Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Short axial distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

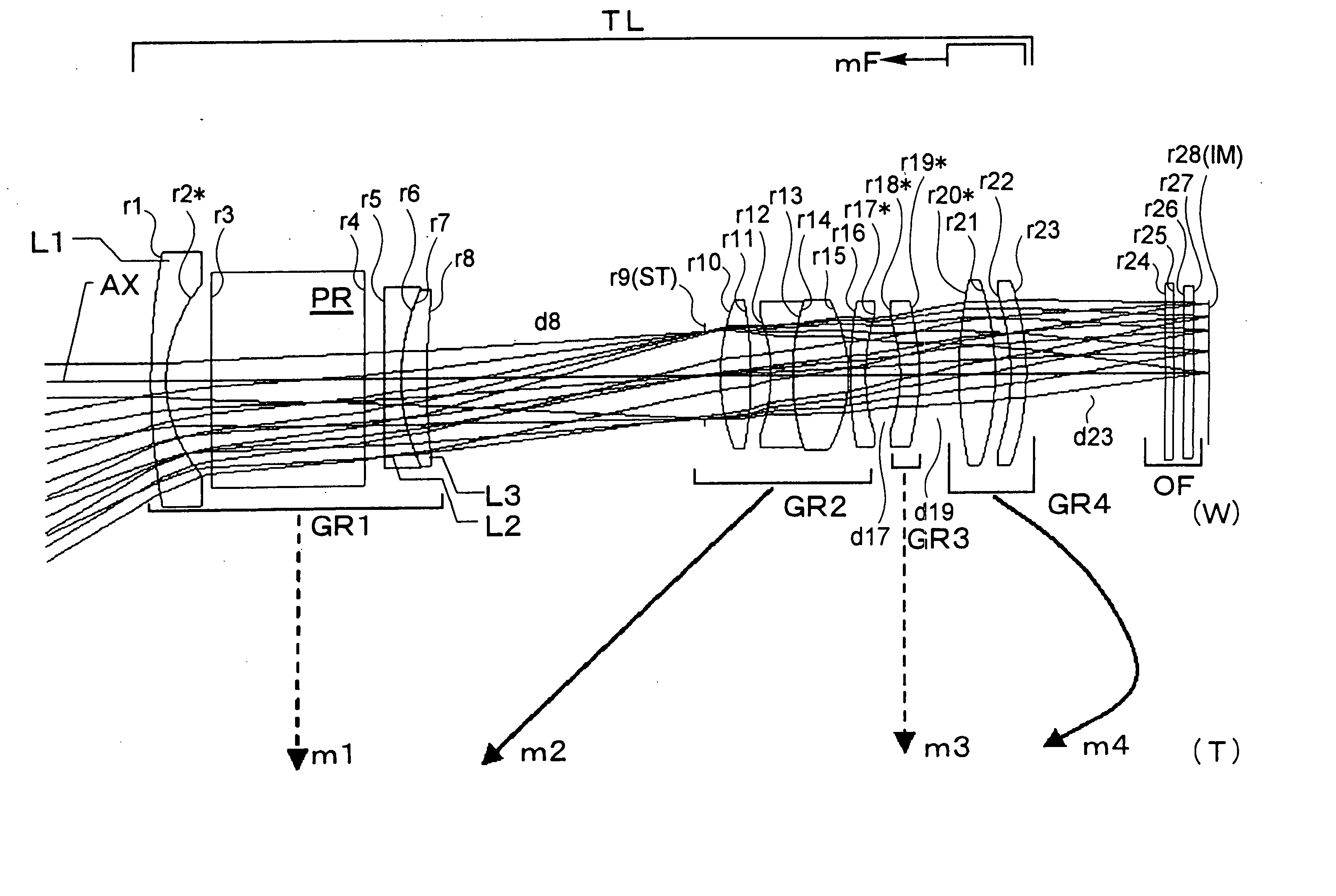

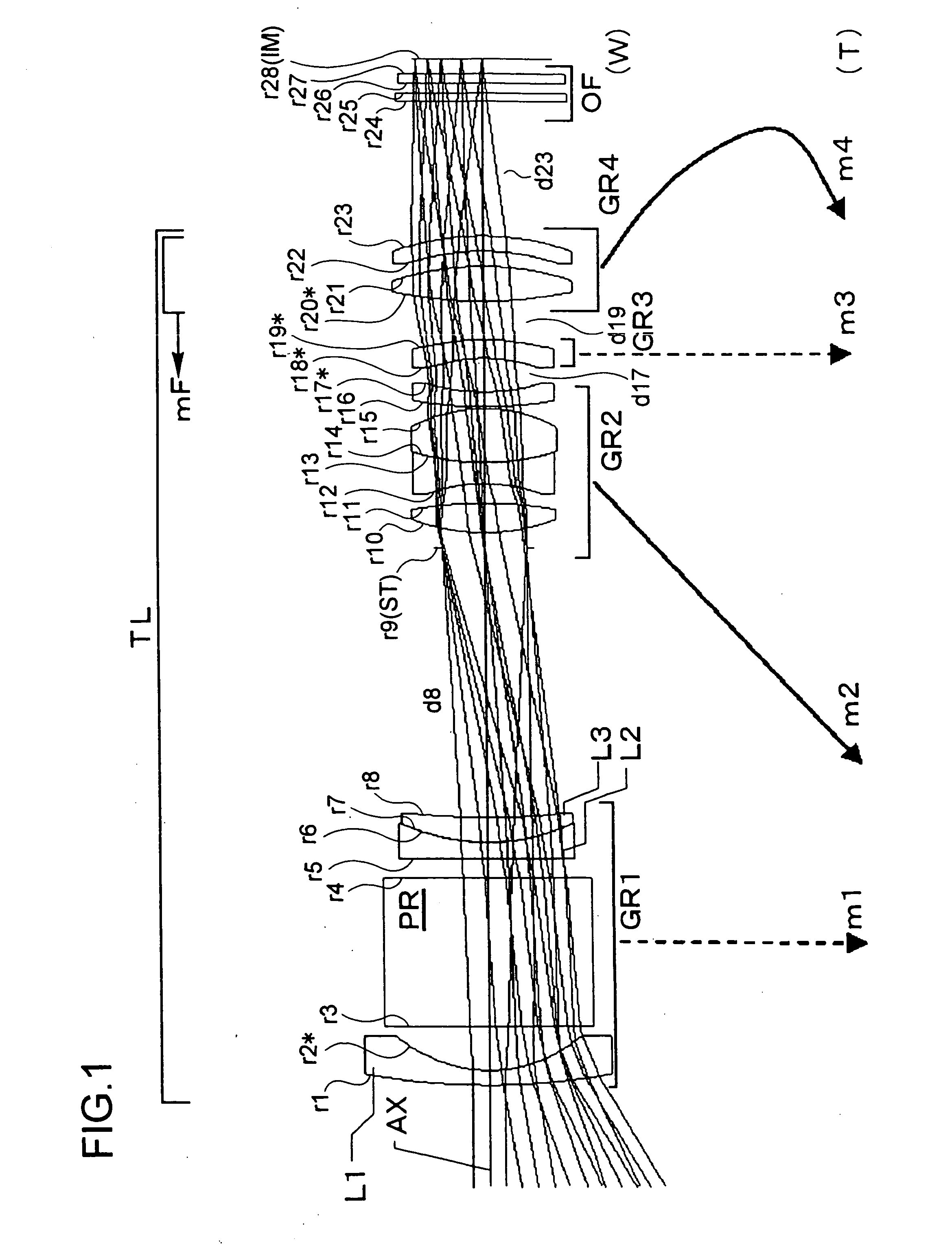

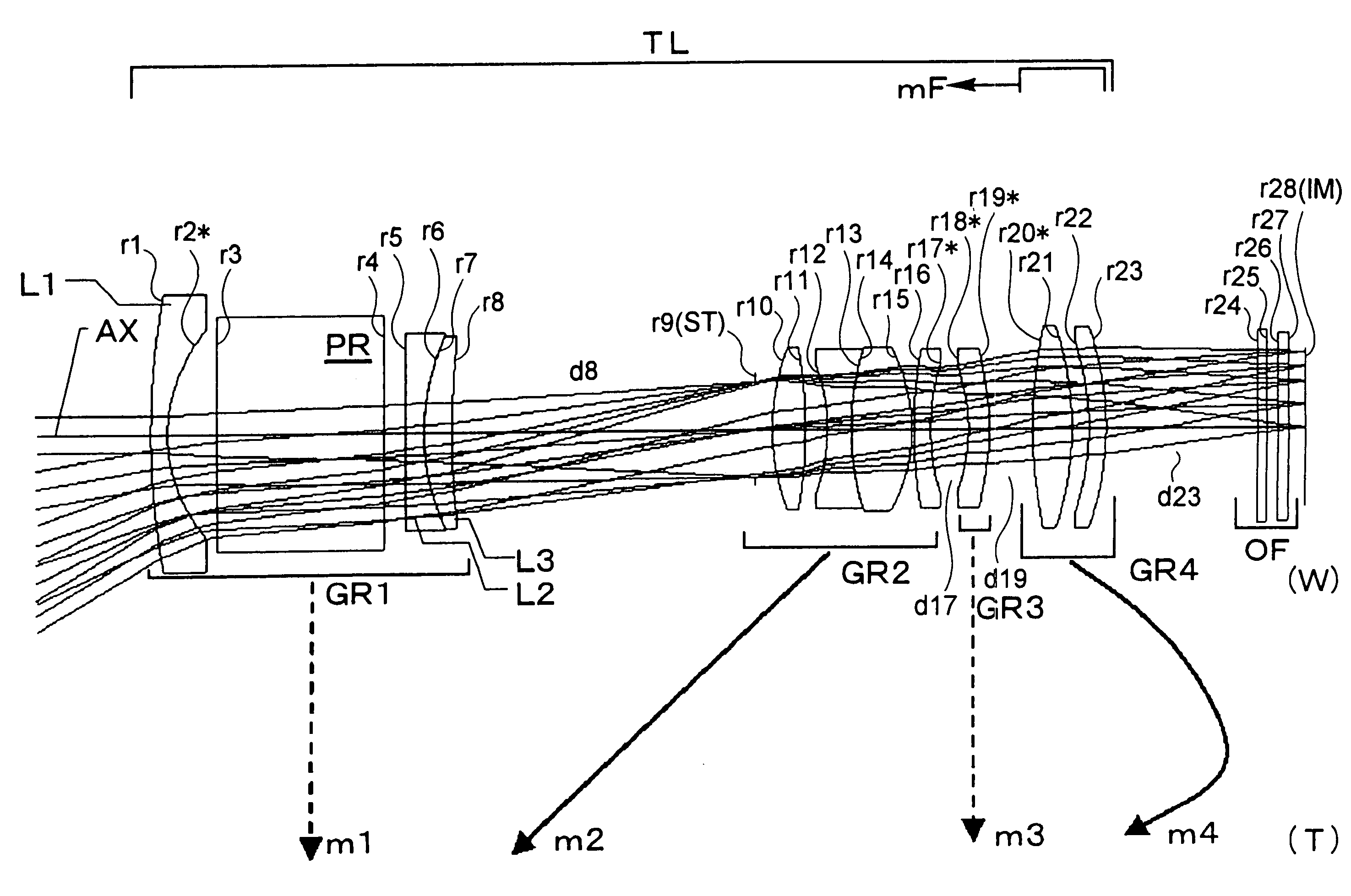

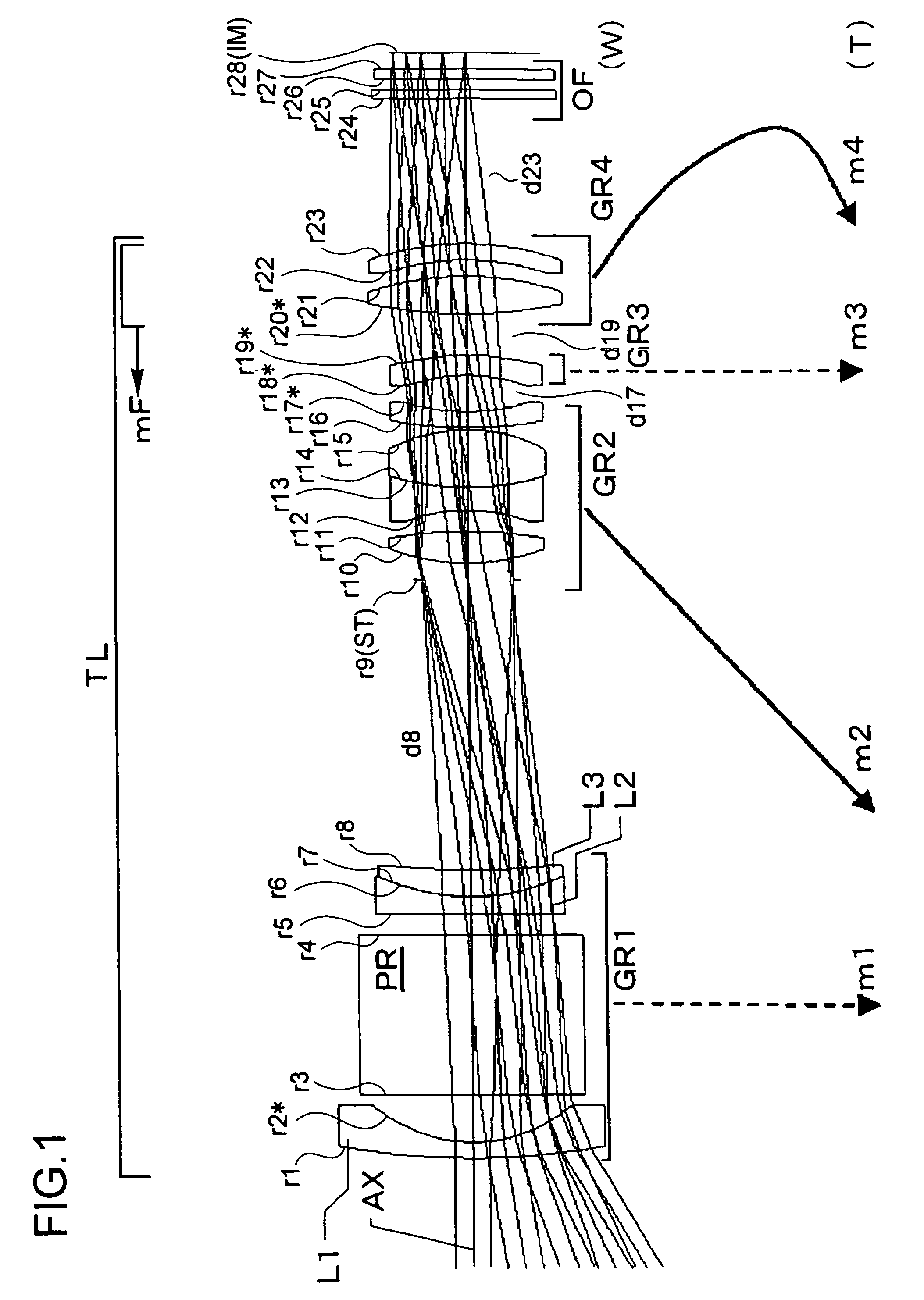

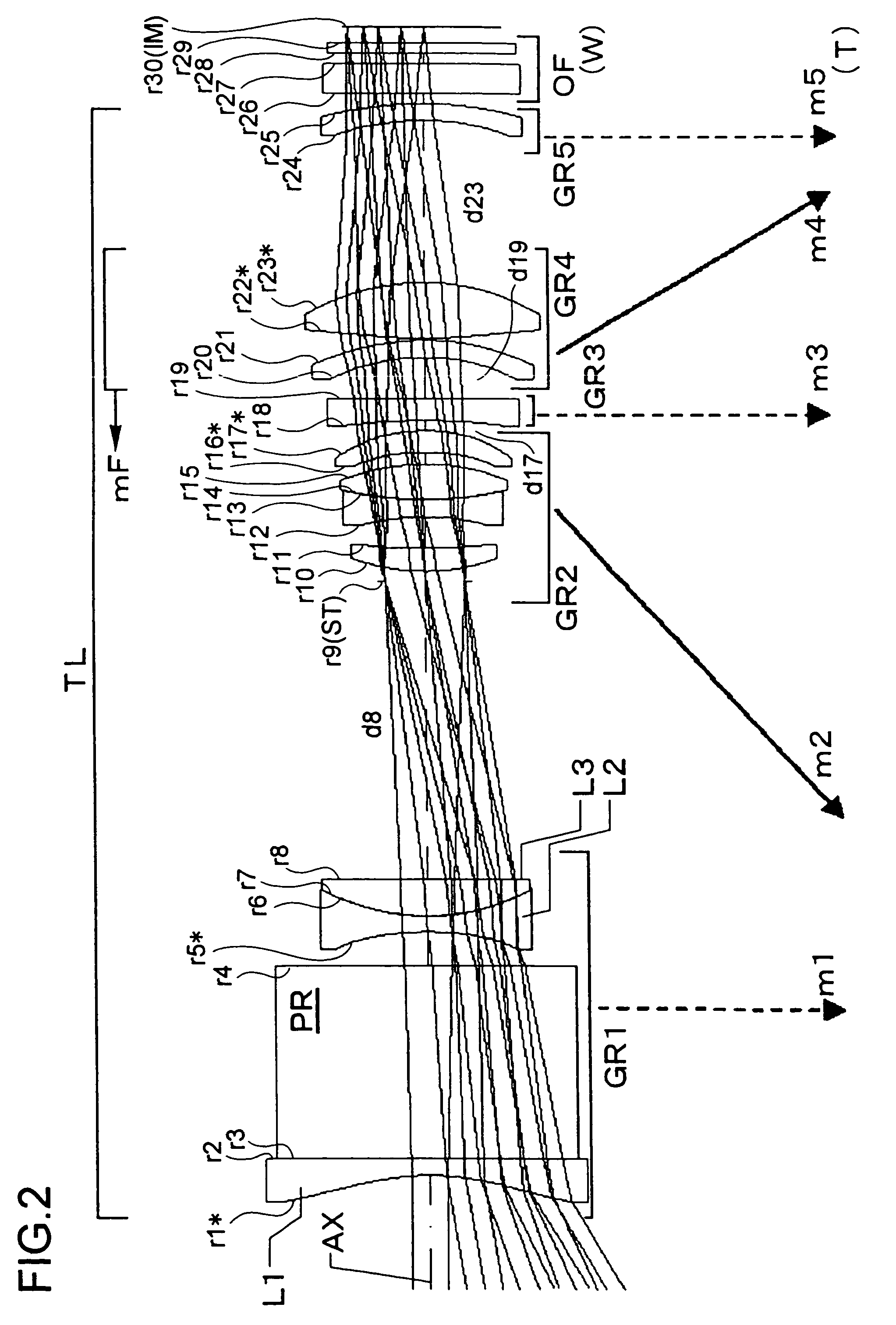

Image-taking lens apparatus

ActiveUS20050259329A1Good optical performanceShort axial distanceTelevision system detailsPrismsRefractive indexPrism

An image-taking lens apparatus has an image sensor for converting an optical image of a subject into an electrical signal and an image-taking lens system for forming the optical image on the image sensor. The image-taking lens system includes a prism for bending the optical path, and the refractive index of the prism fulfills a prescribed conditional formula.

