Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Will not increase consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

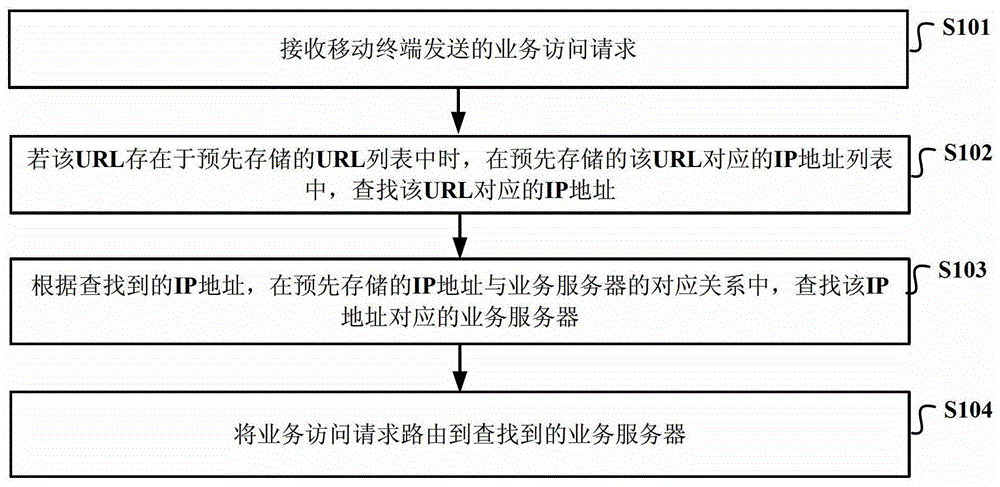

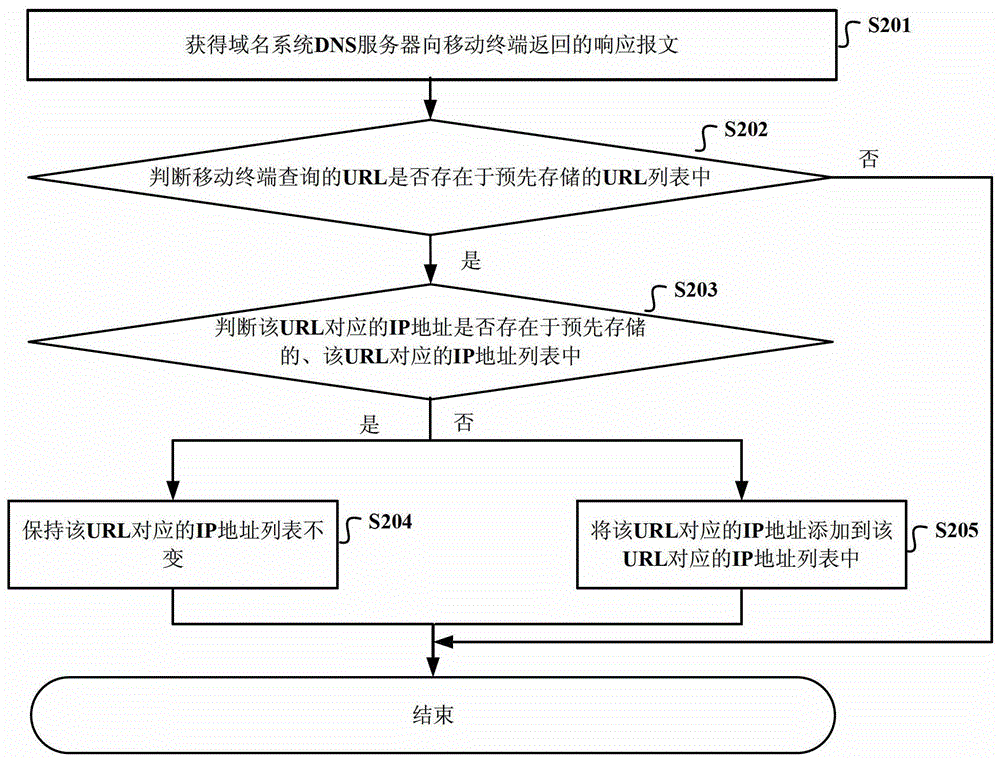

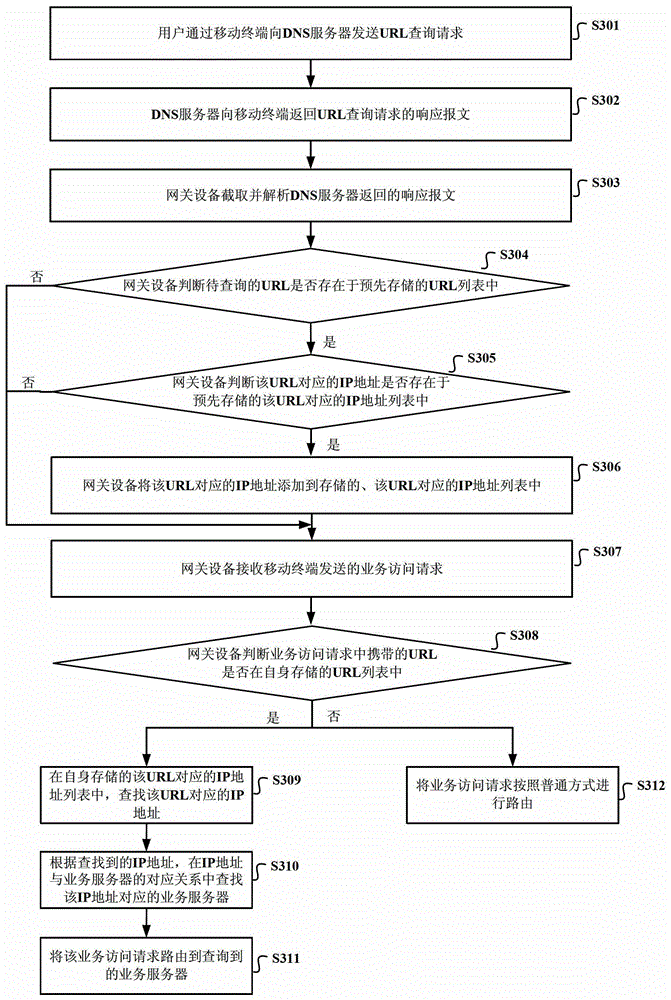

Routing method, device, system and gateway equipment

ActiveCN103888358AWill not increase consumptionSimplify the routing pathData switching networksWireless communicationResource consumptionIp address

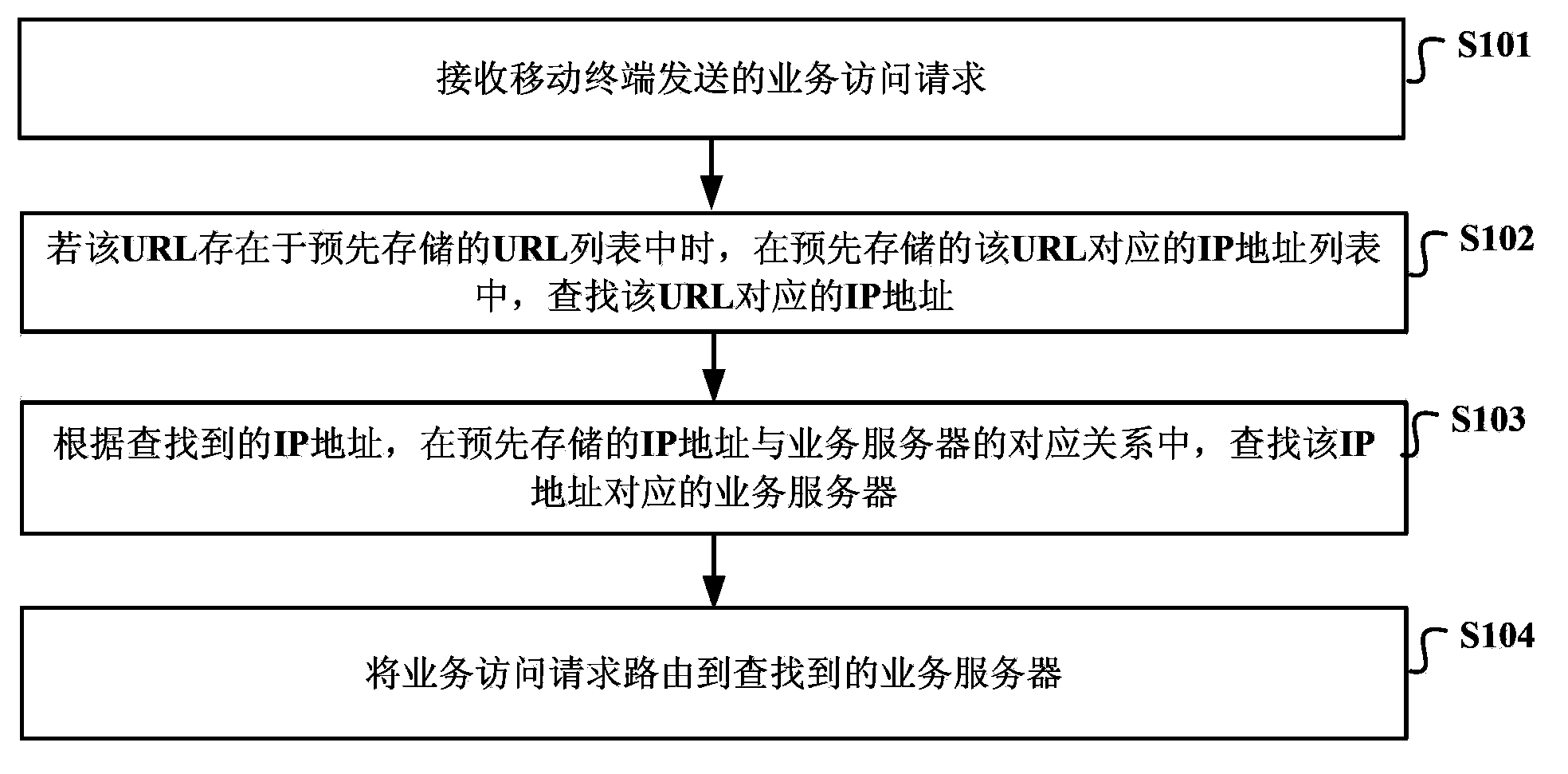

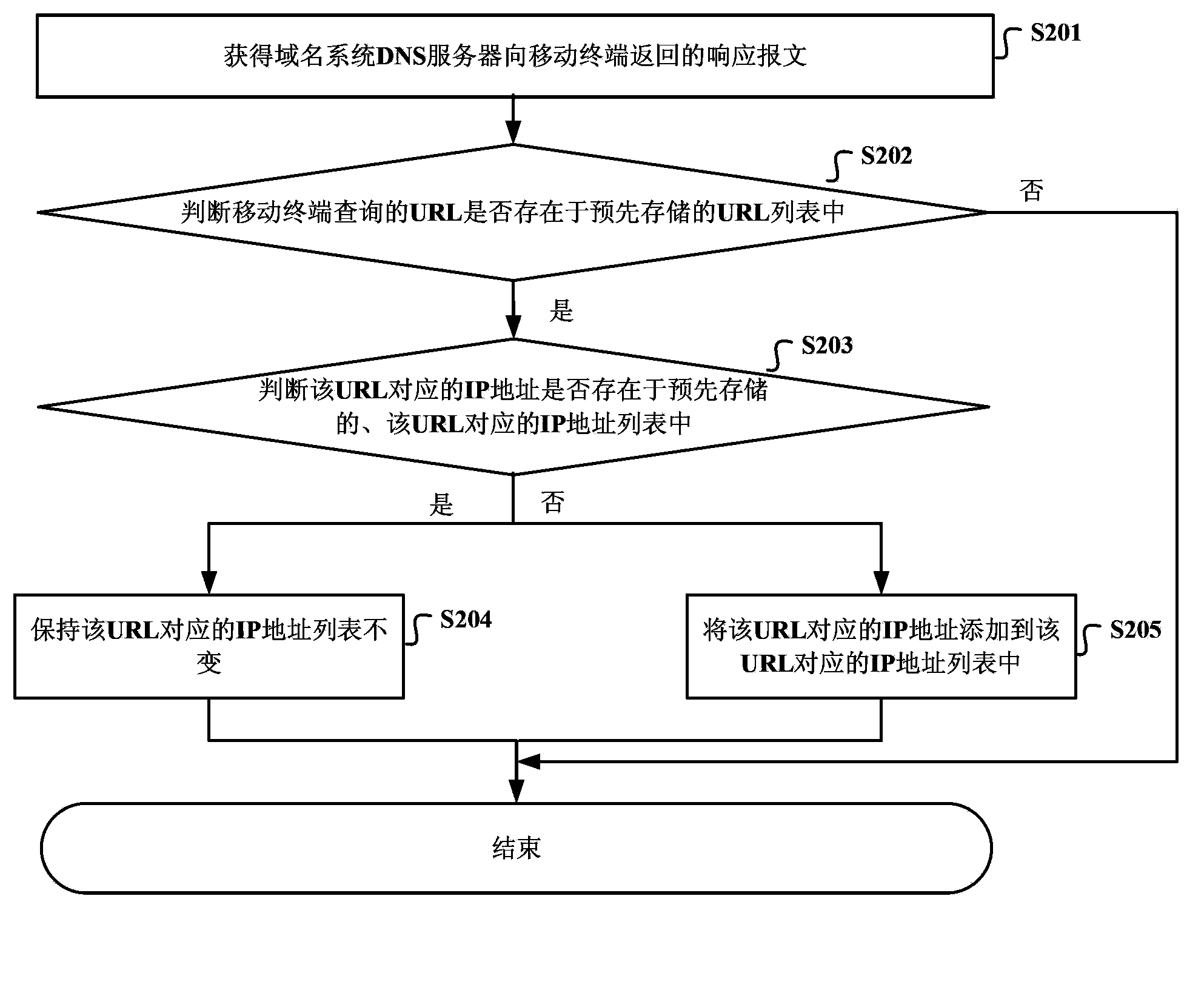

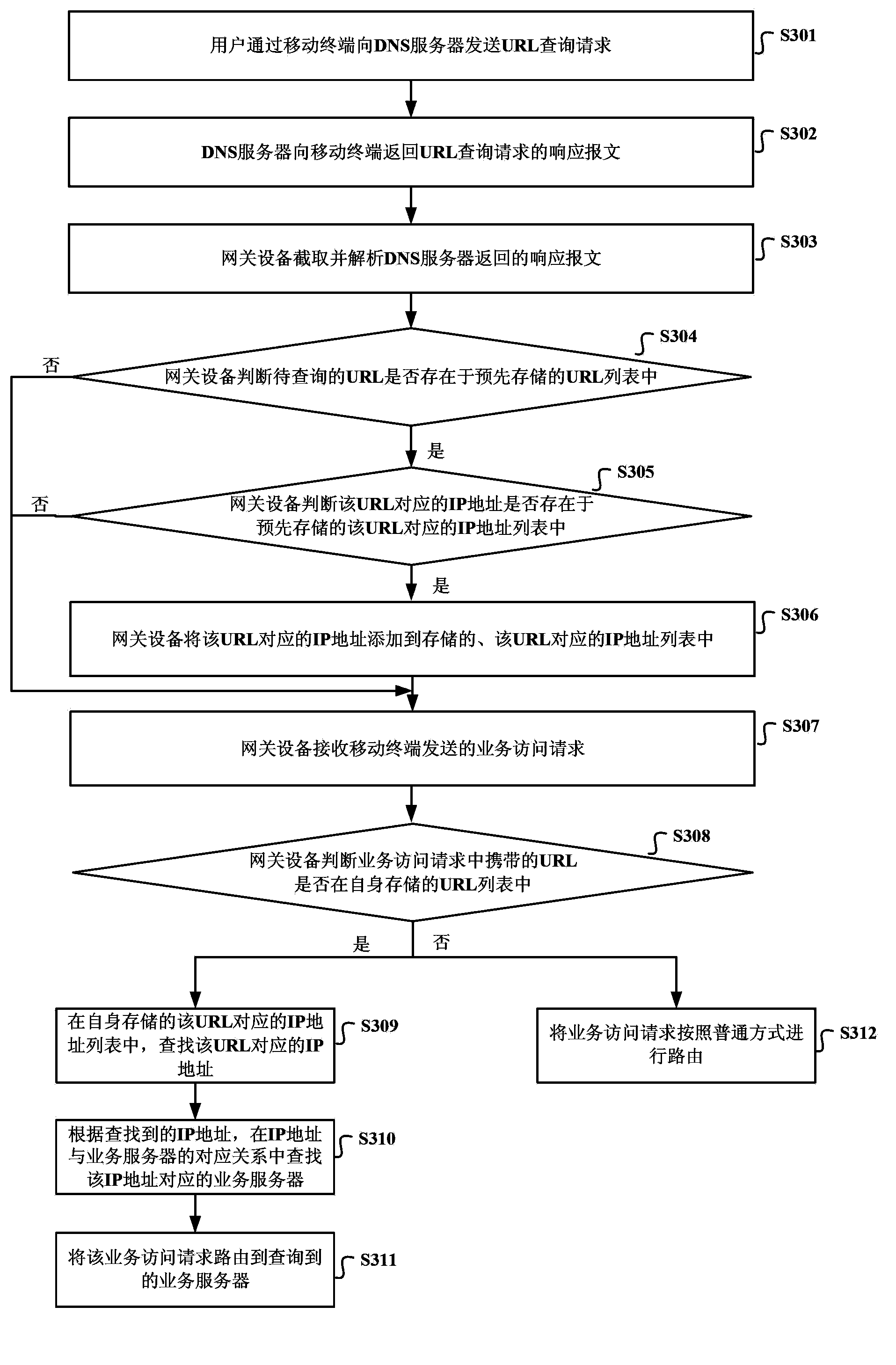

The invention discloses a routing method, a device, a system and gateway equipment and aims to improve routing efficiency without increasing processing resource consumption of the gateway equipment when a user carries out business access through URL. The method comprises steps that: a business access request sent by a mobile terminal is received, and the business access request contains the uniform resource locator (URL); if the URL exists in a pre-stored URL list, an IP address corresponding to the URL is searched in an IP address list corresponding to the pre-stored URL; according to the searched IP address, a business server corresponding to the IP address is searched in corresponding relations of the pre-stored IP address and the business server; the business access request is routed to the searched business server.

Owner:CHINA MOBILE COMM GRP CO LTD

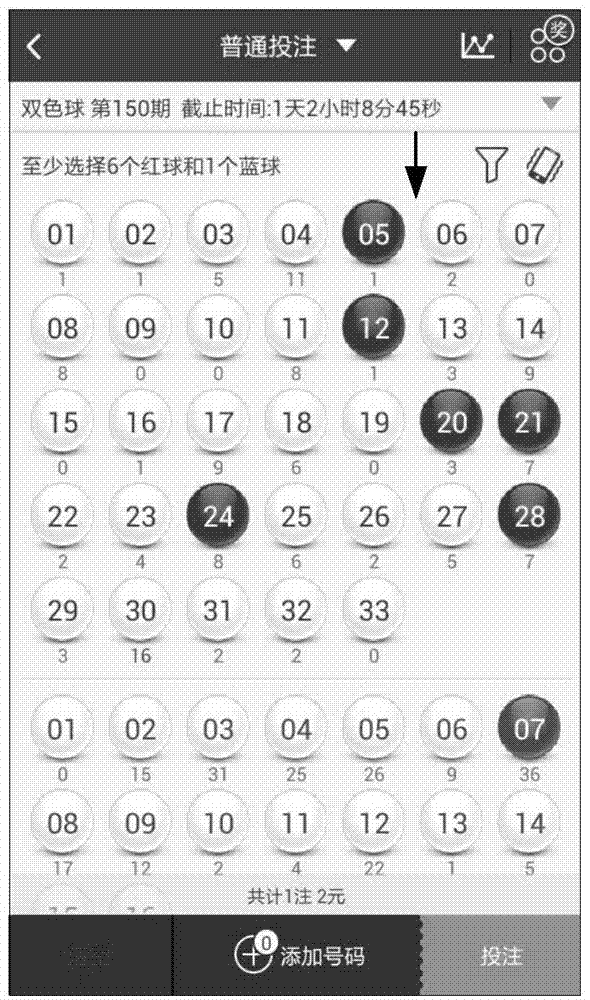

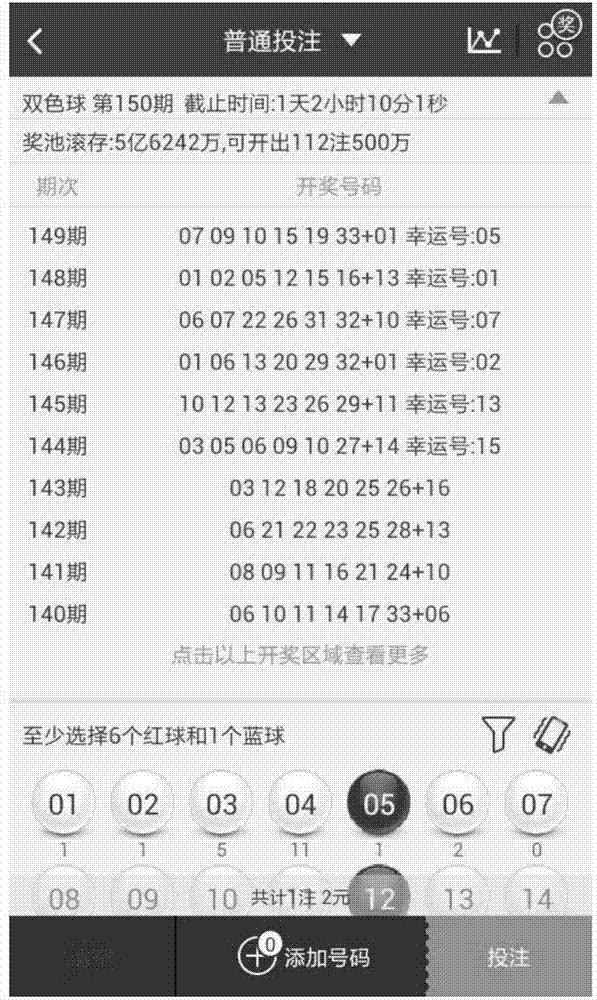

Interface switching display method and display device of mobile terminal

InactiveCN107193445AHeavy loadWill not increase consumptionSpecific program execution arrangementsInput/output processes for data processingSERCOS interfaceElectronic communication

The invention relates to an interface switching display method and an interface switching display device of a mobile terminal, and belongs to the technical field of electronic communication. The method comprises the following steps of receiving a sliding command; judging whether a previous display interface is stored in a current display interface; if yes, tracking a sliding operation of a user in the current interface, and detecting sliding information of the sliding operation; gradually displaying the previous interface according to the sliding information of the sliding operation, and adjusting a display proportion of the current interface and the previous interface in a joint interface, wherein the joint interface is composed of a part of the first interface and a part of the previous interface. According to the method and the device provided by the invention, interface content information before change is stored by monitoring the change of the user interface; switching display of the display interface of the mobile terminal is achieved by sliding instead of using a backspace key in a same application program, and during the sliding process, content of the previous interface is gradually displayed.

