Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

142results about How to "To achieve the purpose of automatic feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

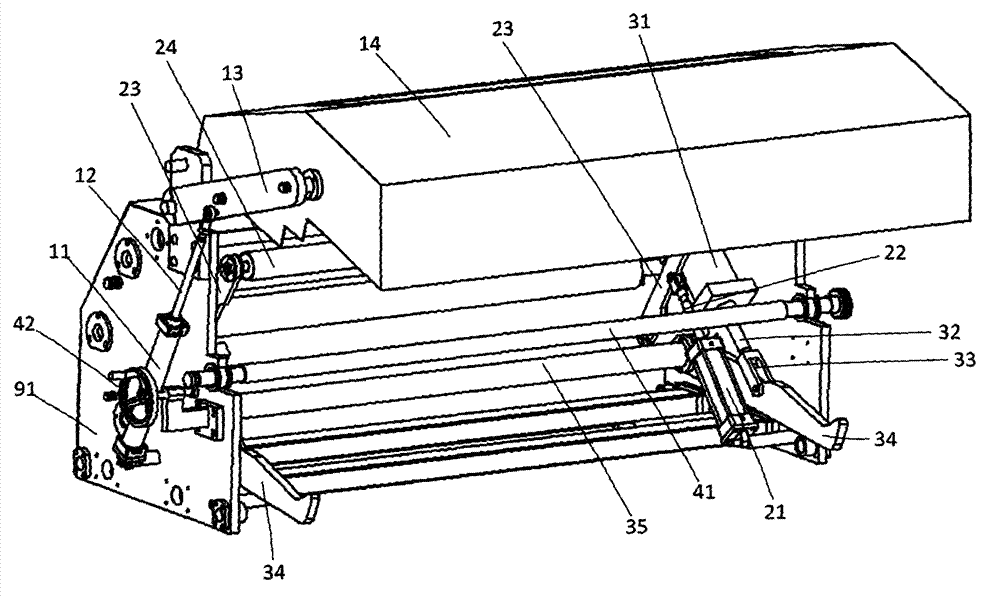

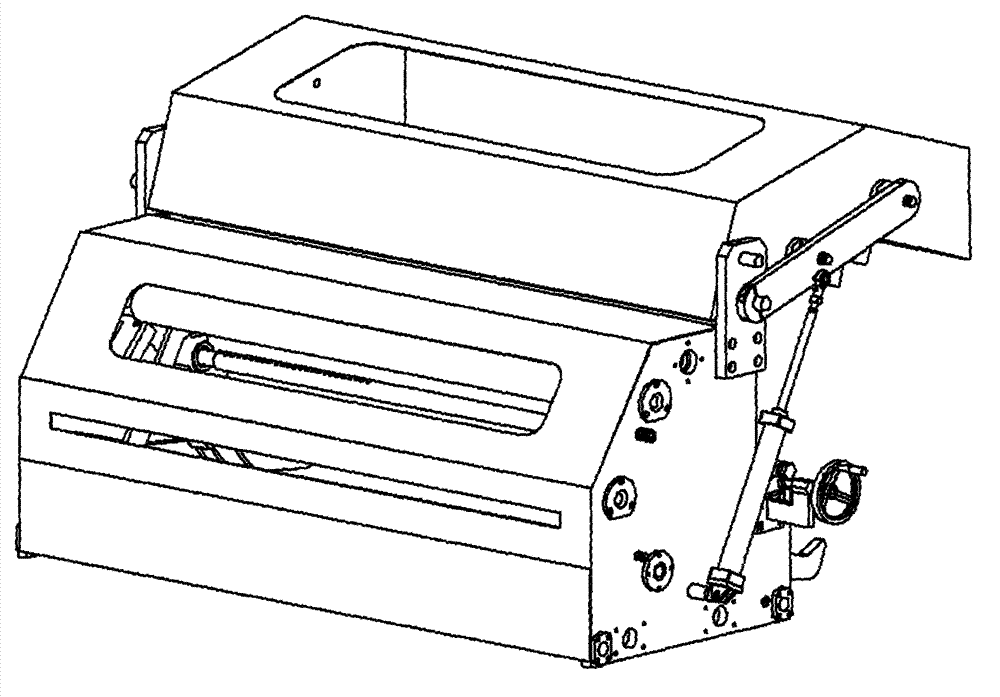

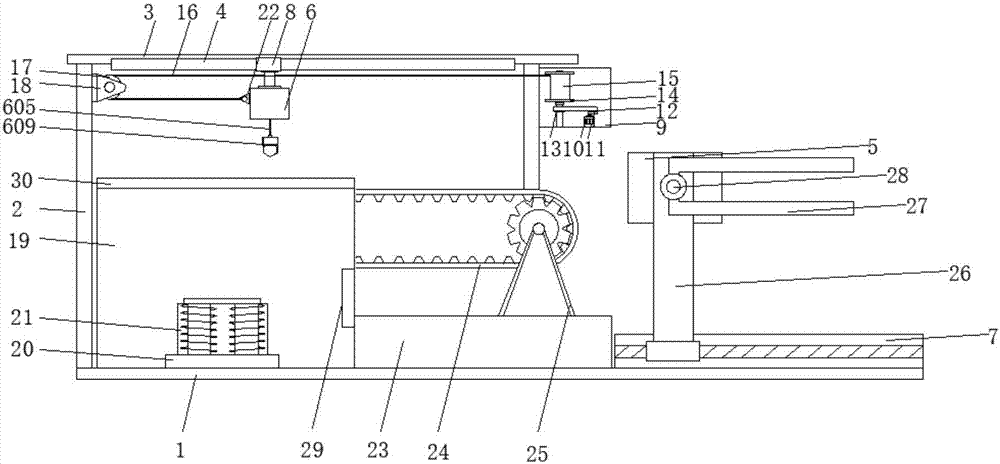

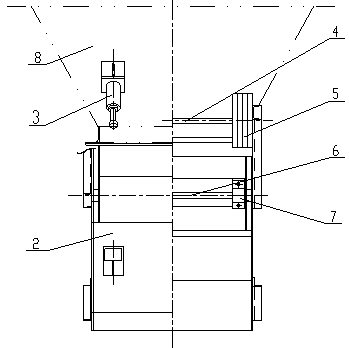

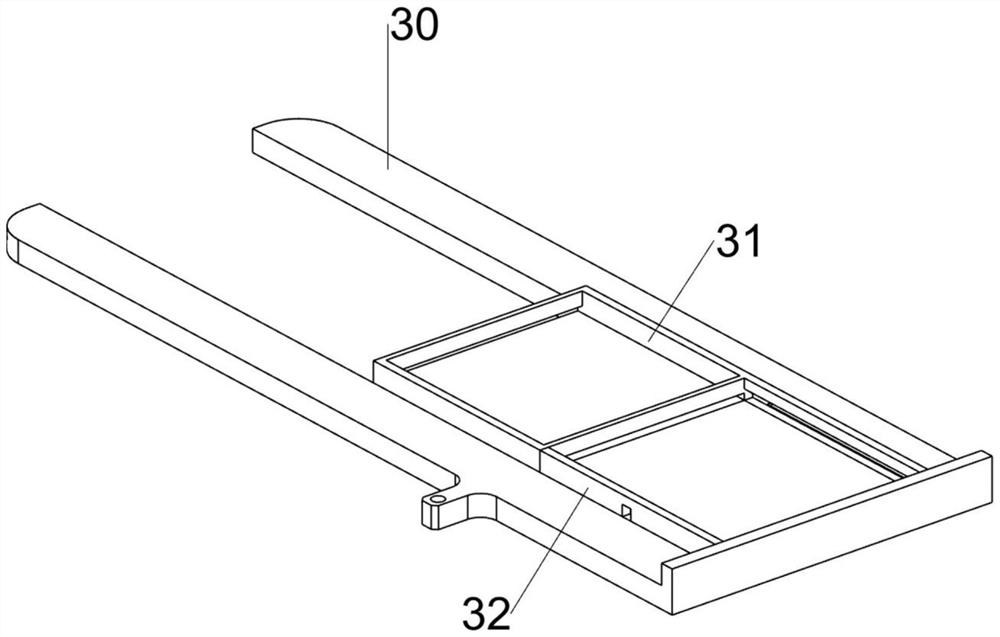

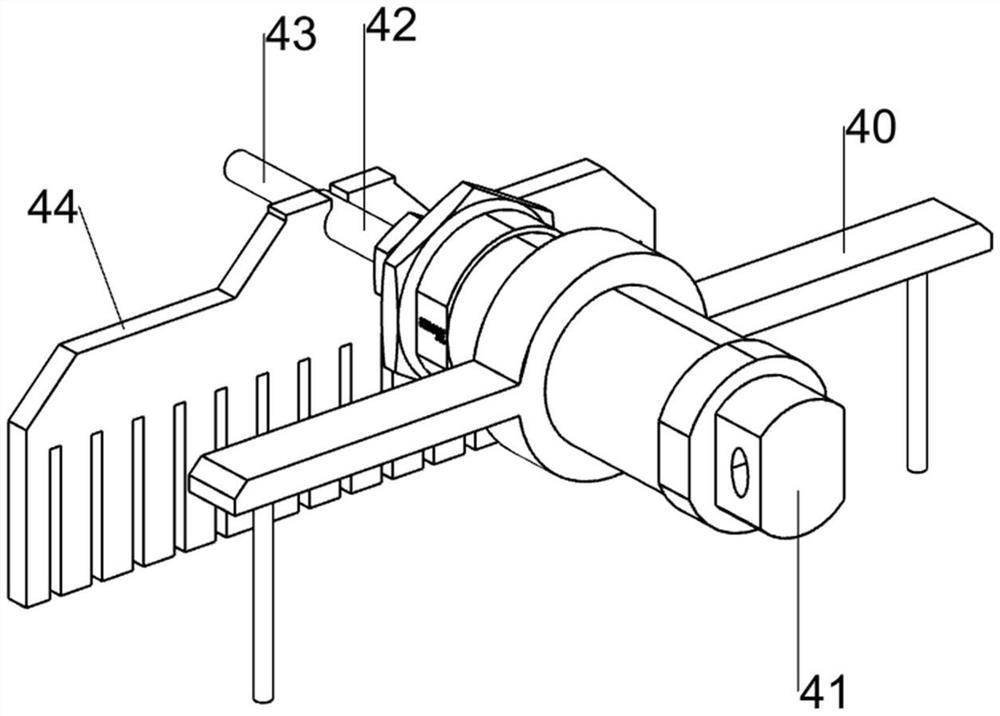

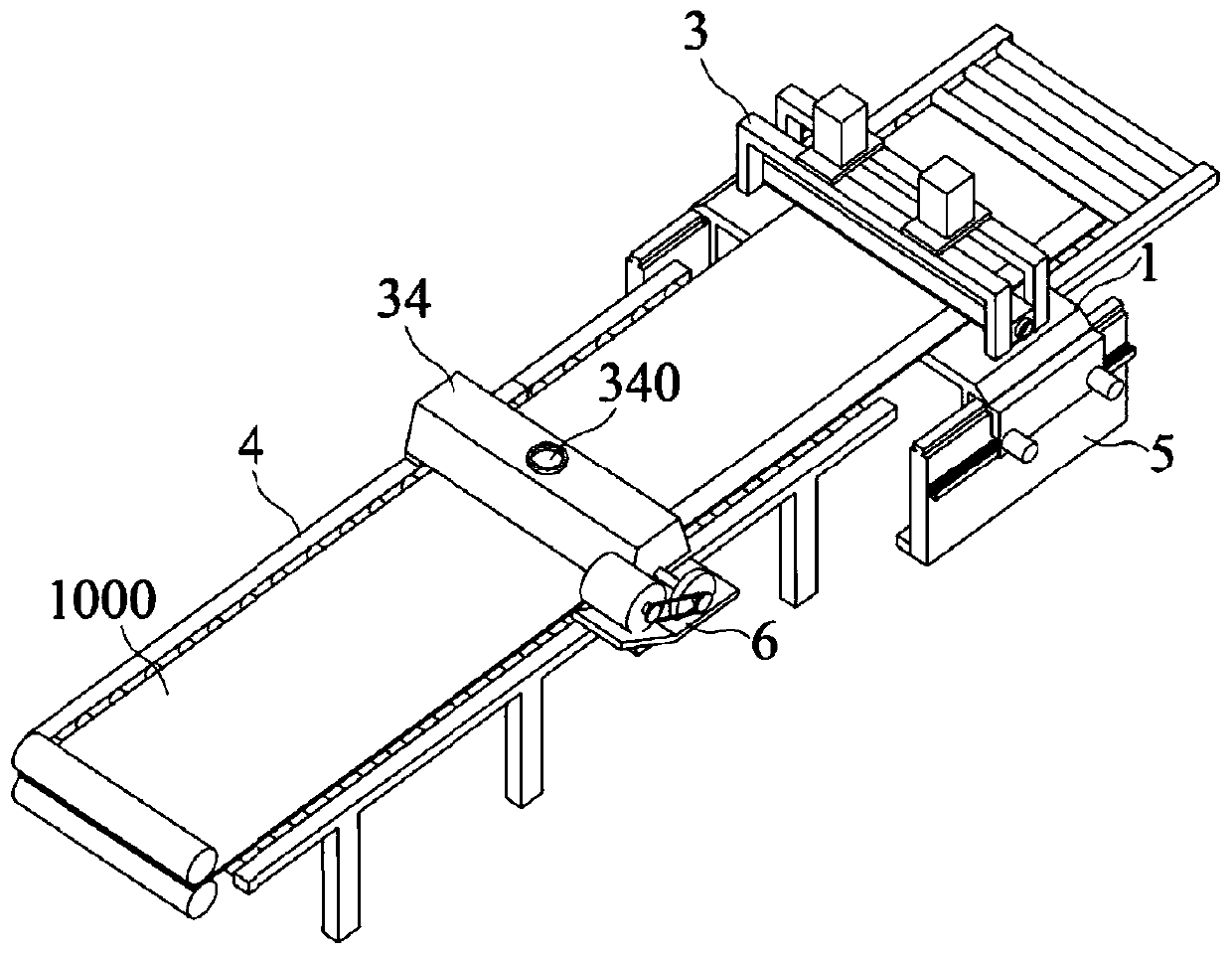

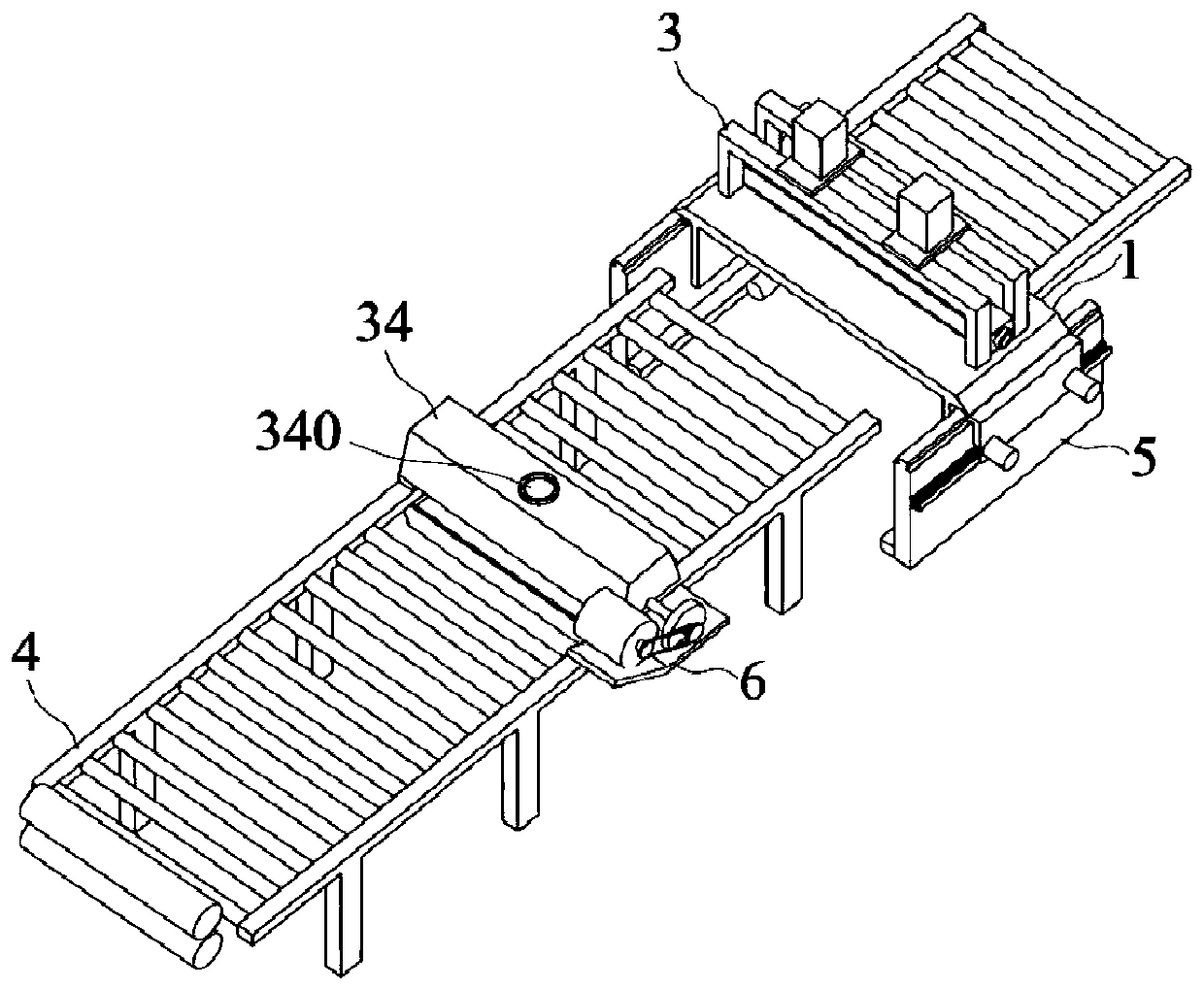

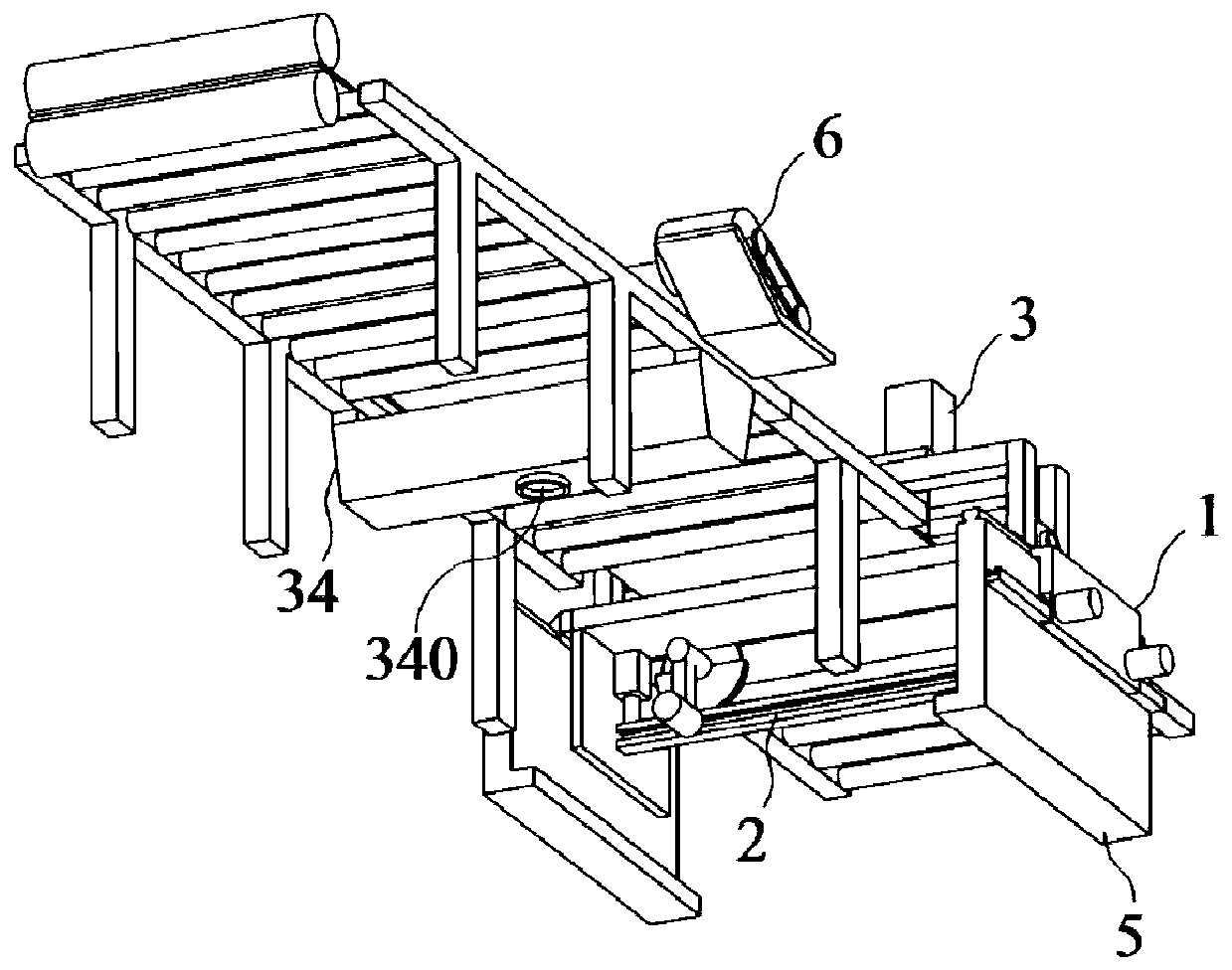

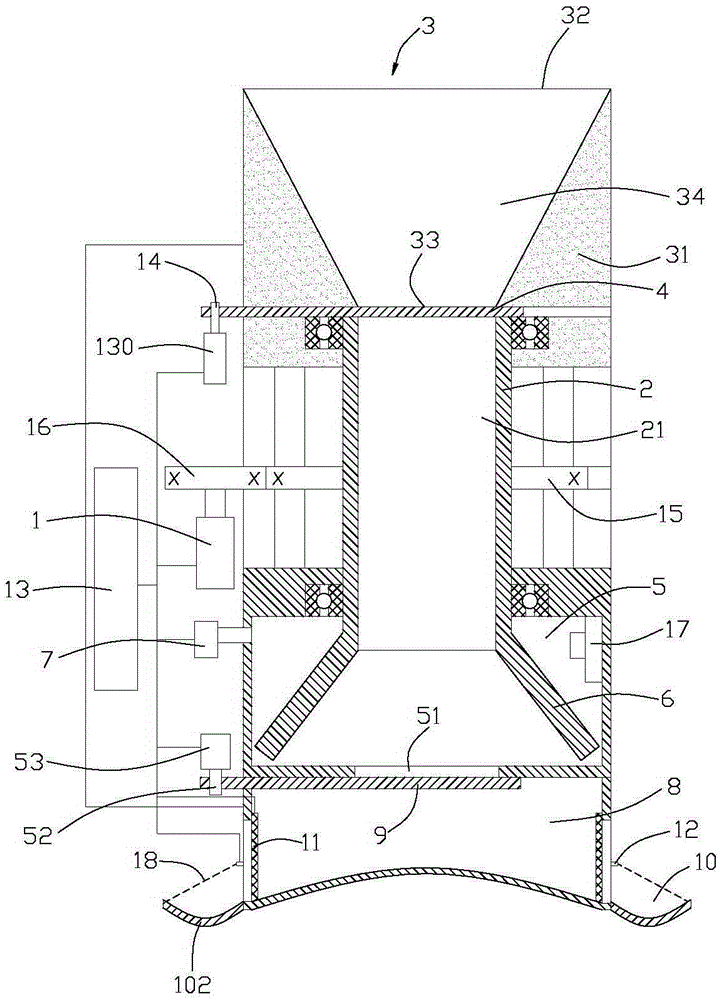

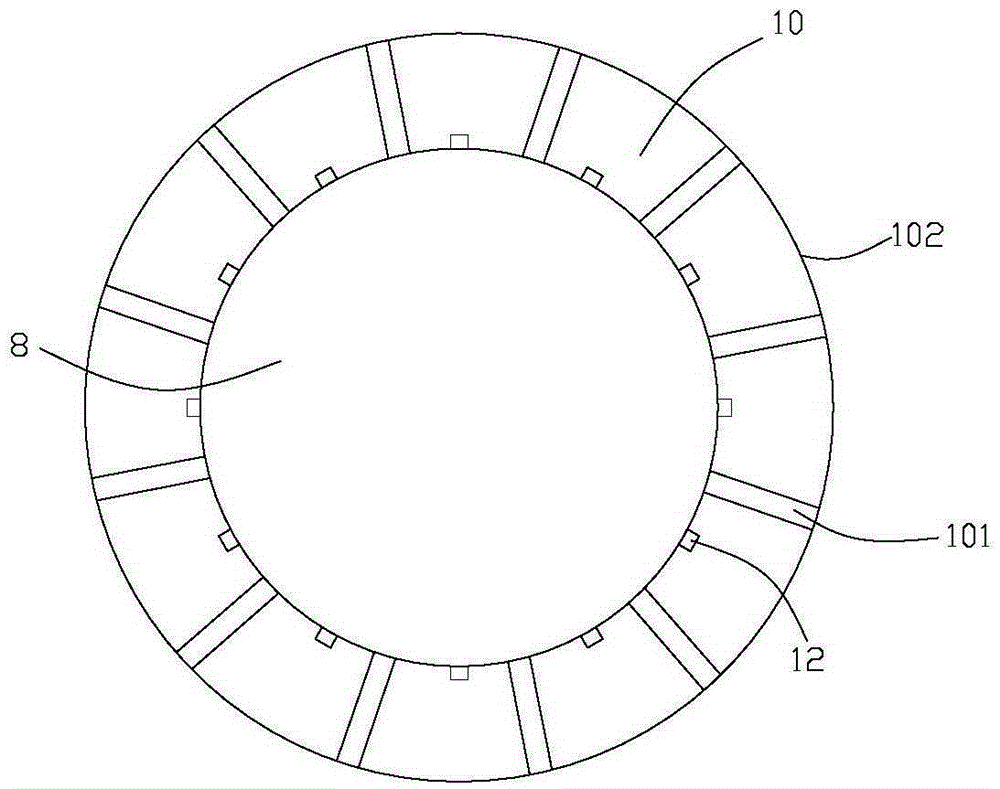

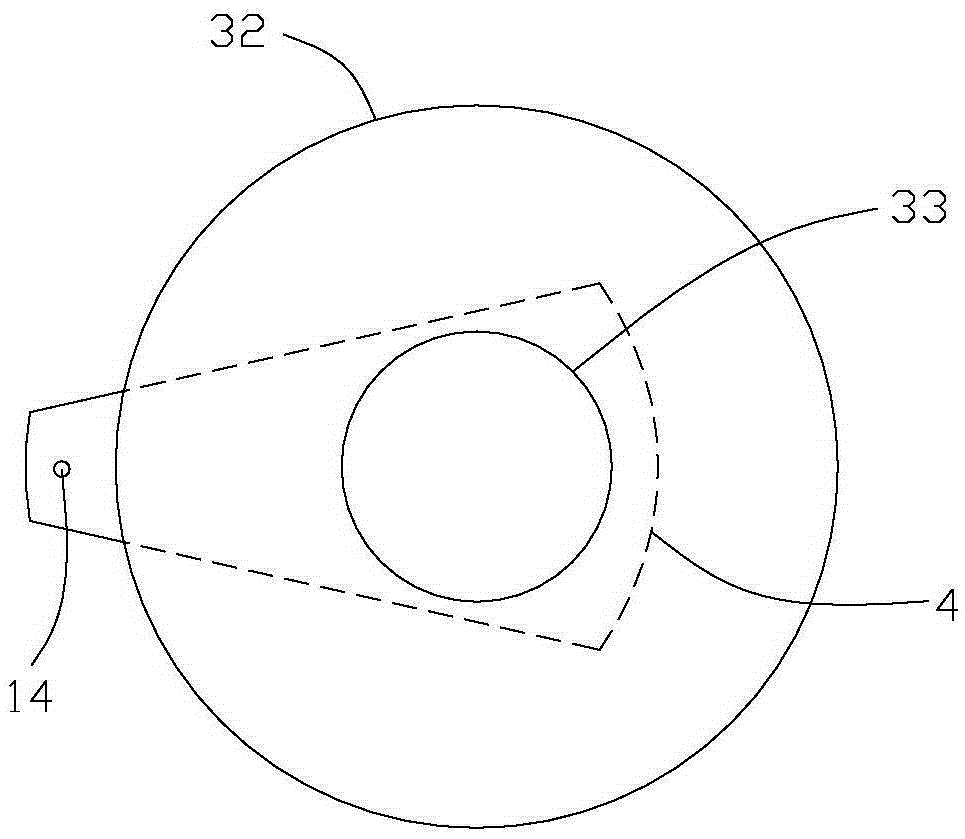

Slitting machine and feeding device thereof

InactiveCN102862846ATo achieve the purpose of automatic feedingReduce processing noiseArticle deliveryWebs handlingMechanical engineeringPiston rod

