Double-cam food feeding and slicing mechanism

A double cam, food technology, applied in metal processing and other directions, can solve the problems of different slice thickness and difficulty in ensuring hygiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

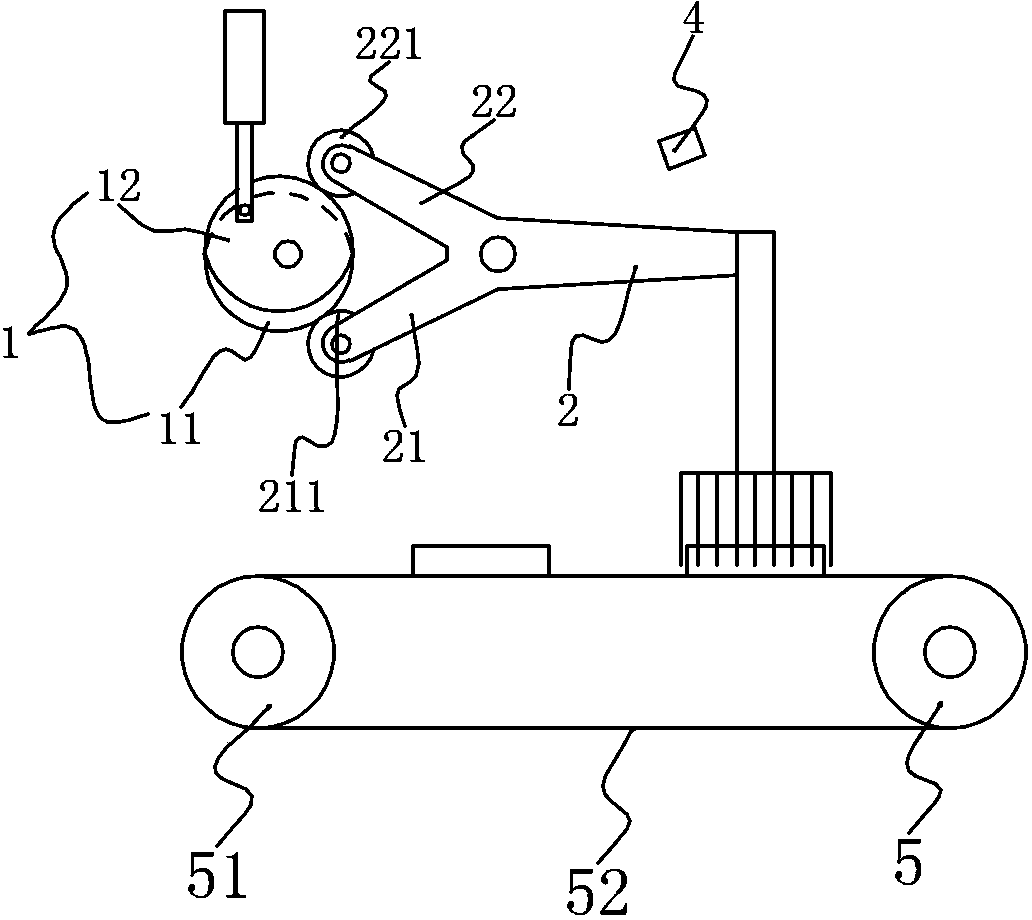

[0011] Such as figure 1 As shown, the double-cam food feeding and slicing mechanism includes a vertically arranged bracket, and a cylinder is arranged on the bracket, and the piston rod of the cylinder is eccentrically hinged on the cam group 1. The cam group 1 includes a left cam 11 and a right cam 12 that fit together. Left cam 11 and right cam 12 cam portions do not overlap; a knife bar 2 is also provided on the support, and the middle part of the knife bar 2 is hinged with the support. The cutter bar 2 includes a cutter head end and a driving end in contact with the cam set 1, and multiple rows of blades for clamping materials are arranged on the cutter head end. A driving pulley 5 is hinged on the support, and a driven pulley 51 is also hinged on the support. The driving pulley 5 and the driven pulley 51 are connected by a conveyor belt 52 . This driving end is divided into upper strut 21 and lower strut 22, and the end of upper strut 21 is hinged with upper cam follower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com