Cutting device for part machining

A cutting device and parts processing technology, applied in the field of metal parts cutting, can solve the problems of cleaning up affecting the normal operation of the device, reducing the work efficiency, affecting the processing progress, etc., and achieving the effects of convenient cleaning, saving resources and improving cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

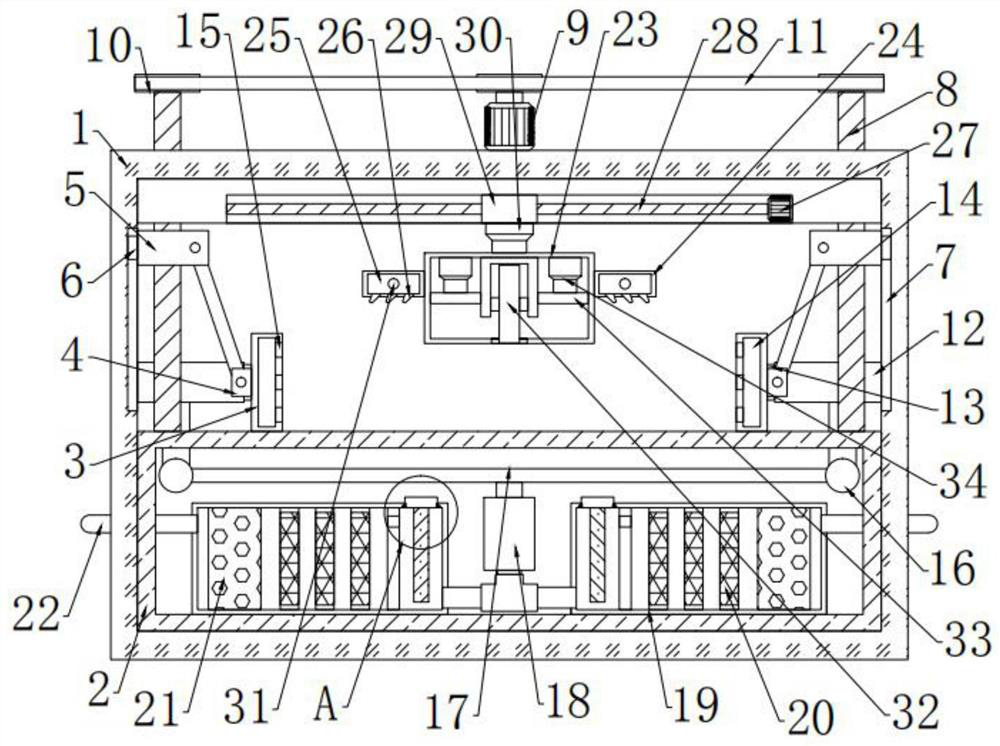

[0026] see Figure 1-4 , in an embodiment of the present invention, a cutting device for parts processing, including a housing 1, the inner side of the housing 1 is fixedly connected with a placement table 2, and the upper side of the placement table 2 is provided with a cutting mechanism, the Clamping mechanisms for fixing parts are arranged on the left and right sides of the cutting mechanism, and the clamping mechanisms are connected with the filter box 19 arranged on the inner side of the placing table 2 through a dust suction mechanism with bolts.