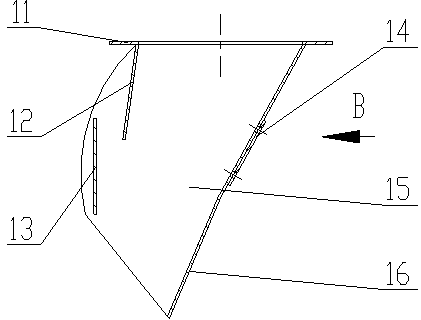

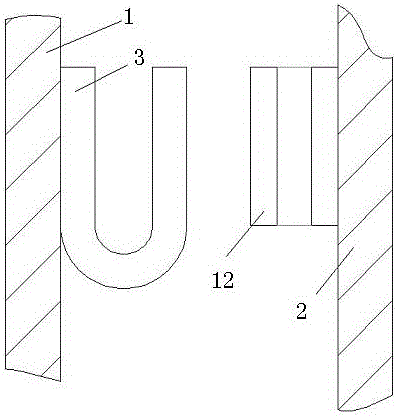

The invention provides a feeding device of a slitting machine. The feeding device comprises a support plate arranged on two sides, a feeding shaft is arranged on a support plate upper frame, and an automatic feeding device is arranged below the feeding shaft. The automatic feeding device comprises a hook claw. One end of the hook claw is a free end, the other end of the hook claw is a fixed end hinged on a machine frame. The hook claw is hinged with a first connecting rod. One end of the first connecting rod is hinged with the hook claw, and the other end of the first connecting rod is connected with a first air cylinder. A first piston rod of the first air cylinder drives the first connecting rod to rotate, and the first connecting rod drives the hook claw to rotate. The feeding device can conduct feeding automatically or semi-automatically. When a whole roll of raw materials is arranged on the hook claw on the rear side of a reeling and unreeling mechanism of the slitting machine, the hook claw can rotate under the driving of the first air cylinder. The raw materials are sleeved on a feeding shaft, and a purpose of automatic feeding is achieved.

Owner:DONGGUAN XINDE MACHINERY TECH

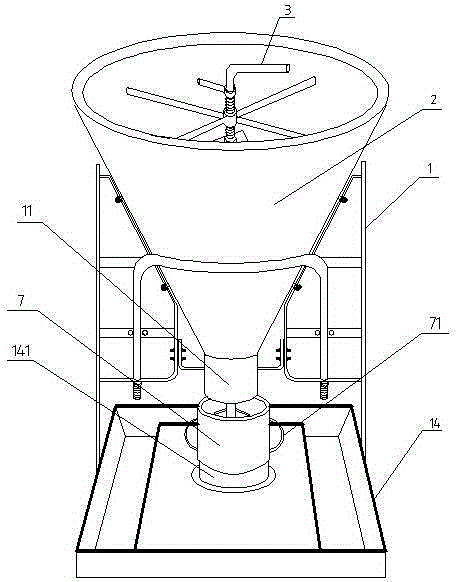

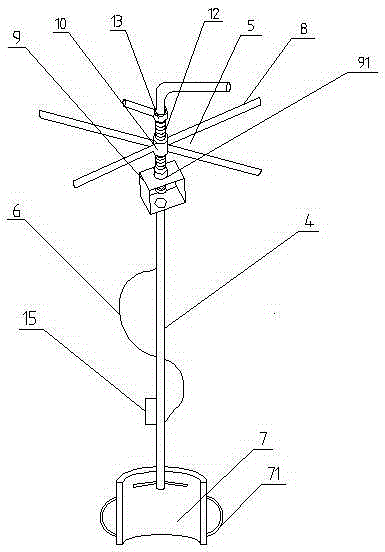

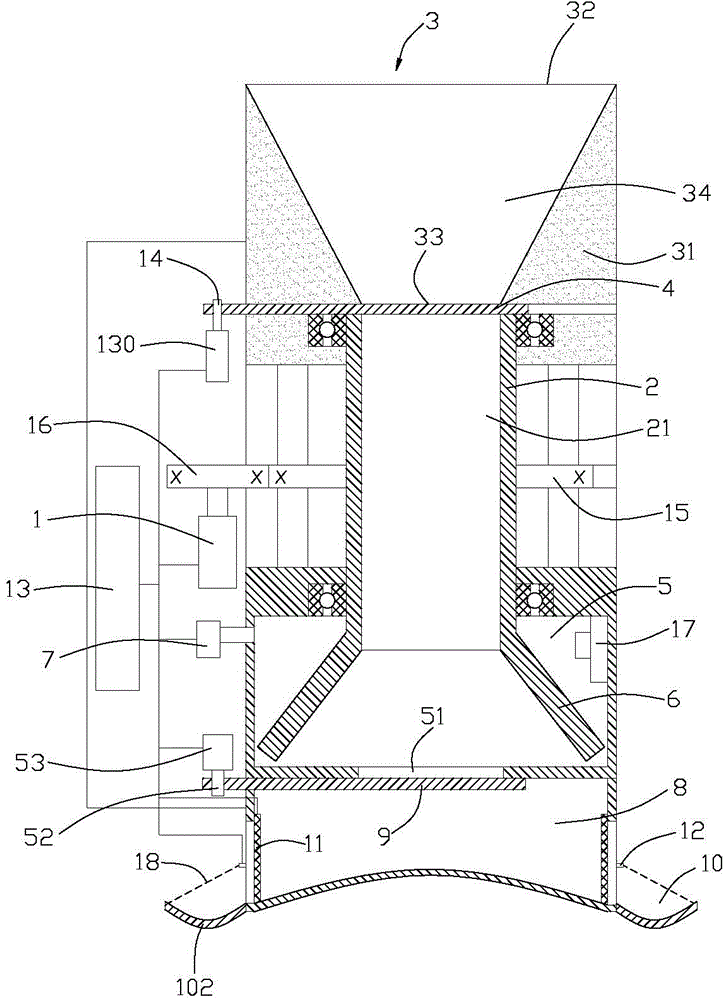

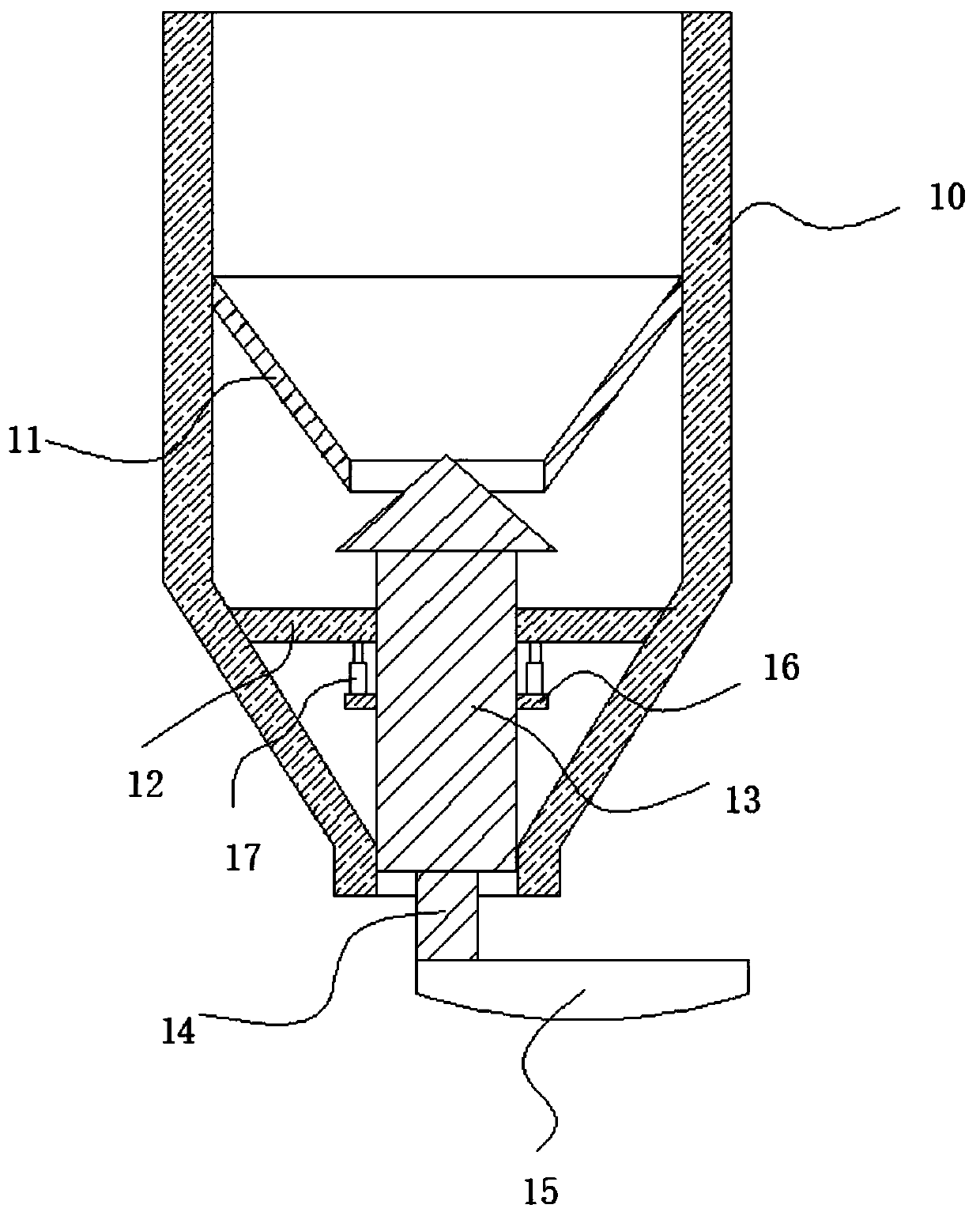

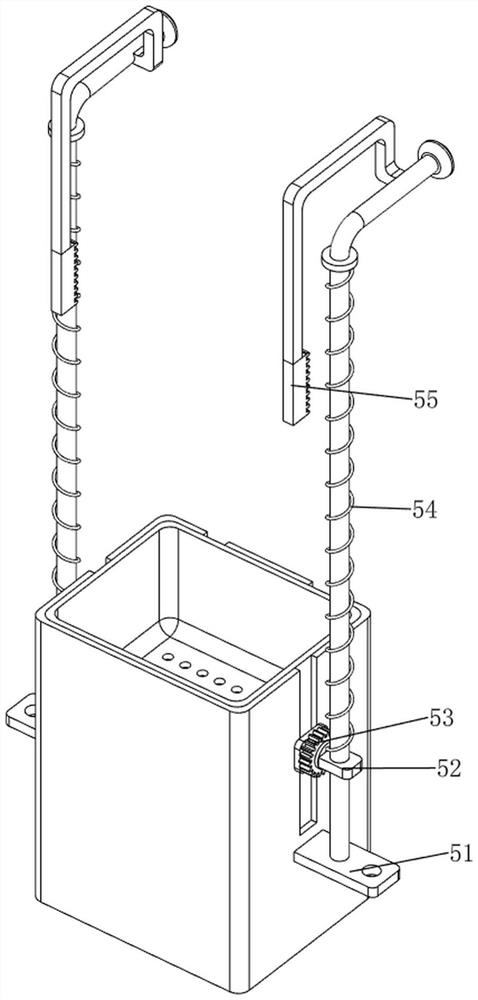

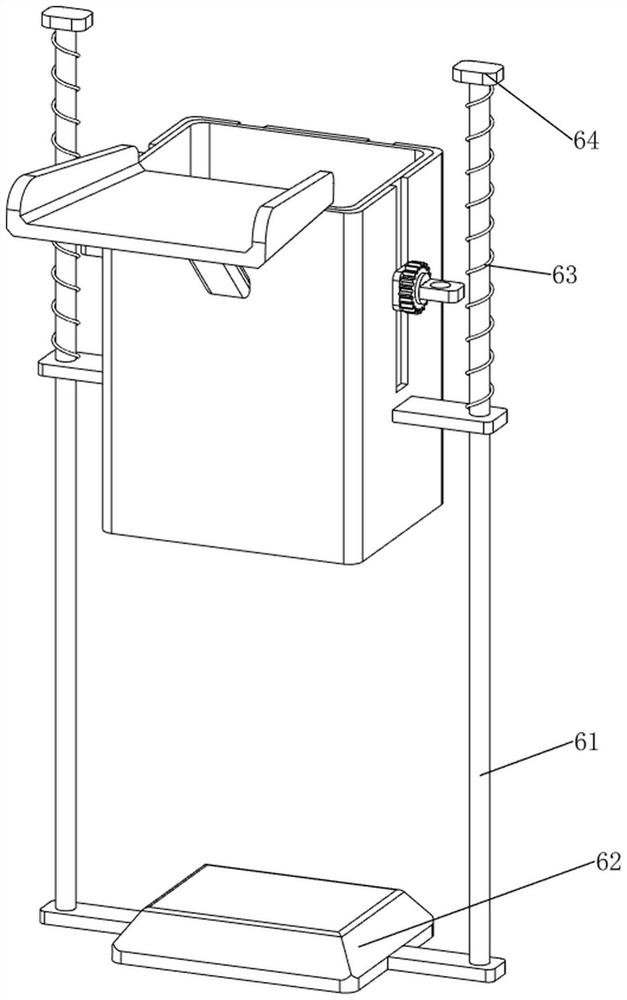

Automatic feeder

InactiveCN105379634AAvoid scraping cornersSimple device structureAnimal feeding devicesEngineeringHabit

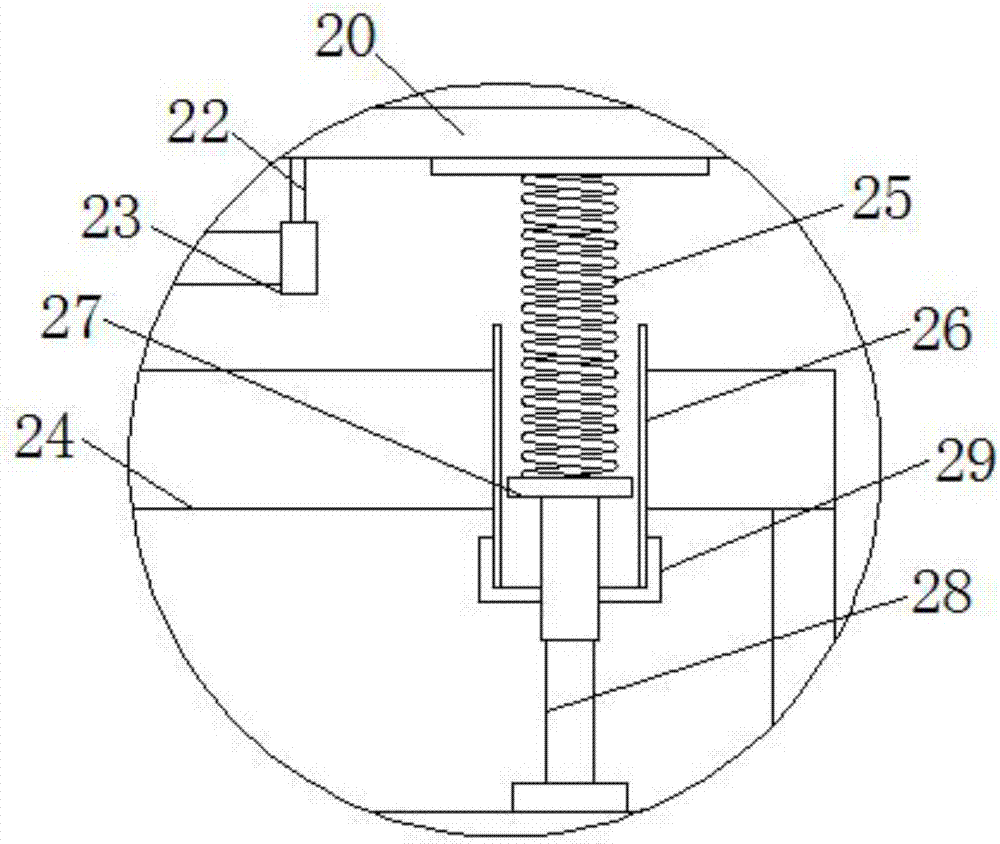

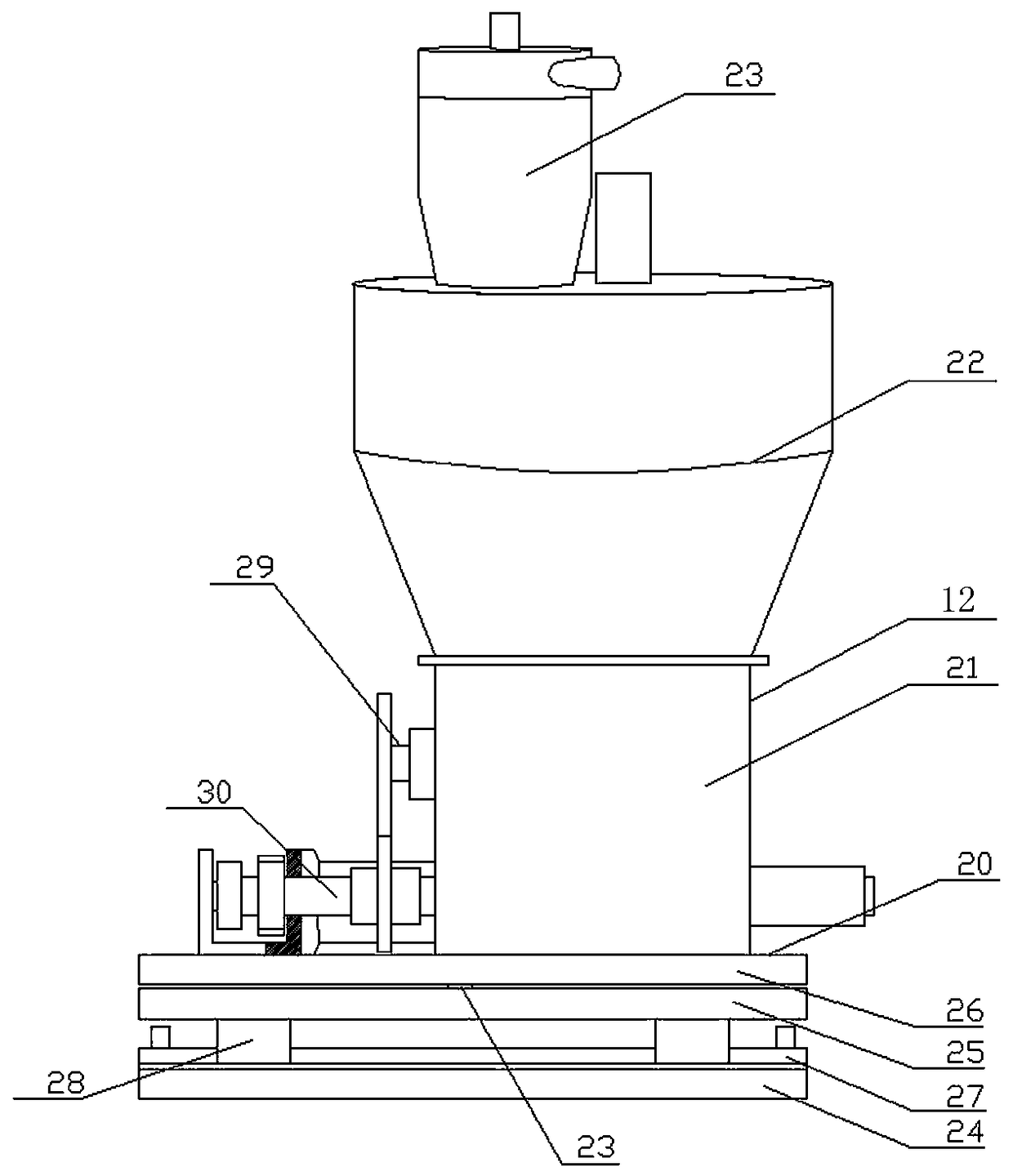

The invention discloses an automatic feeder. The automatic feeder comprises a support, a storage vat, a transmission rod and a discharging device, wherein the inverse-cone-shaped storage vat is fixedly installed on the support, and a discharging pipe is arranged at the lower end of the storage vat; the discharging device comprises an installation frame, the transmission rod, a stirring part I and a stirring sleeve, the installation frame is fixed to the inner wall of the storage vat, the transmission rod is installed on the installation frame and can revolve on its axis, the lower end of the transmission rod penetrates through the discharging pipe and then is fixedly connected with the stirring sleeve, the stirring part I is arranged on the transmission rod, the inner diameter of the stirring sleeve is slightly larger than the outer diameter of the discharging pipe, and one or more lugs are arranged on the outer side wall of the stirring sleeve. The automatic feeder is especially suitable for pig farms. By means of the nosing habit of pigs, when pigs touch the stirring sleeve, the stirring sleeve drives the transmission rod to rotate to enable feed to fall down through the gap between the discharging pipe and the stirring sleeve. The discharging amount can be controlled by adjusting the gap between the discharging pipe and the stirring sleeve.

