Anti-collision mechanism for medium-frequency induction heater of thickening production line

A technology of induction heaters and anti-collision mechanisms, applied in heating/cooling equipment, metal processing equipment, operating devices, etc., can solve the problem of increasing the cost of thickening, the inability of human eyes to make timely and accurate judgments, pipe material and induction heating Problems such as device impact, to achieve the effect of increasing thickening cost, increasing energy consumption, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

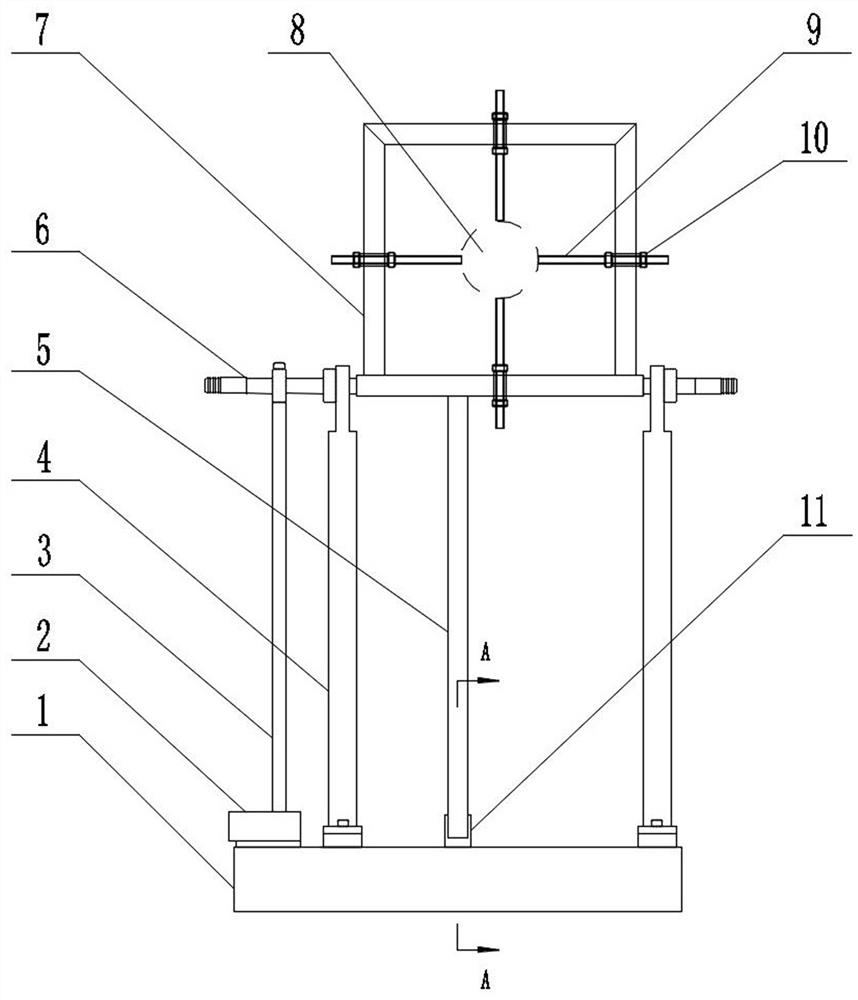

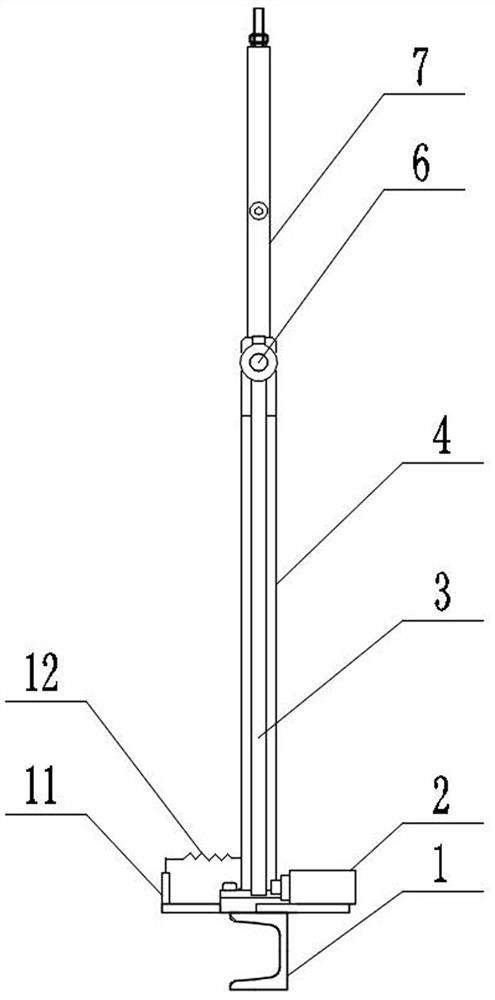

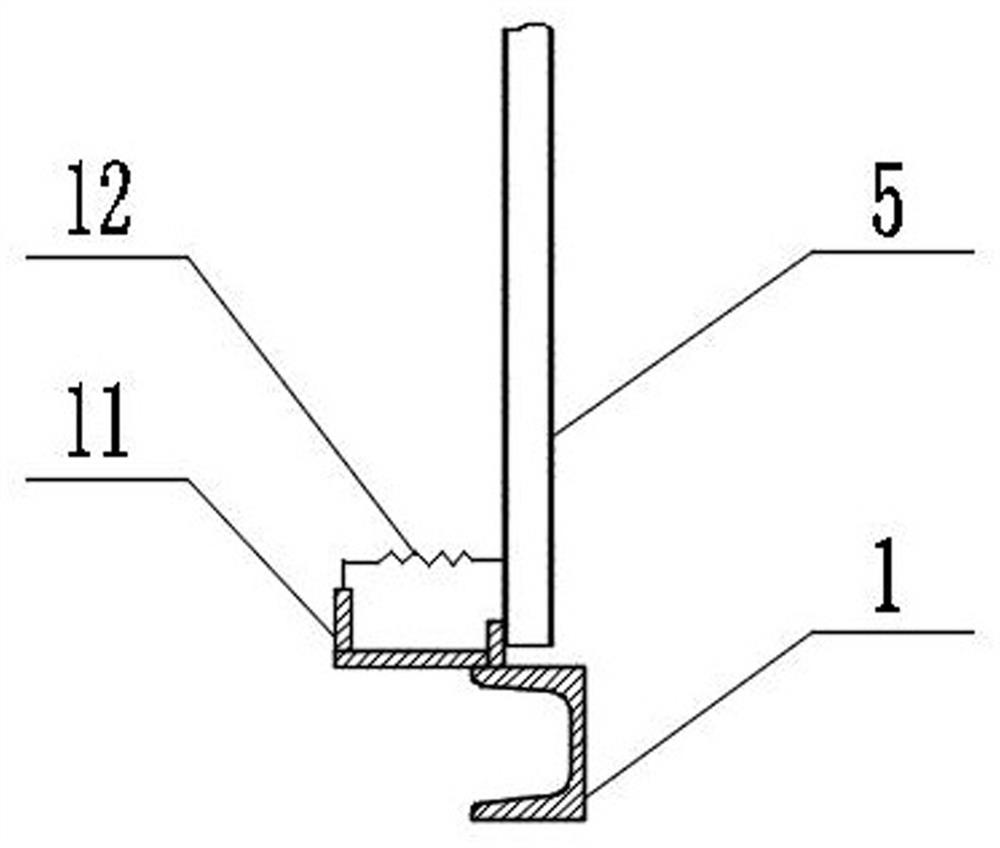

[0019] Such as figure 1 , figure 2 with image 3 As shown, the anti-collision mechanism for the intermediate frequency induction heater of the thickening production line of the present invention includes a base 1, on which the pillars 4 arranged side by side are fixed, and the top ends of the pillars 4 are connected with a horizontal shaft 6, and the horizontal shaft 6 and the pillars 4 Both are rotationally fitted.

[0020] A bracket is fixed above the horizontal rotating shaft 6, and there are limit holes 8 arranged horizontally on the bracket. Described support is square frame 7, and the middle part of every side of this square frame 7 all has screw hole, and screw rod 9 is all arranged in the screw hole, and the two ends of screw rod 9 all protrude outside screw hole and all have locking nut on it 10. The axes of the screw rods 9 all pass through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com