Owner:SHANGHAI TRANSSION CO LTD

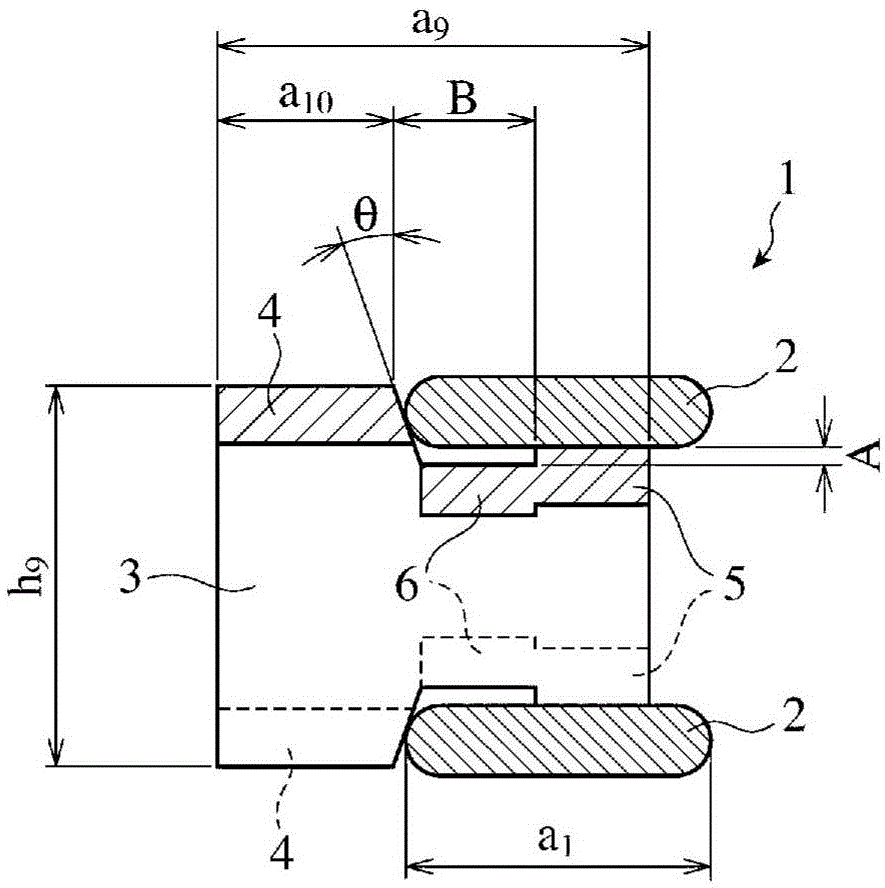

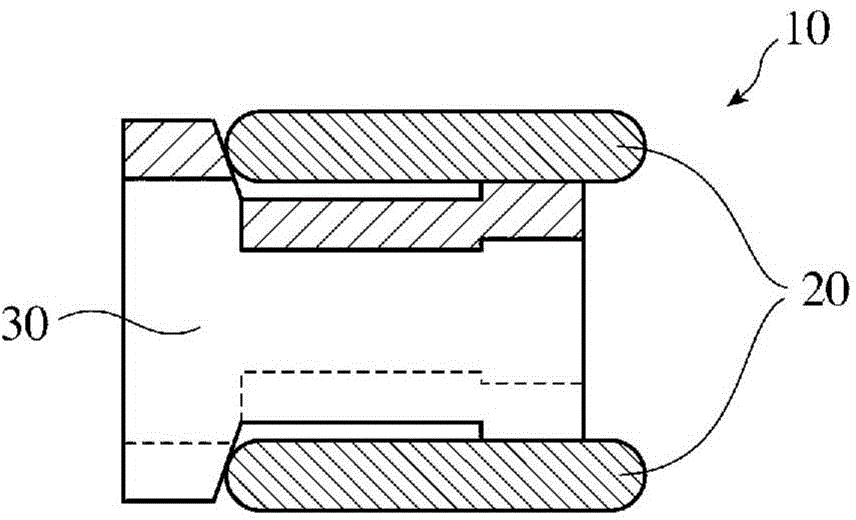

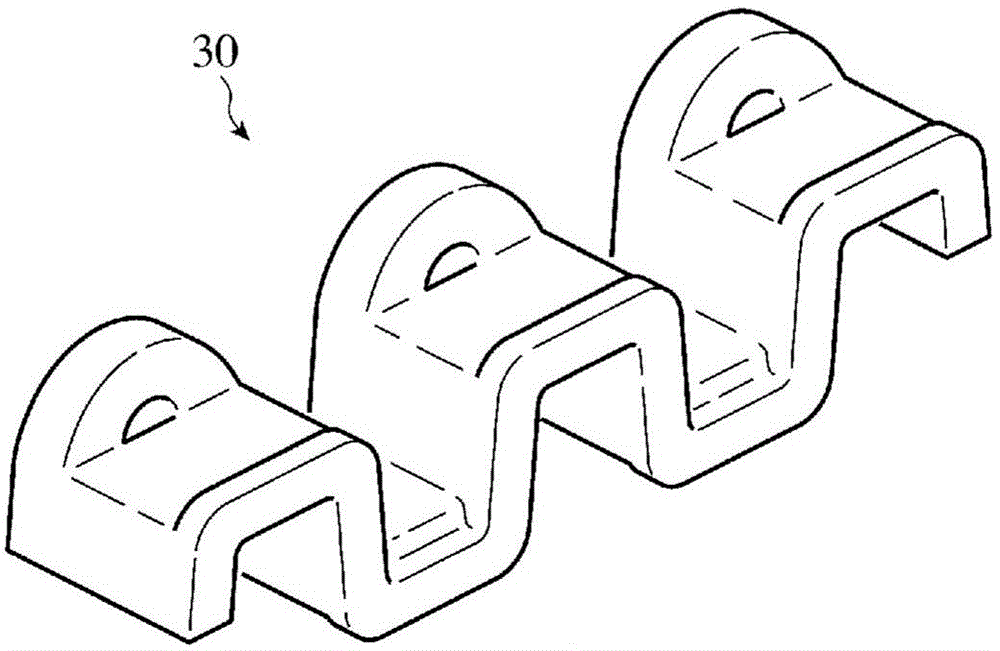

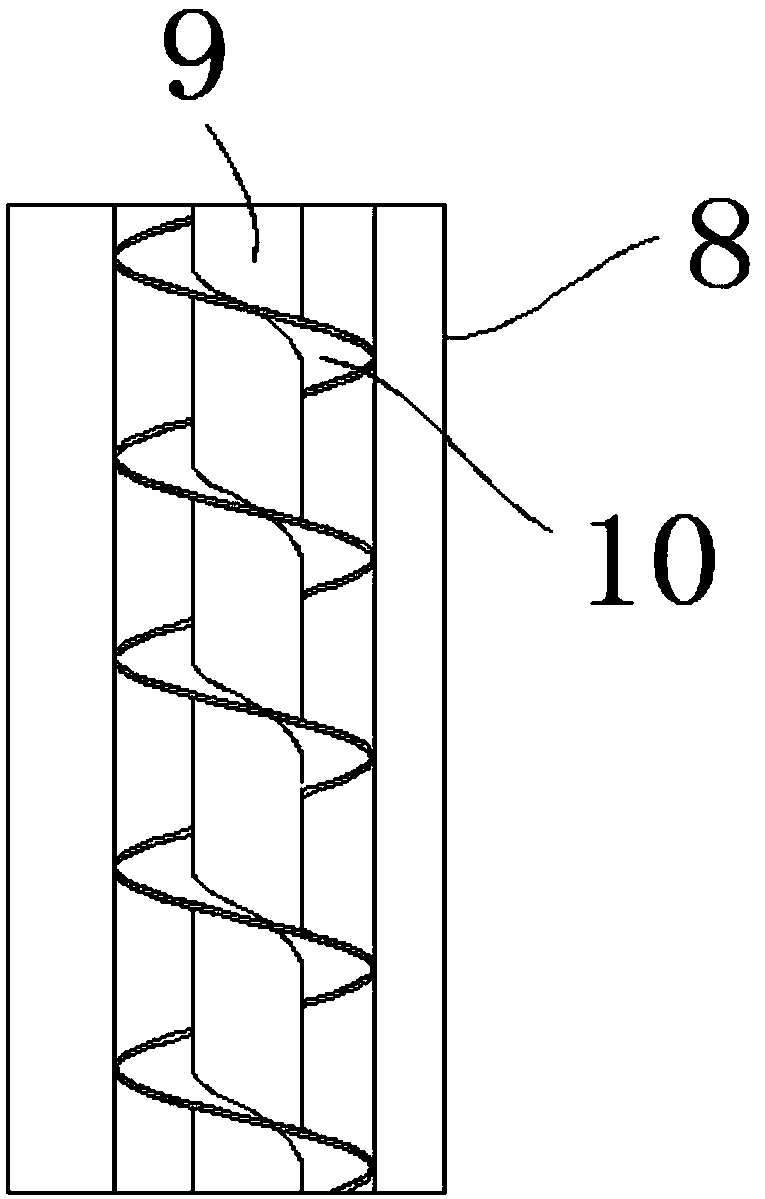

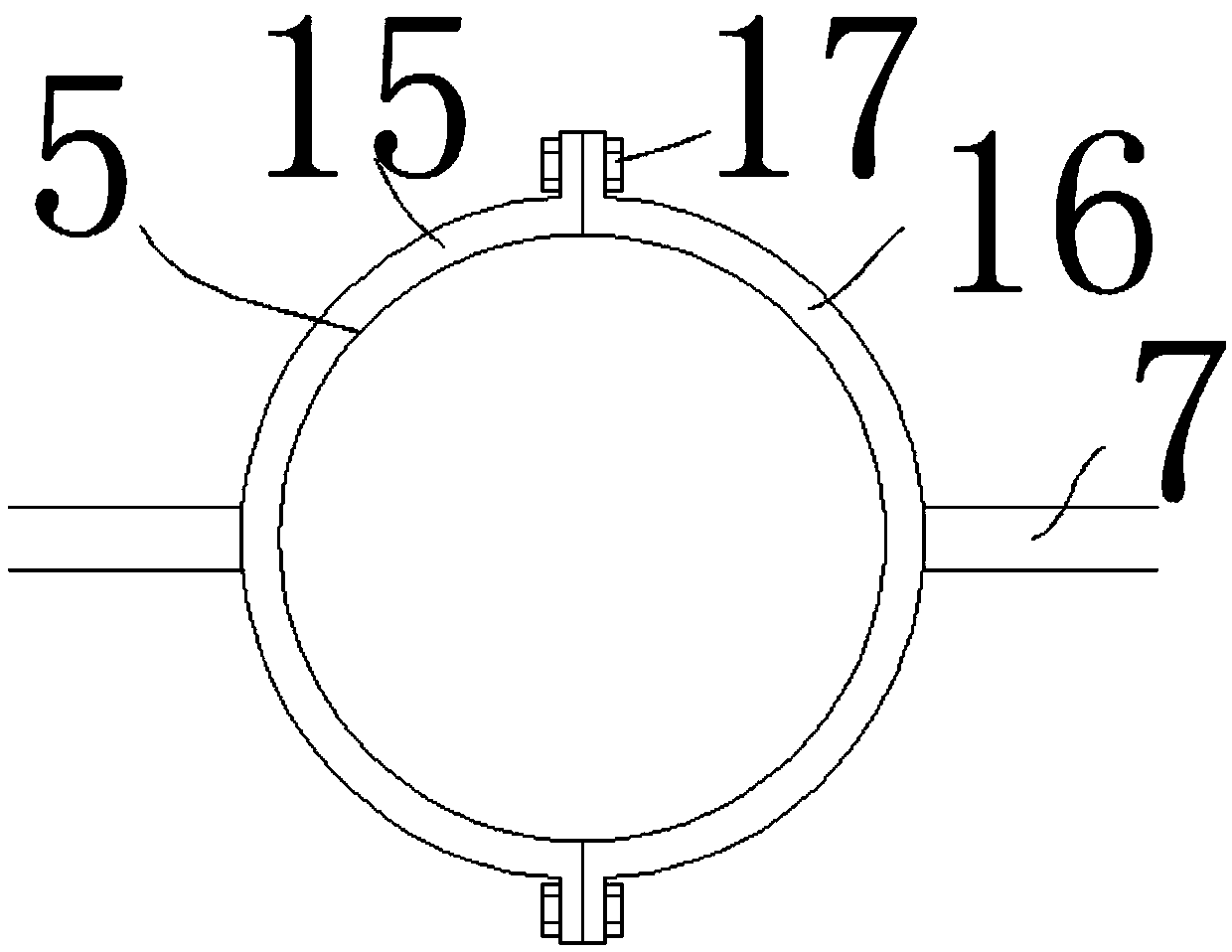

Combined oil-control ring

Provided is a combined oil-control ring which has excellent oil consumption characteristics, abrasive resistance and sludge resistance. The combined oil-control ring comprises a pair of circular ring shaped side rails with openings; and a wave-shaped separating outer tensioner ring clamped between the pair of circular ring shaped side rails and possessing ear parts for pressing inner peripheral surfaces of side rails in the inner periphery, wherein the thickness (a1) of the side riails is set to be 50-90% of a outer tensioner ring height (a9) of the separating outer tensioner ring, or the ear height (a10) of the ear of the separating outer tensioner ring is set to be 23-60% of the outer tensioner ring height (a9).

Owner:RIKEN CO LTD

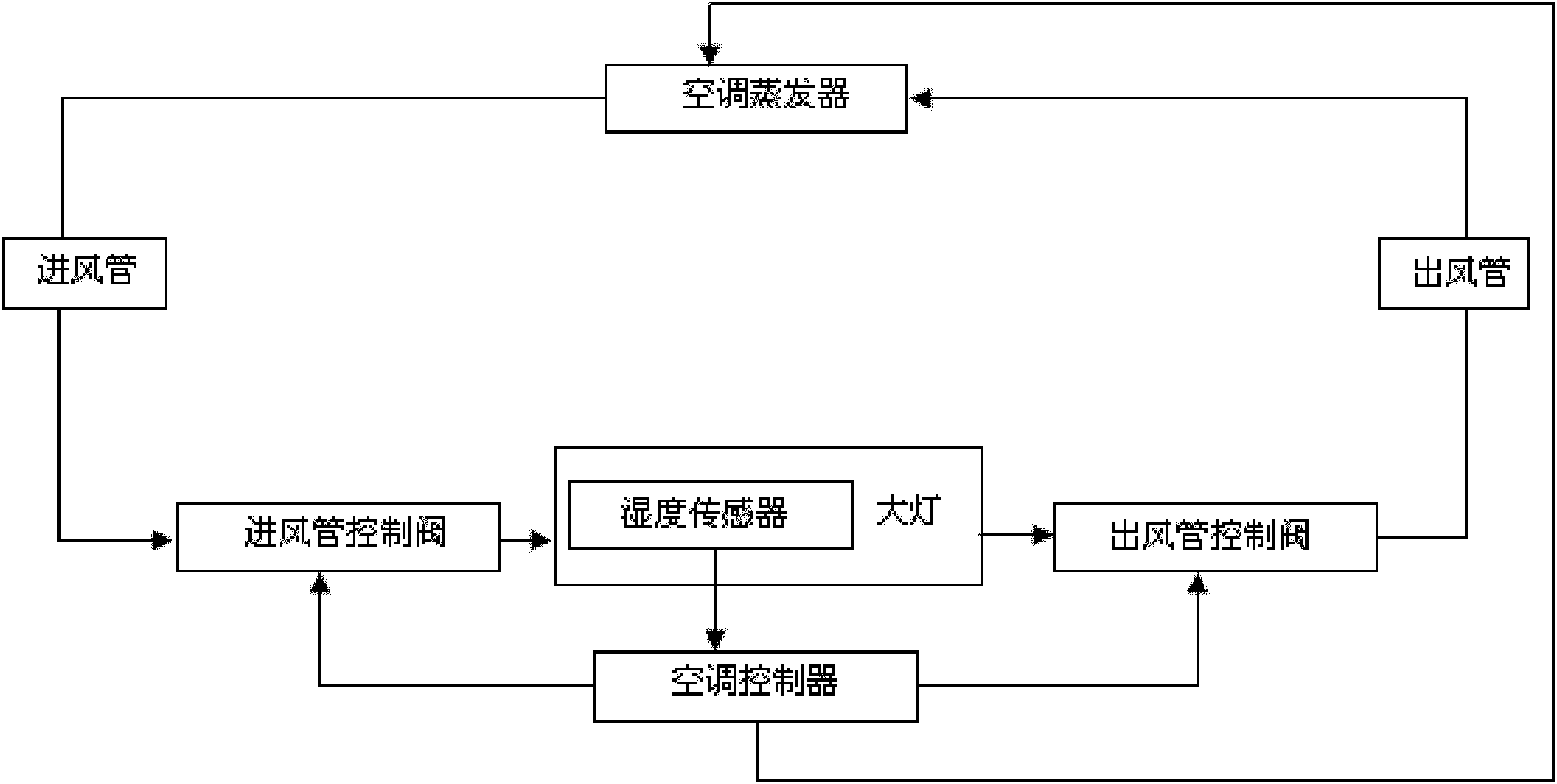

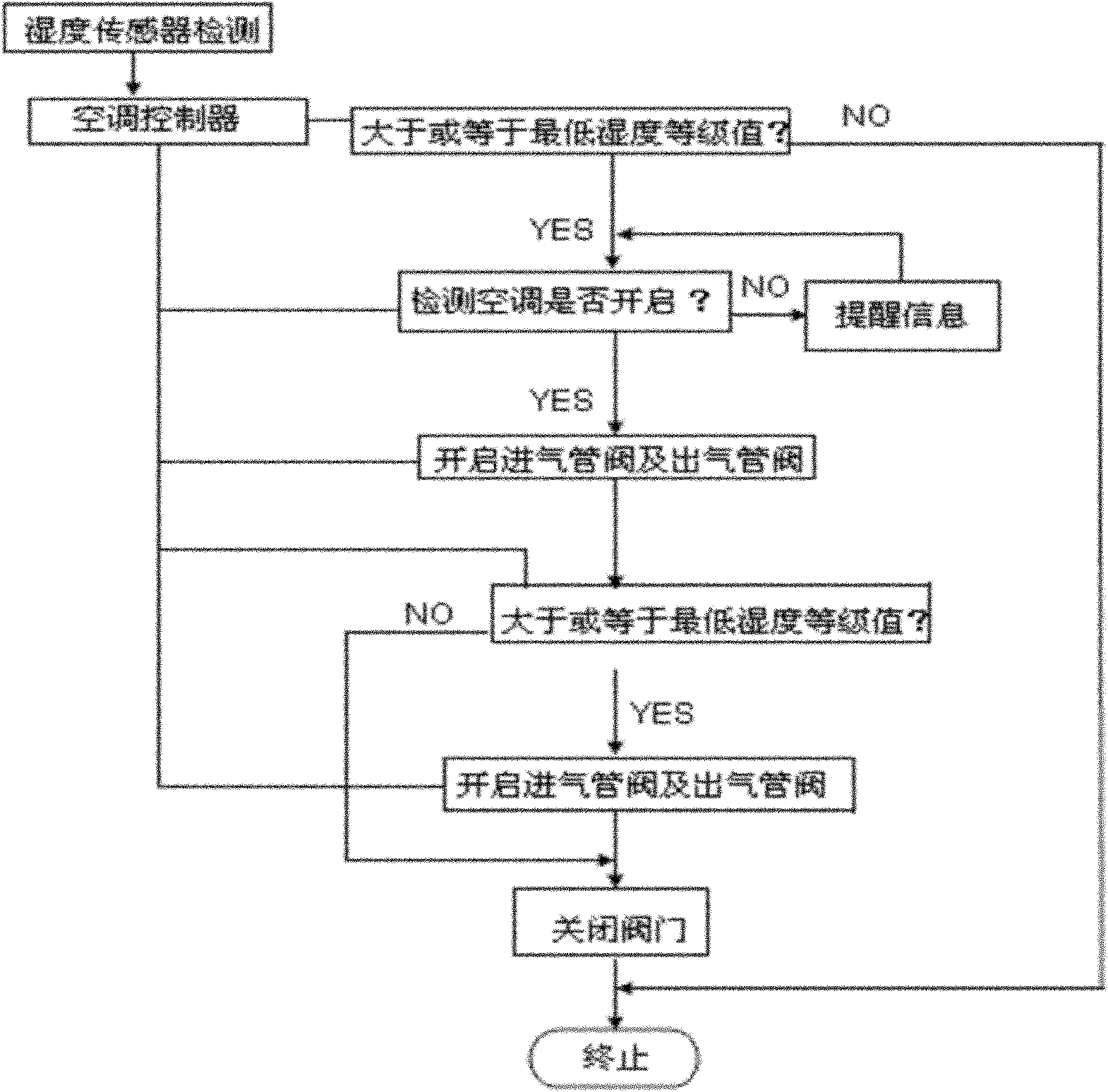

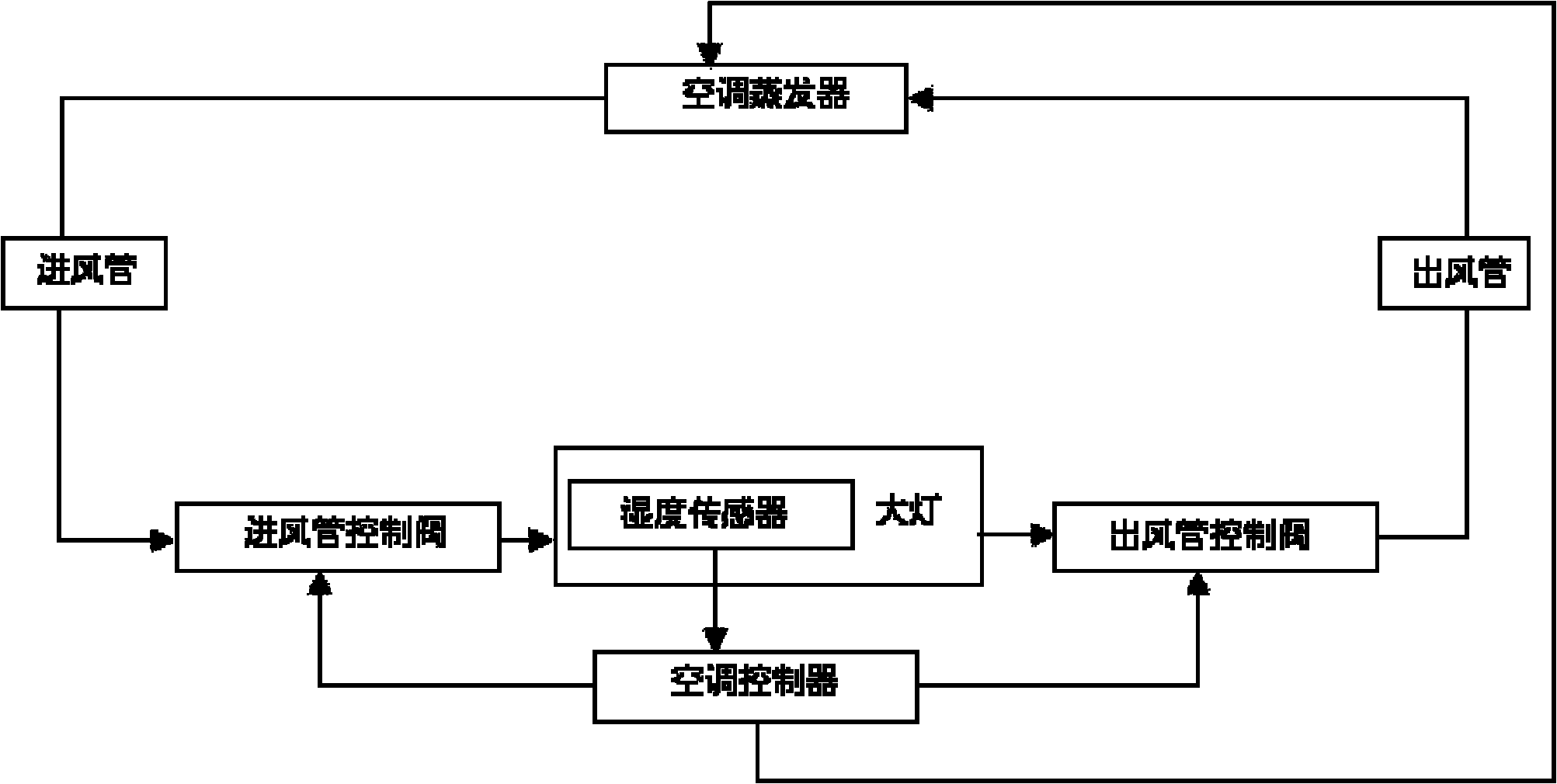

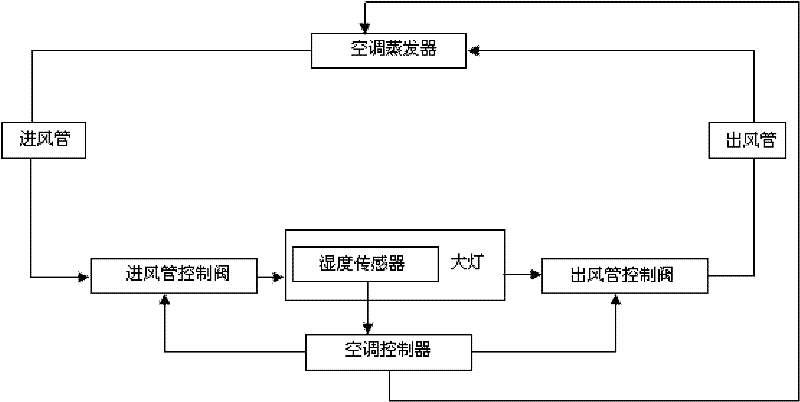

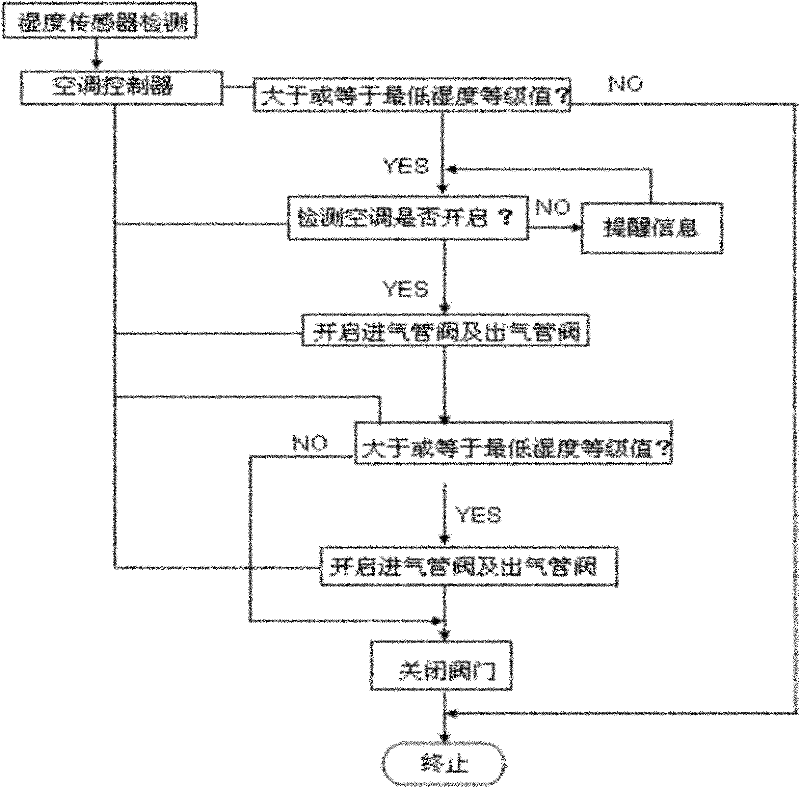

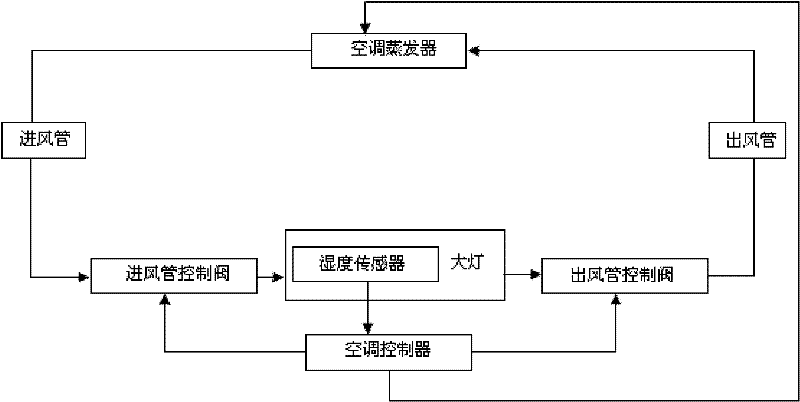

Automobile headlamp demisting device and method

The invention discloses an automobile headlamp demisting device and an automobile headlamp demisting method. The automobile headlamp demisting device comprises an air humidity sensor, an air conditioning controller, an air conditioning evaporator, an air inlet pipe, an air outlet pipe, an air inlet pipe control valve and an air outlet pipe control valve, wherein the air humidity sensor is arranged inside a headlamp; the air inlet pipe is connected with the air outlet side of the air conditioning evaporator; the air outlet pipe is connected with the air inlet side of the air conditioning evaporator; the air inlet pipe control valve and the air outlet pipe control valve are arranged on the air inlet pipe and the air outlet pipe respectively; and the air conditioning evaporator, the air inlet pipe control valve, the air outlet pipe control valve and the air humidity sensor are connected with the air conditioning controller. The automobile headlamp demisting method comprises the following steps of: detecting the humidity level in the automobile headlamp; treating by using the air conditioning controller; demisting in the headlamp; detecting the humidity level in the headlamp again; and demisting in the headlamp again. In the invention, the process requirements of sealing property of the automobile headlamp can be reduced, the manufacturing process can be simplified, and the demisting speed is high and the demisting efficiency is high.