Owner:陈国武

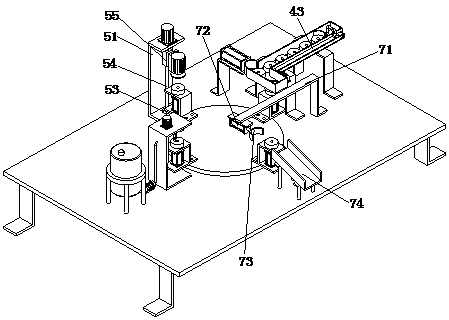

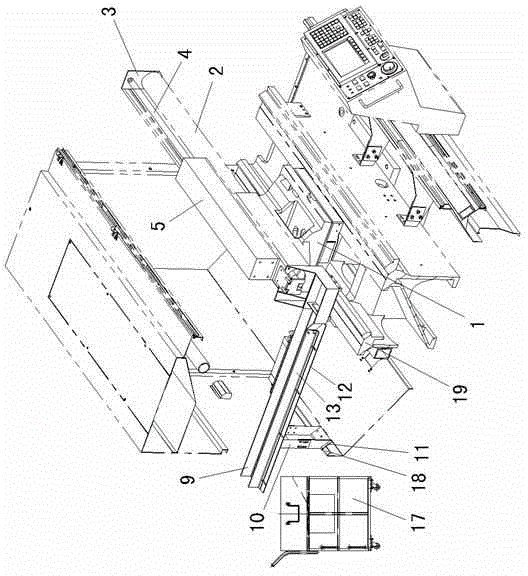

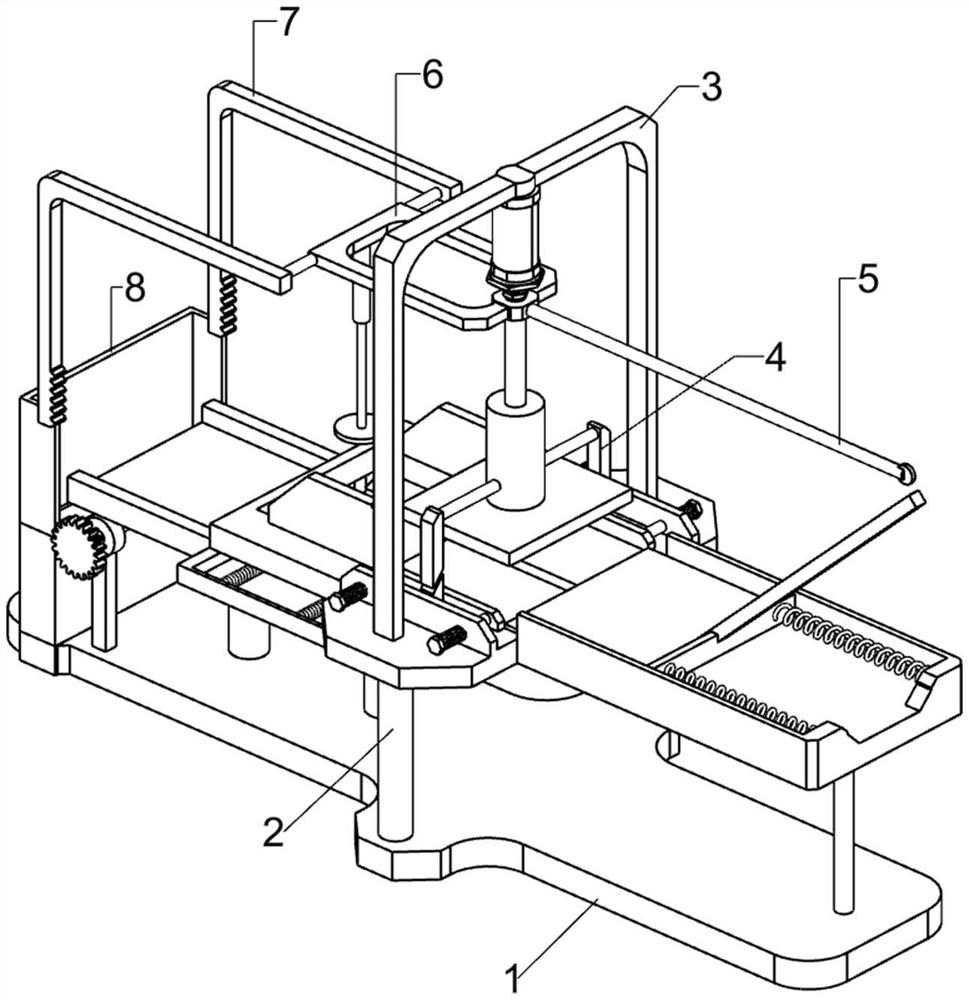

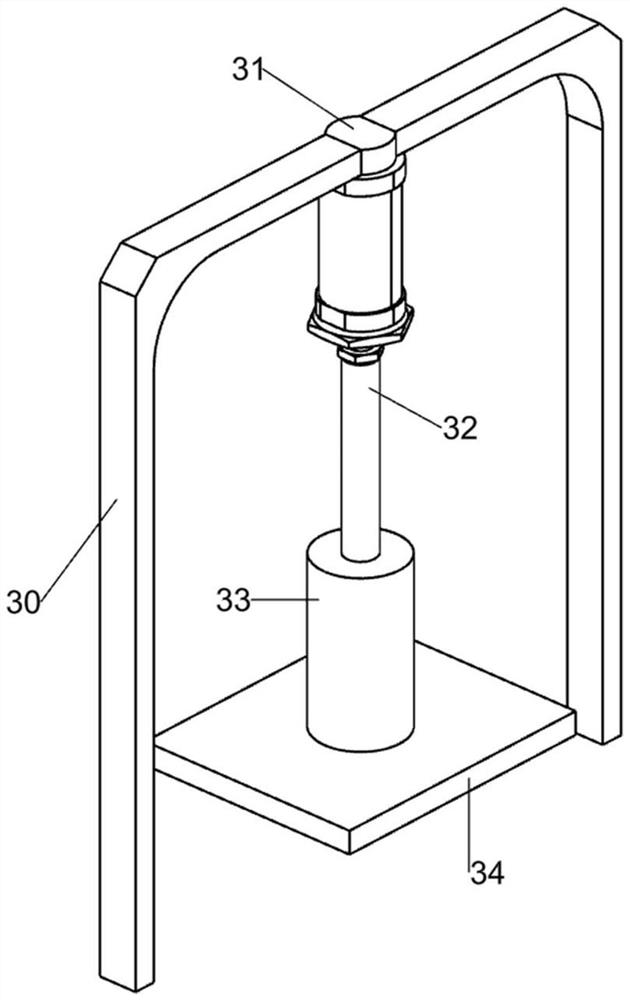

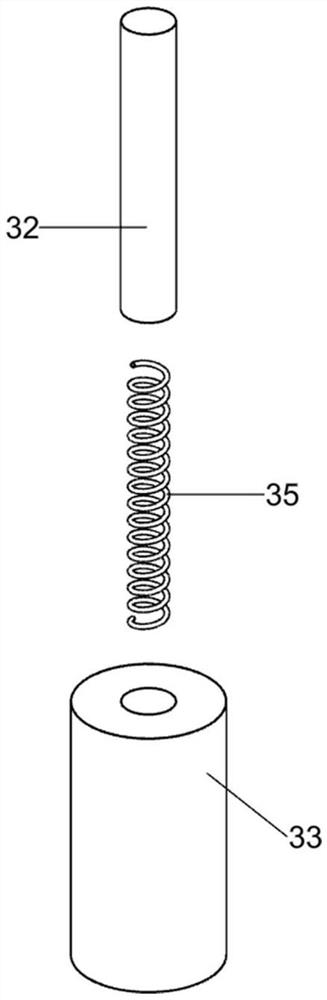

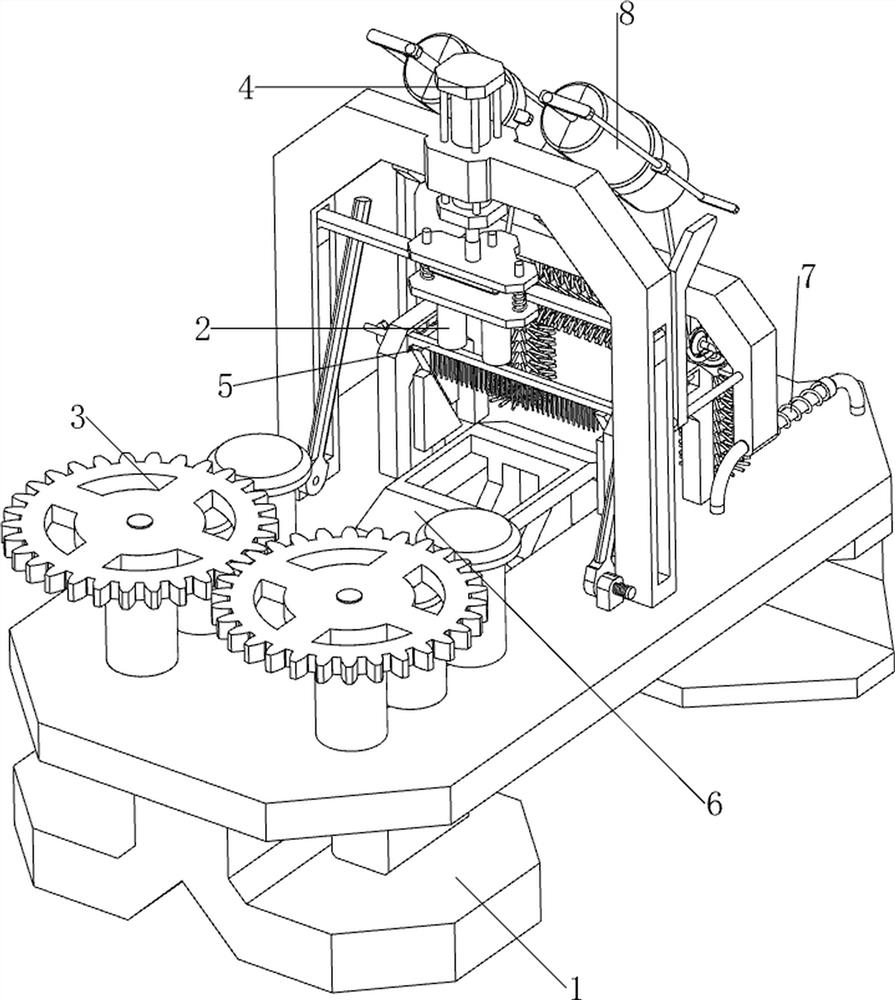

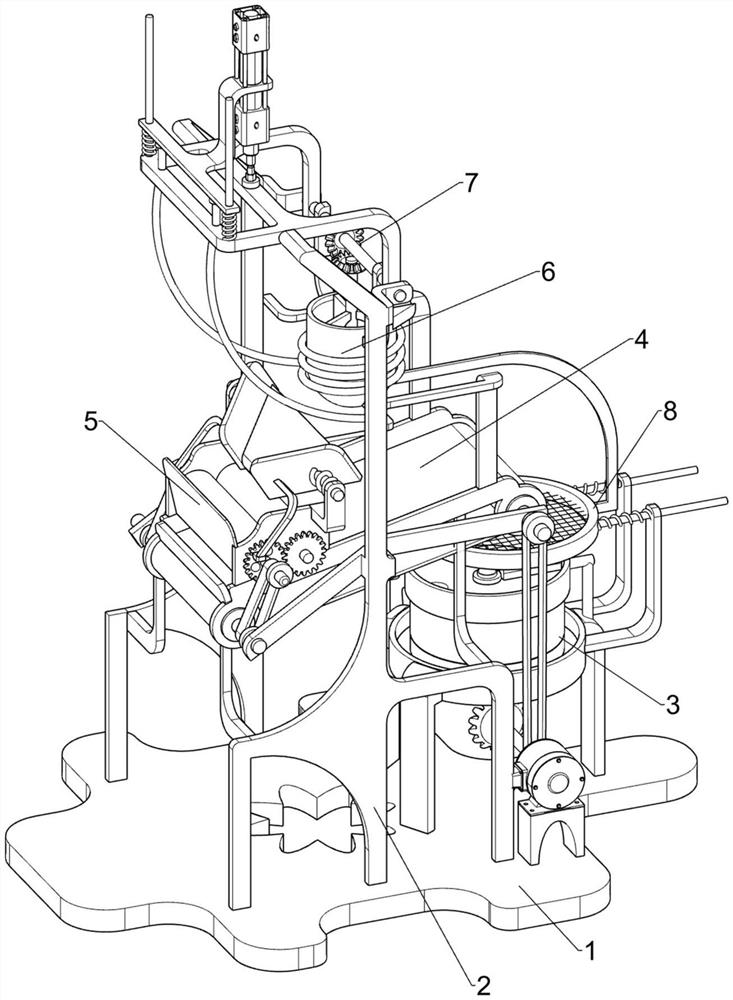

Automobile part integrated processing equipment

InactiveCN110227988ATo achieve the purpose of integrated processing of auto partsShorten the timeGrinding drivesGrinding machinesEngineeringIntegrated processing

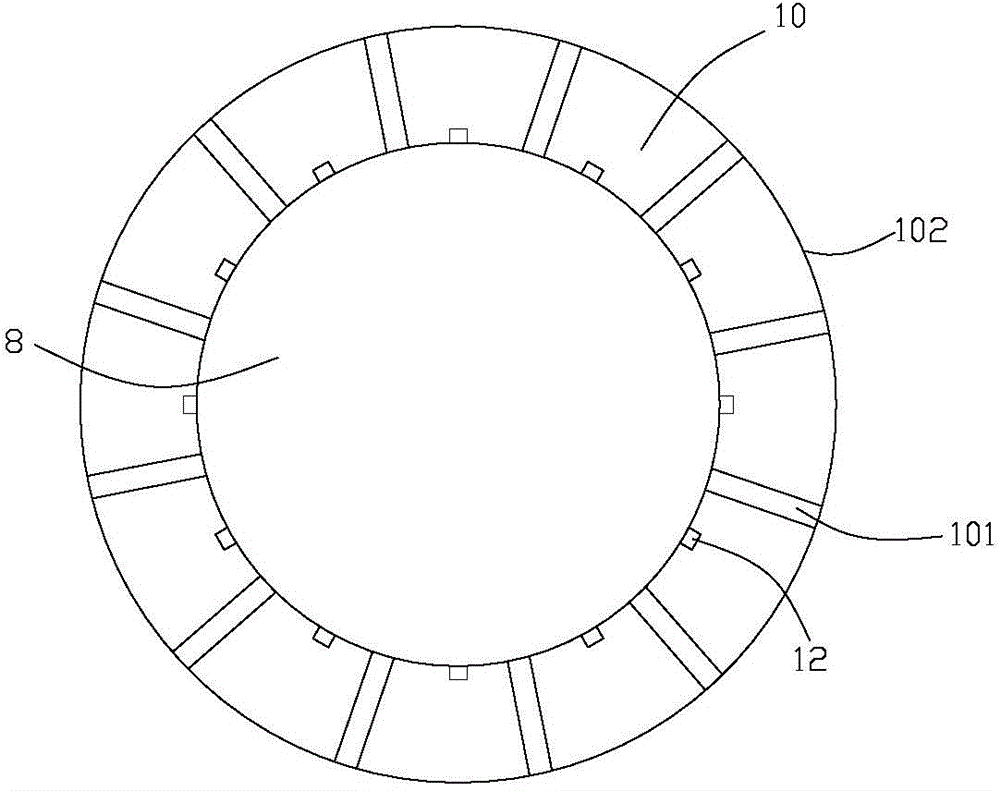

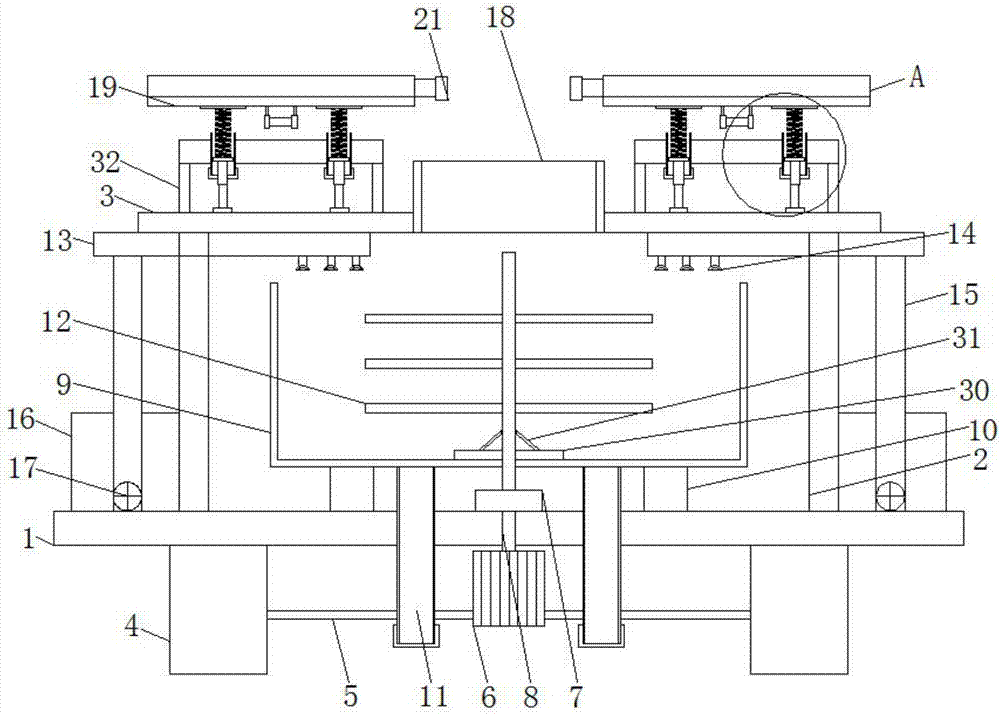

The invention discloses automobile part integrated processing equipment, and belongs to the technical field of automobile part processing. The automobile part integrated processing equipment comprisesa pedestal, a first rotary shaft, a rotary disc, a loading assembly, a grinding assembly, a paint spraying assembly, an unloading assembly and four positioning assemblies, wherein the first rotary shaft is vertically arranged on the pedestal; the first rotary shaft is rotatably matched with the pedestal; the bottom end of the first rotary shaft extends to a position below the pedestal; the rotarydisc is fixedly connected to the top end of the first rotary shaft; a drive assembly for driving the first rotary shaft to rotate is arranged below the pedestal; the loading assembly, the grinding assembly, the paint spraying assembly and the unloading assembly are mounted on the pedestal; the loading assembly, the grinding assembly, the paint spraying assembly and the unloading assembly are arranged in a peripheral direction of the rotary disc; and the four positioning assemblies are arranged on the rotary disc. The automobile part integrated processing equipment disclosed by the invention solves the problems that automobile parts need to separately process on multiple pieces of processing equipment, manual multi-time dismounting positioning is required, operation is complex, time and labor are wasted, and processing efficiency is low.

Owner:李义飞

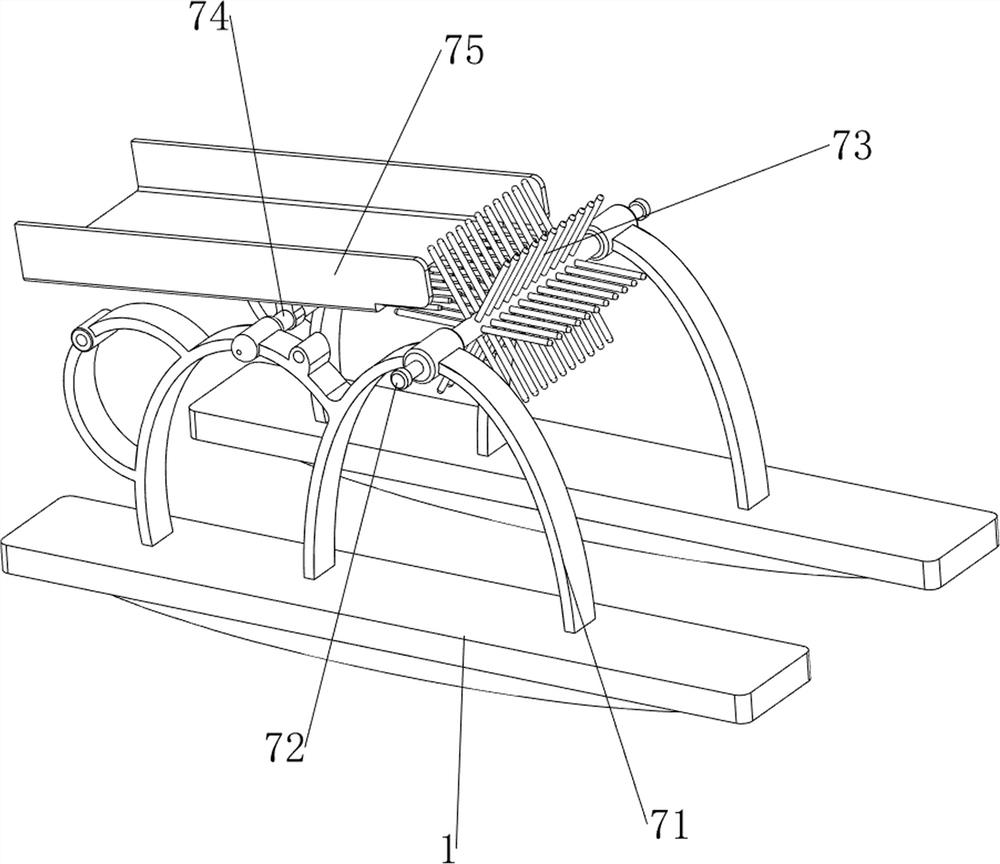

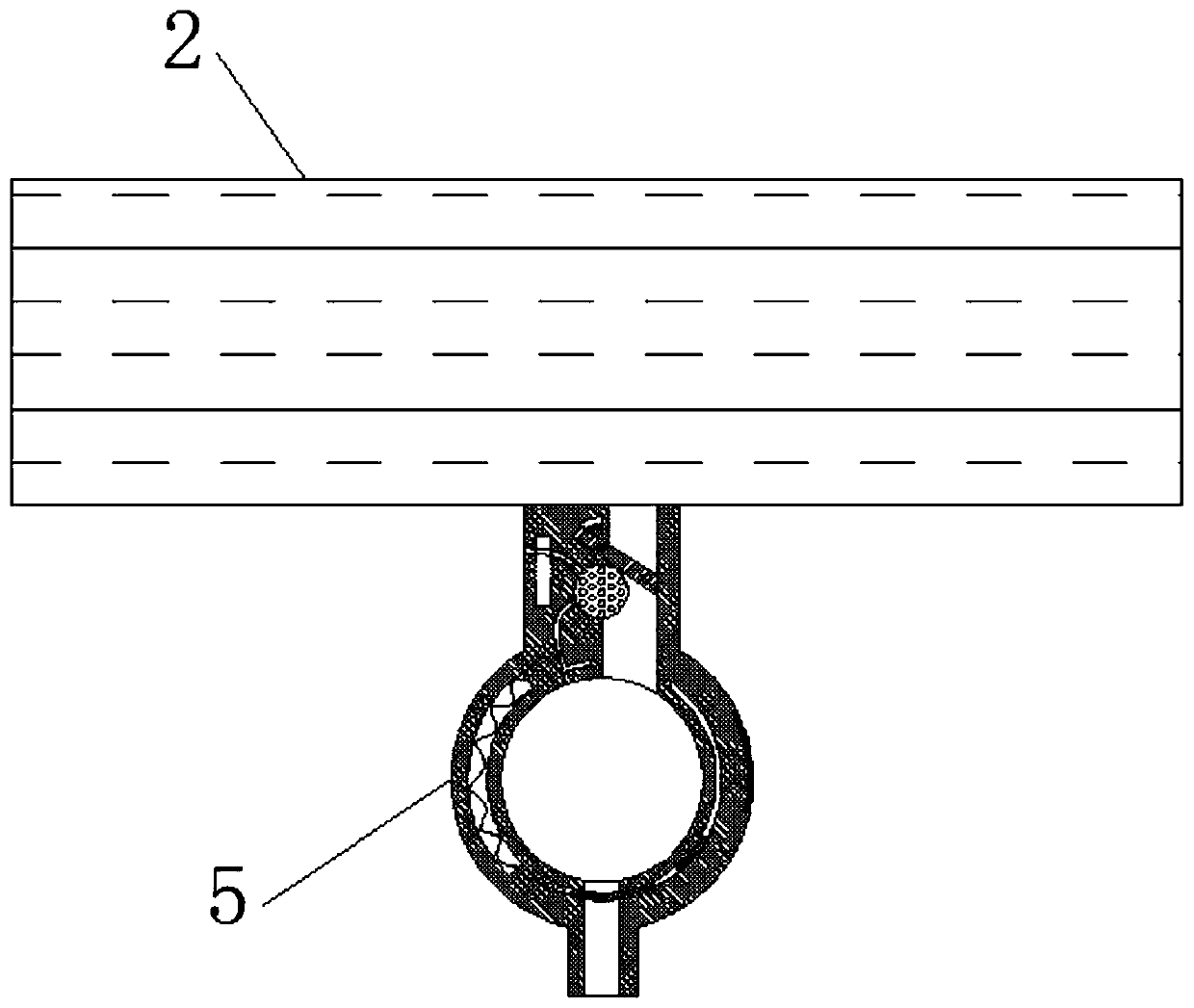

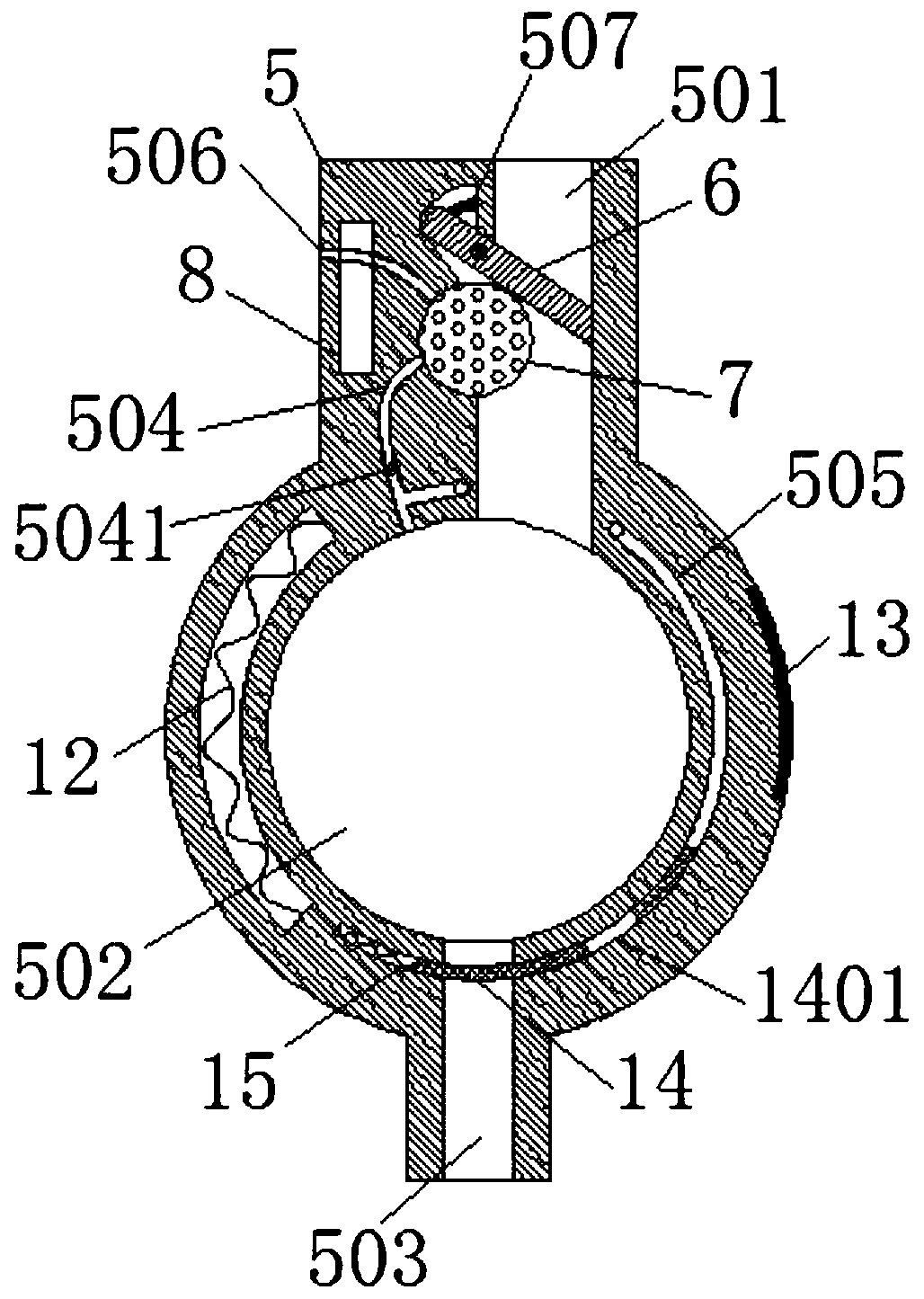

Floating object fishing device for aquaculture

ActiveCN112982348ATo achieve the purpose of automatic feedingTo achieve the purpose of automatic collectionWater cleaningClimate change adaptationElectric machineryZoology

The invention relates to a fishing device, and particularly relates to a floating object fishing device for aquaculture. The floating object fishing device for aquaculture can achieve automatic discharging, automatic scraping and automatic collection. The floating object fishing device for aquaculture comprises mounting plates, stirring fans, a motor, first supports, belt wheels, conveying belts, a fishing rod, a discharging mechanism and a collecting mechanism; the stirring fans are rotationally arranged on the two mounting plates; the motor is mounted on the mounting plate on one side; the two first supports are arranged at the tops of the mounting plates; the belt wheels are rotationally connected between the two opposite first supports; an output shaft of the motor is connected with the belt wheel on one side; the two conveying belts are connected between the two belt wheels; and the fishing rod is connected between the bottoms of the two conveying belts. According to the floating object fishing device for aquaculture, a scraping mechanism and a pulling mechanism are arranged, the pulling mechanism operates to enable the scraping mechanism to operate, then floating objects in a discharging frame are scraped off, and the purpose of automatic scraping is achieved.