Embodiment 2

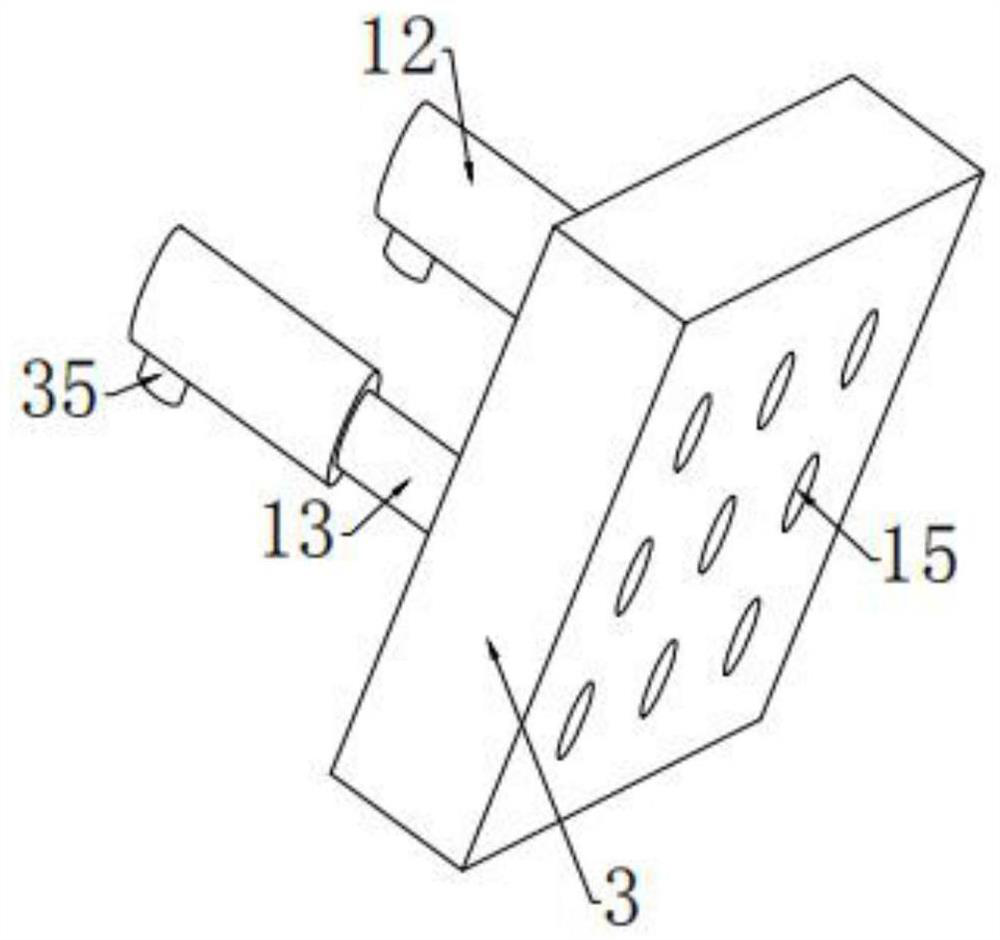

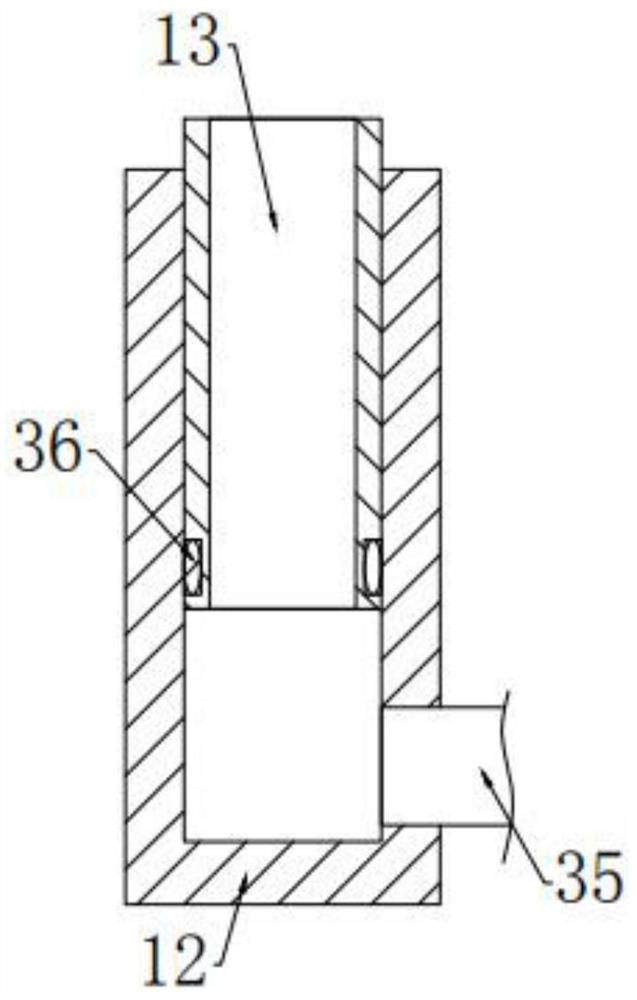

[0028] In this embodiment, the clamping mechanism includes a first motor 9 that is bolted to the top of the housing 1, and the left and right sides of the first motor 9 are provided with threaded rods 8 that are rotatably connected to the housing 1. The outside of the threaded rod 8 and the output end of the first motor 9 are fixedly connected with a pulley 10, and the pulleys 10 are connected by a belt 11, and the outside of the threaded rod 8 is threaded to be provided with a movable block 5, and the movable block The outer side of the 5 is fixedly connected with a guide block 6, and the guide block 6 is slidably connected with the guide groove 7 arranged on the inner side of the housing 1, and the lower side of the movable block 5 on the left and right sides is provided with splints that are slidably connected with the placement table 2 3. The outside of the splint 3 is fixedly connected with a connecting block 4, and a connecting rod is hinged between the connecting block 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com