Owner:CHERY AUTOMOBILE CO LTD

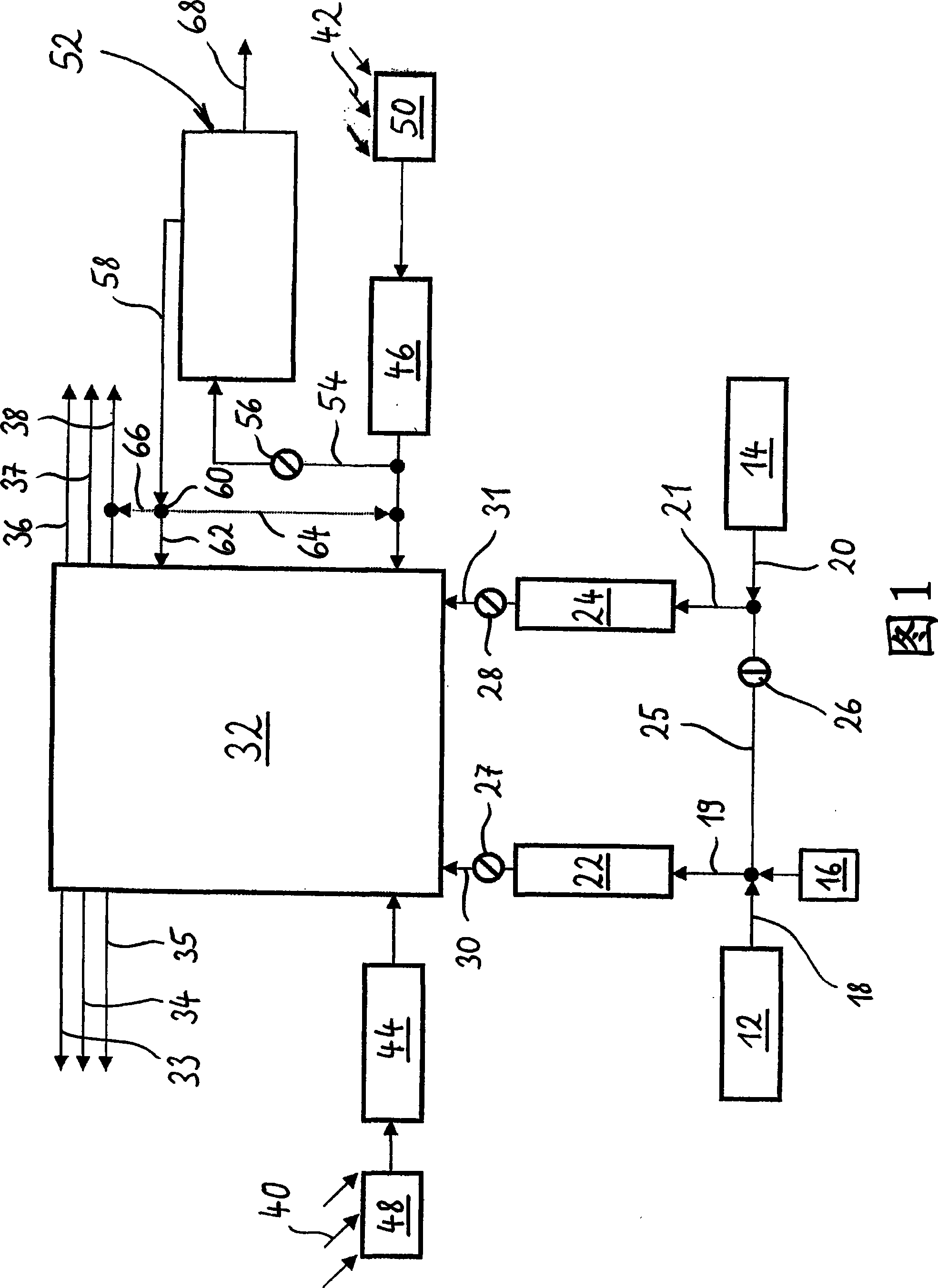

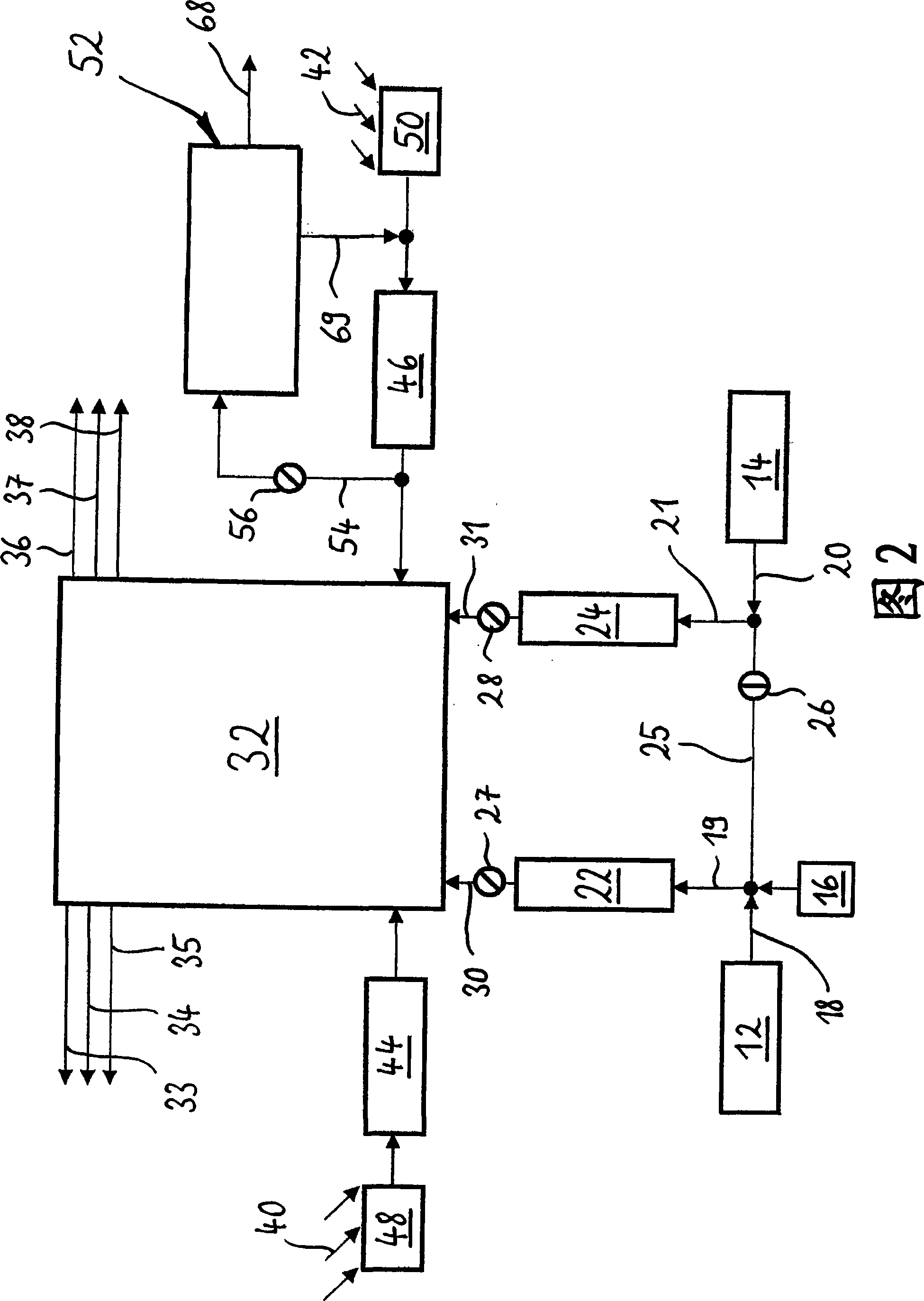

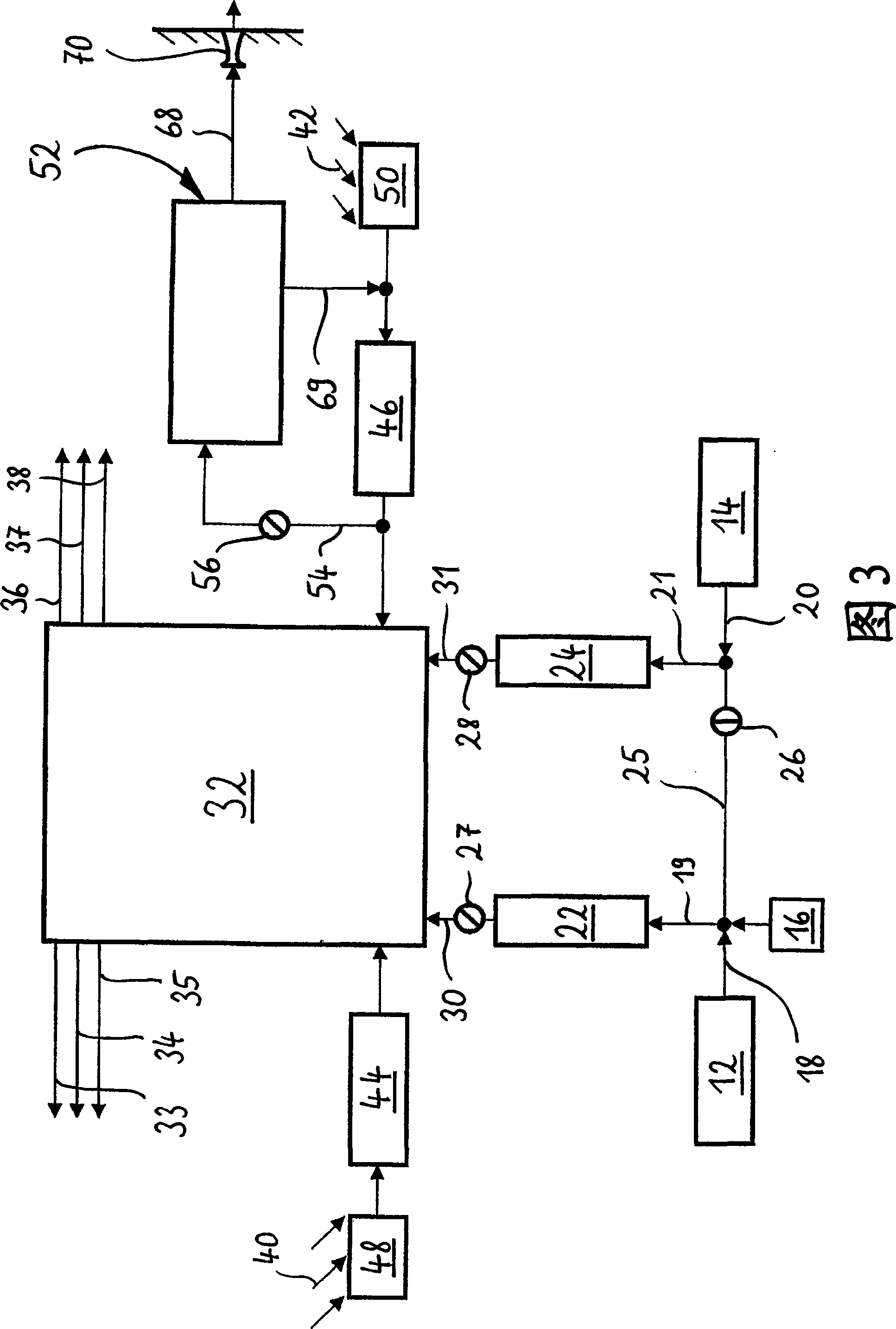

System for improving air quality in an aircraft pressure cabin

ActiveCN101384484ASmall sizeLow costAir-treatment apparatus arrangementsEnergy efficient board measuresNitrogen generatorFlight vehicle

A system for improving the air quality in a pressure cabin of an aircraft comprises a recirculation air circuit by means of which a portion of the cabin air, referred to as recirculation air, is withdrawn from the pressure cabin, filtered and then recirculated into the pressure cabin. To increase the oxygen partial pressure of the air fed back into the pressure cabin, the quantity of recirculation air is passed wholly or partially through a nitrogen generator (52) which generates nitrogen and an oxygen-containing waste gas from the recirculation air supplied. The oxygen-containing waste gas of the nitrogen generator (52), together with any remaining quantity of recirculation air untreated by the nitrogen generator (52), is recirculated into the pressure cabin. The nitrogen generator (52), to which only recirculation air is supplied, utilises a pressure gradient existing in flight between the pressure cabin and the outside of the aircraft for nitrogen generation.

Owner:AIRBUS OPERATIONS GMBH

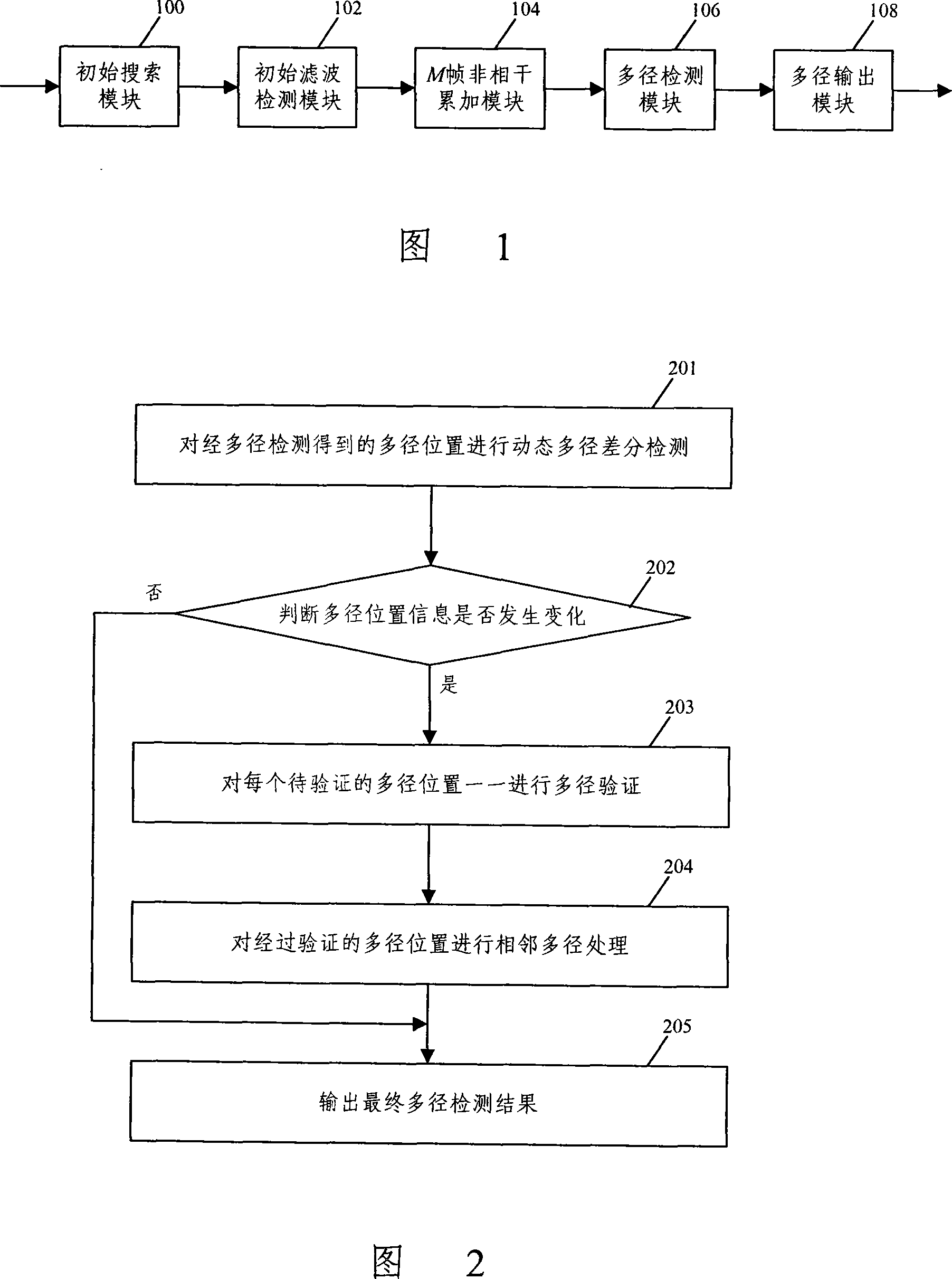

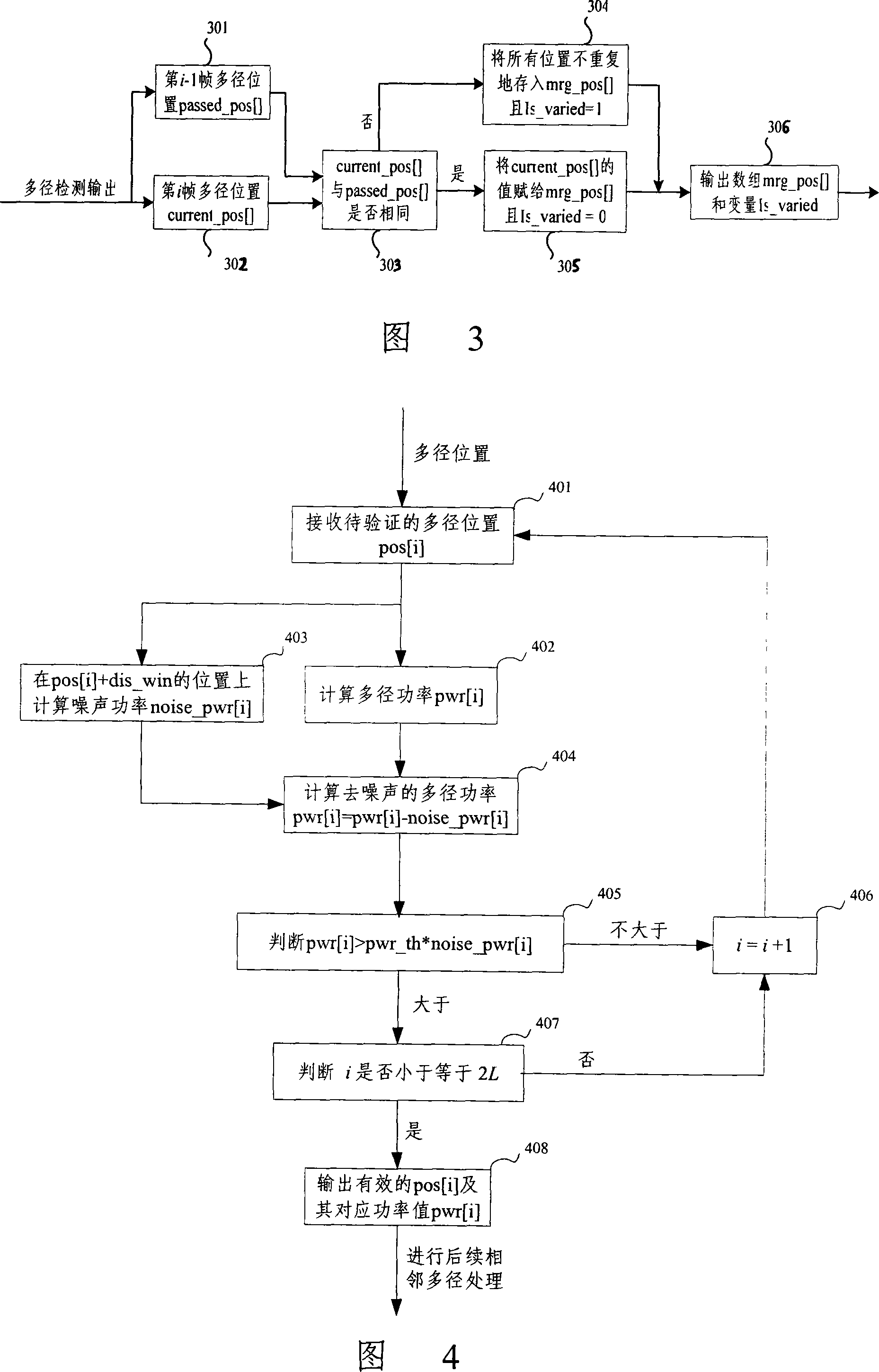

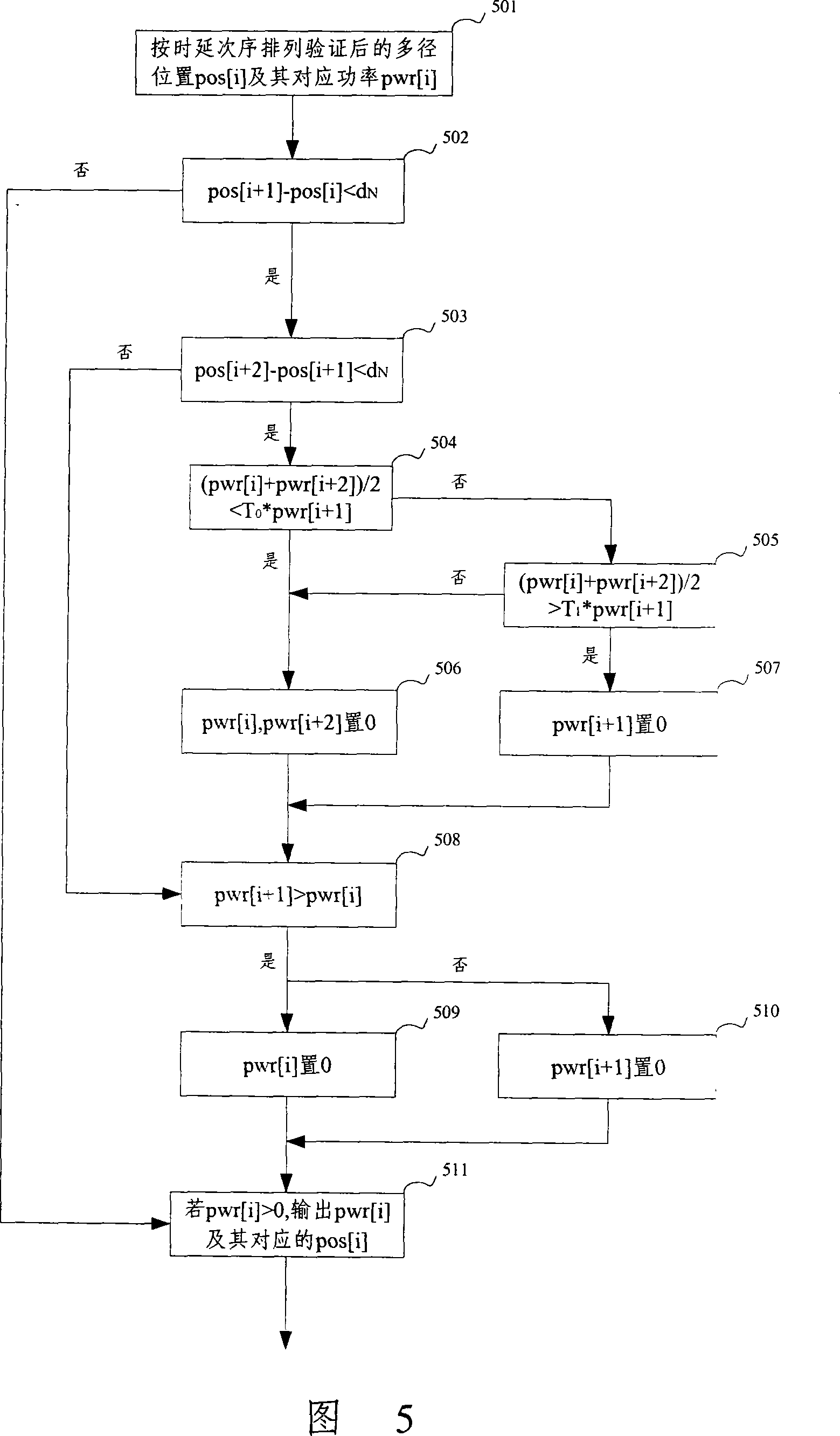

Dynamic multi-path detecting method and device in code division multiple access communication system

InactiveCN101022288AWill not increase consumptionGuaranteed correctnessCode division multiplexTransmissionCommunications systemEngineering

A dynamic multi-path detecting method in CDMA communication system includes carrying out multi-path differential detection and judging whether multi-path position information in adjacent frame is changed or not and outputting all multi-path positions being differential-detected if it is or otherwise using said multi-path positions as final multi-path detection result, making multi-path verification on each output multi-path position and using multi-path position being adjacent-multi-path treated as final multi-path detection result. The multi-path searcher is also disclosed.

Owner:互芯集成电路(北京)有限公司

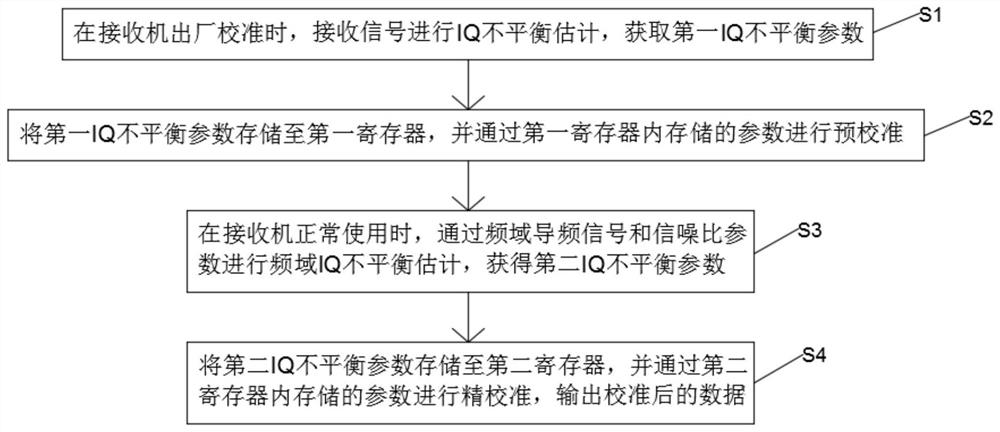

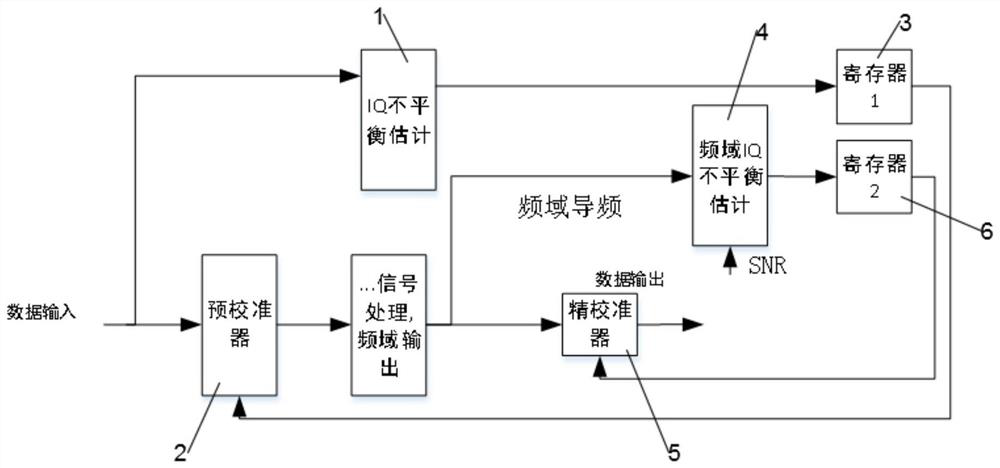

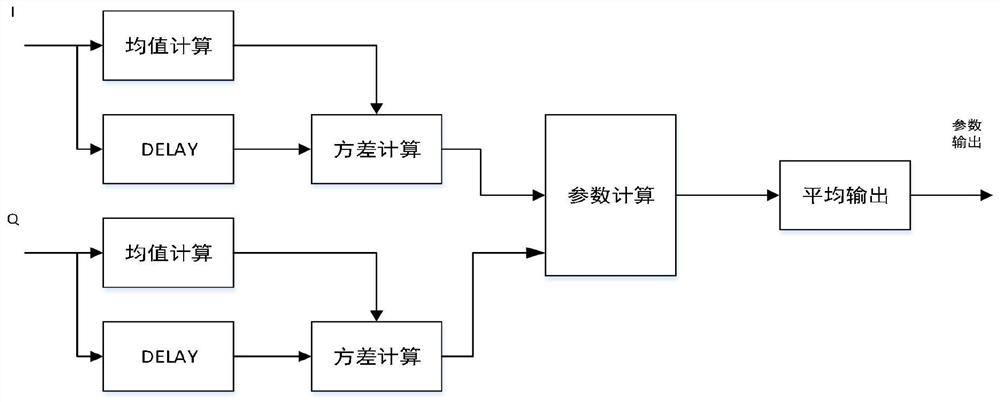

IQ imbalance correction method and system of zero intermediate frequency receiver

PendingCN113541712AAccepts little impact on performanceWill not increase consumptionMultiple carrier systemsFrequency spectrumIntermediate frequency

The invention provides an IQ imbalance correction method and system for a zero intermediate frequency receiver; the method comprises the steps: carrying out the IQ imbalance estimation of a received signal during the factory calibration of the receiver, and obtaining a first IQ imbalance parameter; storing the first IQ imbalance parameter in a first register, and carrying out pre-calibration through the parameter stored in the first register; when the receiver is normally used, performing frequency domain IQ imbalance estimation through the frequency domain pilot signal and the signal-to-noise ratio parameter to obtain a second IQ imbalance parameter; and storing the second IQ imbalance parameter to a second register, performing fine calibration through the parameter stored in the second register, and outputting calibrated data. According to the scheme, a large unbalanced parameter is calibrated during factory calibration, a small amount of unbalance degree is remained, and the residual unbalance parameter is compensated when the receiver is in the receiving state, so that the calibration precision of the system is higher, and extra spectrum resource consumption is not increased.