Owner:KONICA MINOLTA PHOTO IMAGING

Image-taking lens apparatus

ActiveUS7227706B2Improve image qualityGood optical performanceTelevision system detailsPrismsRefractive indexPrism

An image-taking lens apparatus has an image sensor for converting an optical image of a subject into an electrical signal and an image-taking lens system for forming the optical image on the image sensor. The image-taking lens system includes a prism for bending the optical path, and the refractive index of the prism fulfills a prescribed conditional formula.

Owner:KONICA MINOLTA PHOTO IMAGING

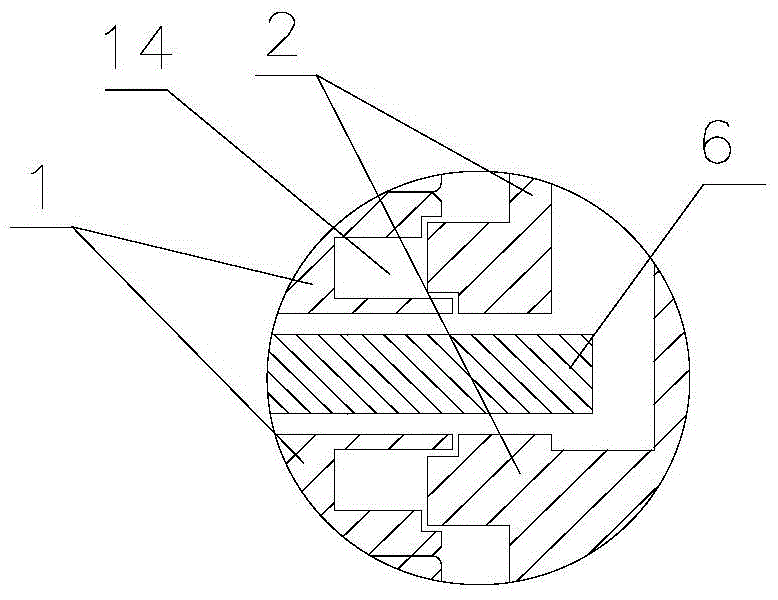

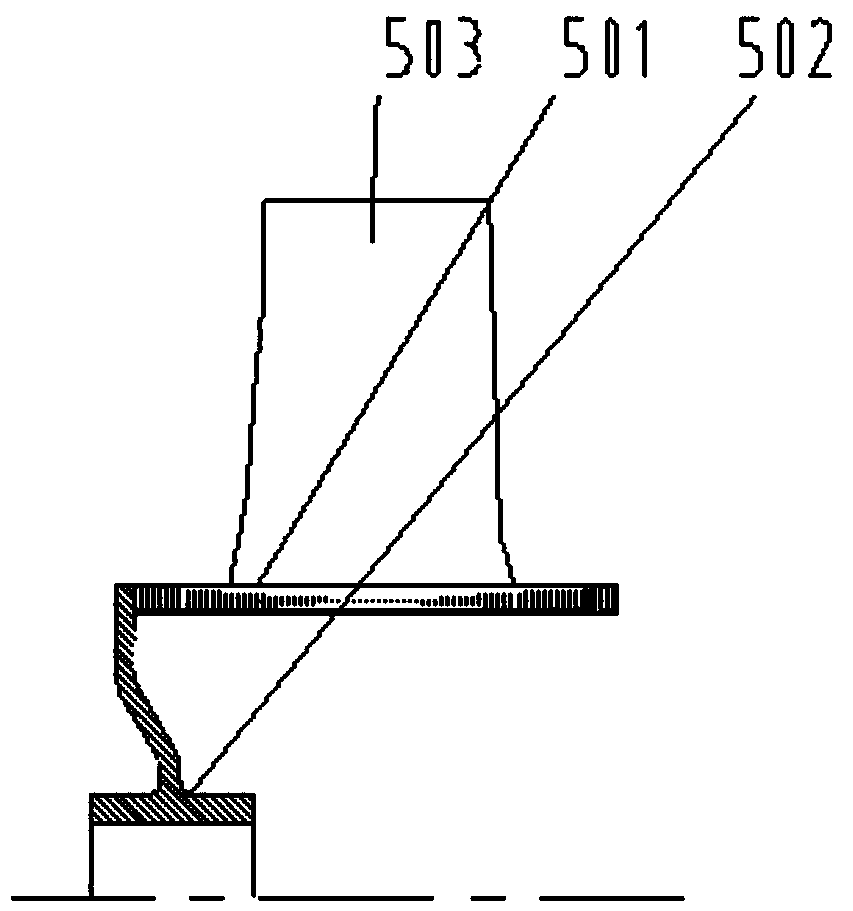

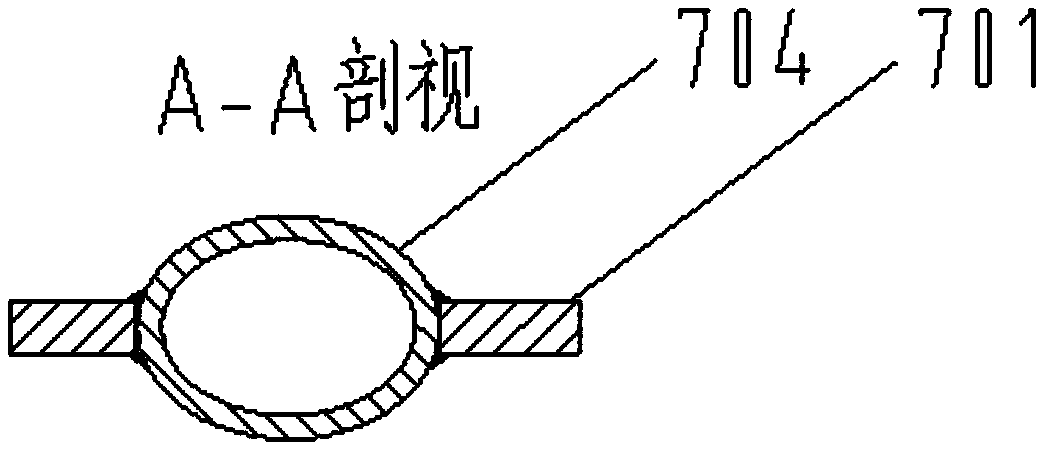

Fluid magnetization tube , magnetization device and magnetization system

InactiveCN1807270ALow costSimple structureWater/sewage treatment by magnetic/electric fieldsMagnetizationElectrical polarity

The disclosed fluid magnetization tube comprises: a magnetic tube with axial-magnetized magnetic rings with opposite polarity between neighbor ones, space rings of non-ferric-magnetic material and an annular tube; a high-permeability guide magnetic tube coaxial with the magnetic tube and owned a flow channel, or another magnetic tube with two magnetic rings in one section with same height and opposite magnetized direction; some members with straight or curve axis for location, fixing and guiding flow; two cove boards on both ends contained arc channels of flat shape or cylinder face to locate the tubes on both radial and axial directions. The opposite magnetization device comprises a plurality of magnetization tubes parallel inserted in the shell, and two end cap grooves to connect near tubes in series or parallel or mixture. The magnetization system uses said magnetization device and normal pump and power gear device for fluid cycle magnetization, which has high efficiency, simple structure, variable forms, small volume, light weight, and low cost.