Owner:杨云娣

Automatic material preparing device

The invention discloses an automatic material preparing device used for preparing materials of plate parts of machining lathe. The automatic material preparing device comprises a tailstock body matching with a guide rail; a sliding rod axially penetrates an upper shaft of the tailstock body, a driving device is connected with one end of the sliding rod, a vertically arranged partition plate is connected with the front end of the tailstock body via a slab, a material collecting box arranged below the partition plate is fixed at the front end of the tailstock body, a spout is communicating with one side of the material collecting box, a push plate is arranged in the spout and the push plate is connected with a pushing mechanism. The automatic material preparing device is simple in structure, convenient to prepare materials, low in cost, easy to operate and control and is time saving and energy saving.

Owner:大连机床(数控)股份有限公司

Automatic feeder

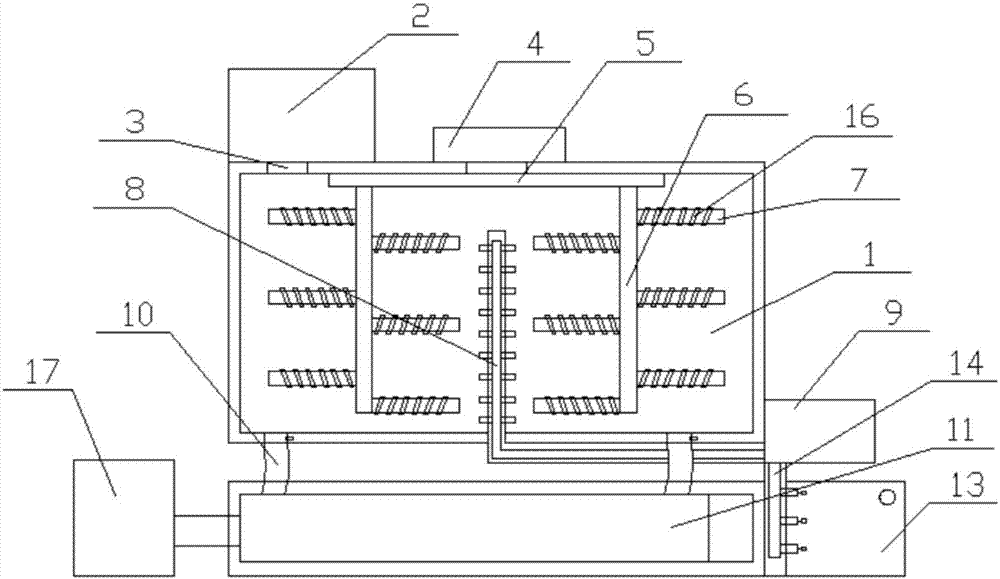

InactiveCN104012422ATo achieve the purpose of automatic feedingAvoid wastingAnimal feeding devicesProgramme control in sequence/logic controllersEngineering

The invention relates to an automatic feeder which comprises a hollow rotating shaft driven by a motor. The upper end of the rotating shaft is provided with a storage compartment for storing a feed. The storage compartment is communicated with a cavity of the rotating shaft through a blanking door. The lower end of the rotating shaft extends into a mixing compartment which is communicated with the cavity of the rotating shaft. Agitating vanes are fixedly arranged at the lower end of the rotating shaft. A water pump conveys water to the mixing compartment. The downside of the mixing compartment is provided with a circular feeding compartment. The bottom of the mixing compartment is communicated with the feeding compartment through a discharge door. Signals of pigs are sensed through infrared rays, and the motor, the blanking door, the water pump, the discharge door, a valve and the like are started by the utilization of a control center. Thus, the feed and water are mixed and stirred, and the mixture enters a feeding area so as to achieve the purpose of automatic feeding. By timely burdening and timely supply and by controlling temperature of the mixture, the feed for pigs is fresh and is appropriate in amount. Thus, waste is avoided.

Owner:HUNAN WEIYE BIOTECH

Automatic feeding device of cooking apparatus

InactiveCN100479720CTo achieve the purpose of automatic feedingCooking vesselsElectrical and Electronics engineering

Owner:AIC ROBOTICS TECH

Automatic bending machine for processing bamboo wood

InactiveCN107322714AHeat upTo achieve the purpose of automatic feedingWood treatment detailsCane mechanical workingElectric machineryFixed frame

The invention discloses an automatic bending machine for bamboo and wood processing, which comprises a bottom plate. A sliding guide rail is fixedly connected, the outer wall of the sliding guide rail is covered with a sliding block, the bottom of the sliding block is fixedly connected with a clamping device through a connecting rod, and a wire rope connecting frame is fixedly connected to one side of the outer wall of the clamping device. A pulling power box is fixedly connected to one side of the outer wall of the frame, and a first motor is fixedly connected to the bottom of the inner wall of the pulling power box. The invention relates to the technical field of bamboo and wood processing machinery. The automatic bending machine for bamboo and wood processing solves the temperature heating and automatic feeding of the workpiece, ensures that the temperature will not be too high and stable, and takes out the heated bamboo and wood workpiece for bending, no need to manually remove the workpiece Parts and feeding, reducing the workload of workers and reducing production costs.

Owner:安吉县瑞旺竹木制品厂

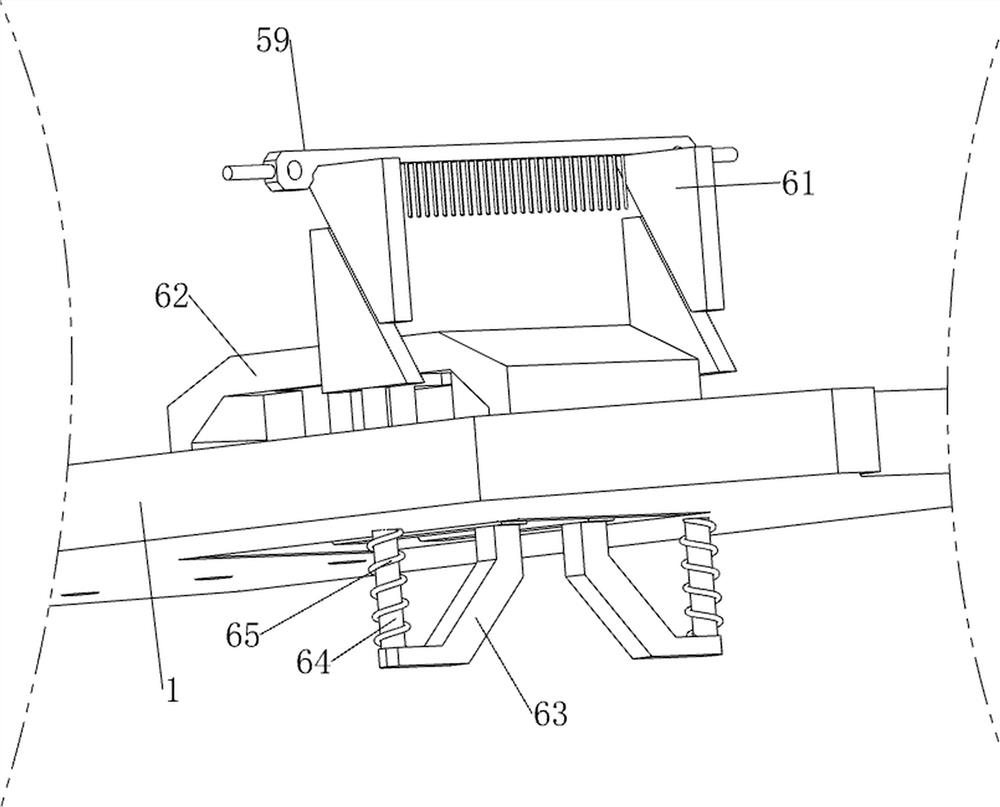

Continuous quantitative feeding and synchronous conveying device for coating production

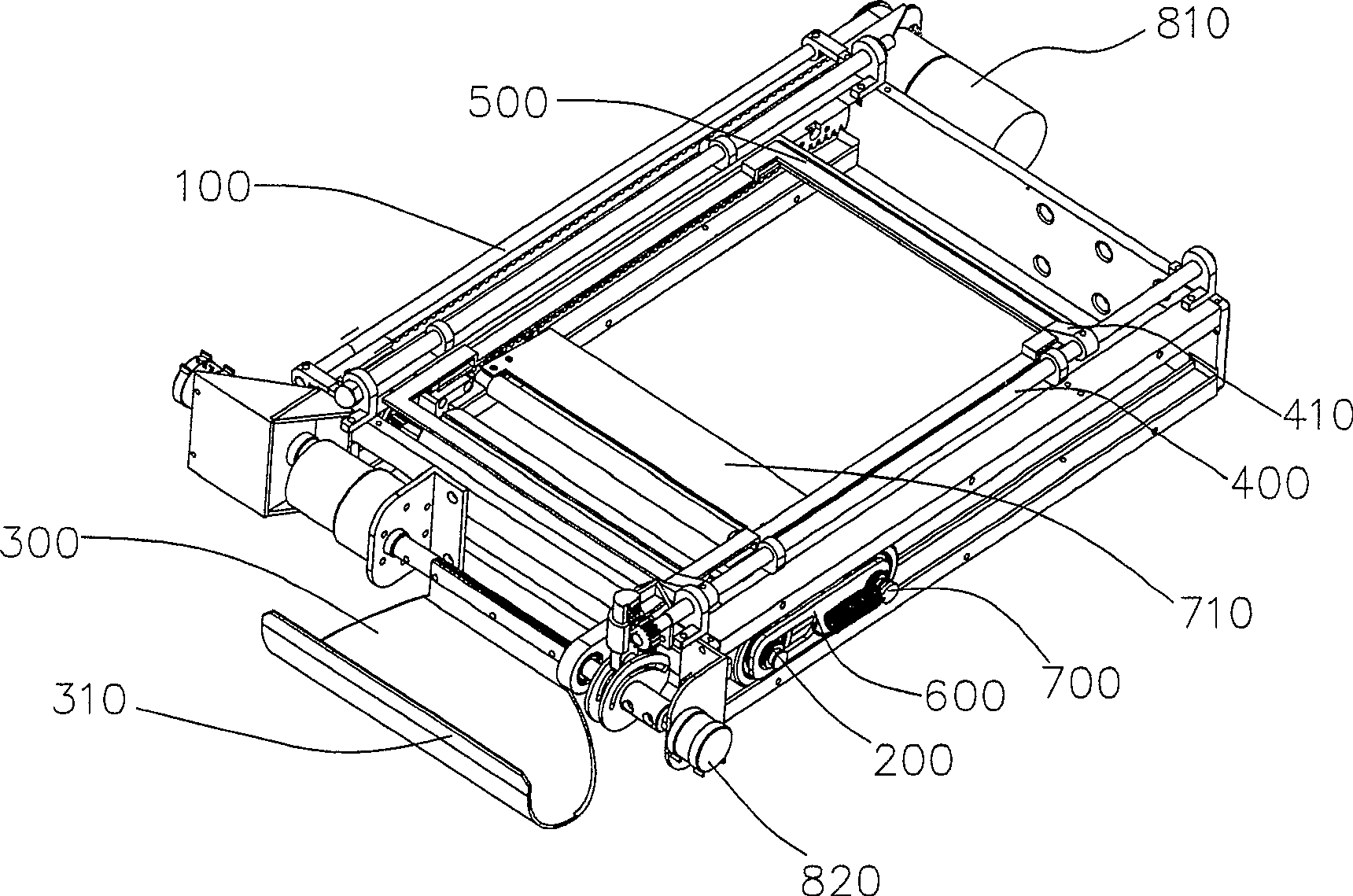

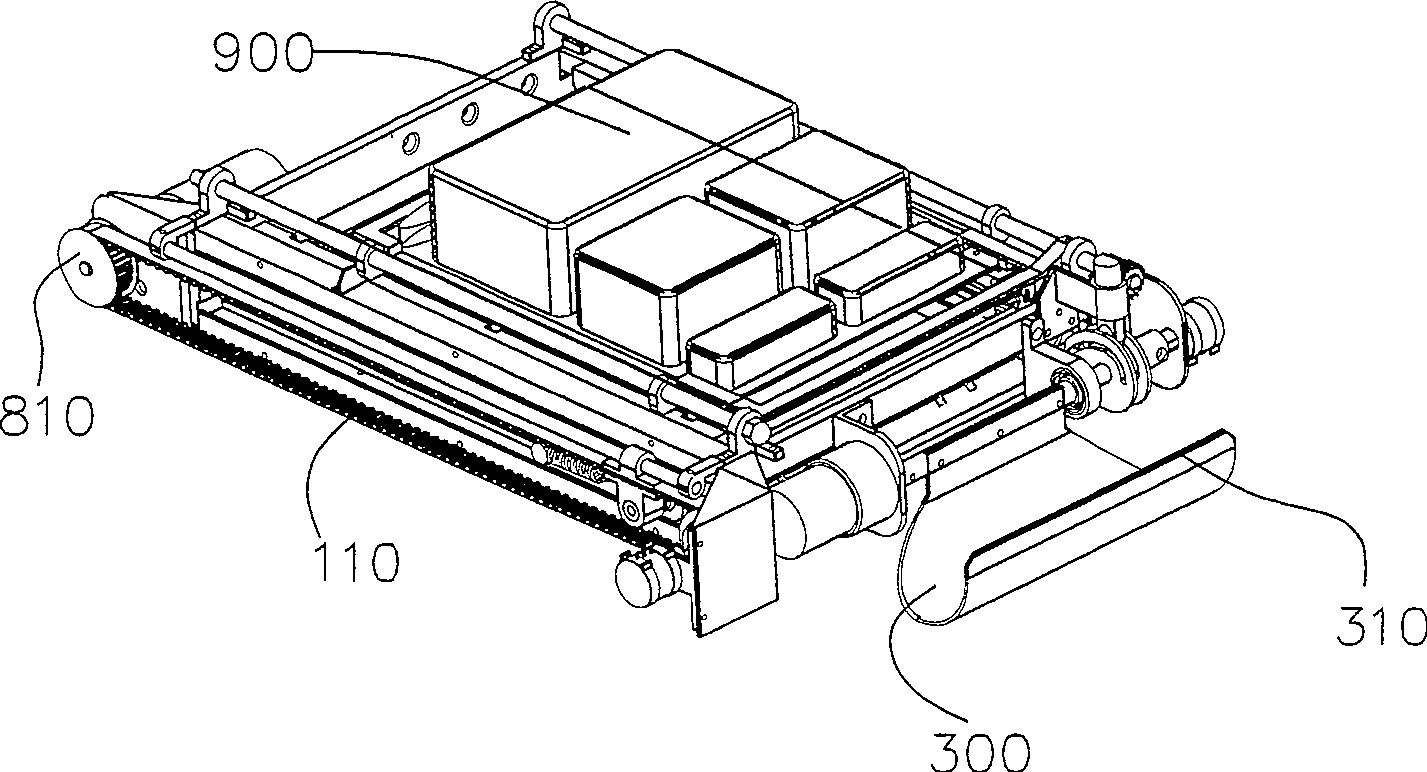

ActiveCN110697337AAvoid spilling raw materialsImprove delivery efficiencyConveyorsConveyor partsProcess engineeringFixed frame

The invention discloses a continuous quantitative feeding and synchronous conveying device for coating production. The continuous quantitative feeding and synchronous conveying device for coating production comprises a bottom plate, wherein a conveying device is arranged on the top part of the bottom plate; a receiving device is fixed onto the conveying device; a fixed frame is fixed to the top part of the bottom plate; two blanking devices located above the conveying device are fixed onto the fixed frame and are interacted with the receiving device on the conveying device; a sealing device fixed onto the bottom plate is arranged at one end of the conveying device and is matched with a receiving hole of the receiving device; and a collecting box placed on the bottom plate is arranged on the lower part of the right end of the conveying device. According to the continuous quantitative feeding and synchronous conveying device for coating production provided by the invention, under the combined action of the various parts, the aim on quantitatively receiving during conveying and receiving can be achieved, raw materials can be prevented from being poured during conveying, the aim on automatically blanking can be further achieved at the same time, the actual demand can be better met, the conveying efficiency is high, and the operation intensity is reduced.