Owner:上海擎昆信息科技有限公司

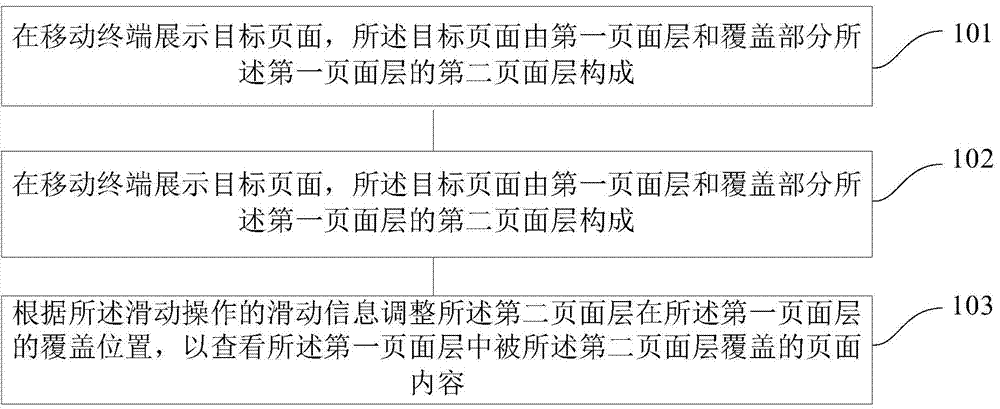

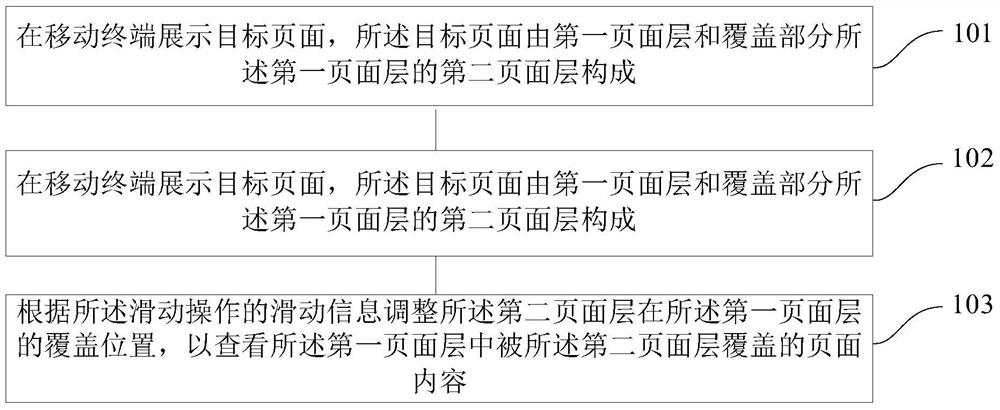

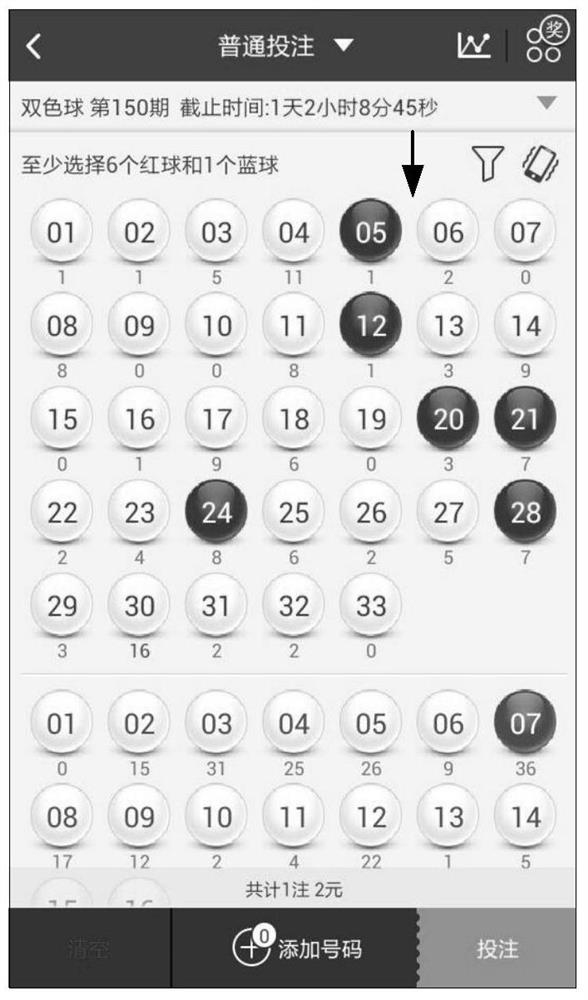

Method and device for viewing page information of mobile terminal

ActiveCN104778198AHeavy loadWill not increase consumptionSpecial data processing applicationsInput/output processes for data processingComputer hardwareComputer science

The invention discloses a method and device for viewing page information of a mobile terminal. The method comprises the following steps: displaying a target page on the mobile terminal, wherein the target page consists of a first page layer and a second page layer covering a part of the first page layer; tracking the sliding operation of a user on the second page layer, and detecting the sliding information of the sliding operation; adjusting the covering position of the second page layer on the first page layer according to the sliding information of the sliding operation in order view page content covered by the second page layer in the first page layer. Compared with the prior art, the method and the device have the advantage that content needing to be viewed and compared synchronously are placed into two page layers without opening a new page, so that increase in the loads of a user terminal and a server is avoided, and the consumption of network flow is not increased.

Owner:BEIJING QIHOO TECH CO LTD +1

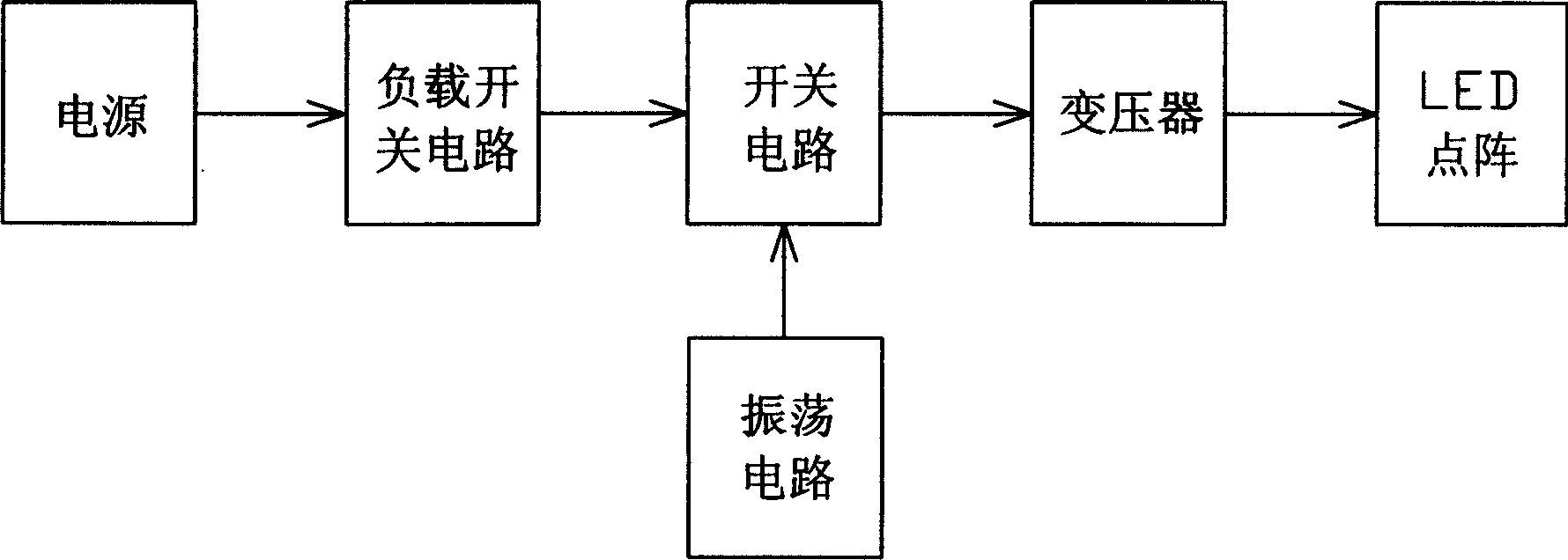

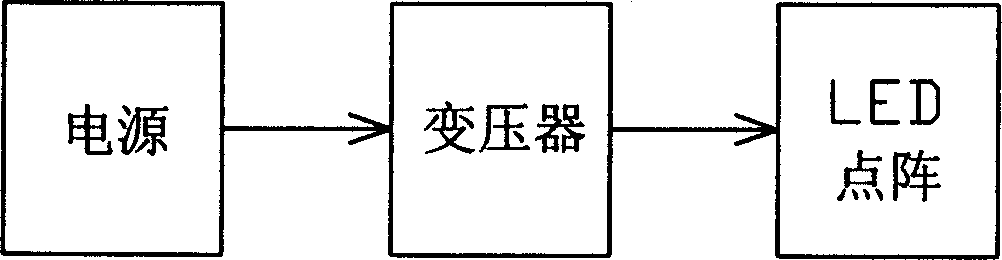

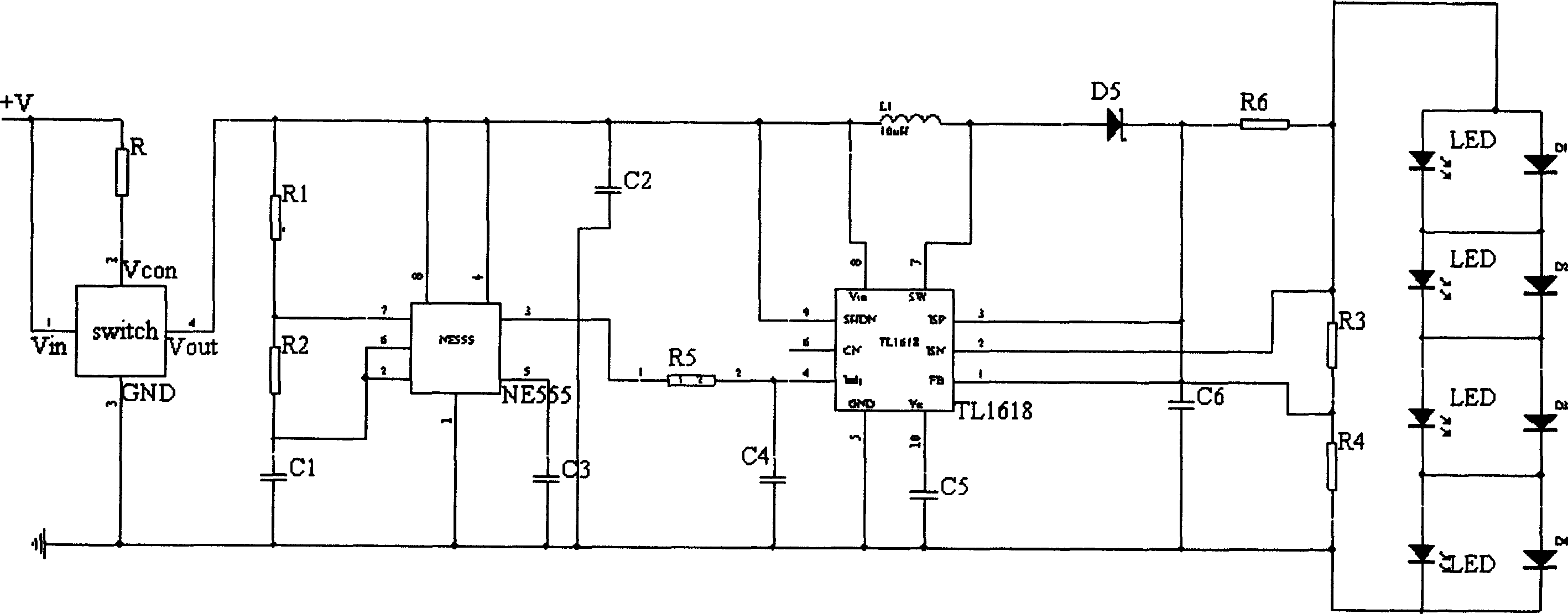

Luminous diode light source

InactiveCN1589078AIncrease instant brightnessLife expectancyElectric light circuit arrangementTransformerEngineering

This invention relates to a LED light source including a power supply, a transformer, a LED lattice, the power supply provides power to the lattice by the transformer having a switch circuit between them controlled by an oscillation circuit. The oscillation circuit and the switch circuit are set in this inverted light source circuit, the oscillation circuit generates square wave signals in a certain frequency to control the on-off of the switch circuit to control the current input into the LED and make LED lattice flash in high frequency to increase its transient brightness.

Owner:WUHAN UNIV OF TECH

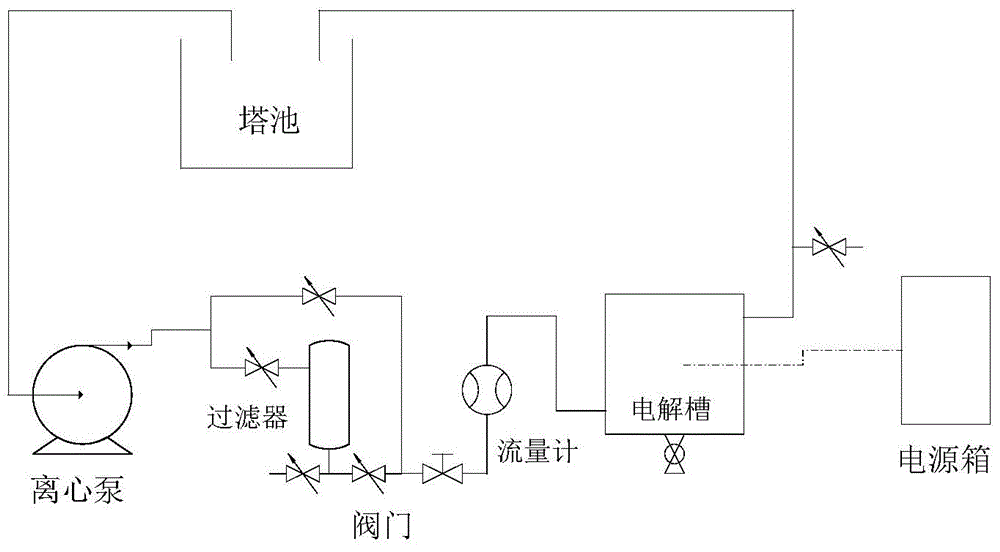

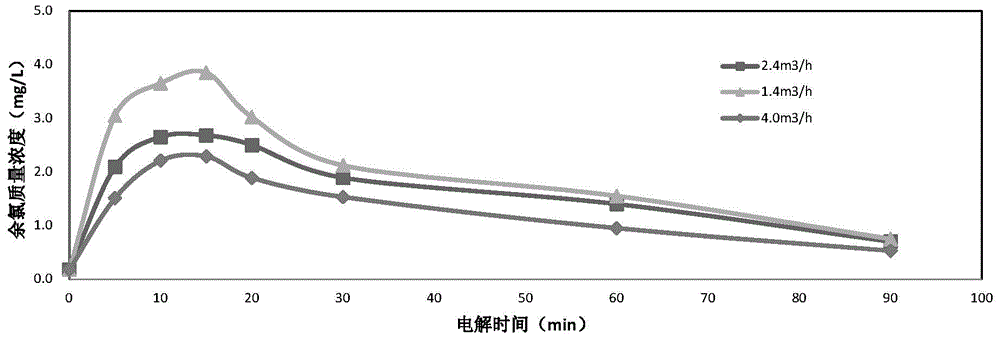

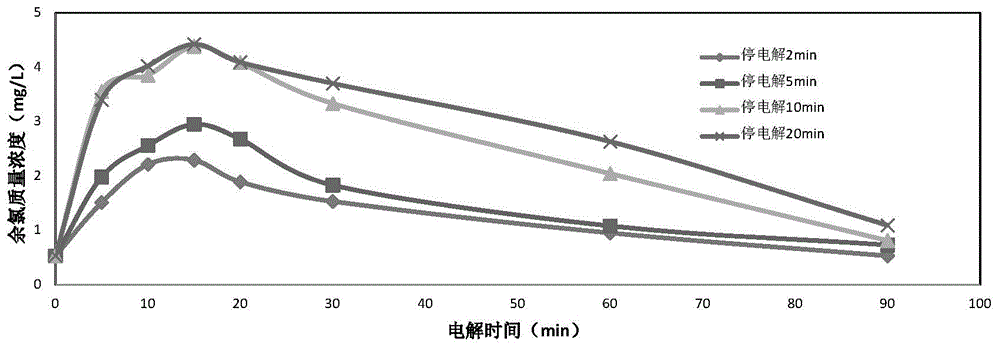

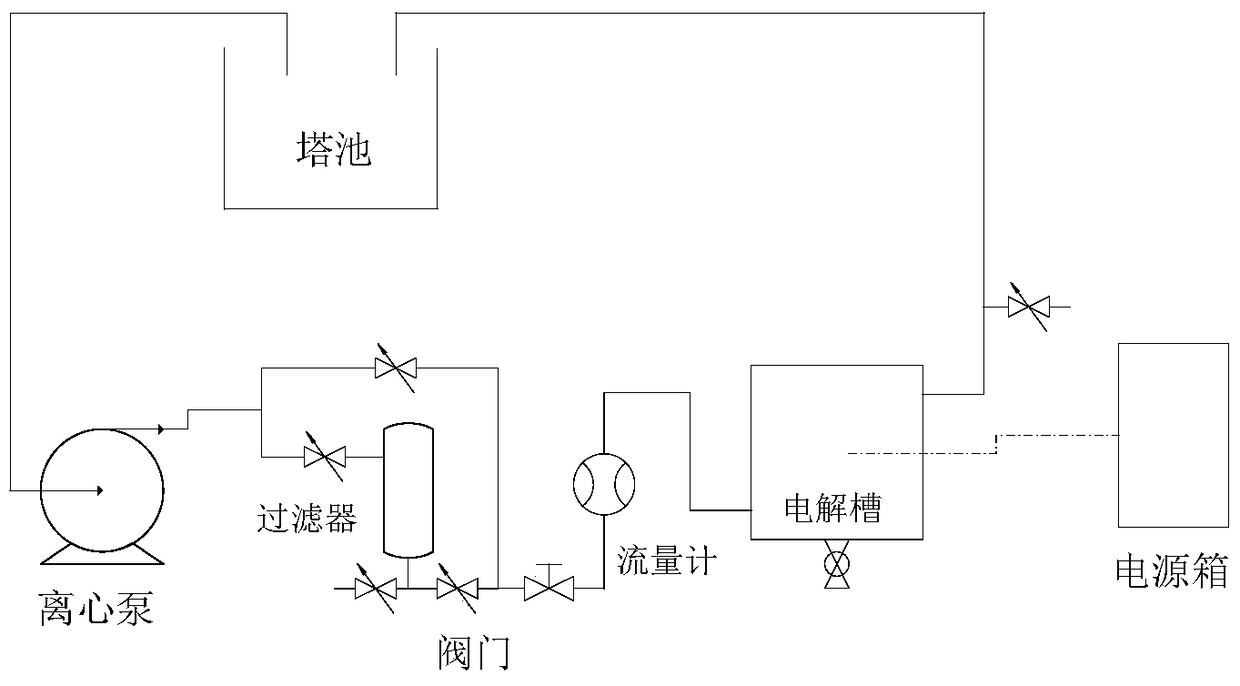

Circulating cooling water sterilizing method and application

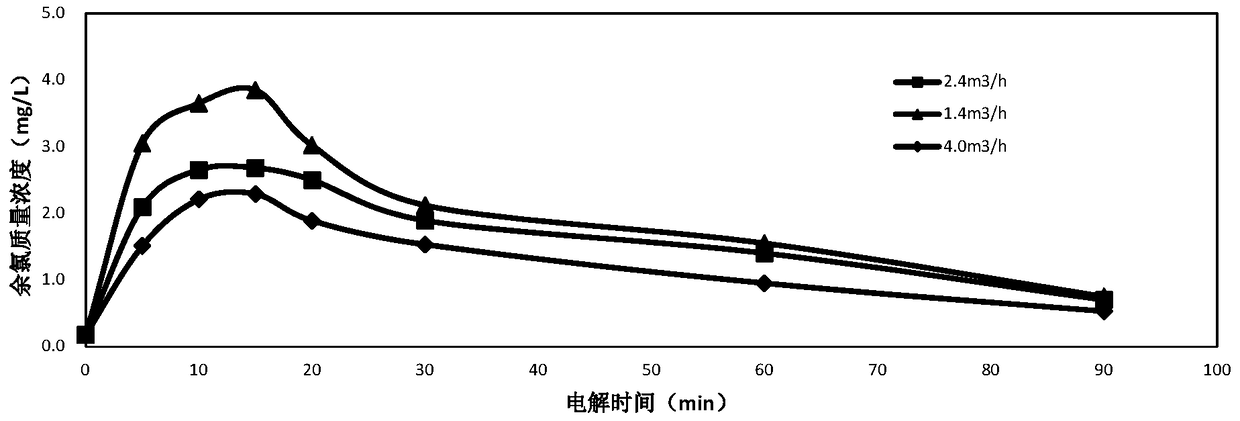

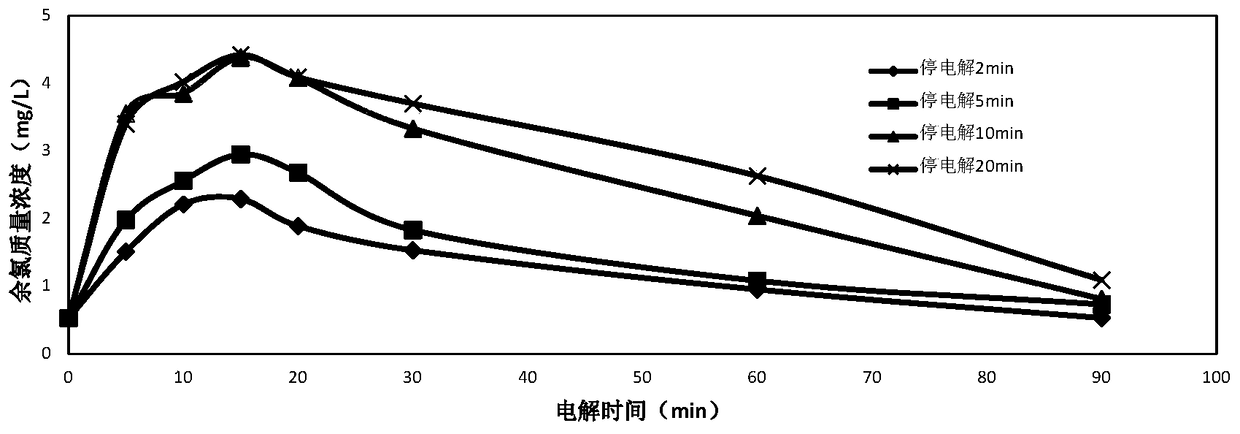

ActiveCN104556311AWill not increase consumptionReduced activitySpecific water treatment objectivesNature of treatment waterElectricityElectrolysis

The invention discloses a circulating cooling water sterilizing method and application. The circulating cooling water sterilizing method comprises the step of electrolyzing at least one part of circulating cooling water in a circulating cooling water system, wherein an electrolyzing process is performed intermittently. According to the electrolysis sterilizing method for the circulating cooling water, provided by the invention, reduction in electrode activity and electrolytic current efficiency can be effectively avoided, mass concentration of residual chlorine in the circulating cooling water is enabled to be in a control range, service lives of electrodes are guaranteed, and extra electricity consumption is not increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

