Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about How to "Shorten the blanking time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

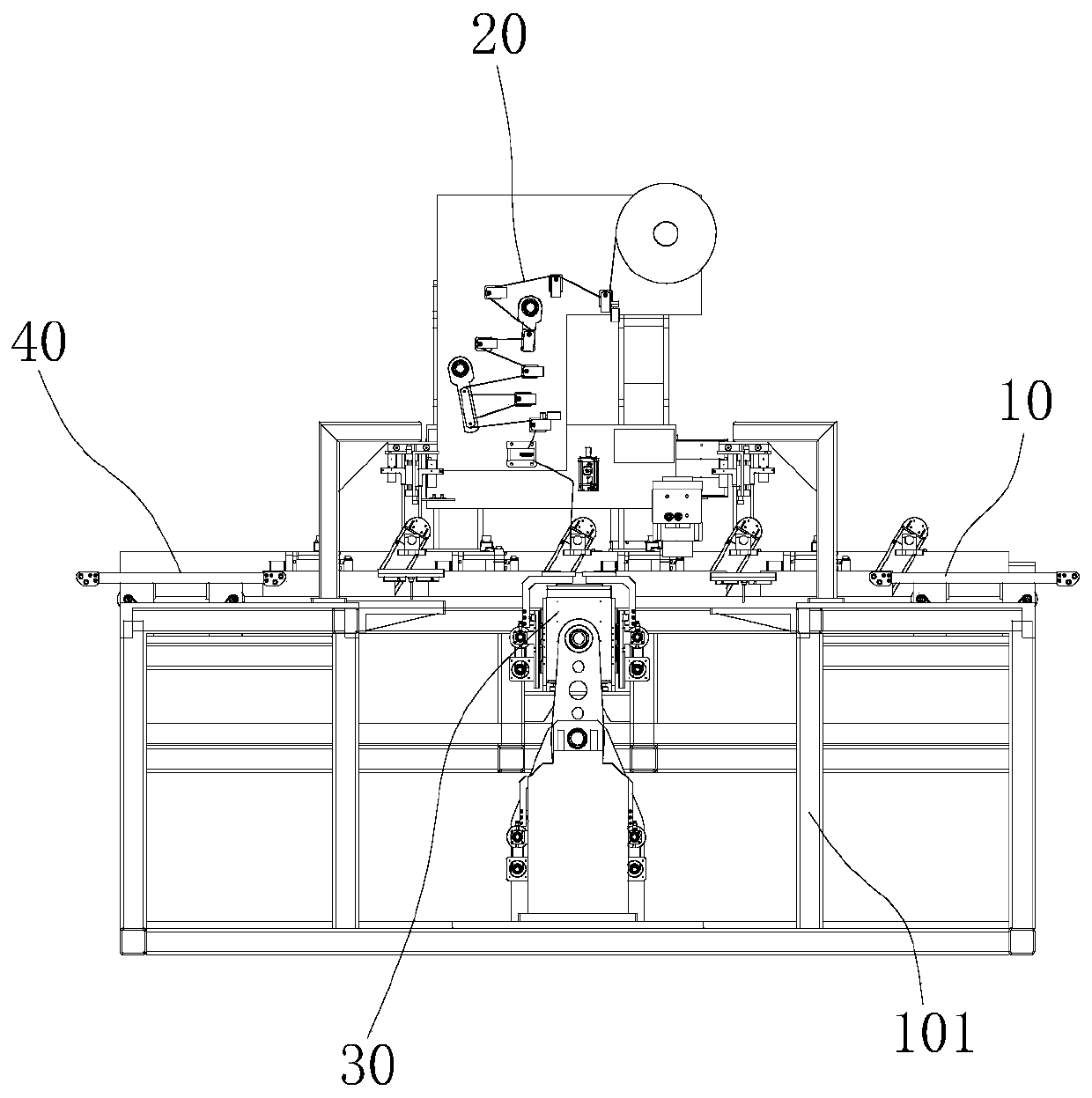

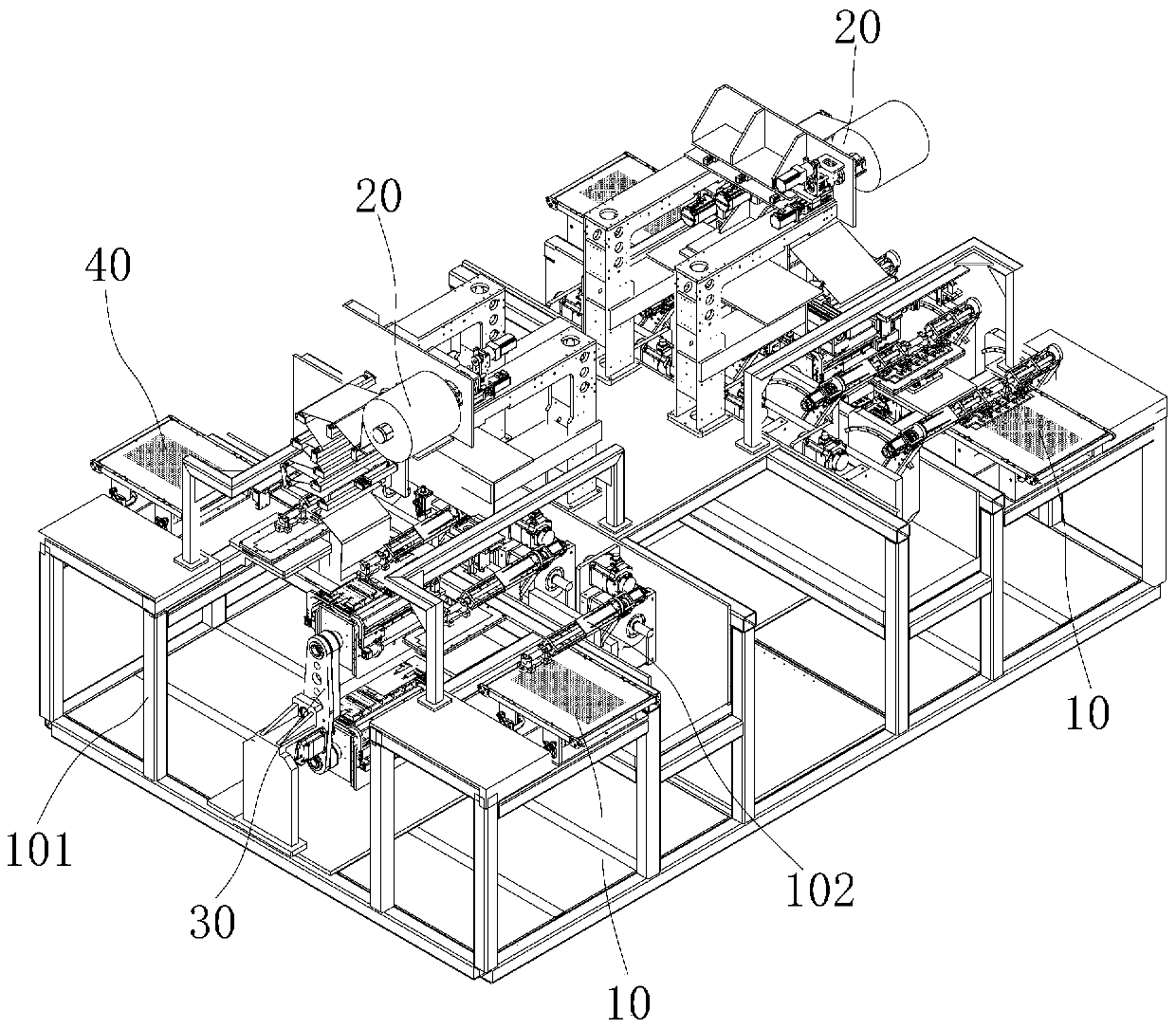

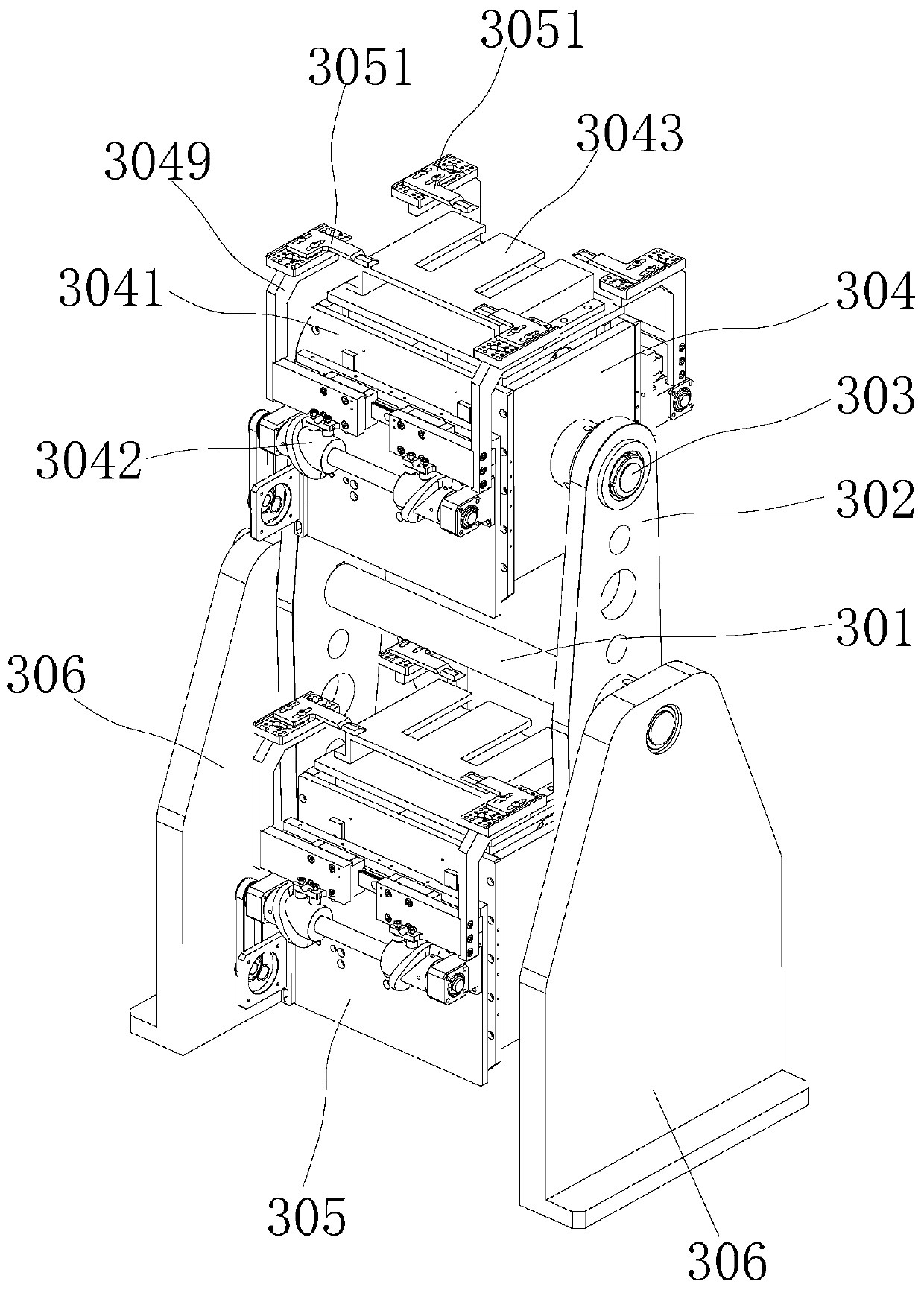

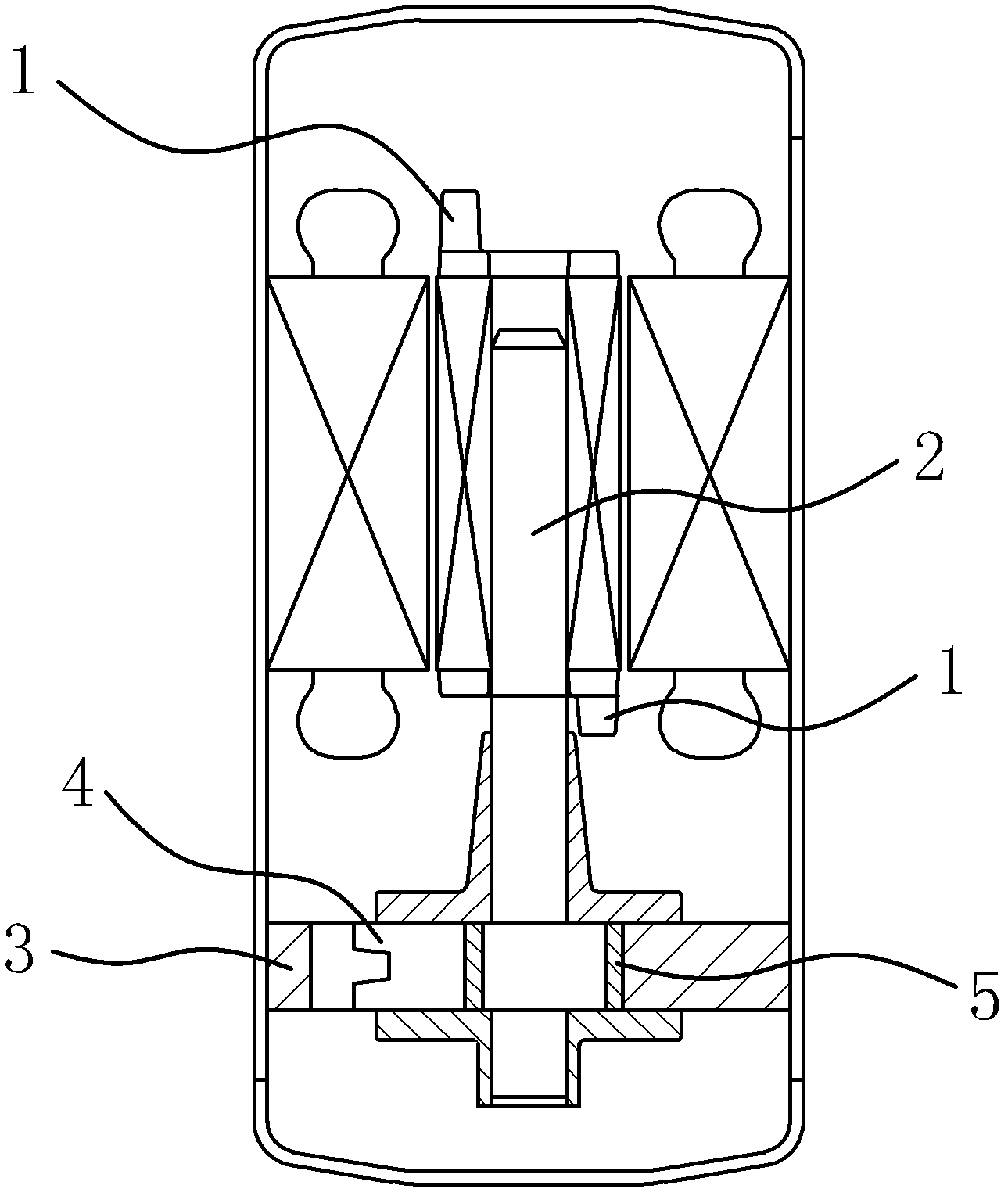

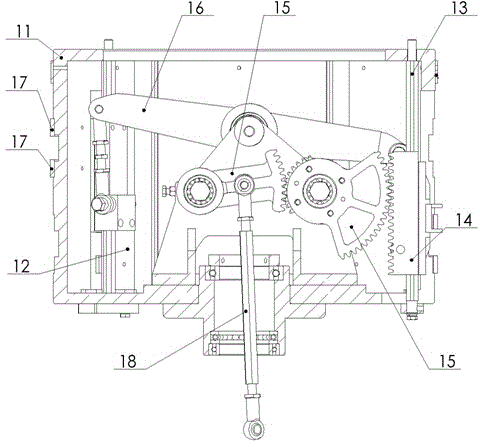

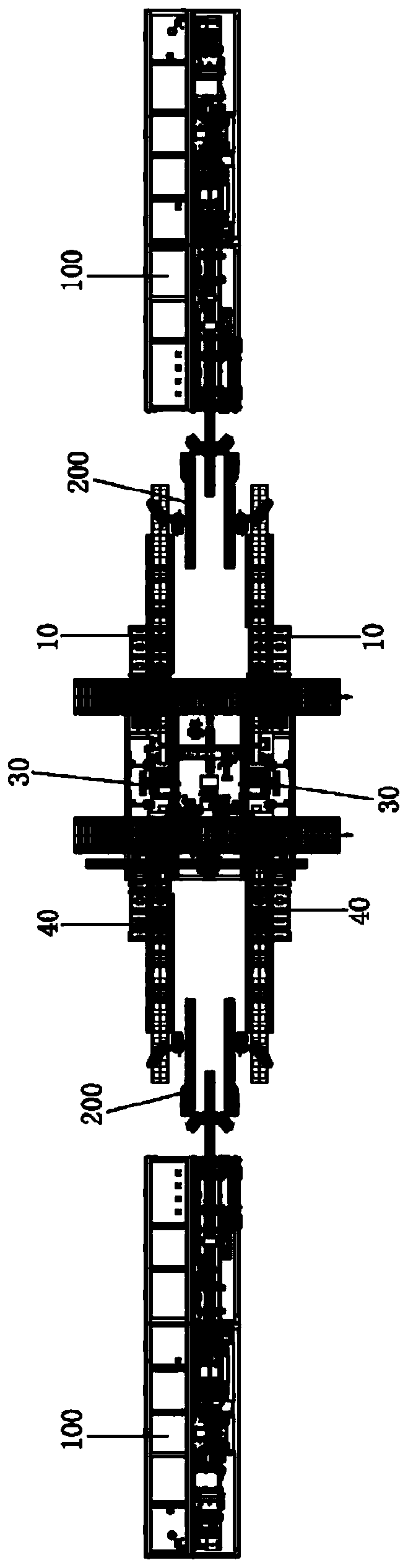

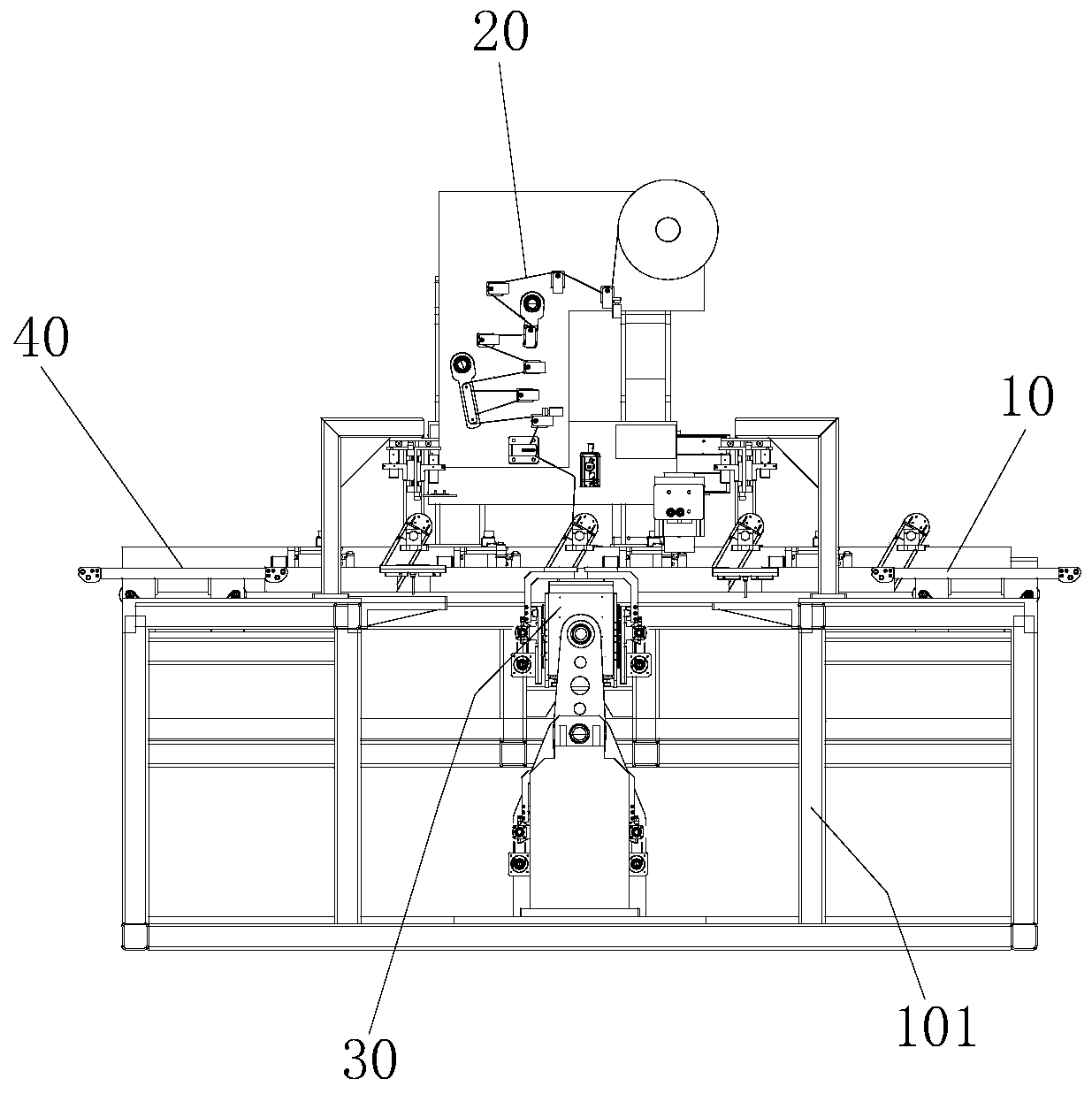

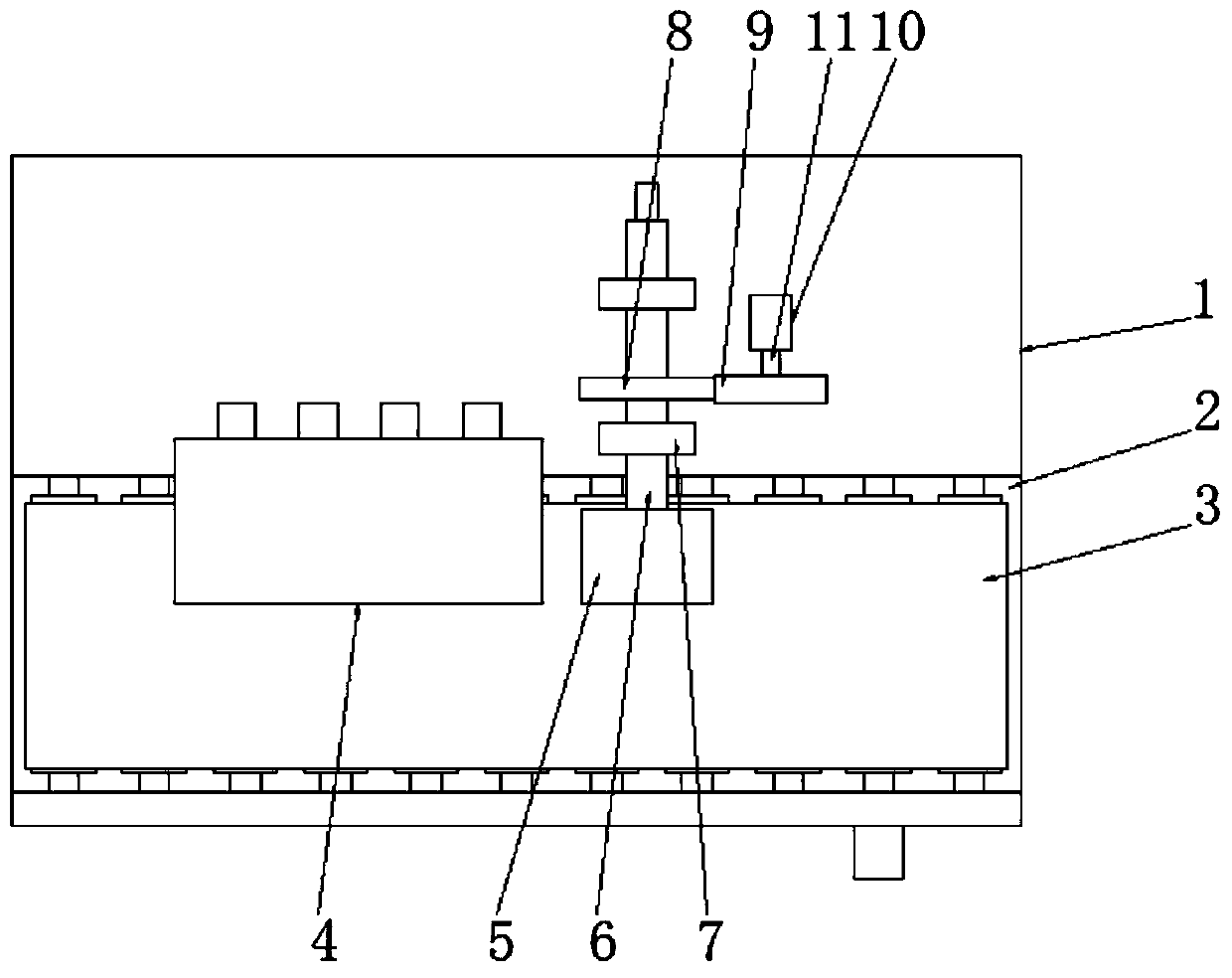

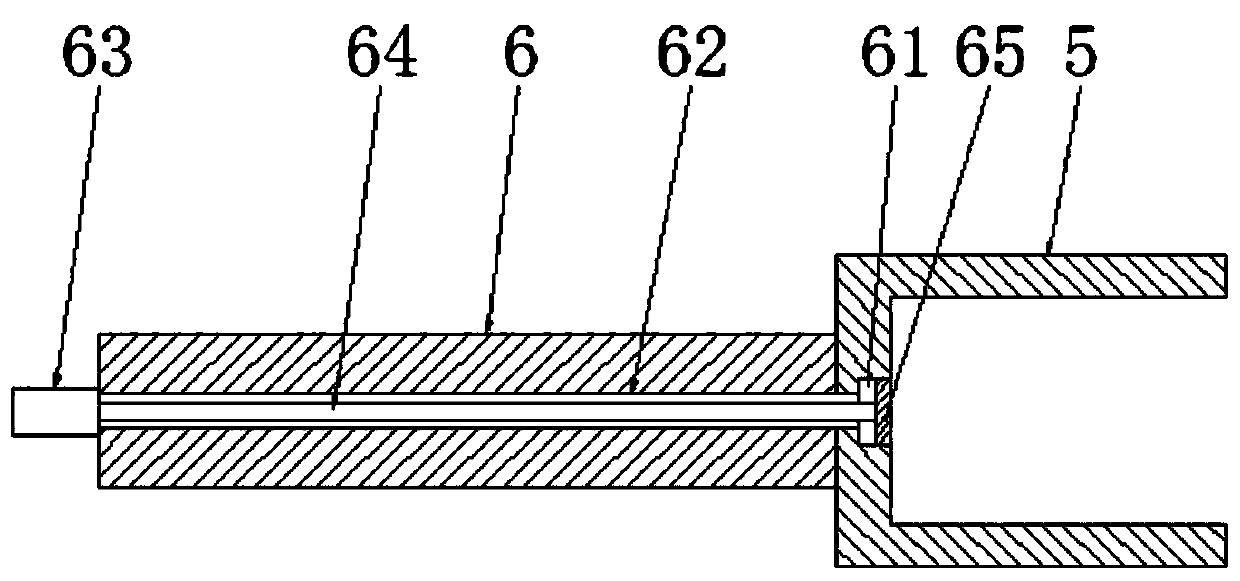

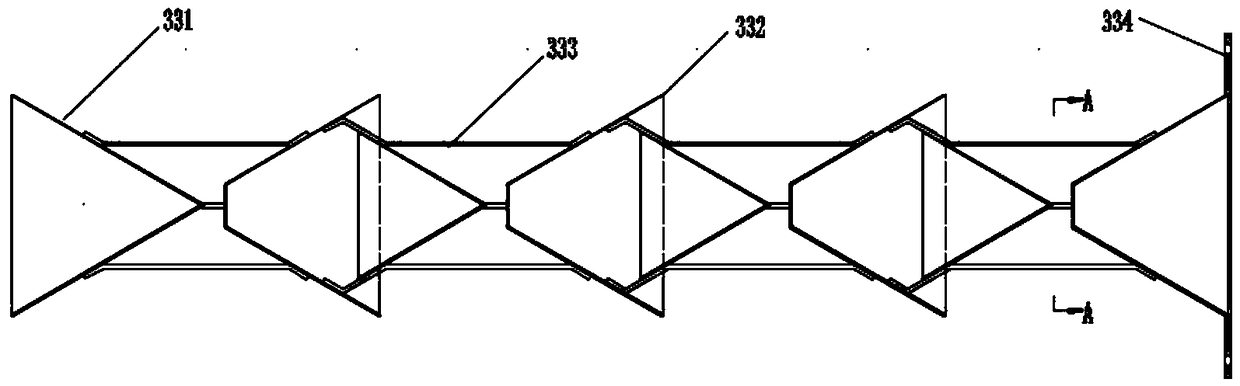

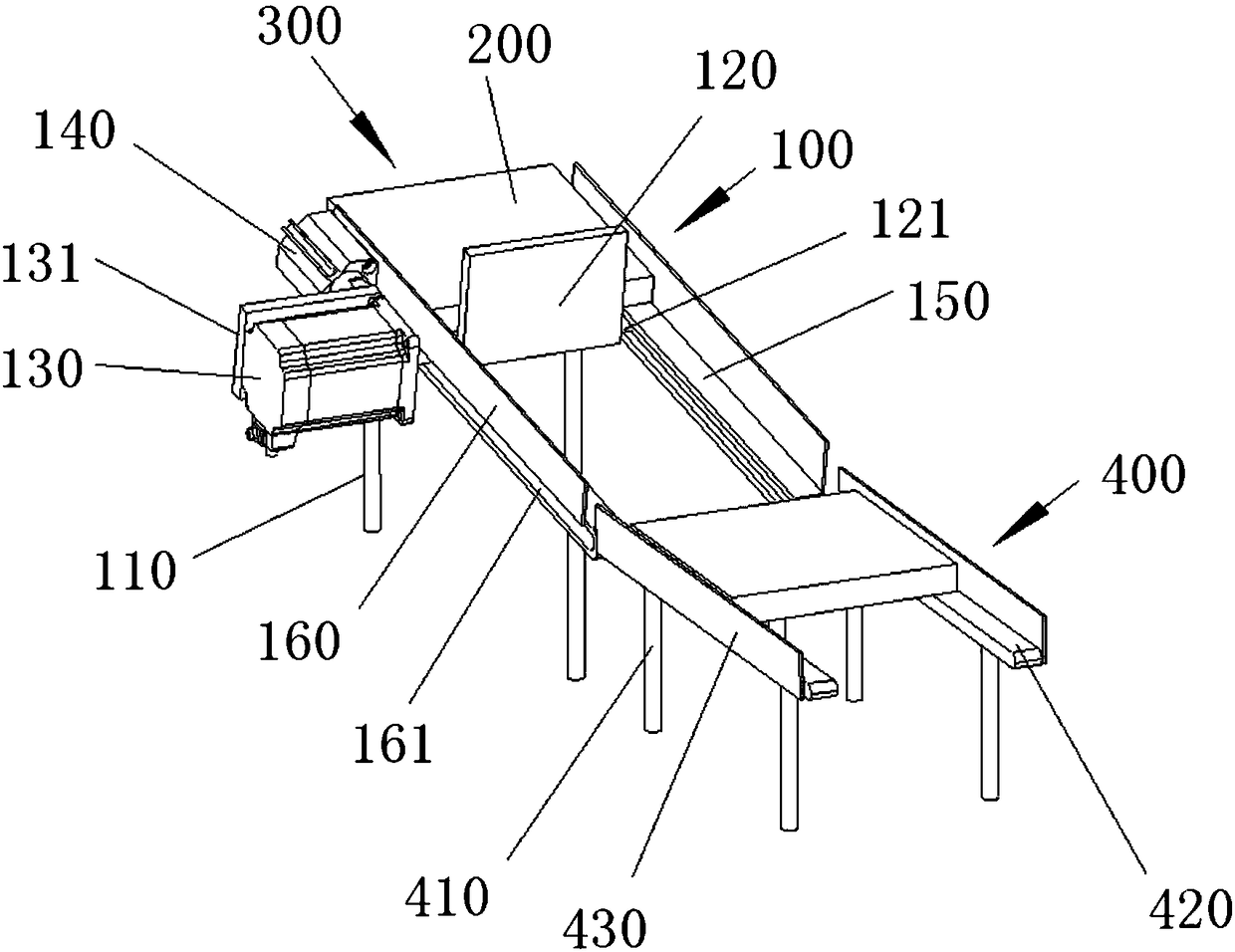

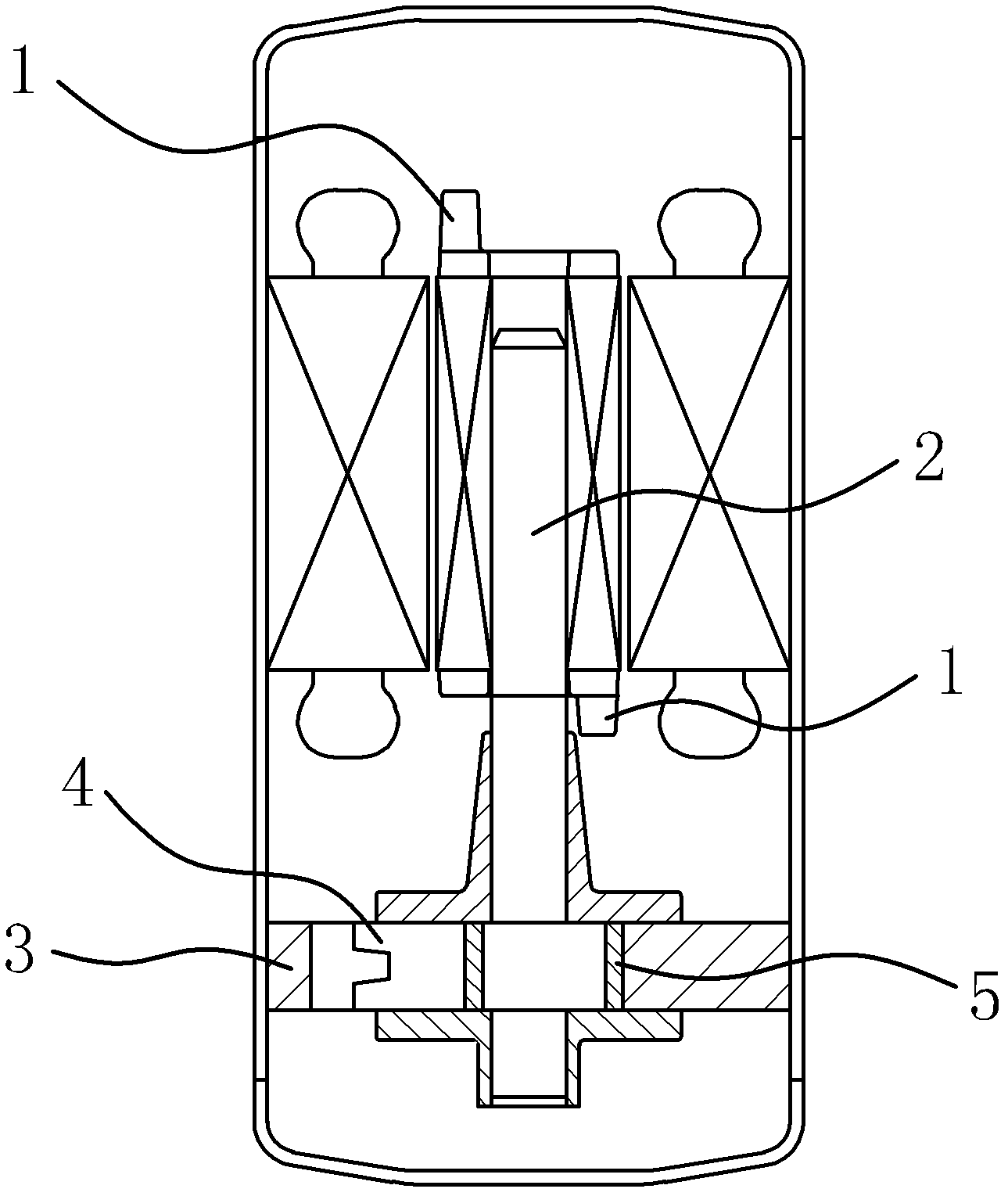

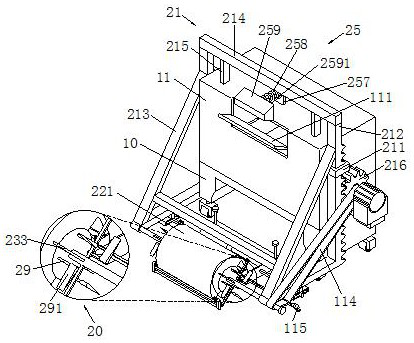

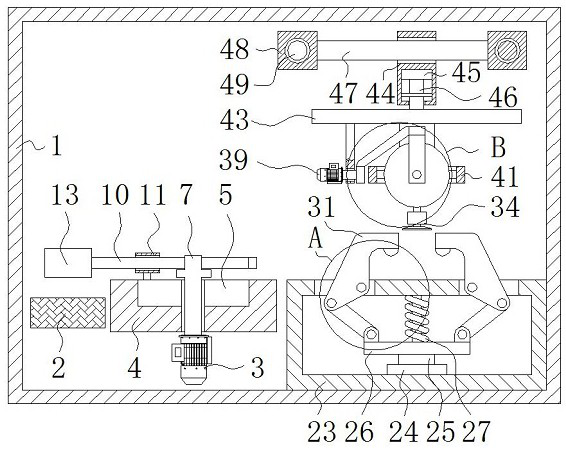

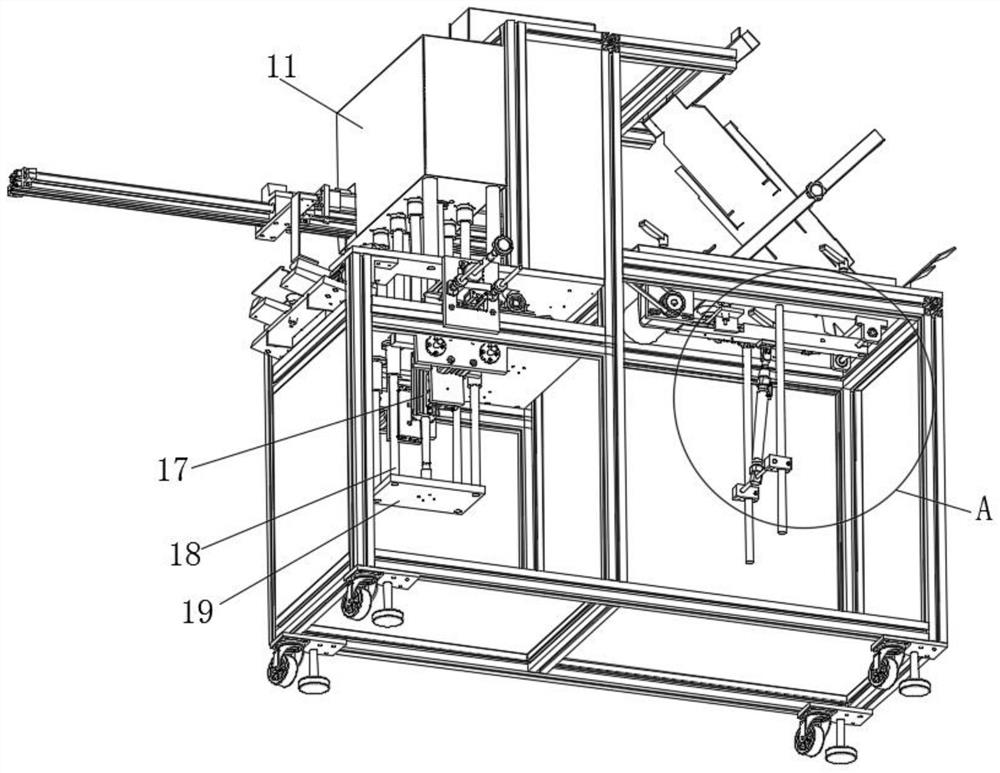

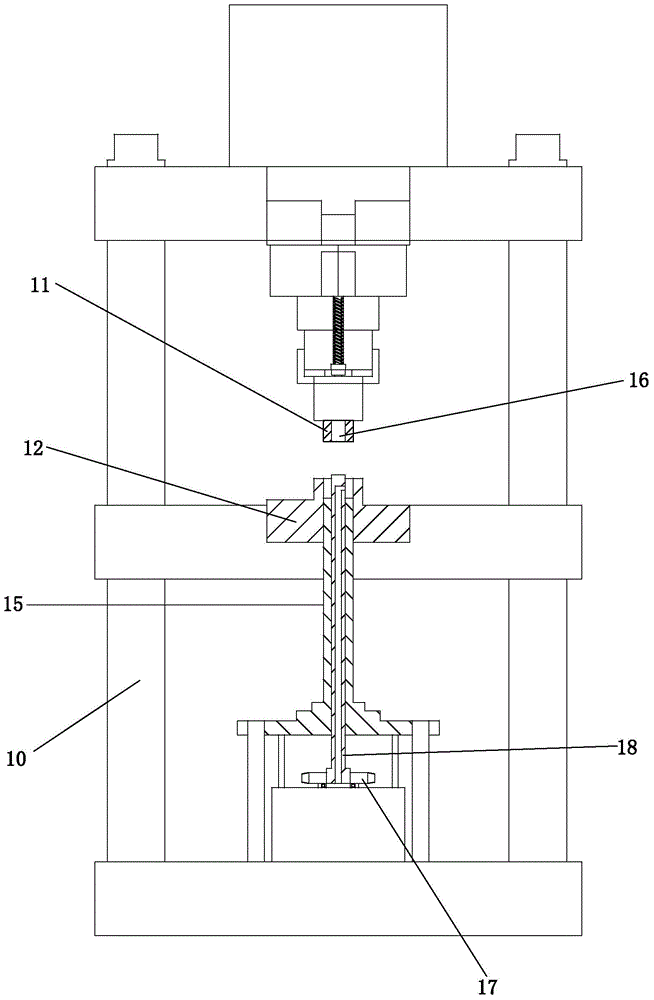

Laminating device with double laminating tables and laminating method thereof

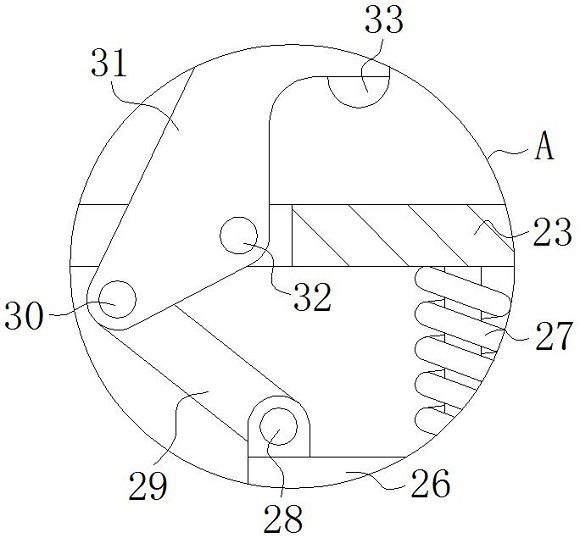

PendingCN110416592ARealize rotation switchingShorten the blanking timeAssembling battery machinesFinal product manufactureEngineeringElectrical and Electronics engineering

The invention discloses a laminating device with double laminating tables and a laminating method thereof and relates to the technical field of battery production equipment. The laminating device comprises positive electrode sheet feeding mechanisms, negative electrode sheet feeding mechanisms, diaphragm unwinding mechanisms and double-laminating-table mechanisms. The positive electrode sheet feeding mechanisms and the negative electrode sheet feeding mechanisms are disposed on left and right sides of the double-laminating-table mechanisms to provide positive and negative electrode sheets to the double-laminating-table mechanisms. The diaphragm unwinding mechanisms are above the double-laminating-table mechanisms and are used for providing diaphragms clamped between the positive and negative electrode sheets to the two double-laminating-table mechanisms. The double-laminating-table mechanisms comprise rotating shafts, rotating arms, central rotating shafts, first laminating tables andsecond laminating tables. The device has the advantages that the device can achieve uninterrupted lamination operation, the blanking time is greatly saved, and the working efficiency of the device isimproved.