Owner:ZHEJIANG ZHONGXIN NEW MATERIAL CO LTD

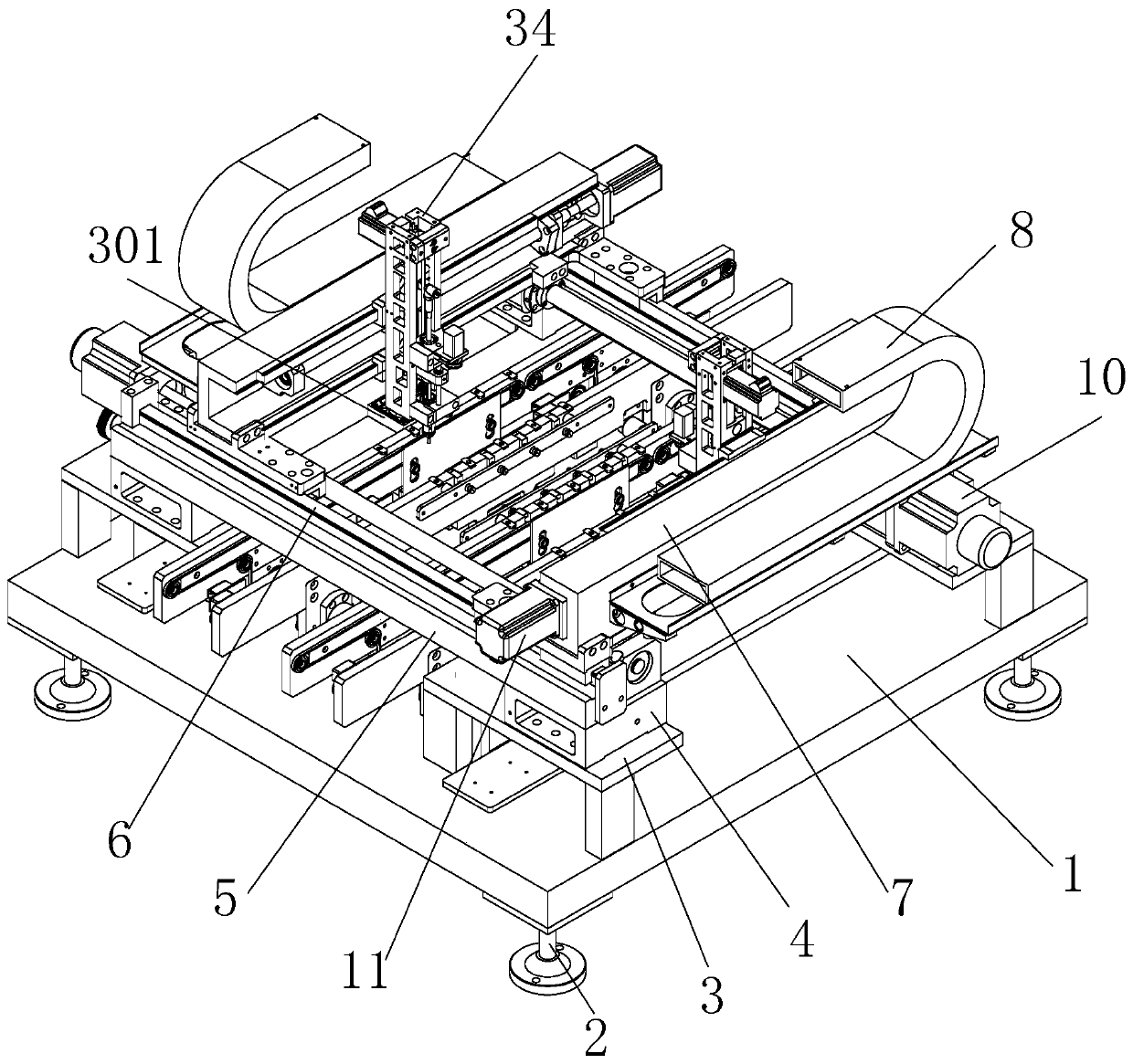

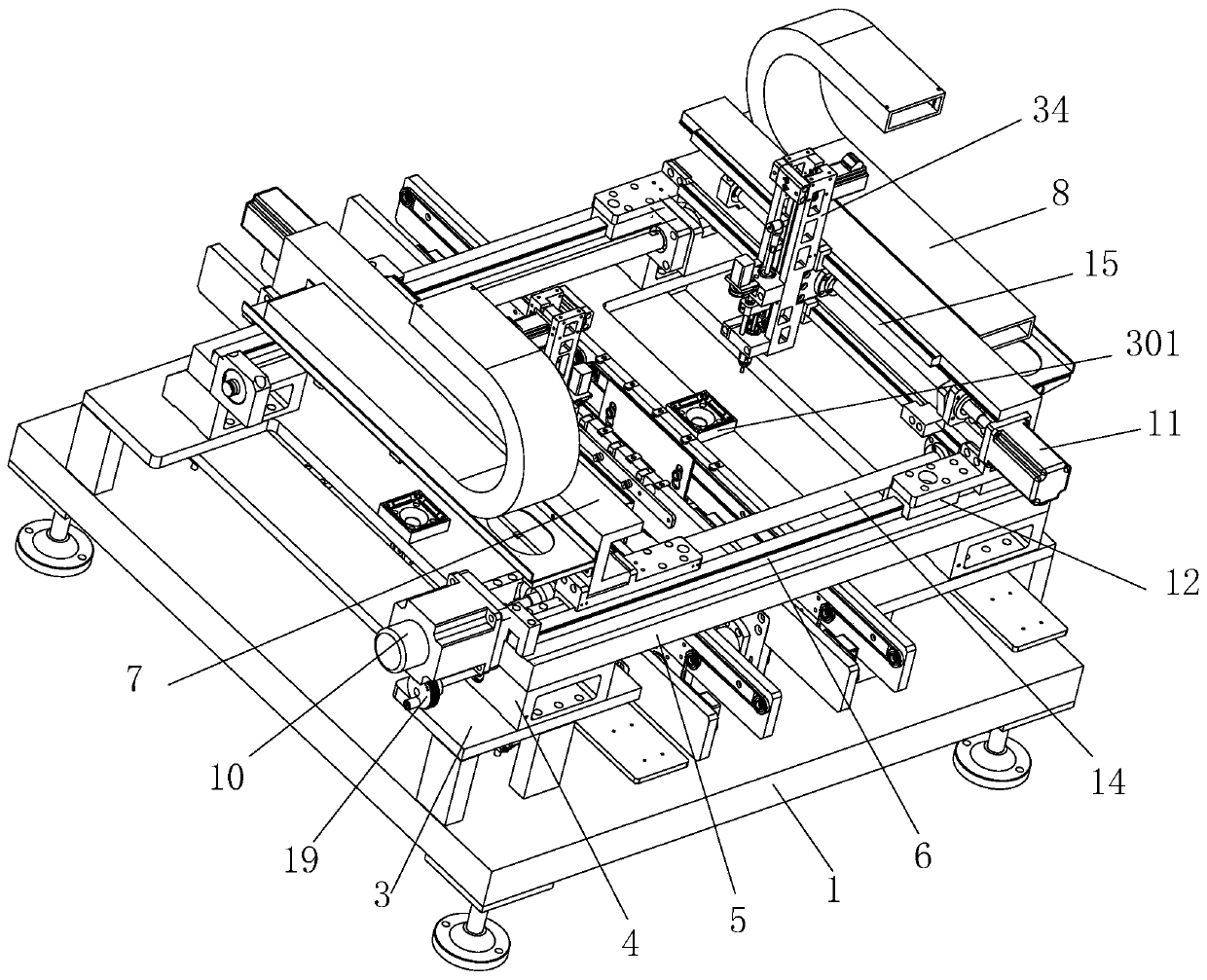

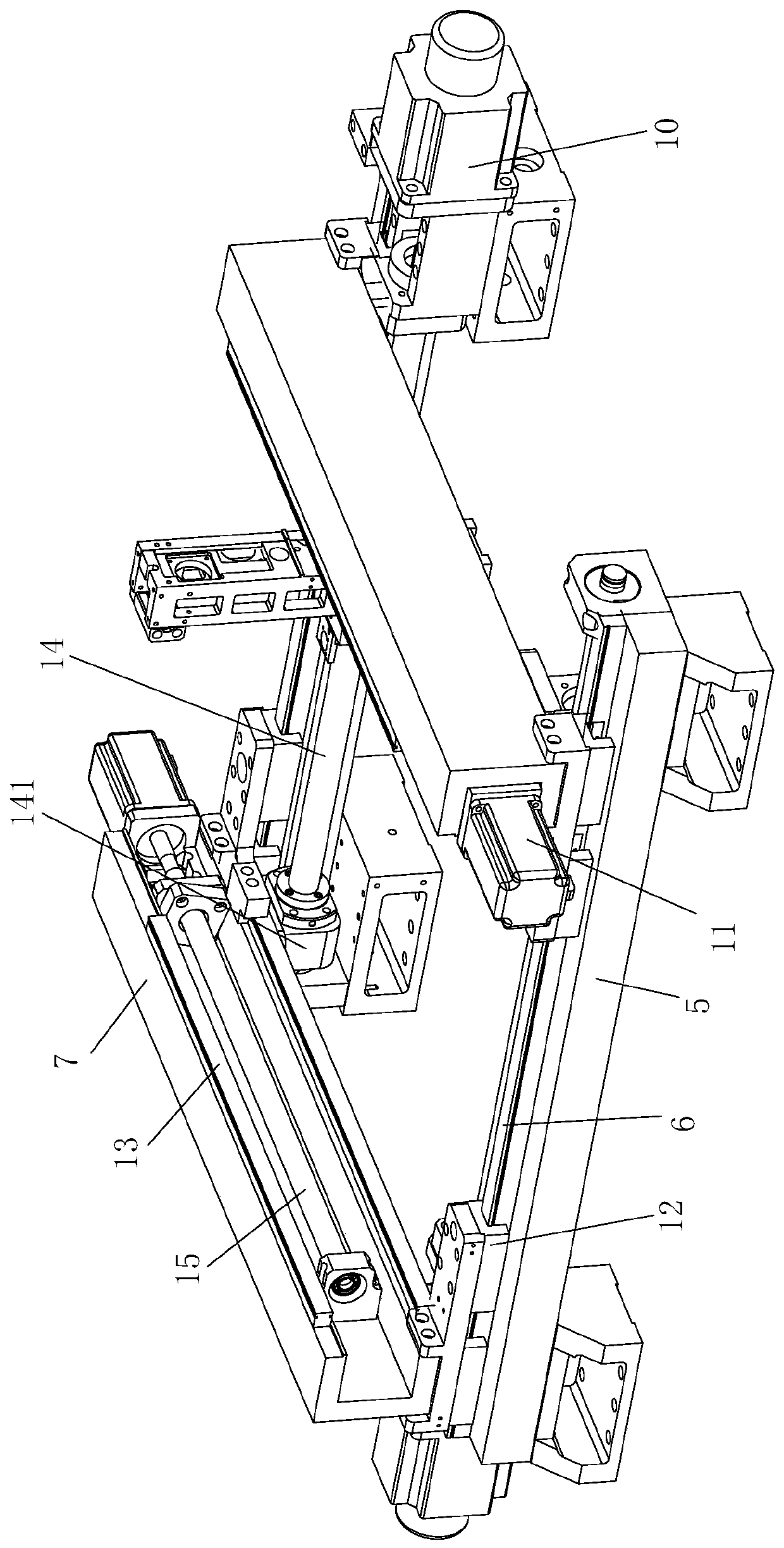

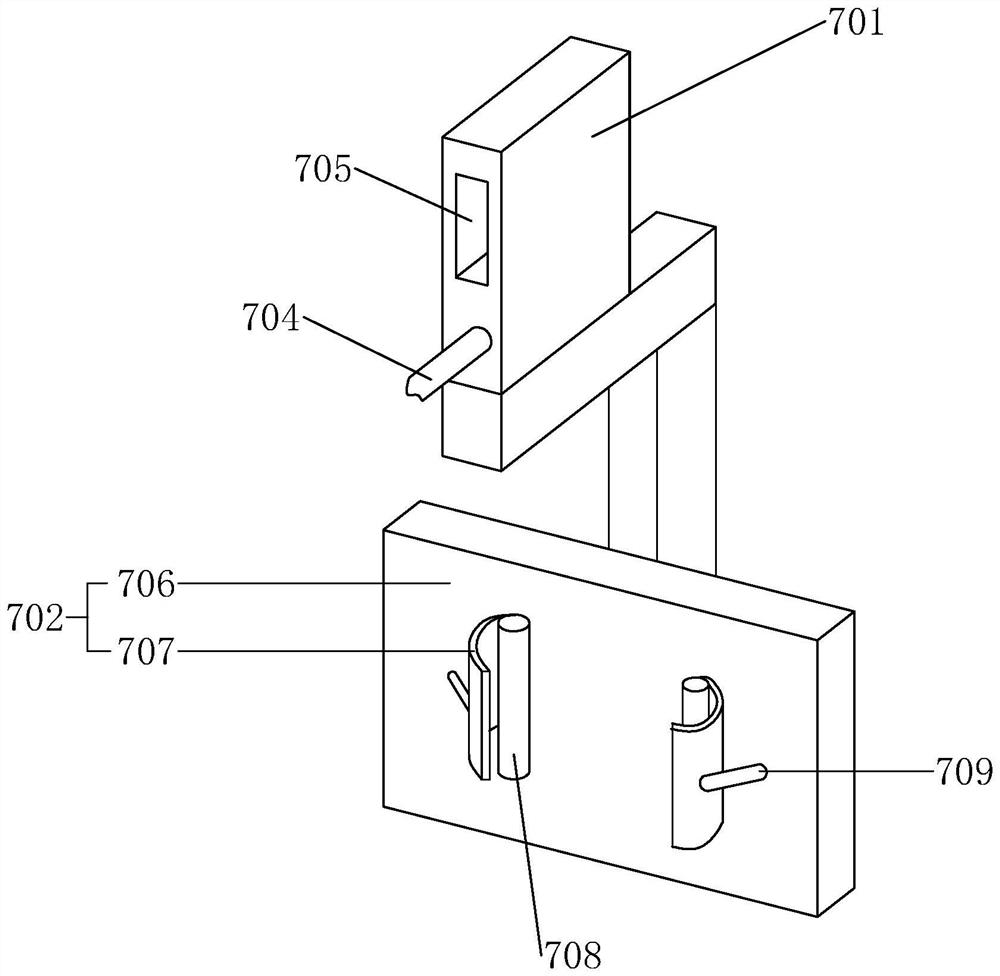

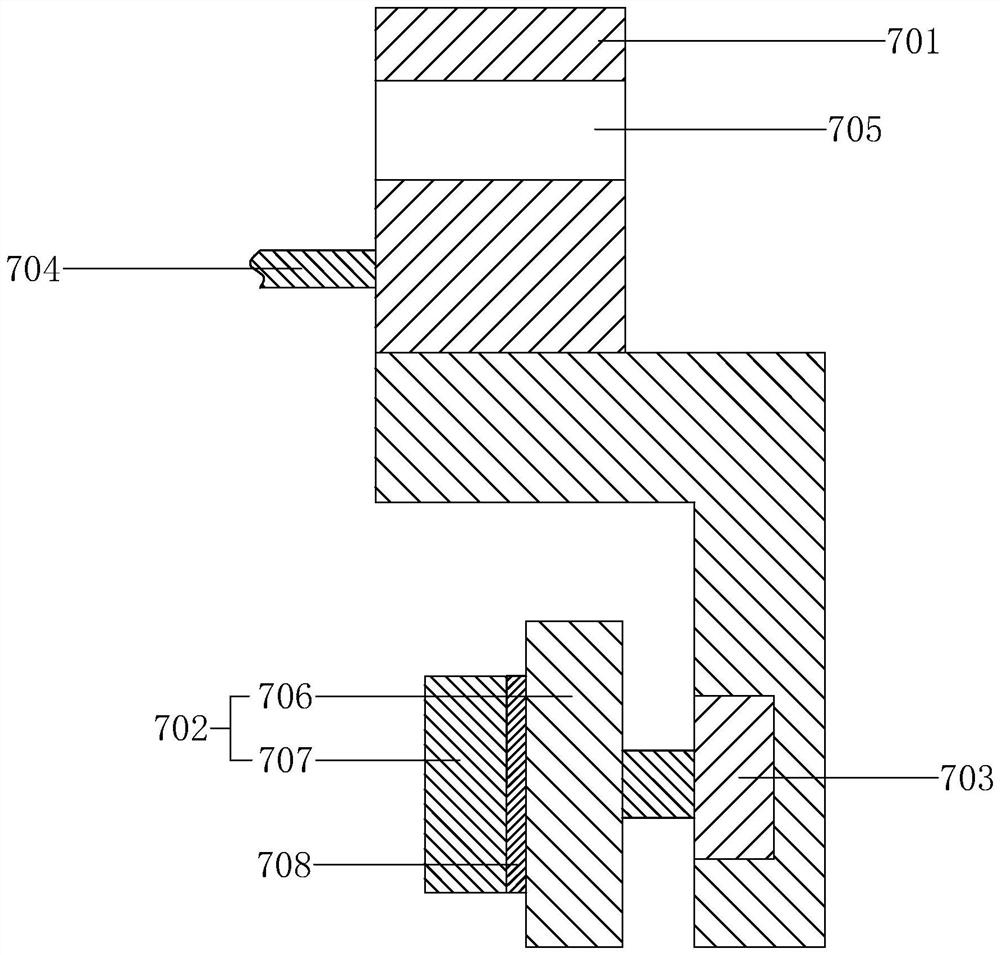

Multi-size chip mounting device

ActiveCN110505801AAchieve installationImprove work efficiencySemiconductor/solid-state device manufacturingElectrical componentsEngineeringElectrical and Electronics engineering

The invention provides a multi-size chip mounting device, comprising a supporting bottom plate, supporting cross bars, U-shaped fixing rods and mounting nozzles, wherein two fixing seats are arrangedon the supporting bottom plate, two supporting cross bars vertical to the fixing seat are installed on the fixing seat, a first lead screw is arranged on one side of the supporting cross bar, one endpart of the first lead screw is connected with a first motor, at least one first lead screw sleeve capable of moving relative to the first lead screw sleeves the first lead screw, a first slide blockis connected with each first lead screw sleeve, the first slide blocks are slidably connected to first slide rails above the supporting cross bars, and at least one first slide block is arranged on each first slide rail. The multi-size chip mounting device provided by the invention can realize the position change of front and rear, left and right, and up and down of the mounting nozzle, can also realize multi-angle rotation of the mounting nozzle in the circumferential direction, and can accurately locate the positions of the ships according to chips with different sizes, so that the mountingnozzle accurately suck the chips and place the chips at designated positions.

Owner:道晟半导体(苏州)有限公司

Compact structure rotating type feeding device

ActiveCN103964166APrevent overflowImprove mechanical propertiesLarge containersConveyor partsEngineeringMechanical engineering

Owner:SHANGHAI ELECTROMECHANICAL DESIGN & RES INST CO LTD

Concrete preparation device for municipal administration

ActiveCN107310027APrevent uneven mixingGuarantee product qualityMixing operation control apparatusIngredients proportioning apparatusArchitectural engineeringVibration motor

The invention discloses a concrete preparation device for municipal administration. The concrete preparation device comprises a fixing base; supporting columns are connected to the two sides of the bottom of a preparation cylinder separately; the bottoms of the supporting columns are connected to the top of the fixing base; the two sides of the bottom of the preparation cylinder communicate with discharging pipes; spraying pipes are connected to the two sides of the bottom of a fixing plate separately; branch pipes are connected to the bottoms of one sides of the spraying pipes; the bottoms of the branch pipes communicate with water tanks; feed ports are connected to one sides of feeding trays; vibration motors are connected to the middles of the bottoms of the feeding trays through supports; supporting springs are connected to the two sides of the bottoms of the feeding trays separately; sealing covers are connected to the bottoms of through pipes in a threaded mode; inner cavities of the through pipes are provided with top plates; and electric telescopic rods are connected to the bottoms of the top plates. The concrete preparation device has the advantage that the proportion error among gravel, cement and water can be reduced, the problem that the concrete preparation quality can be reduced due to the fact that the proportion error among the gravel, the cement and the water is large can be solved.

