Efficient dust-free cutter for plates

A cutter and board technology, applied in the direction of wood processing equipment, sawing components, sawing equipment, etc., can solve the problems of low processing efficiency, inability to simultaneously cut and wide-edge cutting, and achieve the effect of ensuring the workshop environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

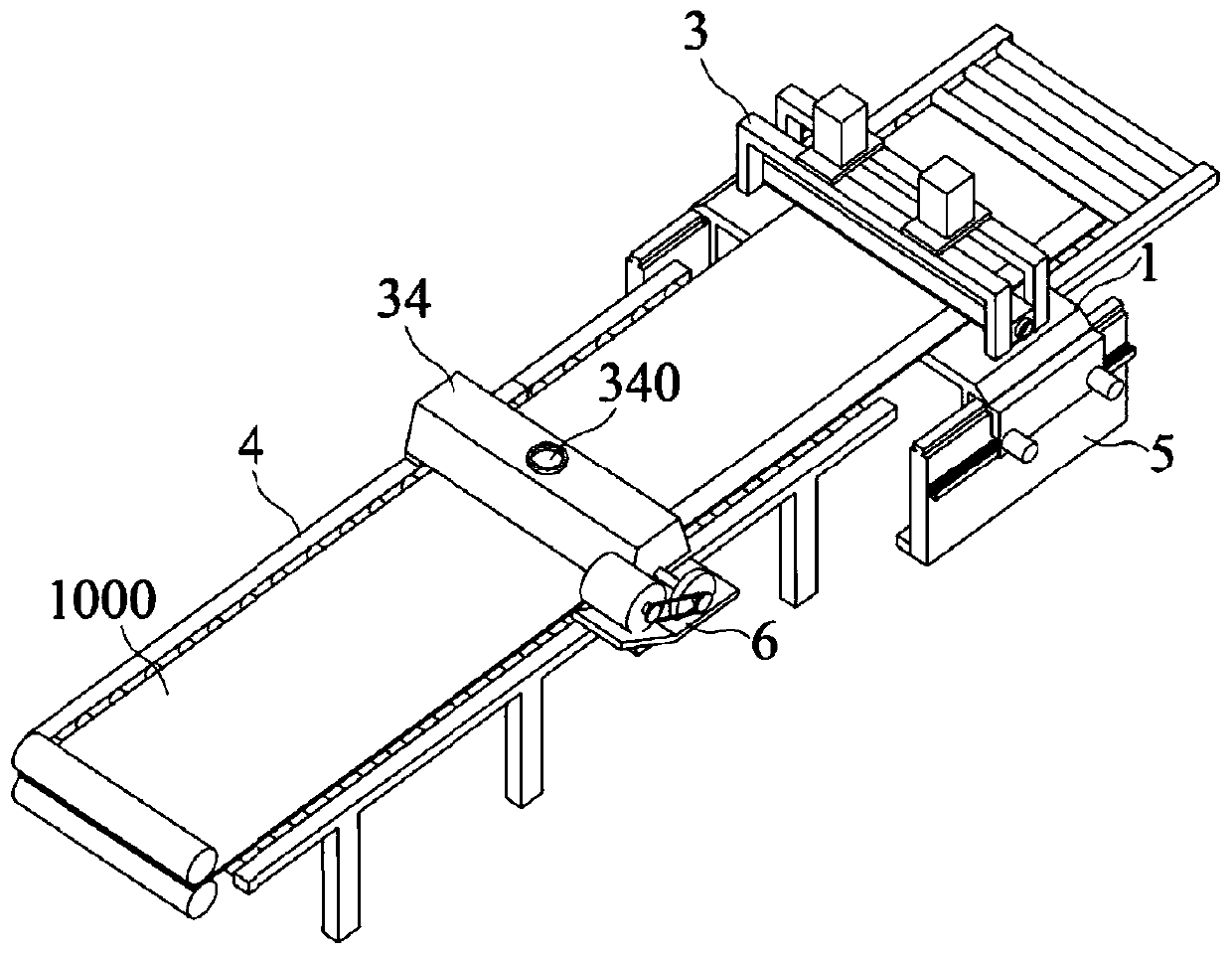

[0078] Such as figure 1 , figure 2 and image 3 As shown, the high-efficiency dust-free cutter for plates in this embodiment includes,

[0079] Transport roller table 4, which transports 1000 plates to be cut;

[0080] The cutting table 1 is arranged in front of the end of the conveying roller table 4, and carries the plate to be cut 1000 transported from the conveying roller table 4, and the cutting table 1 is provided with a saw blade cutting opening 10 through the width direction;

[0081] The cutting unit 2 is arranged under the cutting workbench 1, and the saw blade of the cutting unit 2 passes through the cutting opening 10 of the saw blade to cut the plate 1000;

[0082] Also includes:

[0083] The fixed frame 5 is arranged on both sides of the cutting workbench 1, and the transportation guide rail 50 is arranged on the fixed frame 5 along the transportation direction of the plate 1000, and the cutting workbench 1 is movably connected to the transportation guide ra...

