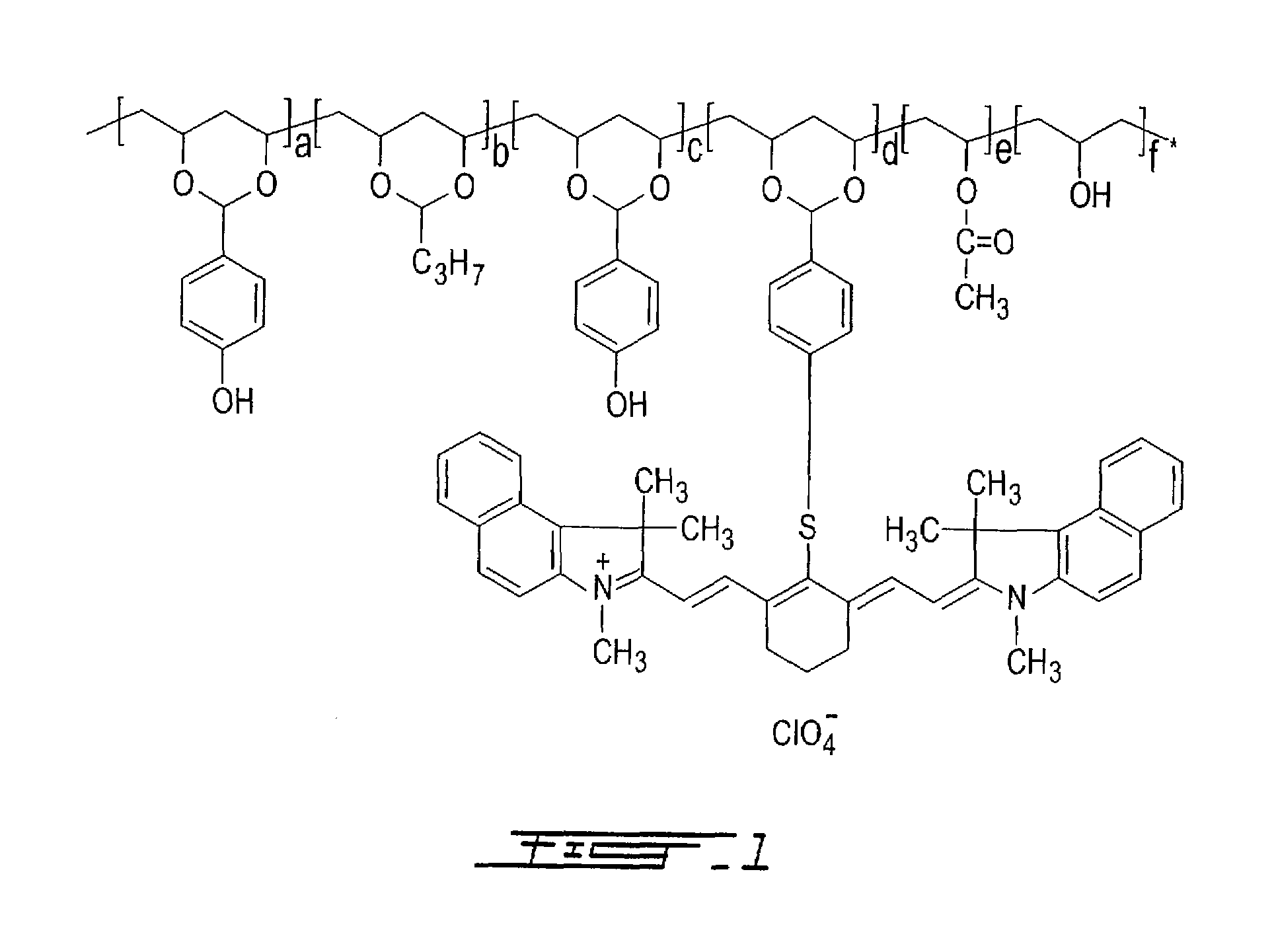

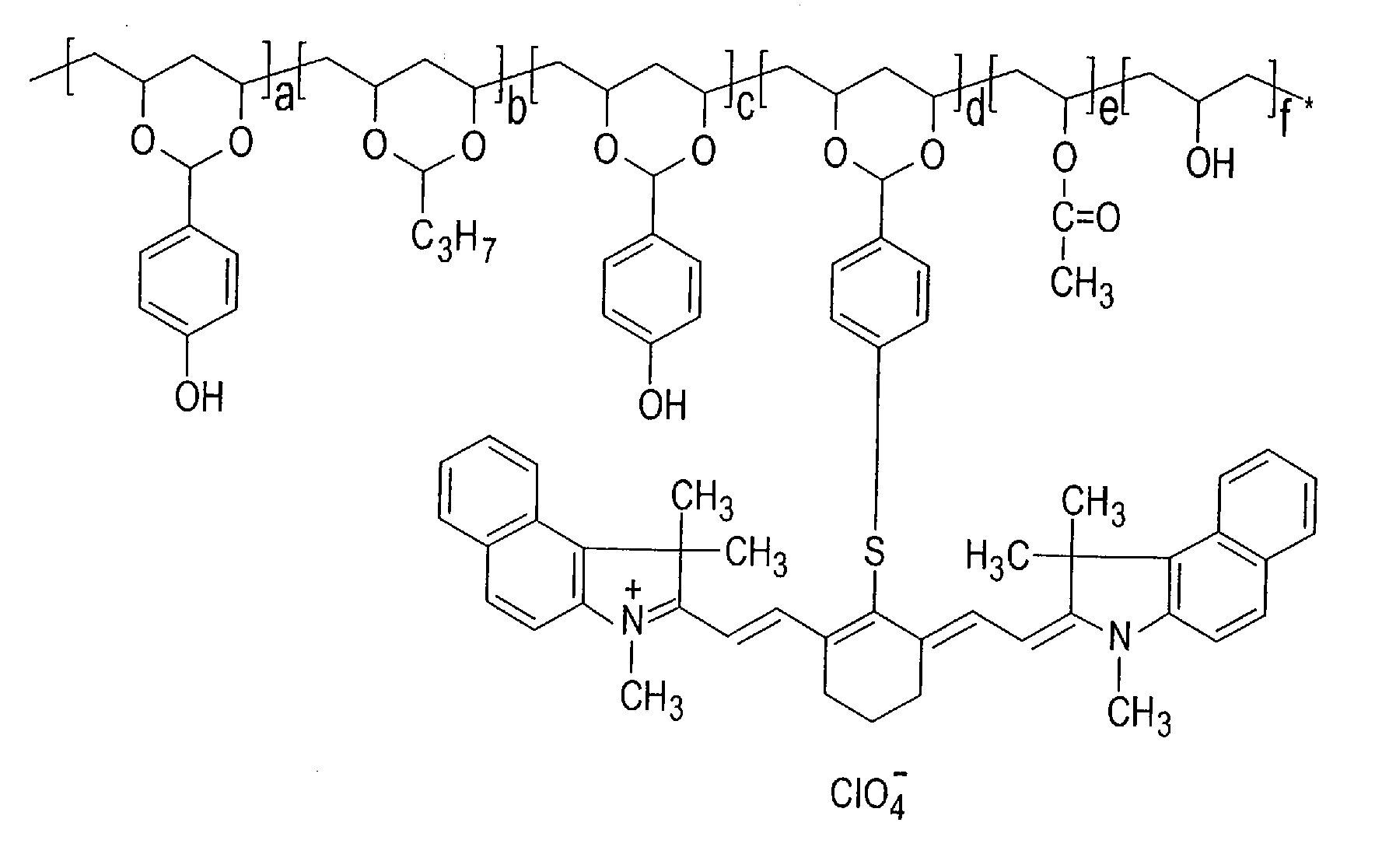

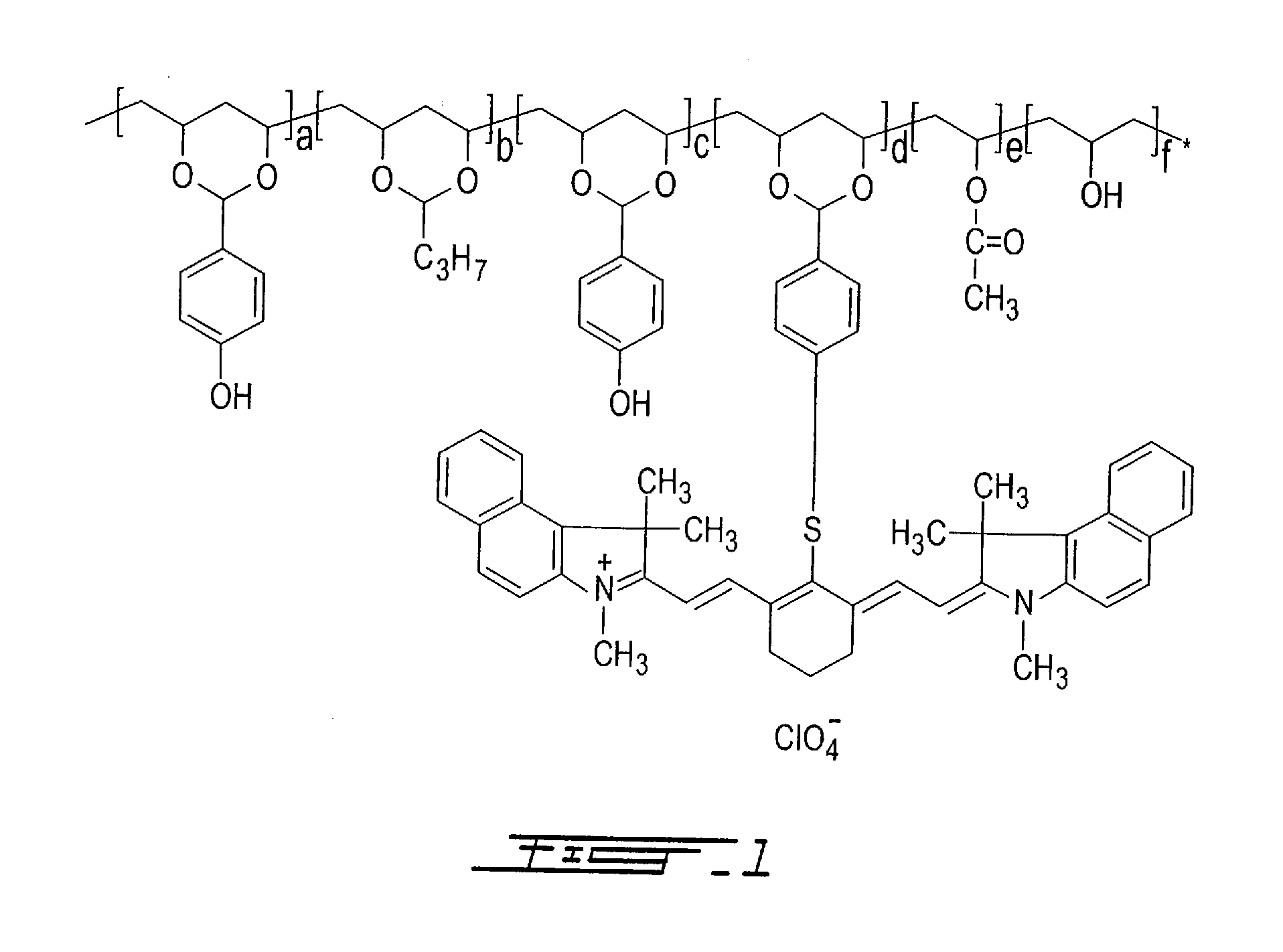

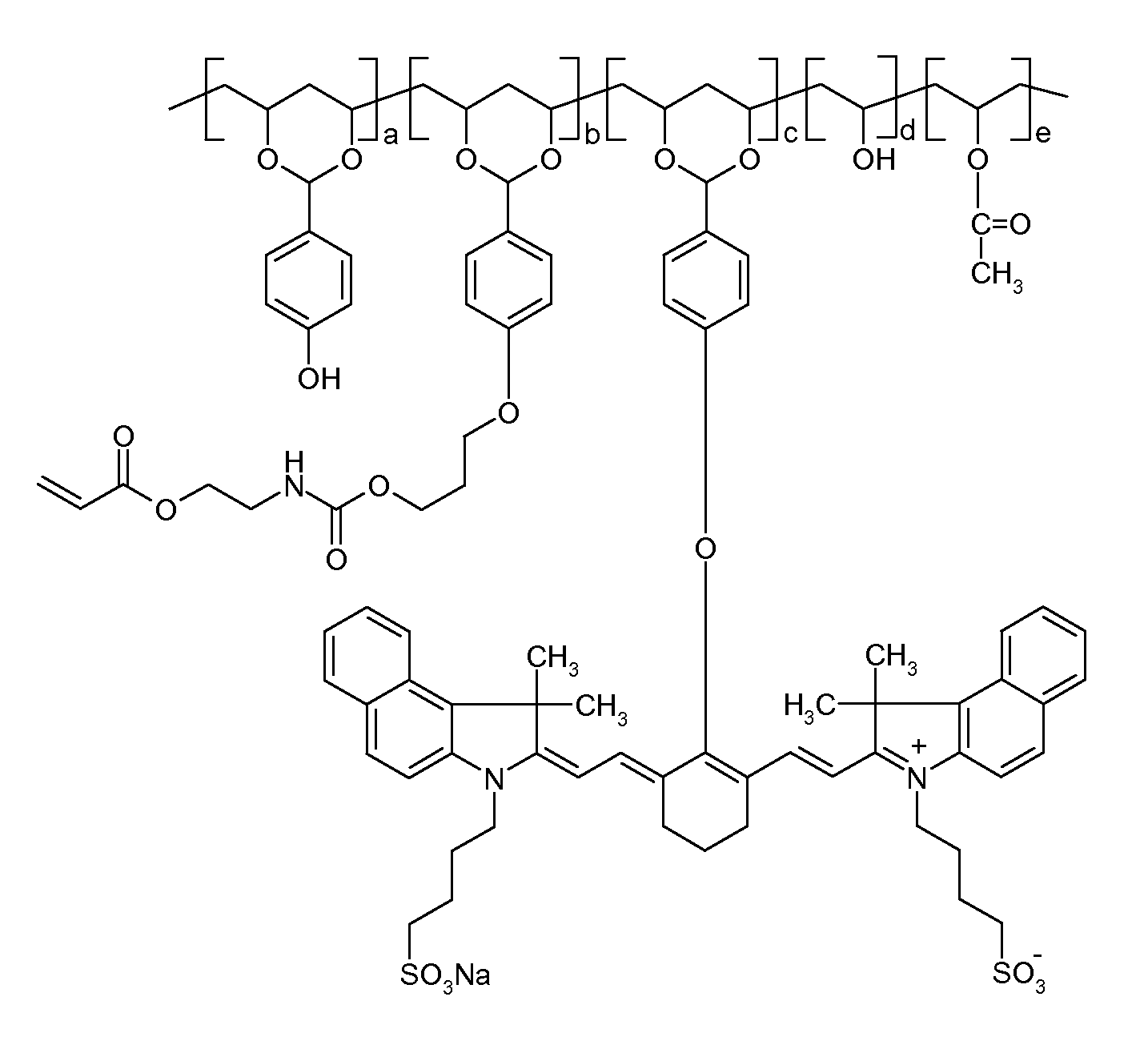

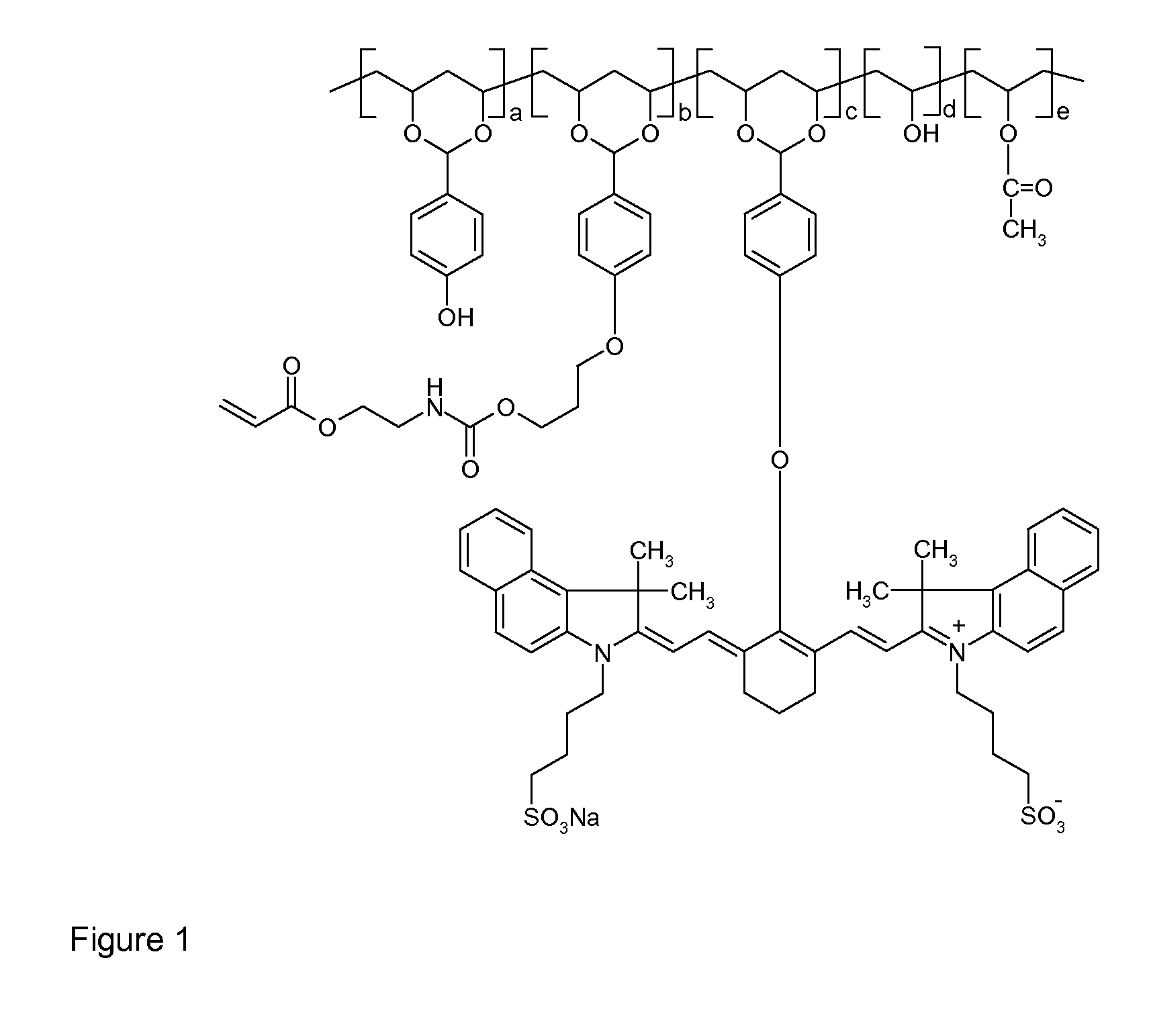

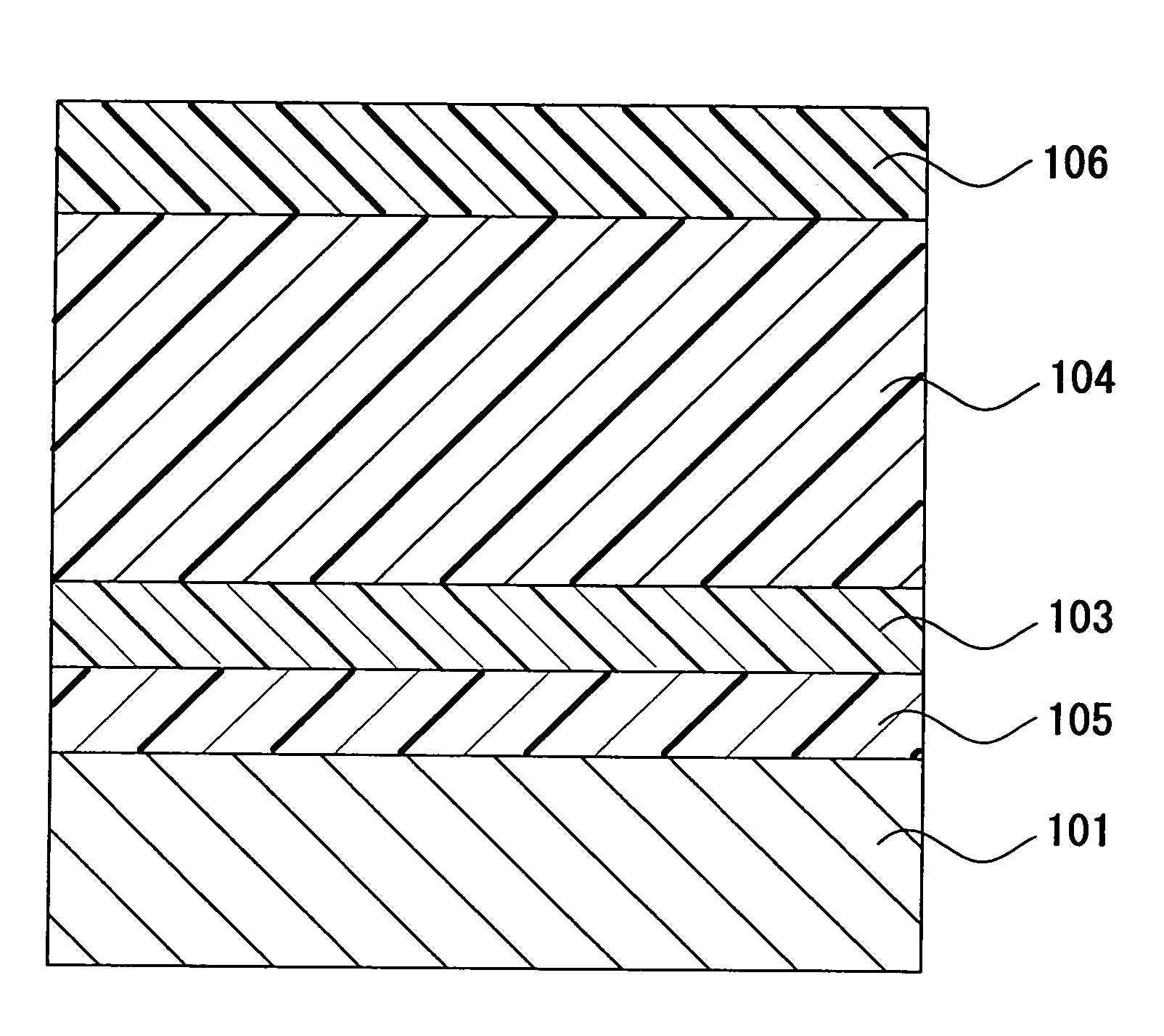

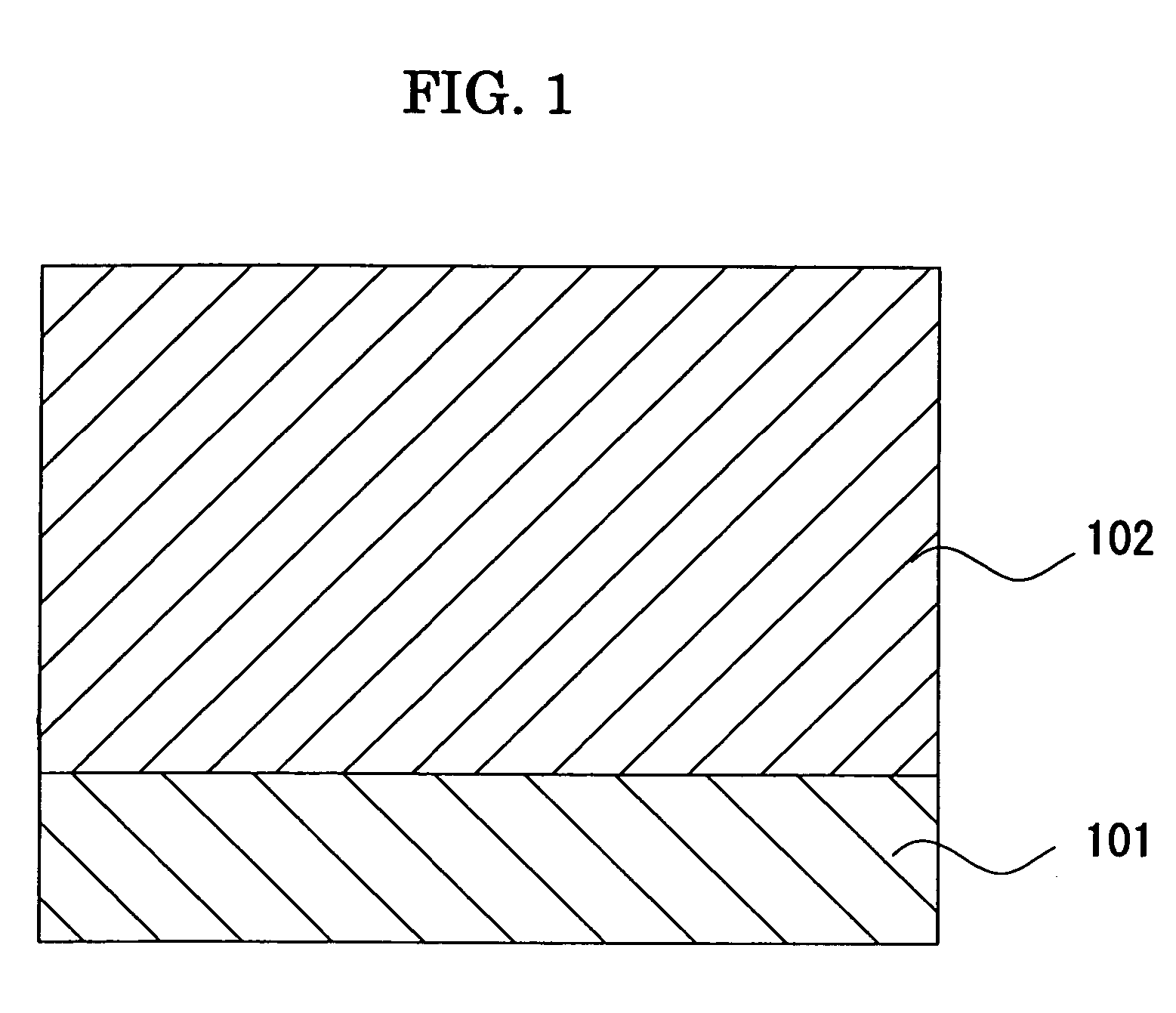

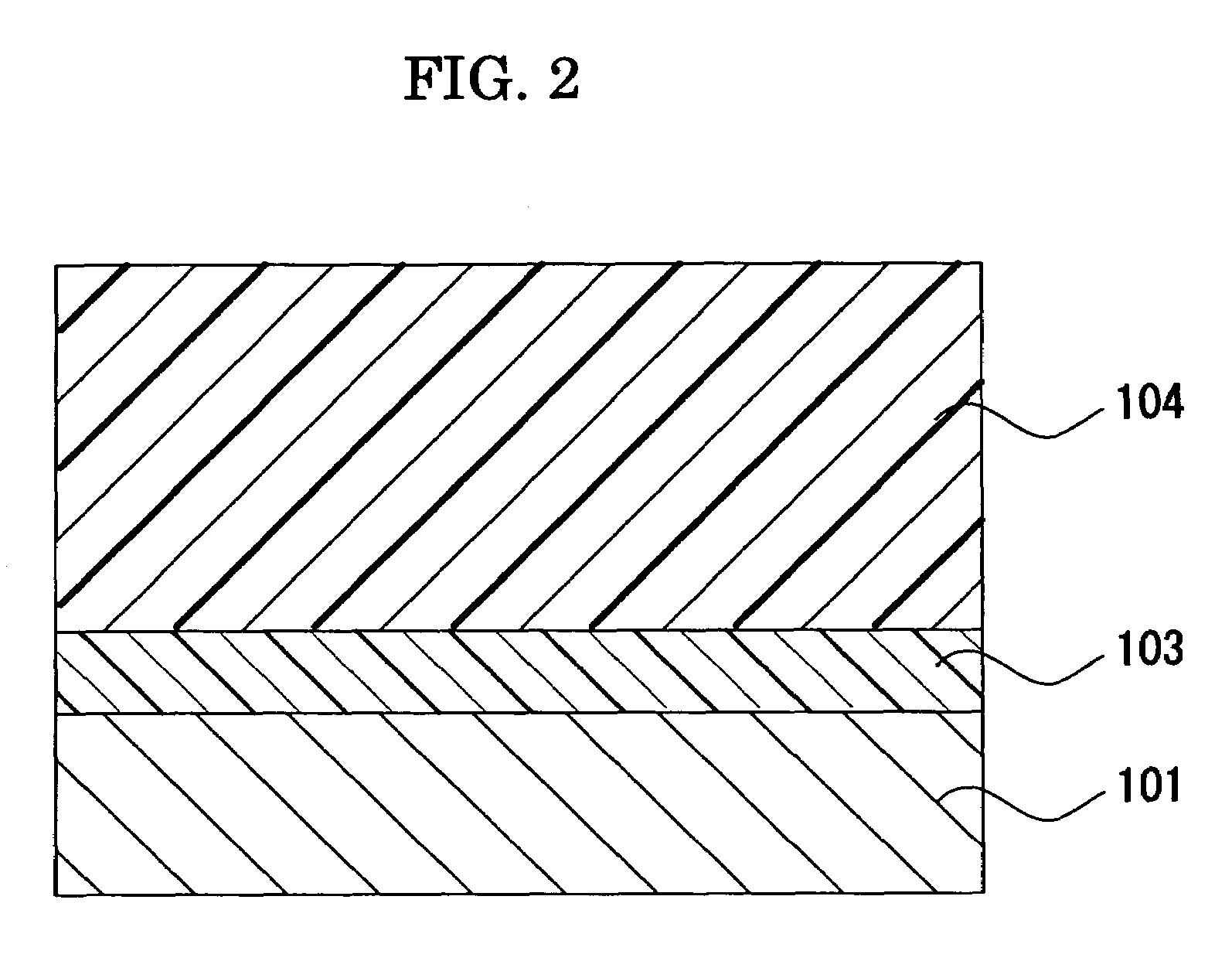

Thermally reactive near-infrared absorbing acetal copolymers, methods of preparation and methods of use

InactiveUS7473515B2Photosensitive materialsSemiconductor/solid-state device manufacturingGum printingAcetal copolymer

Described herein are novel thermally reactive near-infrared absorbing acetal copolymers that undergo chemical and physical changes upon exposure to near-infrared radiation. Also described are the methods of preparation of the novel acetal copolymers starting either with vinyl-alcohol polymers or with acetal copolymers. Also described are the methods of use of the new near-infrared absorbing acetal copolymers in coatings used in lithographic offset printing plates that can be directly imaged with near-infrared laser imaging devices in computer-to-plate and digital offset printing technologies. The novel acetal copolymers are also useful in photoresist applications, rapid prototyping of printed circuit boards and chemical sensor development.

Owner:AMERICAN DYE SOURCE

Polyacetal resin composition and molded article thereof

A polyacetal resin composition comprises a polyacetal resin having a trioxane content of not more than 100 ppm (preferably not more than 50 ppm, and more preferably not more than 10 ppm) and at least one stabilizer selected from the group consisting of an antioxidant, a formaldehyde emission inhibitor, a processing stabilizer and a heat stabilizer. The polyacetal resin may be a polyacetal resin (particularly a polyacetal copolymer) in which the trioxane amount is reduced by a solvent treatment and / or a heat treatment. Moreover, the polyacetal resin composition may further contain at least one additive selected from the group consisting of a weather (light)-resistant stabilizer, an impact resistance improver, a gloss control agent, a sliding improver, a coloring agent, and a filler. Such a polyacetal resin composition can reduce the amount of trioxane elution and / or the amount of a volatile organic compound from a molded product thereof.

Owner:POLYPLASTICS CO LTD

Thermally reactive near-infrared absorbing acetal copolymers, methods of preparation and methods of use

InactiveUS20060275698A1Photosensitive materialsSemiconductor/solid-state device manufacturingAcetal copolymerNear infrared radiation