Owner:SHENZHEN GREENSUN TECH CO LTD

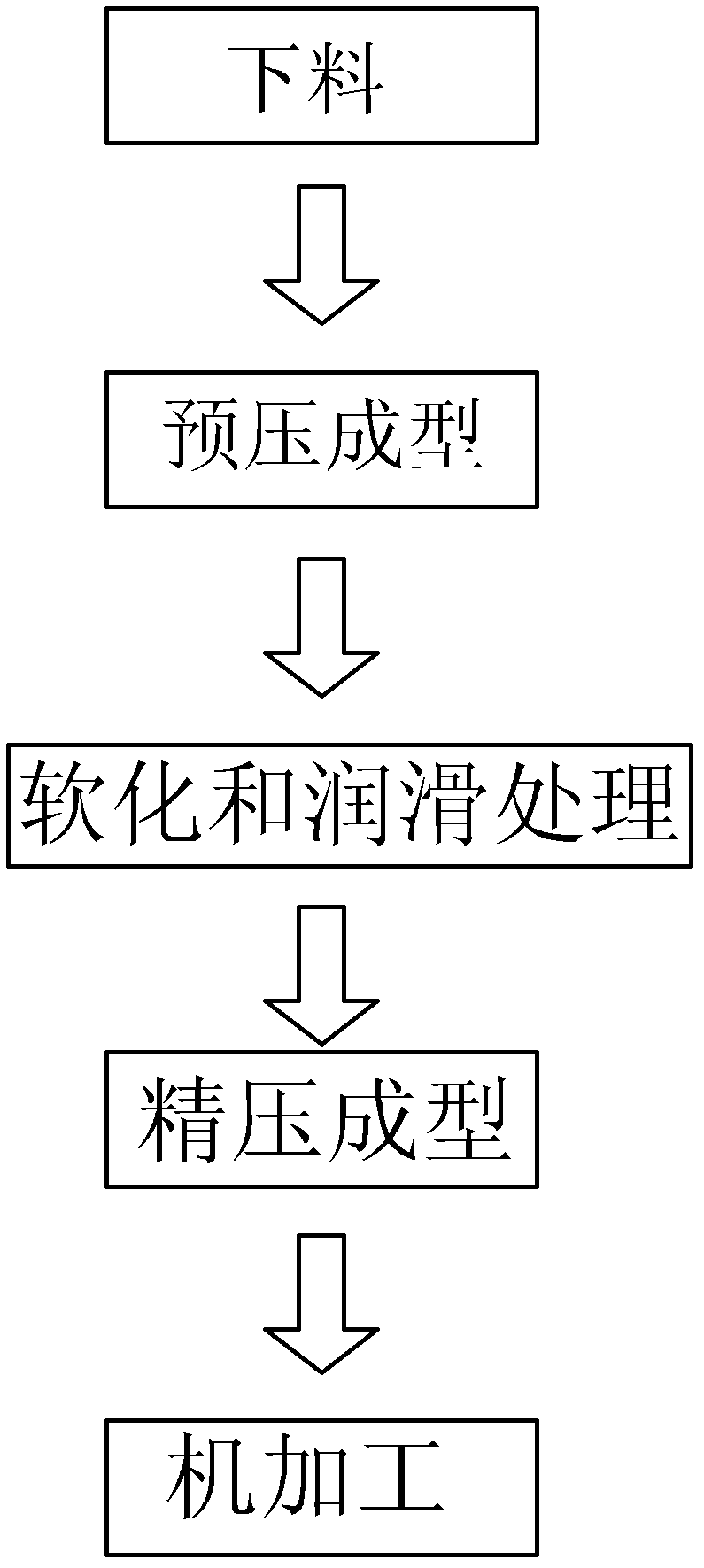

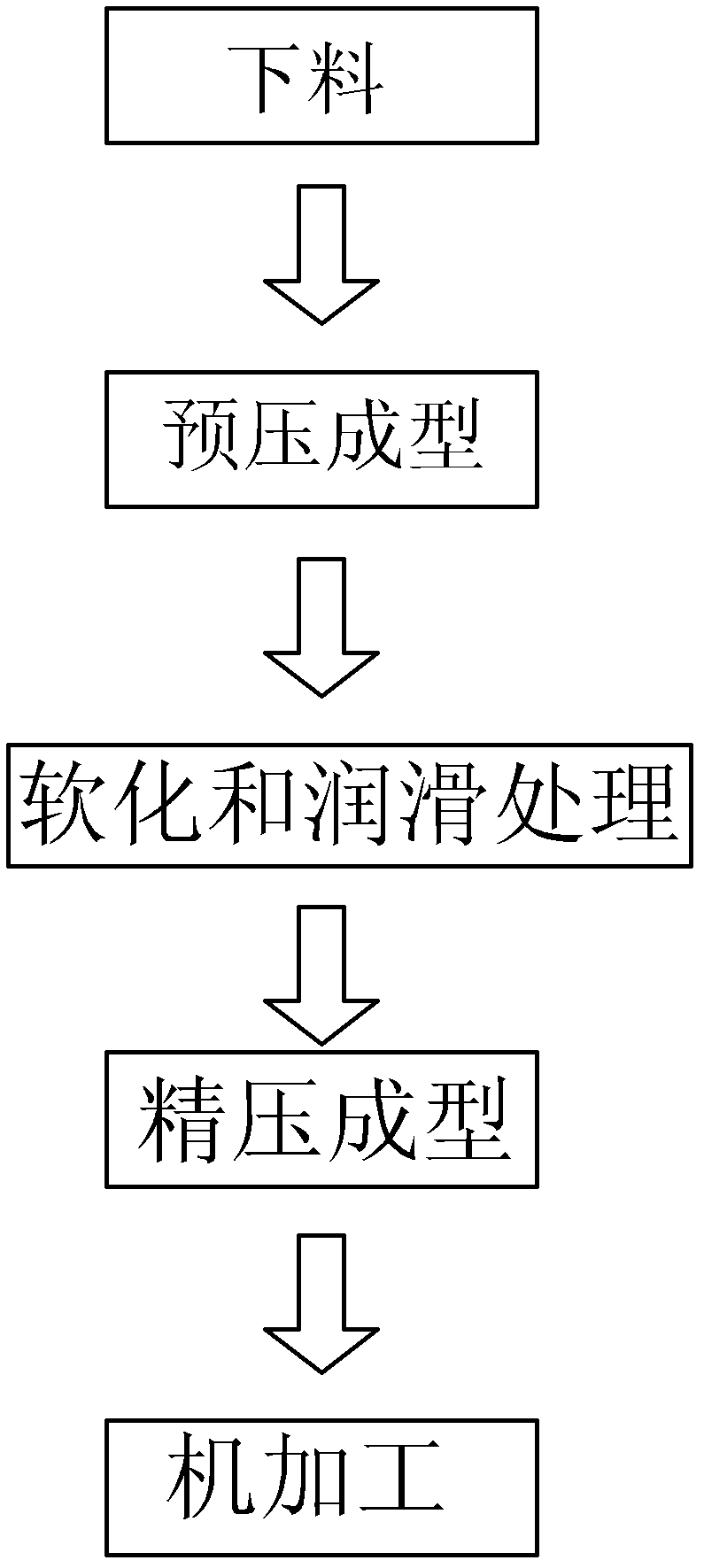

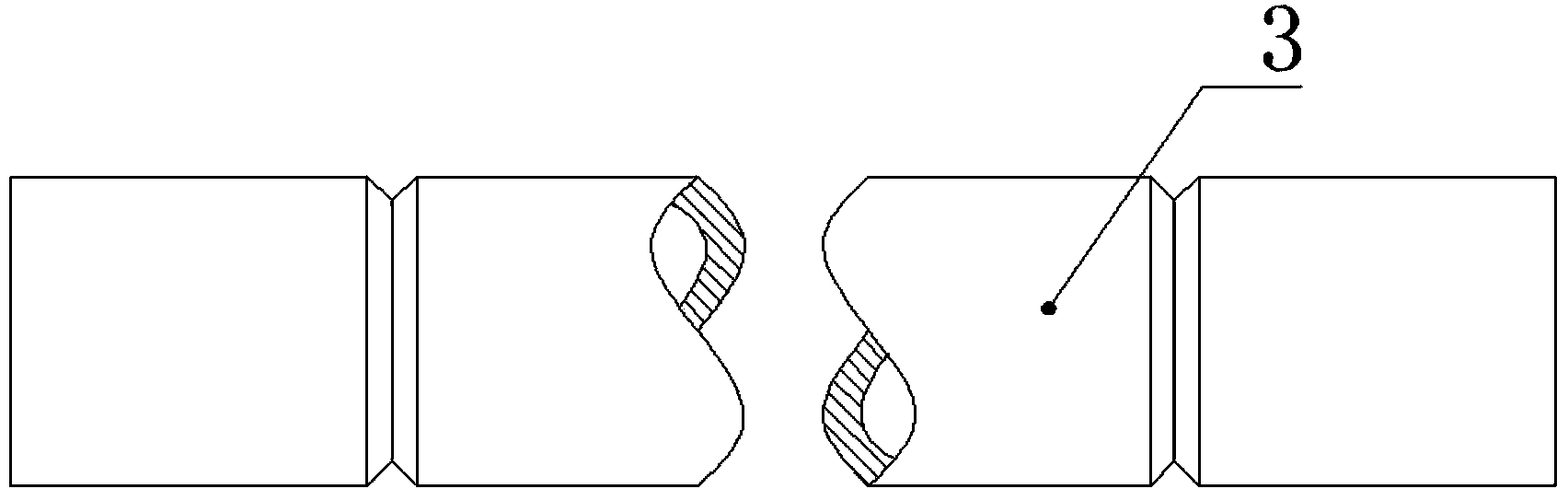

Method for manufacturing air condition compressor balance block

ActiveCN102248373ALow costIncreased production flexibilityMechanical engineering technologyWork in process

The invention provides a method for manufacturing an air condition compressor balance block, belonging to the technical field of mechanical engineering. By means of the method, the technical problems that the production efficiency is low, the reject rate is high and the like when high manganese steel is adopted to manufacture the air condition compressor balance block in a conventional method for manufacturing the air condition compressor balance block are solved. The method for manufacturing the air condition compressor balance block comprises the following steps of: A, blanking: cutting a section made from high manganese steel materials into blanks with a length corresponding to a required length; B, pre-pressing forming: putting the blanks in a mould and extruding into process products with shapes similar to the shapes of finished products; C, softening and lubricating treatments: carrying out the softening treatment and the phosphorization and saponification lubricating treatment on the process products; D, coining forming: putting the process products subjected to softening and the lubricating treatments in the mould to carry out extrusion forming to obtain semi-finished products; and E, machining: clamping the semi-finished products on a machine tool and machining to obtain the finished products. The method provided by the invention has the advantages of low production cost, high production efficiency and the like.