Embodiment 2

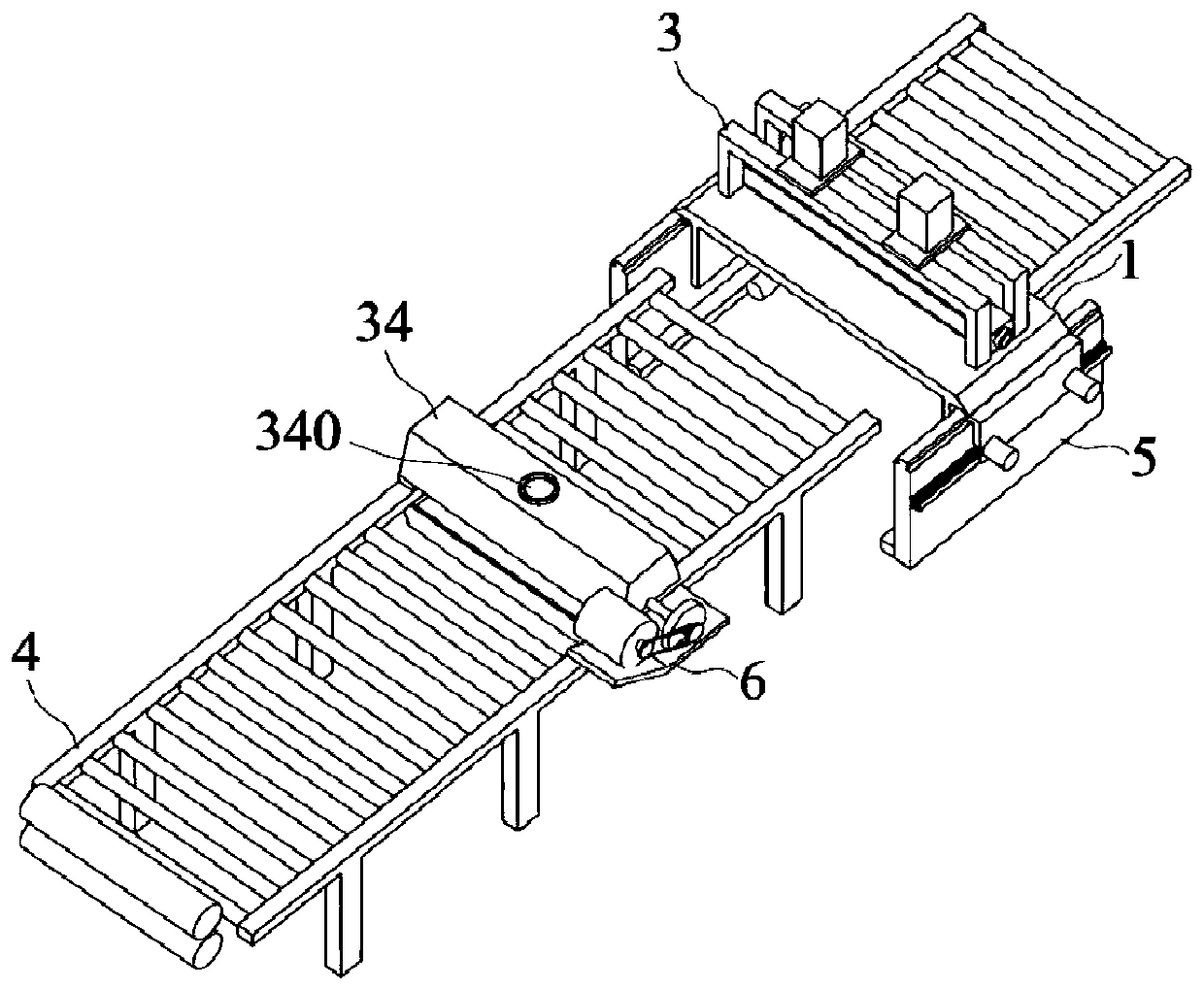

[0092] Such as Figure 4 As shown, the high-efficiency dust-free plate cutter of this embodiment is further improved on the basis of Embodiment 1. The dust removal unit 3 at the broadside cutting unit 6 includes a wideside cutting dust removal cover 34, which is symmetrically arranged on Above and below the transport roller table 4, wrap the wide-side cutting part; the wide-side cutting dust removal cover 34 is provided with a wide-side cutting dust removal air hole 340, and the wide-side cutting dust removal air hole 340 communicates with the dust removal air duct .

[0093] The wide-side cutting dust cover 34 arranged symmetrically up and down can completely wrap the wide-side cutting place up and down, and the dust generated during wide-side cutting will be collected by the wide-side cutting dust cover 34, and further cut the wide-side dust cover 34 is provided with a dust removal air hole 340 at the wide edge cutting part, and the dust removal air duct of the workshop dus...