Described herein are novel thermally reactive near-infrared absorbing acetal copolymers that undergo chemical and physical changes upon exposure to near-infrared radiation. Also described are the methods of preparation of the novel acetal copolymers starting either with vinyl-alcohol polymers or with acetal copolymers. Also described are the methods of use of the new near-infrared absorbing acetal copolymers in coatings used in lithographic offset printing plates that can be directly imaged with near-infrared laser imaging devices in computer-to-plate and digital offset printing technologies. The novel acetal copolymers are also useful in photoresist applications, rapid prototyping of printed circuit boards and chemical sensor development.

Owner:AMERICAN DYE SOURCE

Polyacetal resin composition and molded article thereof

InactiveCN1875066AImprove the surrounding environmentImprove impact resistanceAntioxidantAcetal copolymer

A polyacetal resin composition which comprises a polyacetal resin having a trioxane content of 100 ppm or lower (desirably 50 ppm or lower, preferably 10 ppm or lower) and at least one stabilizer selected among an antioxidant, formaldehyde depressant, processing stabilizer, and heat stabilizer. The polyacetal resin may be a polyacetal resin (especially a copolyacetal) whose trioxane content has been reduced by a solvent treatment and / or heat treatment. The polyacetl resin composition may further contain at least one additive selected among a weathering (light) stabilizer, impact modifier, gloss control agent, sliding modifier, colorant, and filler. This polyacetal resin composition can give a molded article significantly reduced in trioxane extraction and / or volatile-organic amount.

Owner:POLYPLASTICS CO LTD

Heavy duty molded equipment slide

A slide formed from an upwardly cupped plate made of an acetal copolymer matrix into which a lubricant is incorporated with slidability and load baring capability making it suitable for use in moving furniture or other heavy objects across a floor. A non-slip pad formed of a synthetic plastic material is seated in a recess formed in an upper face of the plate. The plate is shaped such that when it is partially inserted under a heavy object, a forward edge of a lower face of the plate rises above the floor such that the slide will pass over obstacles.

Owner:SAFETY CRAFTED TOOL SOLUTIONS

Materials for lithographic plates coatings, lithographic plates and coatings containing same, methods of preparation and use

InactiveUS20100035183A1Easy to processOrganic compound preparationPhotosensitive materialsAcetal copolymerPlanographic printing

This invention relates to iodonium salts, acetal copolymers and polymer binders comprising functional groups capable of undergoing cationic or radical polymerization, their method of preparation and their use in the preparation of coating solutions and coatings. This invention also relates to coatings containing the iodonium salts, acetal copolymers and / or polymer binders and to negative working lithographic printing plates comprising these coatings.