Owner:浙江百达精工股份有限公司

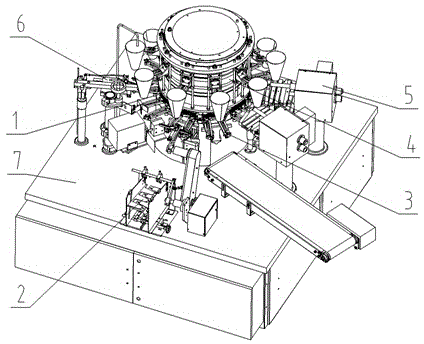

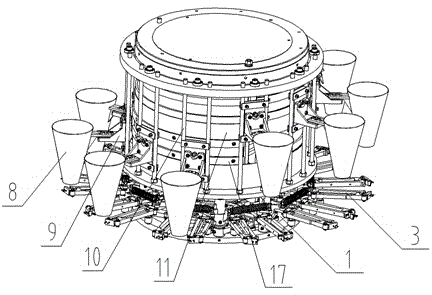

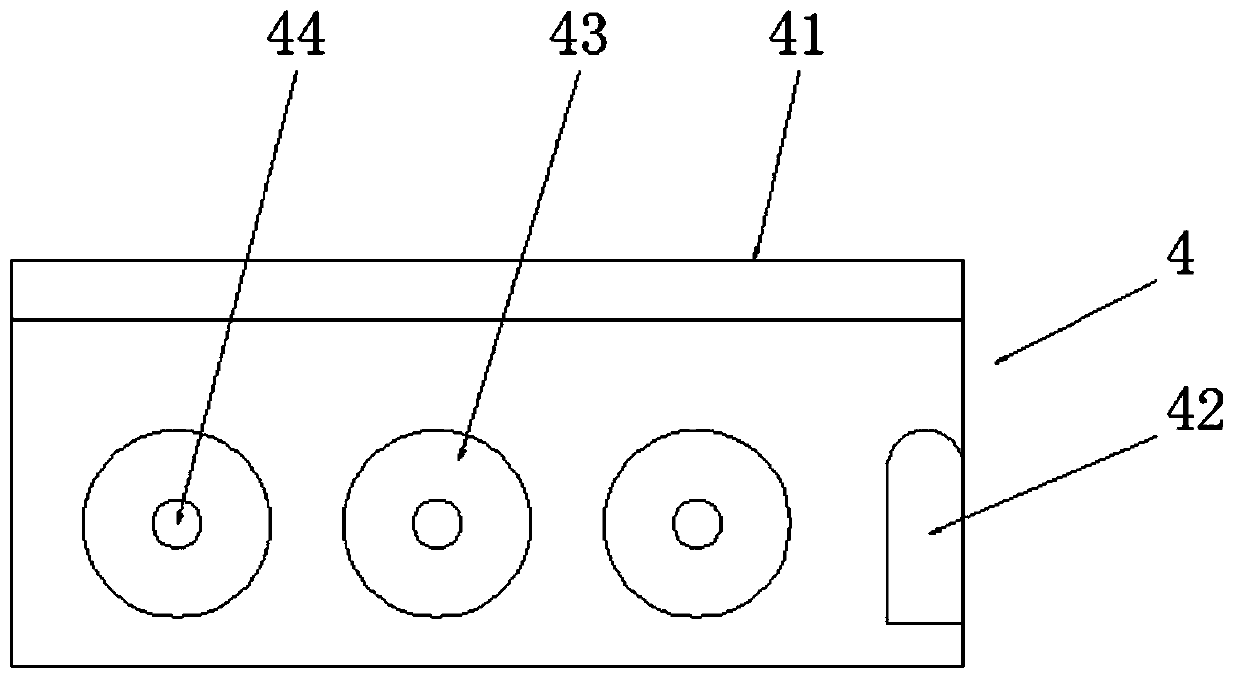

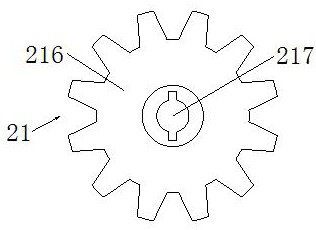

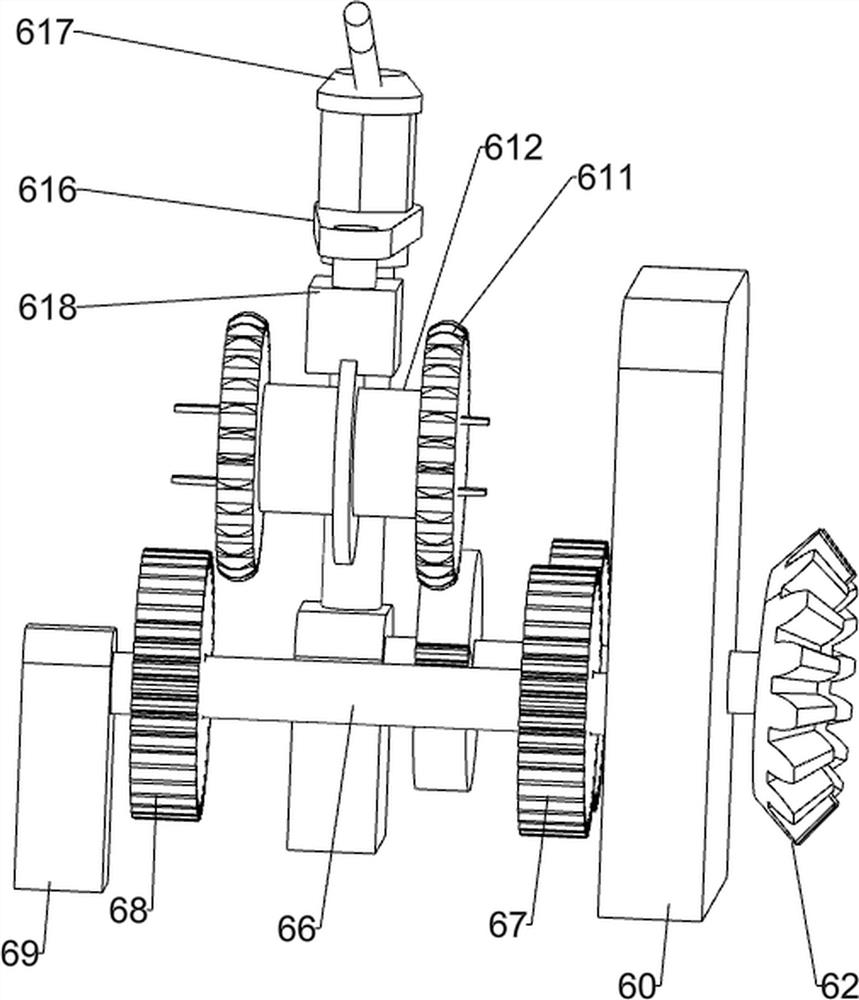

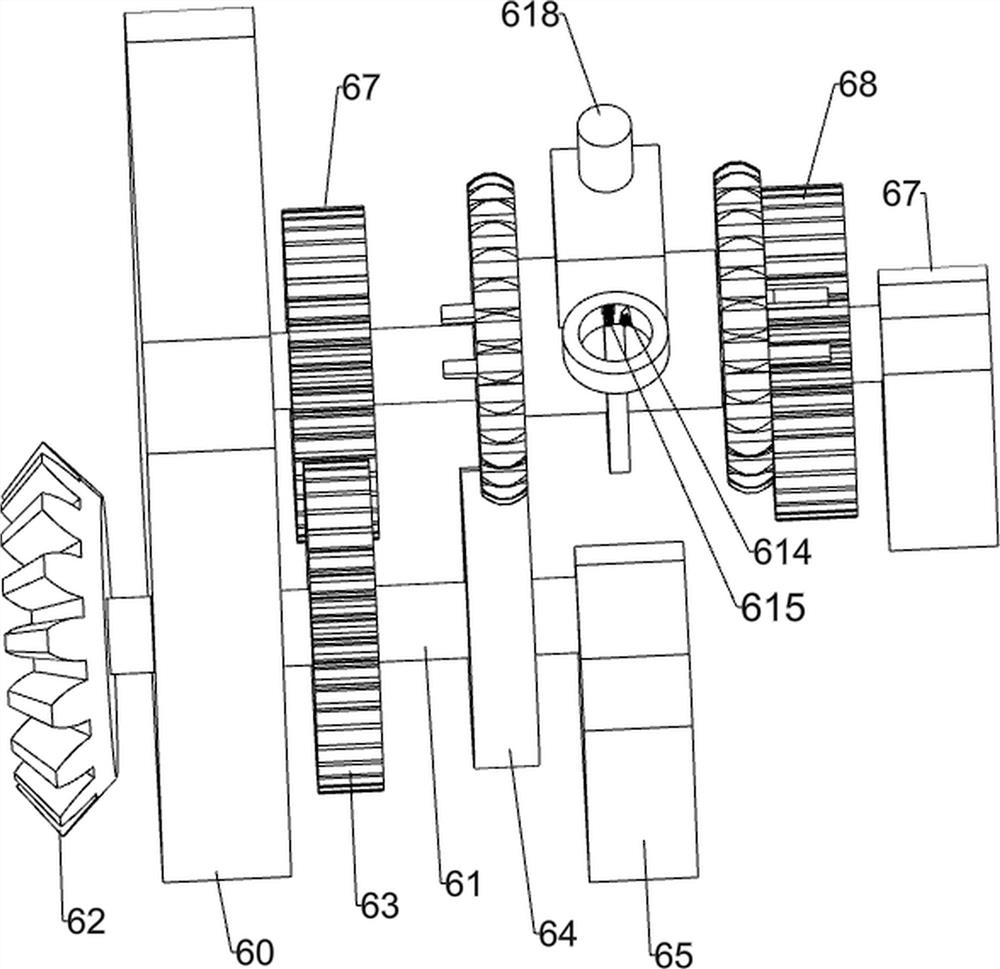

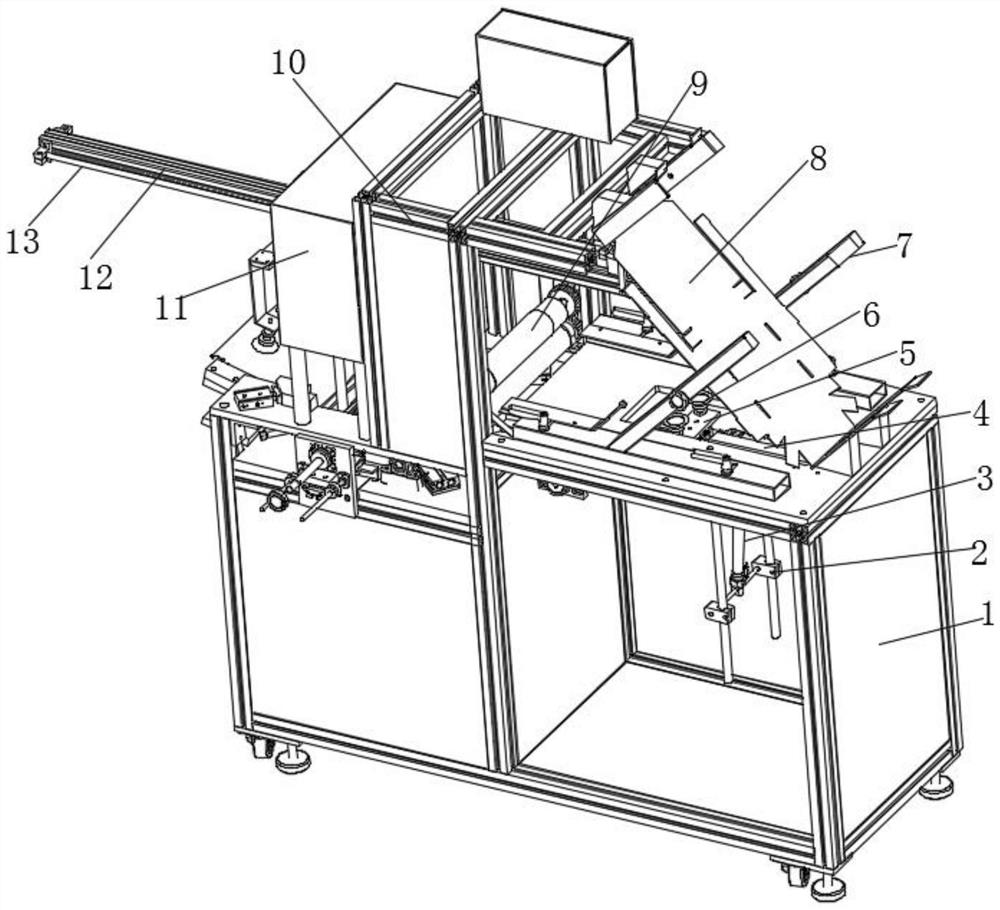

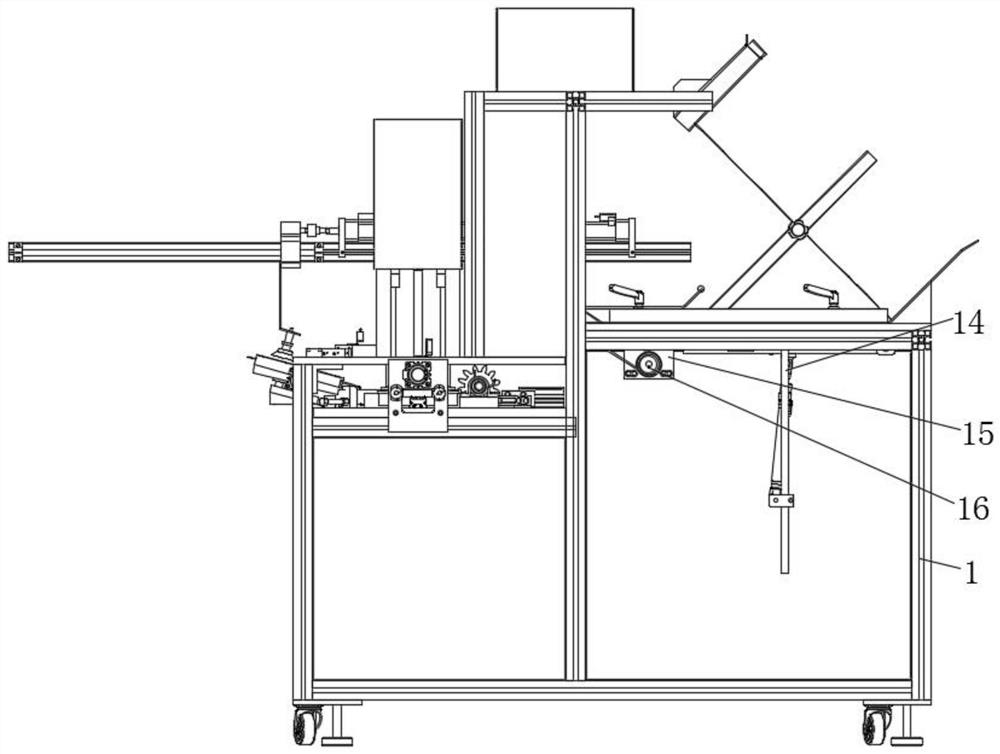

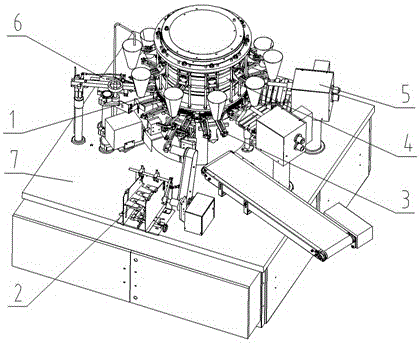

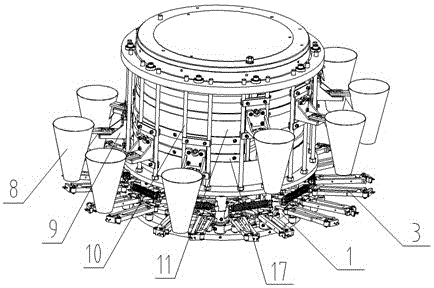

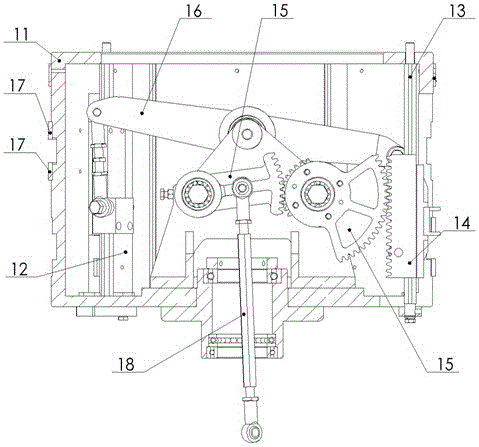

Ten-station continuous filling packing machine

ActiveCN104875910AHigh speedSolve the impact of poor fluidity on the speed of packaging machinesWrapper twisting/gatheringSolid materialEngineeringRocker arm

The invention discloses a ten-station continuous filling packing machine which comprises a workbench, a rotating big disc, a bag feeding device, bag clamping devices, discharging devices, sealing devices and bag opening and air blowing devices. Each discharging device comprises a discharging hopper, a discharging fixing base, a discharging fixing base limiting guide rod, a rotating cylinder, a lifting block, a lifting guide rod, a lifting rack, a special-shaped transmission gear, a lifting and swinging rocker arm, a rotating rail and a transmission pull rod. The discharging hoppers are fixed to the discharging fixing bases respectively, the discharging fixing bases are fixed to the discharging fixing base limiting guide rods respectively, and the discharging fixing base limiting rods are fixed to the rotating big disc. Ten discharging hoppers are provided, the discharging hopper on the seventh station can move upwards, and the discharging hopper on the third station can move downwards. The ten-station continuous filling packing machine is high in production efficiency and short in period, saves manual labor cost, and is simple in structure and attractive in appearance.

Owner:QINGDAO YILONG PACKAGING MACHINERY

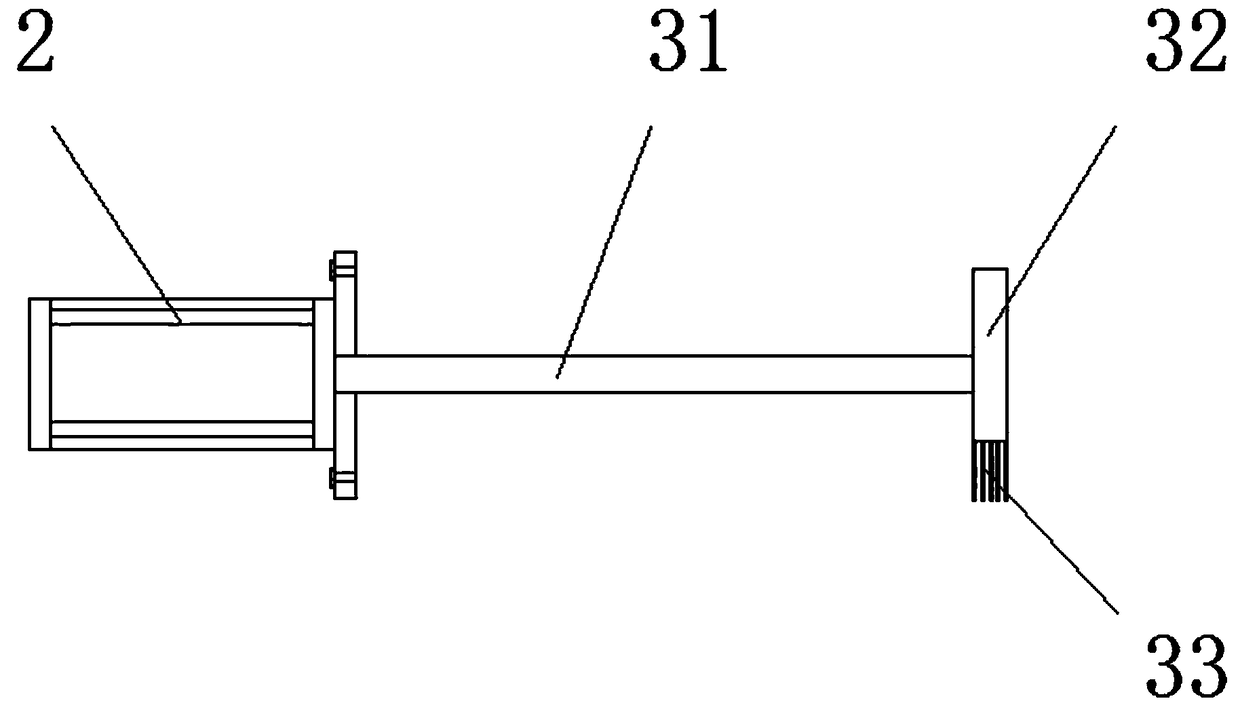

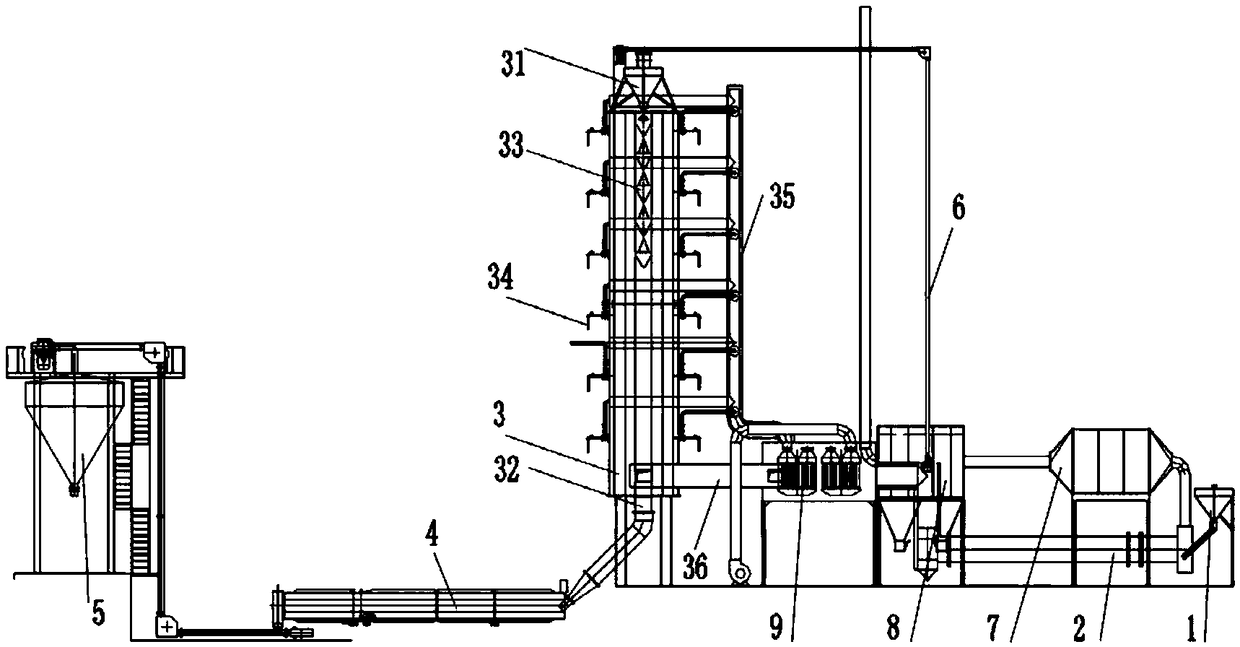

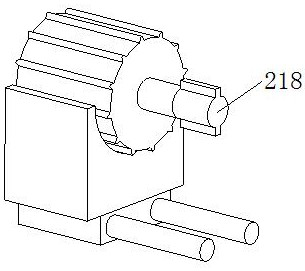

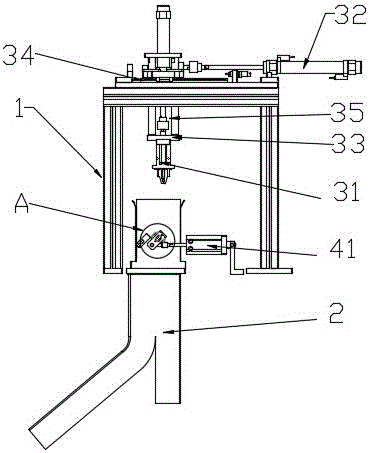

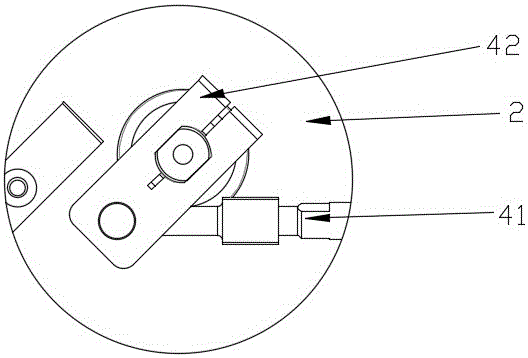

Plasma automatic unloading machine and using method thereof

ActiveCN102029465APrevent jumpingGuaranteed stabilityWelding/cutting auxillary devicesAuxillary welding devicesPhysical hard workAir cylinder Press

The invention discloses a plasma automatic unloading machine and a using method thereof. The unloading machine comprises an unloading machine base, wherein a rotator box component and a rail component are fixedly arranged on the base; a stainless steel tube material rotating main shaft is arranged in the rotary box component, and a three-claw chuck is arranged on one end of the main shaft; two sets of trolley components are arranged on the rail component, a material receiving box component is arranged on the tail trolley component, an upright post component is arranged on the material receiving box component, a cutting component is arranged on the upright post component, and a plasma cutting gun is arranged on the cutting component; and a supporting roller component is arranged on the middle trolley component, a supporting roller is arranged on the supporting roller component, an air cylinder pressing component is arranged on the supporting roller component, and a pressing wheel is arranged on the air cylinder pressing component. The device can continuously and automatically cut the stainless steel tube material into the required tube materials according to the length of a drawing, so that unloading time is greatly shortened, efficiency is improved, cost is reduced greatly, and the labor of operators is reduced.

Owner:BEIJNG HINEN HITECH PETROLEUM TECH DEV

Laser marking device

ActiveCN105058988AShorten the blanking timeShorten the timeOther printing apparatusLaser scanningEngineering

The present invention is applied to the technology field of a marking device, and provides a laser marking device. The laser marking device comprises a rack, a conveyer belt, at least one laser scanning head, a plurality of bearing seats, a rotating mechanism and a discharging mechanism. The conveyer belt is provided with a loading station, a marking station and an unloading station in the order along the moving direction of workpieces; and the rotating mechanism is configured to drive the workpieces on the bearing seats to rotate in the process of marking. The workpieces at the loading station are disposed onto the bearing seats of the conveyer belt, the marking station is driven by the rotating mechanism to rotate with respect to the bearing seats so as to complete rotary marking in a circumference direction, and the workpieces are moved with the bearing seats and the conveyer belt to the unloading station and are taken away from the bearing seats through the discharging mechanism. In this way, the loading, the rotary marking and the grabbing unloading are synchronously completed, the durations of unloading and waiting for laser rotary marking are greatly shortened and productivity is greatly improved.