Owner:秦皇岛中燕机械设备有限公司

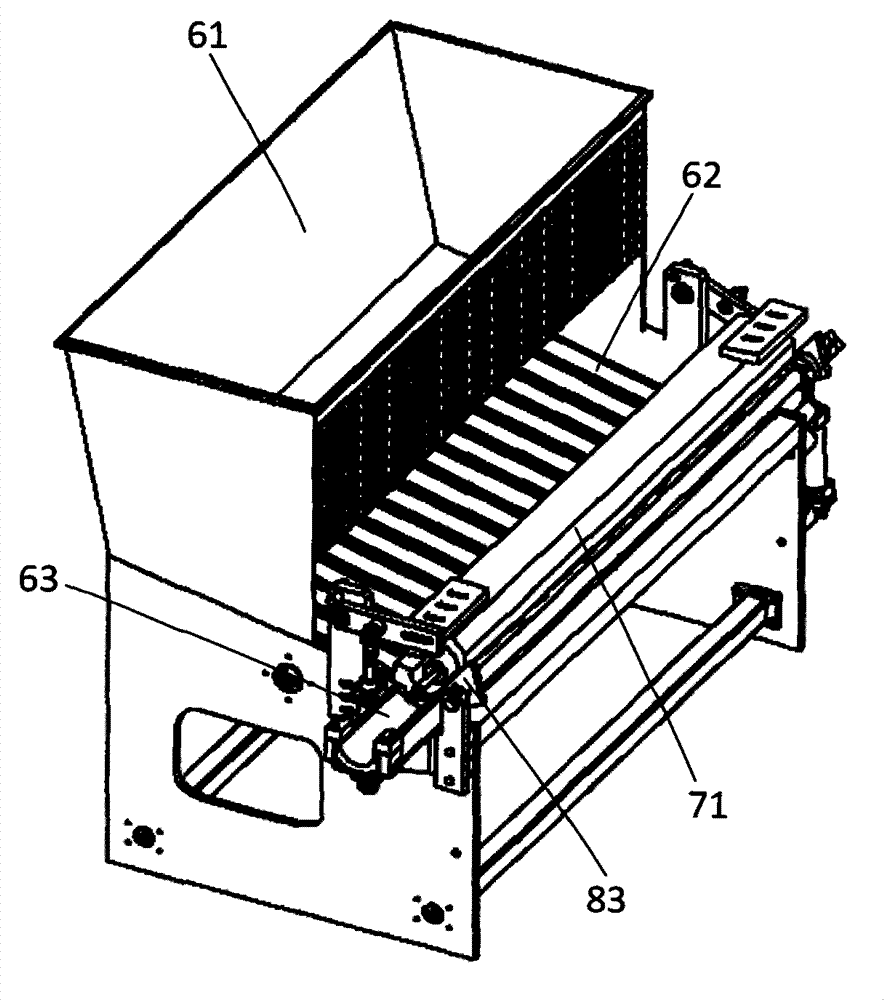

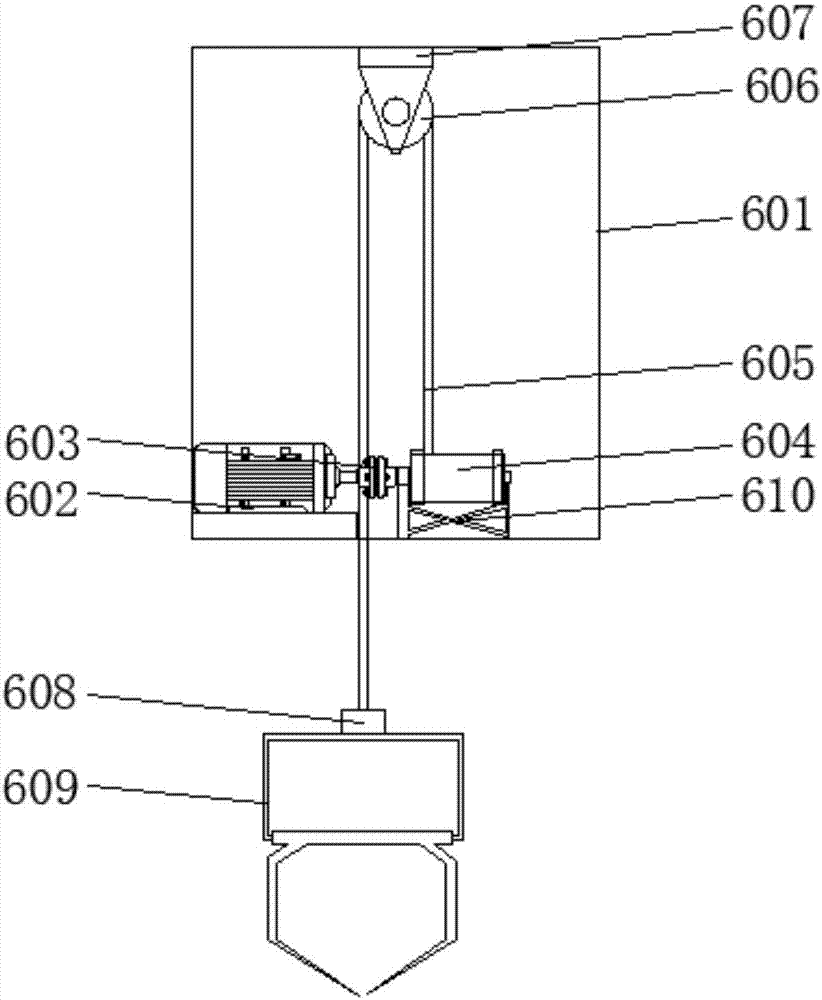

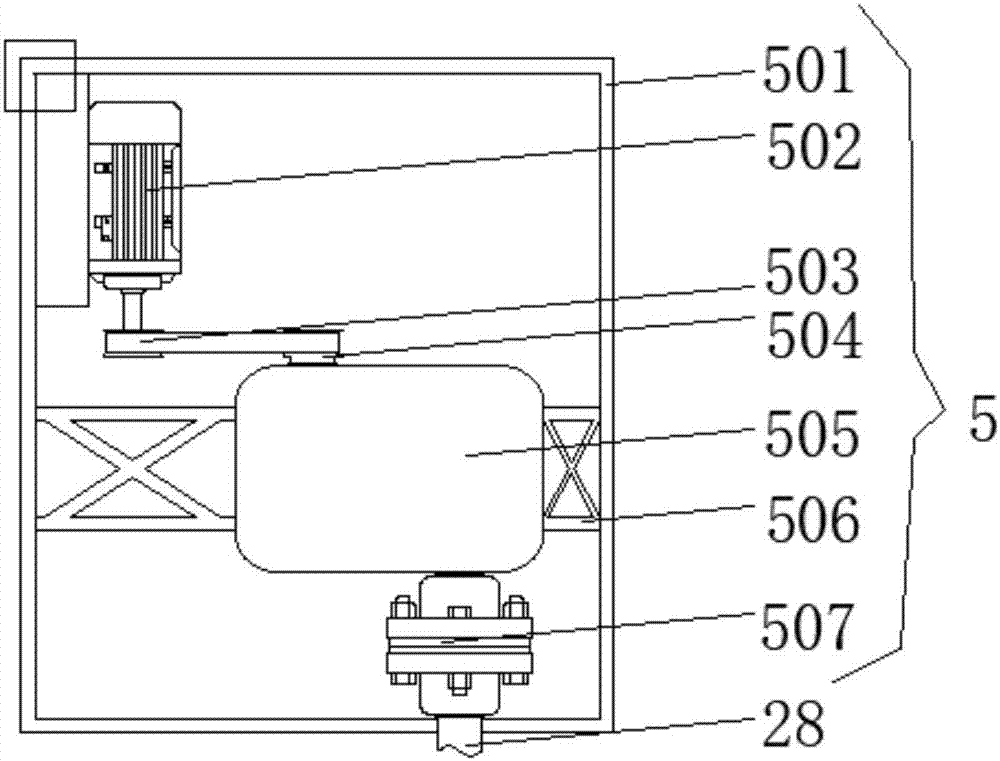

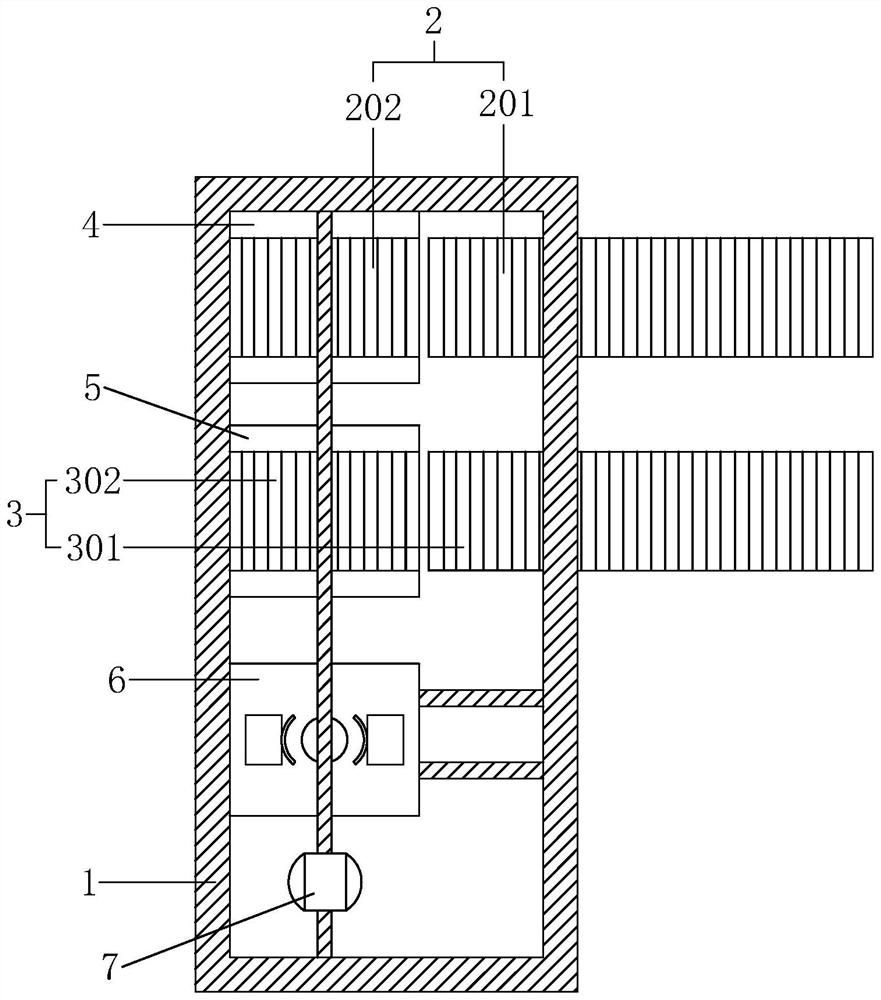

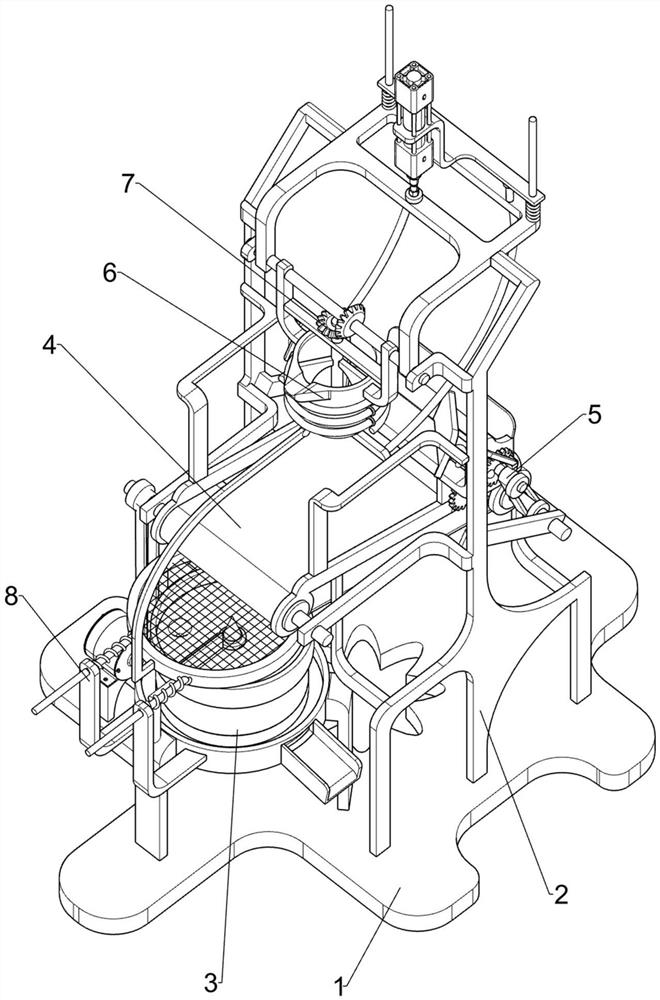

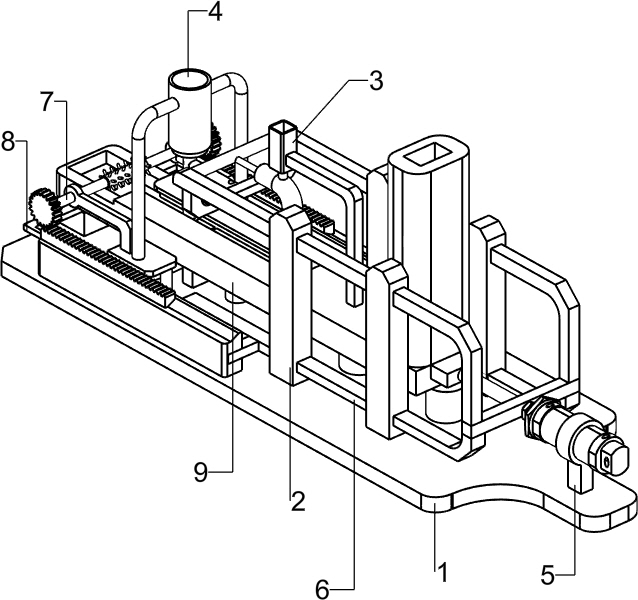

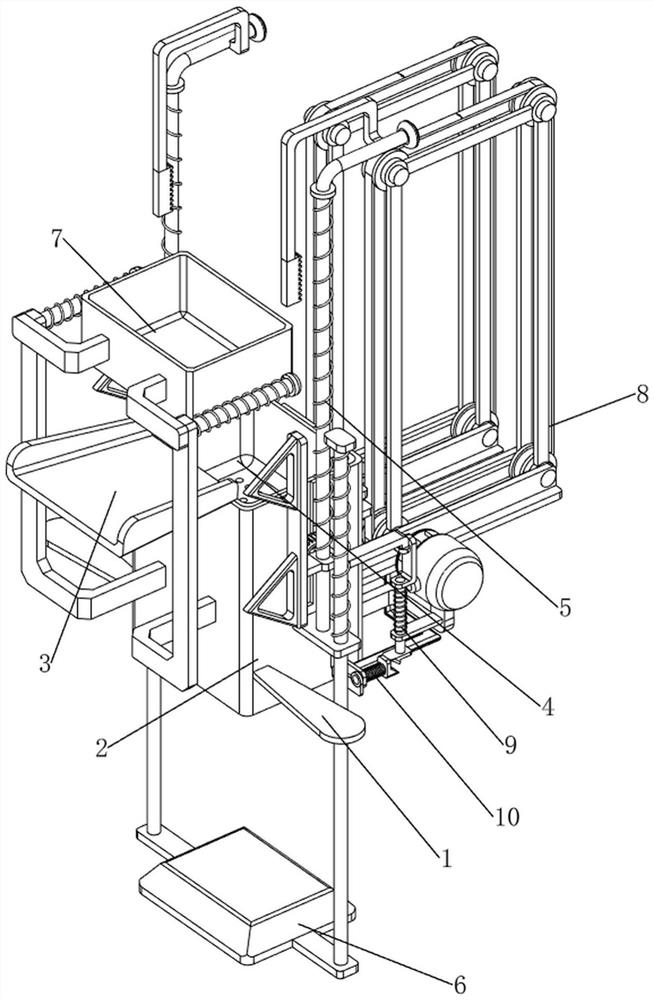

Full-automatic all-in-one machine for rolling moxa

PendingCN109431792ASmall footprintReduce health damageDevices for heating/cooling reflex pointsUltimate tensile strengthMechanical engineering

The invention discloses a full-automatic all-in-one machine for rolling moxa, which comprises a roll-up machine and a moxa feeding mechanism, wherein a roll stand is arranged at one end of a stand ofthe roll-up machine; a paper passing roller, a paper conveying roller, a gluing mechanism, a tamping mechanism and a cloth rolling mechanism are sequentially arranged on the top surface of the stand of the roll-up machine from one end of the roll stand; a strip rolling mechanism is arranged below the tamping mechanism on the bottom surface of the frame of the strip rolling machine; a sliding plateand a conveying belt for guiding moxa sticks are arranged below the strip rolling mechanism; the moxa feeding mechanism is arranged on one side of the strip rolling machine; the moxa feeding mechanism consists of a support frame, a large feed bin and a quantitative feeder. The full-automatic all-in-one machine is simple to operate and easy to use, reduces the labor intensity, saves the labor force, effectively utilizes the space and has a beautiful and elegant appearance.

Owner:南阳普诺瓦自动化设备有限公司

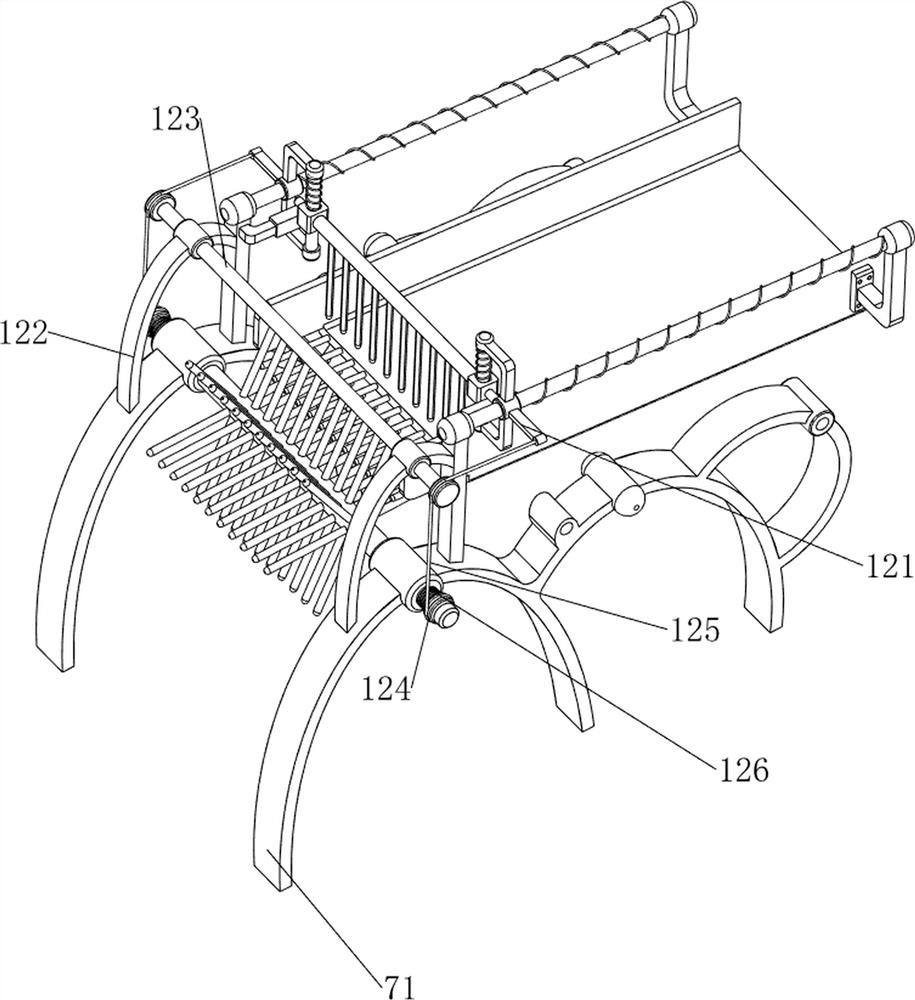

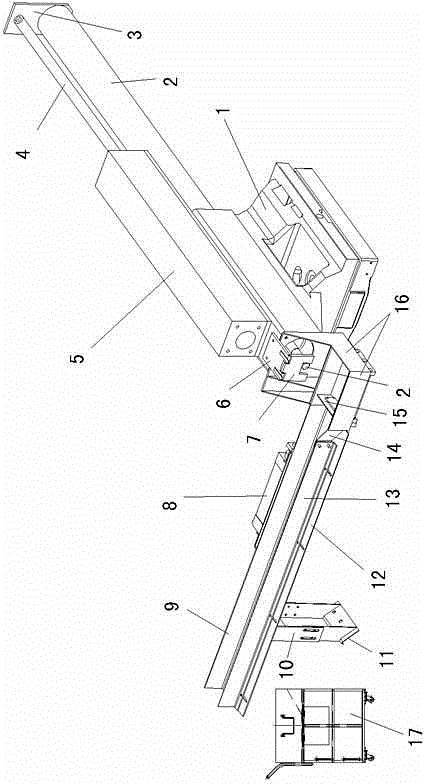

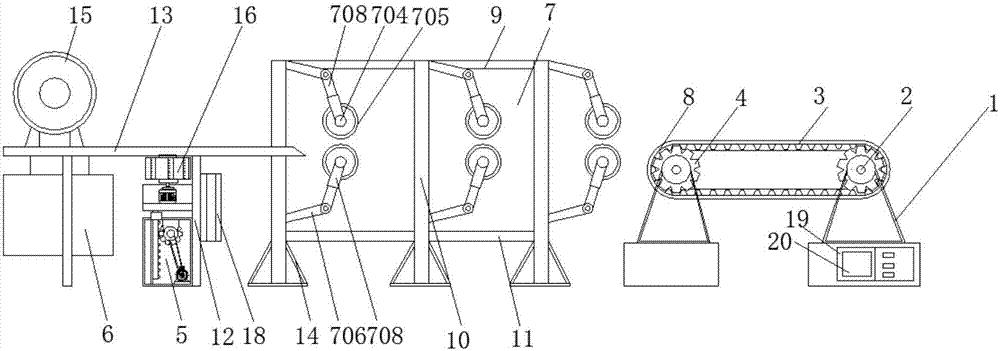

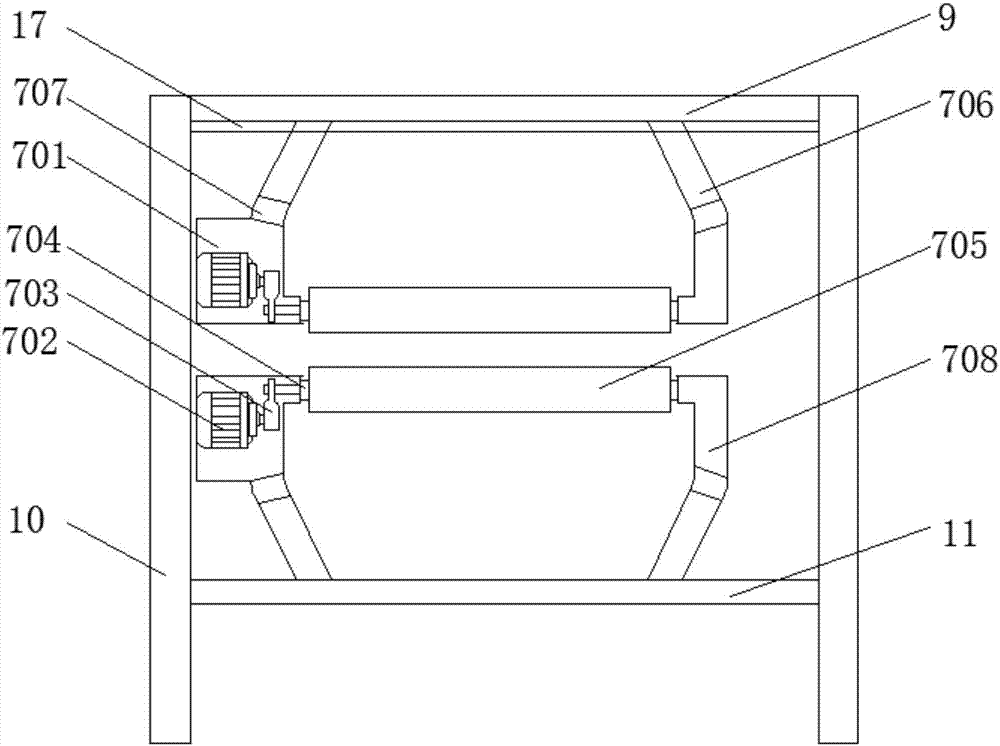

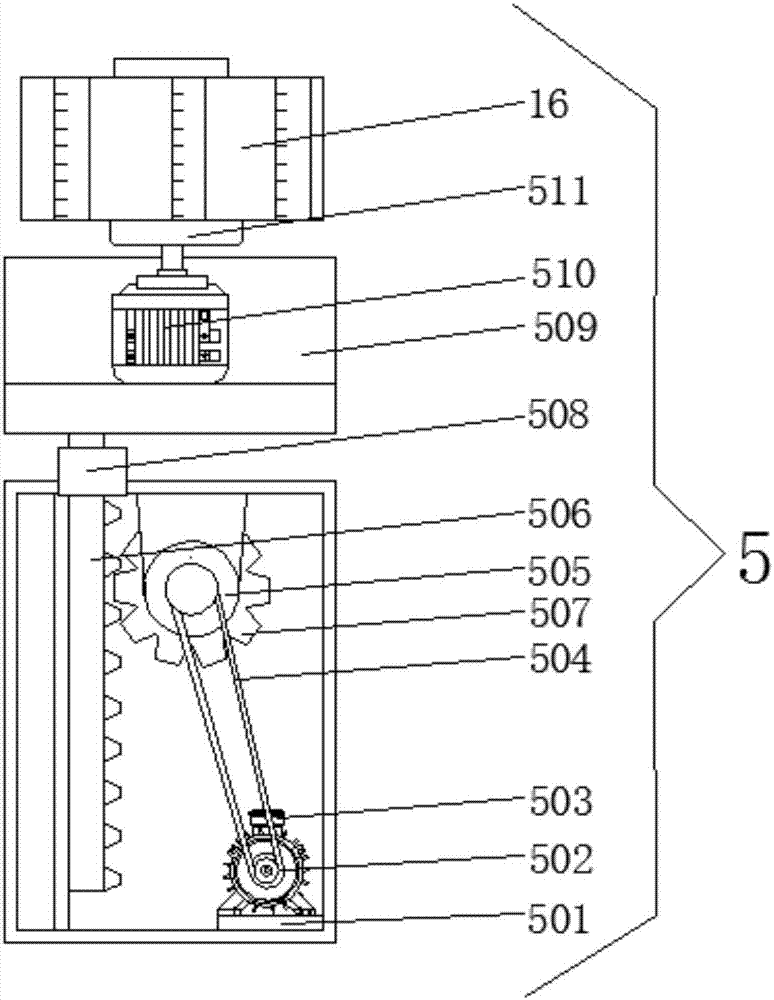

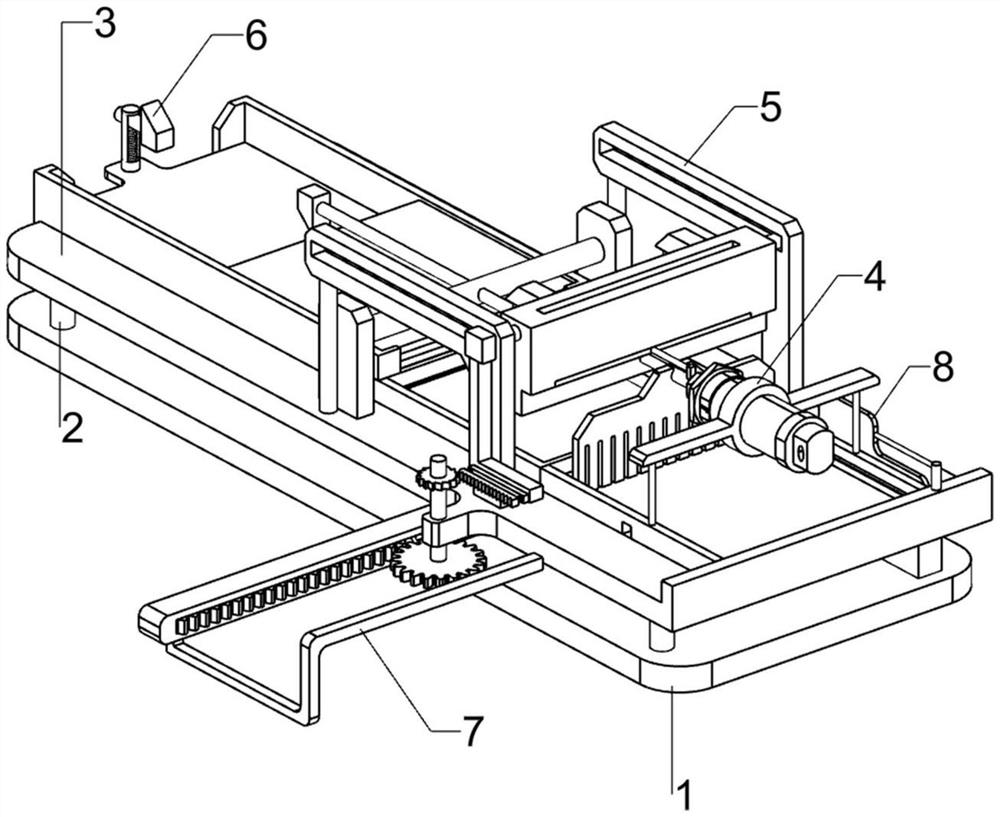

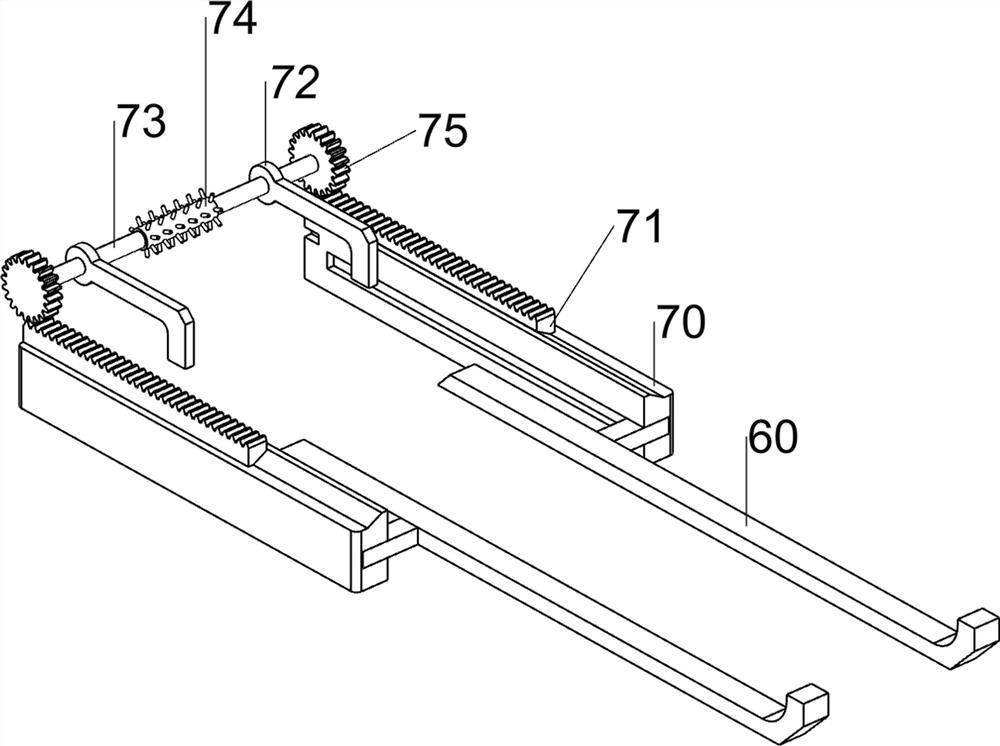

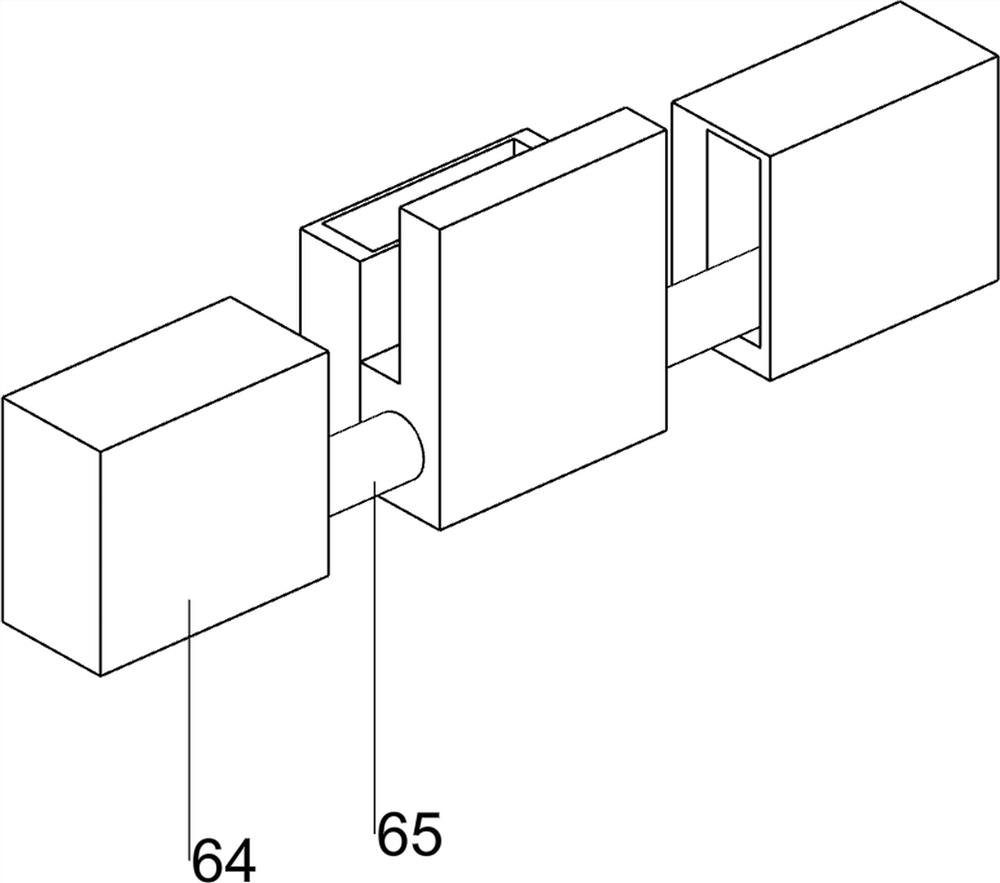

Automatic high-efficiency bamboo processing plate feeding sander

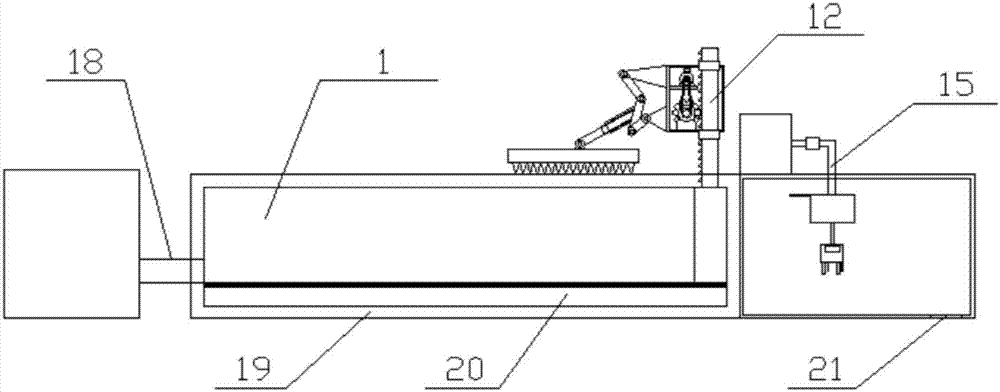

InactiveCN107336100ATo achieve the purpose of automatic feedingGuaranteed speedGrinding feedersGrinding headsSanderEngineering

