Automatic feeding device of cooking apparatus

A technology of a feeding device and cooking equipment, which is applied in the directions of cooking utensils, household utensils, applications, etc., can solve the problems of incapability of mass production, inability to apply non-liquid food materials, inapplicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

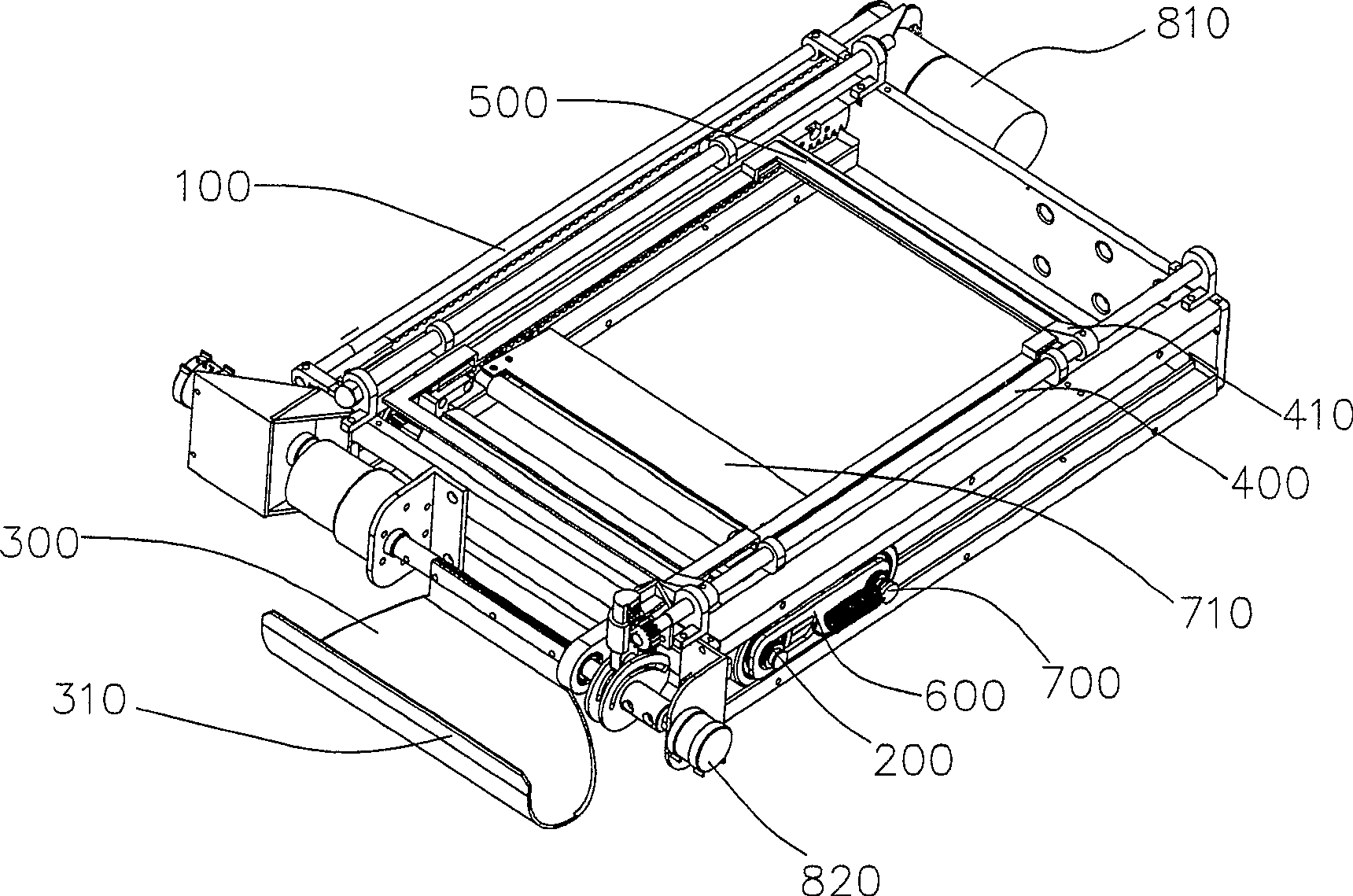

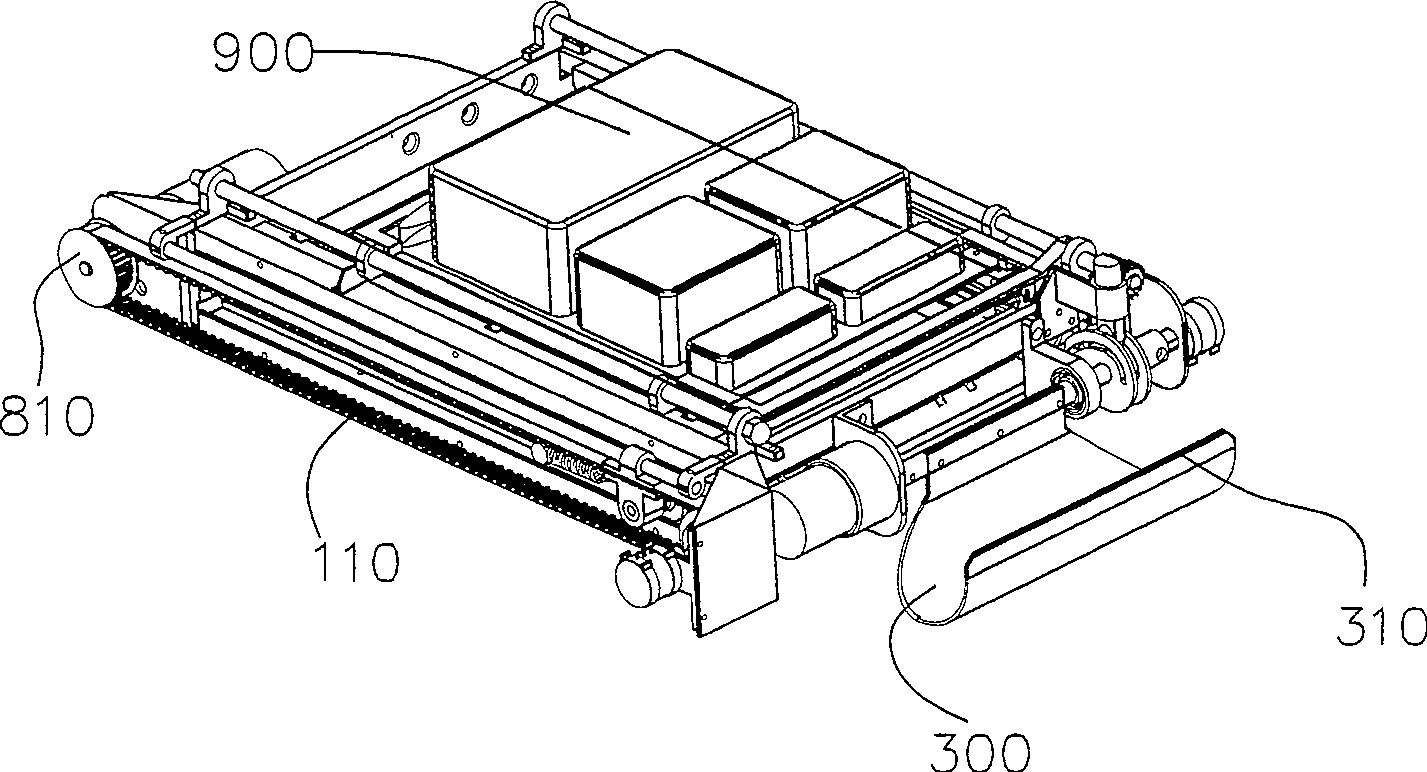

[0041] Please refer to figure 1 and figure 2 , the feeding device of the present invention is used in automatic cooking equipment to put the materials packaged in the material box 900 into the pot according to a predetermined program. The material box 900 includes a material box body with several compartments and a material box for The packaging film that closes the compartment, the packaging film is provided with a packaging film head, the packaging film head is separated from the magazine body, and has an appropriate length, the packaging film is provided with a tearing film along the edge of the magazine body Open line.

[0042] The feeding device includes a frame body 100, a film roll shaft 200 capable of rotating / rolling in the frame body 100, and a press for pressing the packaging film of the material box 900 into the opening of the film roll shaft 200. The film device 300 , and a cartridge positioning device 400 for positioning the cartridge 900 in the frame body 100...

Embodiment 2