Owner:AMERICAN DYE SOURCE

Polyacetal resin composition and molded article thereof

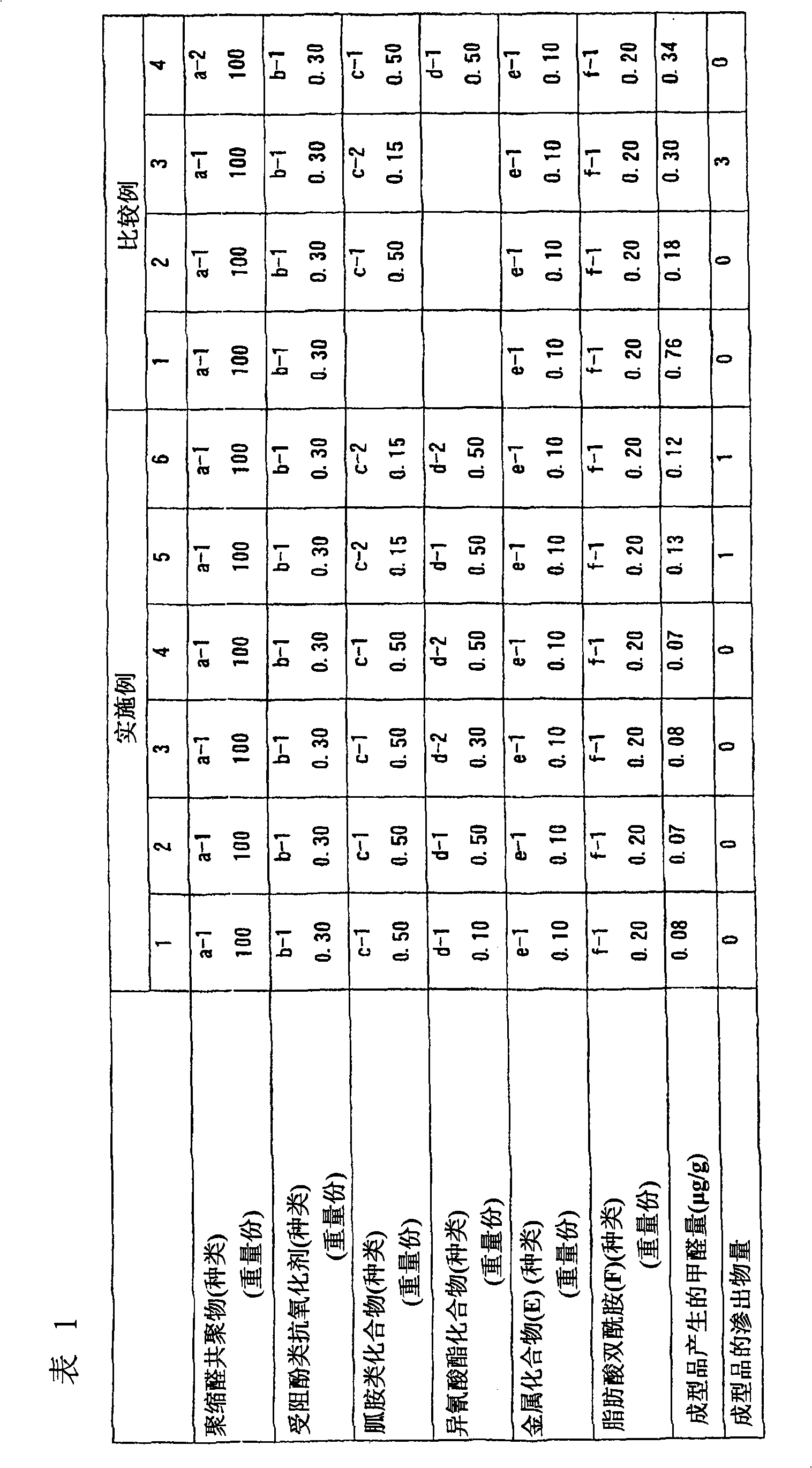

The present invention provides a polyacetal resin composition having excellent processability and stability, significantly suppressing the amount of formaldehyde generated from the molded article thereof, and preventing the bleeding of blending components. Specifically, to 100 parts by weight of (A) a polyacetal copolymer in which the amount of hemiformal terminal group is 1.0 mmol / kg or less, the amount of formyl terminal group is 0.5 mmol / kg or less, and the amount of unstable terminal group is 0.5% by weight or less, there are added: 0.01 to 3 parts by weight of (B) a hindered phenol-based antioxidant; 0.01 to 1 part by weight of (C) a hydrazide compound; and 0.01 to 1 part by weight of a compound selected from (D) an isocyanate compound, an isothiocyanate compound, and a modified compound thereof.