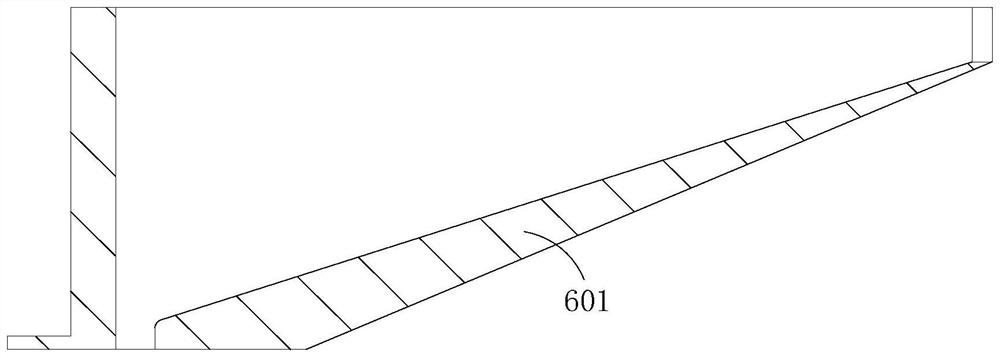

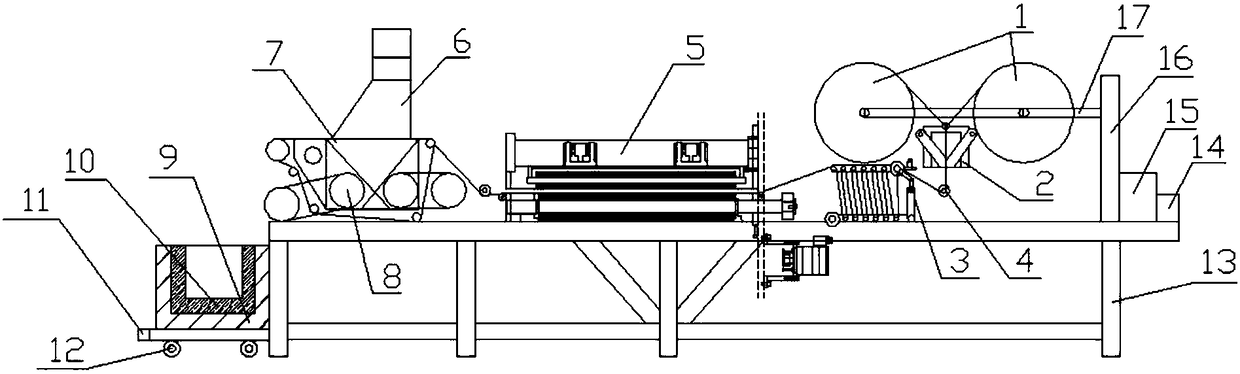

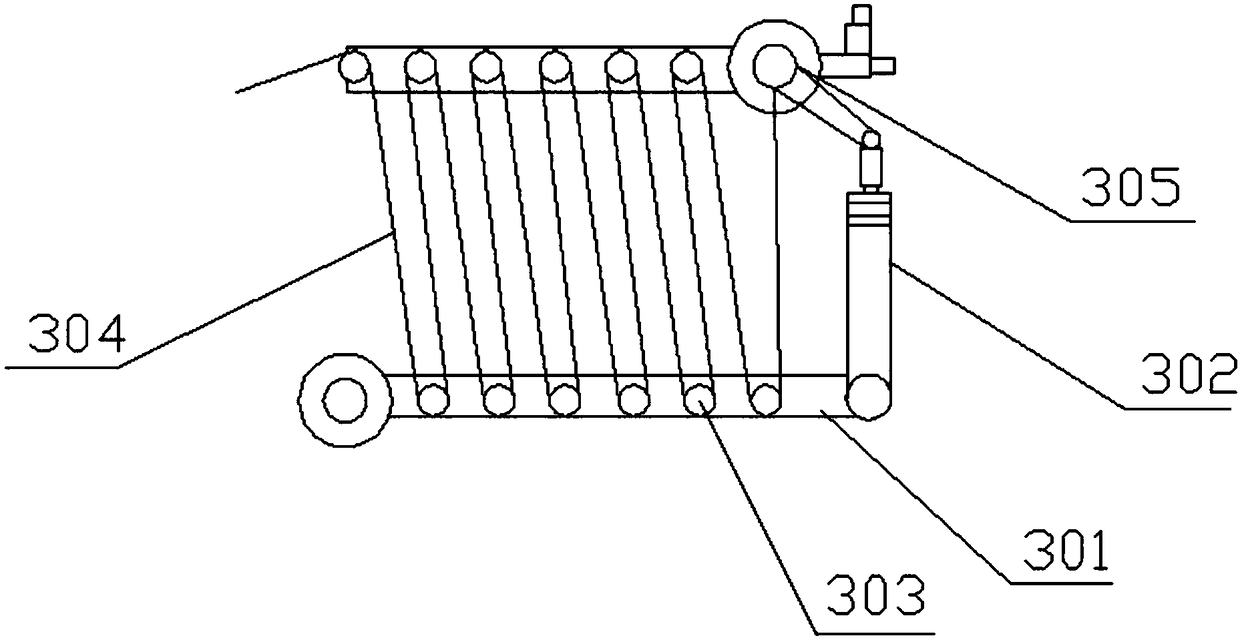

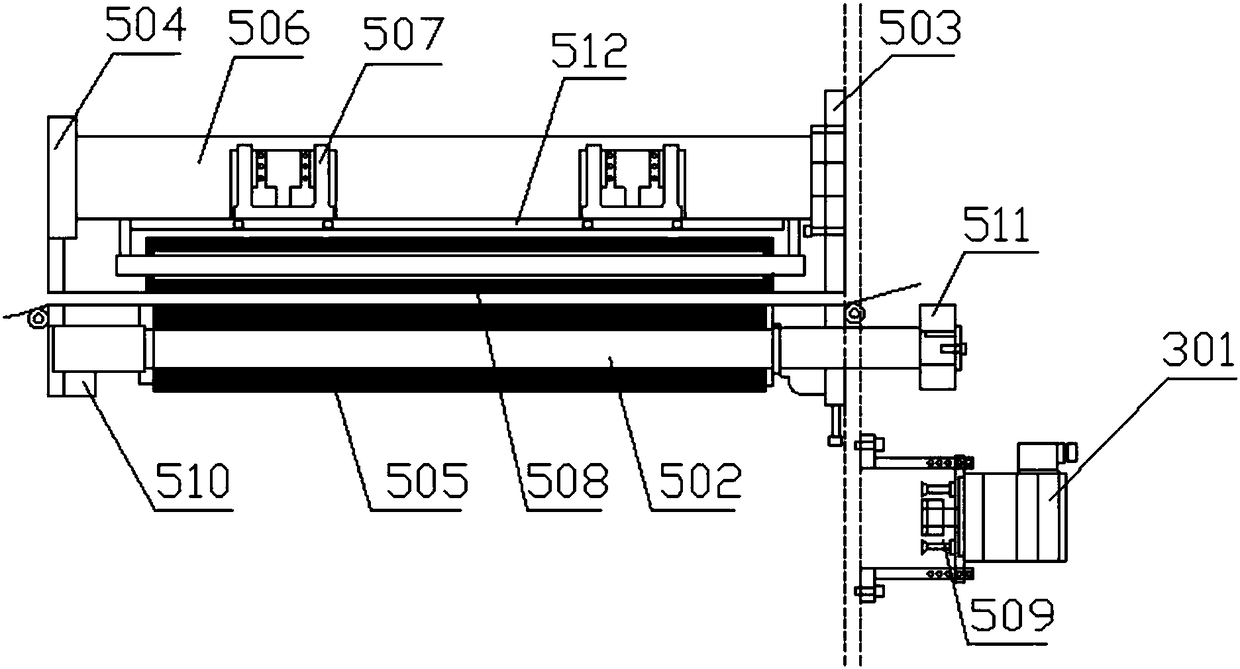

The invention discloses a high-efficiency automatic feeding and grinding machine for bamboo and wood processing boards, which includes a frame. The flat key is fixedly connected with a gear, and the gear is connected with a conveyor belt through rack meshing. A feeding device is provided on the left side of the conveyor belt platform, and a grinding table is provided on the left side of the feeding device. The bottom of the grinding table is fixedly connected to There are frame legs, and the inner walls of the frame legs are fixedly connected with up and down pushing devices. The invention relates to the technical field of bamboo and wood processing machinery. The high-efficiency automatic feeding and grinding machine for bamboo and wood processing boards solves the purpose of automatic feeding and fast grinding, ensures the speed and quality of production, fast and stable feeding for the purpose of fast and comprehensive grinding of bamboo and wood boards, improves production efficiency and reduces staff. The labor intensity and the protection of workers' lives and safety.

Owner:安吉县瑞旺竹木制品厂

Blackboard gluing device with anti-overflow mechanism

ActiveCN112206965APrevent overflowTo achieve the purpose of automatic glue brushingLiquid surface applicatorsCoatingsAdhesive glueStructural engineering

Owner:江西思尔诺科技有限公司

Efficient dust-free cutter for plates

InactiveCN111483015ATo achieve the effect of dust-free cuttingShorten cleaning timeFeeding devicesCircular sawsDust controlElectric machinery

The invention discloses an efficient dust-free cutter for plates, and belongs to the field of plate machining equipment. The efficient dust-free cutter for the plates comprises a conveying roller way,a cutting-off workbench and a cutting-off unit, and further comprises fixing frames, a workbench driving mechanism, a wide edge cutting unit and dust removing units, the fixing frames are arranged onthe two sides of the cutting-off workbench, conveying guide rails are arranged on the fixing frames in the plate conveying direction, the cutting-off workbench is movably connected to the conveying guide rails, the workbench driving mechanism is arranged on the fixing frames and is in transmission connection with the cutting-off workbench, the wide edge cutting unit is arranged on the conveying roller way and comprises a wide edge cutting saw blade driving motor fixed on one side of the conveying roller way and a wide edge cutting saw blade which is in transmission connection with the wide edge cutting saw blade driving motor and is arranged at a plate wide edge cutting position, and the dust removing units are arranged at the cutting-off workbench and the wide edge cutting unit correspondingly and are used for collecting and removing dust generated during cutting. According to the efficient dust-free cutter for plates, through cooperation of the wide edge cutting unit and the movablecutting-off workbench, wide edge cutting and cutting-off operations are conducted on the moving plates at the same time, the machining efficiency is high, and dust dissipation can be greatly reducedthrough the dust removing units.

Owner:ANHUI AIYALUN NEW MATERIAL TECH CO LTD

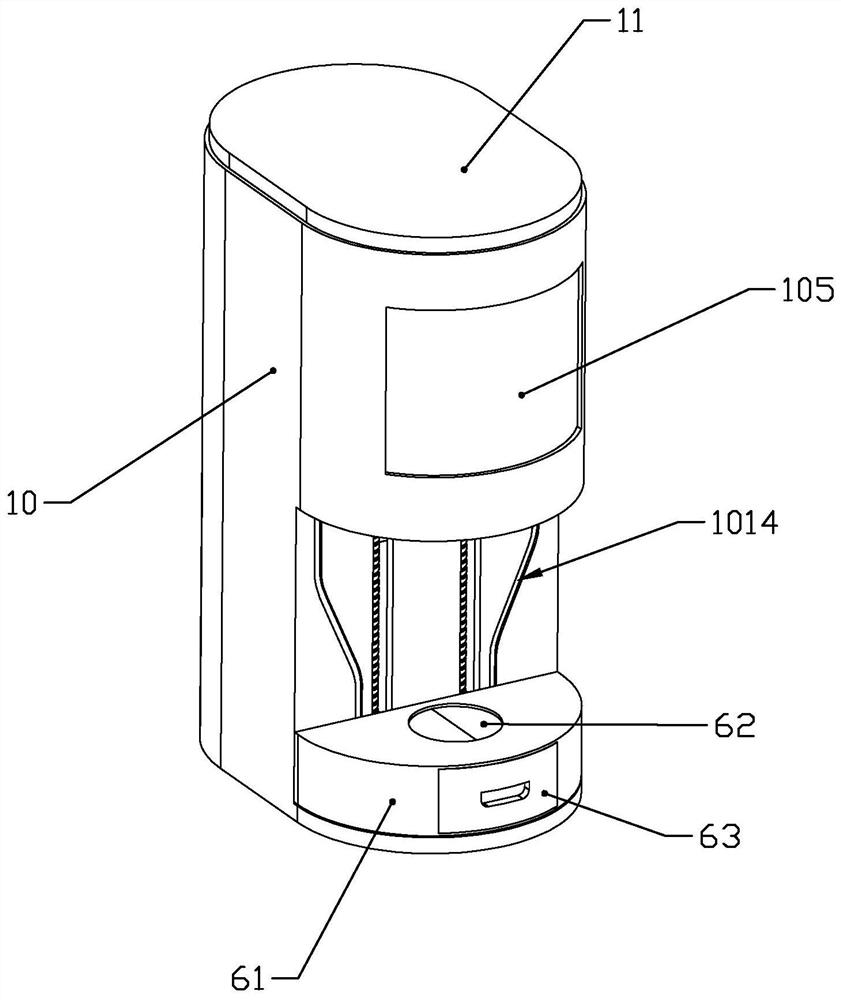

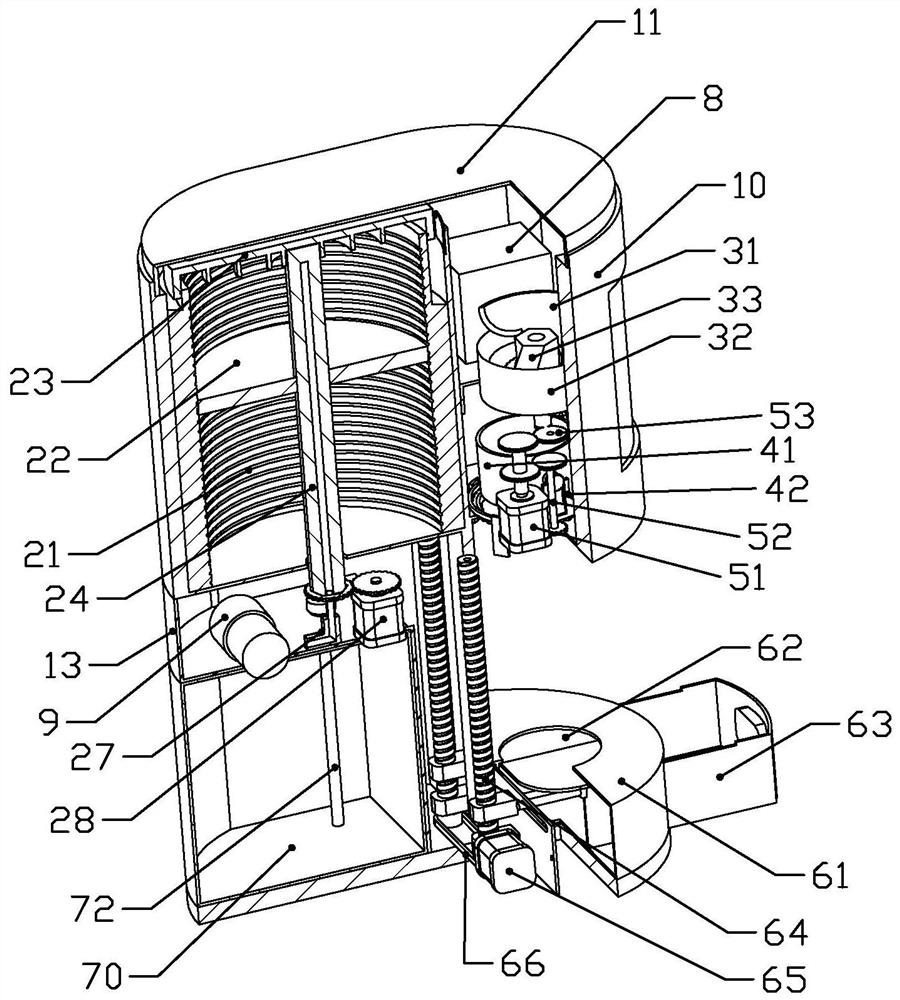

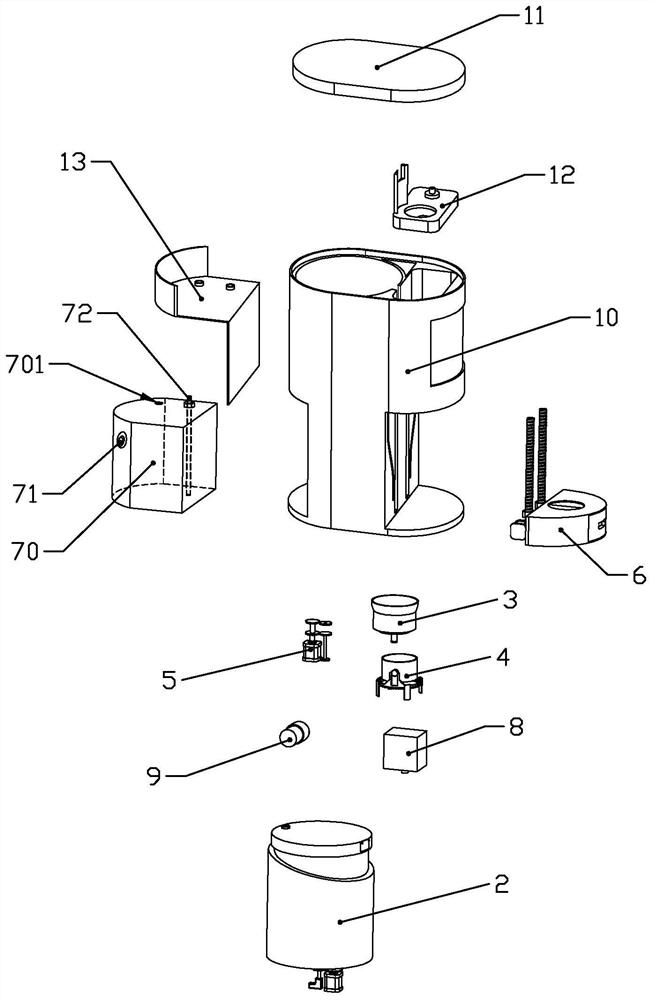

Full-automatic coffee machine

InactiveCN112107226AEasy to storeTo achieve the purpose of automatic feedingBeverage vesselsAgricultural engineeringAir pump

The invention discloses a full-automatic coffee machine, and belongs to the technical field of small household appliances. The full-automatic coffee machine comprises a shell; a filter cup, a grindingassembly and a water tank are installed in the shell; a charging barrel is fixedly connected into the shell; a feeding assembly used for conveying coffee beans in the charging barrel into the grinding assembly is installed in the shell; an air pump for pressurizing the water tank to supply water into the filter cup is fixedly connected into the shell; and an air inlet of the air pump communicateswith the interior of the charging barrel. The full-automatic coffee machine has a coffee bean storage function, and a low-pressure low-oxygen environment can be formed in the charging barrel, so thatthe coffee bean storage time is prolonged; an automatic feeding function is achieved, and coffee beans can be automatically added into a conical grinding hopper according to the coffee demand; and the filter screen cleaning function is achieved, a filter screen can be automatically cleaned, undissolved residues are flushed away, and filtering of the filter screen is smooth all the time. An automatic process is mostly adopted, and the functions of coffee grinding, coffee brewing, cleaning and the like are automatically completed through a touch panel selection function.

Owner:李昆娟

Blackboard surface profiling device with auxiliary turnover mechanism

ActiveCN112406118AFast profilingTo achieve the purpose of automatic dischargeFlat articlesEngineeringMechanical engineering

The invention relates to a blackboard surface profiling device, in particular to a blackboard surface profiling device with an auxiliary turnover mechanism. According to the blackboard surface profiling device with the auxiliary turnover mechanism, the blackboard profiling speed is increased, automatic turnover operation is achieved, and the labor cost is reduced. According to the technical scheme, the blackboard surface profiling device with the auxiliary turnover mechanism is characterized by comprising a supporting base connected with the top of a base, a profiling mechanism connected withthe top side of the supporting seat, and limiting mechanisms connected with the two sides of the profiling mechanism. According to the blackboard surface profiling device, through cooperation of an air cylinder, an air rod, a first hollow cylinder and a contour plate, the purpose of quickly profiling a raw material plate is achieved.

Owner:江西思尔诺科技有限公司

Special-shaped steel pipe machining device for municipal building materials

ActiveCN113059056ATo achieve the purpose of automatic punchingAvoid compromising qualityLiquid surface applicatorsMetal-working feeding devicesPunchingArchitectural engineering

The invention relates to a machining device, in particular to a special-shaped steel pipe machining device for municipal building materials. The invention provides the special-shaped steel pipe machining device for the municipal building materials, which has the advantages that automatic punching, automatic clearing and automatic paint brushing can be realized. The special-shaped steel pipe machining device for the municipal building materials comprises a supporting frame, punching cutters, a conveying mechanism and a downward pressing mechanism, the downward pressing mechanism is arranged in the middle of the top side of the supporting frame, the three punching cutters are arranged on the downward pressing mechanism, and the conveying mechanism is arranged on the supporting frame. According to the special-shaped steel pipe machining device for the municipal building materials, the conveying mechanism and the downward pressing mechanism are arranged, so that people make the conveying mechanism operate intermittently, special-shaped steel pipes move rightwards intermittently, then the downward pressing mechanism conducts intermittent punching on the special-shaped steel pipes, and therefore the purpose of automatic punching is achieved; and a clearing mechanism is arranged, the downward pressing mechanism operates to drive the clearing mechanism to operate, so that the clearing mechanism clears chippings at the punching positions of the special-shaped steel pipes, and therefore the purpose of automatically clearing the chippings is achieved.

Owner:宁夏信泰达建设工程有限公司

Water-based timed feeding device for agricultural cultivation

InactiveCN111567463ALower resistanceReduce germ infectionClimate change adaptationPisciculture and aquariaWater useThermal dilatation

The invention relates to the technical field of agricultural cultivation, and discloses a water-based timed feeding device for agricultural cultivation. The feeding device comprises a floating plate;a metal ball is arranged at the rear end of a first plugging device; an air bag is arranged on the lower side of the first plugging device; an adjusting device comprises a thermal expansion material and a sliding rod; a disc is arranged at the left portion of a swing rod; a heating wire is arranged on the left side in a discharging device; a photoresistor is arranged on the right side of the discharging device; and a round hole is formed in a second plugging device. Expanded air enters the air bag through a one-way valve in a first pipe groove; a second pipe groove pushes the second plugging device; feed in a storage bin is thrown through a discharge hole and the round hole; at night, an expansion material contracts to drive the sliding rod to rotate; the air in the air bag is exhausted through an air outlet pipe; a feed box quantitatively supplements feed to the storage bin through a feed inlet; and the feeding device solves the problems that the feed cannot be automatically and quantitatively thrown and the feed can only be thrown at regular time once in the prior art.

Owner:周邦成

Automatic feeding system for solid waste treatment

ActiveCN113277333AReduce work intensityReduce exposureConveyorsBottle emptyingProcess engineeringWaste treatment

The invention discloses an automatic feeding system for solid waste treatment, and aims at solving the problems that in the solid waste feeding process, the labor intensity of operators is large, and the physical health is affected. The key point of the technical scheme lies in that the device comprises an outer frame and an inner working part, wherein the inner working part comprises a first conveying working part, a first lifting working part and an overturning working part; a long oil cylinder is connected between the overturning working part and the outer frame; the overturning working part comprises a connecting part, a hydraulic clamping device and an overturning oil cylinder; a cylinder barrel of the overturning oil cylinder is fixedly connected with the connecting part; and an output shaft of the overturning oil cylinder is fixedly connected with the hydraulic clamping device. According to the device, automatic feeding of solid waste is achieved, the working intensity of operators is reduced, and meanwhile, contact between the operators and the solid waste is reduced, and the influence of the solid waste on the body health of the operators is avoided to a great extent.