Owner:深圳市艾雷激光科技有限公司

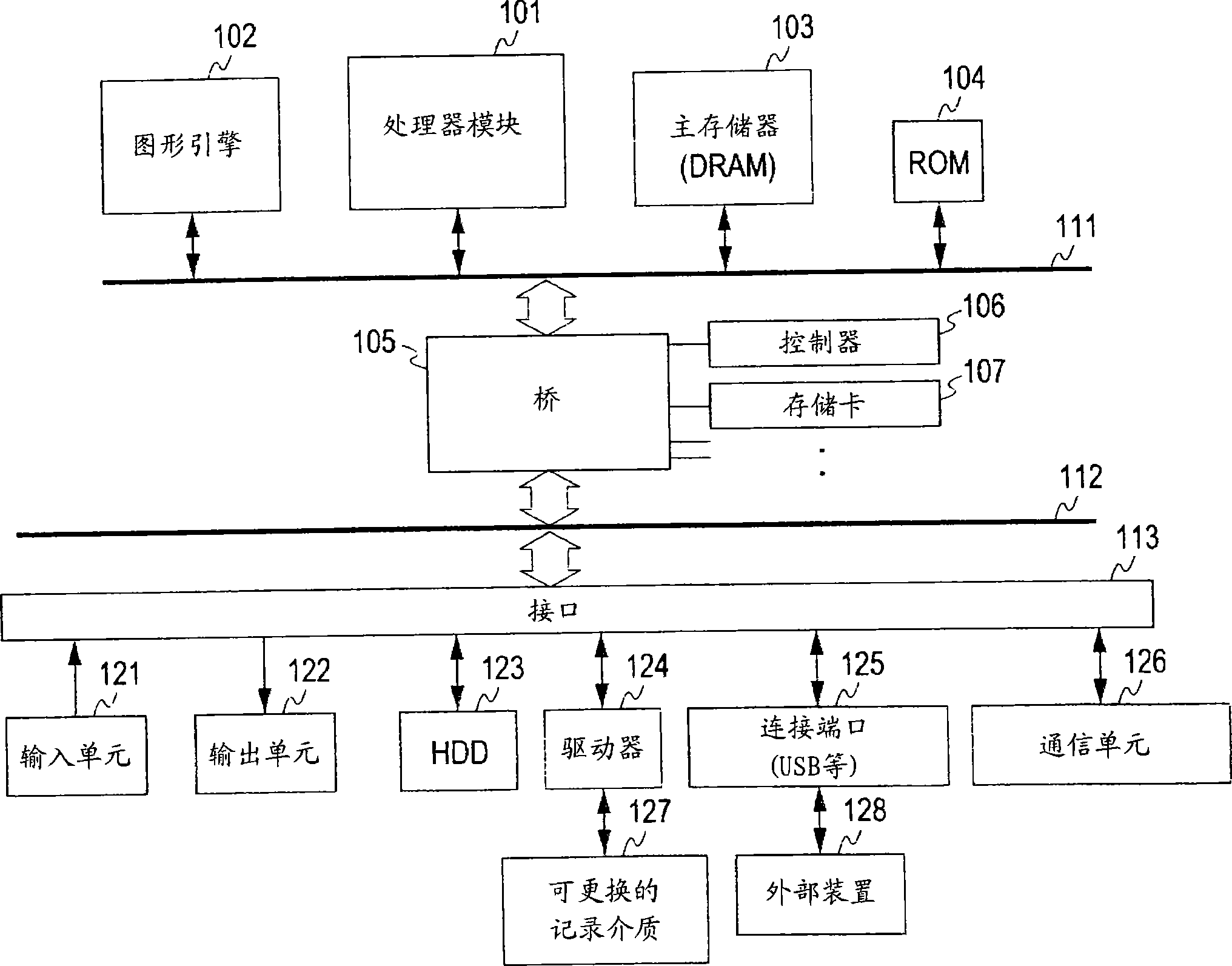

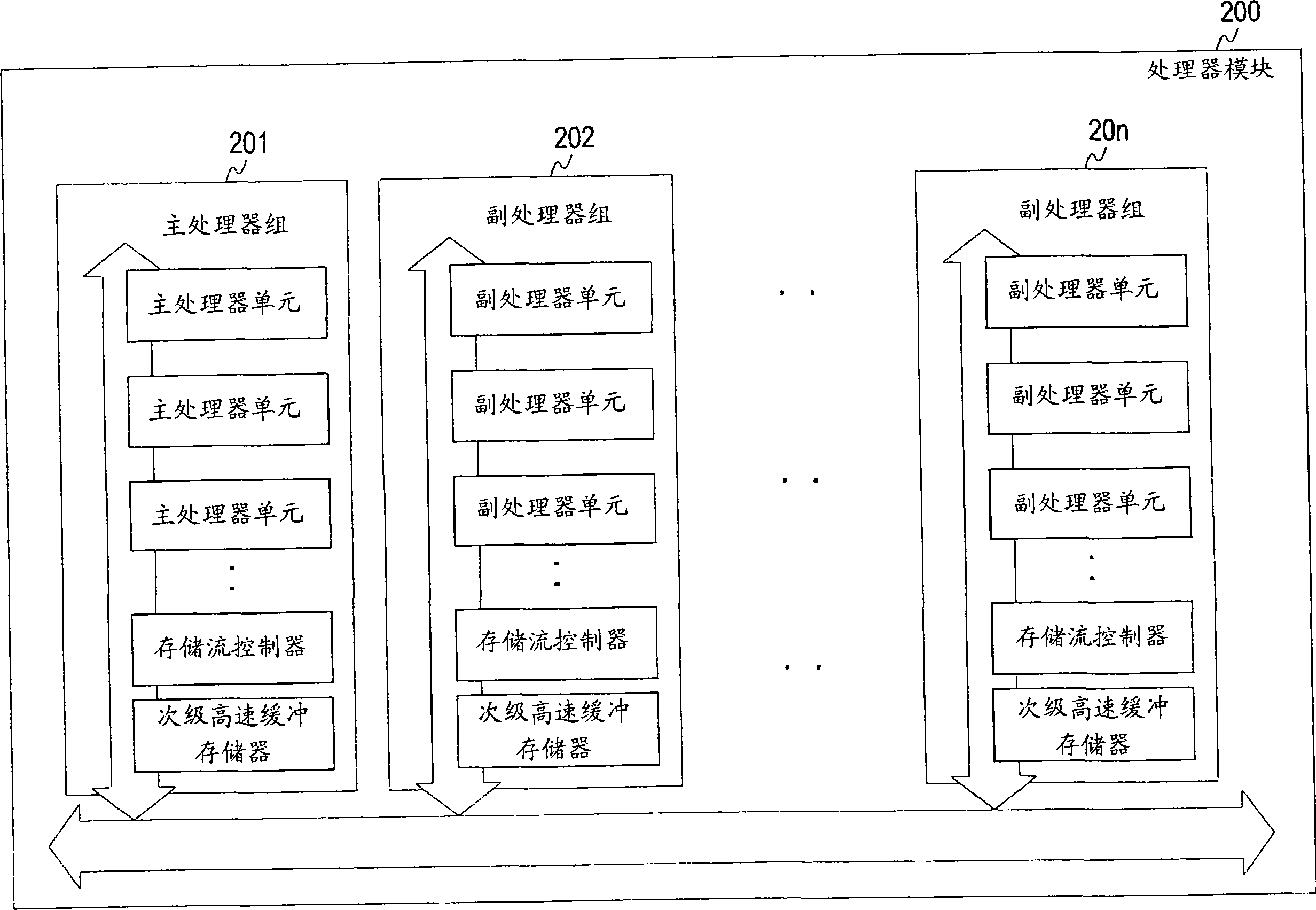

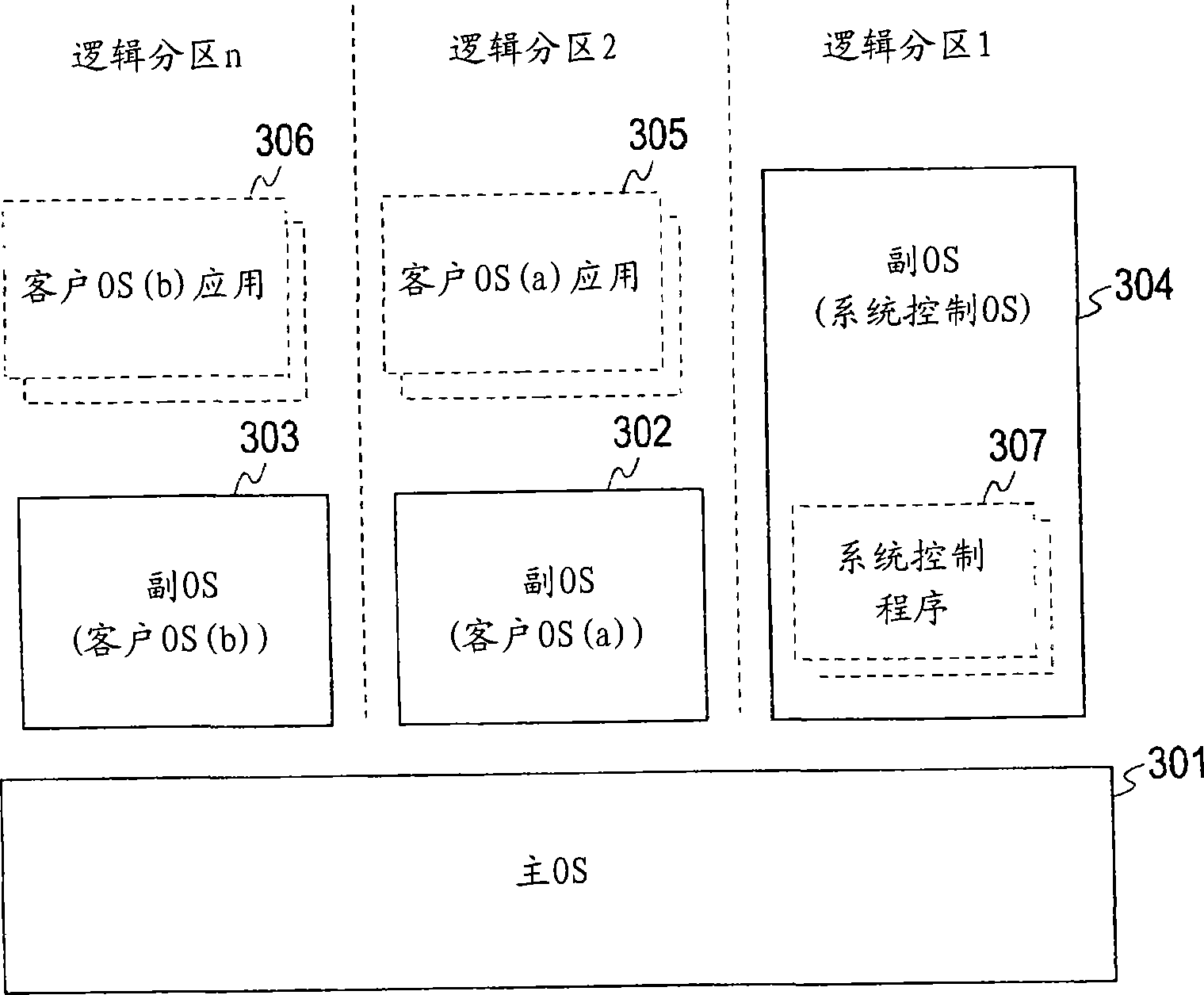

Information processing device, interrupt processing control method, and computer program

InactiveCN1906583AShorten the blanking timeImprove interrupt responseProgram initiation/switchingInformation processingOperational system

There is provided an improved interrupt processing control configuration in a system where a plurality of operation systems (OS) are simultaneously operating. In the system where a plurality of OS are simultaneously operating, a main OS to execute an interrupt processing control is set and no interrupt mask setting authority is given to a sub-OS other than the main OS. The sub-OS reports whether the sub-OS is in an interrupt-enabled state or an interrupt-inhibited state to the main OS. According to the reported information, the main OS performs an interrupt mask control of the sub-OS. With this configuration, it is possible to eliminate the problem of reservation of the interrupt processing by the mask control of the sub-OS itself and perform an interrupt control based on the intention of the main OS. A necessary interrupt processing can be performed with a higher priority. Moreover, since the main OS manages the sub-OS interrupt vector area, it is possible to realize memory area reduction.

Owner:SONY GRP CORP

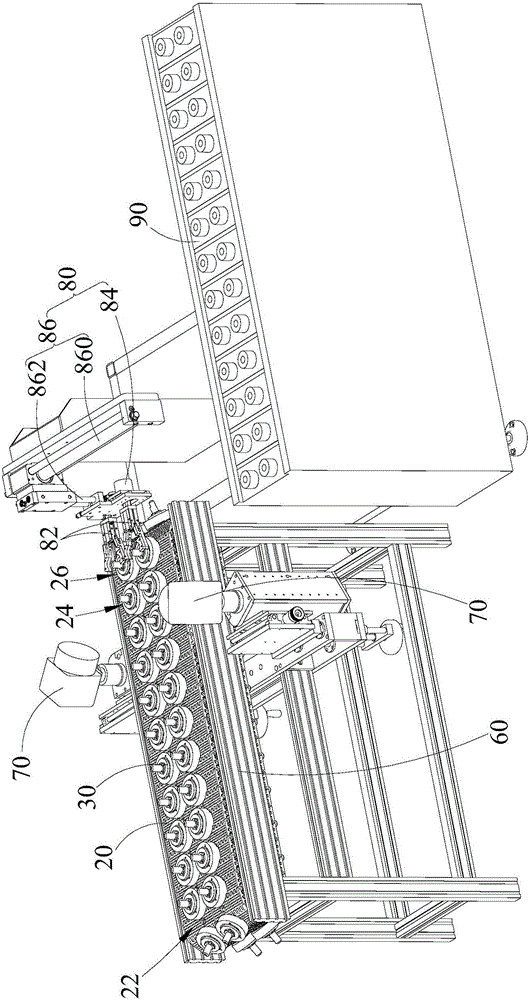

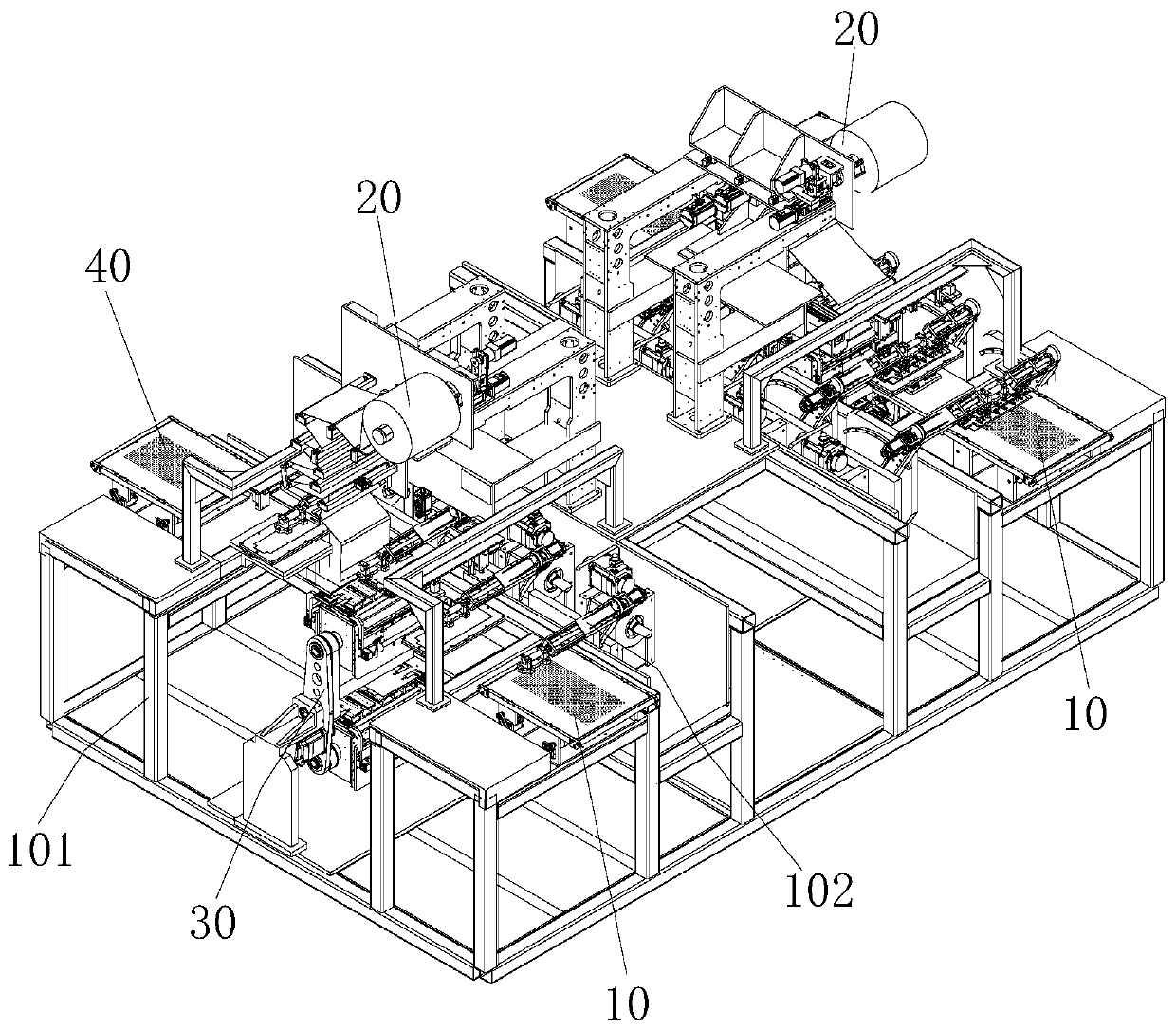

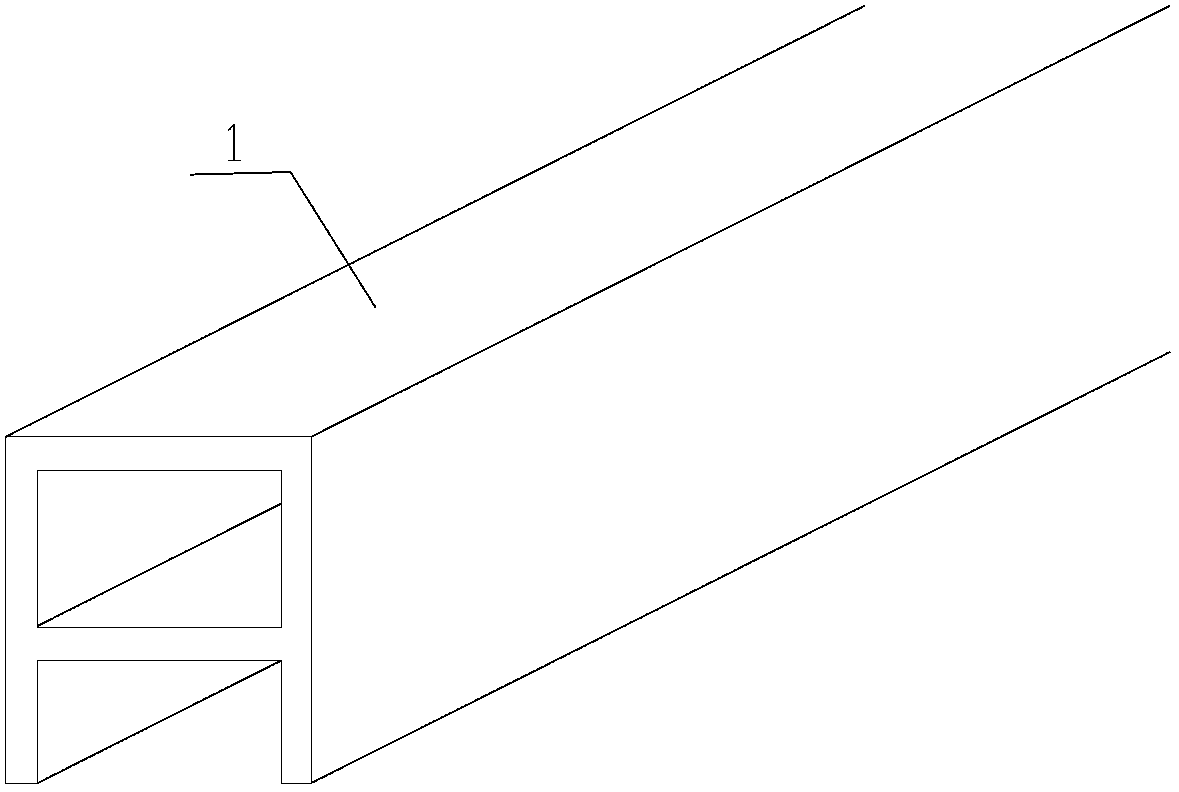

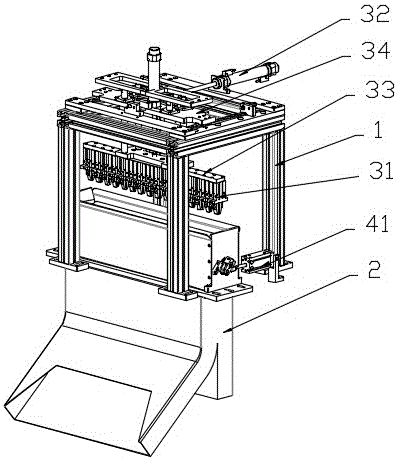

Die cutting and laminating integrated device

PendingCN110416628AHigh degree of automationImprove work efficiencyAssembling battery machinesMetal-working feeding devicesEngineeringAutomation

The invention discloses a die cutting and laminating integrated device and relates to the technical field of battery production equipment. The device includes pole sheet die cutting mechanisms, pole sheet conveying mechanisms, positive electrode sheet feeding mechanisms, negative electrode sheet feeding mechanisms, diaphragm unwinding mechanisms and double-laminating-table mechanisms. The positiveelectrode sheet feeding mechanisms and the negative electrode sheet feeding mechanisms are disposed on two sides of the double-laminating-table mechanisms, and the pole sheet conveying mechanisms aredisposed between the pole sheet die cutting mechanisms and the positive electrode sheet feeding mechanisms and between the pole sheet die cutting mechanisms and the negative electrode sheet feeding mechanisms. The diaphragm unwinding mechanisms are above the double-laminating-table mechanisms which comprise rotating shafts, rotating arms, central rotating shafts, first laminating tables and second laminating tables. The problems of low degree of automation of equipment and low production efficiency in the prior art are solved, the continuous lamination operation can be achieved, and the lamination efficiency is improved.

Owner:SHENZHEN GREENSUN TECH CO LTD

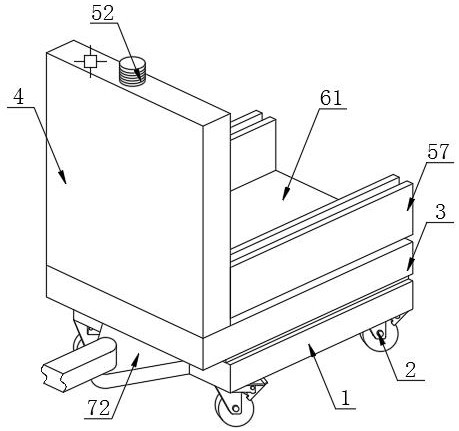

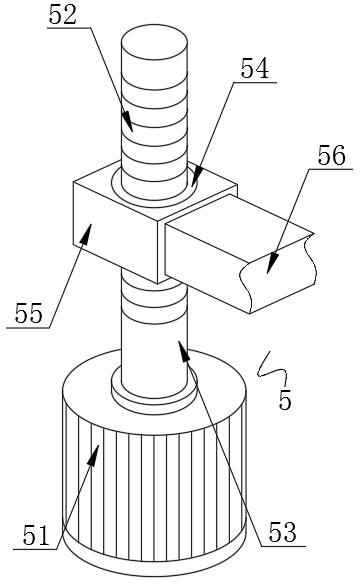

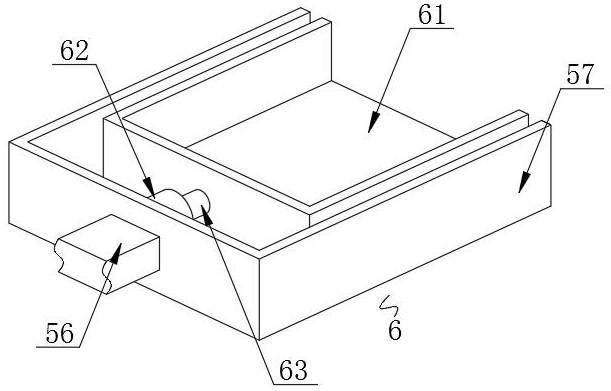

Product automatic tray filling equipment

PendingCN109607028AHigh degree of automationImprove efficiencyConveyorsControl devices for conveyorsEngineeringAutomation

The invention discloses product automatic tray filling equipment. The product automatic tray filling equipment includes a bracket, the outer surface of one side of the bracket is fixedly connected with a first tray full stock bin and a first tray empty stock bin, the first tray full stock bin is located on one side of the first tray empty stock bin, and the lower end of the first tray full stock bin is movably connected with a first tray full transporting trolley; the lower end of the first tray empty stock bin is movably connected with a first tray empty transporting trolley; and a loading work station is arranged in the bracket, a discharging work station is arranged at the position, close to one side, of the interior of the bracket, and a camera is arranged at the position, close to thetop end, of the interior of the bracket. The product automatic tray filling equipment has higher efficiency in the use process by arranging a series of structures, the design of the stock bin is directly compatible with the transporting trolley, the time of manual feeding and discharging is minimized, and the equipment has the advantages of being high in speed, stable in operation, high in degreeof automation, high in efficiency, convenient to operate and so on.