Owner:朱澄清

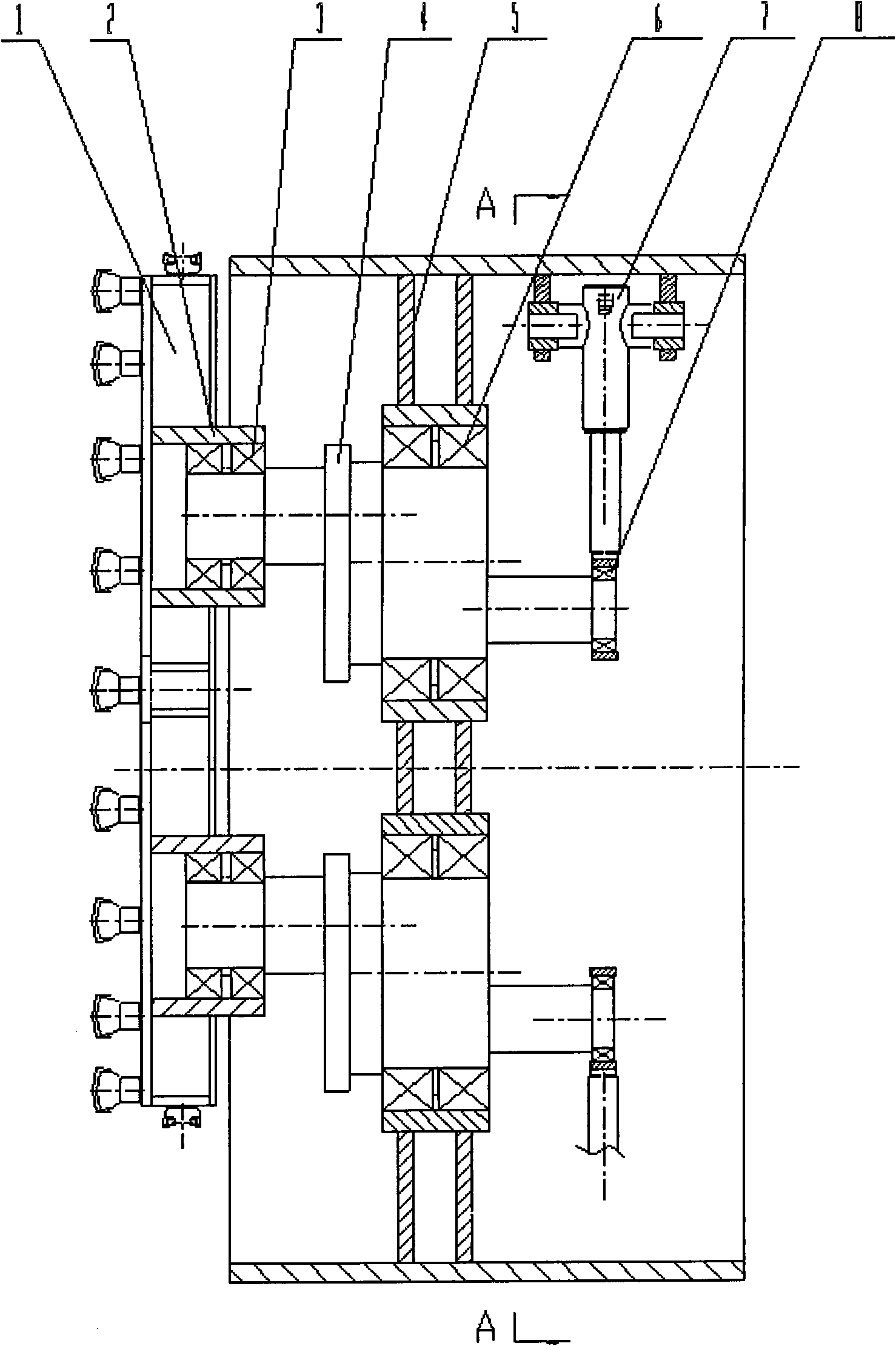

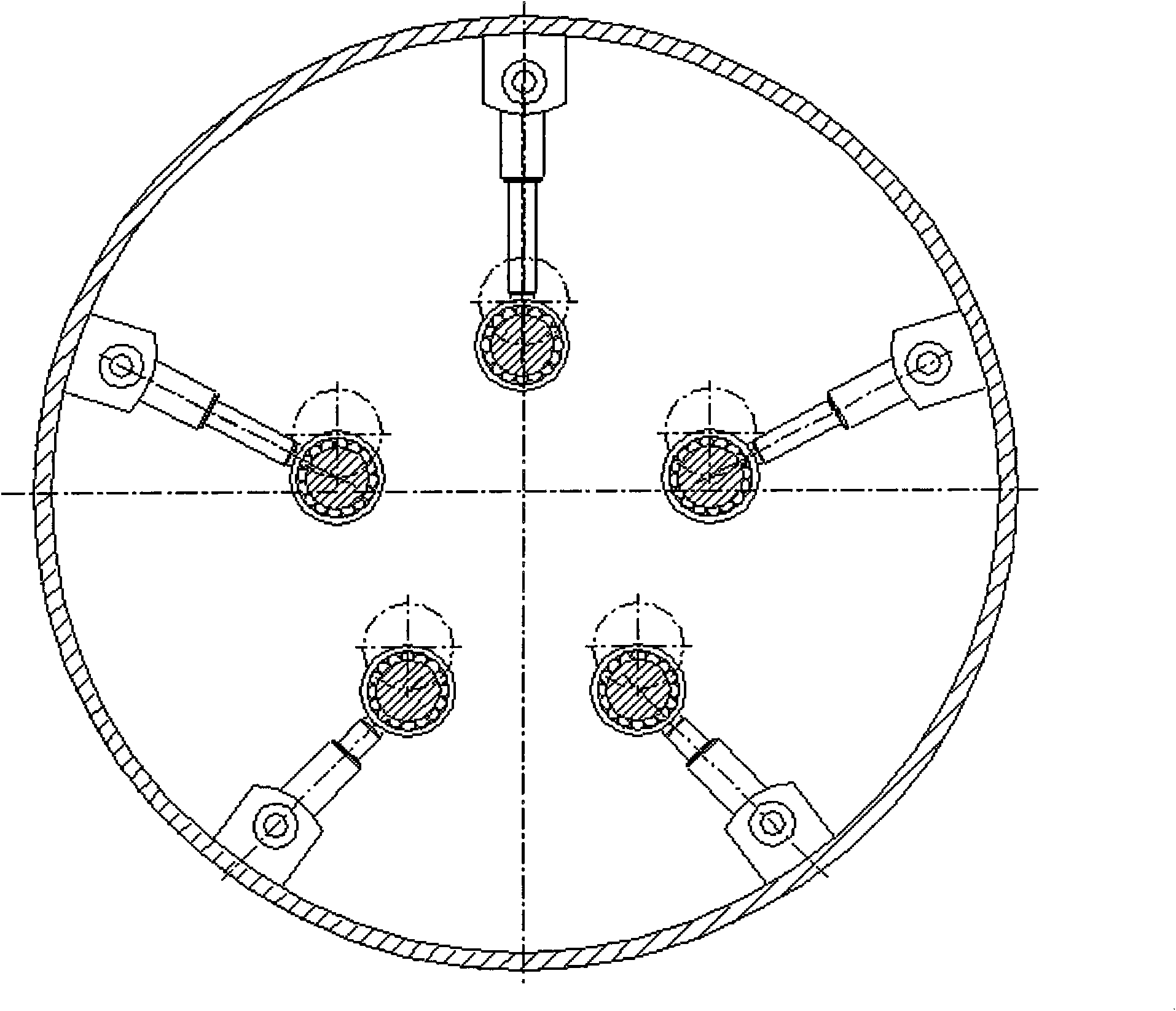

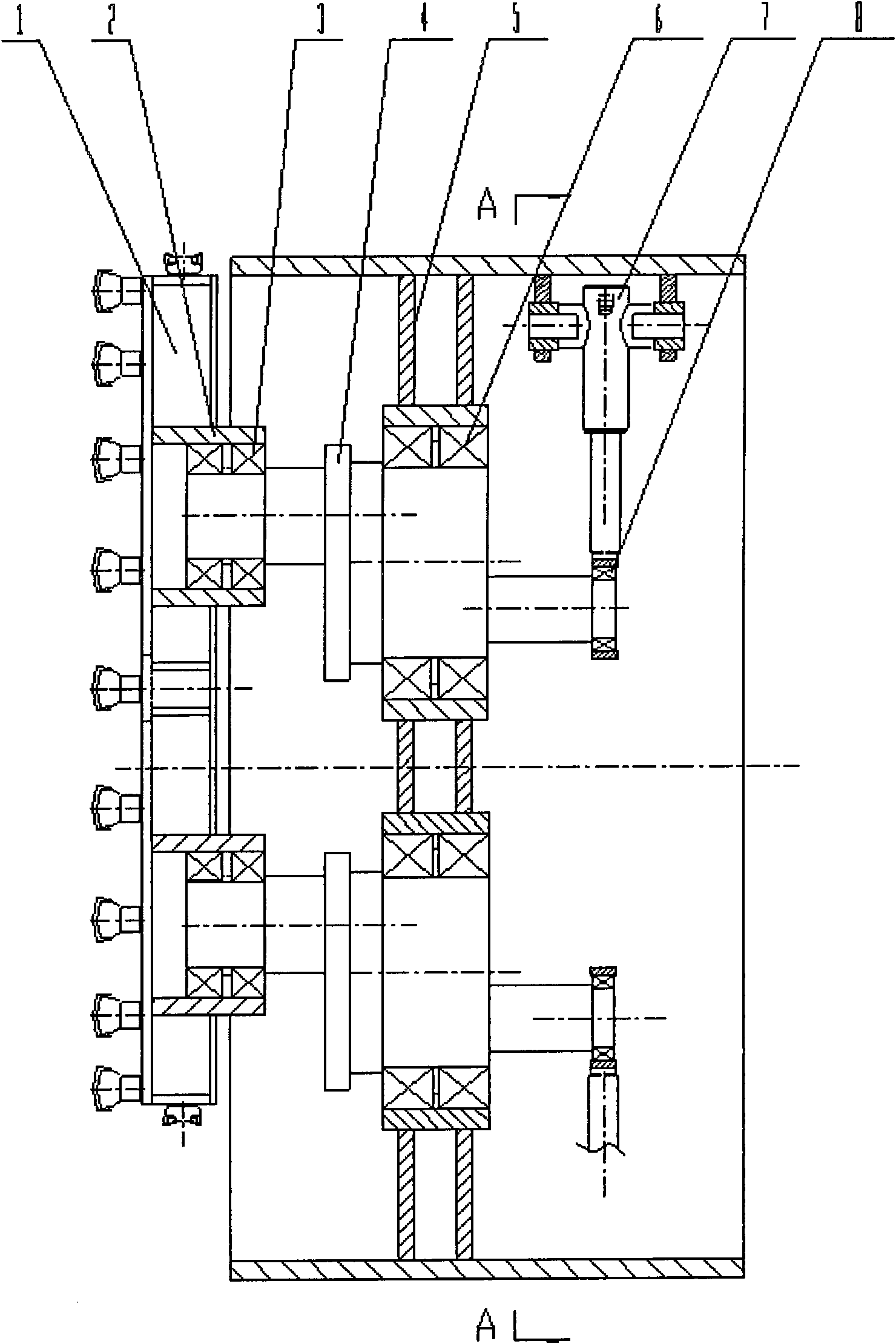

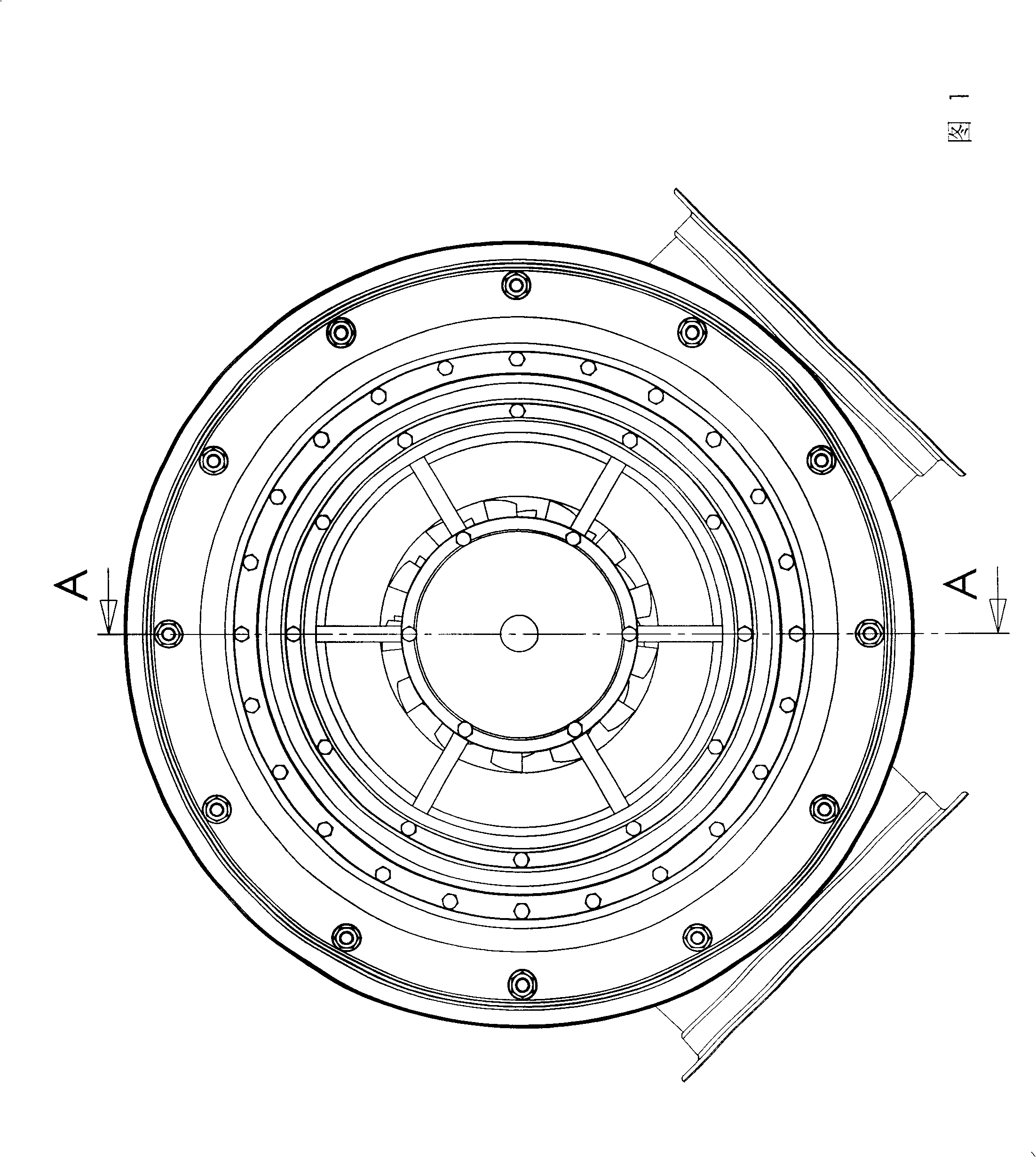

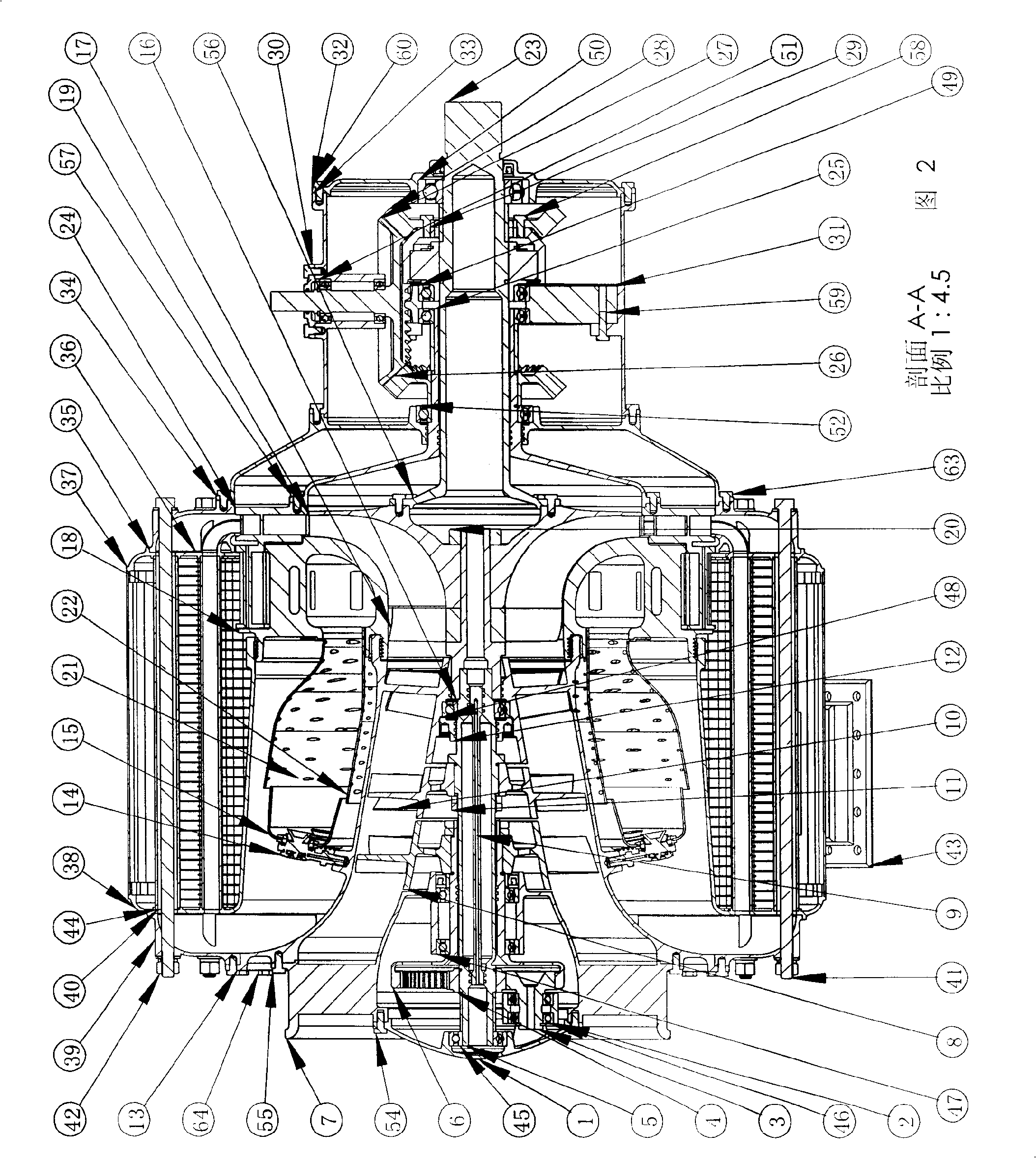

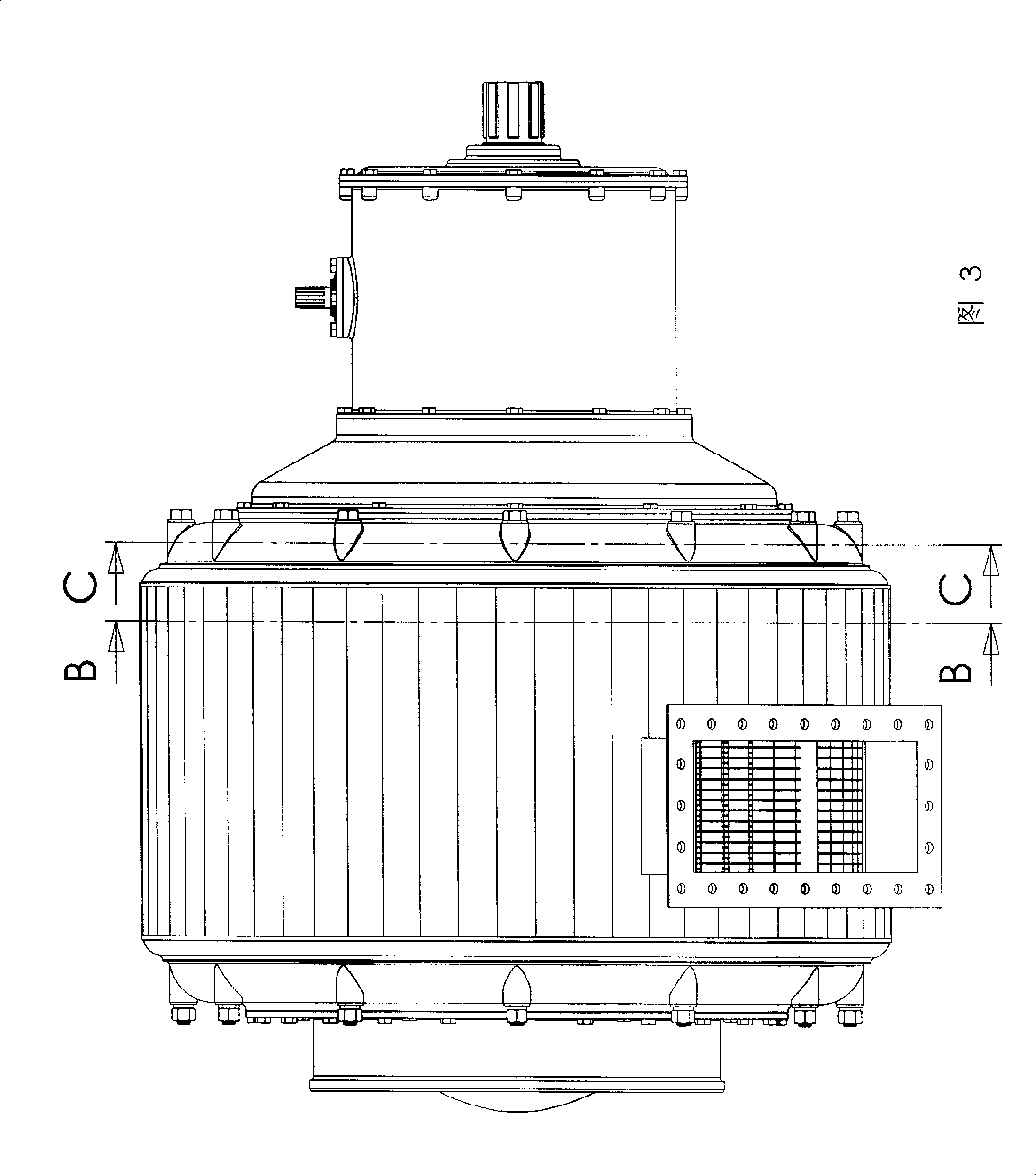

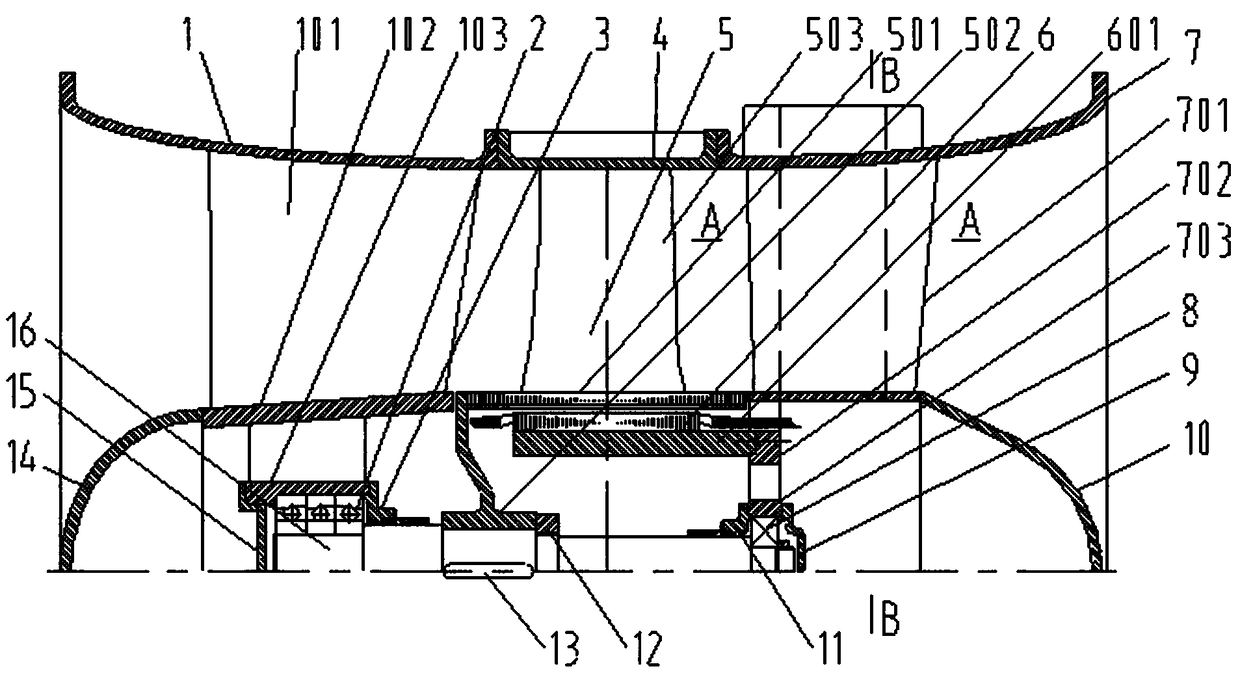

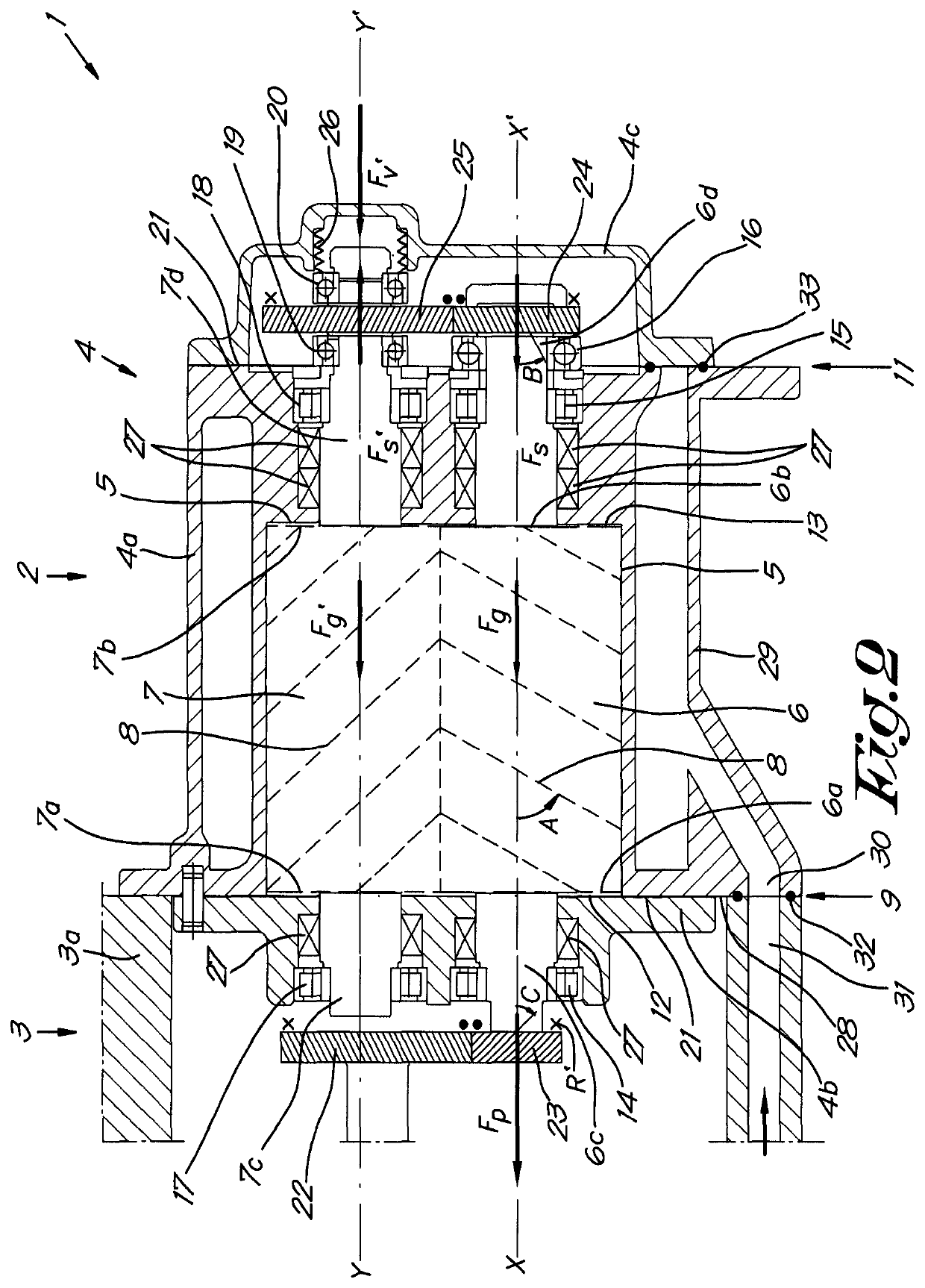

Cutter disc of eccentric multi-shaft tunnel digging machine directly driven by hydraulic cylinders

The invention relates to a cutter disc of an eccentric multi-shaft tunnel digging machine directly driven by hydraulic cylinders, which comprises a digging machine case and a disc body of the cutter disc, wherein the back side of the disc body of the cutter disc is connected five eccentric main shafts through bearings, in addition, the five eccentric main shafts are uniformly distributed along the center of the case, the middle parts of the five eccentric main shaft are supported on the bearings of a partition board of the digging machine case, the back ends of the five eccentric main shafts are respectively and directly connected with corresponding hydraulic cylinders through joint bearings, and eccentric shafts are directly driven to rotate by the hydraulic cylinders to drive the cutter disc body for carrying out rotary cutting. All hydraulic cylinders have identical dimension and installation parameters, and are arranged in the circumferential direction of the digging machine case at equal intervals. The end parts of the hydraulic cylinders are connected with the digging machine case through pin shafts, and ear rings of piston rods are arranged on the joint bearings of the eccentric shafts. Because the omission of a connecting plate, the design and the manufacture are easier, the manufacture cost is lower, the axial distance is shorter, and the stress of the cutter disc driving bearings is smaller. Because the hydraulic cylinders are adopted for driving, the cutter disc driving work is more reliable.