Owner:兰溪恒生机床制造有限公司

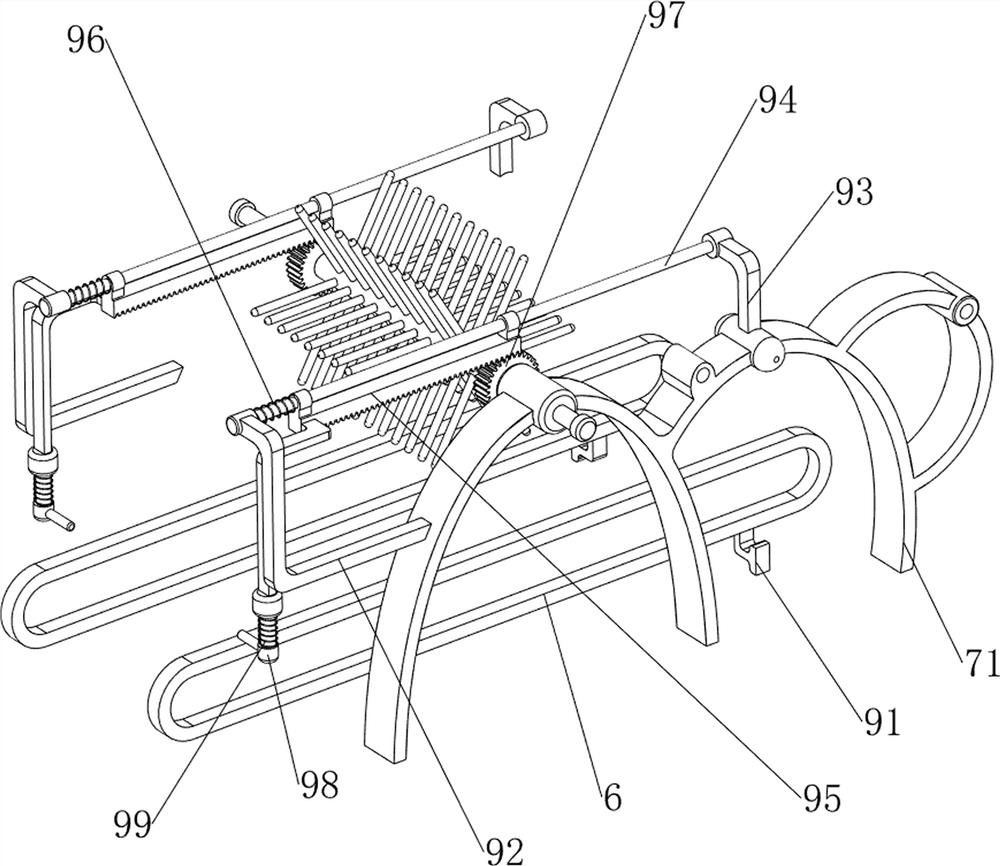

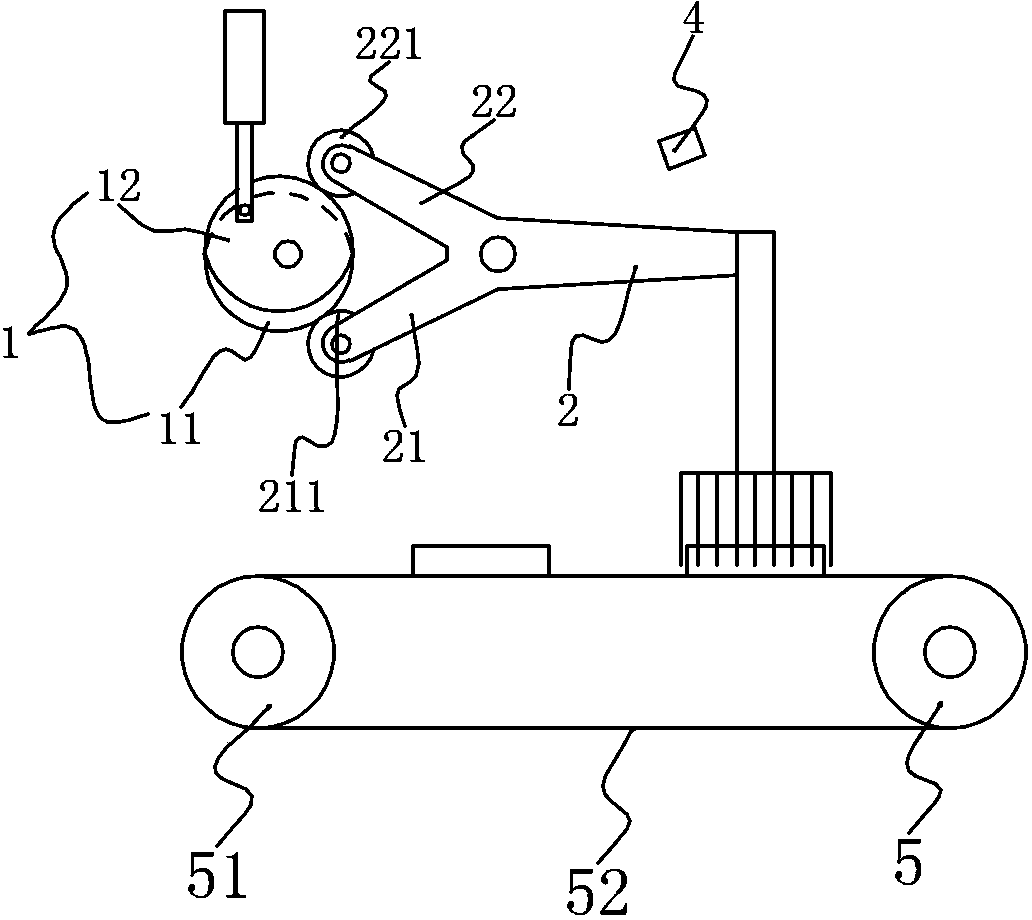

Double-cam food feeding and slicing mechanism

InactiveCN103707352ATo achieve the purpose of automatic feedingMetal working apparatusCamDrive wheel

The invention relates to a double-cam food feeding and slicing mechanism. A cam set is driven to rotate through an air cylinder; because the cam set is divided into two cams attached to each other, the protruding edges of the cams can extrude cam driven wheels at the ends of supporting rods in the rotating process of the cam set. Further, because the middle of a cutter rod is hinged to a support, the cutter bit end of the cutter rod rotates along with rotation of the cam set under the action of the cam set. As long as the cam set keeps rotating, the cutter rod will keep feeding materials repeatedly in a swinging mode. Because a driving belt wheel is hinged to the support, while the materials are conveyed by a conveying belt, the materials can be sliced in the conveying process as long as the placement position of the materials is calculated, and the double-cam food feeding and slicing mechanism has high machining efficiency and machining precision. The double-cam food feeding and slicing mechanism is simple in structure and convenient to clean and disinfect.

Owner:CHONGQING JIDING FOOD

Electric welding machine used for machining of shell of high-voltage transformer

ActiveCN105855677AStable cooling effectImprove continuous operation abilityWelding/cutting auxillary devicesHeat-exchange elementsContinuous operationEngineering

The invention provides an electric welding machine used for machining of a shell of a high-voltage transformer. An automatic feeding device and an oil cooler are arranged on the electric welding machine. The automatic feeding device comprises a feeding channel, a first pushing air cylinder and a second pushing air cylinder. The first pushing air cylinder is used for pushing materials. The second pushing air cylinder is used for pushing the materials out of the automatic feeding device. Materials are rotated in the feeding channel. Elastic pieces are arranged on an inlet channel portion of the feeding channel. The materials are squeezed by the elastic pieces, so that the materials are made to adhere to a baffle till the materials reach an electric welding station, and thus the purpose of automatic feeding is achieved. In addition, the oil cooler hung on the electric welding machine is hung stably and communicates with the interior of the electric welding machine, the oil cooler is used for cooling the electric welding machine, the cooling effect is stable and rapid, the continuous operation capacity of the electric welding machine is improved, the machining efficiency of the shell of the high-voltage transformer is improved to a great extent, and accordingly the production efficiency of enterprises is improved. Meanwhile, the invention discloses novel cooling oil, the novel cooling oil is flexible in heat balance capacity and extremely high in heat conducting capacity, and thus the cooling effect of the interior of the electric welding machine is guaranteed.

Owner:SUQIAN GENERAL MACHINERY

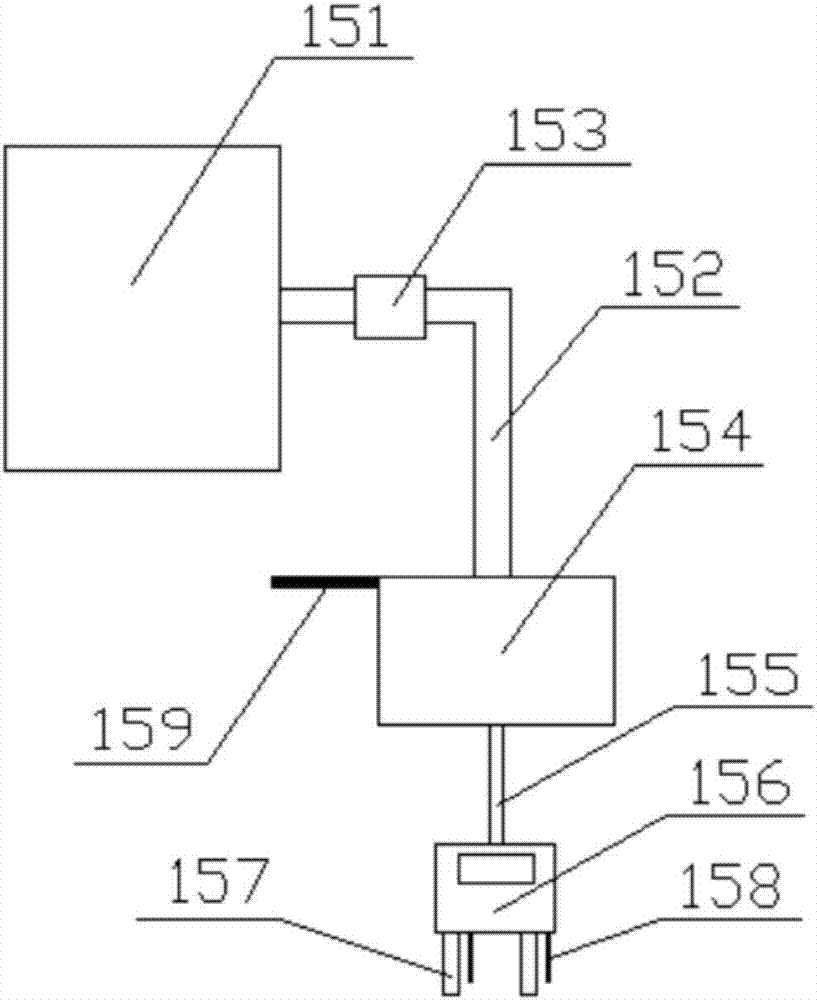

Automatic feeding and water supplying device for poultry breeding

InactiveCN107568110ATo achieve the purpose of automatic feedingImprove cleanlinessAvicultureWater pipeEngineering

The invention relates to the technical field of poultry breeding and discloses an automatic feeding and water supplying device for poultry breeding. The device comprises a storage tank, a hopper is arranged at the left top end of the storage tank, and the joint of the storage tank and the hopper is provided with a feeding port. A driving device is arranged at the right end of the hopper, a rotating plate is arranged in the top middle of the inner wall of the storage tank, and stirring rods are arranged on supporting rods which are arranged on the lower surface of the rotating plate. A first water guide pipe is communicated with the middle of the inner wall of the storage tank, feeding pipes are communicated with two sides of the bottom end of the storage tank respectively, the other end ofeach feeding pipe is communicated with a feed trough, and an automatic cleaning device is fixedly connected to the right end of the inner wall of the feed trough. A water tank is arranged at the right end of the outer wall of the feed trough, the upper end of the water tank is communicated with a second water guide pipe, and automatic water supply devices are distributed at uniform intervals on the second water guide pipe. The automatic feeding and water supplying device for poultry breeding has advantages that automatic feeding, automatic water supplying and automatic cleaning are realized,and high automation level is achieved.

Owner:湖州绿昌生态农业有限公司

an automatic feeder

InactiveCN104012422BTo achieve the purpose of automatic feedingAvoid wastingAnimal feeding devicesProgramme control in sequence/logic controllersEngineering

The invention relates to an automatic feeder which comprises a hollow rotating shaft driven by a motor. The upper end of the rotating shaft is provided with a storage compartment for storing a feed. The storage compartment is communicated with a cavity of the rotating shaft through a blanking door. The lower end of the rotating shaft extends into a mixing compartment which is communicated with the cavity of the rotating shaft. Agitating vanes are fixedly arranged at the lower end of the rotating shaft. A water pump conveys water to the mixing compartment. The downside of the mixing compartment is provided with a circular feeding compartment. The bottom of the mixing compartment is communicated with the feeding compartment through a discharge door. Signals of pigs are sensed through infrared rays, and the motor, the blanking door, the water pump, the discharge door, a valve and the like are started by the utilization of a control center. Thus, the feed and water are mixed and stirred, and the mixture enters a feeding area so as to achieve the purpose of automatic feeding. By timely burdening and timely supply and by controlling temperature of the mixture, the feed for pigs is fresh and is appropriate in amount. Thus, waste is avoided.

Owner:HUNAN WEIYE BIOTECH

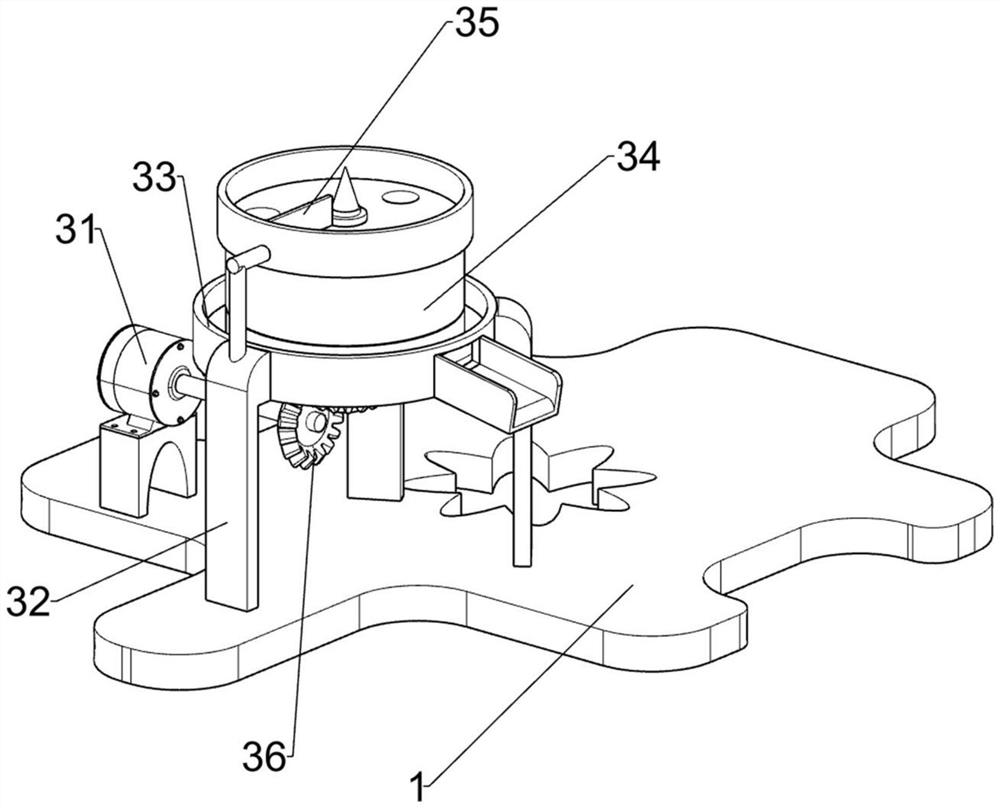

Grinding and crushing mechanism for calcium carbonate extraction

ActiveCN112676018ATo achieve the purpose of automatic grindingTo achieve the purpose of automatic feedingSievingScreeningThermodynamicsMetallurgy

The invention relates to a grinding and crushing mechanism, in particular to a grinding and crushing mechanism for calcium carbonate extraction. The invention provides a grinding and crushing mechanism for calcium carbonate extraction, which can automatically crush, grind and screen calcium carbonate. A grinding and smashing mechanism for calcium carbonate extraction comprises a bottom plate and a support, wherein the support is arranged on the bottom plate, a grinding mechanism is arranged on the bottom plate, a conveying mechanism is arranged on the support, and the conveying mechanism is matched with the grinding mechanism. By arranging the grinding mechanism, the grinding mechanism operates and grinds calcium carbonate, so that blocky calcium carbonate is ground into powder, and the purpose of automatic grinding is achieved; by arranging the crushing mechanism, the conveying mechanism operates to drive the crushing mechanism to operate; the crushing mechanism crushes blocky calcium carbonate, and the effect of automatic crushing is achieved; and by arranging the screening mechanism, a liquid extraction mechanism operates to drive the screening mechanism to operate, and the screening mechanism screens crushed calcium carbonate solids, so that the purpose of automatic screening is achieved.

Owner:江西科越科技有限公司

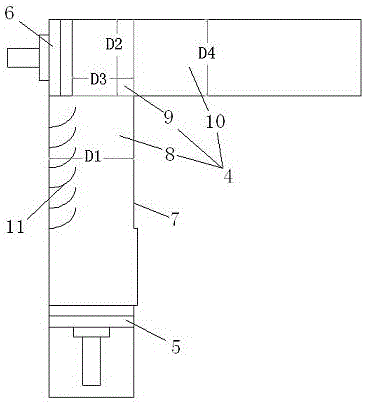

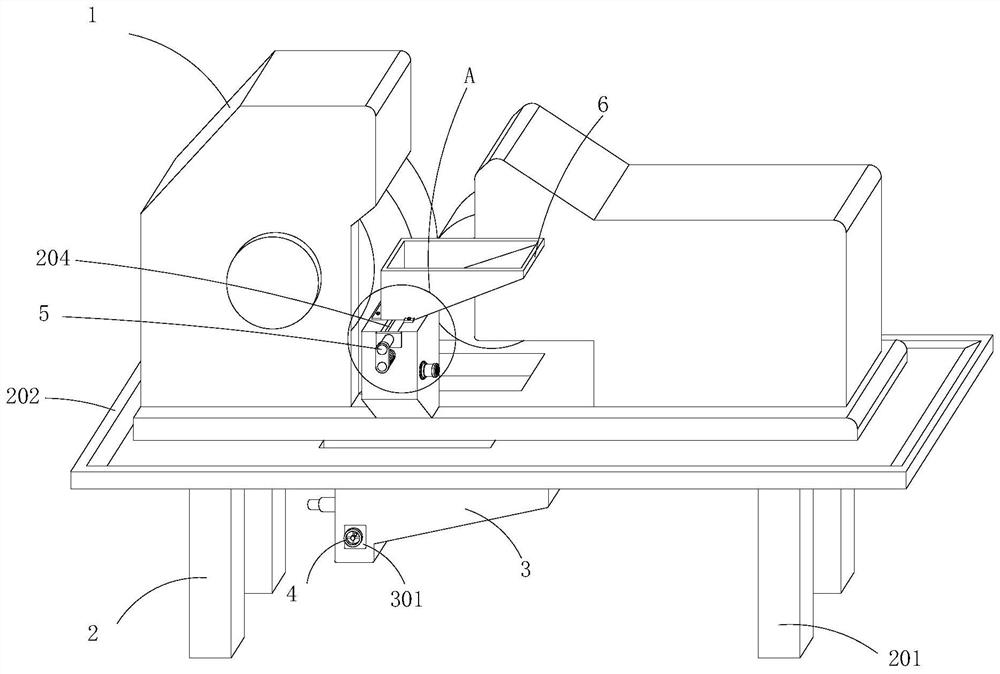

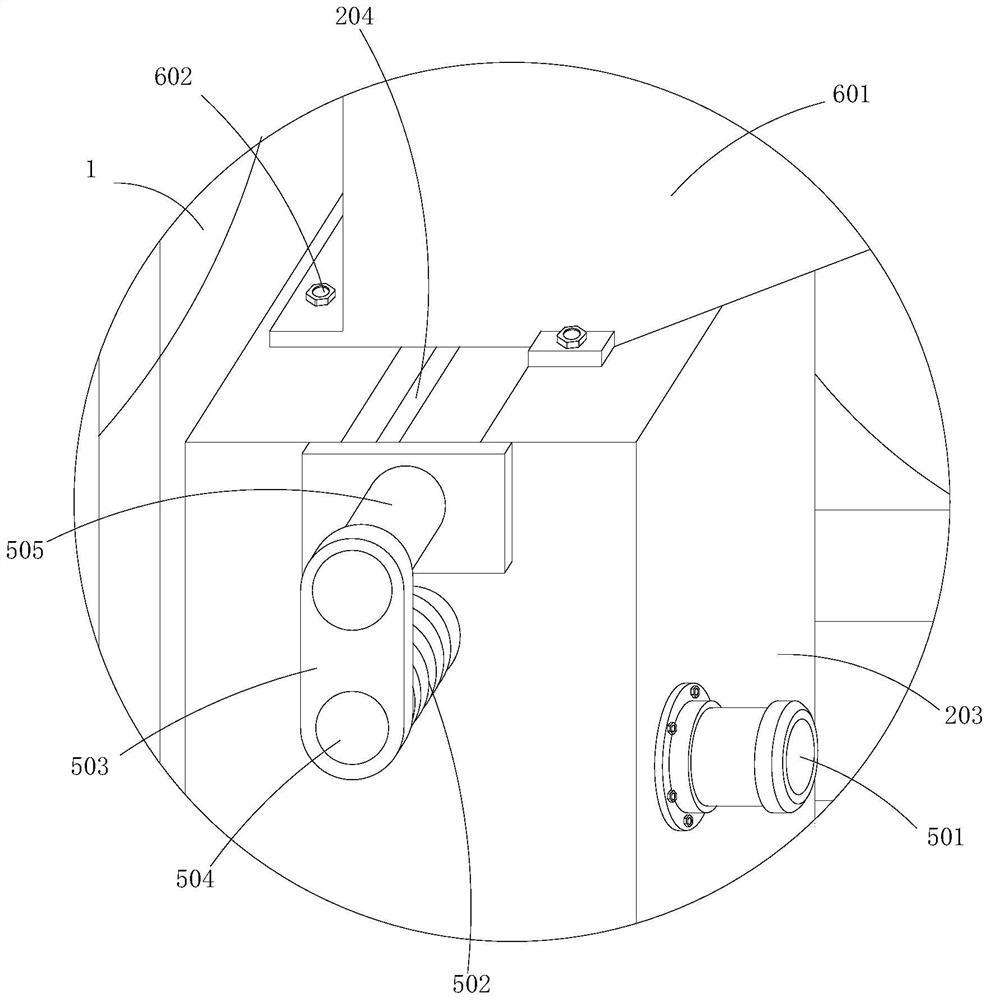

Automatic feeding centerless grinding machine equipment

PendingCN114850985APrevent flowPlay a supporting roleRevolution surface grinding machinesGrinding/polishing safety devicesWater flowProcess engineering

The invention discloses centerless grinding machine equipment with an automatic feeding function. Comprising a centerless grinding machine body, a bearing structure arranged on the centerless grinding machine body and used for supporting and bearing, a feeding structure arranged on the centerless grinding machine body and used for automatic feeding, a discharging structure arranged on the feeding structure and used for loading, and a precipitation structure arranged on the bearing structure and used for precipitating metal scraps. The limiting structure is arranged on the precipitation structure and used for limiting, and the adsorption structure is arranged on the precipitation structure and used for adsorption; water flow during grinding can be received through the bearing structure and prevented from flowing to the ground, the device is supported, the feeding structure can automatically conduct feeding under cooperation of the discharging structure, metal chippings and dust in water can be conveniently precipitated through the precipitation structure and the limiting structure, and therefore discharged water can be conveniently subjected to backflow utilization; and precipitation of metal scraps can be promoted through the adsorption structure.

Owner:杭州萧山鹏达汽车部件制造有限公司

Automatic receiving baby diaper punching production line

PendingCN108247735AAchieve the purpose of punchingHigh degree of automationSanitary towelsMetal working apparatusProduction linePunching

The invention discloses an automatic receiving baby diaper punching production line and relates to the technical field of baby diaper processing machinery. The production line comprises a dischargingroll, and a shaft of the discharging roll is fixedly connected to a supporting rod through a connecting rod; the discharging roll and a zero-speed changing and receiving device are in transmission connection with a tension device through a traction device; the tension device is in transmission connection with a punching machine through a traction device, and the punching machine is in transmissionconnection with a cotton core forming device through a traction device; a feeding box is arranged at the upper end of the cotton core forming device, the bottom of the feeding box is fixedly communicated with a forming air bucket, rotating shafts are arranged on the inner side and the outer side of the forming air bucket, and a receiving trolley is arranged on the left side of a rack; a sensor iselectrically connected with a control system and an intelligent controller. The automatic receiving baby diaper punching production line achieves automatic receiving, the purposes of punching beforea diaper cotton core is formed and high automation degree are achieved, and the production efficiency is improved.

Owner:湖南洁韵生活用品有限公司

Lens cleaning device

PendingCN112547631AReach addUsabilityDrying solid materials without heatFlexible article cleaningOphthalmologyEngineering

The invention relates to a cleaning device, in particular to a lens cleaning device. The invention aims to provide the lens cleaning device for automatically cleaning the lens, improving the cleanliness of the lens and enhancing the practicability of the device. According to the technical scheme, the lens cleaning device is characterized in that the lens cleaning device comprises supports, a cleaning frame, a detergent adding mechanism, and a washing mechanism, wherein the two sides of the top of a base are connected with two supports; the top side of the base is connected with the cleaning frame; the detergent adding mechanism is connected between the supports in a sliding manner; and the washing mechanism is connected between the two sides of the top of the base. Through the cooperationof a pushing rod, a detergent box, a moving rod and a piston, the purpose of adding and using detergents is achieved.

Owner:刘怀安

Energy-saving and environment-friendly river water garbage recycling and treating device

InactiveCN113006022AEasy to collectPrevent outflowWater cleaningEnvironmental engineeringMechanical engineering

The invention relates to a recycling and treating device, and particularly relates to an energy-saving and environment-friendly river water garbage recycling and treating device. The energy-saving and environment-friendly river water garbage recycling and treating device is convenient to operate and capable of automatically receiving materials and automatically blocking the materials. The energy-saving and environment-friendly river water garbage recycling and treating device comprises supporting plates, a connecting frame, a water pouring plate, a screening frame, a rotary material pouring mechanism and a water blocking mechanism, wherein the connecting frame is connected between the two supporting plates, the water pouring plate is arranged on the connecting frame, the screening frame is arranged on the inner side of the connecting frame in a sliding mode, the rotary material pouring mechanism is arranged on the connecting frame, the water blocking mechanism is arranged on the rotary material pouring mechanism, and the water blocking mechanism is matched with the connecting frame. According to the energy-saving and environment-friendly river water garbage recycling and treating device, a material receiving mechanism is arranged, the screening frame rotates and pours garbage into the material receiving mechanism, so that the purpose of automatic material receiving is achieved; and an automatic driving mechanism is arranged, the automatic driving mechanism enables the screening frame and the garbage to move upwards, so that the purpose of automatic ascending is achieved, and the operation is simple and convenient.

Owner:GUANGZHOU SHENJING INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com