Owner:POLYPLASTICS CO LTD

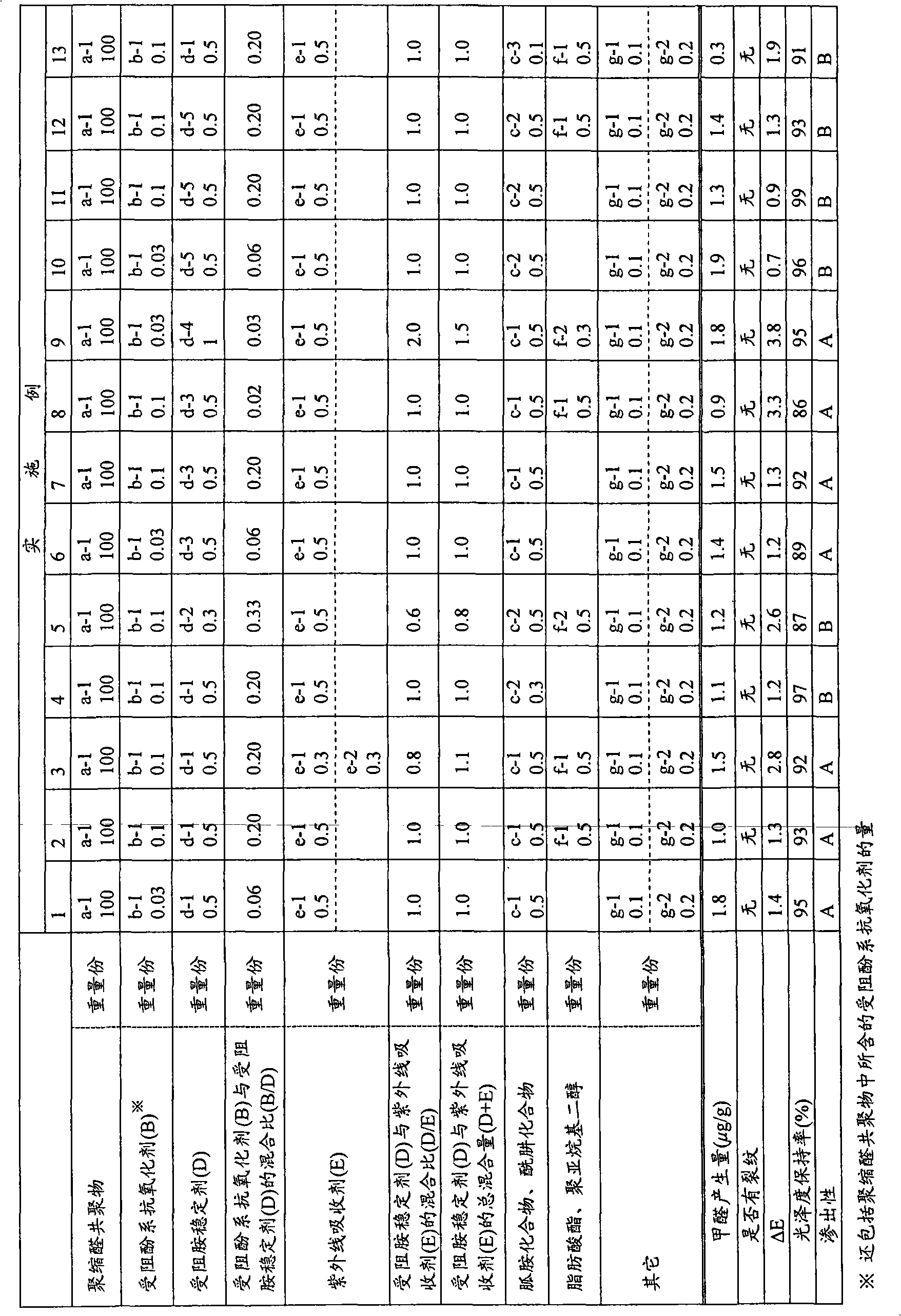

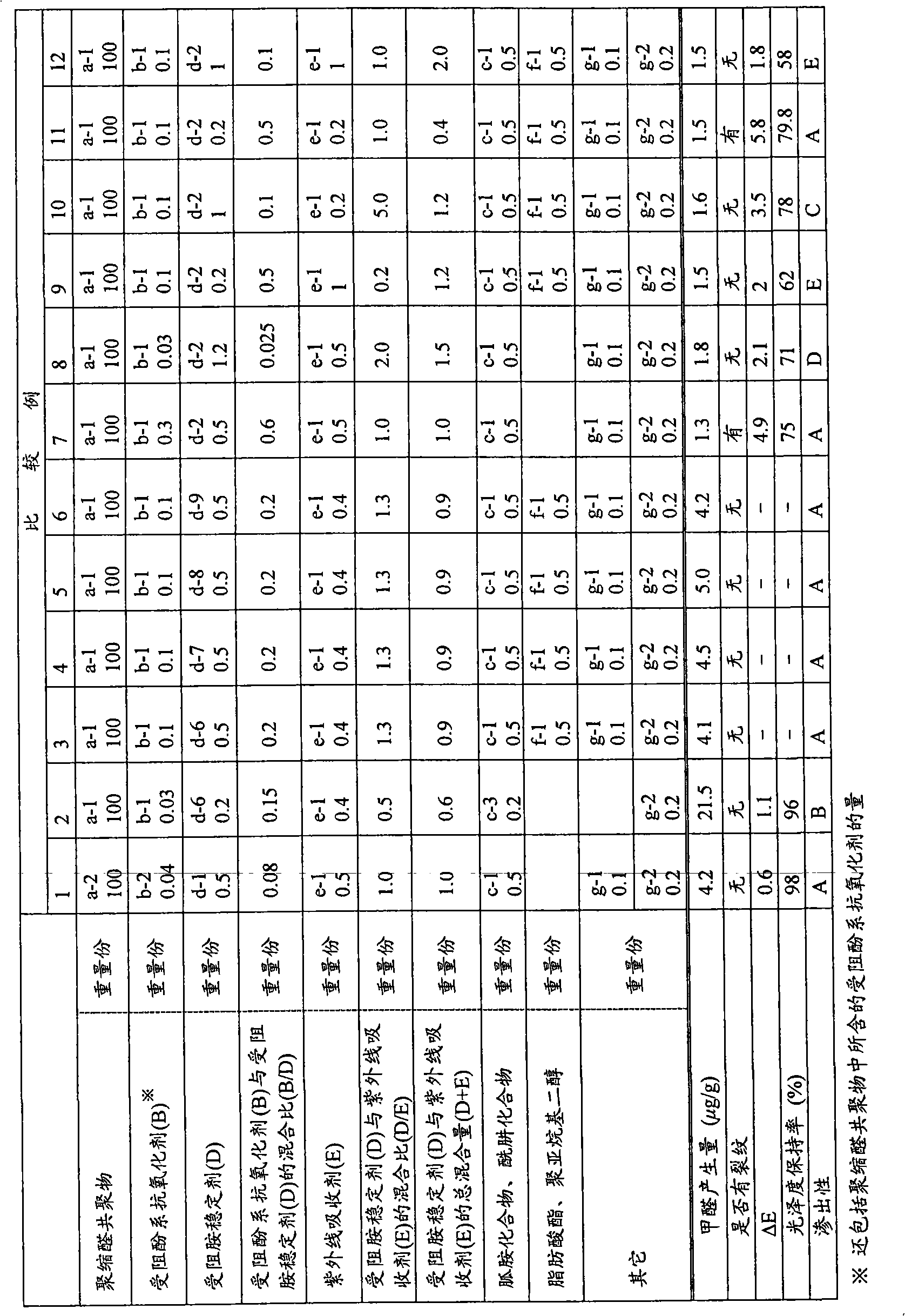

Polyacetal resin composition

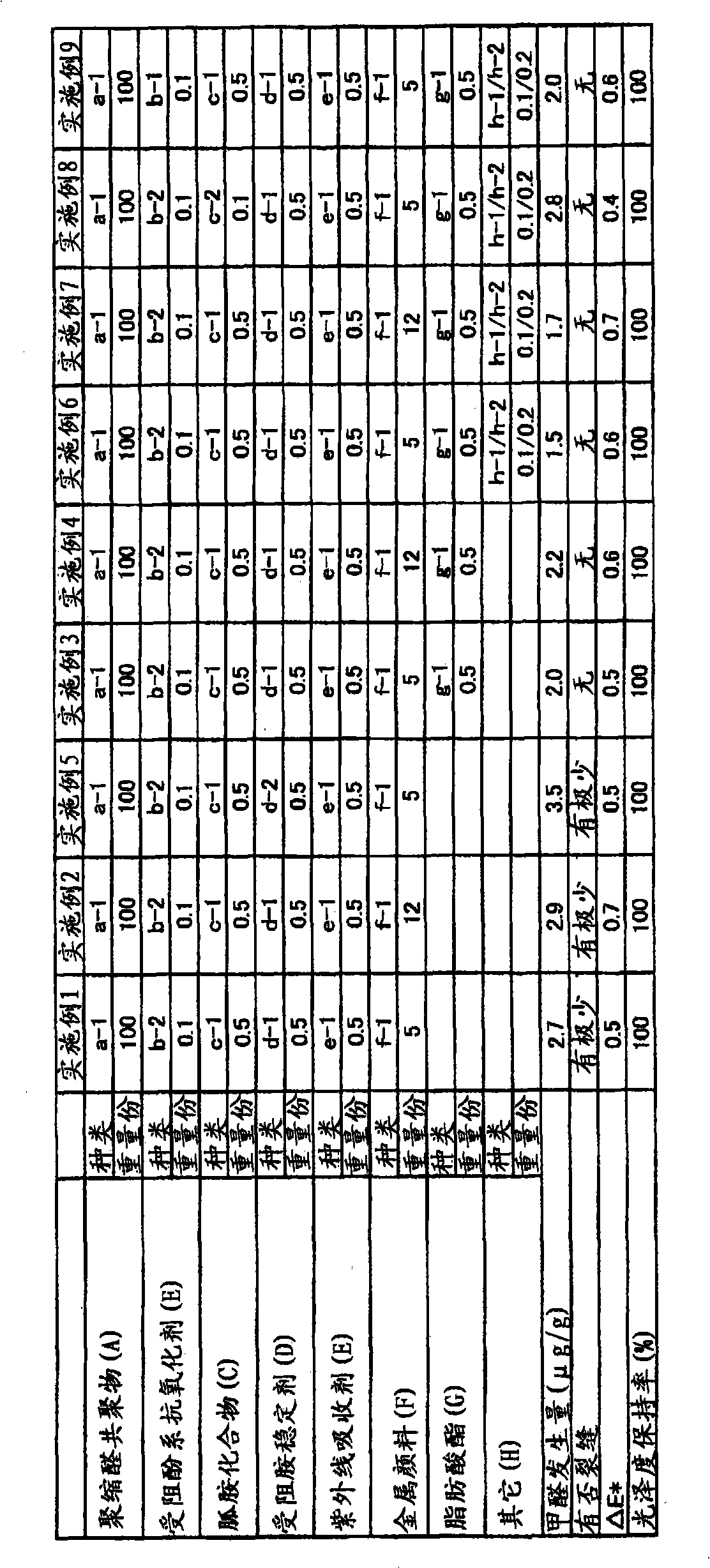

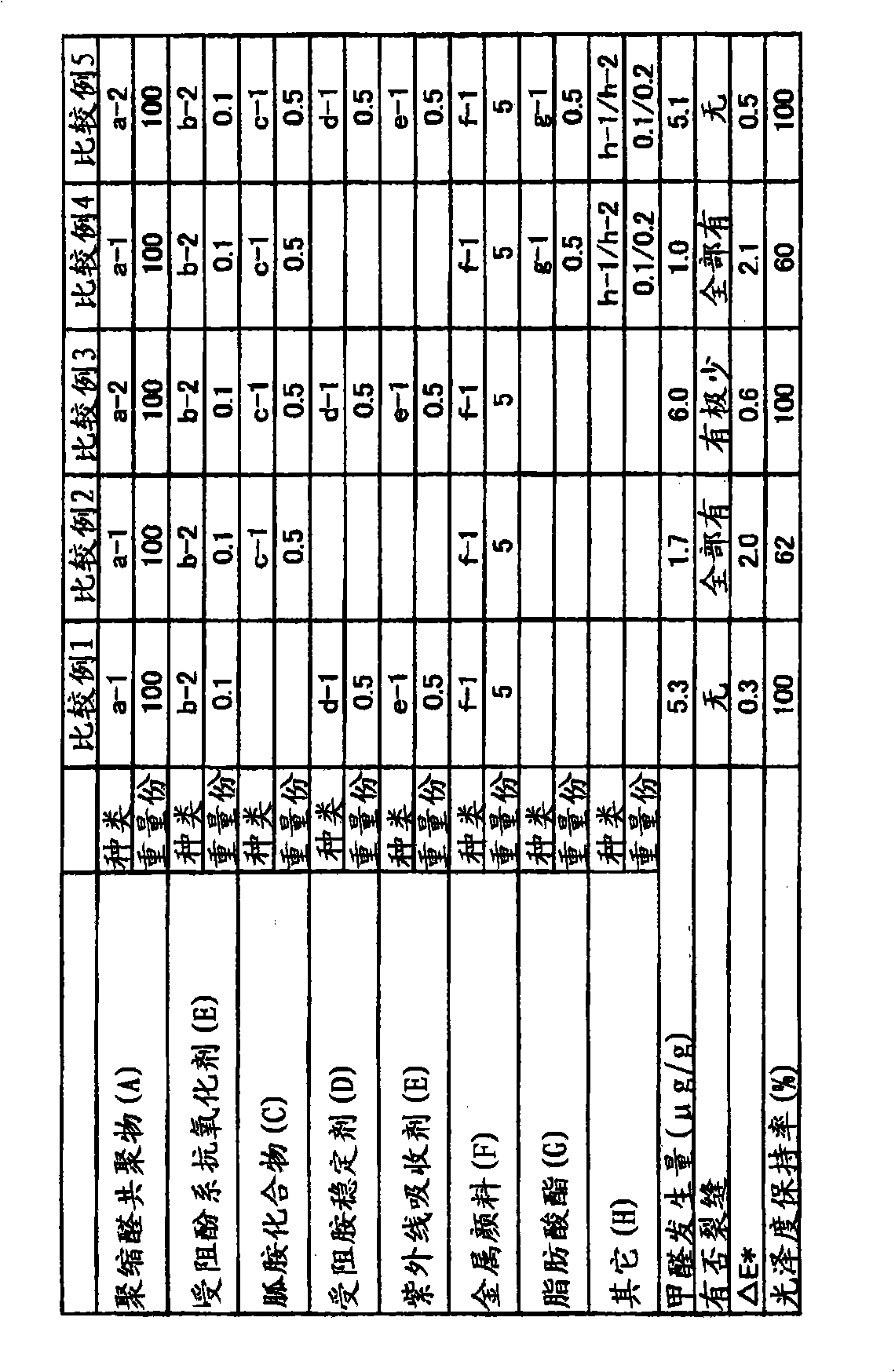

The present invention provides a polyacetal resin composition having a metallic appearance, suppressing the generation of volatile organic compound (VOC), in particular formaldehyde from the molded article thereof to an extremely low level and giving excellent weathering (light) resistance. Specifically, (A) 100 parts by weight of a polyacetal copolymer containing 1.0 mmol / kg or smaller of a hemiformal terminal group, 2.0 mmol / kg or smaller of a formyl terminal group, 0.5 wt % or smaller of an unstable terminal group, (B) 0.03 to 0.30 part by weight of a hindered phenol-based antioxidant, (C) 0.01 to 1 part by weight of a guanamine compound, (D) 0.2 to 1 part by weight of a hindered amine-based stabilizer, and (E) 0.1 to 1 part by weight of an ultraviolet absorber, and (F) 1 to 20 parts by weight of a metallic pigment are blended together.

Owner:POLYPLASTICS CO LTD

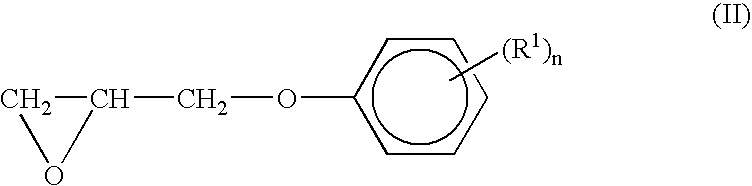

Preparation method of cross-linkable acetal copolymer

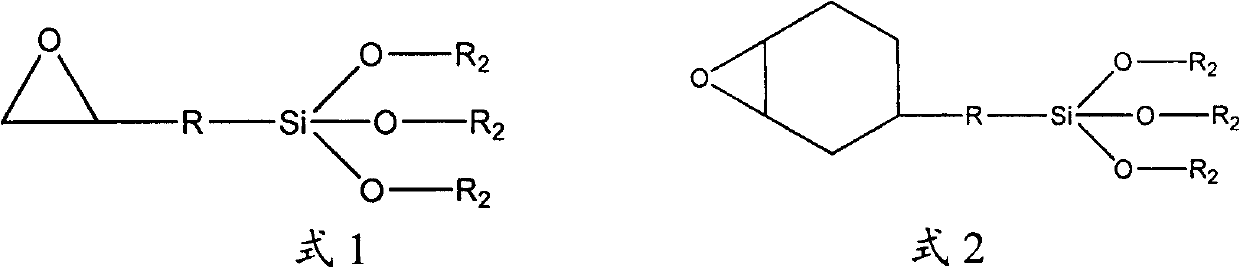

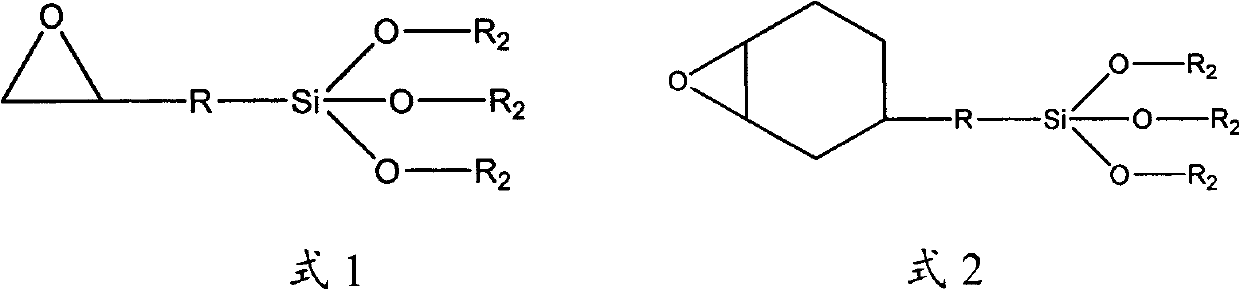

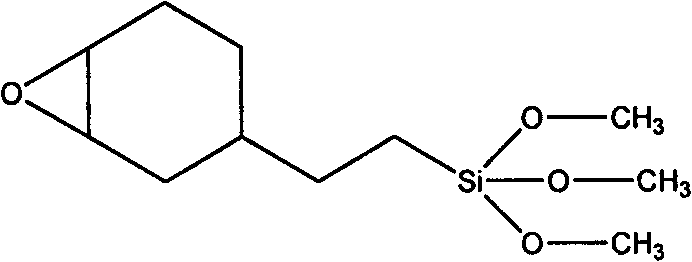

The invention discloses a preparation method of cross-linkable acetal copolymer. The preparation method is characterized in that: ternary polymerization of (a) trioxymethylene (TOX), (b) dioxolane (DXL) or cyclohexene oxide (CHO) and (c) a triethoxysilane compound with an epoxy group is catalyzed under a water-free and oxygen-free condition in the presence of an initiator BF3 complex or HClO4, wherein the triethoxysilane compound is shown as a formula 1 or 2; R is an alkyl group or aryl group containing 1-18 carbon atoms or a halogen-substituted group containing heteroatoms N, O, S and P, containing no active hydrogen and containing 1-18 carbon atoms; and R2 is an alkyl group containing 1-8 carbon atoms.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Load/unload ramps and their compositions

InactiveUS7355816B1Disposition/mounting of recording headsRecord information storagePolyetherimidePerfluoropolyether

Compositions and materials for use in load / unload ramps in magnetic disk drive assemblies are disclosed, particularly compositions or materials to improve at least one of the desired characteristics of low wear, low cost, high mechanical stability and high moldability. Thermoplastic polymers, such as acetal homopolymers, acetal copolymers, polyetherimides, polyphenylene sulfides, and polysulfones, are combined with other compositions, such as polyaramides, to improve the characteristics of a load / unload ramp constructed therefrom. Additionally, another material may be added, such as a polytetrafluoroethylene or perfluoropolyether.

Owner:SEAGATE TECH HDD HLDG +3

Polyacetal resin composition

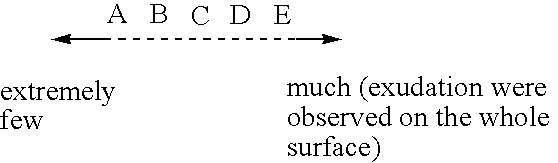

The present invention provides a polyacetal resin composition having an excellent processability and stability, significantly suppressing the generation of formaldehyde from molded articles thereof, preventing exudation of components, and being excellent in weathering (light) resistance. Specifically, (A) a polyacetal copolymer having 1.0 mmol / kg or smaller quantity of a hemiformal terminal group, 2.0 mmol / kg or smaller quantity of a formyl terminal group, and 0.5% by weight or smaller quantity of an unstable terminal group is blended with (B) a hindered phenol-based antioxidant; (C) at least one compound selected from (c-1) a guanamine compound and (c-2) a hydrazide compound; (D) a hindered amine stabilizer in which the nitrogen in a piperidine derivative having a steric hindrance group is tertiary; and (E) a UV absorber in specified quantities and mixing ratios.