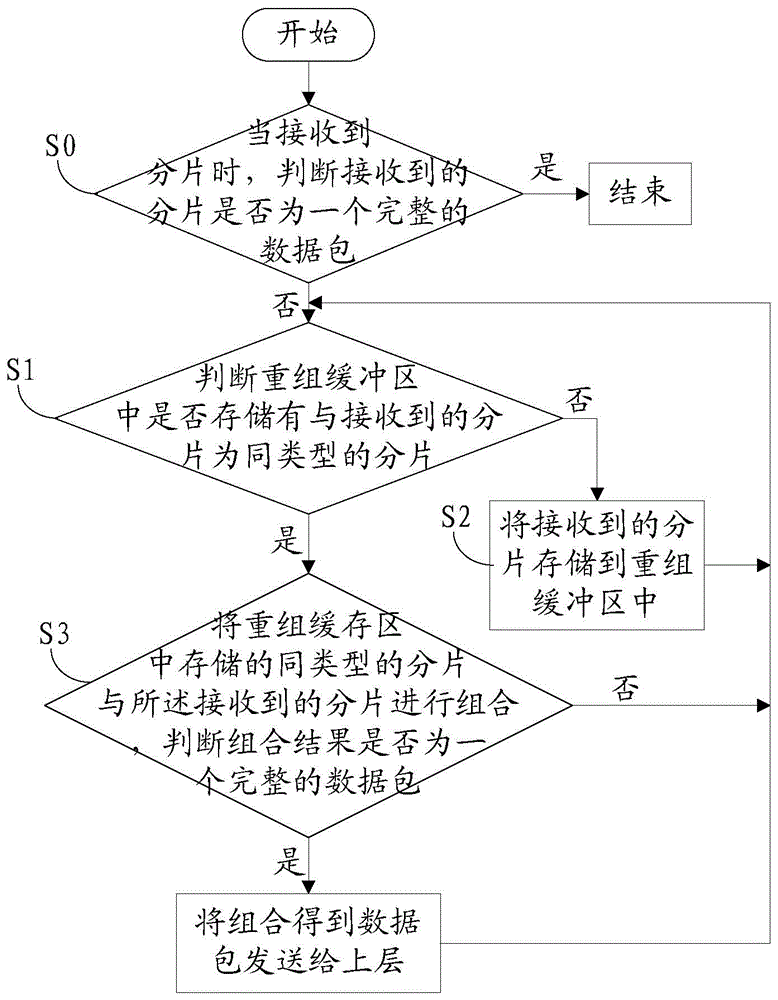

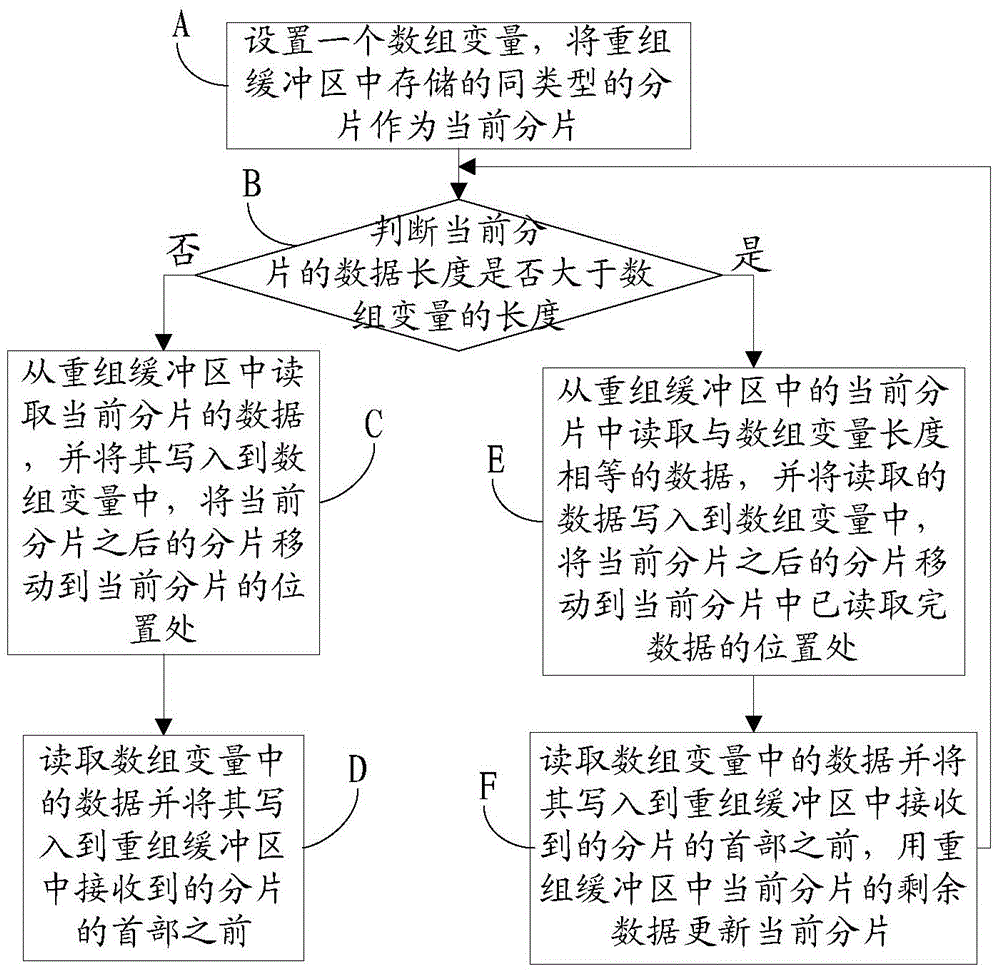

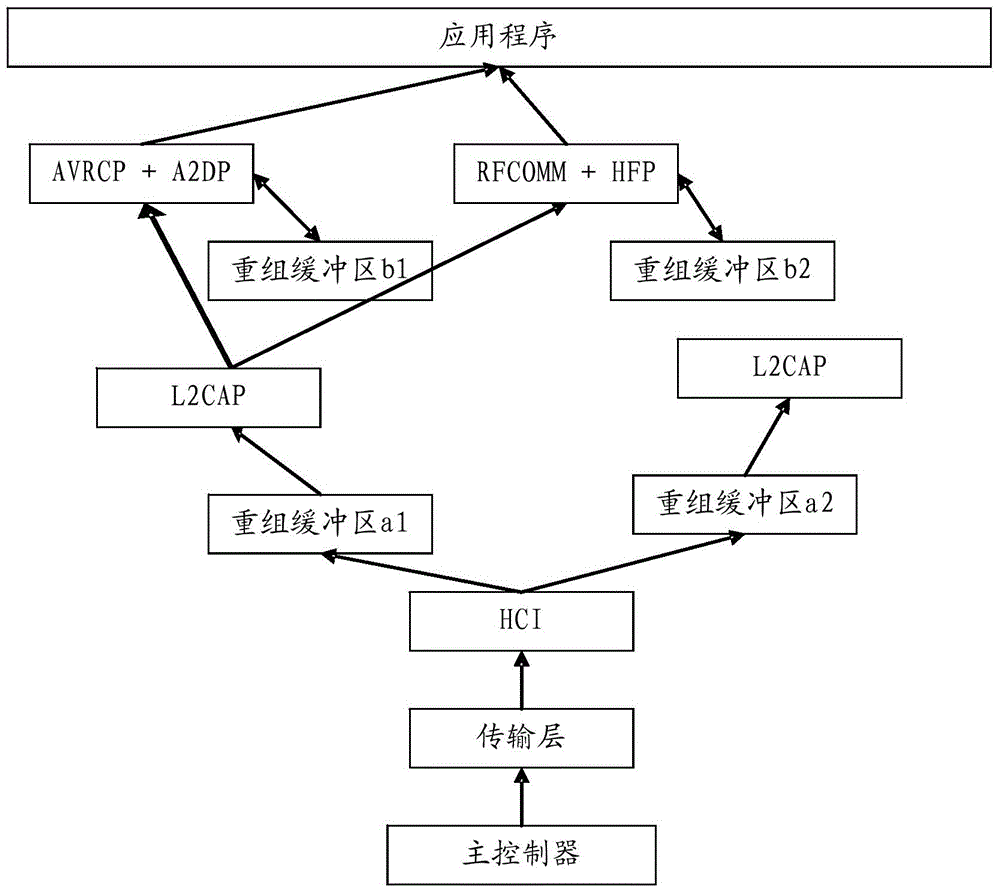

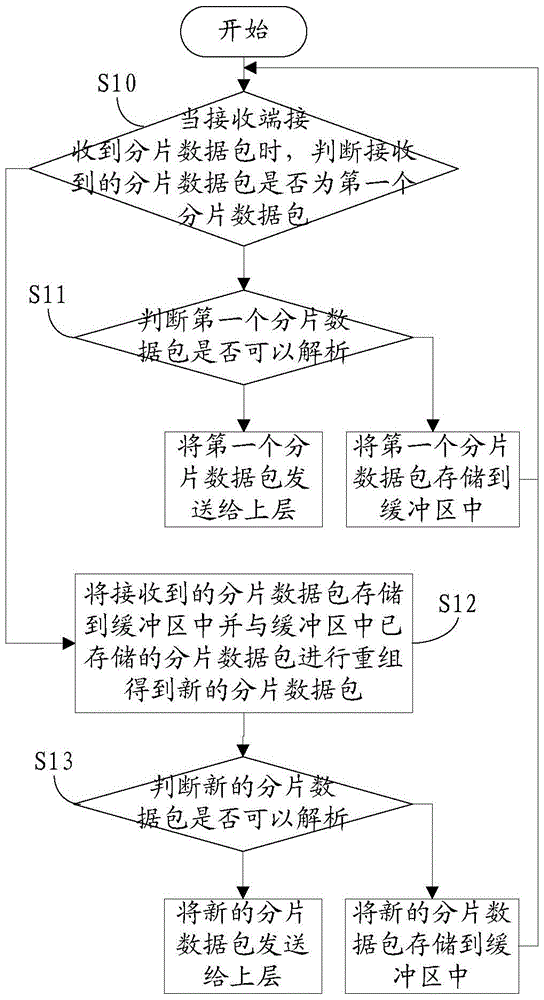

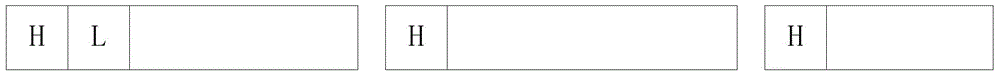

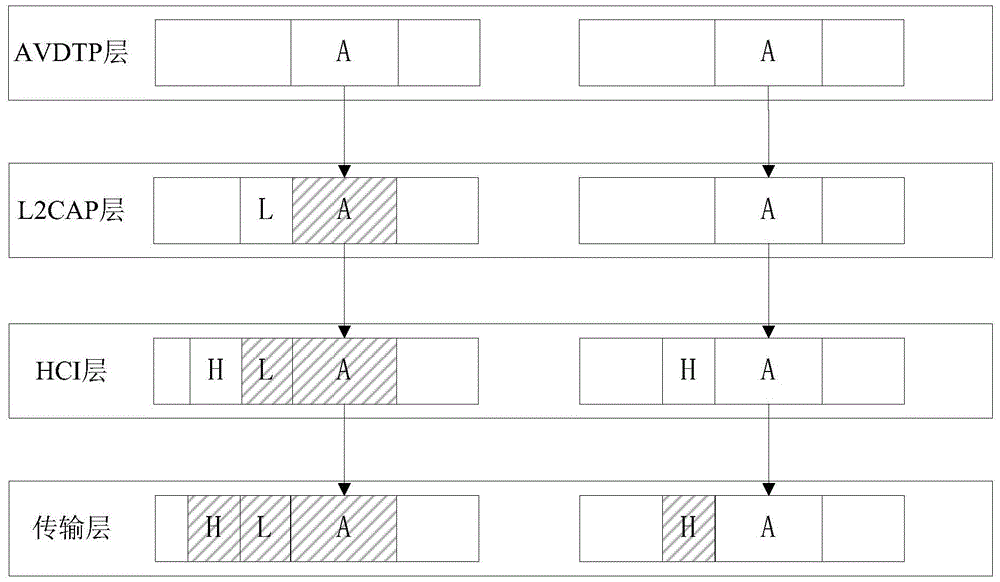

Method and device for saving internal memory

ActiveCN104639511AWill not increase consumptionSave memoryNear-field transmissionInternal memoryComplete data

The invention discloses a method and device for saving internal memory and relates to the technical field of Bluetooth. The method includes: when a fragment is received, judging whether a fragment of the same type of the received fragment is stored in a reassembly buffer area or not, if so, combining the received fragment with the fragment stored in the reassembly buffer area, judging whether the combination is a complete packet or not, and if so, transmitting the combined packet to an upper layer; if not, continuing to receive the fragments, to be more specific, storing the received fragment into the reassembly buffer area and continuing to receive the fragments. By the method, all reassembling is achieved in one buffer area, the internal memory is saved, internal memory consumption of other cooperation software cannot be increased, and original quality standards such as performance and compatibility of products can be guaranteed.

Owner:ANYKA (GUANGZHOU) MICROELECTRONICS TECH CO LTD

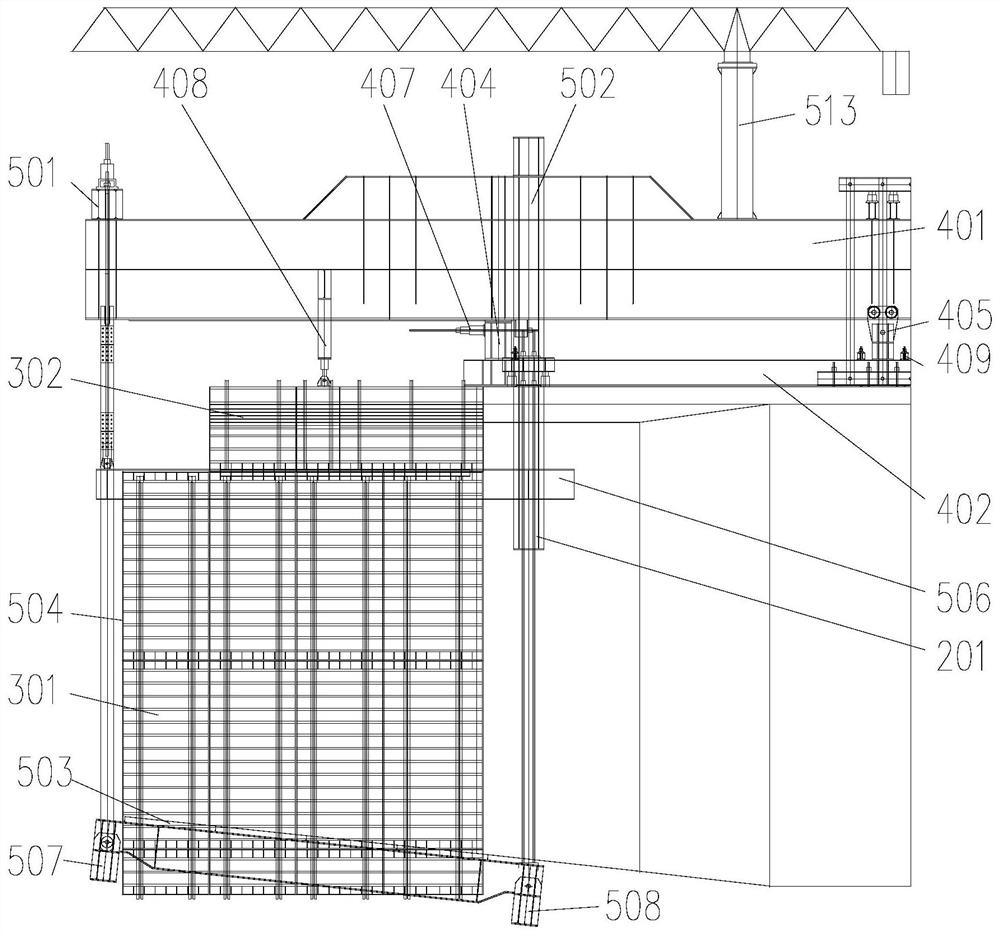

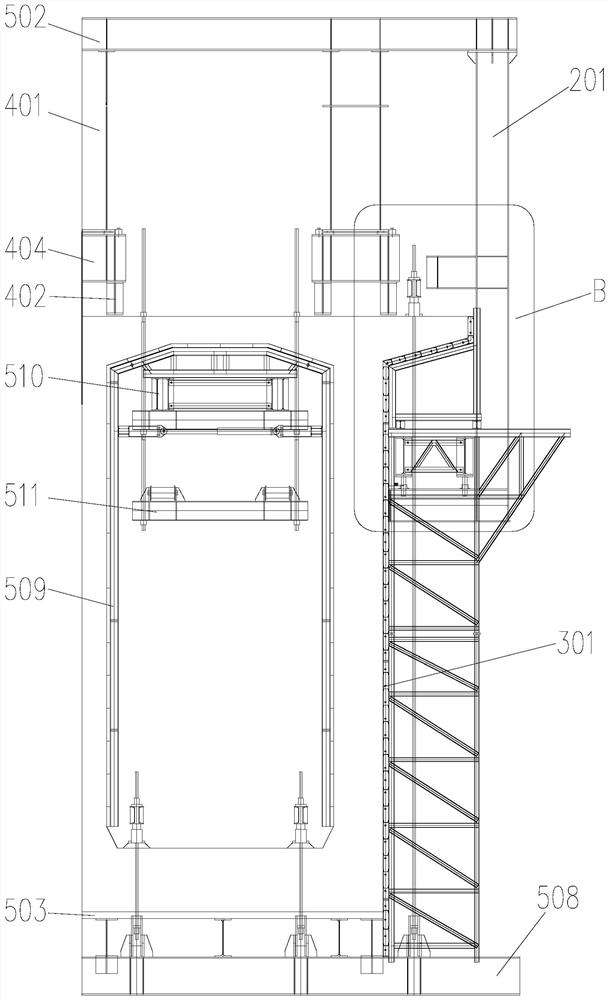

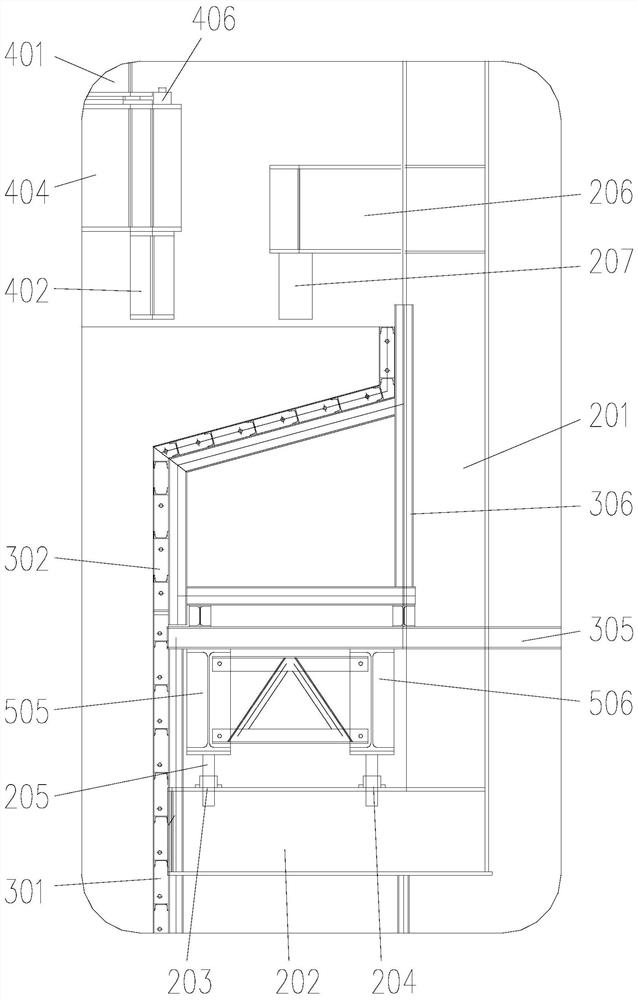

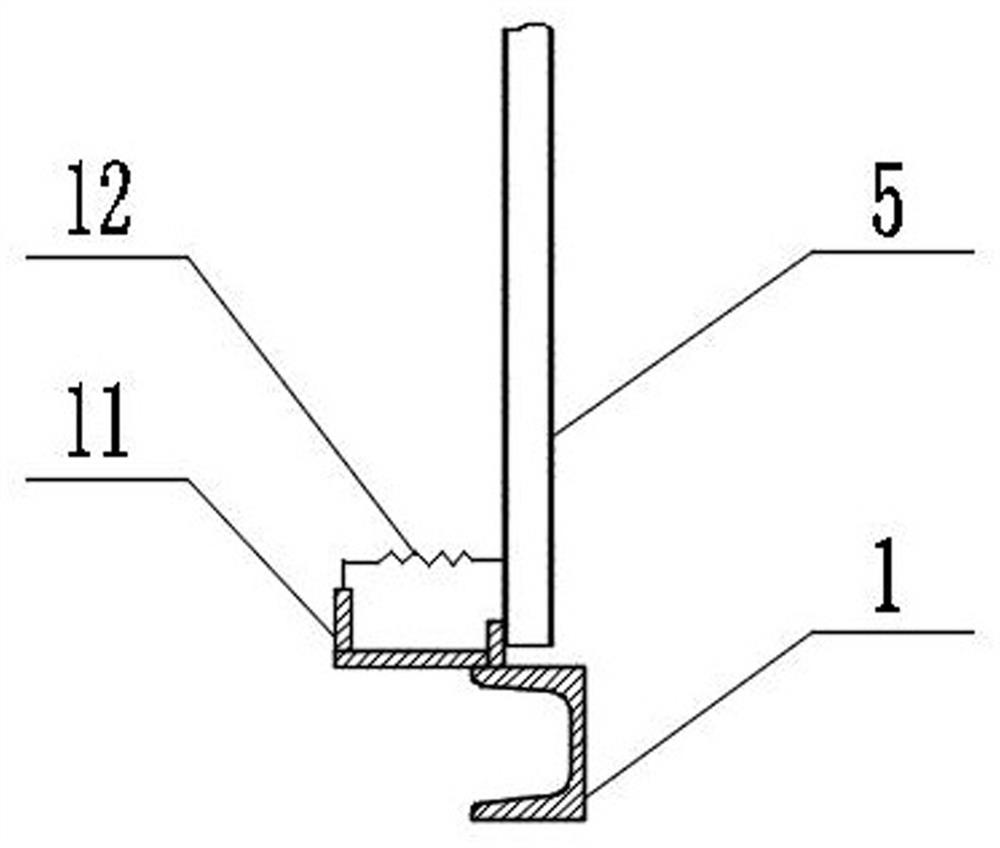

Walking system of cantilever pouring bridge fabrication machine

PendingCN112900286AEasy to moveSimplify the construction processBridge erection/assemblyArchitectural engineeringHanging basket

The invention relates to the technical field of bridge fabrication, in particular to a walking system of a cantilever pouring bridge fabrication machine. The walking system comprises a main beam used for supporting a hanging basket and a walking beam used for supporting the main beam, the main beam and the walking beam are connected through reverse hanging wheels, and the device further comprises a walking limiting part, a walking driving part, a main jacking part and a main driving part; the walking limiting part is used for restraining the walking beam on a bridge top plate; the walking driving part is used for driving the walking beam to move in the longitudinal direction of the bridge after the walking beam is released from the constraint of the bridge top plate; the main jacking part is used for jacking the main beam so as to separate the main beam from the walking beam; the main driving part is used for driving the main beam to move in the longitudinal direction of the bridge after the main beam is separated from the walking beam. Through mutual cooperation of the main beam and the walking beam, overall movement of the hanging basket system can be effectively achieved, the moving mode of the hanging basket system is completely different from that of a hanging basket in the prior art, the overall construction process is relatively simple, and extra equipment consumption is not increased.