Owner:广东若贝特设备制造有限公司

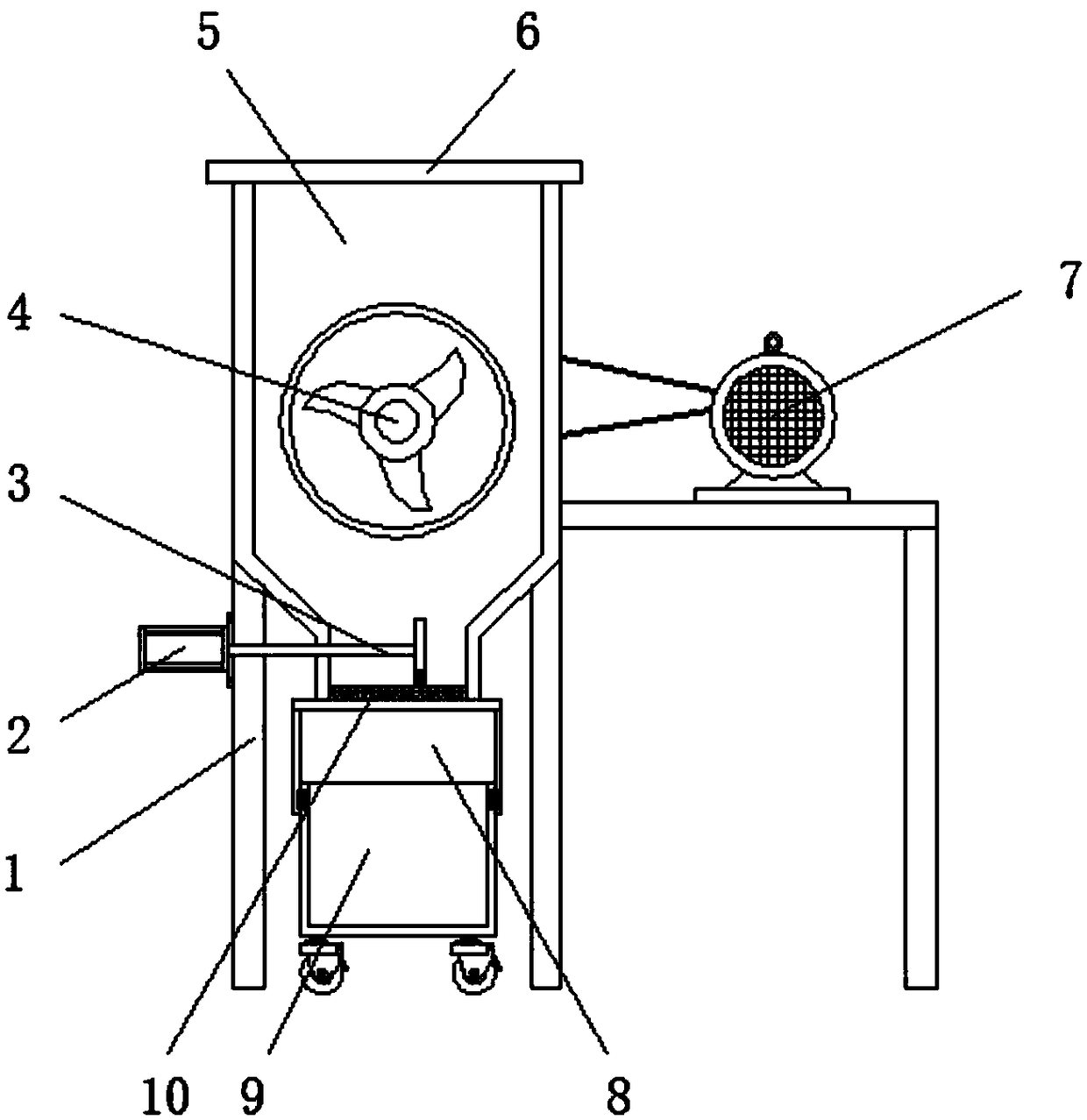

Plastic smashing device for plastic recovering

The invention discloses a plastic smashing device for plastic recovering. The plastic smashing device comprises a machining case, a feeding opening is formed in the top of the machining case, a smashing blade is installed inside the machining case, a driving motor is arranged on one side of the machining case, a rack is installed at the bottom of the machining case, the driving motor is fixed to the rack, a pushing assembly is arranged below the smashing blade, a hydraulic cylinder is arranged on one side of the pushing assembly and is installed on the side wall of one side of the rack, a screen is arranged below the pushing assembly, and a discharging opening is formed in the bottom of the machining case. The pushing assembly and a storing barrel form a plastic recovering system, smashedplastic is turned over on the screen and then falls from the screen, the recovering efficiency can be improved more sufficiently, plastic particles with qualified smashing grain sizes can be quickly sorted, the discharging time is shortened, the screen is not prone to being blocked, and maintenance is convenient.

Owner:FOSHAN JINJINGCHUANG ENVIRONMENTAL PROTECTION TECH CO LTD

Heated vulcanizing device based on seal ring application

PendingCN111633887AIncrease the production processGuaranteed buffer timeDomestic articlesVulcanizationMechanical engineering

The invention discloses a heated vulcanizing device based on seal ring application. The device comprises an operation table, a pressurizing device and a control cabinet, wherein a lifting table is disposed on the top of the operation table, and a baseplate is fixedly connected to the top of the lifting table. The invention relates to the technical field of vulcanizing devices. The heated vulcanizing device based on seal ring application is characterized in that a structure which can realize rapid unloading is formed through configuration of a movable block, a fixation shaft and a first springin a lower mold; at this moment, a worker only needs to move a tool plate from the inner side of the top of the lower mold towards the front side and take out all the formed seal rings, so that all the seal rings can be unloaded at the same time, unloading time is greatly saved, working efficiency is further increased, and processing and production of the seal rings are accelerated; and when a production amount of the seal rings is large, the worker can have certain buffering time and does not need to keep a rapid working state, and thus the worker can make operations more easily and conveniently.

Owner:WUXI TEHENG TECH CO LTD

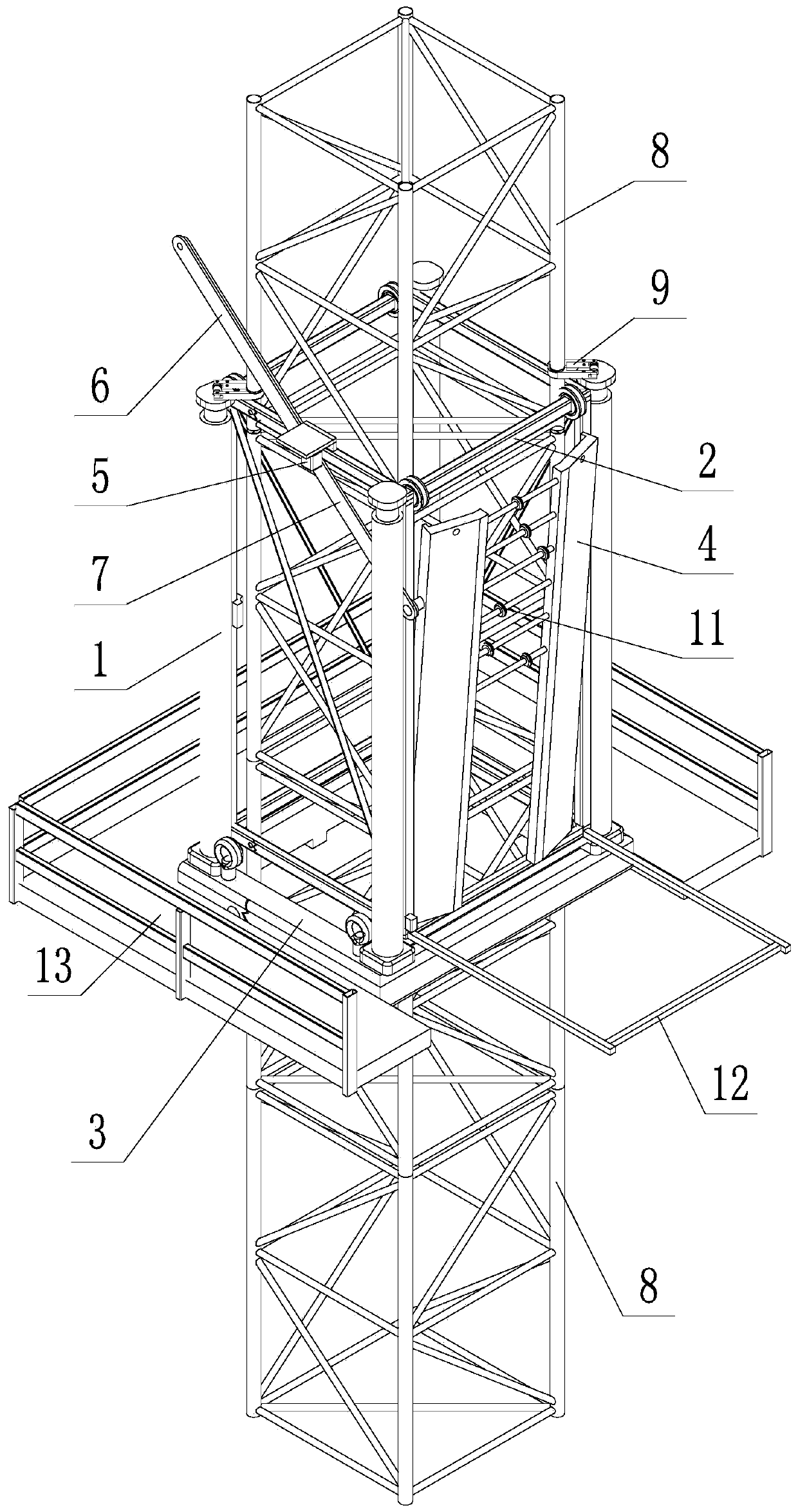

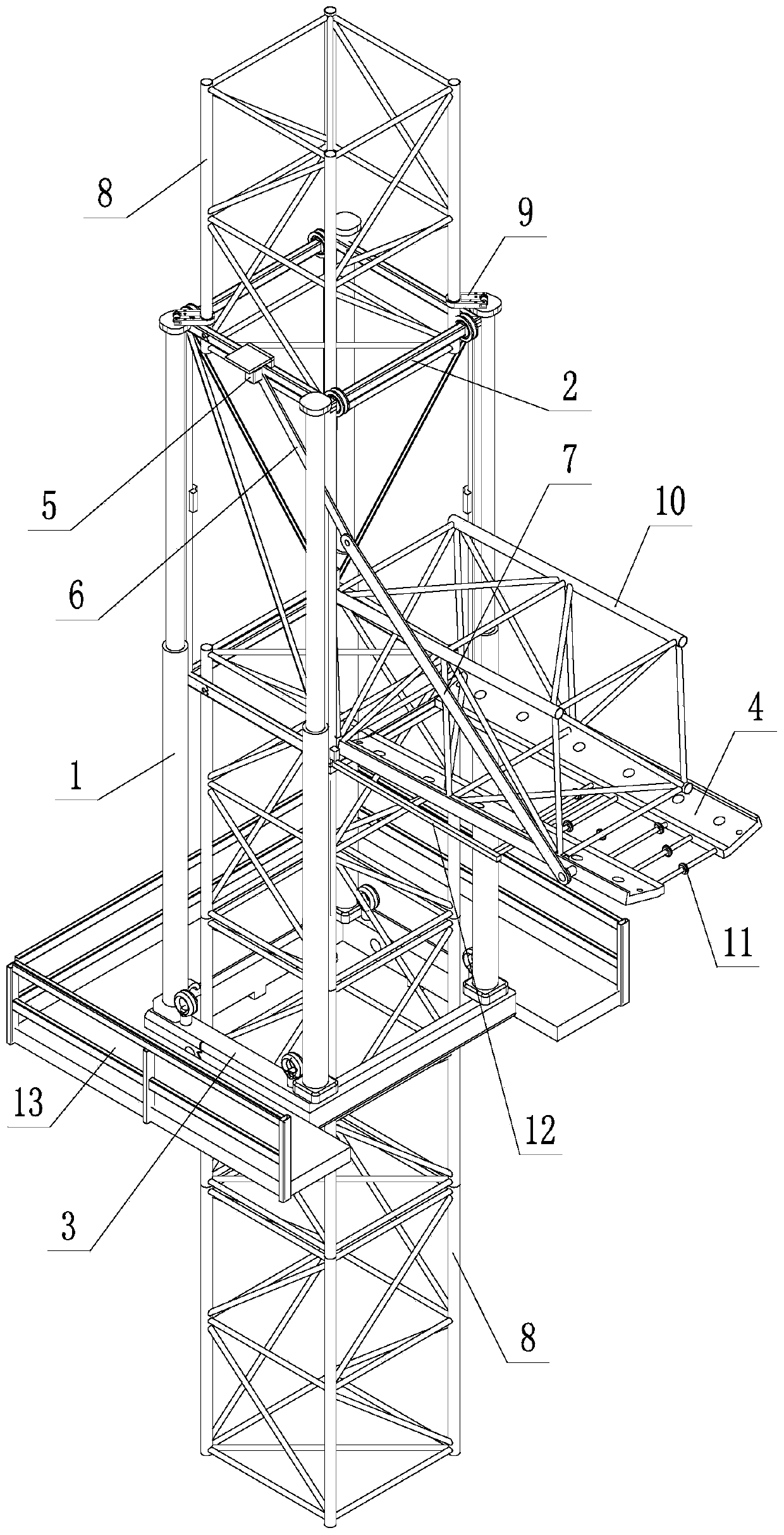

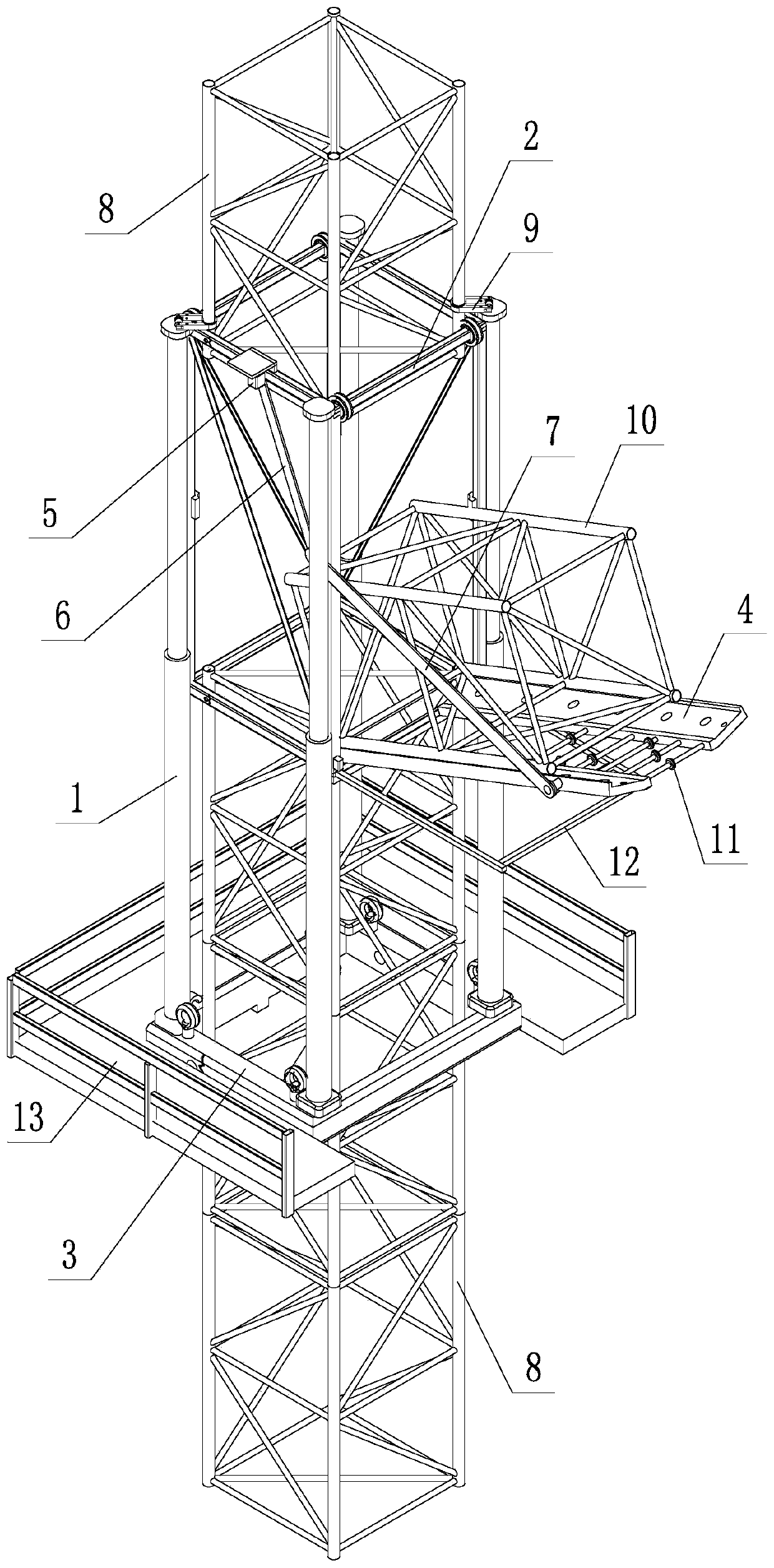

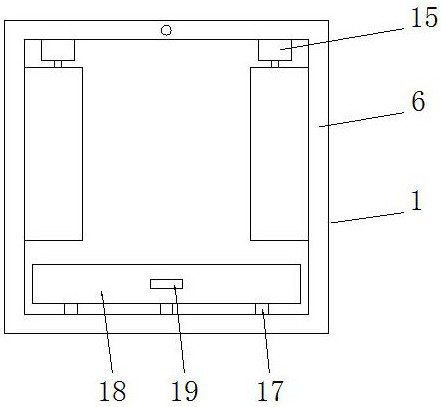

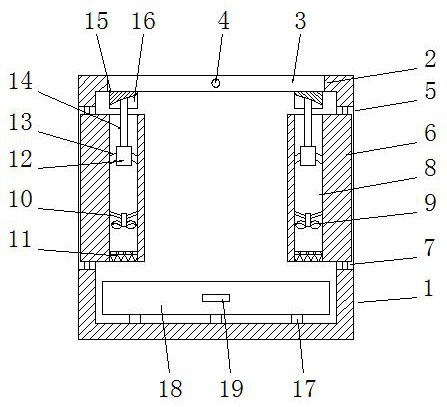

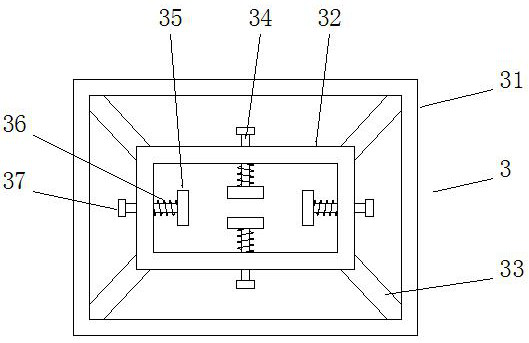

Automatic jacking in-place device and method for tower crane standard section

PendingCN110027992AEfficient and accurate in placeReduce professional requirementsLifting devicesCranesHydraulic cylinderElectric machinery

The invention discloses an automatic jacking in-place device and method for tower crane standard section. An upper frame and a lower frame of the device are fastened and fixed to an upper tower cranestandard section a lower tower crane standard section respectively, four jacking hydraulic cylinders are uniformly distributed and vertically arranged between the upper frame and the lower frame, piston rods of the jacking hydraulic cylinders are fixedly connected to the upper frame, and cylinder barrels of the jacking hydraulic cylinders are fixedly connected to the lower frame; and a turnover platform is hinged to the upper frame and is used for containing a to-be-installed standard section, and the turnover platform is driven by a motor. The method comprises the following steps that the upper tower crane standard section and the lower tower crane standard section are disconnected, and the upper frame and the upper tower crane standard section are synchronously jacked to a specified distance which is met by the requirement; the turnover platform is adjusted to a horizontal state; the to-be-installed standard section is hoisted to the turnover platform in an inverted state; the turnover platform and the to-be-installed standard section are synchronously adjusted to an upright state, the to-be-installed standard section is enabled to fall onto the lower tower crane standard sectionis fixedly connected to the lower tower crane standard section, and the upper tower crane standard section is enabled to fall onto the to-be-installed standard section and is fixedly connected to theto-be-installed standard section; and tightening between the lower frame and the lower tower crane standard section are relieved, and the cylinder barrels of the jacking hydraulic cylinders are lifted back to the initial position.

Owner:SHENYANG JIANZHU UNIVERSITY

PCB welding table based on independent cooling technology

InactiveCN112059355AAvoid scatterAvoid pollutionWelding/cutting auxillary devicesAuxillary welding devicesMachining timePneumatic cylinder

The invention discloses a PCB welding table based on an independent cooling technology. The PCB welding table comprises a table frame; the top end of the table frame is connected with an overturning cavity in a communicating mode; a welding table plate is arranged in the overturning cavity; the welding table plate is rotationally connected to the inner cavity wall of the overturning cavity throughan overturning shaft; side supporting cavities are symmetrically formed in the left side end and the right side end of the table frame; supporting columns are arranged in the side supporting cavities; the supporting columns are rotationally connected to the side supporting cavities through rotating shafts; first protective nets, air cooling fans and pneumatic cylinders are sequentially arranged in inner cavities of air cooling holes from bottom to top; and supporting plate assemblies matched with the welding table plate are fixedly connected to the top ends of pneumatic rods on the pneumaticcylinders. External air is dragged by the air cooling fans to enter the air cooling holes and blows upwards along the air cooling holes, the rising airflow flows to the bottom end of the welding tableplate under the action of a flow guide cavity and obliquely blows the PCB on the welding table plate, thus the PCB can be rapidly cooled, the cooling time of the PCB can be greatly shortened, the non-machining time can be greatly shortened, and the machining efficiency can be greatly improved.

Owner:王文俊

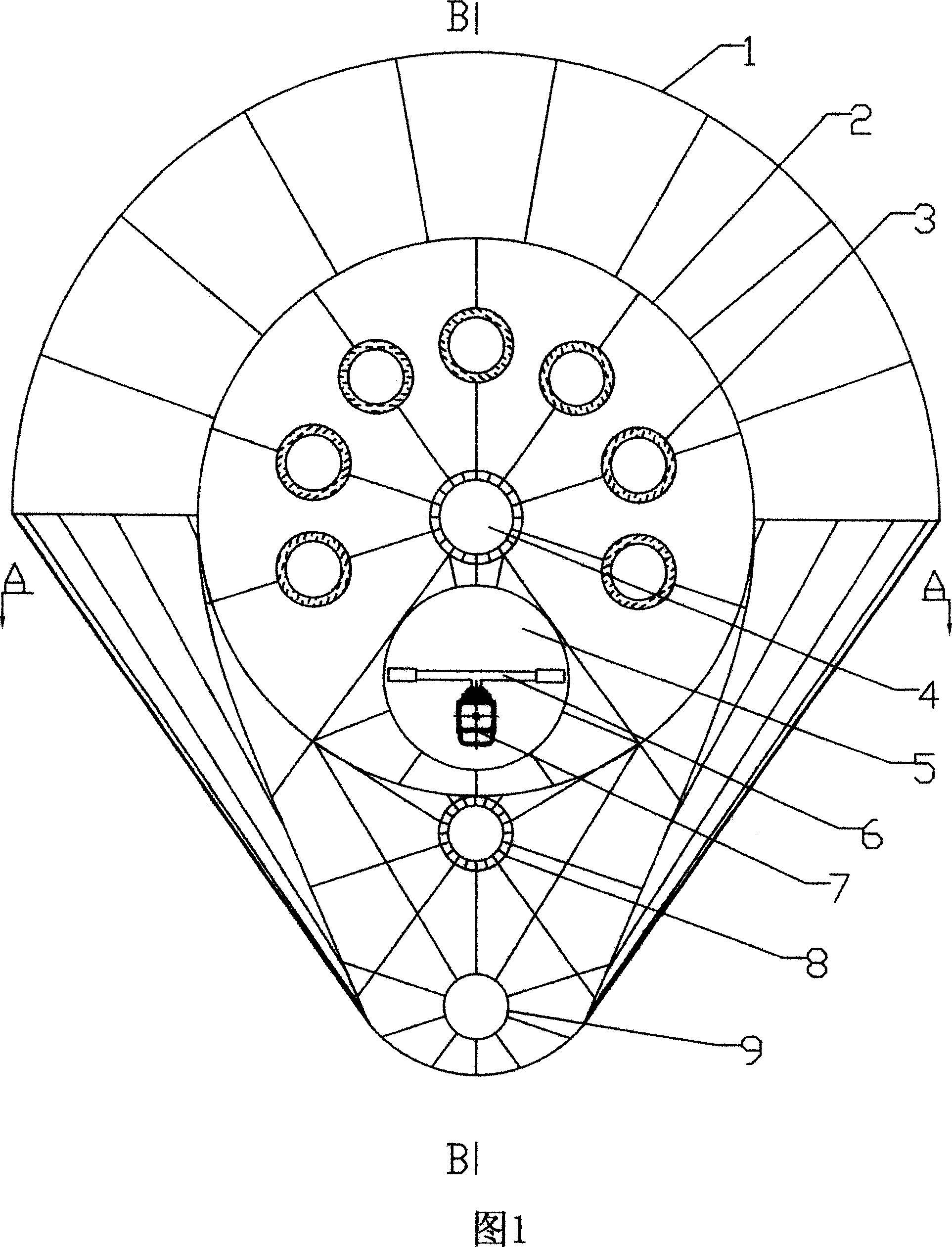

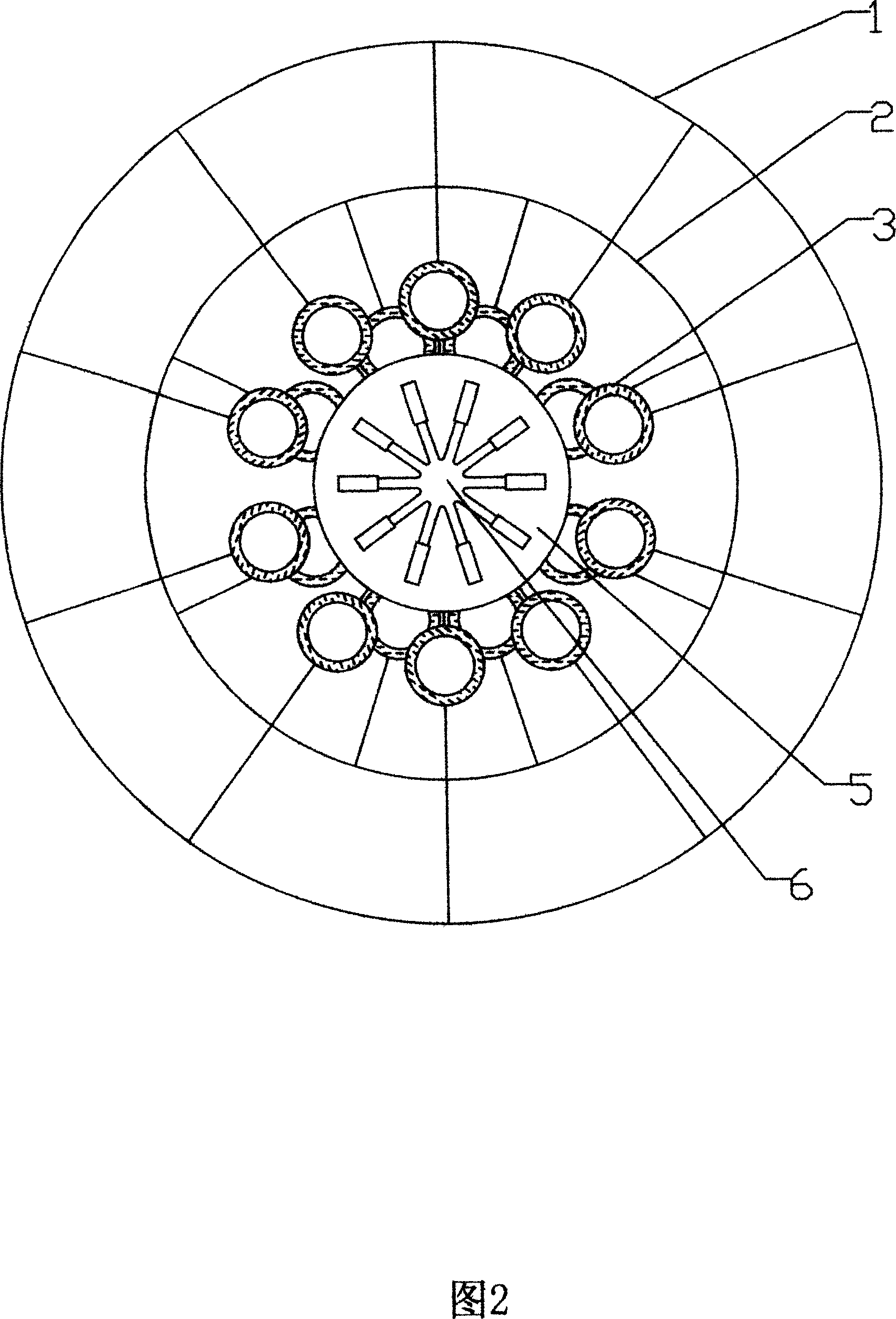

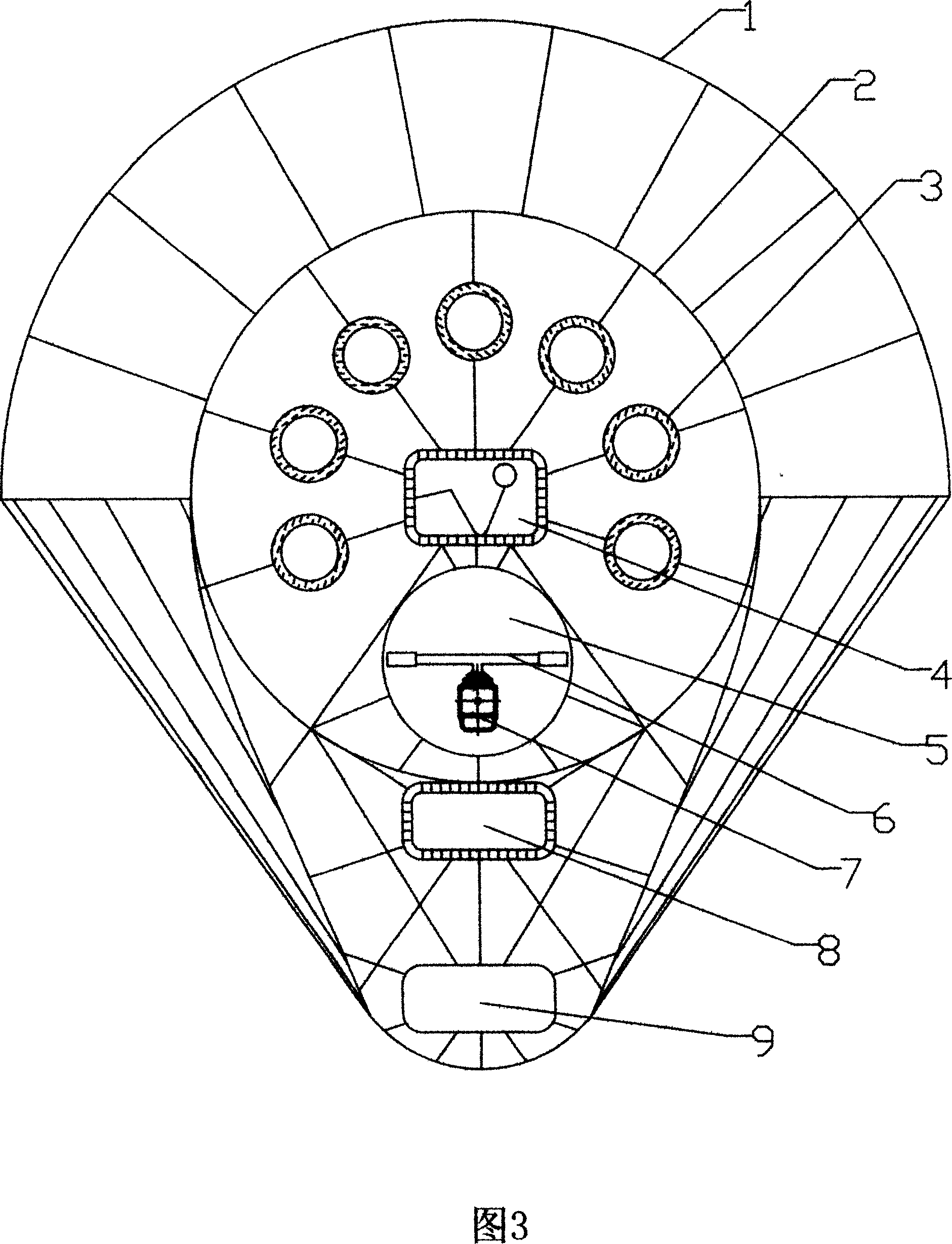

Decklevel parachute jump equipment

InactiveCN101003304AShorten the blanking timeImprove securityBreathing protectionAircraft ejection meansGas cylinderEngineering