Owner:POLYPLASTICS CO LTD

Branched polyacetal resin composition

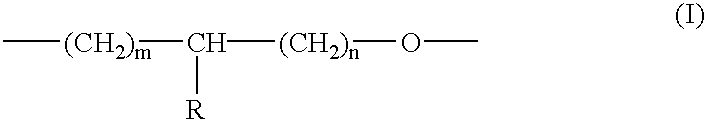

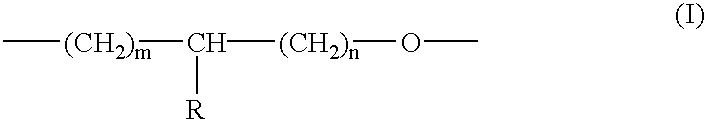

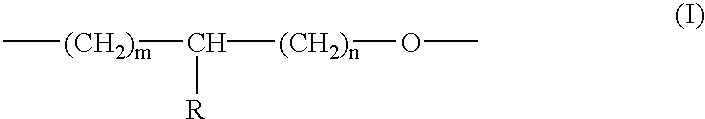

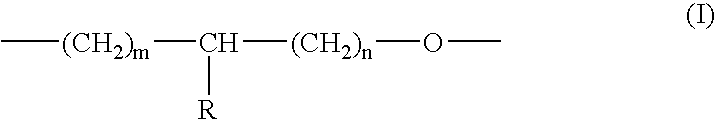

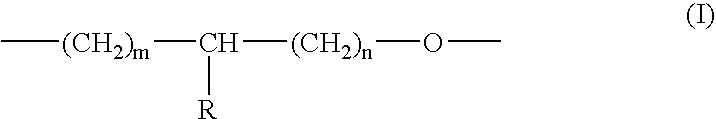

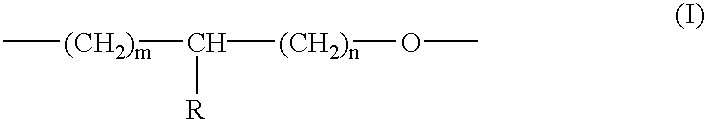

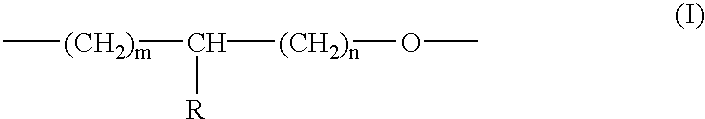

To provide a resin material in which various properties such as excellent appearance and rigidity inherent to a polyacetal resin are maintained and to which the antistatic property is given. That is, a branched polyacetal resin composition, comprising 100 parts by weight of a branched polyacetal copolymer (A) having an oxymethylene group as the main repeating unit and having a branching unit represented by the following formula (I), and 0.1 to 30 parts by weight of a compound (B) having a polyalkylene ether unit as the main constituting component and / or 0.01 to 10 parts by weight of an ester (C) of fatty acid with polyhydroxyl alcohol having a hydroxyl group: wherein m and n each is an integer of 0 to 5; the sum of m+n is 1 to 5; and R is a monovalent organic group having a molecular weight of 40 to 1000.

Owner:POLYPLASTICS CO LTD

Polyacetal resin composition

Owner:POLYPLASTICS CO LTD

Polyacetal resin composition and molded article thereof

Disclosed is a polyacetal resin composition which has excellent workability and stability and, when molded into an article, which is remarkably reduced in the amount of aldehyde generated from the article and shows no leaching out of any compounded component from the article. Specifically disclosed is a polyacetal resin composition comprising (A) 100 parts by weight of a polyacetal copolymer having 1.0 mmol / kg or less of a hemiformal terminal group, 0.5 mmol / kg or less of a formyl terminal group and 0.5% by weight of an unstable terminal group, (B) 0.01 to 3 parts by weight of a hindered phenol-type antioxidant, (C) 0.01 to 1 part by weight of a hydrazide compound, and (D) 0.01 to 1 part by weight of a compound selected from the group consisting of an isocyanate compound, an isothiocyanatecompound and a modified form thereof.

