Preparation method of cross-linkable acetal copolymer

A technology of formaldehyde copolymerization and cross-linking polymerization, which is applied in the field of preparation of cross-linkable polyoxymethylene copolymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

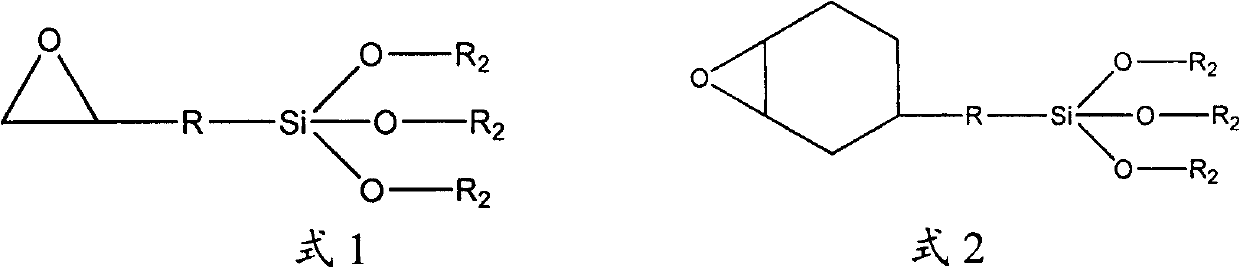

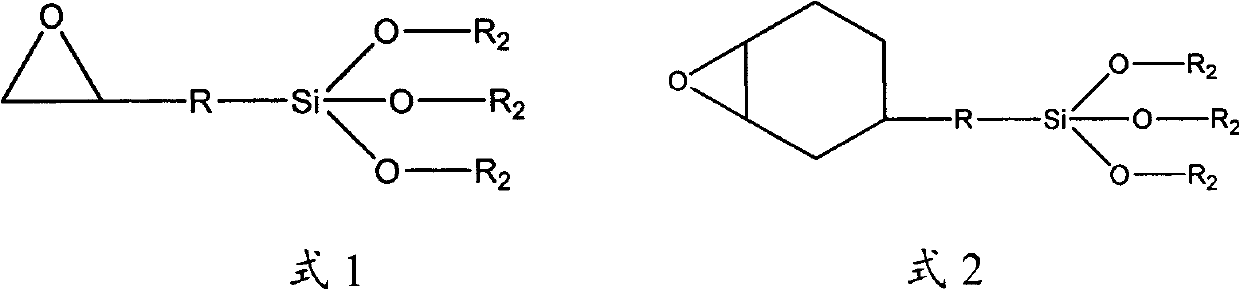

Method used

Image

Examples

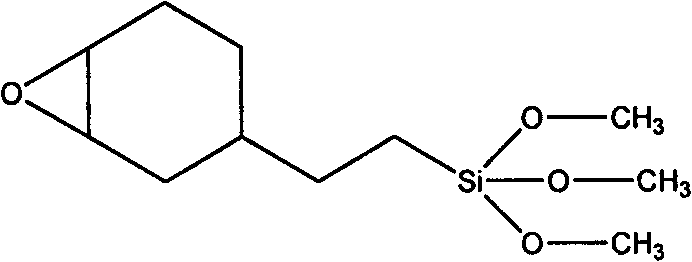

Embodiment 1

[0031] Add freshly distilled 22.44g TOX, 0.98g DXL and 0.31g GPTMS into a dry nitrogen-filled reaction flask, place in an oil bath at 70°C and stir for 0.5h, mix well and add 4.8μL of initiator HClO 4 , continue to stir, after reacting for 1 h, add 11 μL triethylamine to terminate, wash and filter and dry to obtain 20.55 g of crude product, add 82 mL of DMF solution containing 0.78 g triethanolamine to it for post-treatment at 170 ° C, cool to room temperature, and vacuum-dried the resulting product to obtain 15.23 g of white powdery polymer, to which an appropriate amount of water was added to undergo a cross-linking reaction at 170° C. to form a slightly cross-linked polyoxymethylene copolymer with a gel content of 1%.

Embodiment 2-5

[0033] The polymerization process is the same as in Example 1, except that the ratio of comonomer GPTMS to TOX and DXL is changed. The results are shown in Table 1.

Embodiment 6

[0035] Add freshly distilled 37.97g TOX, 7.81g DXL, 9.96g GPTMS and 19mL cyclohexane into a dry reaction flask filled with nitrogen, place in an oil bath at 70°C and stir for 0.5h, mix well and add 57μL of Initiator HClO 4 , continue to stir, after reacting for 12 hours, add 136 μ L of triethylamine to terminate, wash and filter and dry to obtain 30.55 g of crude product, add 122 mL of DMF solution containing 1.15 g of triethanolamine to it for post-treatment at 170 ° C, and cool to room temperature, and vacuum-dried the resulting product to obtain 10.60 g of white powdery polymer, to which an appropriate amount of water was added to undergo a cross-linking reaction at 170° C. to form a slightly cross-linked polyoxymethylene copolymer with a gel content of 69%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com