Owner:CHINA RAILWAY 16TH BUREAU GRP 5TH ENG

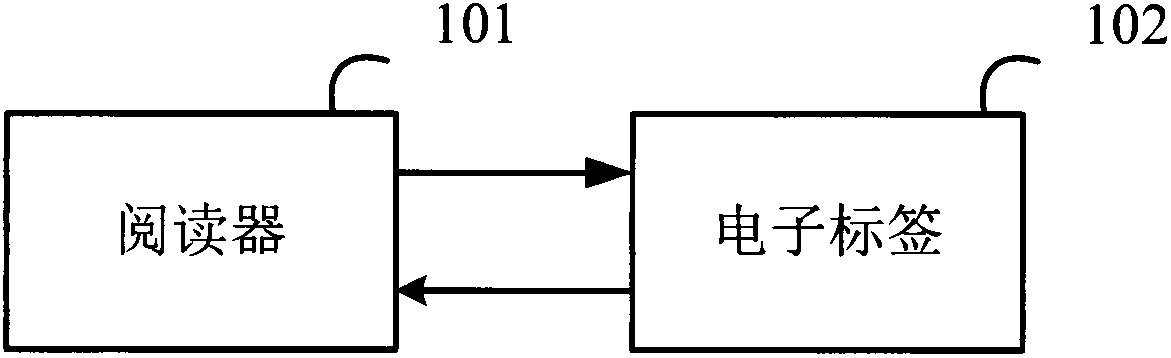

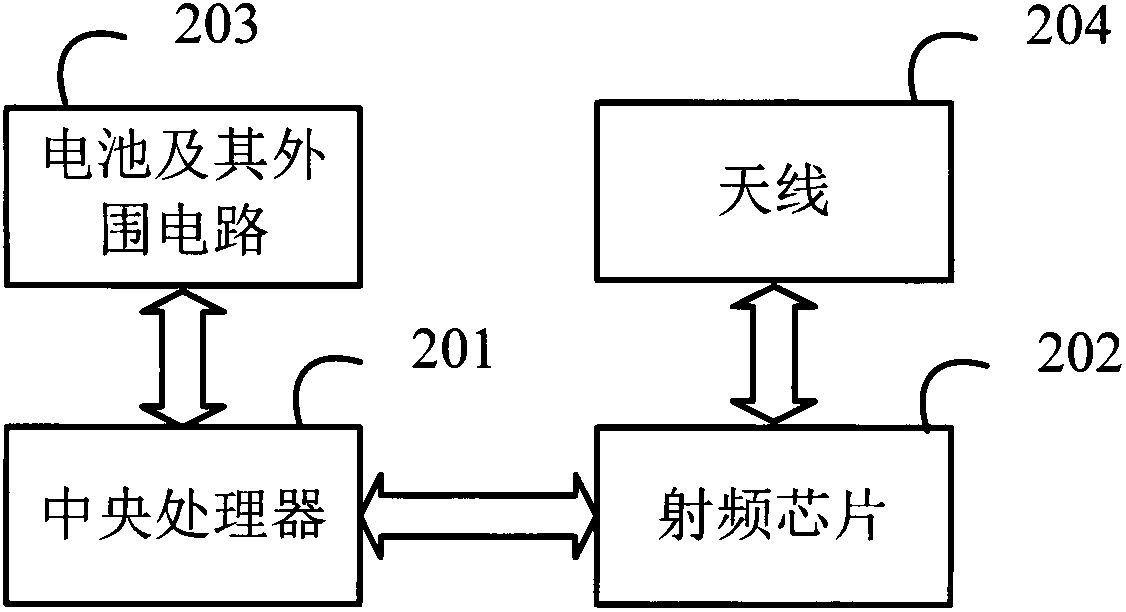

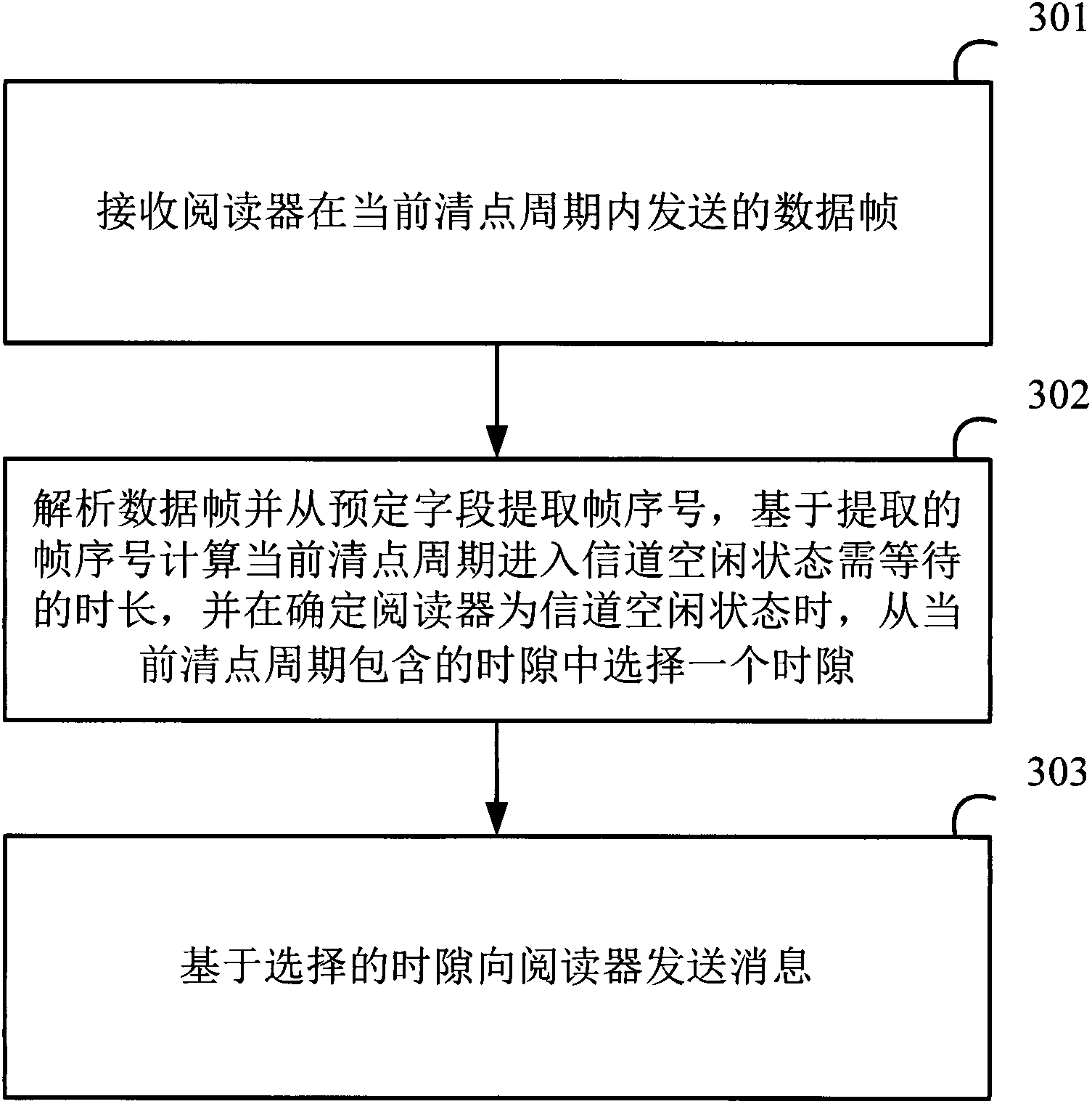

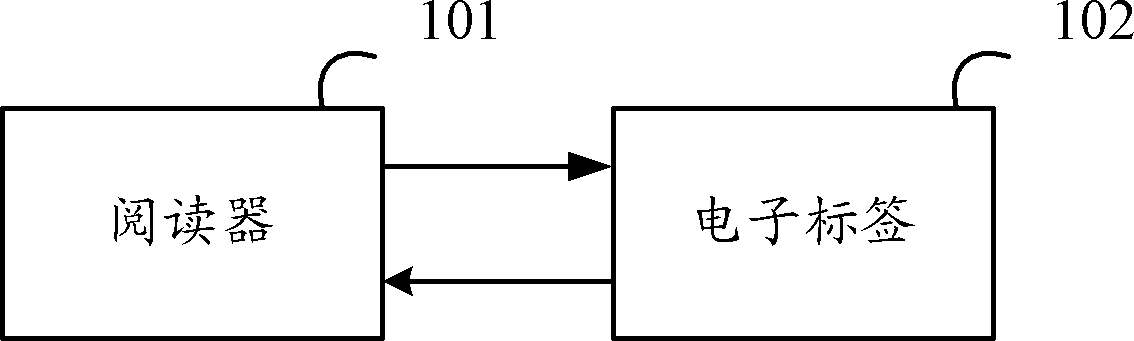

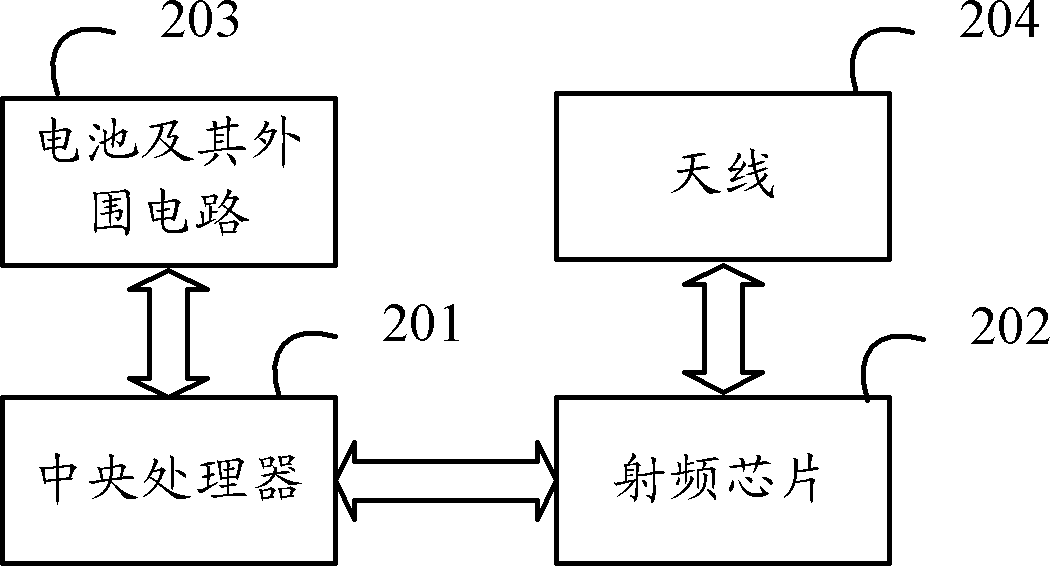

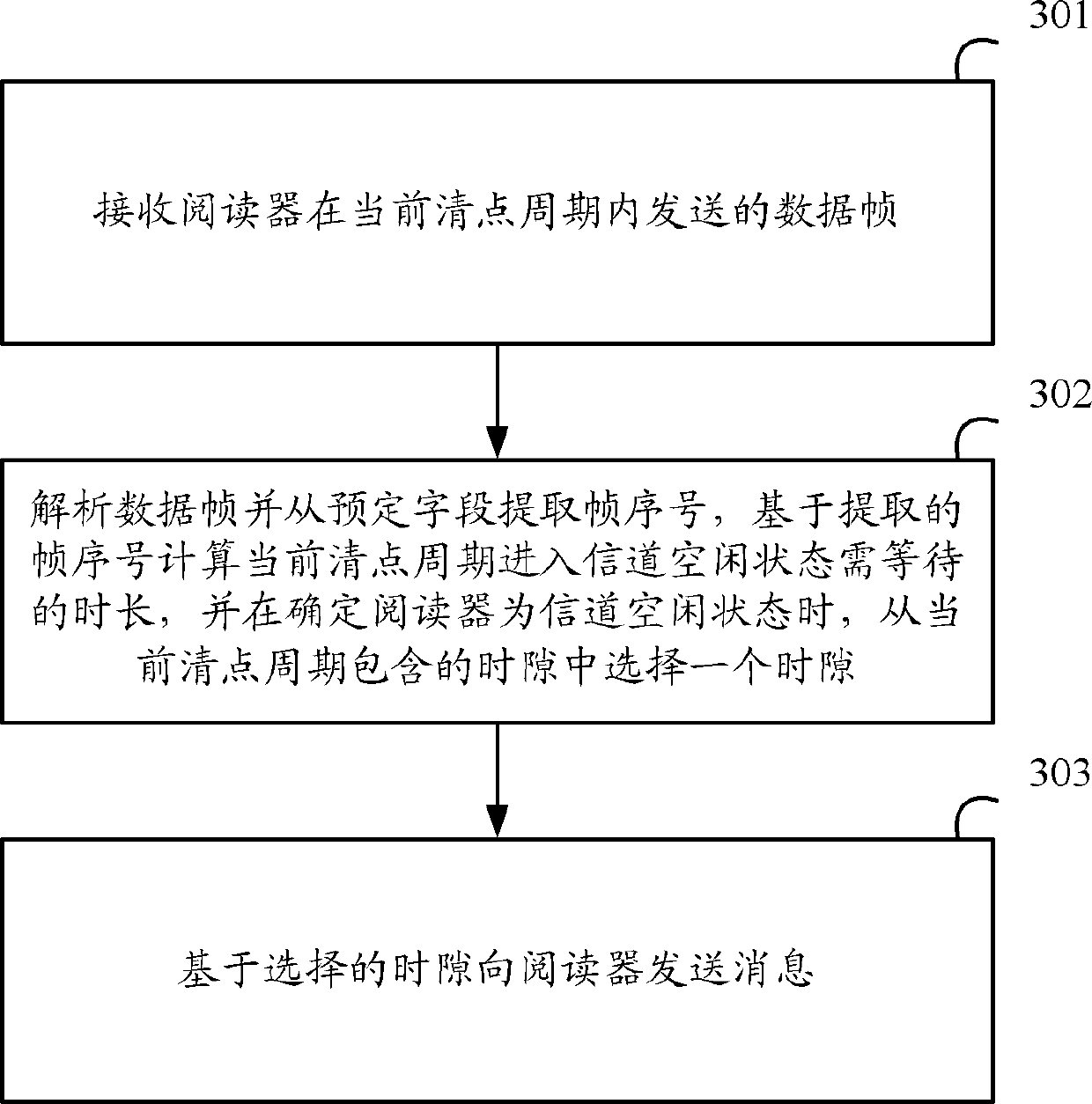

Communication method based on radio frequency identification system

InactiveCN103123681AEnable two-way communicationTwo-way communication is simpleEnergy efficient ICTSensing record carriersRadio frequencyComputer science

The invention discloses a communication method, a device and a system based on radio frequency identification system. The communication method, device and system are used for achieving both-way communication between an electronic tag and a reader in the radio frequency identification system, saving battery energy consumption of an active electronic tag, and guaranteeing communication stability between the electronic tag and the reader. The method includes steps of receiving data frames sent by the reader during a current inventory cycle, analyzing the data frames and extracting a frame number from a pre-set field, calculating a required waiting time of the current inventory cycle entering a channel idle state based on the extracted frame number, choosing a slot time from slot times contained in the current inventory cycle while determining the reader is in the channel idle state, and sending a message to the reader based on the chosen slot time. The invention discloses a communication device based on radio frequency identification system and a communication system based on radio frequency identification at the same time.

Owner:TIANJIN ZHONGXING SOFTWARE

Slag high-heat-strength blast-furnace magnesium filler

InactiveCN102864250ASmall sizeEasy to put inBlast furnace detailsBlast furnace smeltingMechanical force

The invention discloses a slag high-heat-strength blast-furnace magnesium filler which is prepared from the following raw materials in percentage by mass: 70-90% of light-burned magnesium powder, 1-8% of binding agent, 5-12% of aggregate and 2-11% of water. The slag high-heat-strength blast-furnace magnesium filler comprises the following components in percentage by mass: 60-75% of MgO, 4-14% of SiO2, 2-6% of CaO, 2-8% of H2O, and 12-17% of binding agent and other components. The raw materials are pressed into oblate spheroids under the mechanical force of a briquetting machine; and the physical dimension of the oblate spheroid magnesium filler is 35-65mm, and the compression strength at room temperature is 1500-3500N. The magnesium filler has the advantages of small volume and high compression strength, is convenient for addition, does not increase the thermal energy consumption of the blast-furnace smelting, improves the comprehensive metallurgical properties of furnace slag, relieves the wind resistance of the blast furnace, promotes the yield increase, consumption reduction and effect enhancement of the blast furnace, and enhances the economic benefit of the blast furnace.

Owner:KUNSHAN QUANRUN RESOURCE TECH

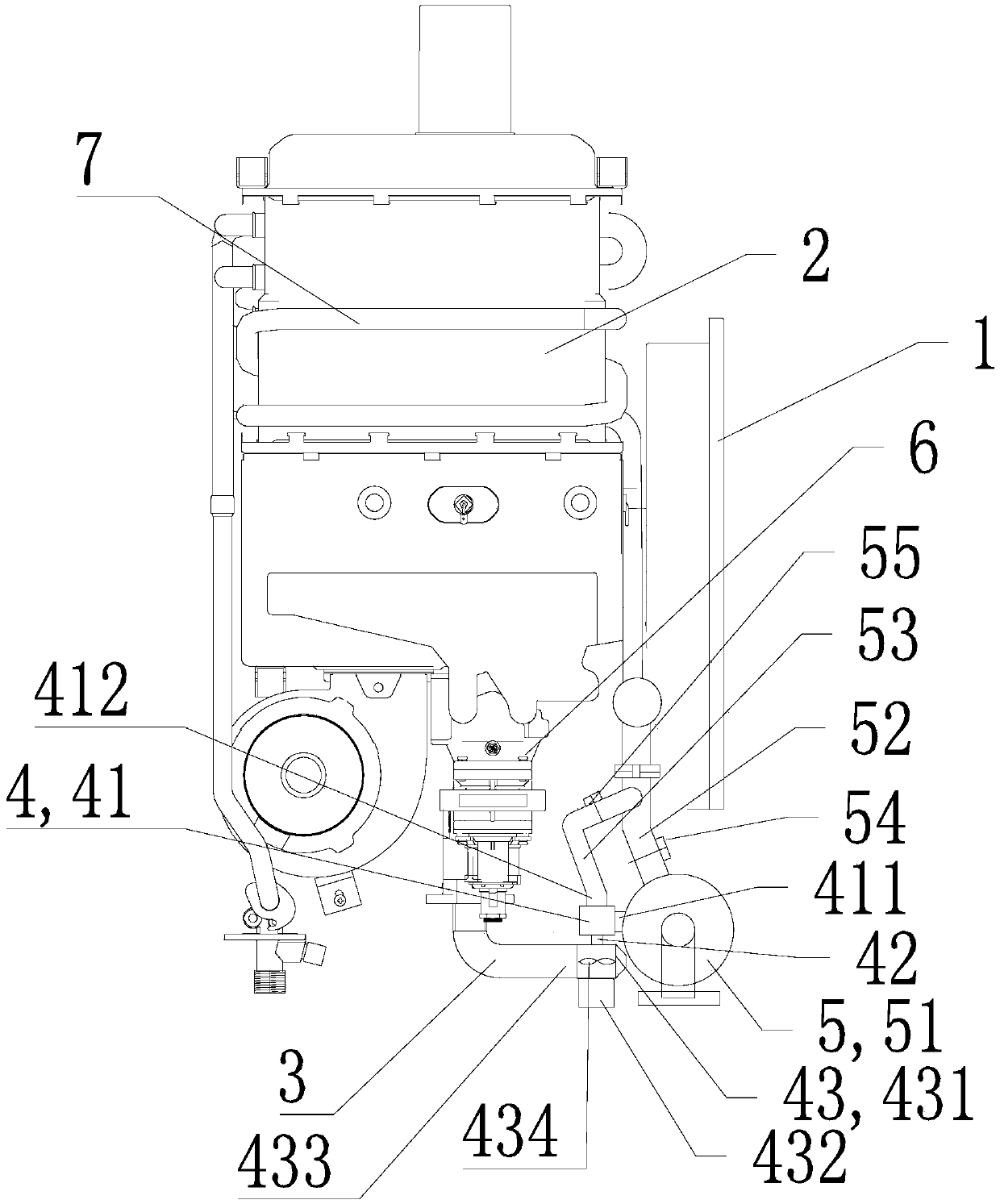

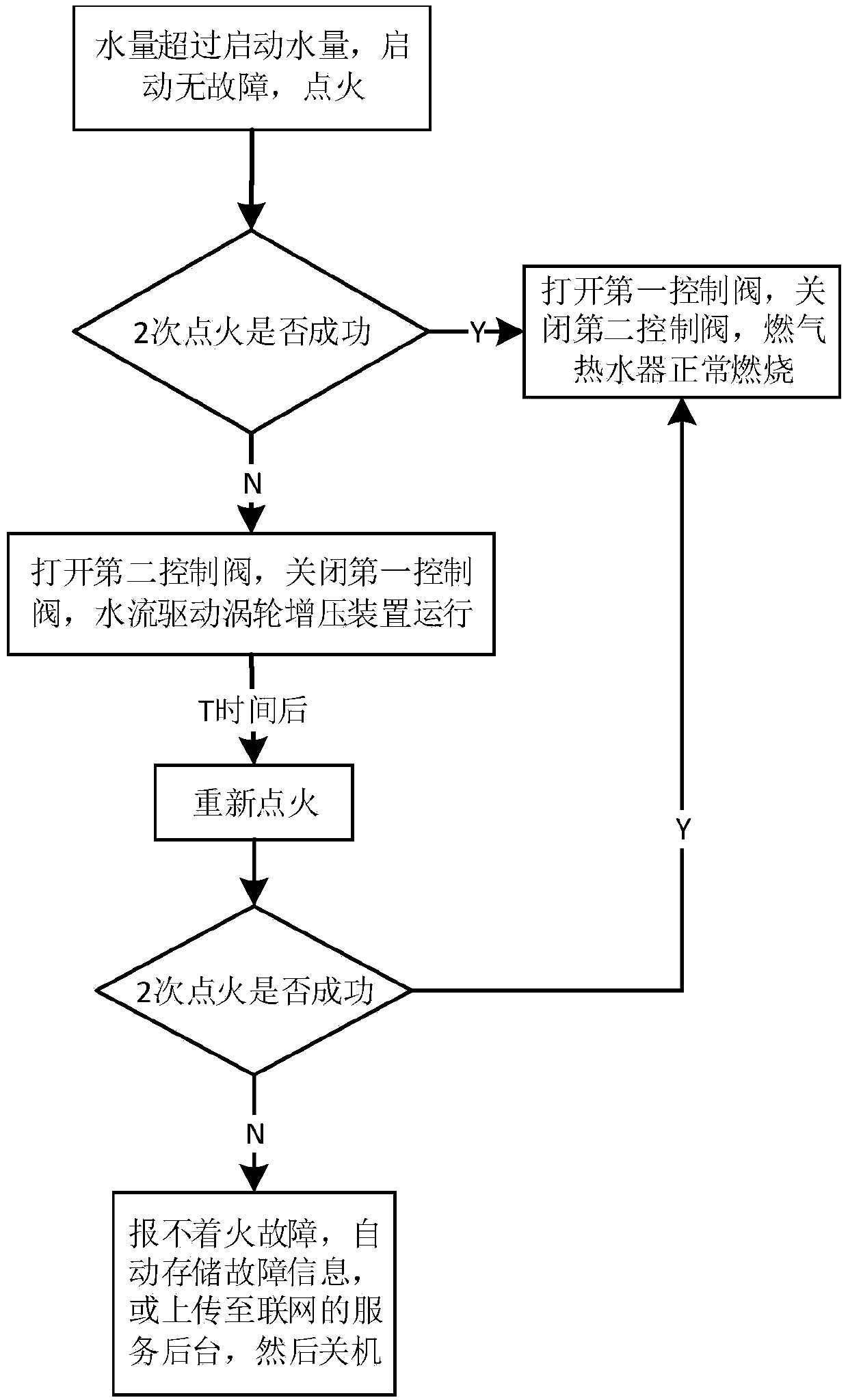

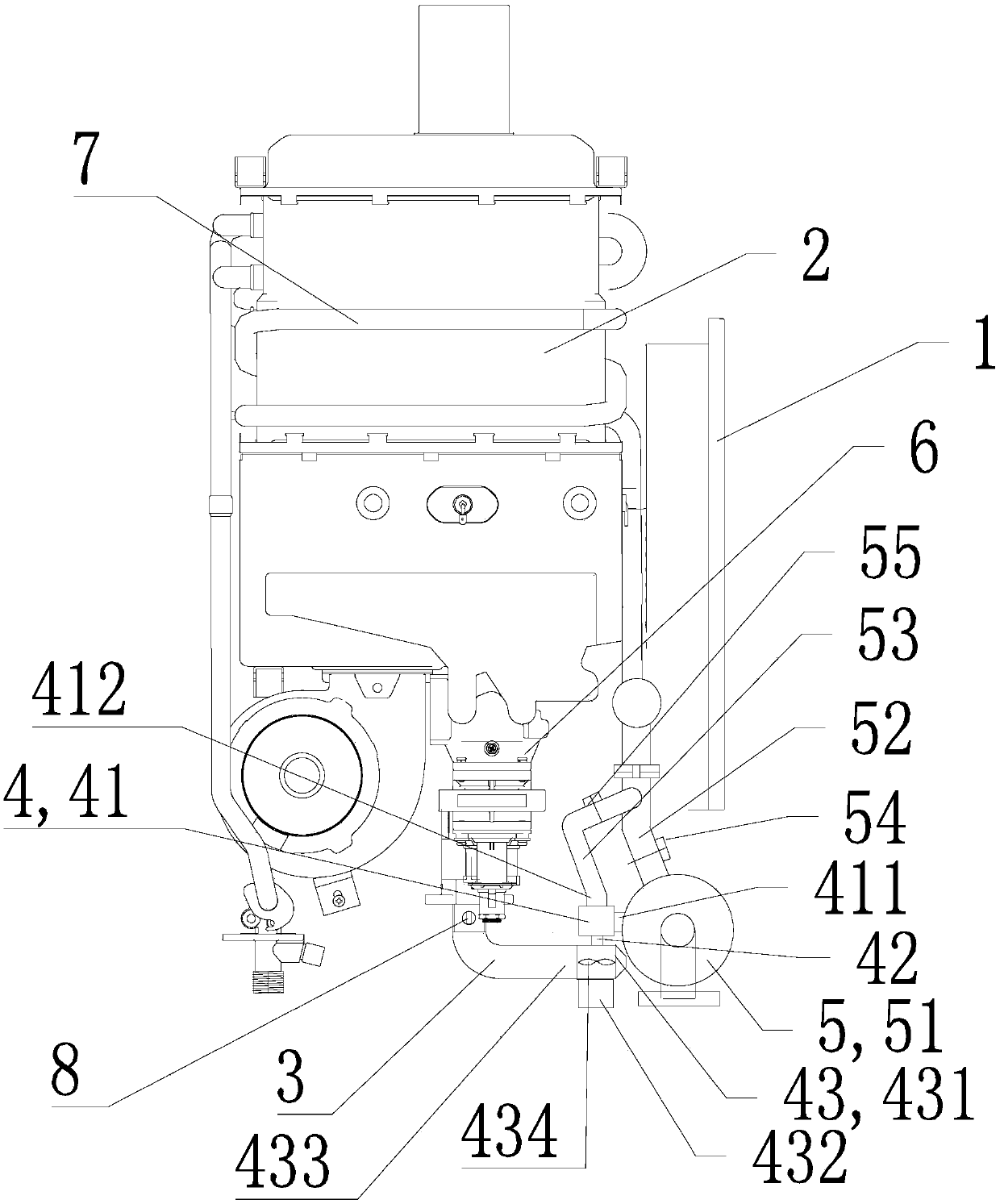

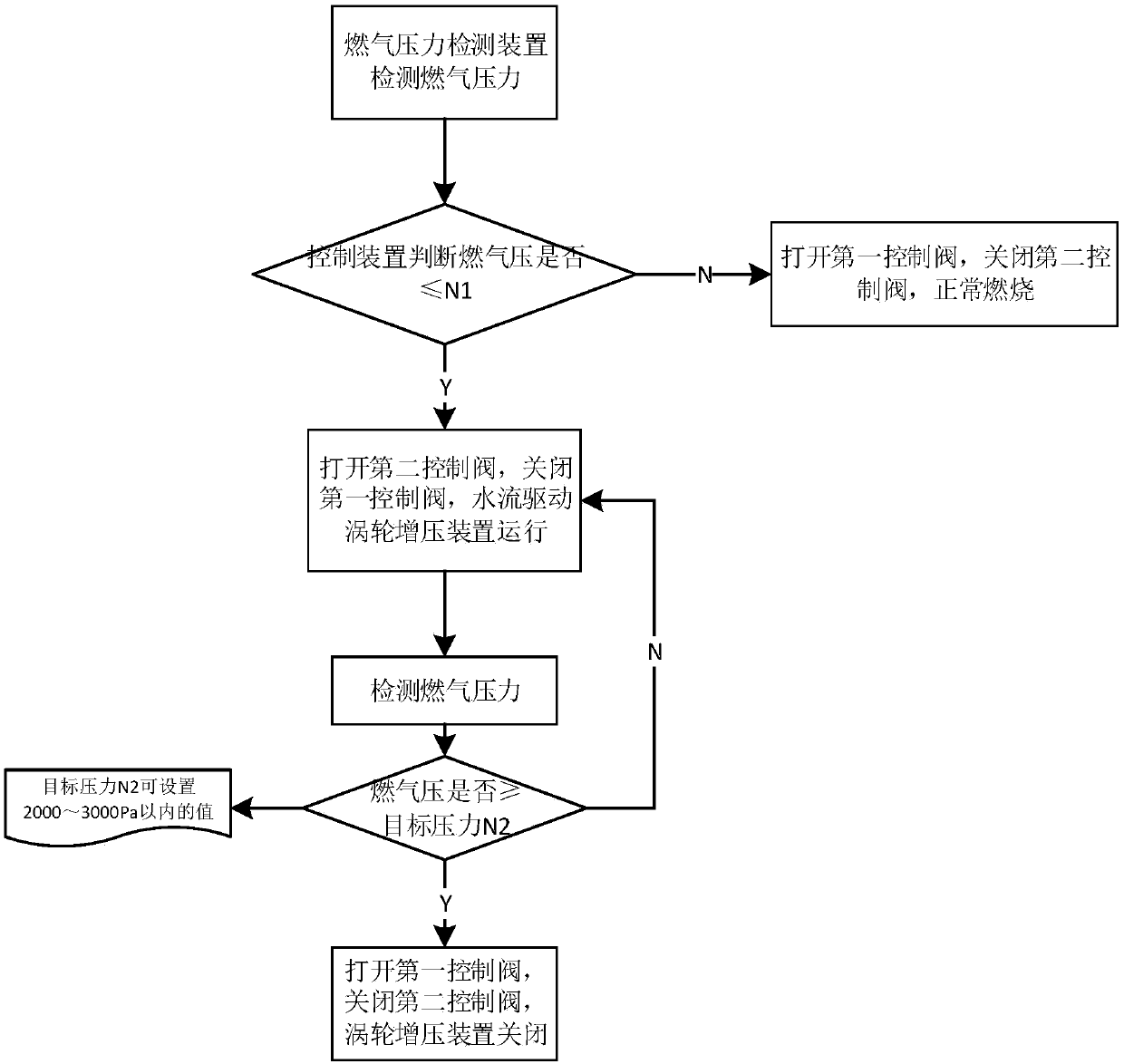

Control method for pressure boost gas water heater, and gas water heater

PendingCN110966765AGuaranteed pressure and stabilityGuaranteed stability and temperatureWater heatersAutomotive engineeringProcess engineering

The invention discloses a control method for a pressure boost gas water heater, and the gas water heater. The gas water heater comprises a turbocharging device and a liquid driving device, wherein theturbocharging device is arranged on a gas inlet pipeline; the liquid driving device drives the turbocharging device to operate; after the gas water heater is started, ignition is firstly started, andif the ignition is successful, normal work is carried out; and if the ignition is not successful, a judgment result shows that gas inlet pressure is excessively low, the liquid driving device is controlled to drive a liquid to enter the turbocharging device so as to drive the turbocharging device to operate, and gas is subjected to pressure boost. The control method disclosed by the invention istimely and quick in gas pressure boost, the gas inlet pressure and stability can be guaranteed so as to guarantee to match an optimal combustion working condition, a water discharging temperature andstability can be guaranteed, and the bathing experience of a user is greatly improved.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER

Heavy stubble cleaning harrow and stubble cleaning operation method of high-stubble straw

PendingCN111972056AImprove job performanceImprove stubble removal effectMowersHarrowsAgricultural engineeringStructural engineering

The invention discloses a heavy stubble cleaning harrow. The heavy stubble cleaning harrow is characterized by comprising a main harrow frame assembly, a middle harrow frame assembly, a left folding harrow frame assembly and a right folding harrow frame assembly, wherein the left folding harrow frame assembly and the right folding harrow frame assembly are connected to the left side and the rightside of the main harrow frame assembly in a foldable mode; the middle harrow frame assembly is fixedly connected to the lower portion of the main harrow frame assembly; the front end of the main harrow frame assembly is movably connected with a traction frame assembly; the rear end of the main harrow frame assembly is movably connected with a rear adjusting tail frame assembly; walking wheels areconnected to the rear portion of the rear adjusting tail frame assembly; the front end of the left folding harrow frame assembly is connected with a left pressing roller assembly; and the front end ofthe right folding harrow frame assembly is connected with a right pressing roller assembly. According to the heavy stubble cleaning harrow, high-stubble straw is pressed down, the straw is crushed and mixed through the front row of harrow pieces and the rear row of harrow pieces, and straw rhizomes are subjected to secondary cutting through disc slices, so that the straw can be fully crushed, repeated operation of the stubble cleaning harrow on an operated residual stubble field is not needed, and the operation efficiency is improved.