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Contrarotating rotary spraying engine

InactiveCN101349197AShort axial distanceShort thermal stressContinuous combustion chamberGas turbine plantsHigh energyMechanical energy

The invention provides a contra-rotating rotary-jetting engine which can remarkably raise heat efficiency and reduce pollutant emission, manufacturing cost as well as maintenance cost. The engine works by utilizing a principle that a rotary jet turbine of the engine ejects fuel gas at high speed from a tangential spout to allow the self of the rotary jet turbine to rotate reversely so as to convert fuel gas internal energy into mechanical energy; meanwhile, the engine also utilizes a tangential impact turbine to recycle the kinetic energy of the fuel gas ejected from the rotary jet turbine, utilizes a heat regenerator to realize regenerative cycle, adopts a contra-rotating axial flow and contra-rotating centrifugal pressure gas technique to obtain high total pressure ratio, adopts a rotary flame tube technique to obtain high fuel gas temperature in front of the turbine, adopts the novel structural design to greatly reduce the number of components and the consumption of precious materials, and adopts a power confluence mechanism of a cone gear and an overrunning clutch to realize the power confluent output of the mechanical energy of the rotary jet turbine and the tangential impact turbine. Therefore, the engine has high energy conversion efficiency, low manufacturing cost and pollutant emission.