Owner:POLYPLASTICS CO LTD

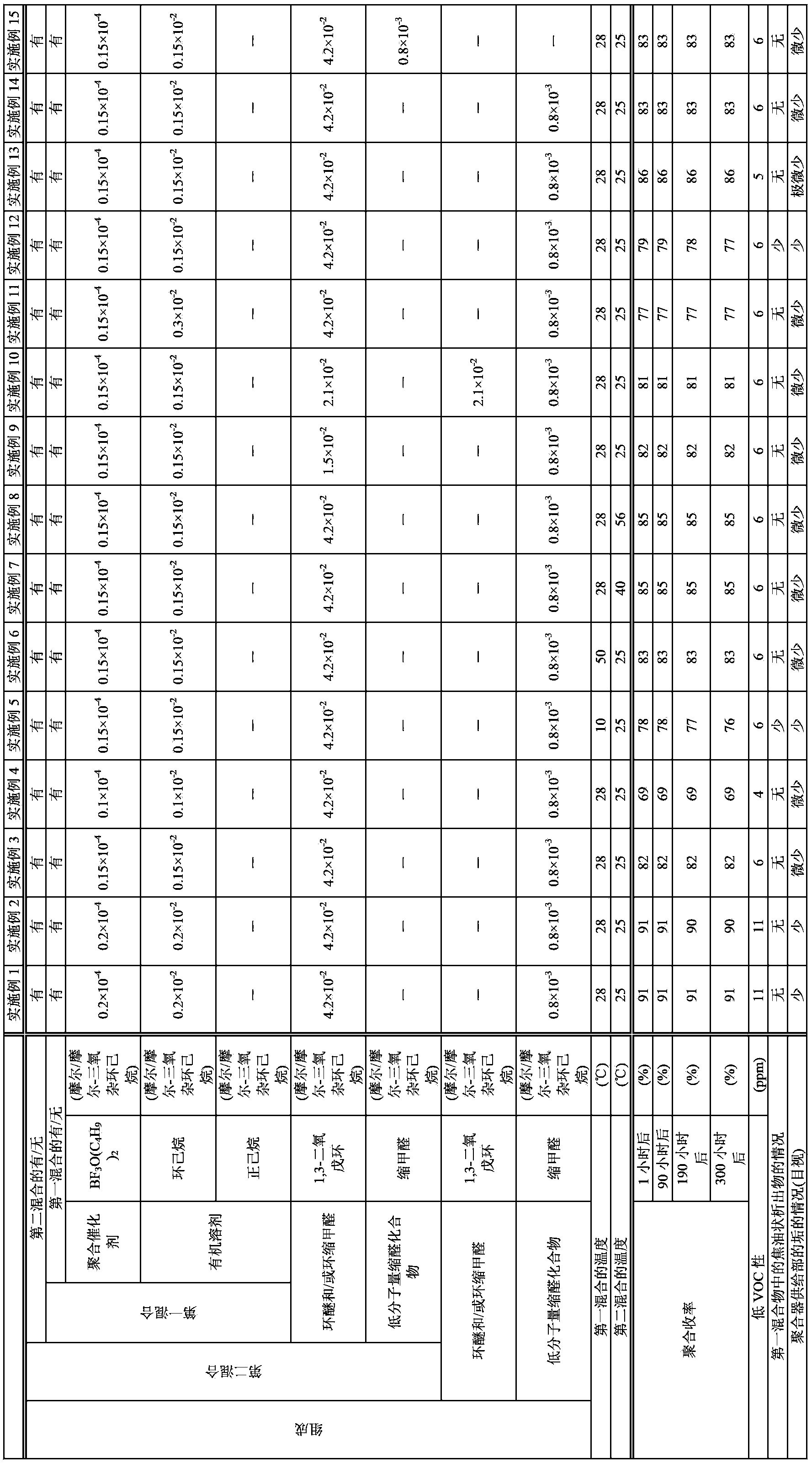

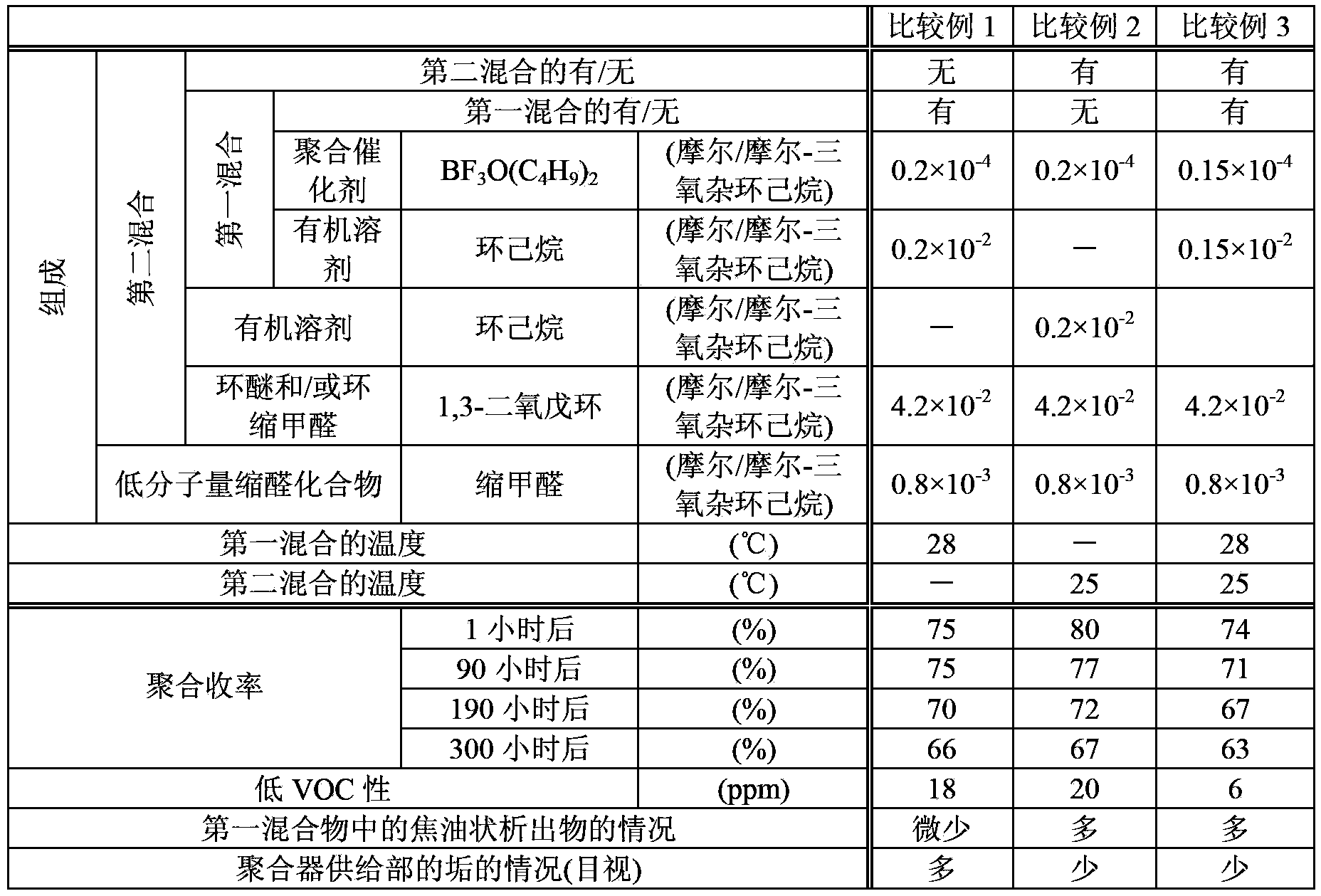

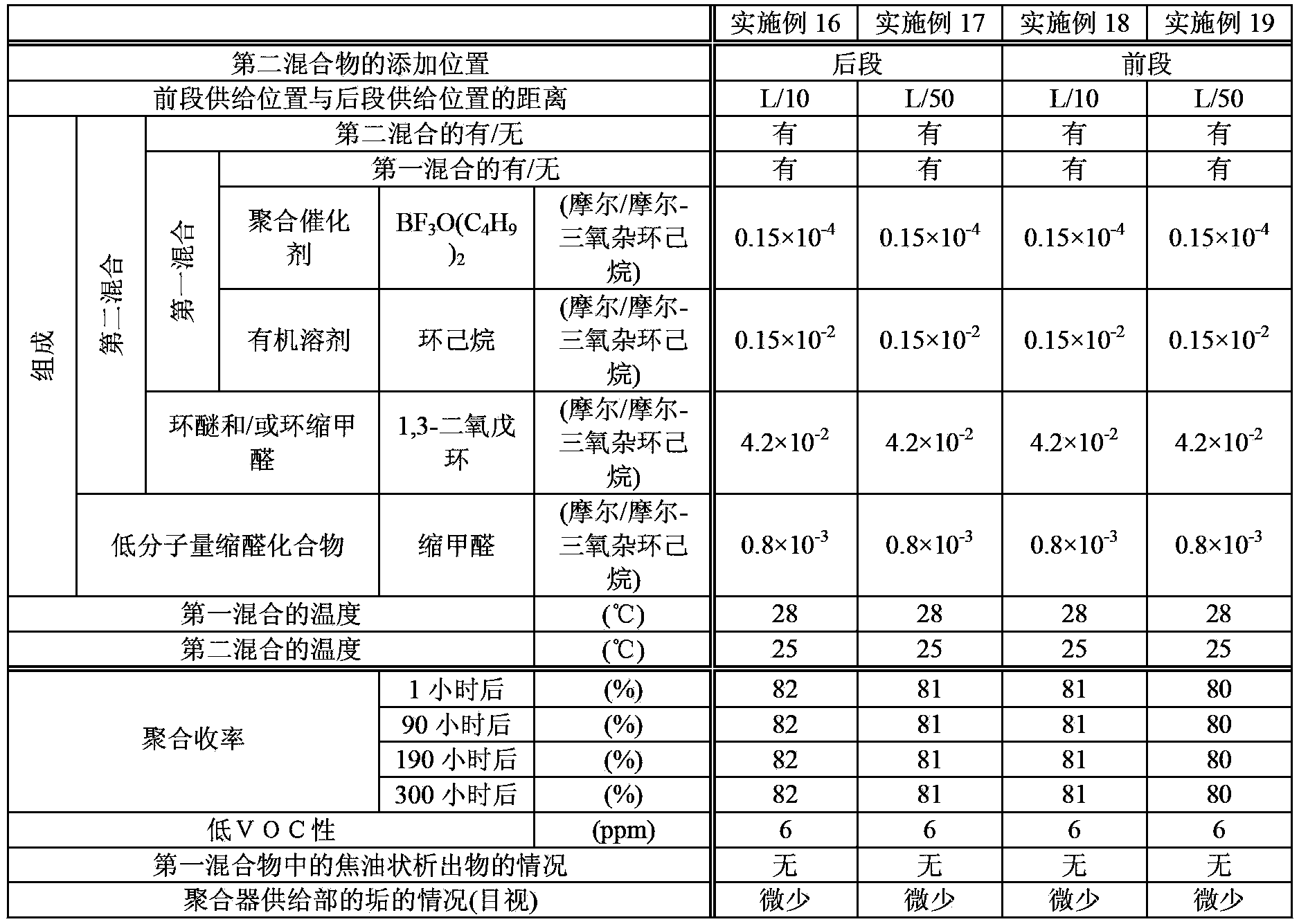

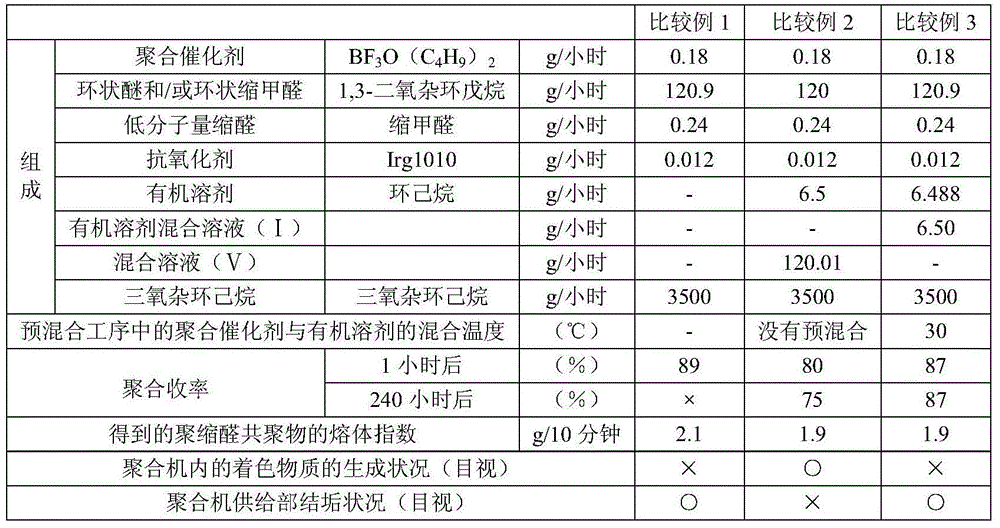

Manufacturing method of polyacetal copolymer

The invention provides a manufacturing method of polyacetal copolymer. During the process of copolymerization between trioxacyclohexane and cyclic ether / cyclic formal, the scales on the feeding part of the polymerization device are reduced, and the tar-liked precipitate caused by the catalyst will not appear, so the device can be operated stably for a long term even if the operation conditions are changed, and only a little of catalyst can maintain the polymerization yield. Before the copolymerization between trioxacyclohexane and cyclic ether / cyclic formal, a polymerization catalyst should be mixed with an organic solvent at first, then cyclic ether and / or cyclic formal is added into the solvent, and finally the mixture and trioxacyclohexane are fed into a polymerization reactor.

Owner:ASAHI KASEI KK

Branched polyacetal resin composition

To provide a polyacetal resin material in which an excellent sliding property is given and the appearance, dimensional precision, mechanical properties, etc. of the molded article thereof are improved as well. That is, a branched polyacetal resin composition, comprising 100 parts by weight of a branched polyacetal copolymer (A) having an oxymethylene group as the main repeating unit and having a specific branching unit, and0.5 to 40 parts by weight of at least one polymer (B) selected from the group consisting of the following polymer (B-1) and (B-2), i.e.polymer (B-1): a graft or block copolymer prepared from an olefin polymer (b-1) and at least one vinyl polymer (b-2); andpolymer (B-2): a modified olefin polymer in which an olefin polymer (b-3) is modified with at least one compound selected from the group consisting of an unsaturated carboxylic acid, an unsaturated carboxylic acid anhydride and derivatives thereofand / or 0.1 to 5 parts by weight of a lubricant (C).

Owner:POLYPLASTICS CO LTD

Polyacetal resin composition and molded article thereof

InactiveUS20100056676A1Reduced generation of formaldehydeSuppressing bleedingLayered productsPHENOL LIQUIDEnd-group

The present invention provides a polyacetal resin composition having excellent processability and stability, significantly suppressing the amount of formaldehyde generated from the molded article thereof, and preventing the bleeding of blending components. Specifically, to 100 parts by weight of (A) a polyacetal copolymer having 1.0 mmol / kg or less of hemiformal terminal group, 0.5 mmol / kg or less of formyl terminal group, and 0.5% by weight or less of unstable terminal group, there are blended: 0.01 to 3 parts by weight of (B) a hindered phenol-based antioxidant; 0.05 to 1 part by weight of (C) at least one compound selected from a guanamine compound and a triazine compound; and 0.01 to 1 part by weight of (D) a compound selected from an isocyanate compound, an isothiocyanate compound, and a modified compound thereof.

Owner:POLYPLASTICS CO LTD

Production method for polyacetal copolymer

A production method for a polyacetal copolymer that makes deactivation of a catalyst simple and efficient and that achieves a high polymerization yield and high quality using equipment that does not require a cleaning step and a process that involves a simple operation technique. The production method for a polyacetal copolymer uses trioxane as a main monomer and a cyclic ether and / or a cyclic formal having at least one carbon-carbon bond as a comonomer. In the production method, a predetermined heteropoly acid is used as a polymerization catalyst to perform copolymerization, a predetermined salt is added to the reaction product, melt kneading processing is performed, and the polymerization catalyst is deactivated.

