Combined oil-control ring

A technology of oil control ring and expansion ring, which is applied to piston rings, machines/engines, mechanical equipment, etc., can solve problems such as consumption, and achieve the effect of realizing oil consumption, small tension deviation, excellent wear resistance and sludge resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

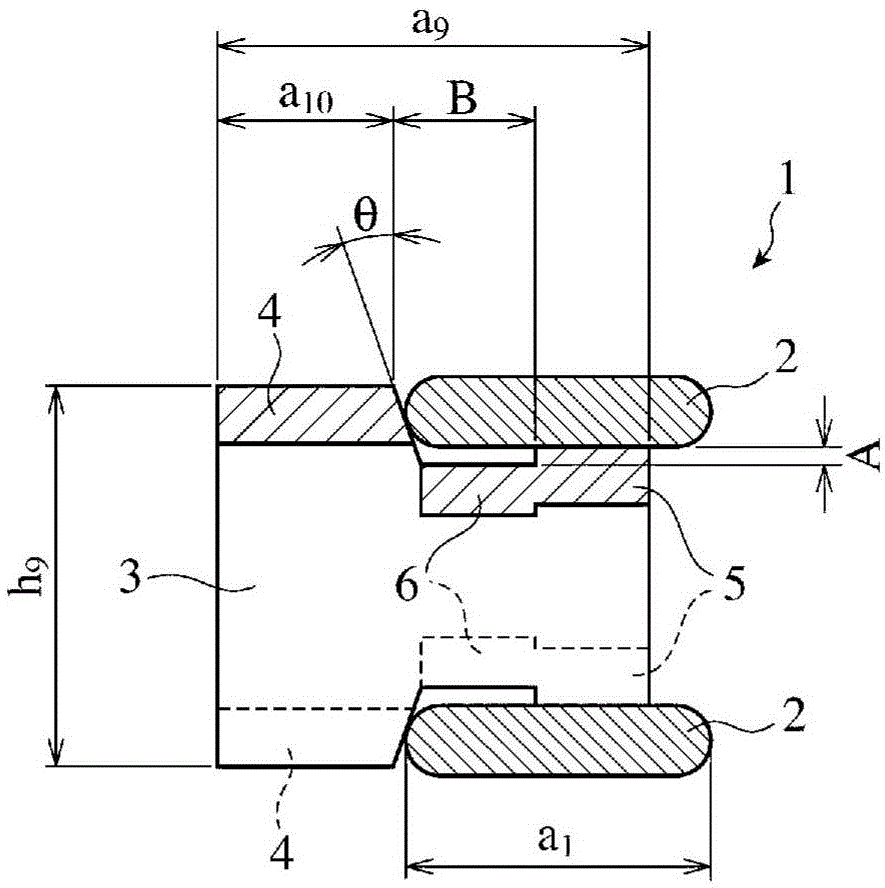

[0037] The spacer expansion ring is formed from a 2.50mm×0.25mm rolled strip (SUS304 material) using a gear forming method, and the side rail is formed from a 1.60mm×0.40mm rolled strip (SUS440B) by a coiling method. The following dimensions. The size of the combined oil ring produced is:

[0038] Nominal diameter: 82.5mm

[0039] Expanding ring width h 9 : 2.43mm

[0040] Height of external expansion ring a 9 : 2.5mm

[0041] ear height a 10 : 1.2mm

[0042] Support width A: 0.12mm

[0043] Middle part height B: 0.8mm

[0044] Side rail thickness a 1 : 1.6mm. In addition, the tension value is 23N as the target value to adjust the expanded length of the spacer expansion ring.

Embodiment 2~5 and comparative example 2

[0057] Using the same rolled strips for spacer expansion rings and rolled strips for side rails as in Example 1, a formed gear having the dimensions shown in Table 1 was prepared, and a combination oil ring was produced so that the tension value was 22N. . For these combined oil rings, an engine test was conducted under the same conditions as in Example 1, and the amount of oil consumption was measured. The above results are shown in Table 1 together with the results of Example 1 and Comparative Example 1.

[0058] 【Table 1】

[0059]

[0060] Here, the width A in the axial direction of the supporting portion was 0.12 mm in all except for Comparative Example 1 which was 0.05 mm.

[0061] The above results show that the thinner (shorter) the thickness of the side rail, or the thicker (longer) the ear height of the spacer expansion ring is, that is, a 1 / a 9 smaller, or a 10 / a 9 The larger the value, the less oil consumption. It is considered that reducing the thicknes...

Embodiment 6~8、 comparative example 3

[0064] In Examples 6 to 8 and Comparative Example 3, combined oil rings with the same size and shape as those of Examples 1, 4, 5 and Comparative Example 2 were used respectively. Using the same engine as the engine, the durability test was carried out, and the oil ring groove wear of the piston was measured. Durability test The combination oil rings of Examples 6-8 and Comparative Example 3 were respectively attached to four cylinders, and the test conditions were 6500 rpm and full load (WOT: Wide Open Throttle) conditions. Of course, the rings used for the above-mentioned engine are used for the first and second rings. The amount of groove wear of the oil ring groove was evaluated based on the amount of increase in the axial width of the end portion of the oil ring groove of the piston of each cylinder before and after the test for a predetermined time. The results are shown in Table 2.

[0065] 【Table 2】

[0066]

[0067] [3] Determination of sludge accumulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com