Embodiment 3

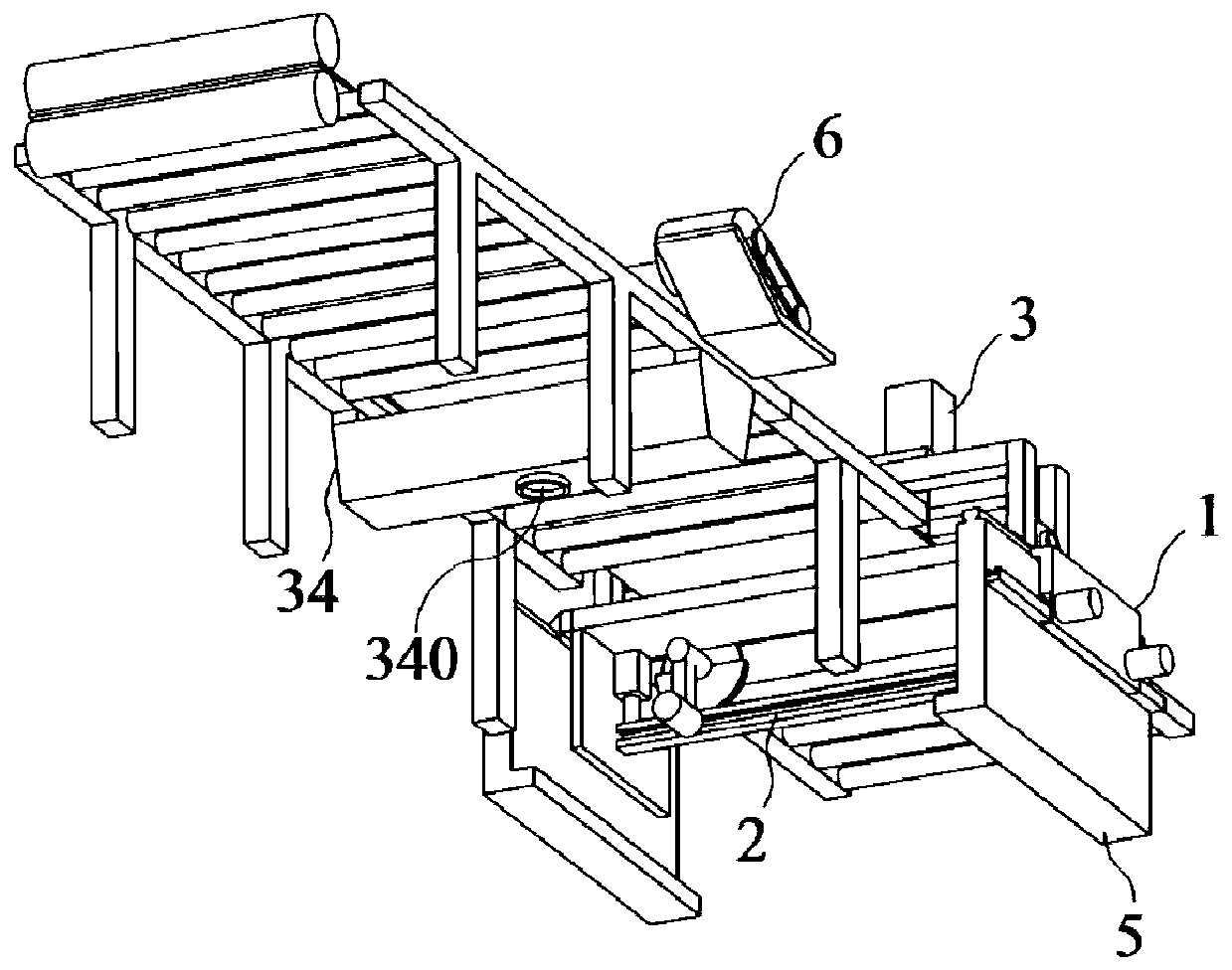

[0095] Such as Figure 6 and Figure 7 As shown, the high-efficiency dust-free cutter for plates in this embodiment is further improved on the basis of Embodiment 2, and the dust removal unit 3 at the cutting workbench 1 includes:

[0096] A guide support frame 30, which is fixedly connected to the upper surface of the cutting table 1, and is arranged above the cutting edge 10 of the saw blade;

[0097] Dust removal pressure cover 31, which is a hollow cover body with an opening at the bottom, is located directly above the saw blade cutting opening 10. Dust removal pressure cover 31 is movably connected with guide support frame 30, and moves vertically up and down under the limit position of guide support frame 30;

[0098] Dust removal pressing cover drive mechanism 32, it is fixedly connected on the guide support frame 30, drives dust removal pressing cover 31 to move;

[0099] An upper dust removal air hole 310 is opened at the end of the dust removal pressure cover 31 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com