Owner:POLYPLASTICS CO LTD

Polyacetal resin composition

The present invention provides a polyacetal resin composition having an excellent processability and stability, significantly suppressing the generation of formaldehyde from molded articles thereof, preventing exudation of components, and being excellent in weathering (light) resistance. Specifically, (A) a polyacetal copolymer having 1.0 mmol / kg or smaller quantity of a hemiformal terminal group, 2.0 mmol / kg or smaller quantity of a formyl terminal group, and 0.5% by weight or smaller quantity of an unstable terminal group is blended with (B) a hindered phenol-based antioxidant; (C) at least one compound selected from (c-1) a guanamine compound and (c-2) a hydrazide compound; (D) a hindered amine stabilizer in which the nitrogen in a piperidine derivative having a steric hindrance group is tertiary; and (E) a UV absorber in specified quantities and mixing ratios.

Owner:POLYPLASTICS CO LTD

Manufacturing method of polyacetal copolymer

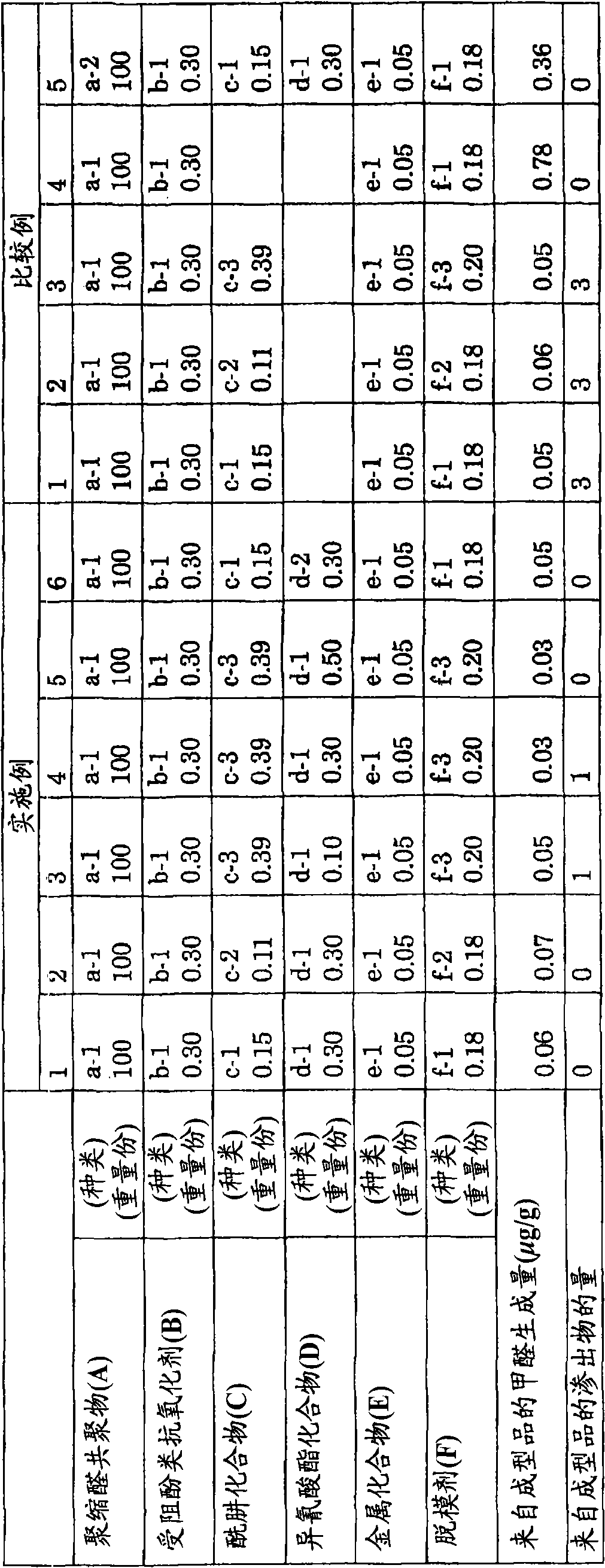

The invention relates to a manufacturing method of polyacetal copolymer. The manufacturing method is capable of reducing scales, and can stably and continuously produce high quality polyacetal copolymer in a long term in a high yield. The manufacturing method comprises the following steps: mixing cyclic ether and / or cyclic condensed formaldehyde, a polymerization catalyst, acetal, which is represented by the formula (1), with a low molecular weight, an organic solvent, and an antioxidant to obtain a pre-mixed solution; and then feeding the pre-mixed solution and trioxane into a polymerization machine to carry out polymerization. Formula (1): R-(CH2-O)n-R.... in the formula (1), the R represents a free hydrogen atom, a straight chain alkyl group or a branched alkyl group, a straight chain alkoxyl group or a branched alkoxyl group, or a hydroxyl group, and n represents an integer in a range of 1 to 20.

Owner:ASAHI KASEI KK

Foamed injection molded item and method of foam injection molding

According to the present invention, a foamed injection molded article of excellent mechanical properties and small surface roughness is obtained by injection-molding a resin composition in which a polyacetal copolymer resin with a crystallization time of 5 minutes or more is impregnated with a fluid in a supercritical state as a foaming agent by use of a mold made of a material having a thermal conductivity of 5 W / m·K or less in at least a part of a surface on a cavity side.

Owner:POLYPLASTICS CO LTD

Image forming apparatus, image forming process, and process cartridge for image forming apparatus

ActiveUS7391994B2Reduce coefficient of frictionLower surfaceDevelopersElectrographic process apparatusElectrical conductorAcetal copolymer

Disclosed is an image forming apparatus for lowering friction coefficient and lowering surface energy of photoconductor surface in particular, which comprises an electrophotographic photoconductor, charging unit, light exposure unit, developing unit, transferring unit, and fixing unit,the electrophotographic photoconductor comprises a photosensitive layer on a conductive support and fluoropolymer fine particles at the outermost layer, a part of the fluoropolymer fine particles are exposed above the surface of the outermost layer in configurations of primary particles and secondary particles formed by flocculation of plural primary particles, and sum of area ratios of particles in the configurations of the primary particles and the secondary particles, each particles having an average diameter D of 0.15 μm≦D≦3.0 μm as respective projected figures of exposed portion above the surface of the outermost layer, is 10% to 60% based on the entire surface area of the outermost layer, and wherein the binder resin in the outermost layer comprises a polyalylate copolymer resin having a structural unit of alkylene-aryldicarboxylate.