Owner:蔡盛龙

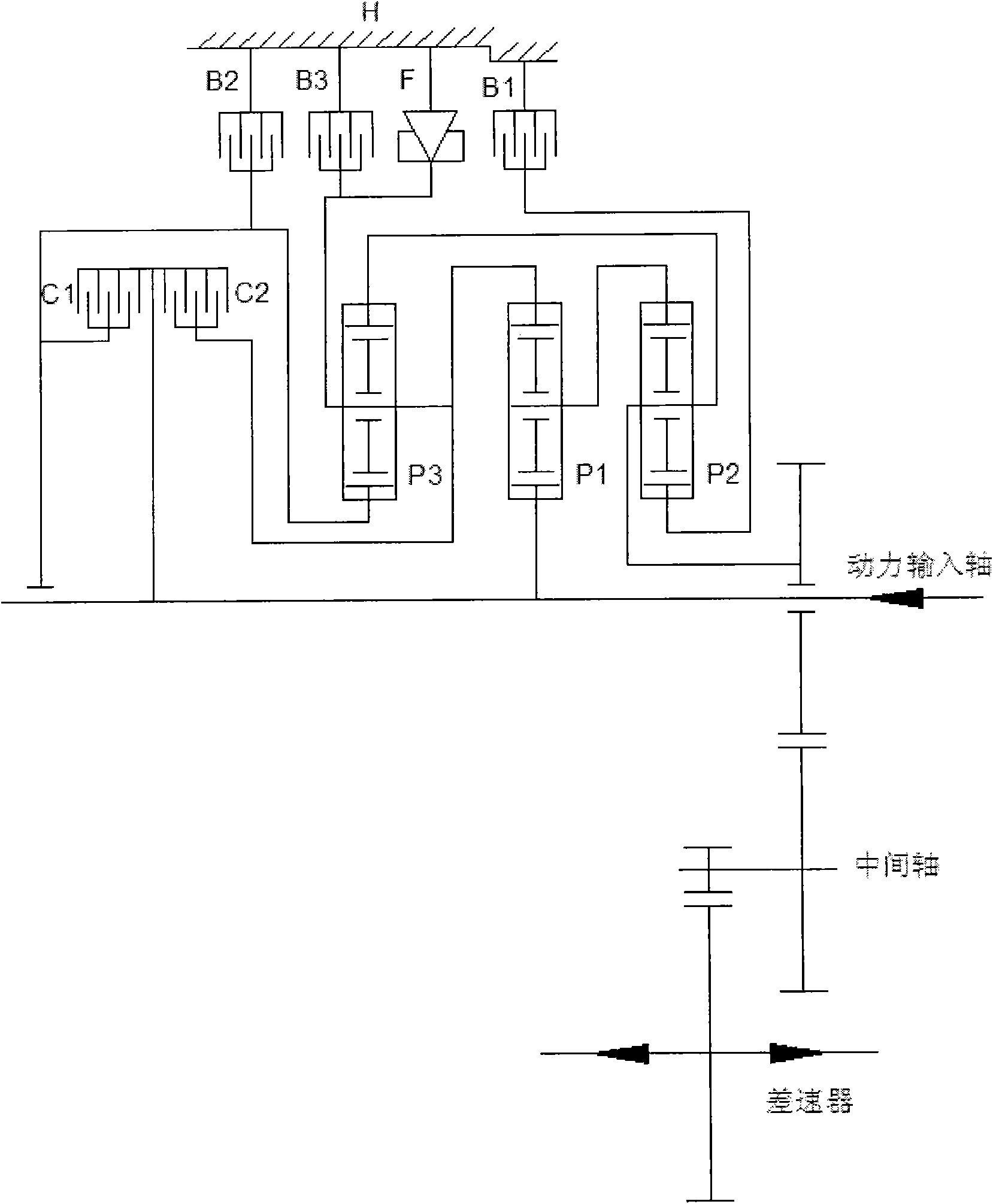

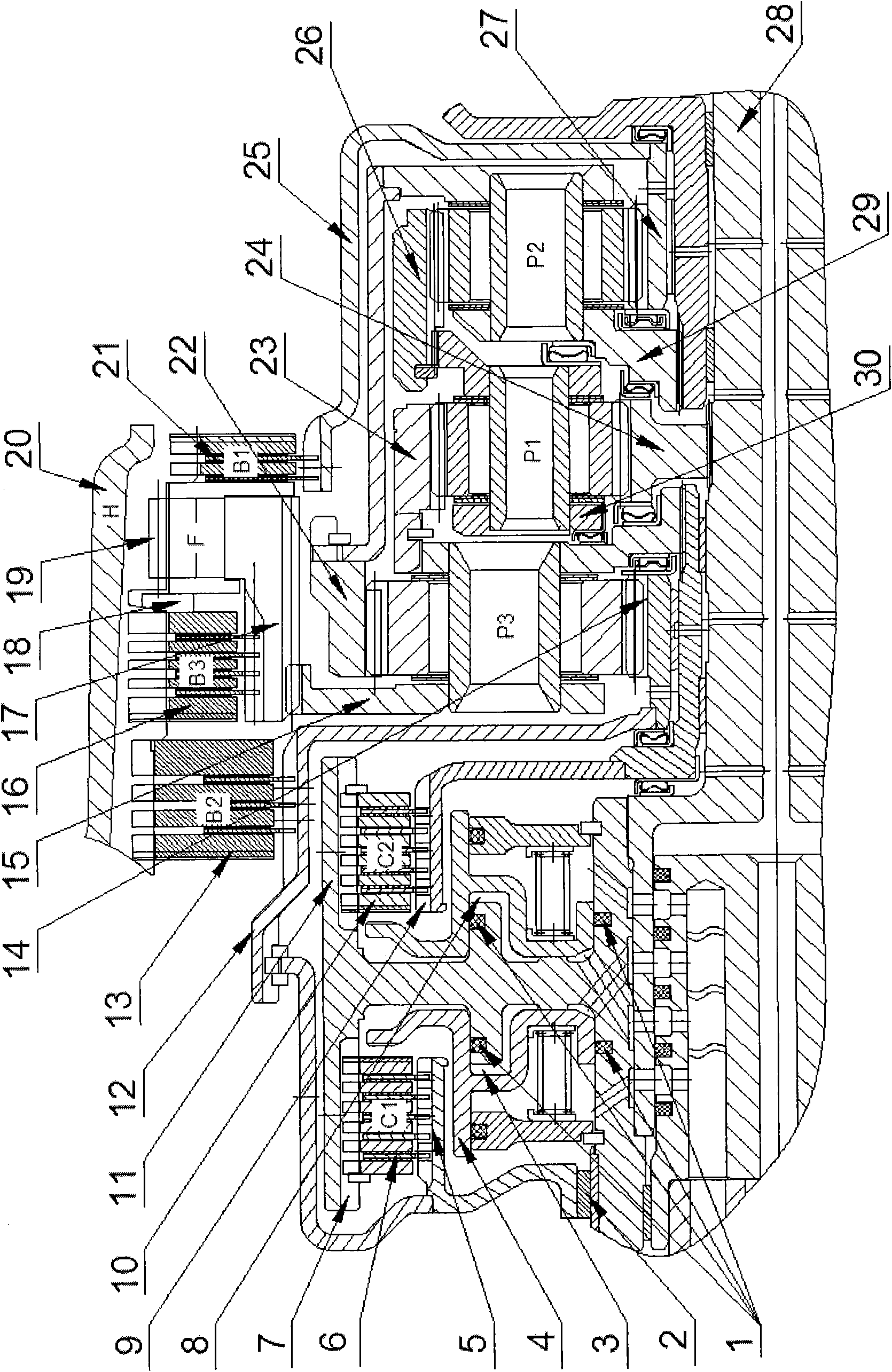

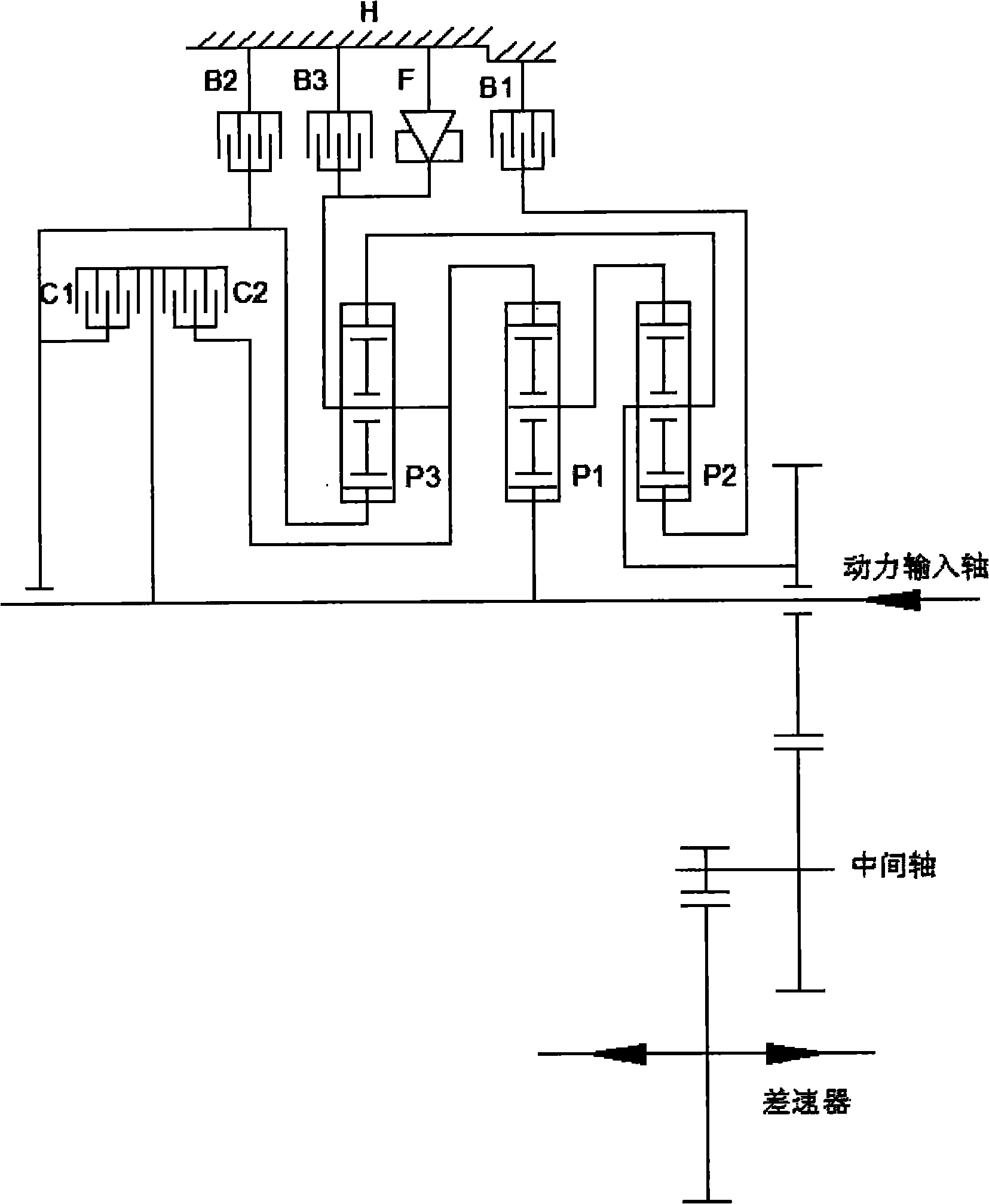

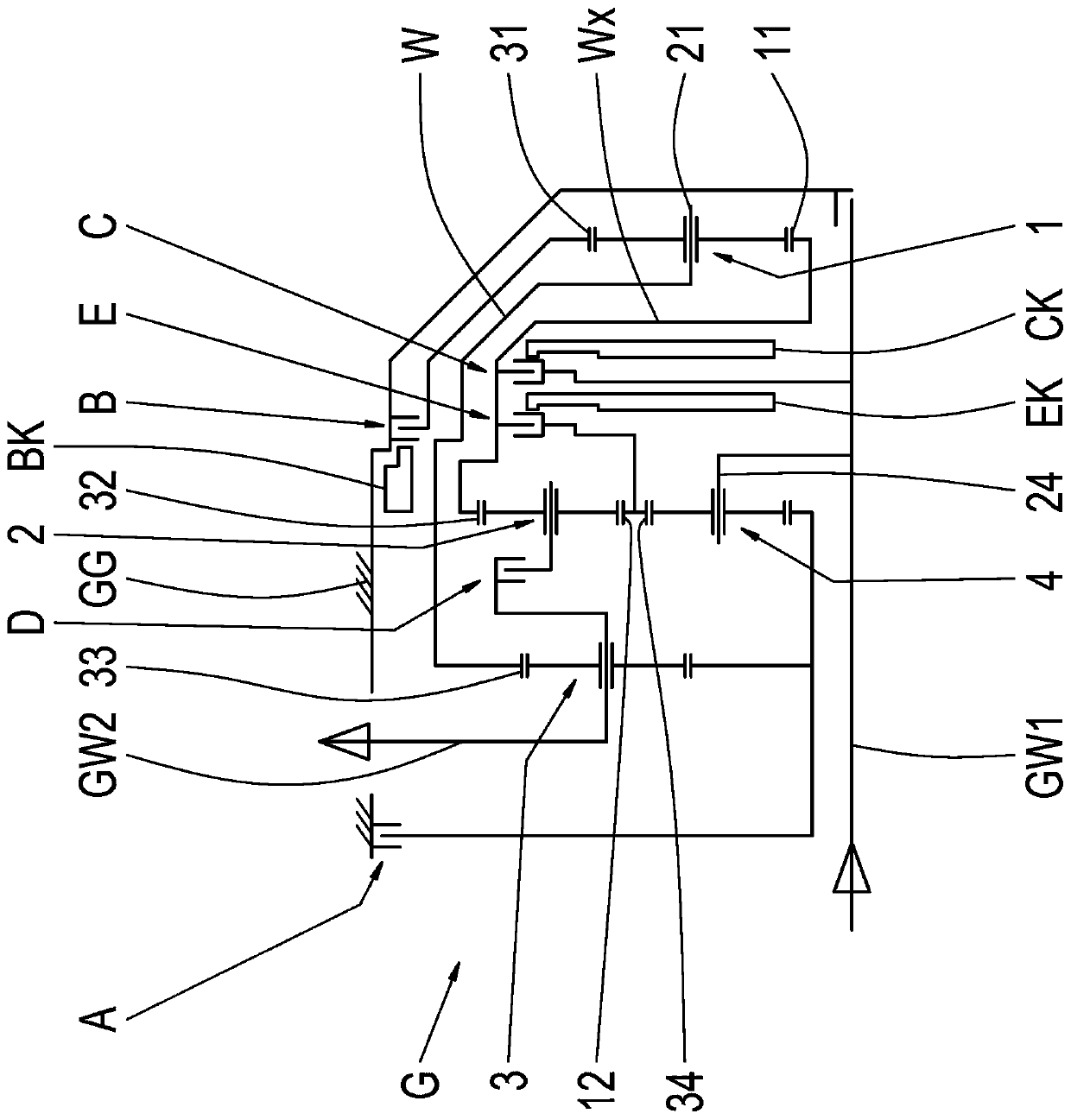

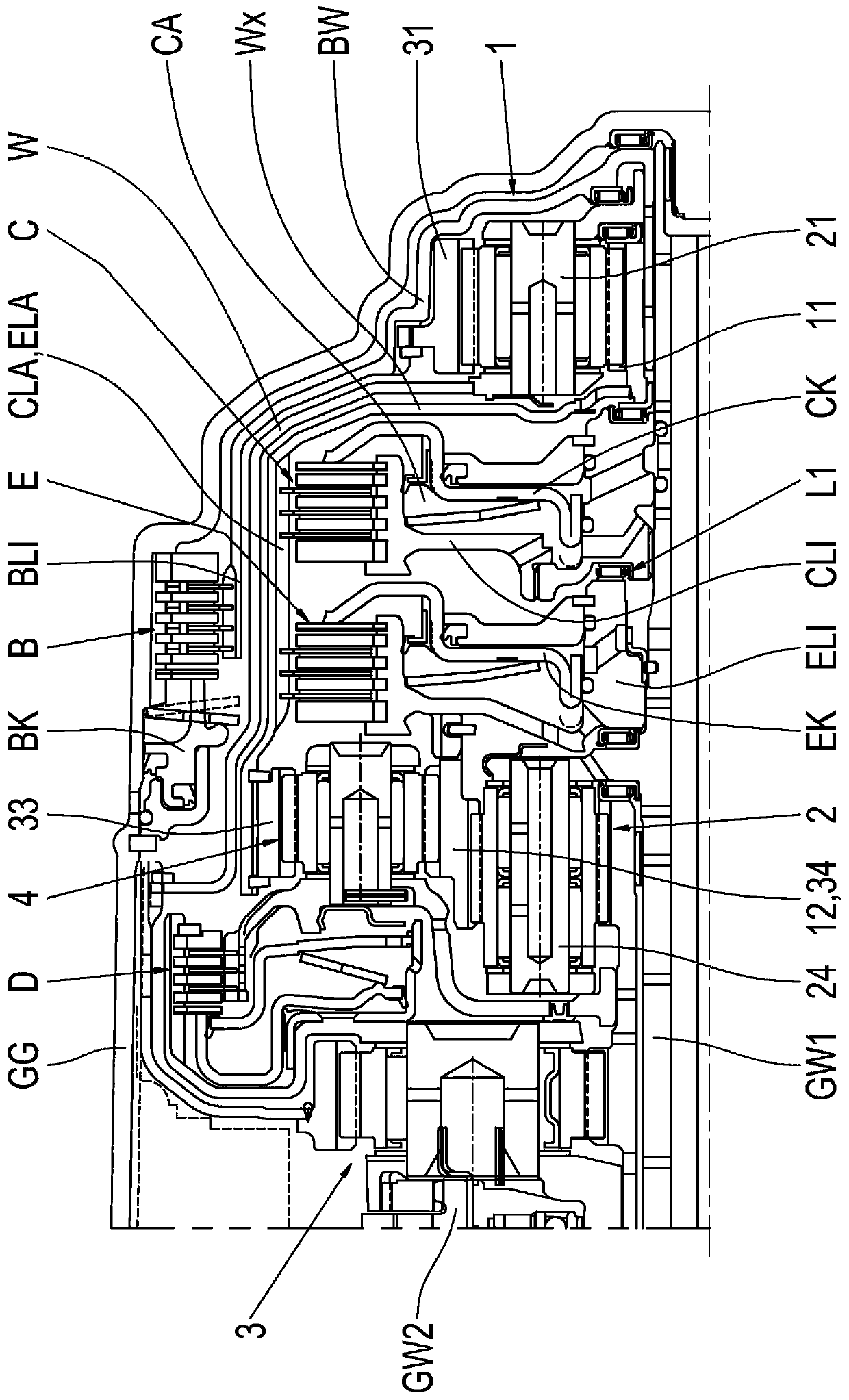

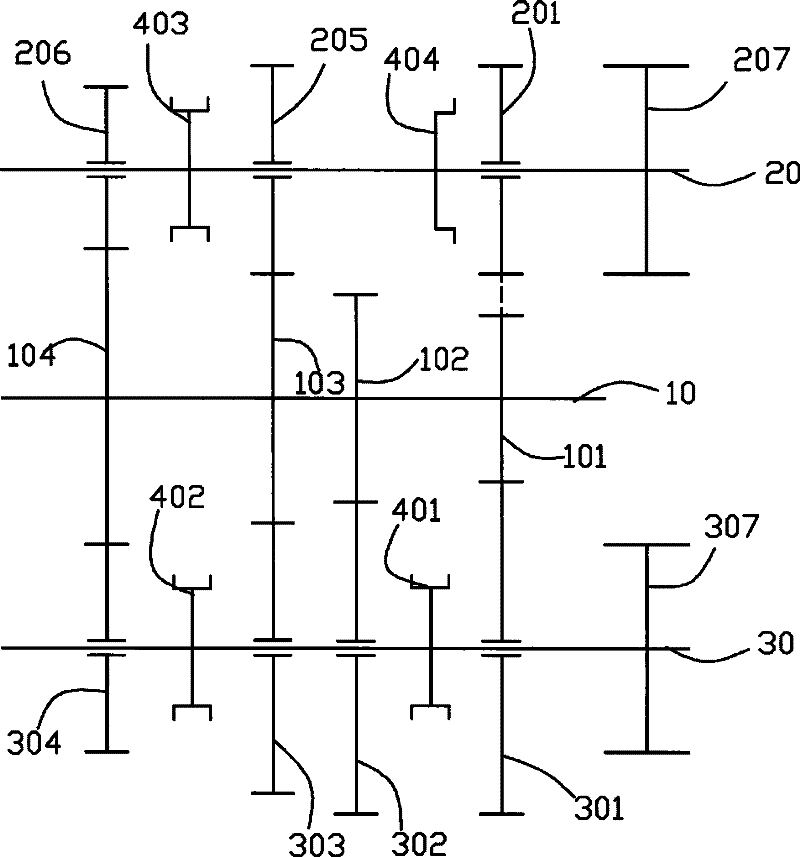

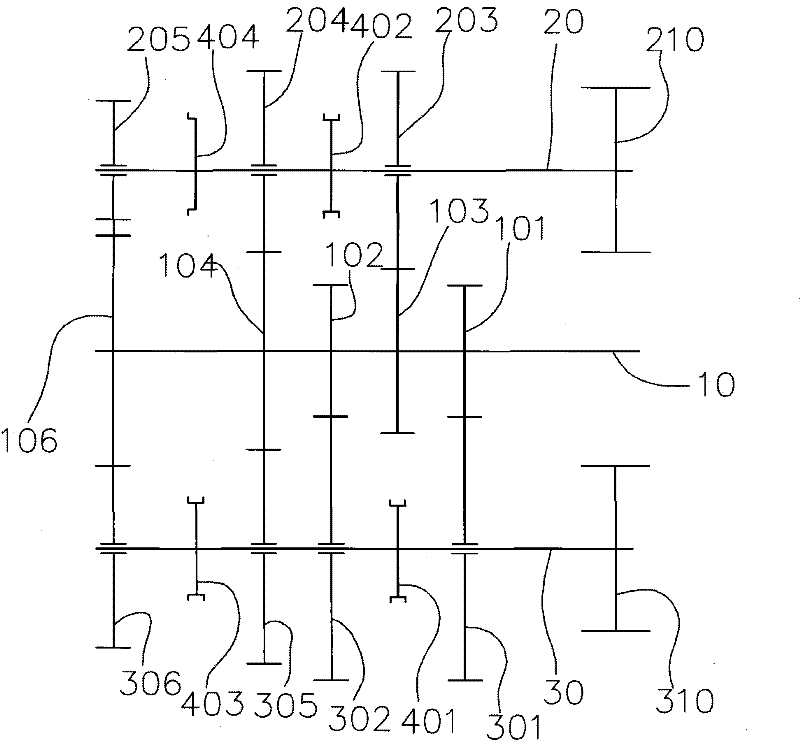

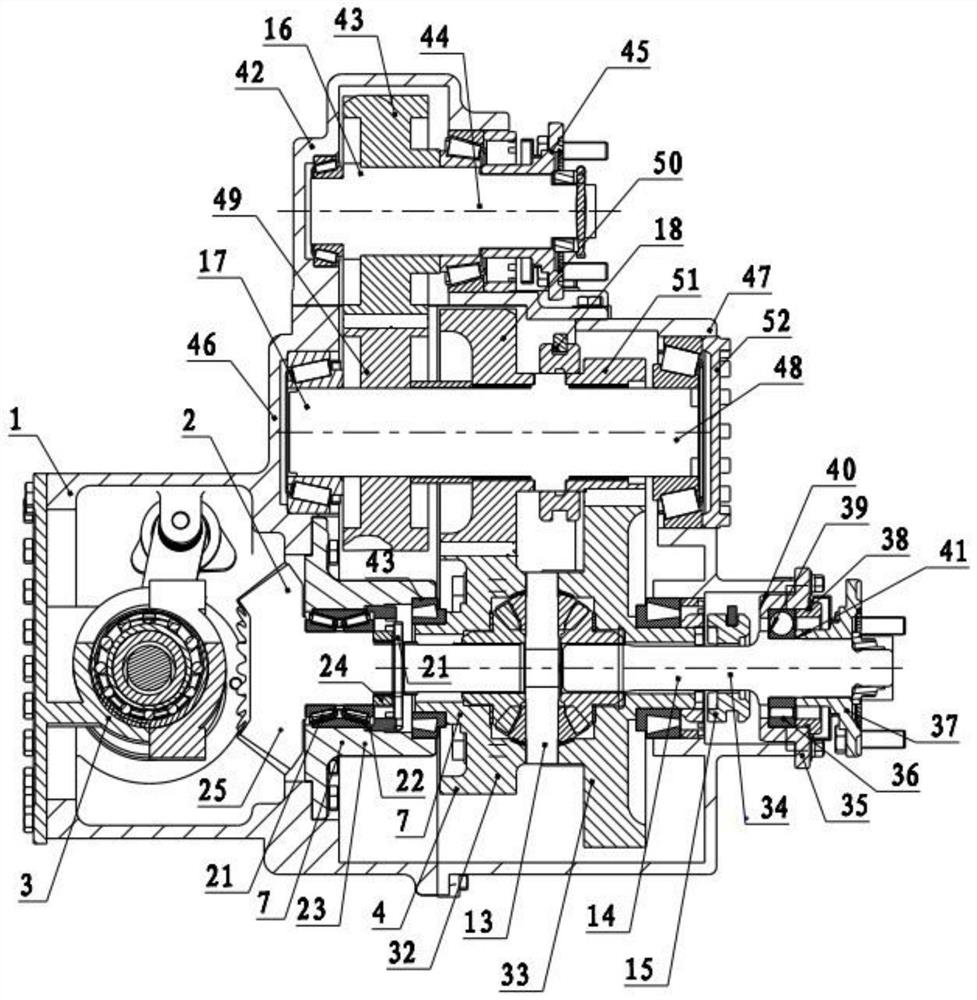

Arrangement of 6AT power drive system

InactiveCN101832371ACompact structureShort axial distanceToothed gearingsGear wheelCar manufacturing

The invention discloses arrangement of a 6AT power drive system, belonging to the field of vehicle manufacture. A shell, a power input shaft, a speed shifting mechanism and a gear shifting part are provided, wherein the speed shifting mechanism comprises an input planetary gear set, an output planetary gear set and a counteraction planetary gear set; the gear shifting part comprises a first clutch, a second clutch, a one-way clutch, a first brake, a second brake and a third brake; the first clutch and the second clutch are axially and symmetrically arranged at the rear end of the speed shifting mechanism in parallel; and the one-way clutch, the first brake, the second brake and the third brake are compactly arranged outside the speed shifting mechanism. The technical scheme has the advantages of ensuring compact structure and short axial distance of the speed shifting mechanism by compactly arranging the gear shifting part around the speed shifting mechanism, reducing the varieties of parts by symmetrically arranging the first clutch and the second clutch, lowering the design cost and effectively preventing the error installation when in assembly.

