Electric welding machine used for machining of shell of high-voltage transformer

A high-voltage transformer and electric welding machine technology, which is applied in metal processing, metal processing equipment, welding accessories, etc., can solve the problem of affecting the welding effect and service life of electric welding machines, affecting the processing efficiency of high-voltage transformer shells, and destroying the safety of electric welding machines To achieve the effect of improving continuous operation ability, super heat conduction ability and sensitive heat balance ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

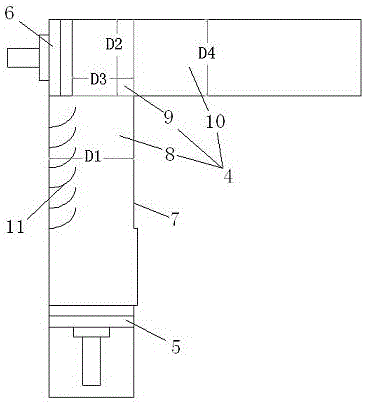

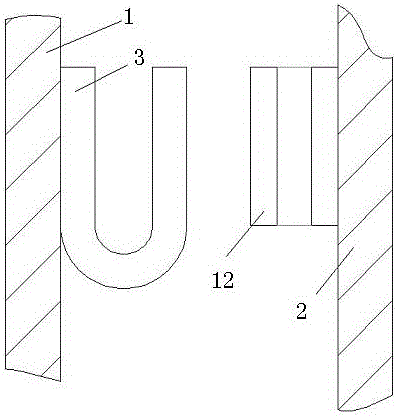

Image

Examples

Embodiment 1

[0043] An electric welding machine for processing high-voltage transformer shells according to the present invention, wherein the preparation method of the novel cooling oil is as follows:

[0044] 1. Take propylene glycol, hexylene glycol and dodecane glycol, put them into a blender in a weight ratio of 1:0.5:3, mix and stir until fully mixed, and obtain a glycol mixture;

[0045] 2. Take polyethylene glycol, ethanol and methanol, put them into a blender in a weight ratio of 1:0.2:0.7, mix and stir until fully mixed to obtain an organic mixture;

[0046] 3. Take sodium hydroxide and potassium hydroxide, mix and stir at a ratio of 1:0.5 until fully mixed to obtain a caustic mixture;

[0047] 4. Add the diol mixture and organic matter in steps 1 and 2 into the preparation kettle, heat and stir, raise the temperature to 95°C and keep it warm for 1.2 hours, then let it stand and cool down to normal temperature to obtain mixture A;

[0048] 5. Add caustic mixture to deionized wat...

Embodiment 2

[0052] An electric welding machine for processing a high-voltage transformer shell of the present invention, wherein the preparation method of the novel cooling oil is as follows:

[0053]1. Take propylene glycol and dodecane glycol, put them into a blender at a weight ratio of 1:2.5, mix and stir until fully mixed to obtain a glycol mixture;

[0054] 2. Take ethanol and methanol, put them into a blender at a weight ratio of 1:0.6, and mix and stir until fully mixed to obtain an organic mixture;

[0055] 3. Take sodium hydroxide and potassium hydroxide, mix and stir at a ratio of 1:0.7 until fully mixed to obtain a caustic mixture;

[0056] 4. Add the diol mixture and organic matter in steps 1 and 2 into the preparation kettle, heat and stir, raise the temperature to 102°C and keep it warm for 1.1 hours, then let it stand and cool down to normal temperature to obtain mixture A;

[0057] 5. Add caustic mixture to deionized water, pressurize and dissolve until fully dissolved, ...

Embodiment 3

[0061] The above-mentioned electric welding machine for processing high-voltage transformer shells, wherein the preparation method of the novel grease is as follows:

[0062] An electric welding machine for processing high-voltage transformer shells according to the present invention, wherein the preparation method of the novel cooling oil is as follows:

[0063] 1. Take propylene glycol and hexylene glycol, put them into a blender at a weight ratio of 1:1.2, mix and stir until fully mixed to obtain a glycol mixture;

[0064] 2. Take polyethylene glycol and ethanol, put them into a blender at a weight ratio of 1:1.7, and mix and stir until fully mixed to obtain an organic mixture;

[0065] 3. Take sodium hydroxide and potassium hydroxide, mix and stir at a ratio of 1:0.75 until fully mixed to obtain a caustic mixture;

[0066] 4. Add the diol mixture and organic matter in steps 1 and 2 into the preparation kettle, heat and stir, raise the temperature to 101°C and keep it warm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com