Owner:宜兴博登泰科工业装备有限公司

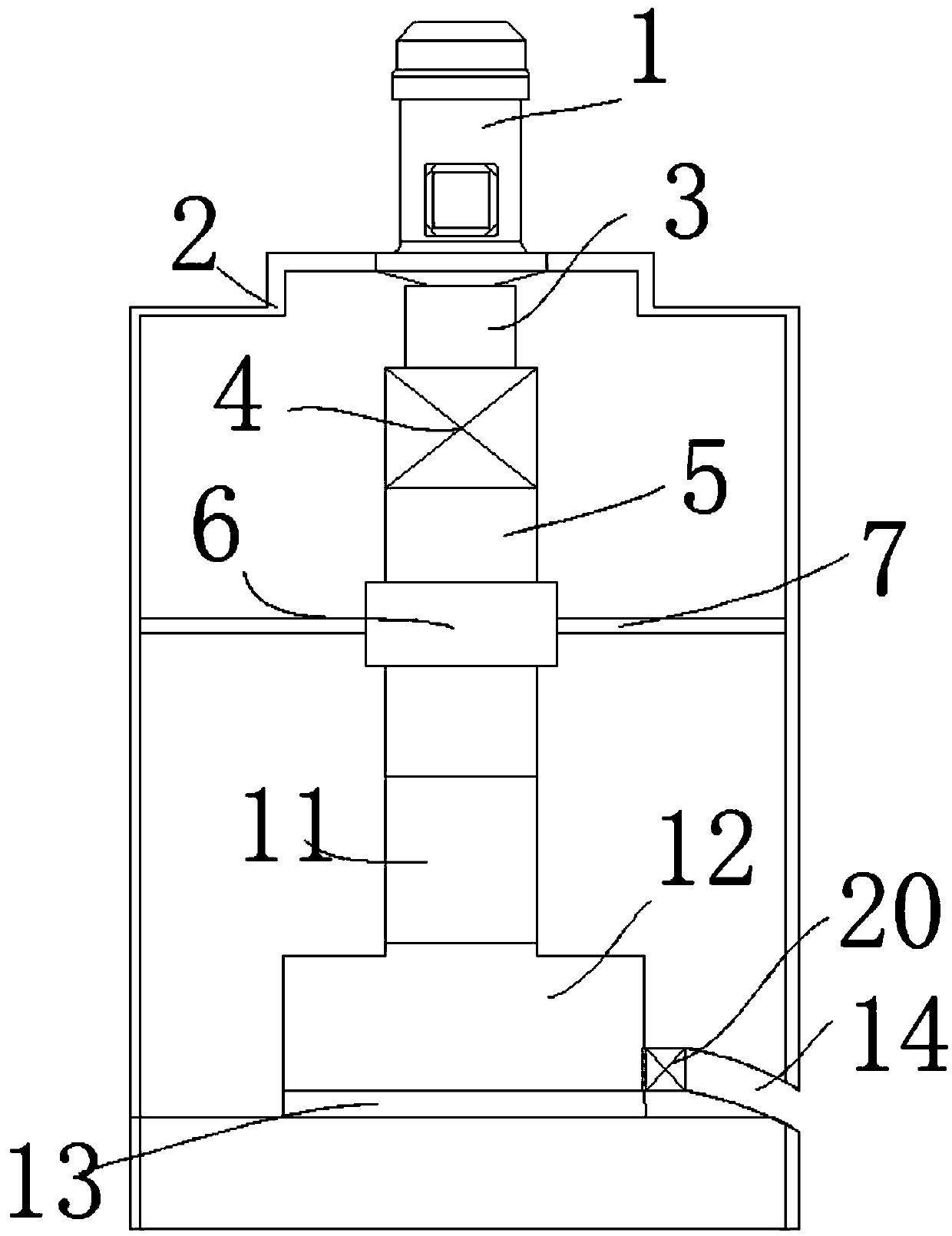

Self-rotation turbine magnet feeding pump

ActiveCN109607712AWill not increase consumptionAchieve limescale-free operationWater treatment compoundsSpecific water treatment objectivesHydrogenEngineering

The invention discloses a self-rotation turbine magnet feeding pump. The feeding pump comprises a pump body and a supporting frame; the pump body is arranged on the supporting frame; one end of the pump body is provided with a discharge port; the other end of the discharge port is connected with a shunting valve; the other end of the shunting valve is connected with a magnetizing cavity; a fixingpipe sleeve sleeves the outer side of the magnetizing cavity; two sides of the fixing pipe sleeve are connected with the supporting frame through supporting rods; the magnetizing cavity comprises an outer magnetic cavity and an inner magnetic rod; the inner magnetic rod is suspended in the outer magnetic cavity; a spiral flow guide groove is formed in the outer surface of the inner magnetic rod; and the other end of the magnetizing cavity is connected with a material conveying pipe. According to the invention, solid-liquid separation is realized by utilizing the combined action of centrifugalforce and magnetic force, and in addition, a magnetic field can cause breaking of a part of hydrogen bonds between water molecules, so that the internal structure of water is changed, excess superoxide anion groups appear in the water, and thus a sterilizing effect, a beneficial physiological effect and a water energy increasing effect are achieved.

Owner:WUHAN GINO NANO TECH

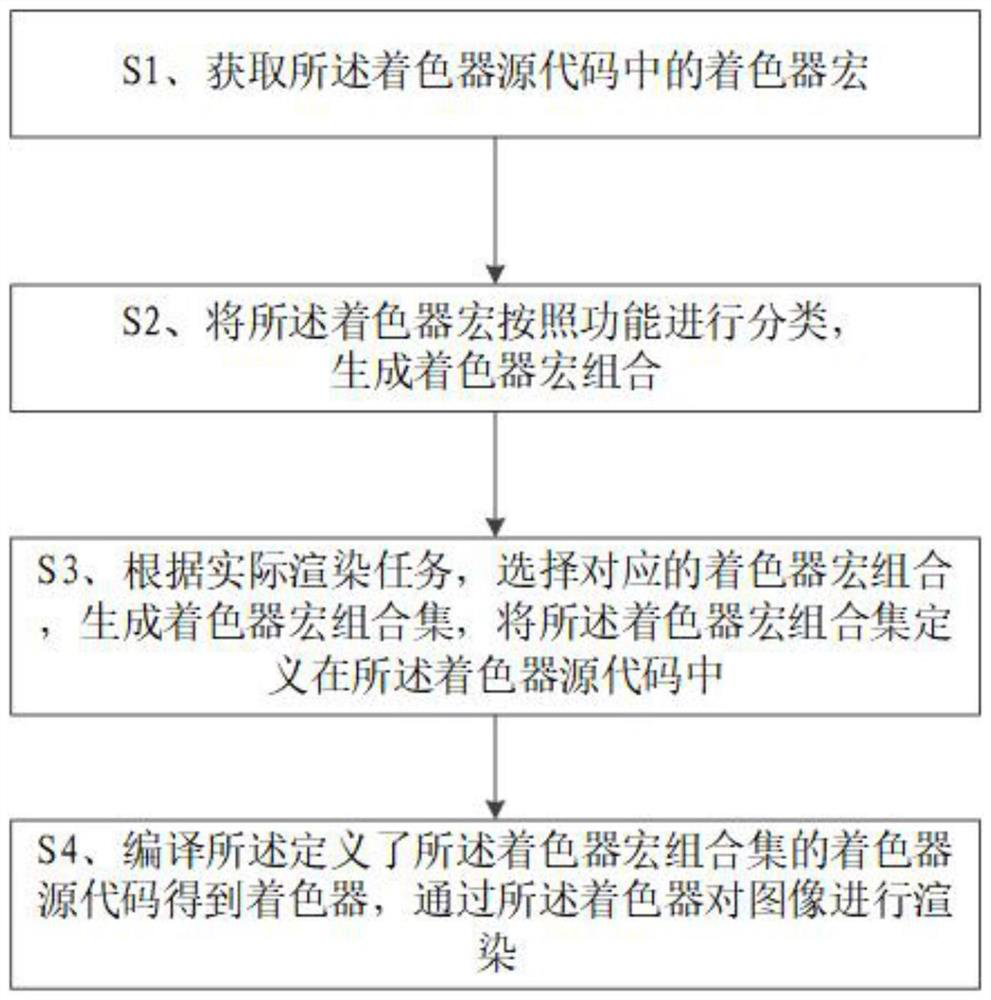

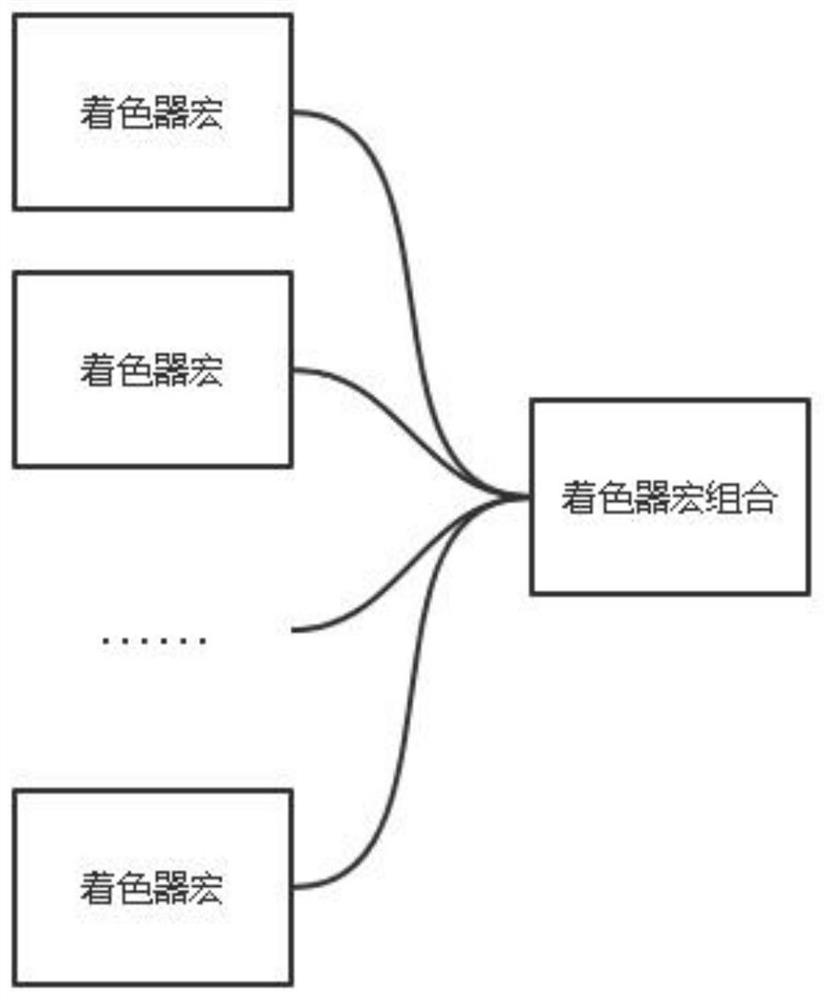

Shader code multiplexing method and terminal

PendingCN111767046AWill not increase consumptionTexturing/coloringSoftware reuseShaderComputer graphics (images)

The invention provides a shader source code multiplexing method and a terminal. The shader source code multiplexing method comprises the following steps: acquiring a shader macro in a shader source code; classifying the shader macros according to functions to generate shader macro combinations; selecting a corresponding shader macro combination according to an actual rendering task, generating a shader macro combination set, and defining the shader macro combination set in the shader source code; compiling the shader source code defining the shader macro combination set to obtain a shader, andrendering an image through the shader; and obtaining the shader macro in the shader source code, and achieving different computing logics by changing the shader macro combination set, namely different shader is generated to achieve different rendering effects, and the different rendering effects can be achieved without modifying the shader source code or changing the analysis mode of the shader source code.

Owner:FUJIAN TQ DIGITAL

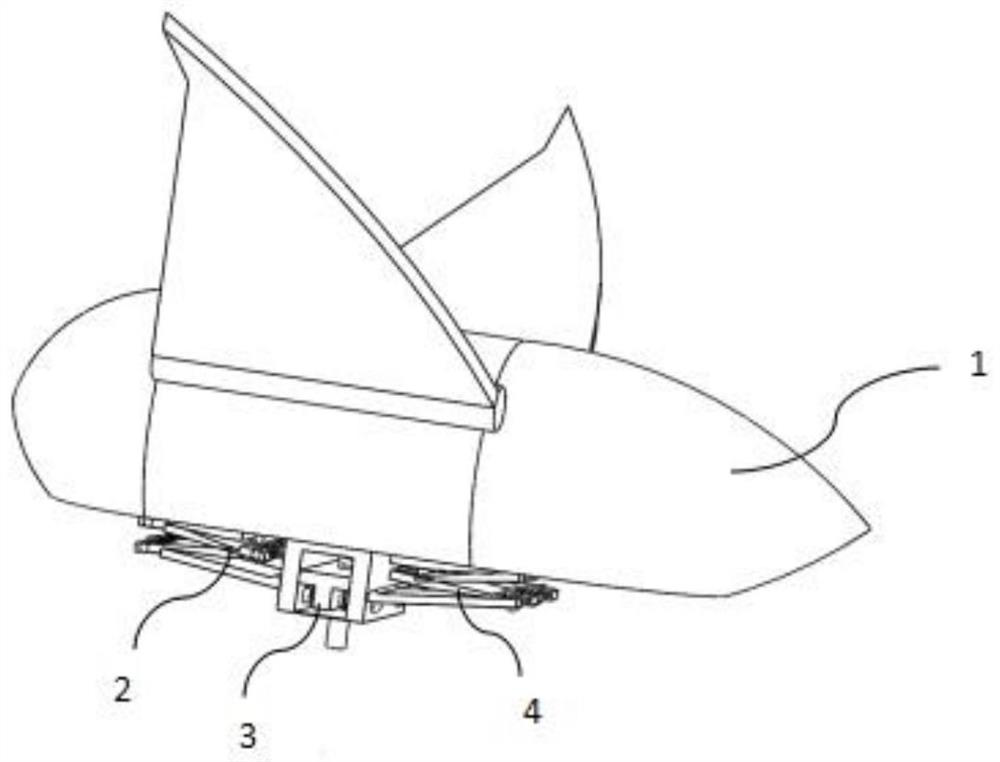

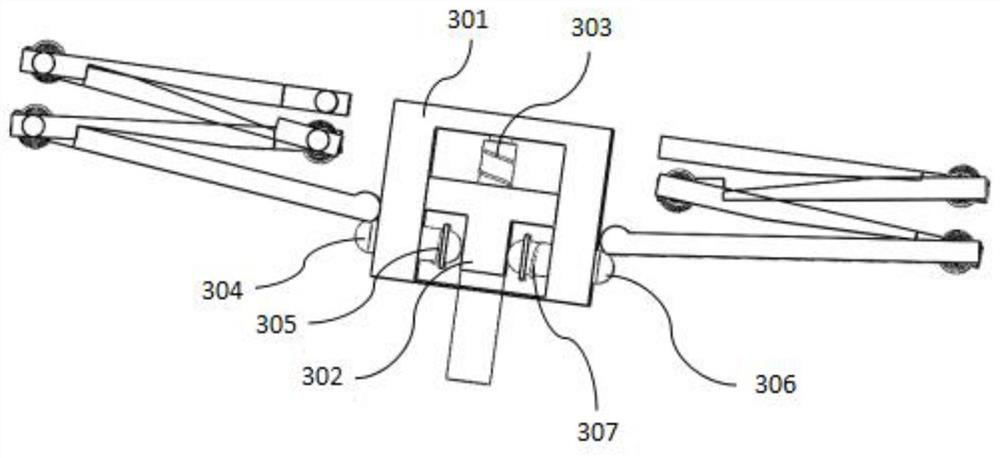

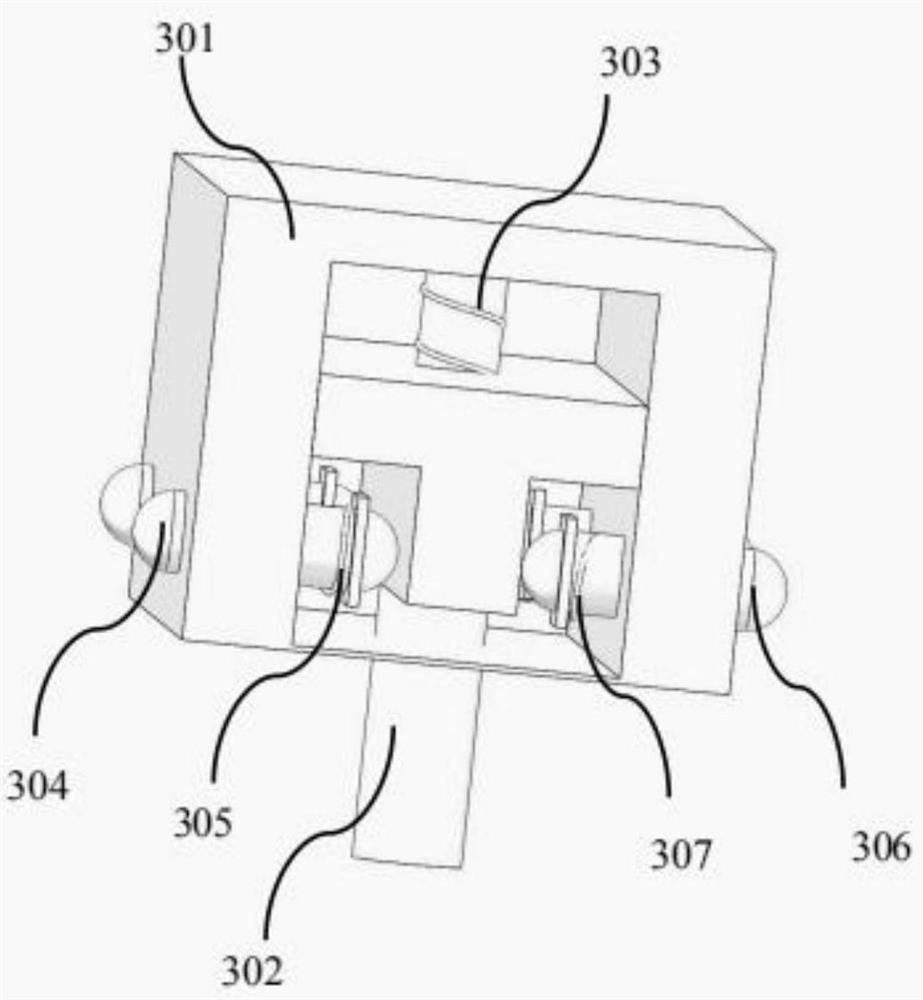

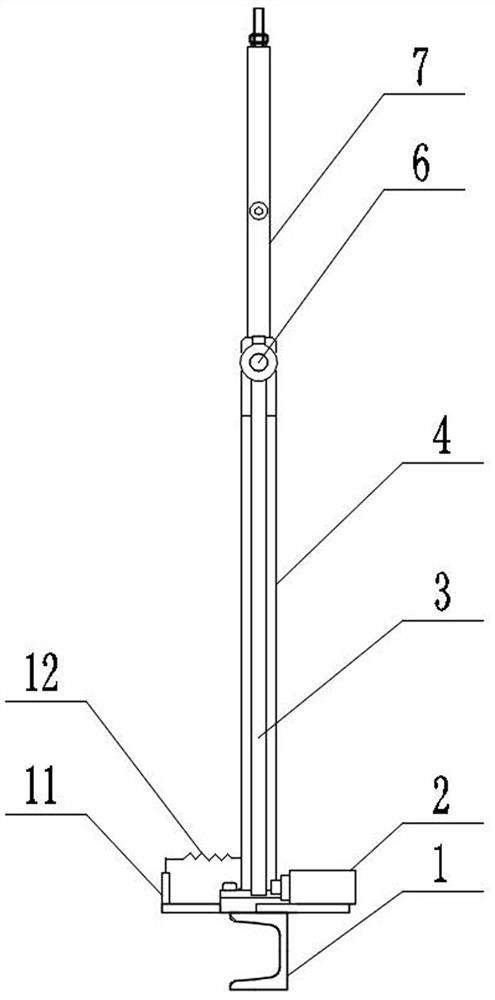

A kind of landing device for miniature flapping-wing aircraft

ActiveCN112977805BSecure landingAchieve autonomous landingOrnithoptersUndercarriagesFlight vehicleImpact

The invention discloses a landing device for a miniature flapping-wing aircraft, comprising: a front supporting leg, an unlocking module and a rear supporting leg; one end of the front supporting leg, the unlocking module and one end of the rear supporting leg are sequentially installed on the bottom of the aircraft; When the aircraft is in the flying state, the unlocking module locks the other ends of the front support leg and the rear support leg after being folded; when the aircraft is in the pre-landing state, the unlocking module collides with the ground, and the impact force Under the action of the unlocking module, the front support legs and the rear support legs are unlocked from the folded and locked state, and the front support legs and the rear support legs are unfolded and supported on the ground. The present invention deploys the front support legs and the rear support legs during landing through the unlocking module, buffers the impact force during landing, protects the aircraft body from landing stably, and realizes autonomous landing of the aircraft; and the invention is small in size and light in weight, and does not affect the flight of the aircraft performance without increasing the energy consumption of the aircraft.

Owner:BEIHANG UNIV

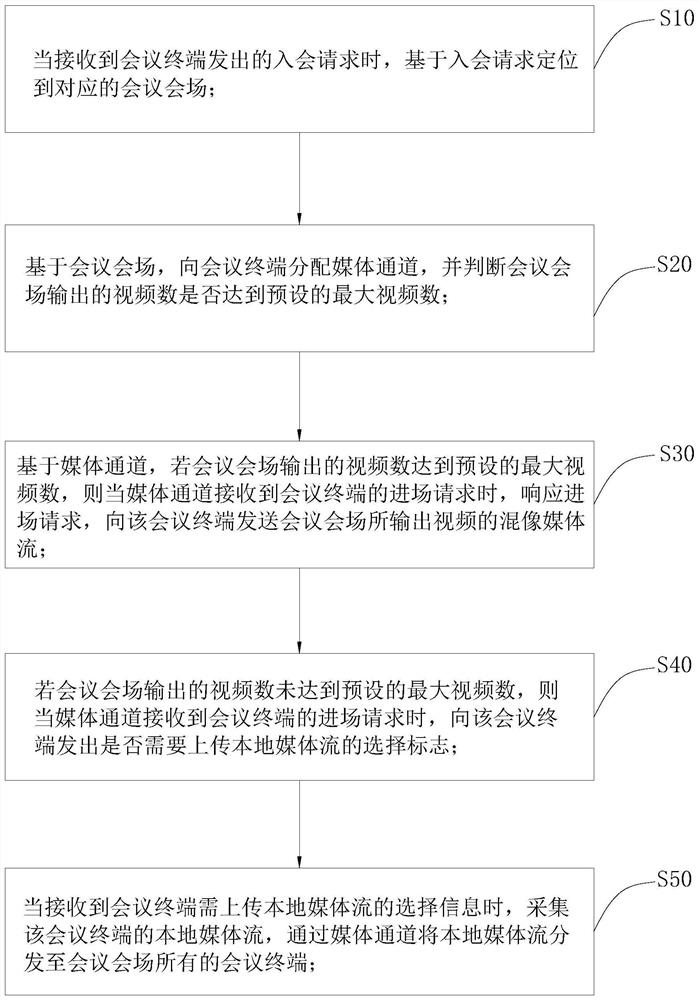

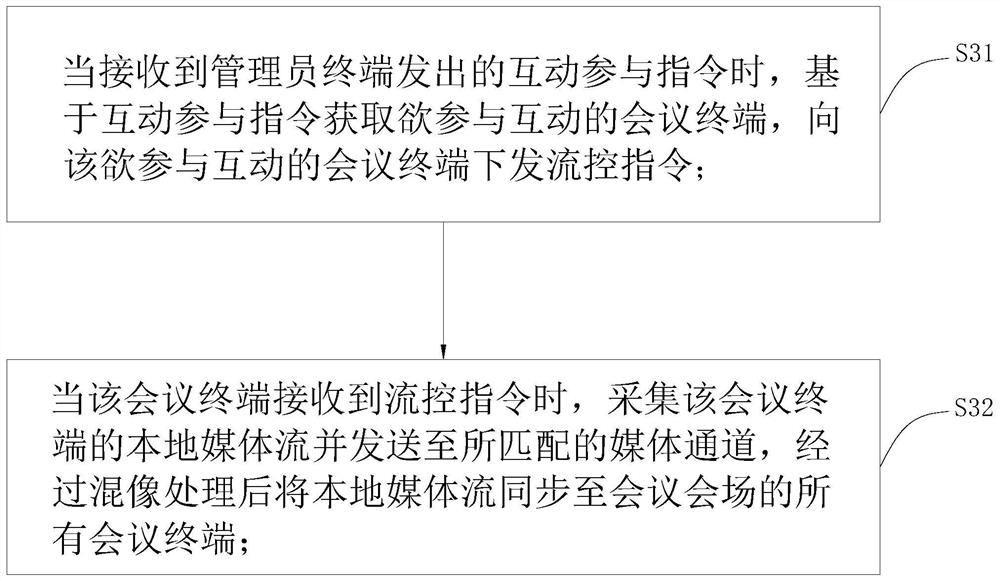

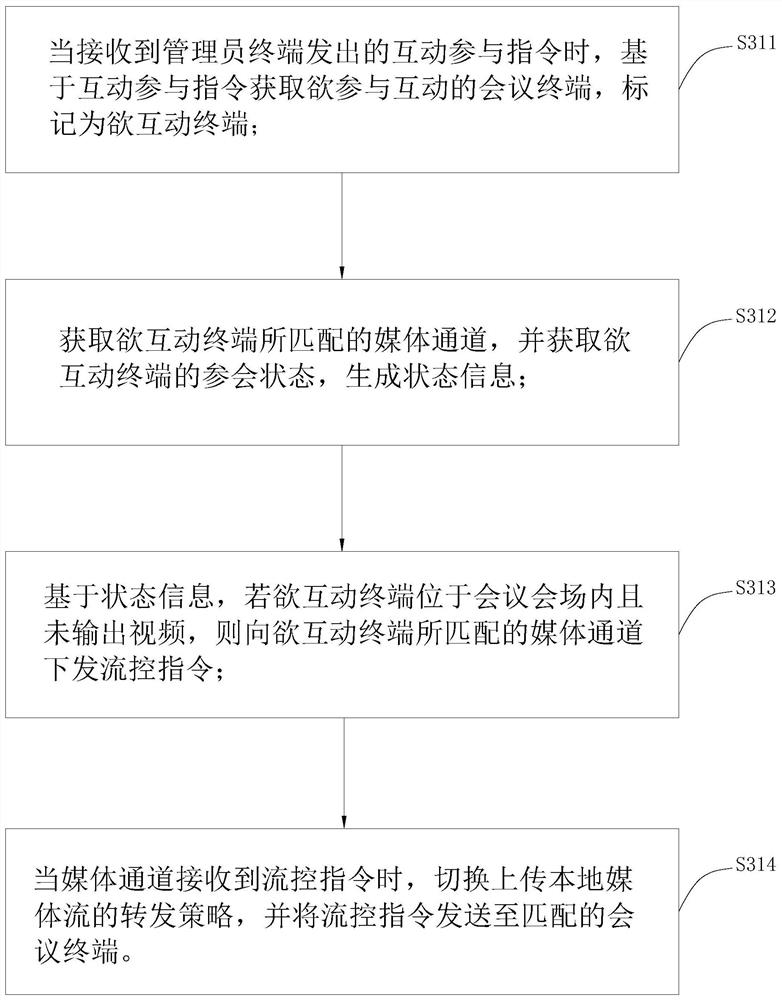

Expandable distributed media processing method and system

PendingCN114125359AReduce consumptionReduce decoding loadTelevision conference systemsTwo-way working systemsTelecommunicationsMediaFLO

The invention relates to an expandable distributed media processing method and system, and the method comprises the steps: positioning a corresponding conference place based on a conference joining request when the conference joining request sent by a conference terminal is received; distributing a media channel to the conference terminal, and judging whether the number of videos output by the conference hall reaches a preset maximum number of videos or not; if the number of the videos output by the conference place reaches the preset maximum number of the videos, an image mixing media stream of the videos output by the conference place is sent to the conference terminal; if the number of videos output by the conference hall does not reach the preset maximum number of videos, sending a selection mark for judging whether a local media stream needs to be uploaded or not to the conference terminal; and when the selection information that the conference terminal needs to upload the local media stream is received, collecting the local media stream of the conference terminal and distributing the local media stream to all the conference terminals in the conference place. The application has the effect of reducing the operation cost of the service operator.