Owner:CHERY AUTOMOBILE CO LTD

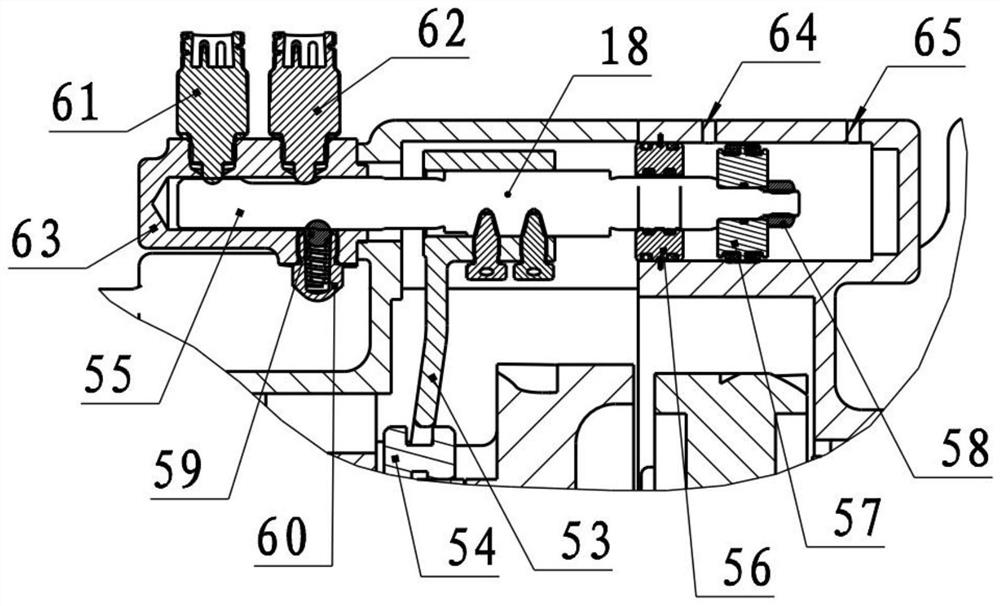

Three-channel microwave rotary joint

The invention discloses a three-channel microwave rotary joint which comprises a single-waveguide rotor, a double-waveguide rotor, a double-waveguide stator, a single-waveguide stator, a first bearing, a second bearing, a first connection arm, a second connection arm, a first inner conductor, a second inner conductor and a third inner conductor. According to the three-channel microwave rotary joint, the axial distance is short, the signal transmission loss is reduced, the problem of multi-channel Ka frequency band signal transmission is solved, the transmit-receive insulation degree is good, double-bearing design is adopted, coaxiality is guaranteed through precise machining and assembling, electrical performance fluctuation generated in the rotating process is greatly lowered, and the reliability of spacecraft moving components is improved.

Owner:BEIJING RES INST OF TELEMETRY +1

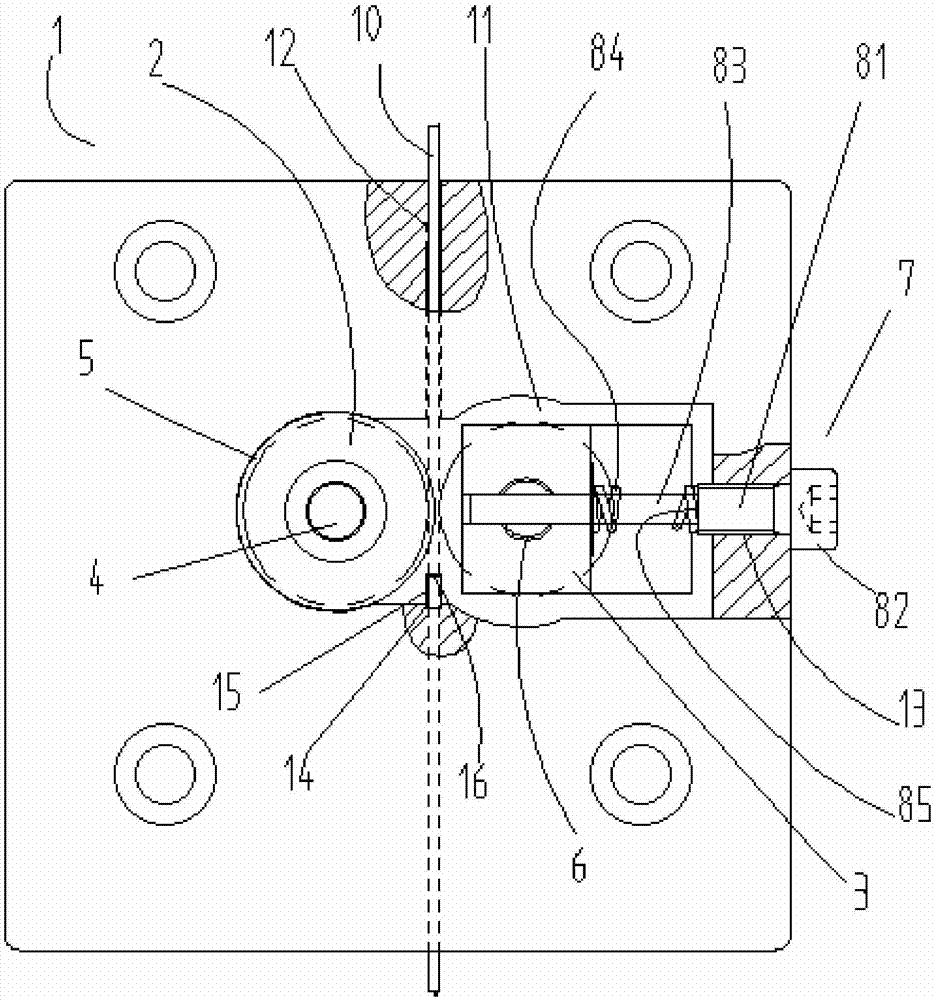

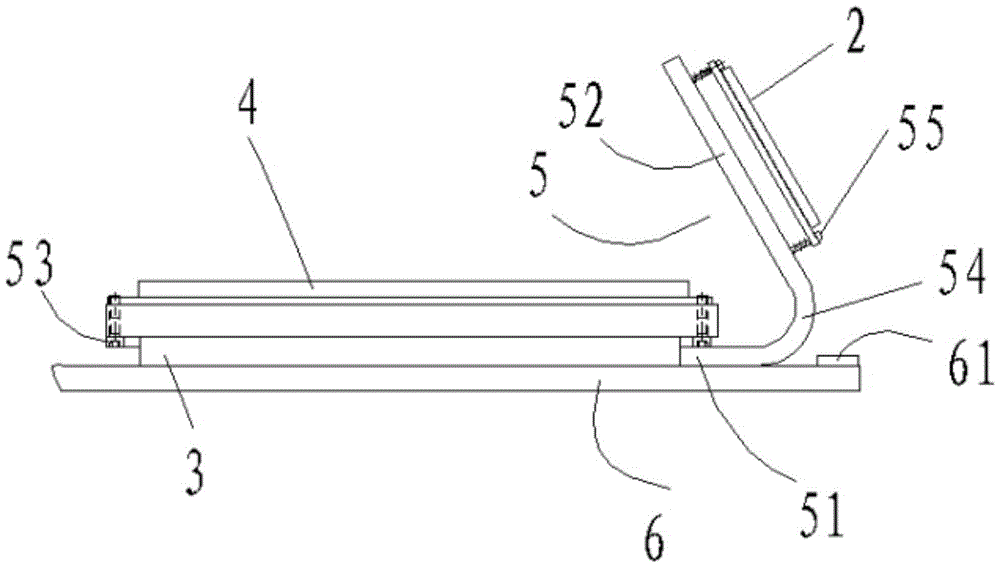

3D printer wire feeding structure

InactiveCN105437550AEasy to replaceEasy to replace and maintainAdditive manufacturing apparatusDrive wheelElectric machinery

The invention discloses a 3D printer wire feeding structure. The 3D printer wire feeding structure comprises a fixed base; the fixed base is connected with a wire feeding motor; a cavity is formed in middle of the fixed base; a wire feeding driving wheel is arranged on one side in the cavity, and a driven wheel structure is arranged on the other side in the cavity; the driving wheel is connected with a driving wheel shaft; the driving wheel shaft is supported on the inner wall of the cavity of the fixed base through a bearing; the driven wheel is connected with a driven wheel shaft; a printing wire channel is formed in the fixed base in the perpendicular direction; the driven wheel shaft is connected with a driven wheel shaft horizontal position adjusting structure; and the driving wheel is matched with the driven wheel to convey printing wires to a printing head part. The 3D printer wire feeding structure is simple and compact in structure, is convenient for disassembly, replacement and maintenance, can conveniently and precisely adjust a shaft distance between the driving wheel and the driven wheel through the horizontal position adjusting structure, and can reliably convey the printing wire materials to a melting position of the printing head part for timely melting to satisfy the printing requirements.

Owner:UNIV OF JINAN

Hydraulic cylinder

The hydraulic cylinder having a portion on a side of a lip tip end of an annular clearance between an inner circumferential face of a shaft hole of a cylinder and a piston is made up of a minute clearance in order to suppress protrusion of the lip, wherein an annular clearance area for suppressing occurrence of the cavitation and for shortening an axial distance of the annular clearance portion made up of the minute clearance is formed on an opposite side of the annular clearance portion from a mounting groove.

Owner:NOK CORP

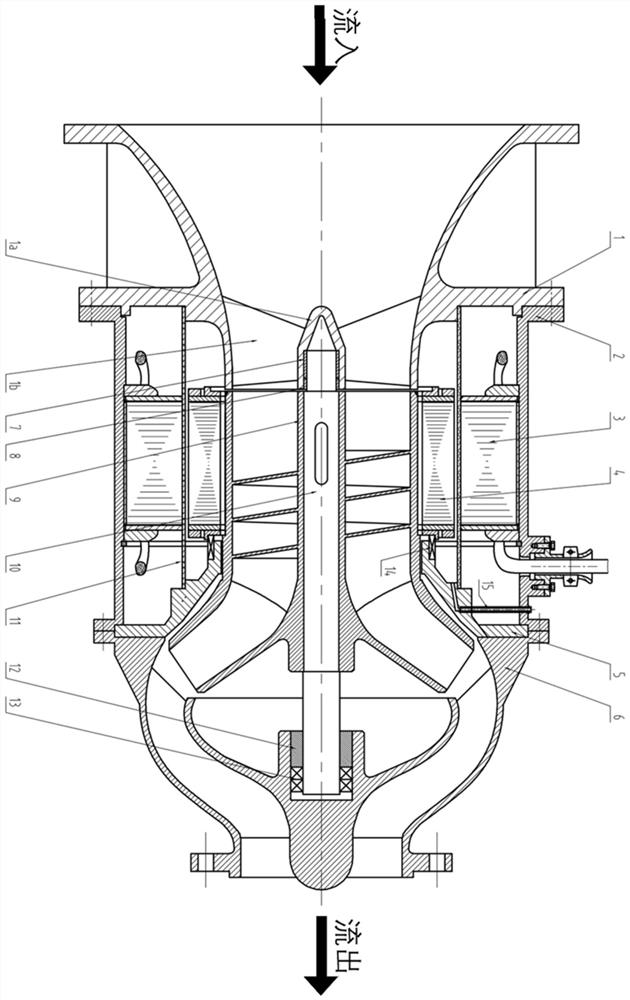

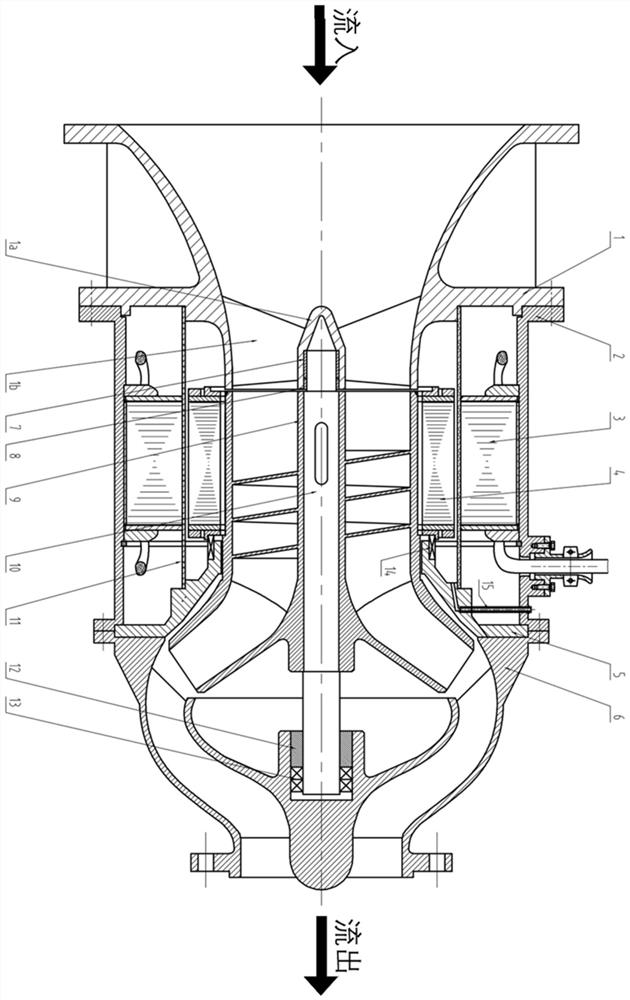

Impeller built-in type high-speed centrifugal pump

ActiveCN112460031ABalance axial forceOptimize layoutSpecific fluid pumpsPump componentsElectric machineEngineering

The invention provides an impeller built-in type high-speed centrifugal pump which comprises a shell and a rotating wheel. The rotating wheel is rotatably mounted in the shell. The impeller built-in type high-speed centrifugal pump is characterized in that the impeller built-in type high-speed centrifugal pump further comprises a motor stator and a motor rotor, the motor stator is mounted on the shell, the motor rotor is fixedly connected with the rotating wheel, the rotating wheel comprises an inducer and a centrifugal impeller, an outer ring is arranged on the edge of the outer side of the inducer, and the outer ring of the inducer is fixedly connected with the inner circle of the motor rotor; the motor stator is electrified, so that the motor rotor rotates; the centrifugal impeller andthe inducer rotate synchronously; and the rotating speed of the rotating wheel is not lower than 2800 r / min. The problem that the water outlet direction of a traditional centrifugal pump is perpendicular to the rotation axis of the pump is solved, meanwhile, the structural size of the traditional centrifugal pump is reduced, the axial force of the rotor is reduced, and the requirements of high-speed navigation devices such as torpedoes for high lift, large flow, stable operation and compact structures of water jet propulsion pumps can be met.