An ultralow-sky parachute system for parachutist or lifesaving of high building is composed of a parachute, an inflatable anti-shock clothing, and a parachute bag consisting of a person carrying cavity, posture control cavity, an equipment cavity for parachutist, and an apparatus cavity containing high-pressure air cylinder for inflating said clothing.

Owner:王宝根

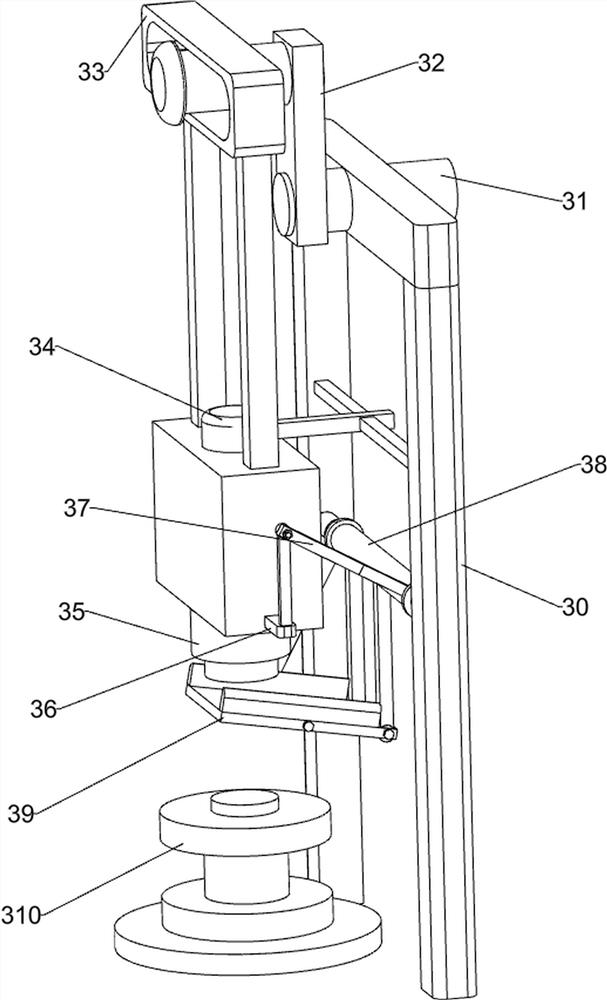

Bending machine for machining auto parts and method of bending machine

InactiveCN110639993AAvoid bruisesKeep healthyMetal-working feeding devicesPositioning devicesGear wheelElectric machinery

The invention discloses a bending machine for machining auto parts and a method of the bending machine. The bending machine include a seat frame, a conveying groove is formed in one side of the top end of the seat frame, a conveying mechanism is arranged in the conveying groove, a feeding mechanism and two brackets matched with the conveying mechanism are fixedly mounted at the top end of the seatframe, the two brackets are jointly and rotatably connected with a bending rod, one end of the bending rod is fixedly connected with a bending arm, a driven gear is arranged in the middle of the bending rod in a sleeving mode, a bending motor is also fixedly mounted at the top end of the seat frame, a first rotating shaft is rotatably connected to the bending motor, and a driving gear matched with the driven gear is fixedly mounted on the first rotating shaft. According to the bending machine for machining auto parts and the method of the bending machine, a telescopic rod is used for jackinga push plate, the push plate directly pushes out a workpiece machined in the bending arm, and the workpiece falls directly on the conveying mechanism and is sent to a material frame with the conveyingmechanism, the entire blanking process is automatically completed, the blanking time is greatly shortened, and thus the processing efficiency is improved; and the entire process does not require manual participation, and hurting of workers by the machine can be effectively avoided.

Owner:南京沃瑞新能源科技有限公司

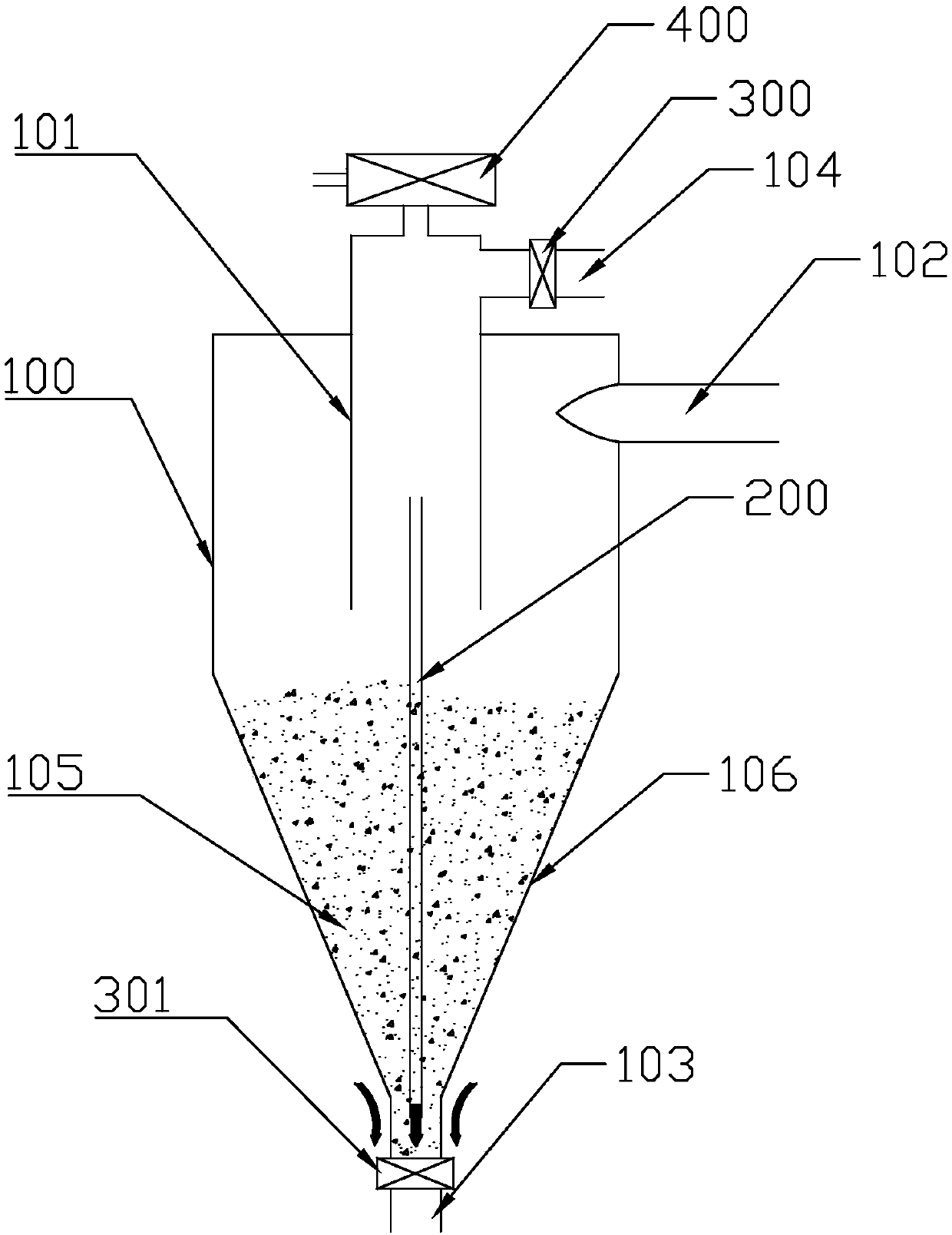

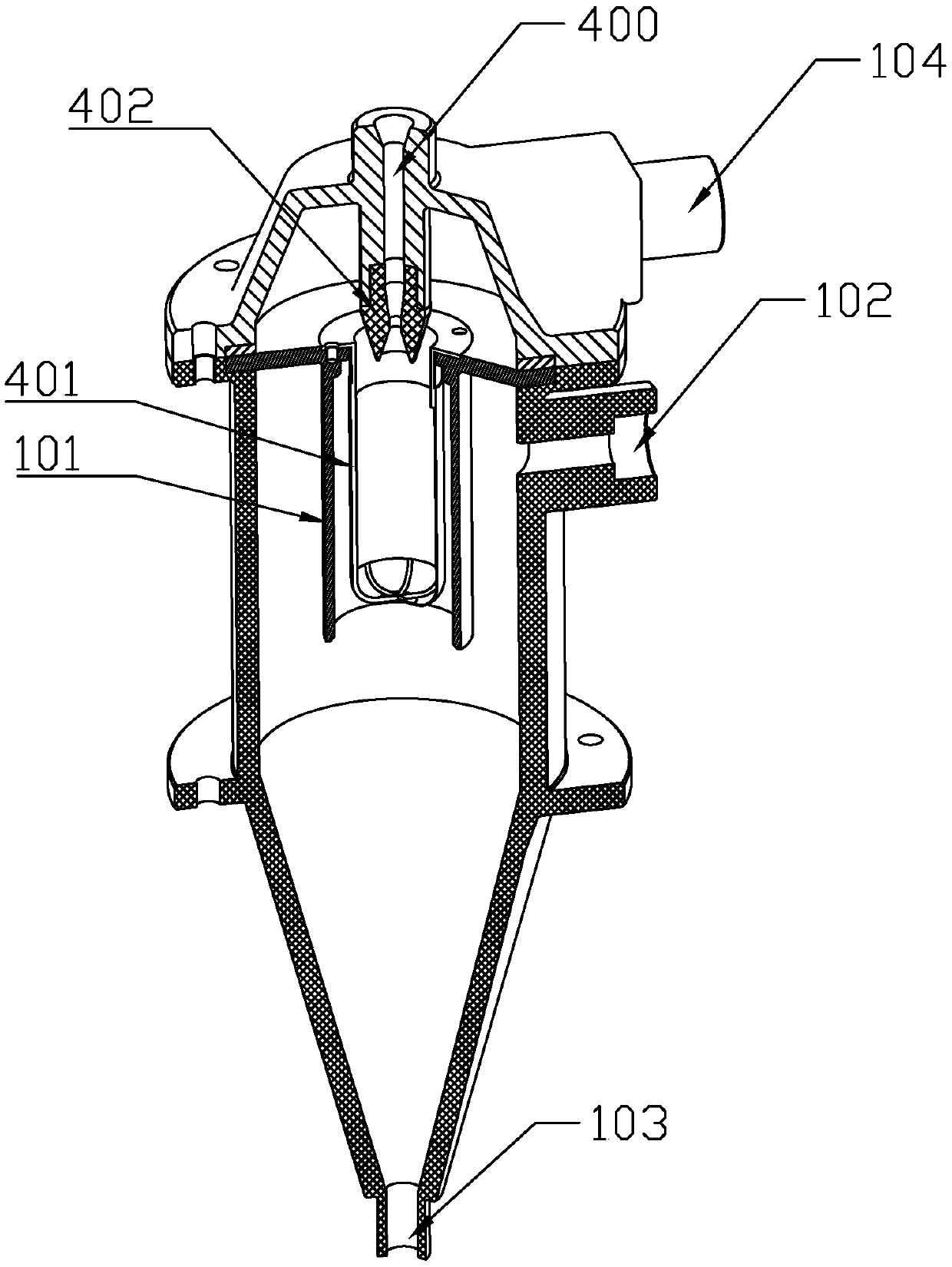

Microcrystalline heat insulation particles and continuous production apparatus thereof

PendingCN109180043AEfficient deliveryIncreased puffing endothermic timeGlass shaping apparatusVitrificationEngineering

The invention provides a continuous production apparatus of a microcrystalline heat insulation particle. The apparatus comprises a raw material bin, a preheating furnace, a kiln, a cooler and a finished product bin which are sequentially connected, a raw material is preheated by the preheating furnace and then is conveyed into the kiln through a tubular chain lifter, the kiln comprises a furnace body, a feeding bin is arranged at the upper end of the furnace body, a discharging port is arranged at the lower end of the furnace body, the furnace body comprises an expansion section and a vitrification section, a discharging device is arranged in the expansion section of the furnace body, the discharging device comprises at least one set of funnel and conical bucket, and the preheated sands are dispersed and gathered through the inner walls of the funnel and the cone; and the furnace body is symmetrically provided with a plurality of sets of burners. The perlite ore sands are dispersed andthen gathered in the furnace body, so the discharging time is delayed, and the expansion heat absorption time of the preheated sands is prolonged to ensure sufficient heat absorption and reach a expansion temperature; and the microcrystalline heat insulation particle wrapped with a smooth surface and having a cavity structure is produced through the apparatus, and the heat insulation particle hasthe advantages of no water absorption, high strength and excellent heat insulation performance.

Owner:湖南斯多孚节能科技有限公司

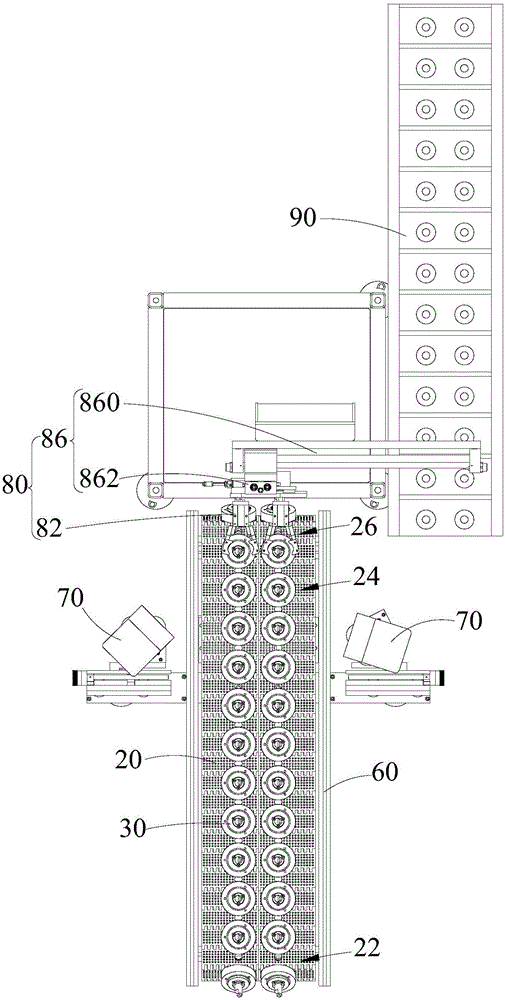

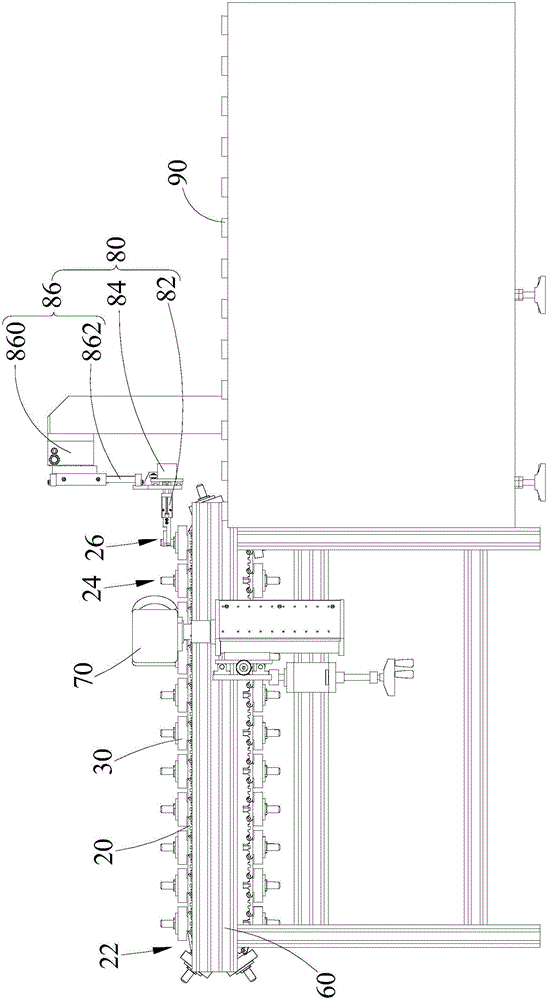

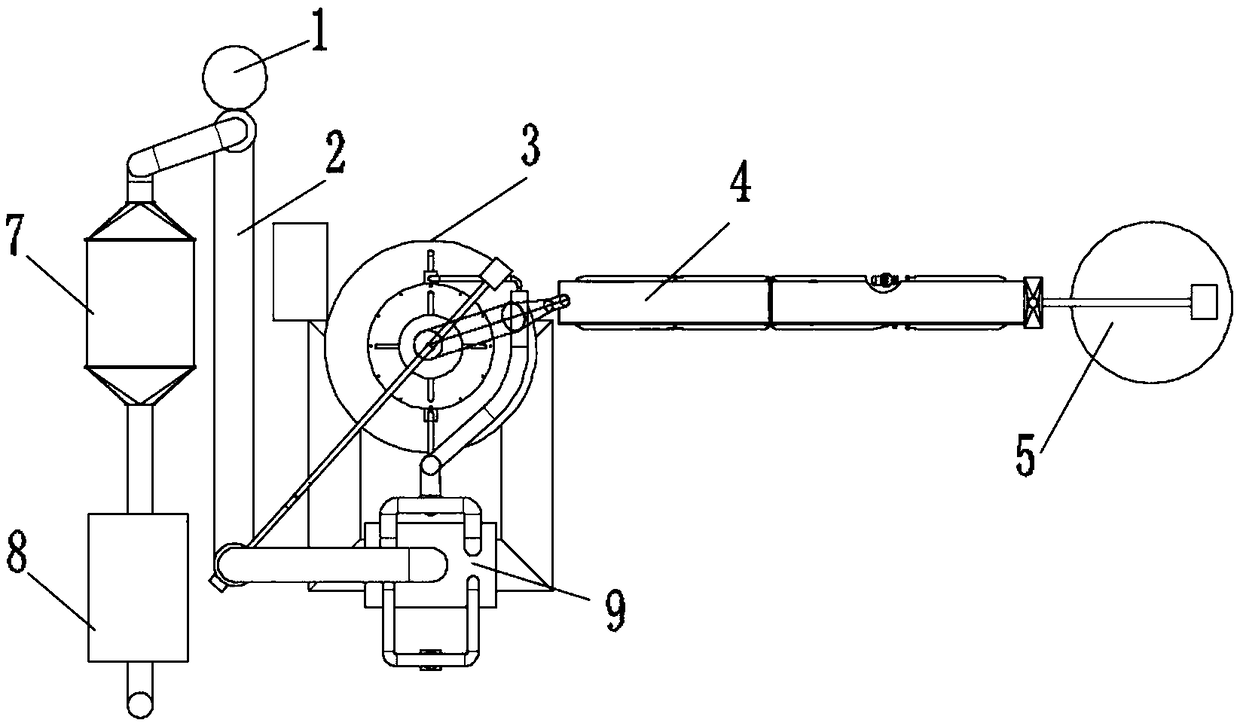

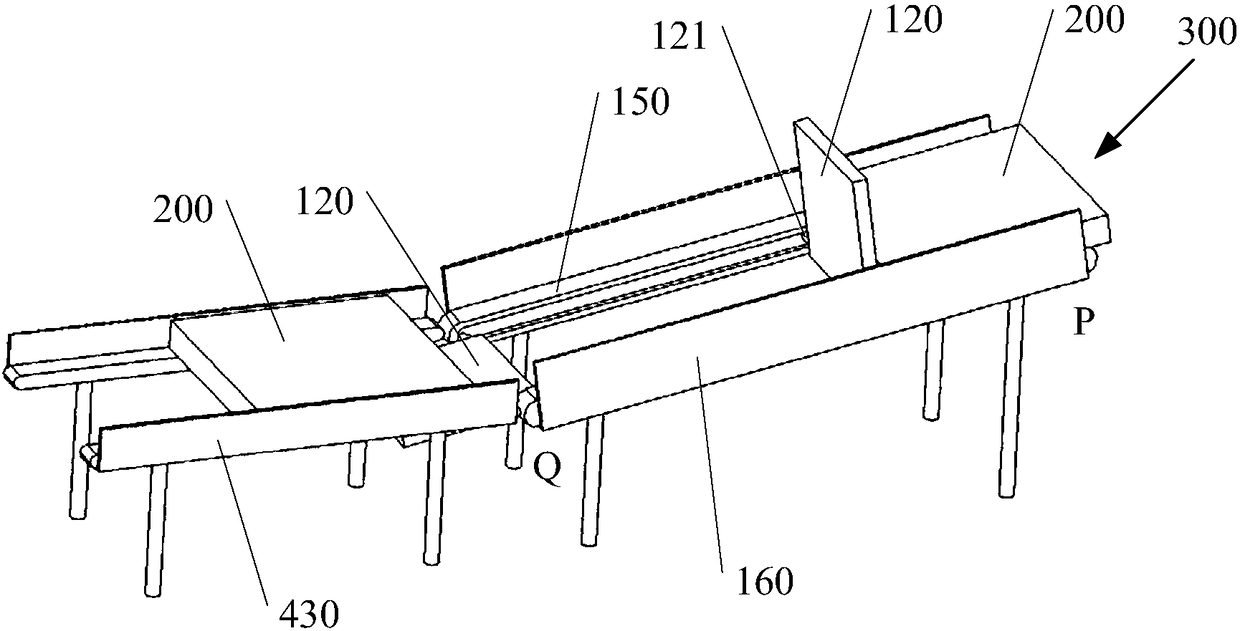

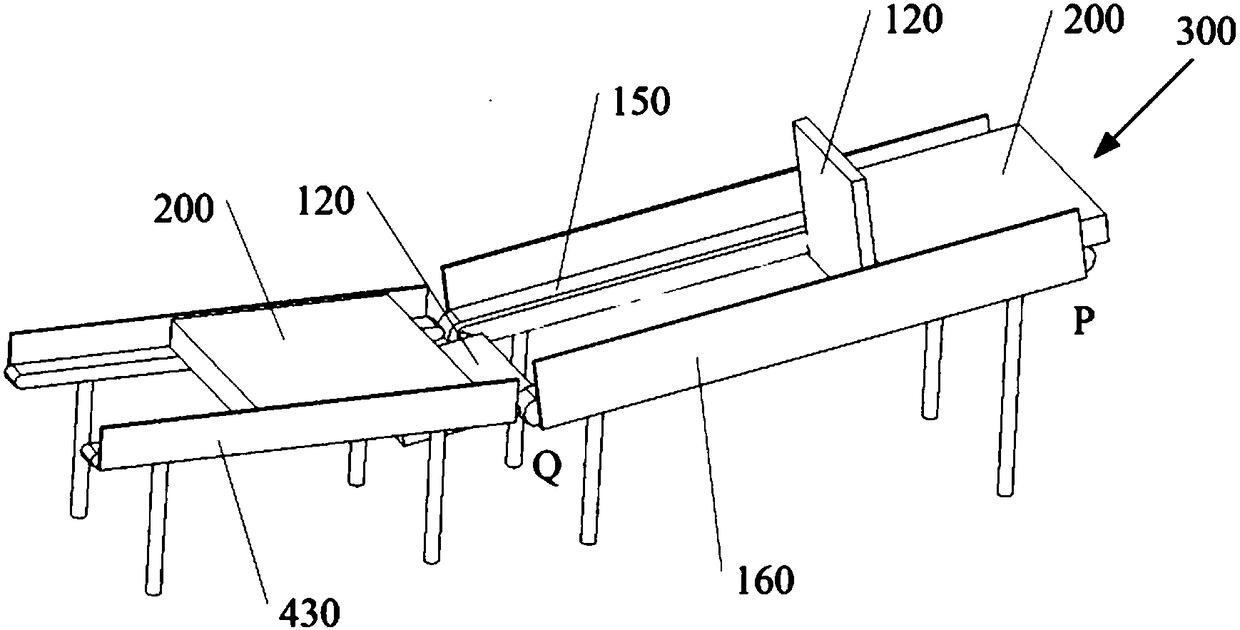

Automatic blanking device for conveying battery pieces

ActiveCN108069245ARealize deliveryShorten the blanking timePackaging automatic controlConveyor partsConveyor beltAutomation