Owner:SHENZHEN TAIDEN INDAL

A kind of sterilization method and application of circulating cooling water

ActiveCN104556311BWill not increase consumptionReduced activitySpecific water treatment objectivesNature of treatment waterElectricityPower flow

The invention discloses a circulating cooling water sterilizing method and application. The circulating cooling water sterilizing method comprises the step of electrolyzing at least one part of circulating cooling water in a circulating cooling water system, wherein an electrolyzing process is performed intermittently. According to the electrolysis sterilizing method for the circulating cooling water, provided by the invention, reduction in electrode activity and electrolytic current efficiency can be effectively avoided, mass concentration of residual chlorine in the circulating cooling water is enabled to be in a control range, service lives of electrodes are guaranteed, and extra electricity consumption is not increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

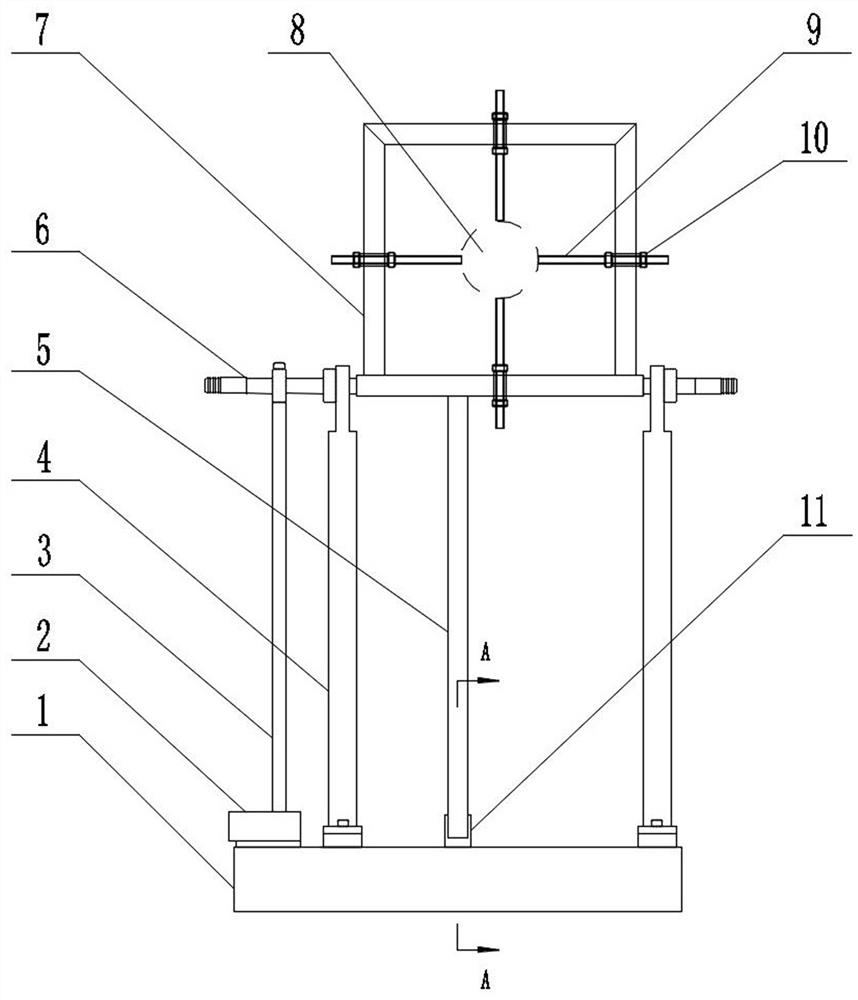

Anti-collision mechanism for medium-frequency induction heater of thickening production line

PendingCN112570637AAvoid collisionNo need to enlarge the apertureHandling devicesHeating/cooling devicesProduction lineThermodynamics

The invention relates to the technical field of petroleum and natural gas drill rod machining, in particular to an anti-collision mechanism for a medium-frequency induction heater of a thickening production line, which is used in a thickening process of petroleum and natural gas drill rods. The anti-collision mechanism for the medium-frequency induction heater of the thickening production line ischaracterized by comprising a base, wherein supporting columns arranged side by side are fixed onto the base; a horizontal rotating shaft is connected between the top ends of the supporting columns; and the horizontal rotating shaft is in running fit with the supporting columns. A support is fixed to the upper part of the horizontal rotating shaft; and a horizontally-arranged limiting hole is formed in the support. A first swing rod is fixed below the horizontal rotating shaft, and a contact switch is arranged on the base corresponding to the lower end of the first swing rod. The anti-collision mechanism is arranged at the front end of an inlet of the medium-frequency induction heater, so that a severely bent pipe can be effectively prevented from approaching the induction heater, the collision between the pipe and the induction heater is thoroughly avoided, and meanwhile, the energy consumption and the thickening cost are not increased.

Owner:江阴雷特斯钻具有限公司

A method and device for realizing memory optimization

ActiveCN104639214BWill not increase consumptionRealize the effect of memory optimizationNear-field transmissionData switching networksNetwork packetBluetooth

Owner:ANYKA (GUANGZHOU) MICROELECTRONICS TECH CO LTD

Method for controlling supercharged gas water heater and gas water heater

InactiveCN110966769AReal-time monitoring of intake pressureGuaranteed intake pressureWater heatersThermodynamicsInlet pressure

The invention discloses a method for controlling a supercharged gas water heater and the gas water heater. The gas water heater comprises a turbocharging device, a liquid driving device and a gas pressure detecting device. The turbocharging device is arranged on a gas inlet pipeline, and the liquid driving device drives liquid to flow through the turbocharging device and drives the turbocharging device to run. According to the gas water heater, the liquid driving device is controlled to drive / close the turbocharging device according to a gas pressure value detected by the gas pressure detecting device, and gas is supercharged / stopped from being supercharged. According to the gas water heater, the gas can be supercharged when the gas pressure is low, the gas inlet pressure and stability areguaranteed, and therefore it is guaranteed that the optimum combustion work condition is matched; and the temperature and stability of water output are guaranteed, energy consumption can be reduced,and the bath experience of a user is improved.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER +1

Method and device for viewing page information of a mobile terminal

ActiveCN104778198BHeavy loadWill not increase consumptionInput/output processes for data processingWeb data browsing optimisationComputer hardwareInternet traffic

Owner:BEIJING QIHOO TECH CO LTD +1

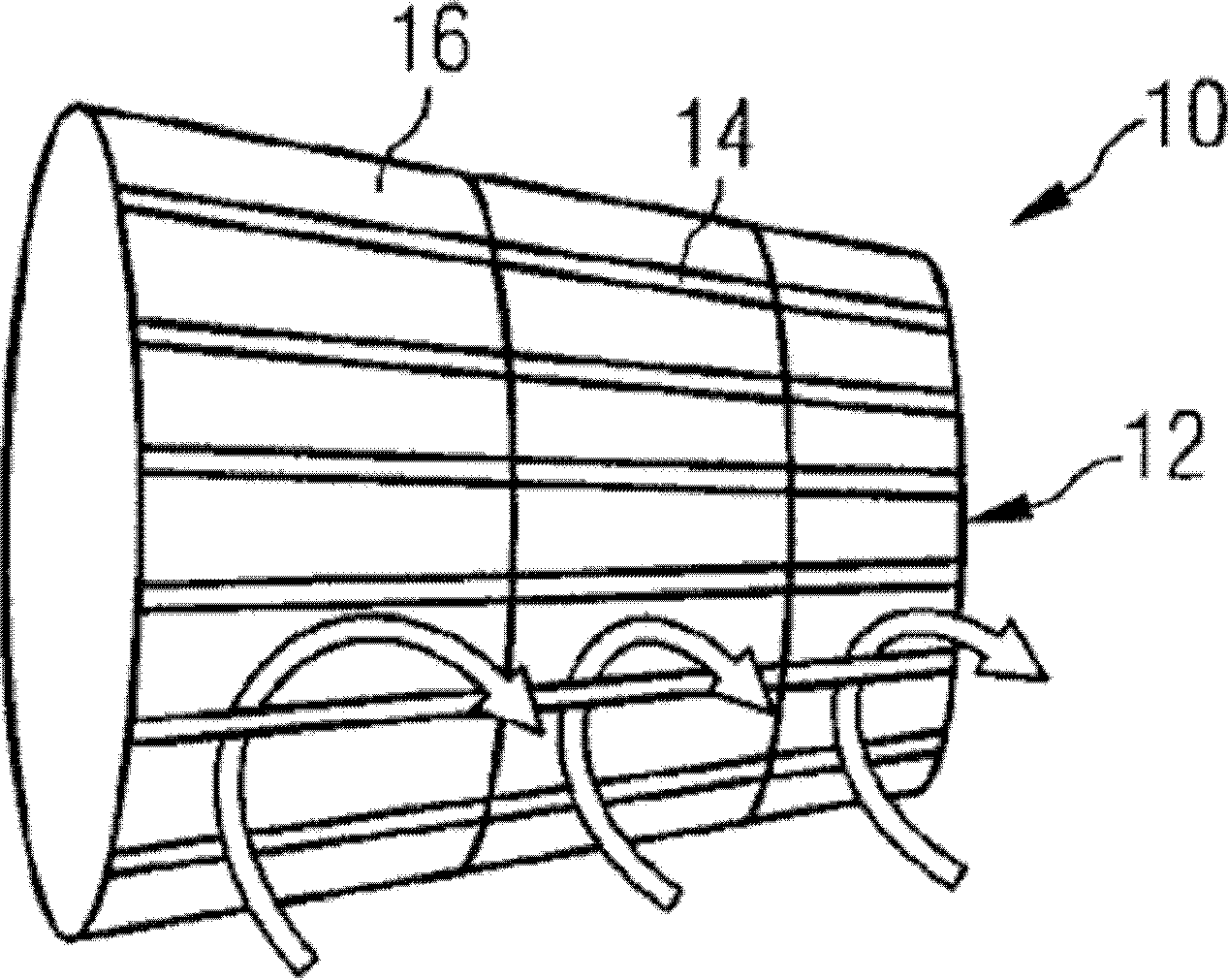

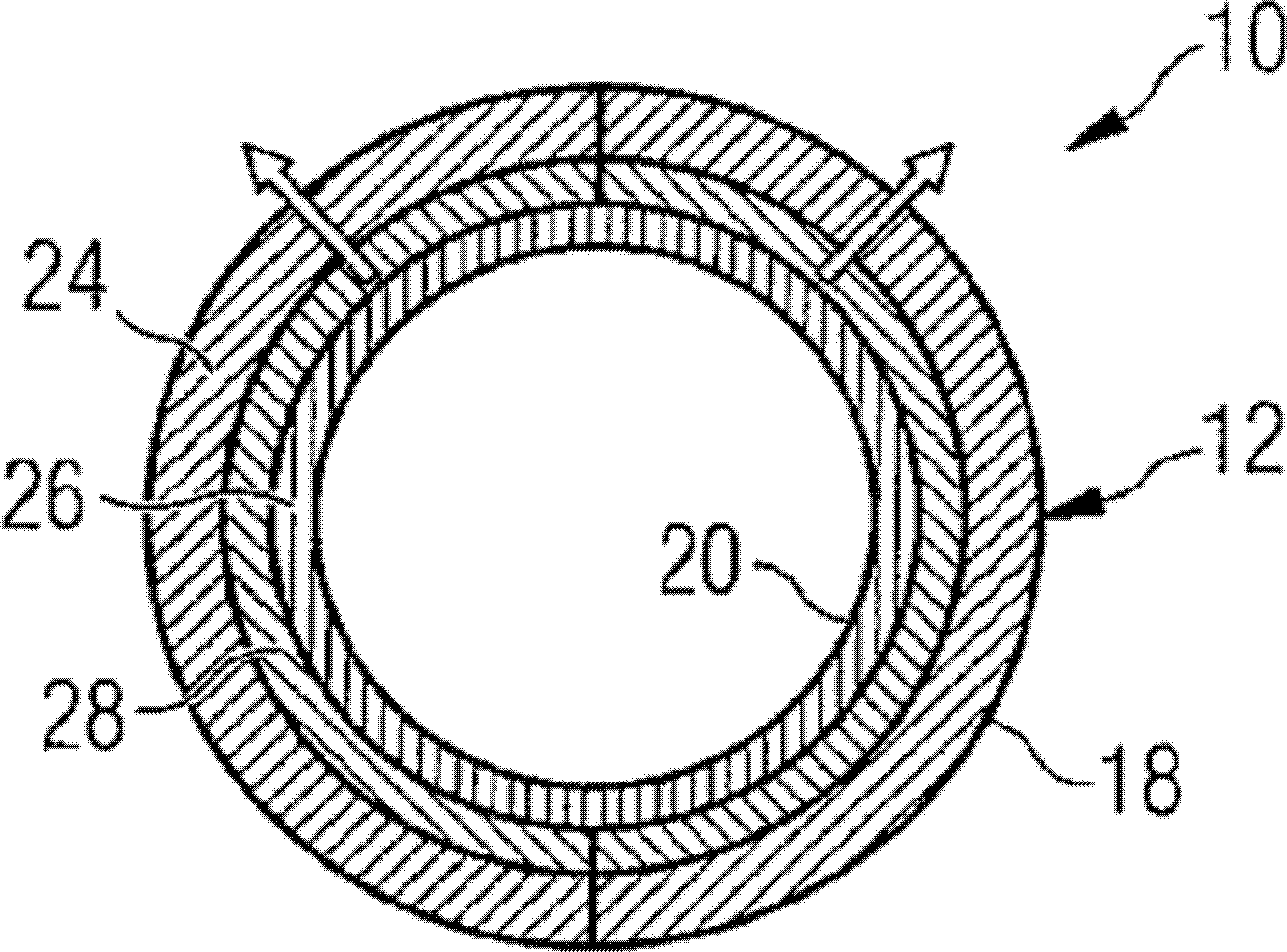

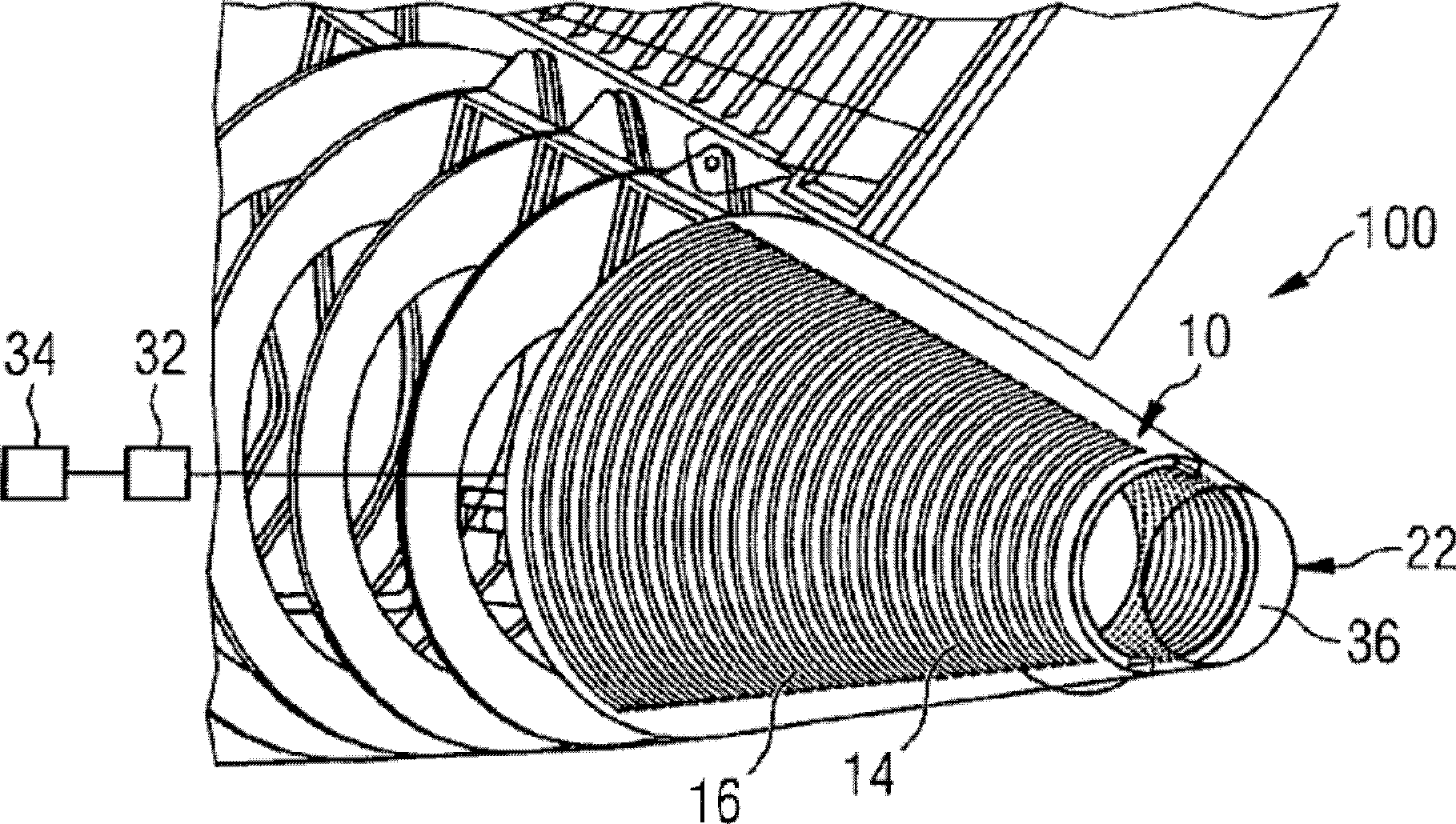

Cooler for an aircraft cooling system, aircraft cooling system and method for operating an aircraft cooling system

ActiveCN102428004BReduce weightImprove cooling effectPower plant cooling arrangmentsPower installationsChillerAirplane

The invention relates to a cooler (10) of an aircraft cooling system (100). The cooler includes a base body (12), on which a plurality of coolant passages (16) are designed, and the coolant passages extend from the base body ( The first surface (18) of 12) extends to the second surface (20) of the base body (12) to allow coolant to flow through said base body (12). The base body (12) of the cooler is designed to form part of an aircraft skin.

Owner:AIRBUS OPERATIONS GMBH

Communication method based on radio frequency identification system, apparatus and system thereof

ActiveCN102737207BEnable two-way communicationTwo-way communication is simpleEnergy efficient ICTMemory record carrier reading problemsFrame sequenceRadio frequency

A radio frequency identification system based communication method, apparatus and system are disclosed, which are used for implementing bi-directional communication between an electronic tag and a reader in the radio frequency identification system, saving battery power consumption in an active electronic tag, and guaranteeing communication stability between the electronic tag and the reader. Wherein, the method includes: receiving data frames sent by the reader in the current checking period, analyzing the data frames and extracting frame sequence numbers from preset fields, calculating waiting time required for the current checking period to enter into a channel idle state based on the extracted frame sequence numbers, selecting one timeslot from timeslots included in the current checking period when determining the reader is in the channel idle state, and transmitting messages to the reader based on the selected timeslot.

Owner:ZTE INTELLIGENT IOT TECH

Automobile headlamp demisting device and method

The invention discloses an automobile headlamp demisting device and an automobile headlamp demisting method. The automobile headlamp demisting device comprises an air humidity sensor, an air conditioning controller, an air conditioning evaporator, an air inlet pipe, an air outlet pipe, an air inlet pipe control valve and an air outlet pipe control valve, wherein the air humidity sensor is arranged inside a headlamp; the air inlet pipe is connected with the air outlet side of the air conditioning evaporator; the air outlet pipe is connected with the air inlet side of the air conditioning evaporator; the air inlet pipe control valve and the air outlet pipe control valve are arranged on the air inlet pipe and the air outlet pipe respectively; and the air conditioning evaporator, the air inlet pipe control valve, the air outlet pipe control valve and the air humidity sensor are connected with the air conditioning controller. The automobile headlamp demisting method comprises the followingsteps of: detecting the humidity level in the automobile headlamp; treating by using the air conditioning controller; demisting in the headlamp; detecting the humidity level in the headlamp again; and demisting in the headlamp again. In the invention, the process requirements of sealing property of the automobile headlamp can be reduced, the manufacturing process can be simplified, and the demisting speed is high and the demisting efficiency is high.

Owner:CHERY AUTOMOBILE CO LTD

A routing method, device, system and gateway device

ActiveCN103888358BWill not increase consumptionSimplify the routing pathData switching networksWireless communicationIp addressResource consumption

The invention discloses a routing method, device, system and gateway equipment, which are used for improving routing efficiency without increasing the processing resource consumption of the gateway equipment when users access services through URLs. The method includes: receiving a service access request sent by a mobile terminal, the service access request carrying a uniform resource locator URL; if the URL exists in a pre-stored URL list, corresponding to the pre-stored URL Search the IP address corresponding to the URL in the list of IP addresses; according to the found IP address, search for the service server corresponding to the IP address in the pre-stored correspondence between the IP address and the service server; The service access request is routed to the found service server.

Owner:CHINA MOBILE COMM GRP CO LTD

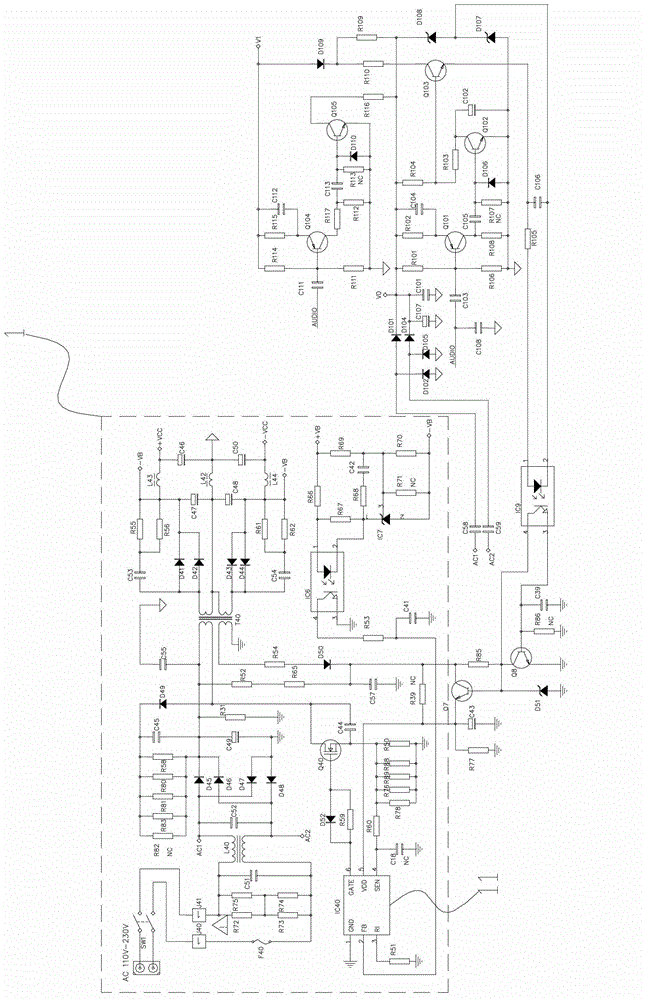

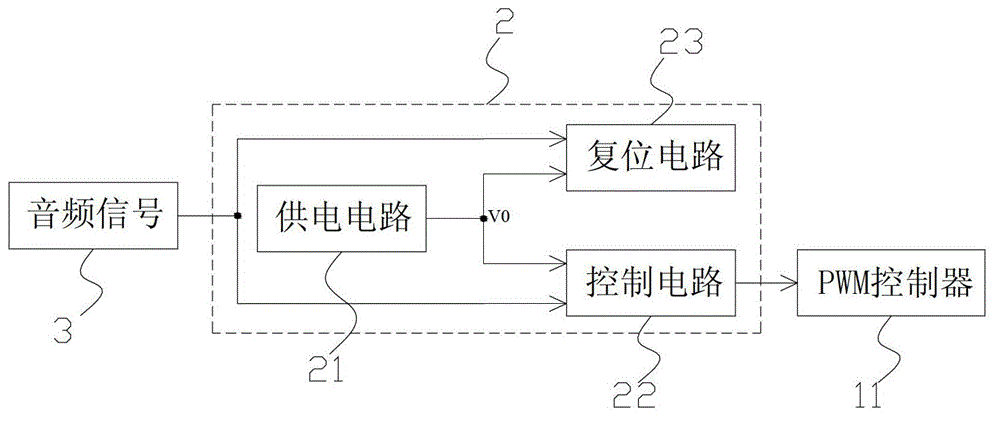

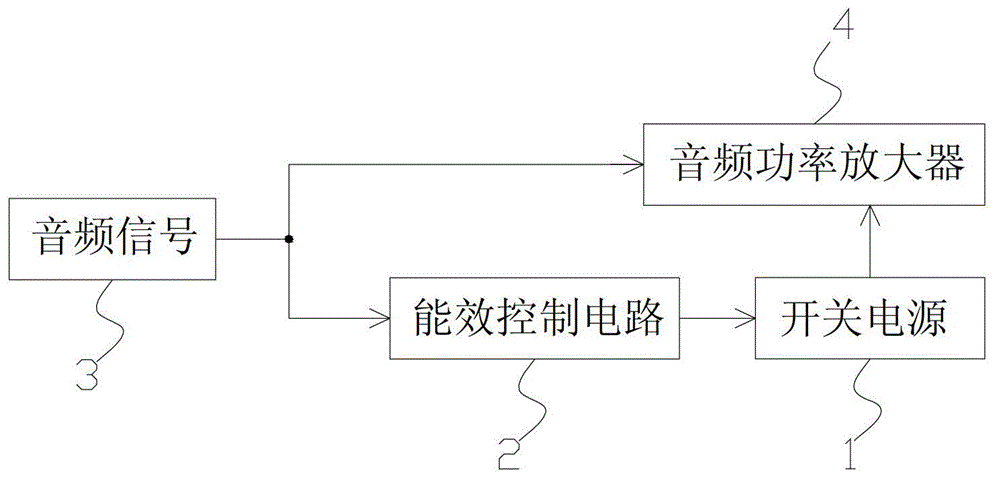

Intelligent control circuit and intelligent control method of switch power supply efficiency

InactiveCN102780401BReduce standby power consumptionEasy to operateEfficient power electronics conversionDc-dc conversionStandby powerEngineering

The invention relates to an intelligent control circuit and an intelligent control method of switch power supply efficiency. The control circuit comprises a switch power supply circuit with a pulse width modulation (PWM) controller, an efficiency control circuit and an audio signal. The efficiency control circuit comprises a control voltage end V0, a power supply circuit for charging the control voltage end V0, a reset circuit for discharging voltage of the control voltage end V0 and a control circuit for controlling the PWM controller to work. The control circuit and the reset circuit are both connected with the audio signal. The control method includes controlling the switch power supply circuit to be in a standby state, an awaken state and a normal working state. The intelligent control circuit and the intelligent control method of the switch power supply efficiency do not need to improve the switch power supply circuit, save improvement cost, are strong in generality, adopt the audio signal to control the working state of a switch power supply, reduce standby power consumption of the switch power supply circuit, and adopt the efficiency control circuit of a pure electronic component so as to further reduce standby power consumption of the circuits.

Owner:SHENZHEN MAOHONG ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com