Owner:JIANGSU UNIV

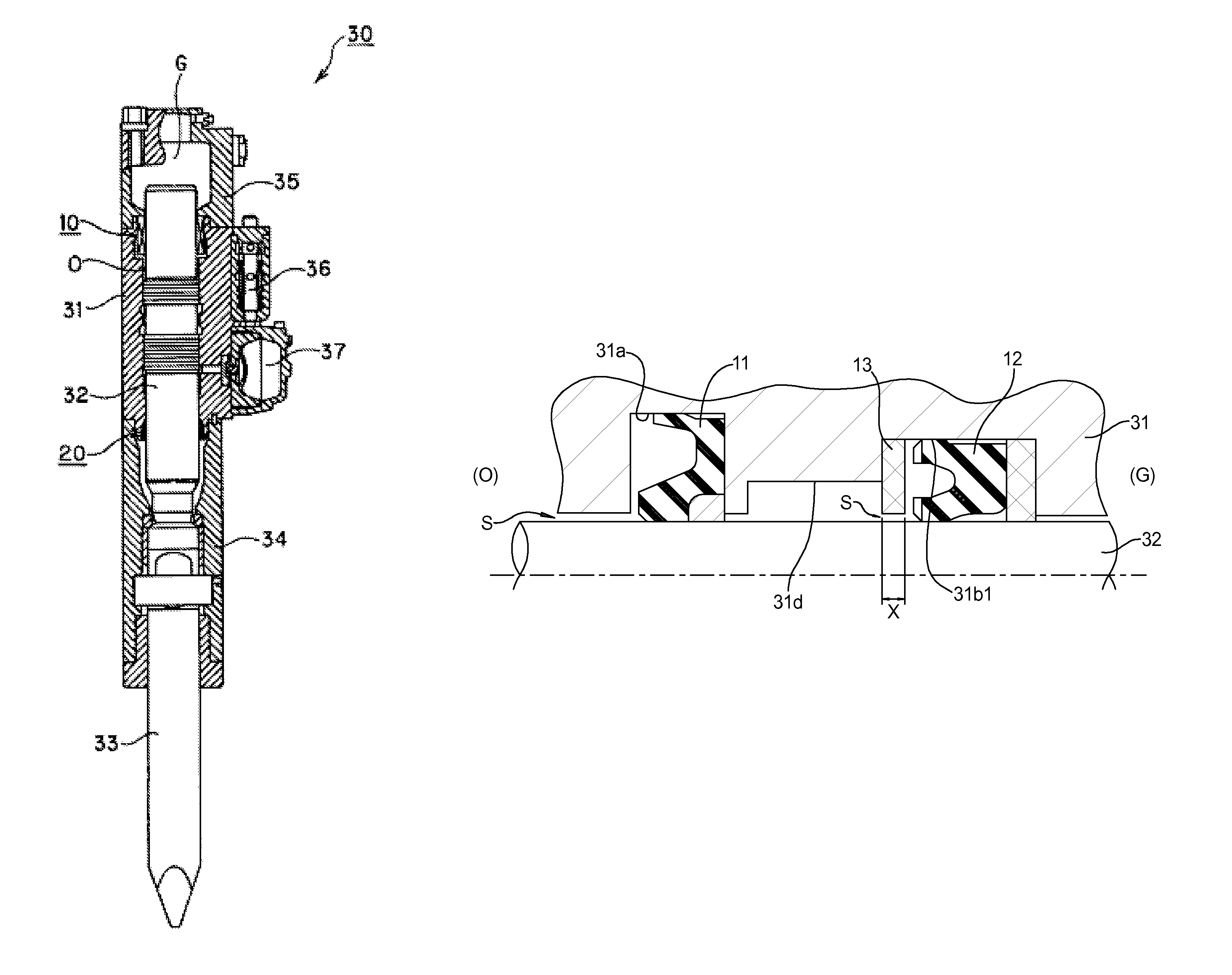

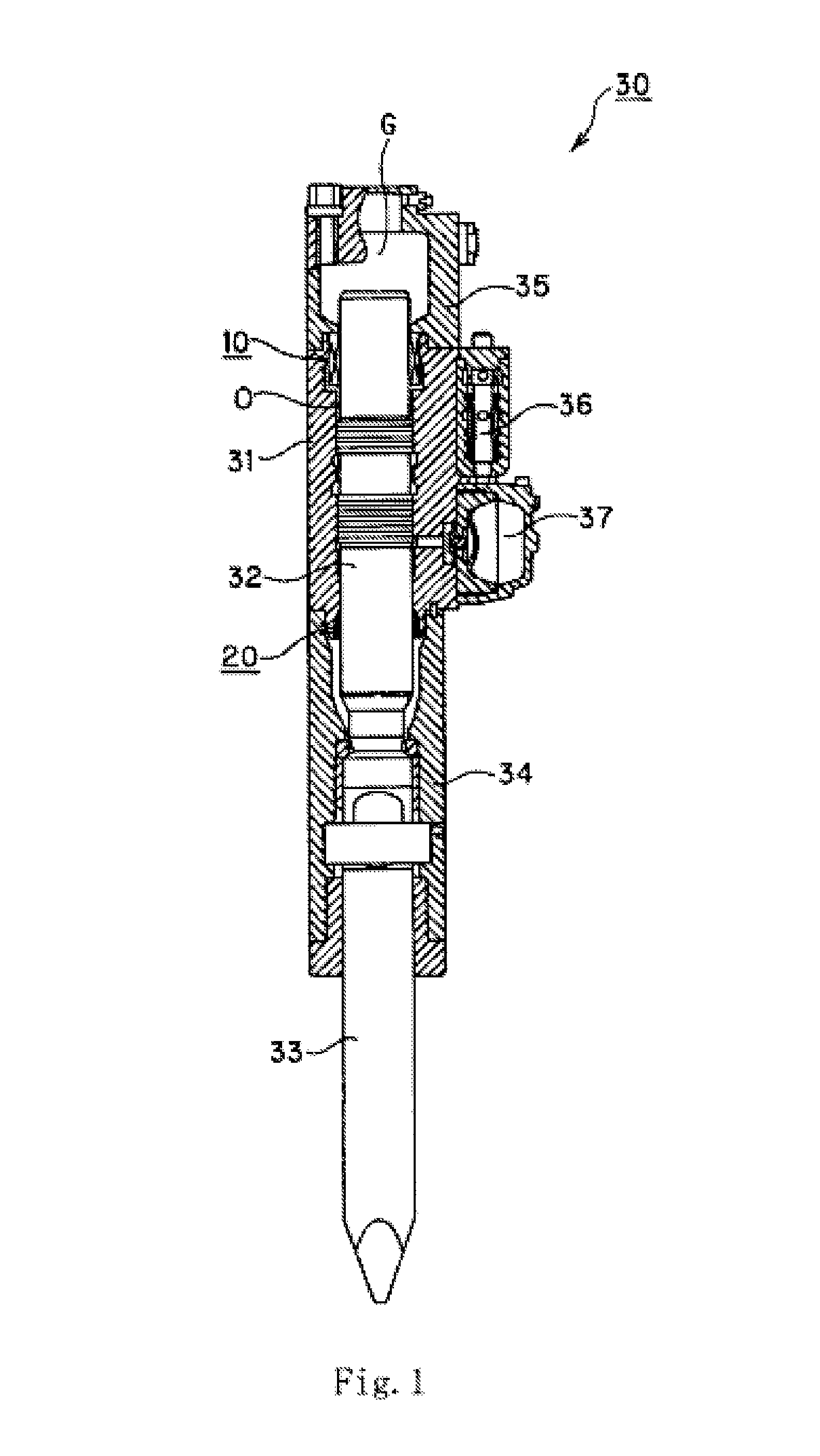

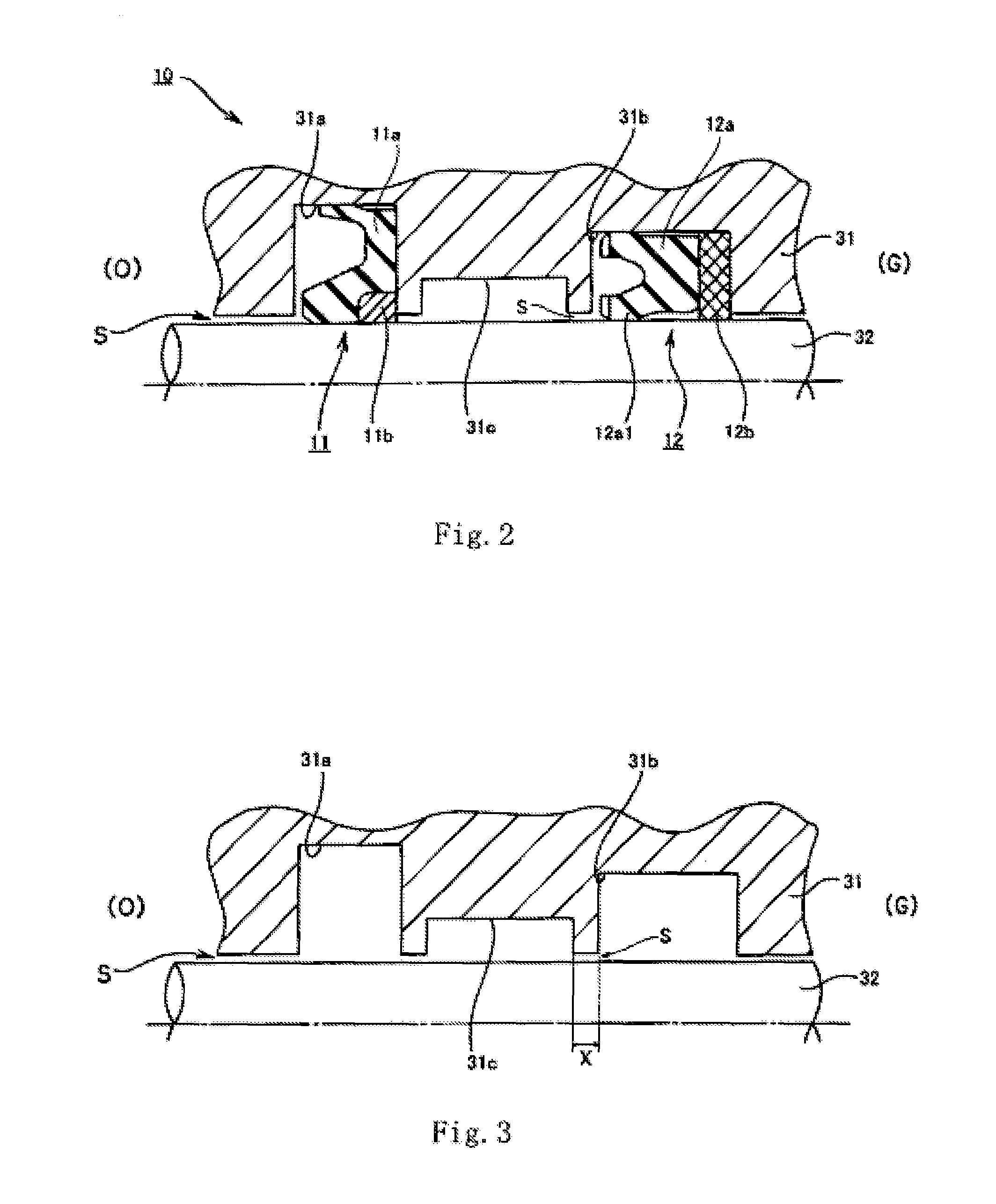

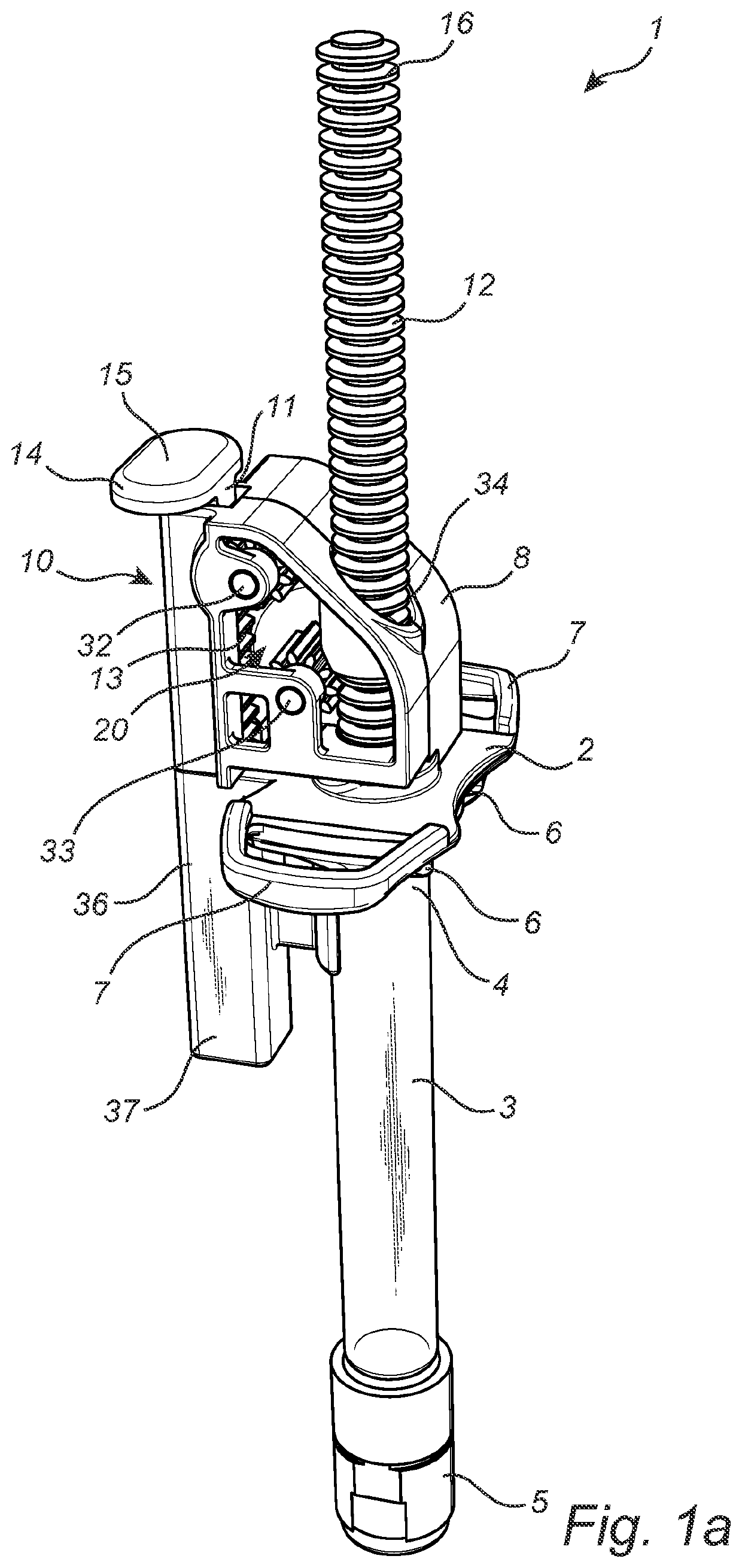

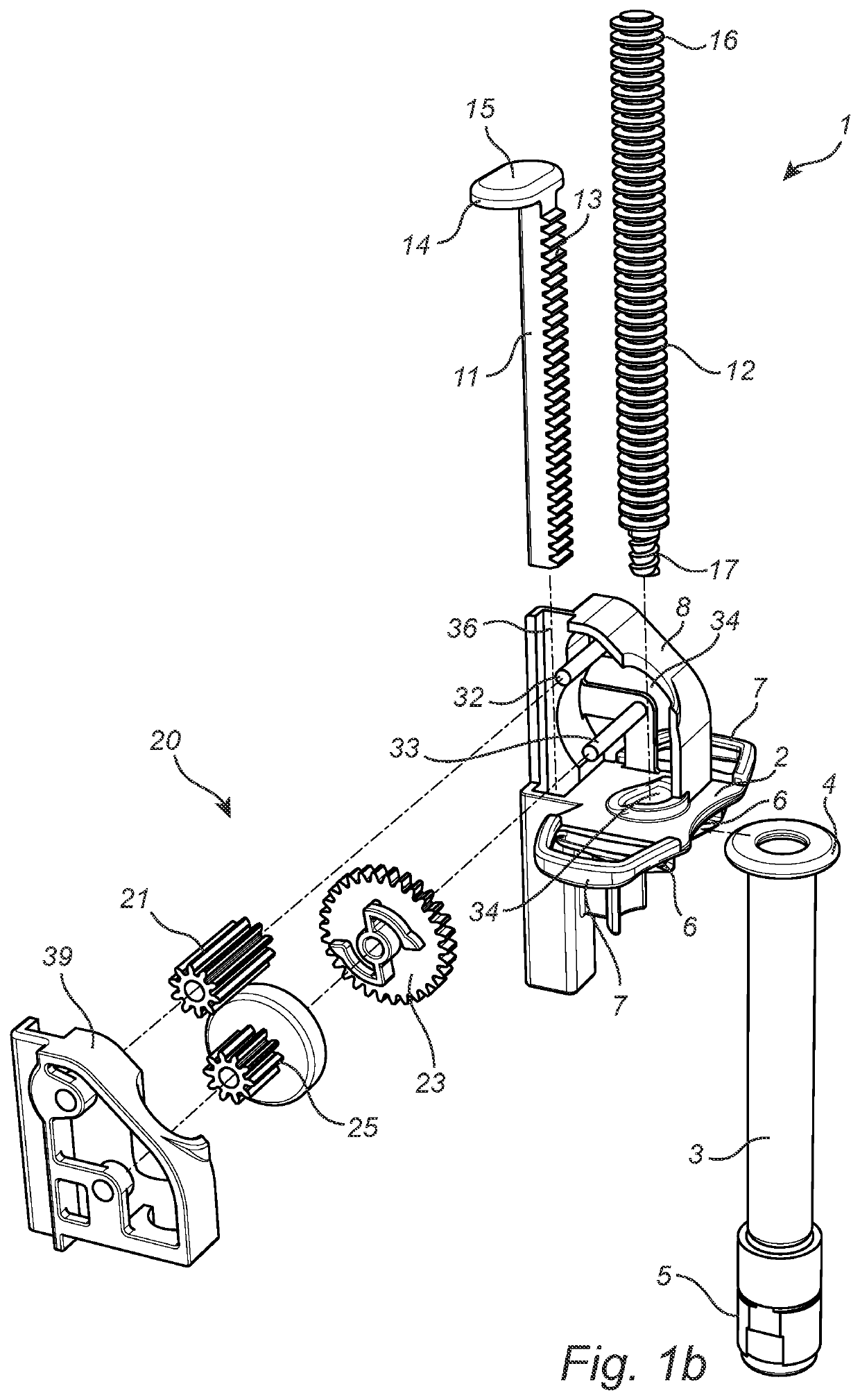

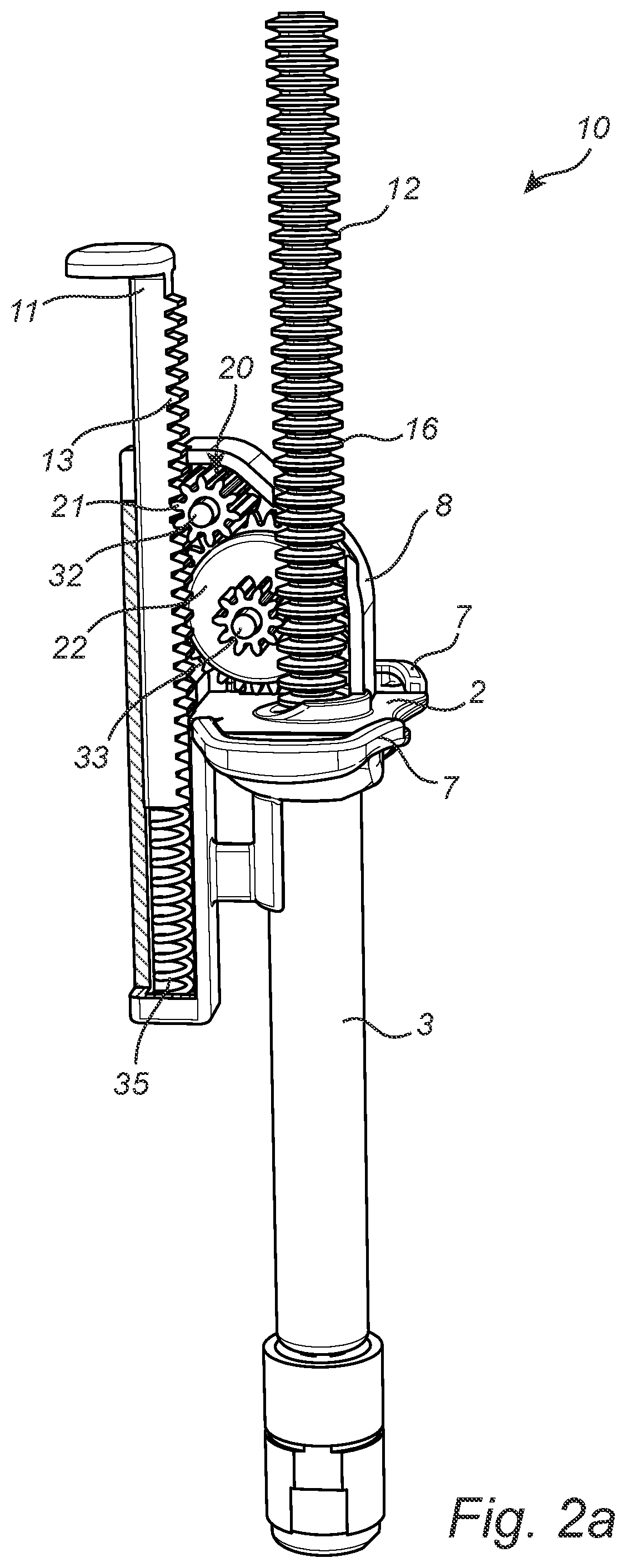

Injection device

PendingUS20210213205A1Helps to expelCircumference smallAmpoule syringesIntravenous devicesGear wheelEngineering

An injection device includes a drive mechanism, and the drive mechanism in turn includes a drive rod being axially moveable, a plunger rod being axially moveable, and a gear assembly. The gear assembly is arranged such that an axial movement of the drive rod generates an axial movement of the plunger rod. This allows for a force transmission between the drive rod and the plunger rod, facilitating the expelling of viscous substances from the injection device.

Owner:GALDERMA SA

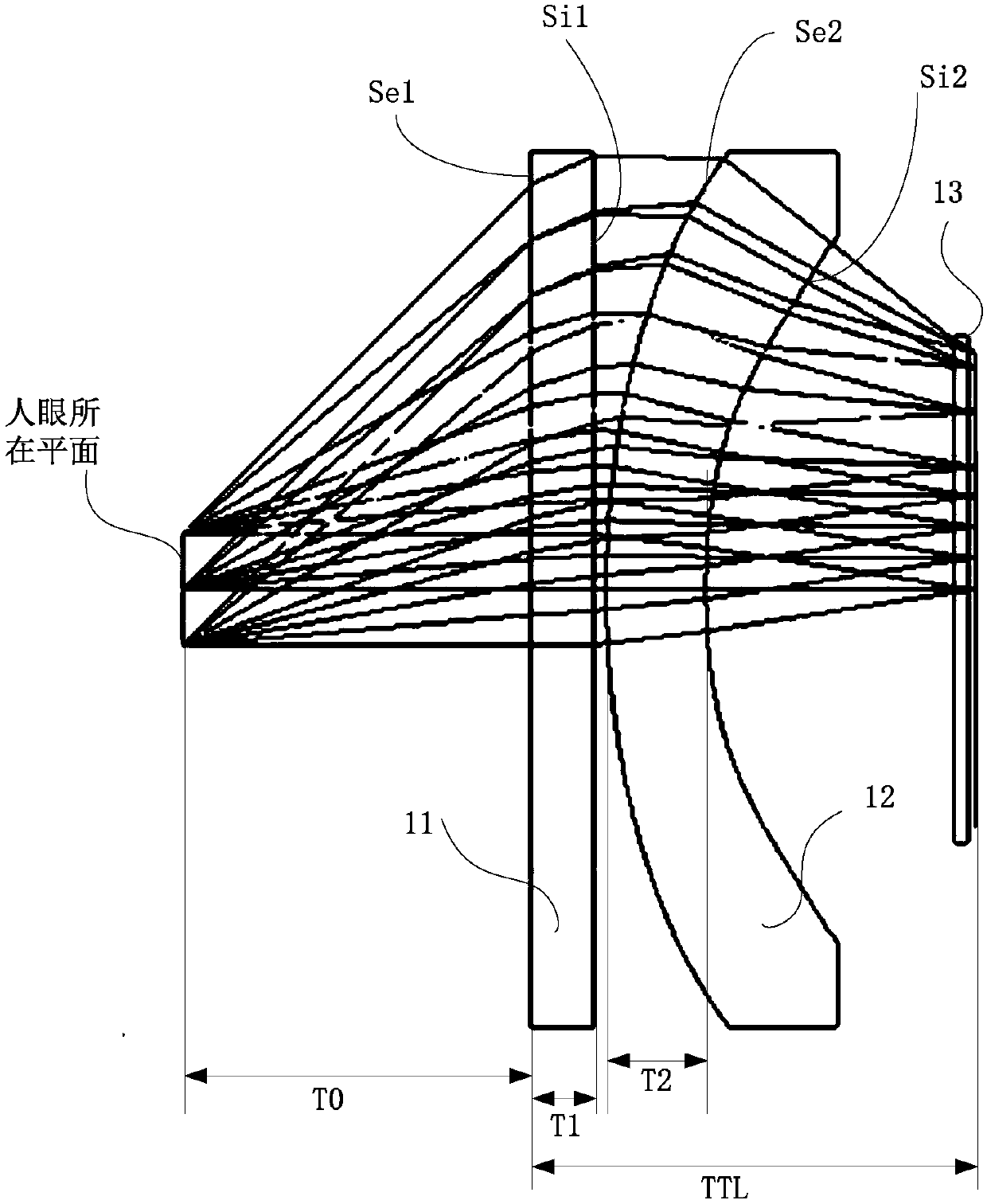