[0050] Please refer to Figure 7 , As another embodiment of the present invention, a driven shaft 700 can be further designed. The driven shaft 700 and the film rolling shaft 200 are combined through the coupling plate 600 . The driven shaft 700 is provided with a film support plate 710 . It is used to keep the film tearing line vertical and tangent to the inner side of the film reel 200, so as to ensure that the material does not pollute or stick to the film reel 200 when feeding.

[0051] The drive belt 110 can also be designed as a V-shaped belt or a flat belt, correspondingly fixing a V-shaped wheel or a flat wheel that rotates synchronously with the film winding shaft 200 at both ends.

[0052] The drive belt 110 or the rack 120 can be correspondingly arranged on both sides of the frame body 100 .

[0053] The elastic element can also be elastic rubber or other elastic materials.

[0054] The feeding device can be applied to automatic or semi-automatic cooking equipment...

Embodiment 3

[0060] Please refer to Figure 8 , another embodiment of the feeding device of the present invention. The magazine 900 is fixed on the frame 170, and the motor 830 installed on the fixed plate 181 drives the clamping body 224 to move along the slide bar 226 to the other clamping body 223 through the lead screw 225, and the film head is clamped (the film head Located on the left edge of the material box 900 in the figure), the motor 840 drives the belt 111 mounted on the pulley 112 to move, and the connecting body 171 connected to the frame 170 drives the frame 170 and the material box 900 fixed thereon to the diagram Move in the middle left to separate the sealing film from the material box (the figure shows the state where the sealing film has been partially torn off).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com