The invention discloses an automatic blanking device for conveying battery pieces. The automatic blanking device comprises a first conveying device which comprises a first bracket, steering stop dogs,a steering drive, a linear reciprocating drive and two first conveyor belts; the two first conveyor belts are arranged between two first side plates on the first bracket; the two first conveyor beltsare arranged parallelly in a spaced manner; the steering stop dogs are slidably arranged on the first side plate; the steering drive drives the steering stop dogs to overturn, and the linear reciprocating drive drives the steering stop dogs to reciprocate; the steering stop dogs at the input end of the first conveyor belts are in vertical states, and overturn below the battery pieces at the output ends of the first conveyor belts; the automatic blanking device also comprises a second conveying device which comprises a second bracket and two second conveyor belts, wherein the two second conveyor belts are arranged between two second side plates on the second bracket, the second conveyor belts are arranged parallelly in a spaced manner, and the input ends of the second conveyor belts and the output ends of the first conveyor belts are docked, so that the automatic blanking device has the advantages of being free of staff to participate in the full course and high in degree of automation.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

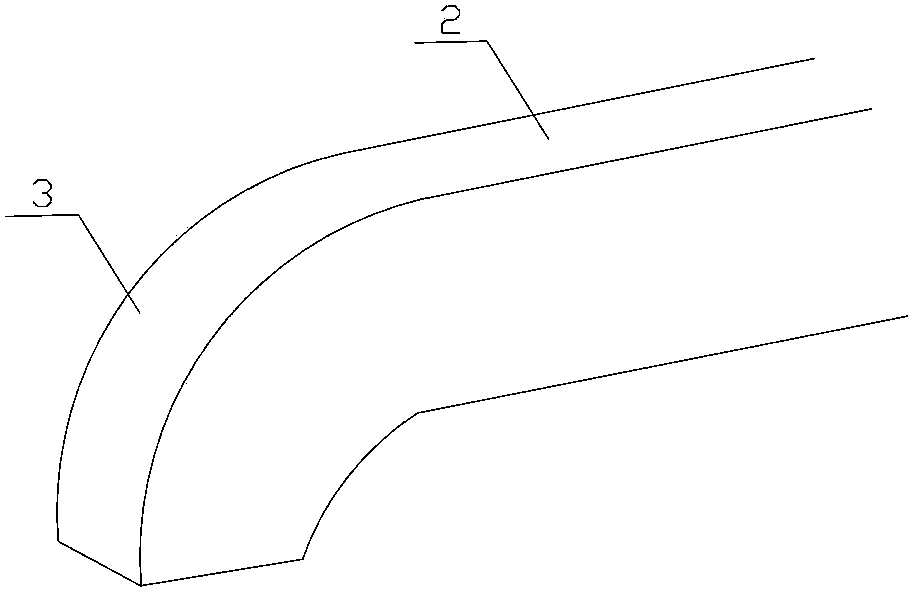

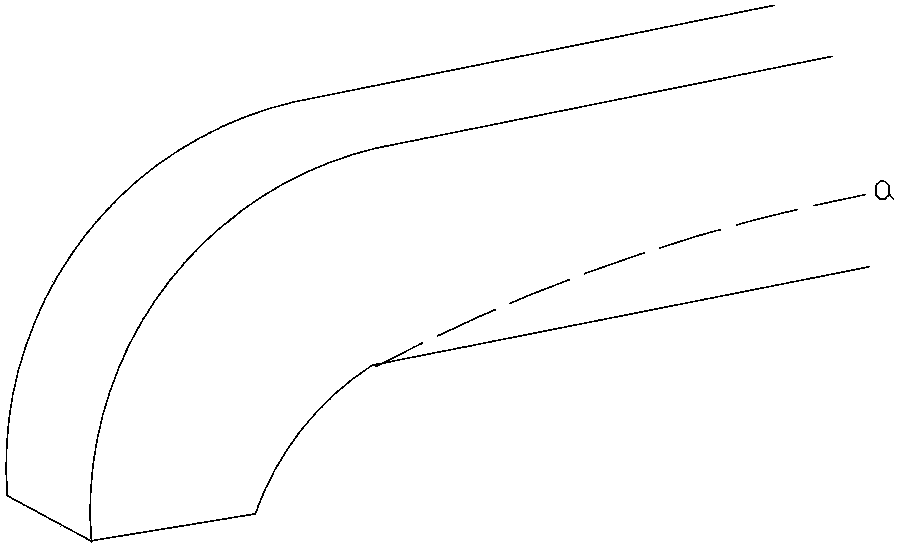

Boom manufacturing method, boom manufactured by using method and pump truck using boom

ActiveCN103470043AMeet the exercise requirementEasy to processBuilding material handlingTruckAluminium alloy

The invention aims at providing a method for manufacturing a boom by using aluminum alloy sections, the boom and a pump truck using the boom provided by the invention. The technical scheme is that the boom manufacturing method comprises the steps of extruding the aluminum alloy sections; performing variable-cross-section treatment to the aluminum alloy sections, i.e. removing partial materials at positions which bear small force to form cross sections with different sizes. The boom provided by the invention is formed by performing bending treatment and variable-cross-section treatment to the aluminum alloy sections and comprises a main body and a head which form a preset included angle. The pump truck provided by the invention uses the boom provided by the invention.

Owner:SNTO TECH GRP

Method for manufacturing air condition compressor balance block

ActiveCN102248373BIncrease productivitySuitable for mass productionMechanical engineering technologyWork in process

Owner:浙江百达精工股份有限公司

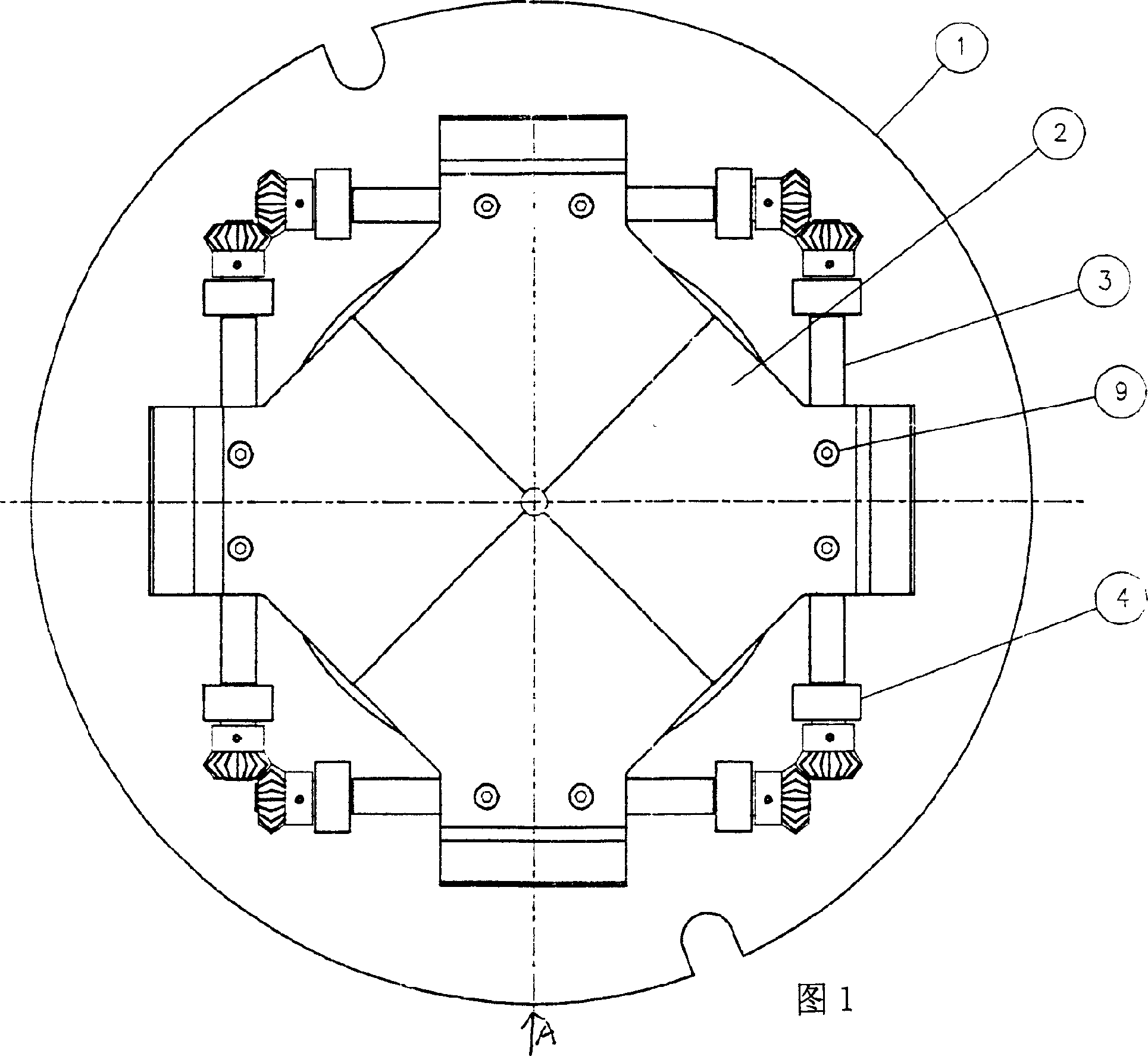

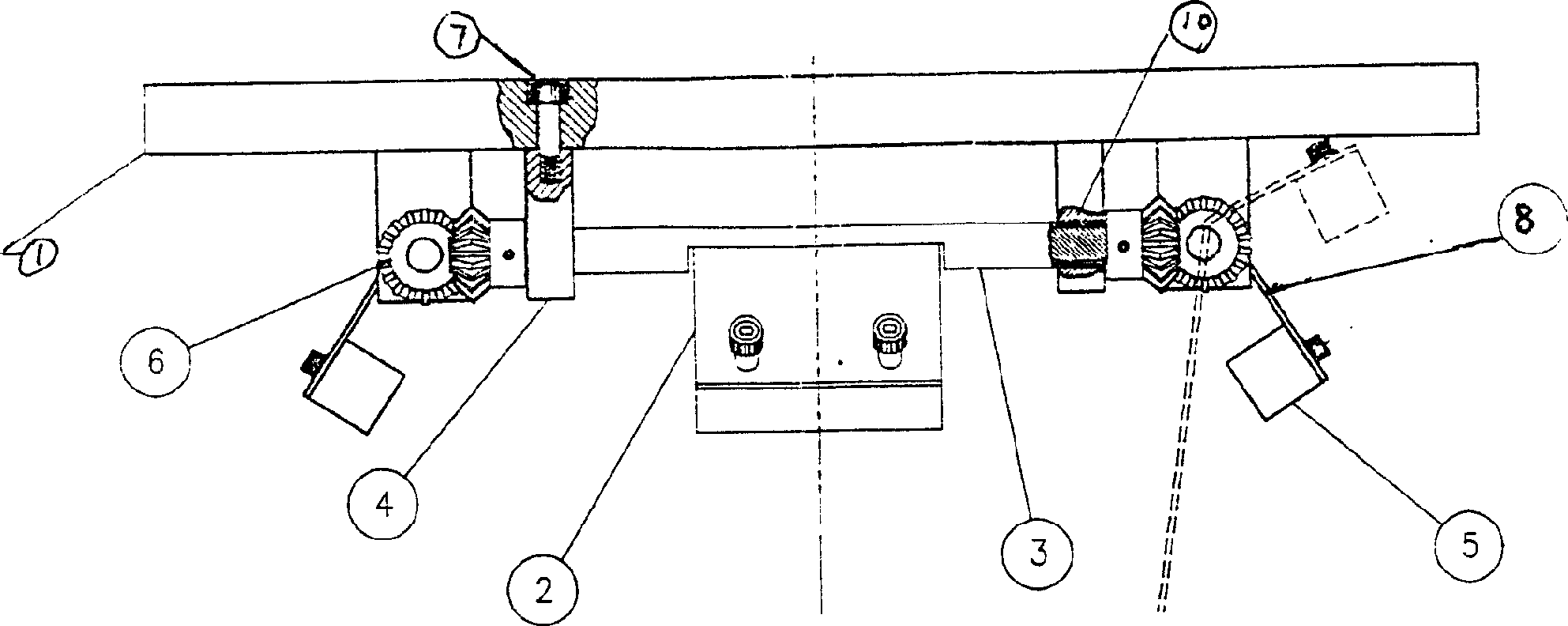

Automatic blanking device

InactiveCN1594156AImprove productivity and precisionShorten the blanking timeGlass fibre drawing apparatusRound barEngineering

Disclosed is an automatic blanking device for controlling air enter wiredrawing furnace during optical fiber drawing process, characterized in that, four round sticks with copper wheel gears on the two ends engage each other to form a square frame, four iron sheets are mounted vertically centering the round stick, the area formed by the four iron sheets covers the internal diameter of the annealing tube, the gear wheel on one end of each round stick is also provided with a iron rod with a balancing iron block on the end.

Owner:浙江富春江罗依尔光纤制造有限公司

Sweeping and collecting equipment for municipal garden environmental sanitation

InactiveCN113832898AAvoid clearingBig spaceRoad cleaningGrain treatmentsAgricultural scienceAgricultural engineering

The invention relates to sweeping and collecting equipment for municipal garden environmental sanitation, which comprises a moving seat and a storage box arranged at the top of the moving seat, and a sweeping device is arranged on the left side of the storage box. The cleaning device comprises lifting mechanisms arranged on the front side and the rear side of the storage box, material blocking mechanisms arranged on the front side and the rear side of the storage box, a discharging mechanism arranged on one side of the storage box, a crushing mechanism arranged on one side of the storage box and a discharging mechanism arranged on the crushing mechanism. Swept fallen leaves and short branches are crushed and rolled through linkage among the blanking groove, the crushing mechanism and the discharging mechanism, so that the space for storing the fallen leaves in a first collecting frame is increased, sanitation workers are prevented from frequently removing the fallen leaves, the short branches and gravel in the first collecting frame and a second collecting frame, the working time is saved, and the labor force is reduced.

Owner:尹国强

Rectangular iron sheet punching equipment

PendingCN112059007AShorten the blanking timeImprove securityMetal-working feeding devicesPositioning devicesPunchingPulley

The invention relates to punching equipment, in particular to rectangular iron sheet punching equipment. The rectangular iron sheet punching equipment is high in safety, automatic in feeding and rapidin punching. The rectangular iron sheet punching equipment comprises a base, a punching mechanism and a belt pulley assembly, wherein a servo motor is arranged on one side of the top of the base; thepunching mechanism is arranged in the middle of the top of the base; and the belt pulley assembly is arranged between an output shaft of the servo motor and the punching mechanism. The servo motor isused for controlling the punching mechanism and a pushing mechanism to operate, the pushing mechanism performs automatic feeding on rectangular iron sheets, rapid punching is conducted in cooperationwith the punching mechanism, the blanking time is saved, and after excess materials fall onto a storage plate, the excess materials slide forwards along the inclined face of the storage plate and fall into a storage box, so that a worker can conveniently collect and treat the excess materials.

Owner:刘子军

Machining equipment with burr grinding function for special-shaped bolt fault diagnosis

InactiveCN111993192AEasy to sendRealize automatic feeding operationEdge grinding machinesGrinding carriagesVisual inspectionAbnormal shaped

The invention discloses machining equipment with burr grinding function for a special-shaped bolt fault diagnosis. The machining equipment with the burr grinding function for the special-shaped bolt fault diagnosis comprises a main body frame, a clamping and conveying frame and a clamping frame, and a conveying belt is arranged on the left side of the lower portion of the interior of the main bodyframe. According to the machining equipment with the burr grinding function for the special-shaped bolt fault diagnosis, compared with existing common visual inspection equipment, a first groove is formed, a first servo motor rotates to drive a first rotating shaft to rotate, the first rotating shaft drives a first sliding block to move along the first groove through a second groove in a rotatingrod, a first moving rod is driven to move along the first groove, the first groove is in a semi-closed type, and the lengths of the two sides of the first groove are equal, the distance between the conveying belt and a clamping table is equal to the distance between the clamping table and a second clamping block, the distance between the conveying belt and the clamping table is equal to the lengths of the two sides of the first groove, bolts can be conveniently clamped to the second clamping block from the conveying belt, and automatic feeding operation is achieved.