Owner:RICOH KK

Polyacetal resin composition and molded article

Provided is a polyoxymethylene resin composition which has excellent molding characteristics (releasing property and molding cycle) and suppresses the generation of formaldehyde. Specifically the polyoxymethylene resin composition is prepared by blending (A) 100 parts by weight of a polyacetal copolymer containing 1 mmol / kg or less of hemiformal terminal, mmol / kg or less of formyl terminal, and 0.5% by weight or less of unstable terminal; (B) 0.01 to 20 parts by weight of one or a mixture of two or more of a guanamine compound (b-1) and a hydrazide compound (b-2); and (C) 0.1 to 5 parts by weight of an ester compound having 50% or more of esterification percentage.

Owner:POLYPLASTICS CO LTD

Antimicrobial fibers

InactiveUS20180080149A1Improve antibacterial propertiesGarment special featuresMonocomponent polyethers artificial filamentFiberPolymer science

The invention provides an antimicrobial fiber which exhibits excellent antimicrobial properties even without the addition of antimicrobial agents and can remain antimicrobial even after repeated washing. The antimicrobial fiber comprises a fiber having on a surface thereof a polyacetal copolymer (X) containing oxyalkylene groups, the molar amount of oxyalkylene groups in the polyacetal copolymer (X) being 0.2 to 5 mol % relative to the total of the molar amount of oxymethylene groups and the molar amount of oxyalkylene groups.

Owner:MITSUBISHI GAS CHEM CO INC

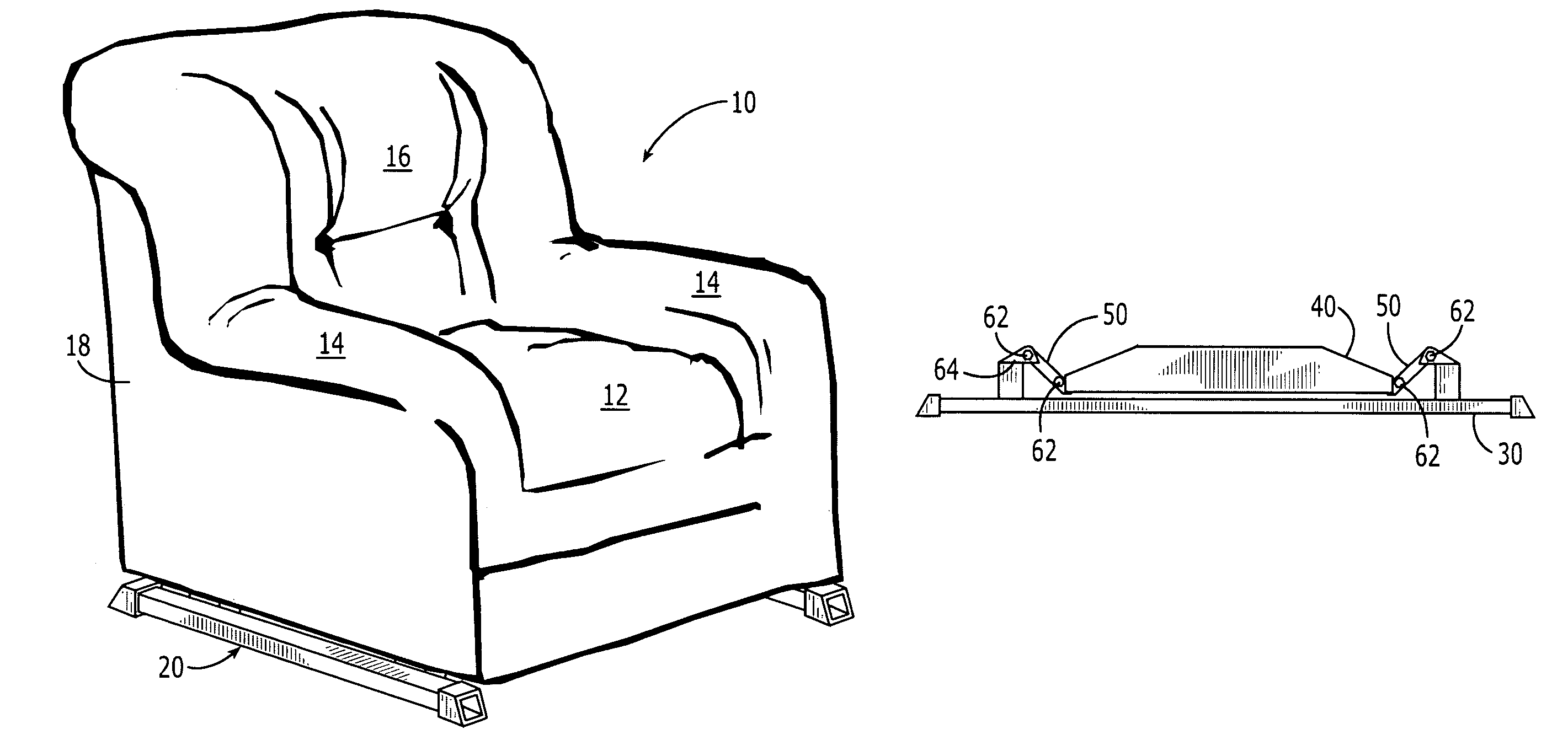

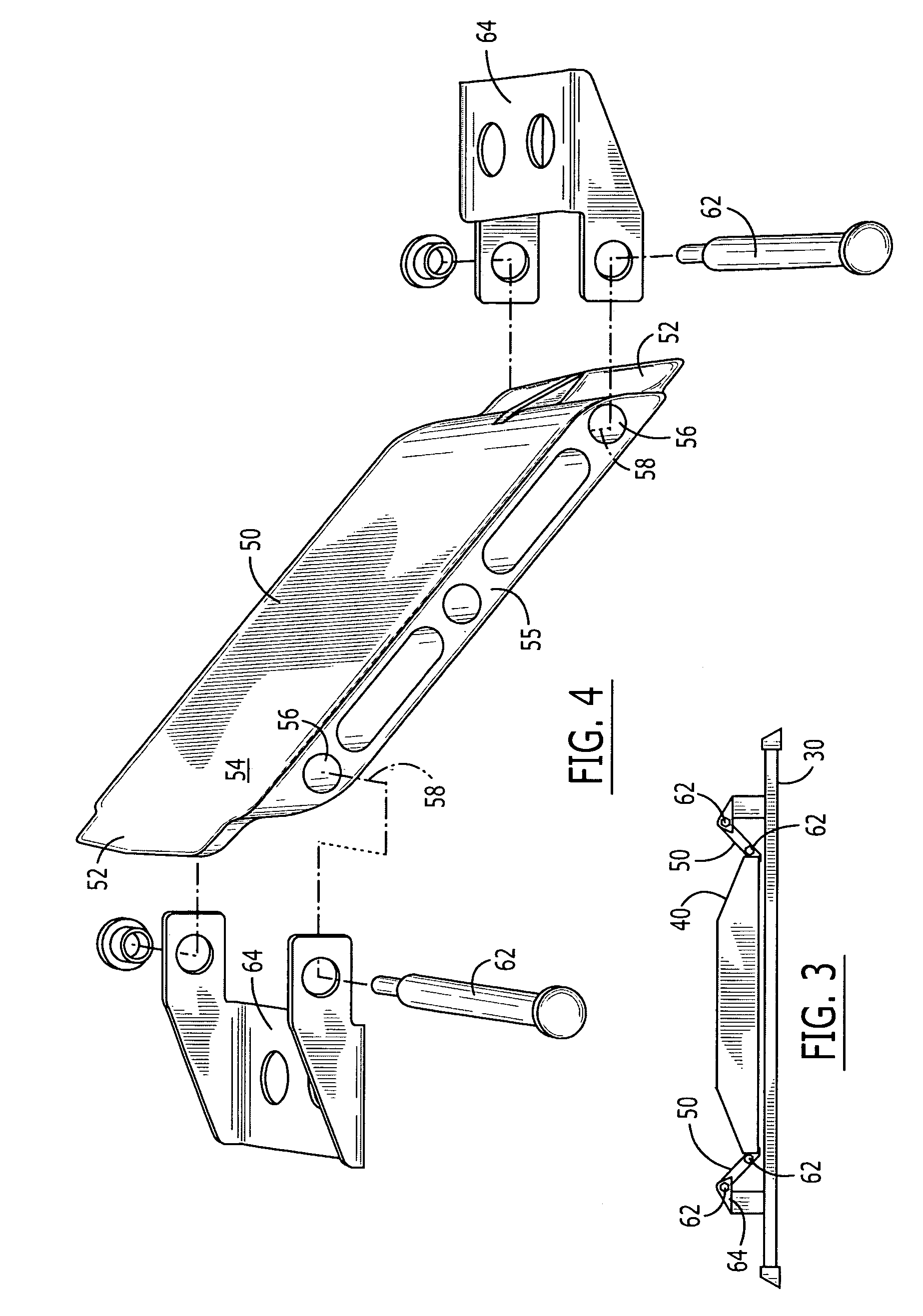

Hinged glider mechanism

ActiveUS7377587B1Solve the lack of durabilityHigh strengthAdjustable chairsHingesAcetal copolymerEngineering

A hinged glider mechanism includes a hinge device for pivoted mounting in a chair between a stationary base frame and a seat frame, for supporting the seat frame for oscillatory gliding motion generally longitudinally relative to the base frame. The hinge device is configured for repeated substantially silent pivotal oscillating cycles over an extended life. The hinge device includes a hinge panel consisting essentially of a polymeric material, such as acetal copolymer, that is characterized by a sufficient strength and durability to support the seat frame and a seat occupant during repeated and extended pivotal oscillating cycles without failure and a sufficient lubricity not to generate noise during the repeated and extended pivotal oscillating cycles.

Owner:HICKORY SPRINGS MFG

Branched polyacetal resin composition

To provide a resin material in which various properties such as excellent appearance and rigidity inherent to a polyacetal resin are maintained and to which the antistatic property is given. That is, a branched polyacetal resin composition, comprising 100 parts by weight of a branched polyacetal copolymer (A) having an oxymethylene group as the main repeating unit and having a branching unit represented by the following formula (I), and 0.1 to 30 parts by weight of a compound (B) having a polyalkylene ether unit as the main constituting component and / or 0.01 to 10 parts by weight of an ester (C) of fatty acid with polyhydroxyl alcohol having a hydroxyl group:wherein m and n each is an integer of 0 to 5; the sum of m+n is 1 to 5; and R is a monovalent organic group having a molecular weight of 40 to 1000.

Owner:POLYPLASTICS CO LTD

Process for producing polyacetal copolymer

ActiveUS20170073451A1Improve thermal stabilityLittle formaldehyde formationPolymer sciencePtru catalyst

A process for producing a polyacetal copolymer, the process making catalyst deactivation easy and efficient. Trioxane as a major monomer is copolymerized with one or more comonomers that are a cyclic ether and / or cyclic formal having at least one carbon-carbon bond, using a nonvolatile protonic acid as a polymerization catalyst at 100° C. or lower until the conversion reaches 50% and thereafter at a polymerization environment temperature of 115° C. to 140° C. This process includes: a crushing step in which a dry-process crusher is used to obtain a crude polyacetal copolymer crushed to such a degree that when the crude copolymer is screened with a sieve having an opening size of 11.2 mm, 90 parts by weight or more thereof passes therethrough; and a deactivation step in which a basic compound (e) is added to the crude copolymer and the mixture is melt-kneaded to thereby deactivate the polymerization catalyst.

Owner:POLYPLASTICS CO LTD

Polyacetal resin composition and molded article thereof

The present invention provides a polyacetal resin composition having excellent processability and stability, significantly suppressing the amount of formaldehyde generated from the molded article thereof, and preventing the bleeding of blending components. Specifically, to 100 parts by weight of (A) a polyacetal copolymer having 1.0 mmol / kg or less of hemiformal terminal group, 0.5 mmol / kg or less of formyl terminal group, and 0.5% by weight or less of unstable terminal group, there are blended: 0.01 to 3 parts by weight of (B) a hindered phenol-based antioxidant; 0.05 to 1 part by weight of (C) at least one compound selected from a guanamine compound and a triazine compound; and 0.01 to 1 part by weight of (D) a compound selected from an isocyanate compound, an isothiocyanate compound, and a modified compound thereof.

Owner:POLYPLASTICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com