Owner:重庆数智源智能装备科技有限公司

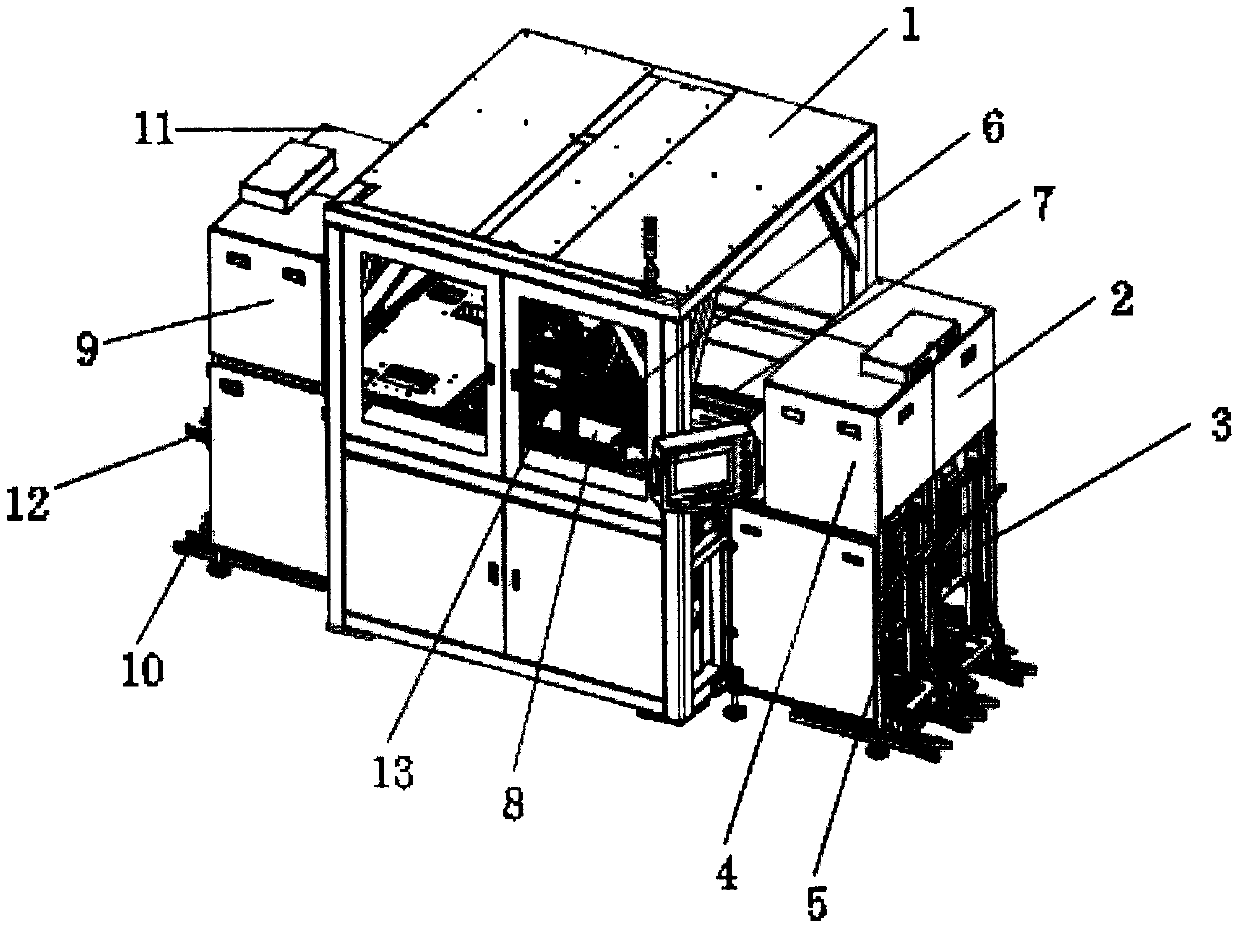

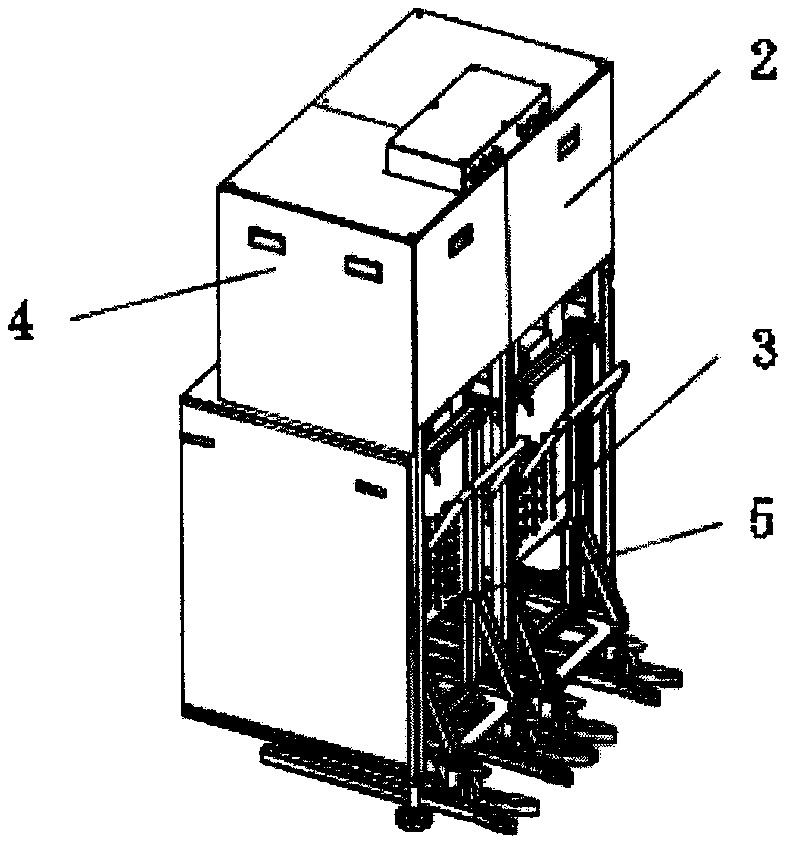

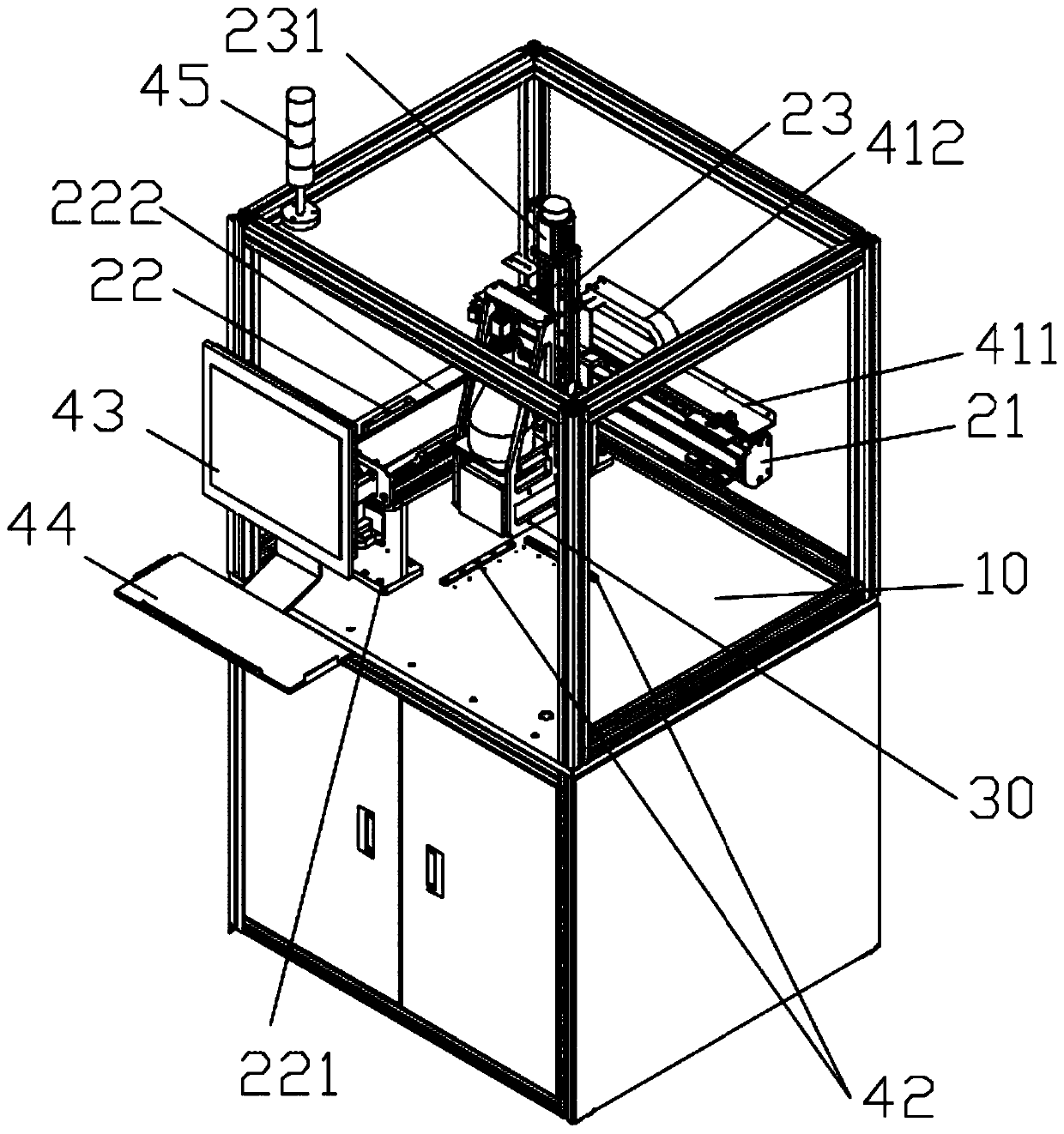

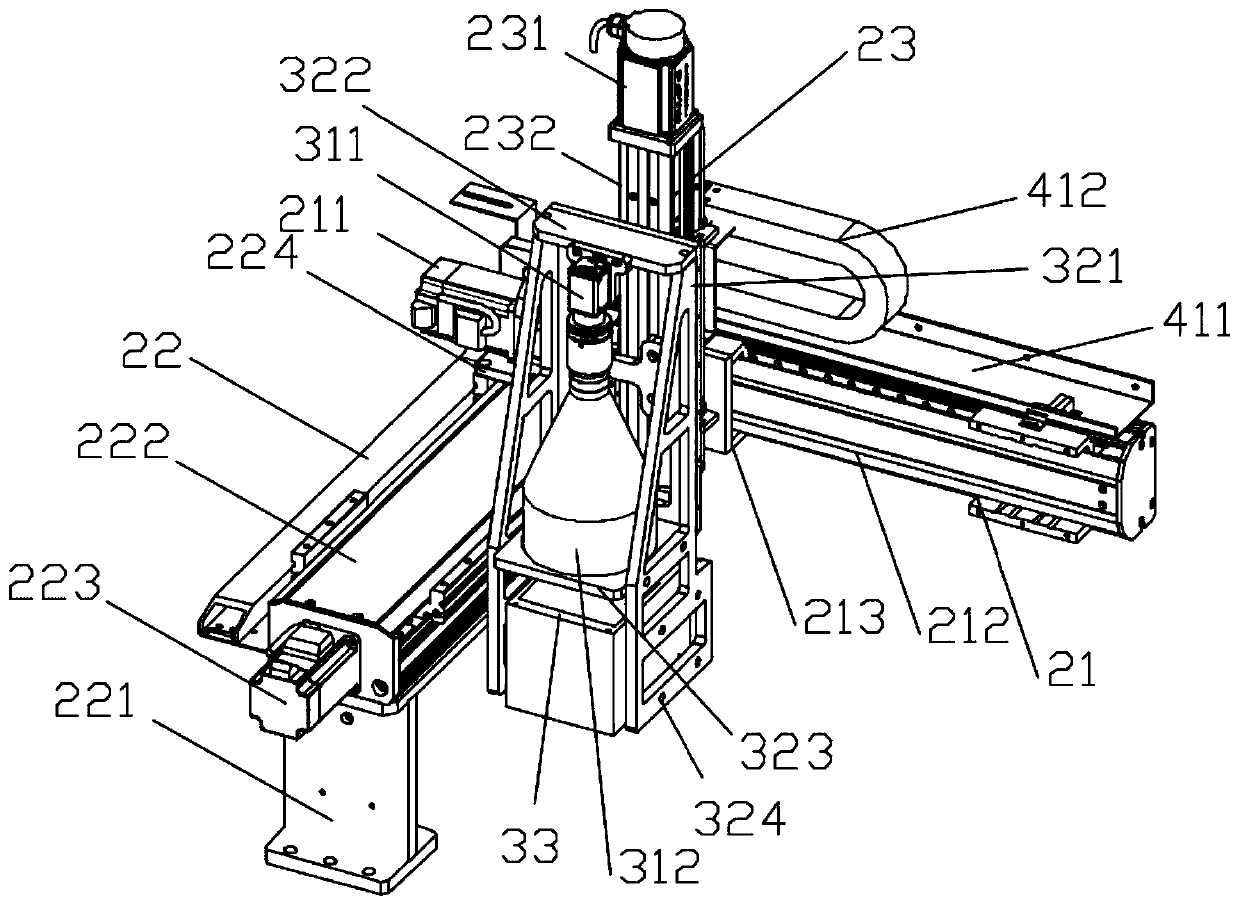

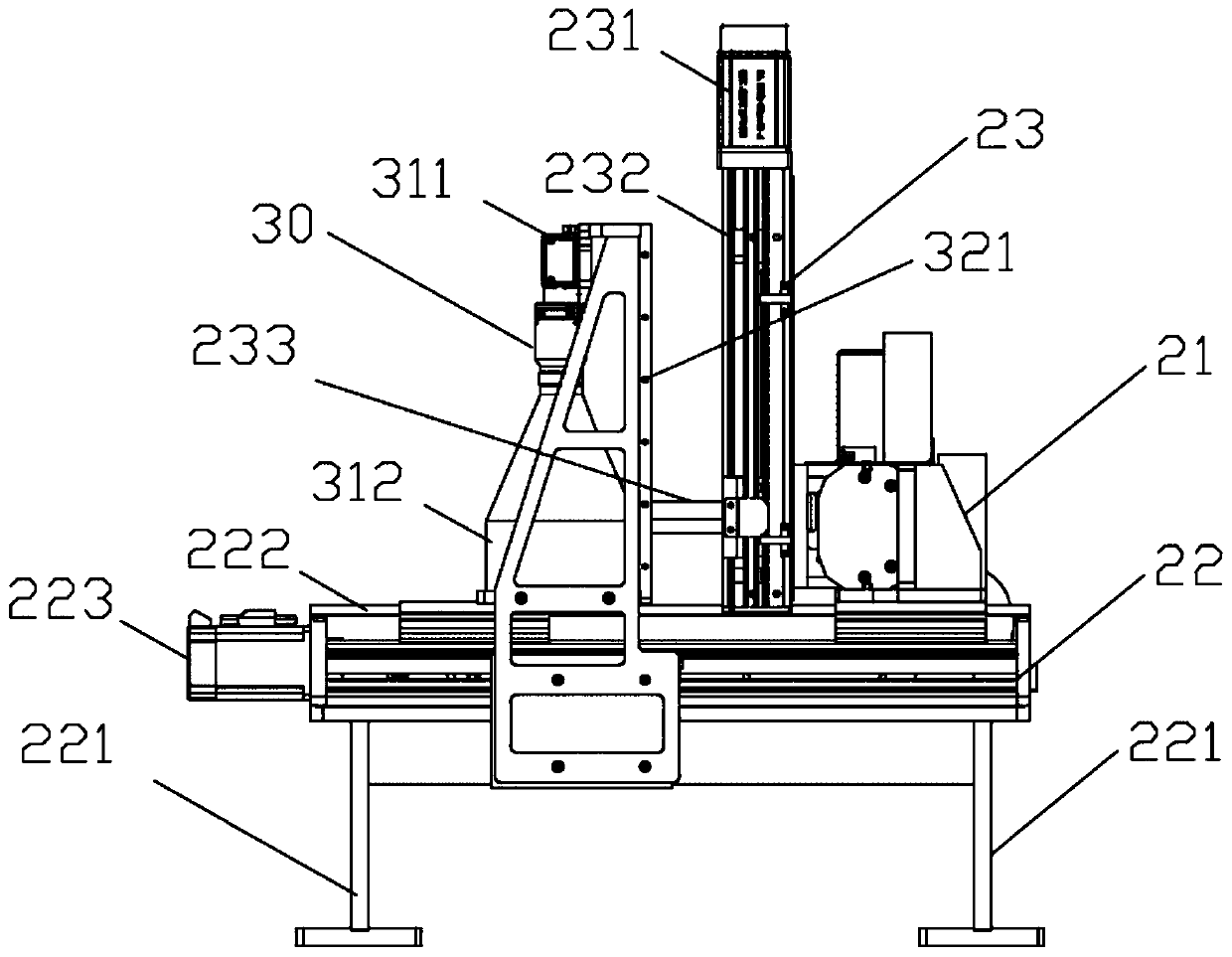

Connector detection equipment, detection method and production line

PendingCN111044840AExpand the shooting rangeReduce stepsContact member assembly/disassemblyElectrical testingProduction lineKinematic controller

An embodiment of the invention discloses connector detection equipment, a detection method and a production line. The connector detection equipment comprises a supporting mechanism used for accommodating a connector, a controller, an X-axis movement mechanism, a Y-axis movement mechanism, a Z-axis movement mechanism and a camera shooting mechanism used for shooting a contact pin of the connector,wherein the X-axis movement mechanism, the Y-axis movement mechanism and the Z-axis movement mechanism are located above the supporting mechanism; the Z-axis movement mechanism is connected with the camera shooting mechanism so as to drive the camera shooting mechanism to move back and forth in the Z-axis direction; the X-axis movement mechanism is connected with the Z-axis movement mechanism so as to drive the Z-axis movement mechanism and the camera shooting mechanism to move back and forth in the X-axis direction; the Y-axis movement mechanism is connected with the X-axis movement mechanismso as to drive the X-axis movement mechanism, the Z-axis movement mechanism and the camera shooting mechanism to move back and forth in the Y-axis direction; and the controller is electrically connected with the X-axis movement mechanism, the Y-axis movement mechanism, the Z-axis movement mechanism and the camera shooting mechanism. The connector detection equipment is high in automation degree,improves the detection accuracy, improves the detection efficiency, and reduces the production cost.

Owner:河南金华电气有限公司

A broken arch bin and a cutting machine with the same

ActiveCN106473628BImprove versatilityGuaranteed uniformityKitchen equipmentGrain treatmentsEngineeringCrystallization

The invention discloses an arch breaking bin, comprising an outer separation barrel; a feed port is arranged in the sidewall of the outer separation barrel, a condiment is fed from the feed port into the outer separation barrel, gas subjected to gas-solid separation is discharged from a gas outlet, and the condiment is dropped into the outer separation barrel and discharged from a discharge port. The arch breaking bin is characterized in that the outer separation barrel is also provided with a pulse valve, the pulse valve can provide a pulse flow, an arch breaking tube is also arranged between the pulse valve and a discharge port passage and is provided with pores, and part of the pulse flow passes through the arch breaking tube and is scattered via the pores to break an arch of the condiment during discharging. The invention also discloses a discharge unit comprising the arch breaking bin. The arch breaking bin is simple in structure, can effectively eliminate arching and bridging due to dampening and crystallization of the condiment, allows smooth discharging, and provides improved discharging stability.

Owner:ZHUHAI YOUTE SMART KITCHEN TECH CO LTD

Carton bending forming device and working method thereof

InactiveCN111959035AImprove feeding efficiencyReduce labor intensityBox making operationsPaper-makingCylinder blockStructural engineering

The invention discloses a carton bending forming device. The device comprises a bottom frame and a middle frame, the middle frame is arranged at the top of the bottom frame, a placing frame is arranged on one side of the middle frame, a paperboard is placed in the placing frame, two vertical rods are arranged below the placing frame, the top ends of the two vertical rods are arranged on the innerwall of the top face of the bottom frame, fixing blocks are arranged on the two vertical rods correspondingly, and a first rotating rod is arranged between the two fixing blocks. According to the device, a paper box is sucked through a second suction cup, a third hydraulic cylinder controls a third piston rod therein to move towards the outer side of a cylinder body, a through hole is formed in asliding block, and a sliding rod penetrates through the interior of the through hole in the sliding block so that a clamping base can move along the sliding rod to move out the processed paper box from the device, the discharging work is facilitated, the situation that the paper box sucked by the second suction cup falls off due to shaking generated when the clamping base moves on a long plate isavoided, the discharging time is saved, the operation and use of the whole device can be completed by one person, and the manpower is saved.

Owner:王娜娜

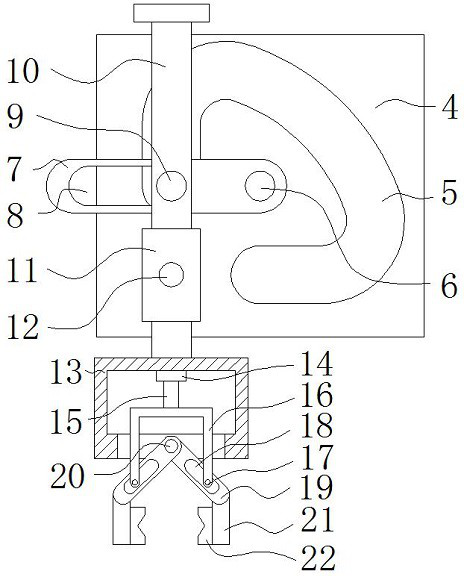

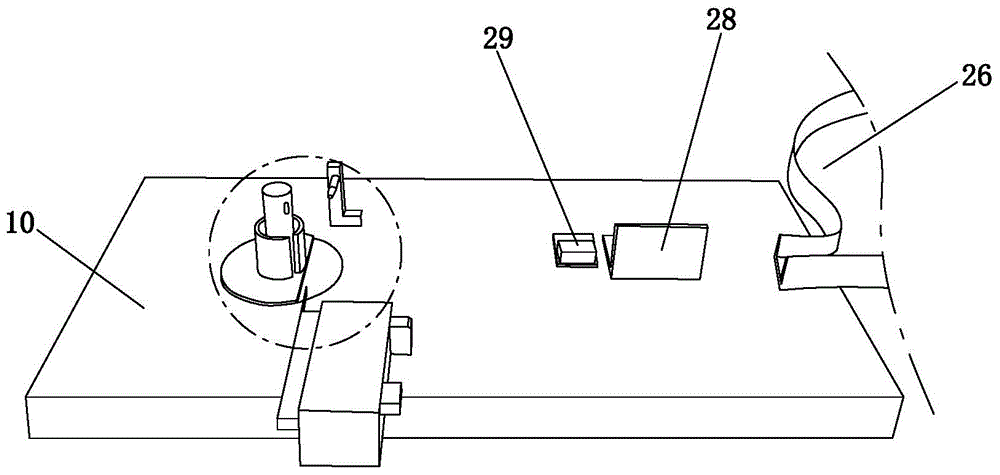

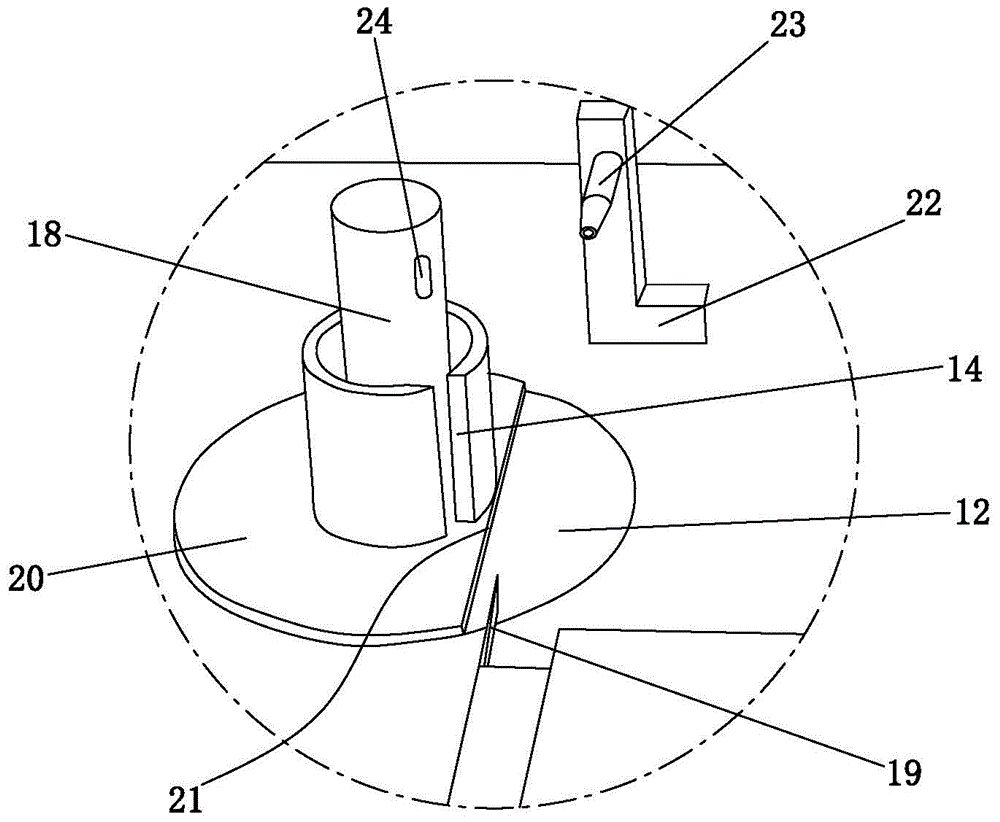

Automatic forming machine of flexible graphite seal rings

ActiveCN104553025AHigh degree of automationIncrease productivityShaping pressMaterial resourcesEngineering

The invention relates to the technical field of forming machinery of seal rings, in particular to an automatic forming machine of flexible graphite seal rings. A punch driven by a power device is arranged on the upper portion of a frame; a forming base located right below the punch is arranged in the middle of the frame; the forming base is provided with a through hole penetrating from top to bottom of the forming base and allowing entry of the punch; a rotating jacking device driven by the power device is arranged on the lower portion of the frame, and the upper end of the rotating jacking device extends into the through hole of the forming base; the forming base is provided with a feed opening communicated with its through hole. The automatic forming machine has the advantages that drum forming is automatically operated mechanically, automation level is high, productivity is high, the demand of the manufacturing process for manpower, financial and material resources is effectively decreased, yield is greatly increased, and product scrappage is greatly decreased.

Owner:浙江宝伦流体智控设备有限公司

Urban logistics distribution tractor and use method

InactiveCN112793487AShorten the blanking timeImprove convenienceVehicle with parallel load movementTowing devicesAgricultural engineeringElectric machinery

The invention discloses an urban logistics distribution tractor and a use method. The urban logistics distribution tractor comprises a tractor base, pulleys are fixedly connected to the bottom of the tractor base, a transmission box is fixedly connected to the top of the tractor base, a threaded box is fixedly connected to the left side of the top of the transmission box, and a lifting mechanism is arranged in the threaded box; and an extension mechanism is arranged on the right side of the threaded box, a traction mechanism is arranged on the left side of the vehicle base, and the lifting mechanism comprises a driving motor and a threaded column. The invention relates to the field of logistics distribution technology. According to the urban logistics distribution tractor and the using method, the lifting mechanism is arranged, a driving motor is used for driving a rotating shaft to rotate, the rotating shaft drives a threaded column to rotate, and a rotating bearing and a sliding block are matched to move, so that goods needing to be unloaded can be adjusted to the proper height position, and in addition, automatic goods discharging can be carried out, so that the goods discharging time of the tractor is saved, and meanwhile the convenience is improved.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

Medical syringe needle discharging device simple in structure

PendingCN106044195ASimple structureReduce manufacturing costConveyorsLoading/unloadingSyringe needleBiomedical engineering

The invention discloses a medical syringe needle discharging device simple in structure. The medical syringe needle discharging device comprises a support, a clamping part, a containing box and a control part. The clamping part is arranged in the support, and the containing box is located below the clamping part. Operation of the clamping part is controlled by the control part. The discharging device further comprises a separation part. The separation part comprises a separation plate arranged in the containing box and a separation air cylinder, and the separation air cylinder is fixed to the support and connected with one end of the separation plate and drives the separation plate to turn over, so that a finished product box and a degraded product box are opened or closed at different times. In the medical syringe needle discharging device, the separation plate is arranged in the containing box, and therefore the finished product box and the degraded product box are at the same position but do not interfere with each other during discharging, the discharging device is simple in structure, and the manufacturing cost of the discharging device is reduced.

Owner:梁启明

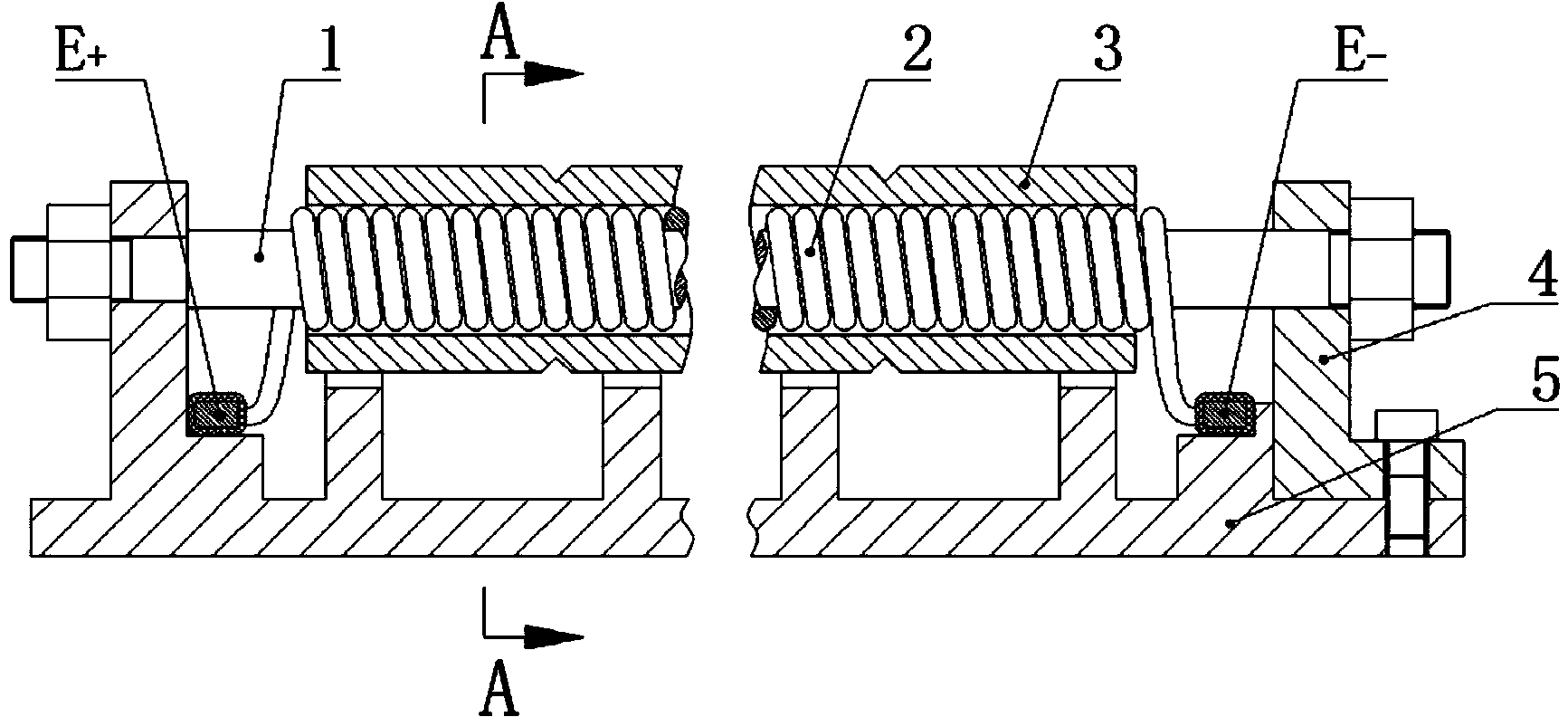

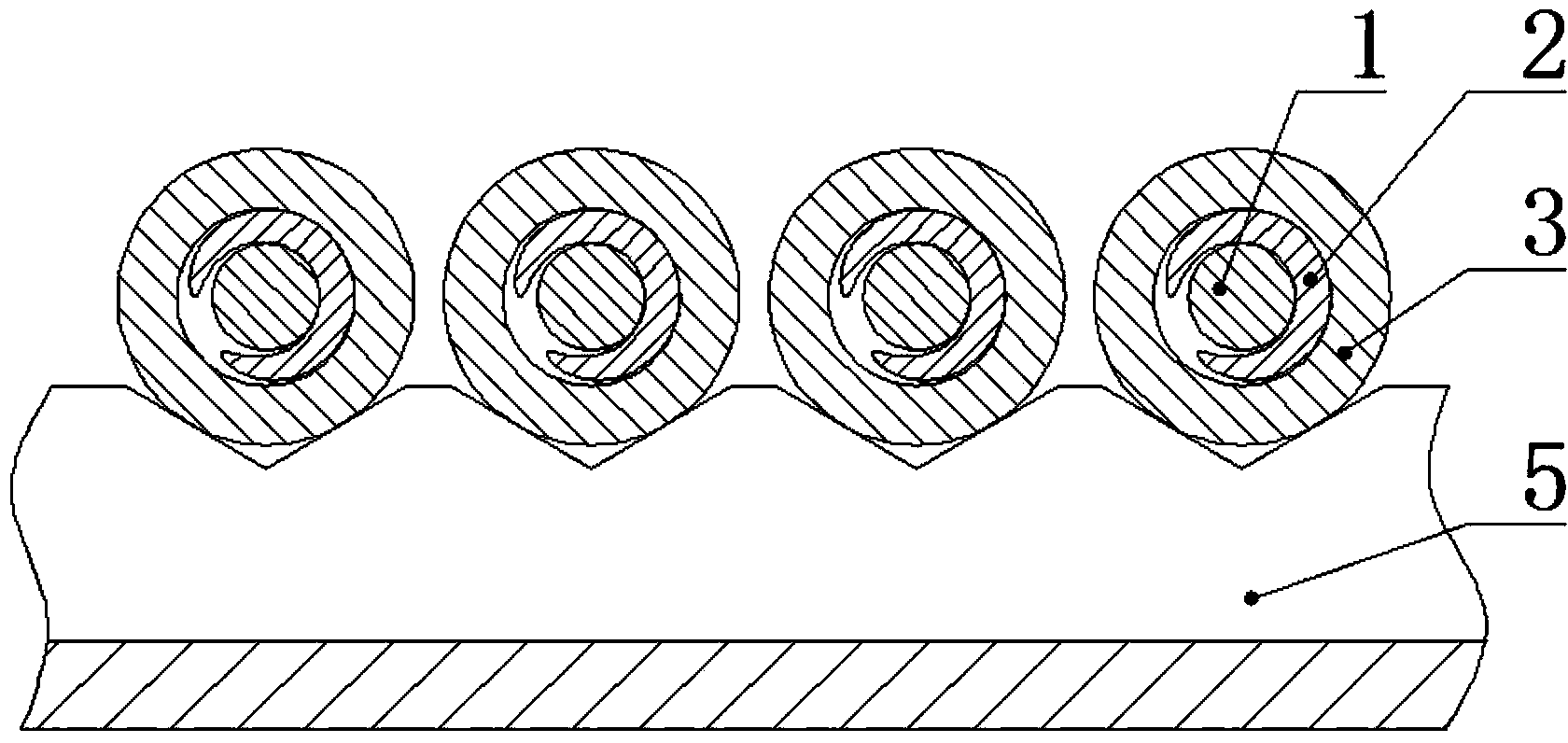

Notched pipe material micro-crack batch initiating device and method for fine blanking

InactiveCN104388658AShorten the blanking timeImprove cutting efficiencyFurnace typesIncreasing energy efficiencyMicro structureFree cooling

The invention provides a notched pipe material micro-crack batch initiating device and method for fine blanking. The device comprises a rack, wherein a plurality of metal pipe materials can be arranged side by side on the rack; a heating coil is arranged in the inner hole of each metal pipe material, and two ends of each heating coil are respectively connected with an anode E+ and a cathode E-, which are arranged at two ends of the rack, of a high-frequency cable; each heating coil is fixedly arranged on a supporting plate by virtue of an insulating core rod; the supporting plate is connected to the rack; annular V-shaped grooves with equal intervals are pre-formed in each metal pipe material; the inner walls of the pipe materials are quickly heated by virtue of the heating coils, heating is stopped when the temperature of the inner walls of the pipe materials reaches 500-1000 DEG C, and then the pipe materials are naturally cooled; micro-structure crack groups which are uniformly distributed are generated at notch root positions of V-shaped grooves outside the pipe materials under action of expansive force since temperature difference exists between inside and outside of the pipe materials, so that dynamic crack propagation in a subsequent blanking process can quickly enter into a propagation stage. By adopting the device, the whole blanking time can be shortened and the whole blanking efficiency can be improved.

Owner:XI AN JIAOTONG UNIV

Ten-station continuous filling and packaging machine

ActiveCN104875910BHigh speedSolve the impact of poor fluidity on the speed of packaging machinesWrapper twisting/gatheringSolid materialEngineeringRocker arm

The invention discloses a ten-station continuous filling packing machine which comprises a workbench, a rotating big disc, a bag feeding device, bag clamping devices, discharging devices, sealing devices and bag opening and air blowing devices. Each discharging device comprises a discharging hopper, a discharging fixing base, a discharging fixing base limiting guide rod, a rotating cylinder, a lifting block, a lifting guide rod, a lifting rack, a special-shaped transmission gear, a lifting and swinging rocker arm, a rotating rail and a transmission pull rod. The discharging hoppers are fixed to the discharging fixing bases respectively, the discharging fixing bases are fixed to the discharging fixing base limiting guide rods respectively, and the discharging fixing base limiting rods are fixed to the rotating big disc. Ten discharging hoppers are provided, the discharging hopper on the seventh station can move upwards, and the discharging hopper on the third station can move downwards. The ten-station continuous filling packing machine is high in production efficiency and short in period, saves manual labor cost, and is simple in structure and attractive in appearance.

Owner:QINGDAO YILONG PACKAGING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com