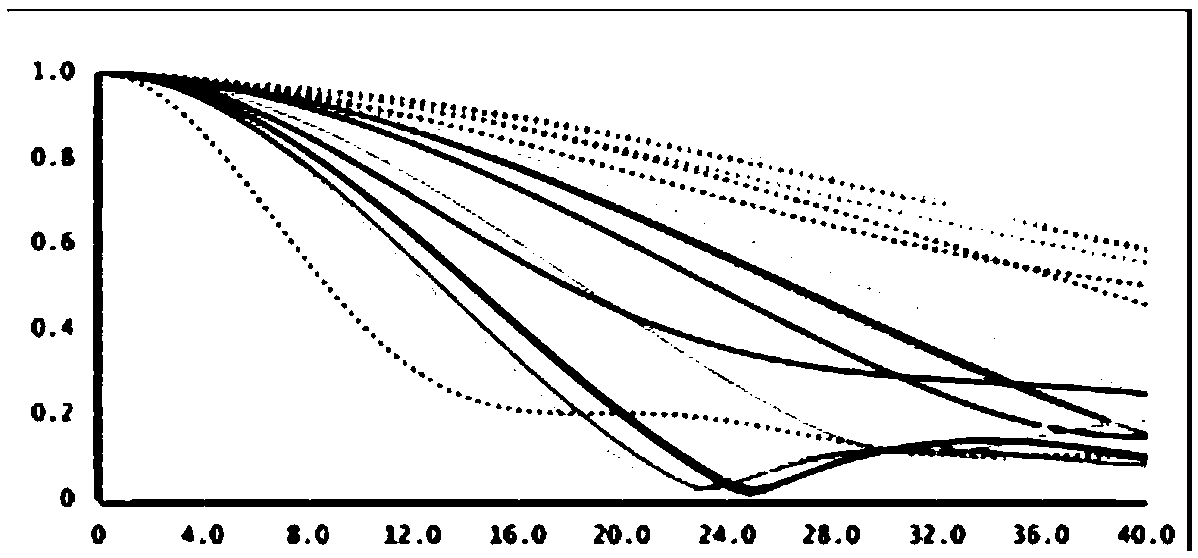

Head-mounted display device

The invention provides a head-mounted display device. The device comprises a first positive lens, a second positive lens and a micro-display device which are coaxially arranged in sequence; the lightinlet surface of the first positive lens is close to the light outlet surface of the second positive lens, and the light inlet surface of the second positive lens is close to the micro-display device;the light outlet surface of the second positive lens is a convex Fresnel surface, and the light inlet surface of the first positive lens is a plane Fresnel surface. According to the head-mounted display device, the size can be reduced, and meanwhile the view field angle is effectively increased.

Owner:GOERTEK OPTICAL TECH CO LTD

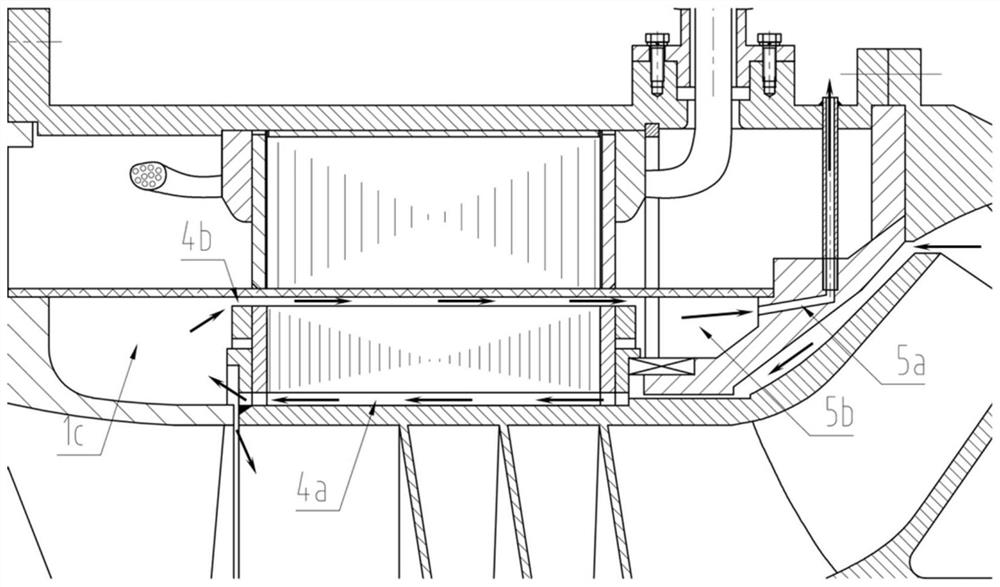

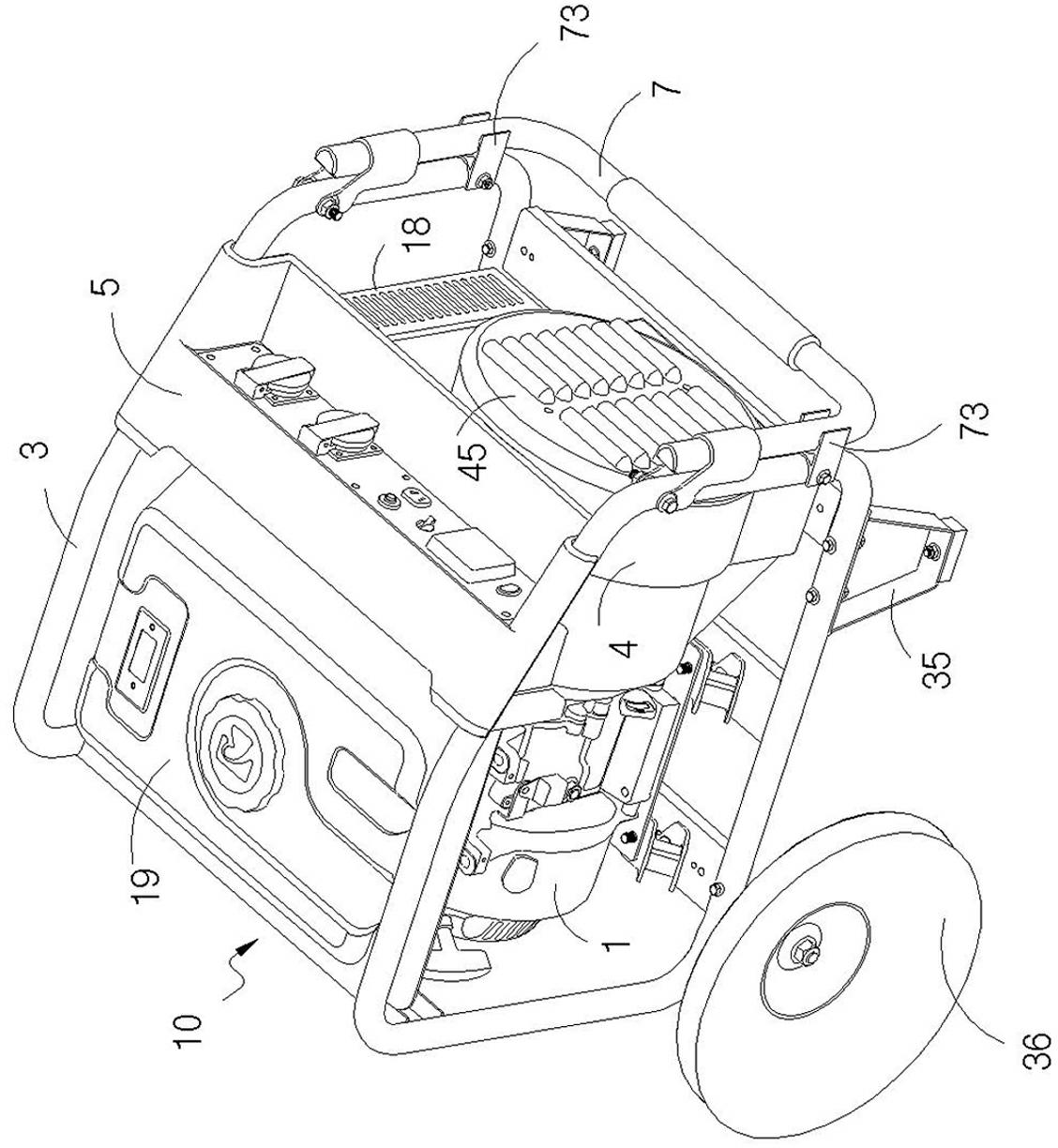

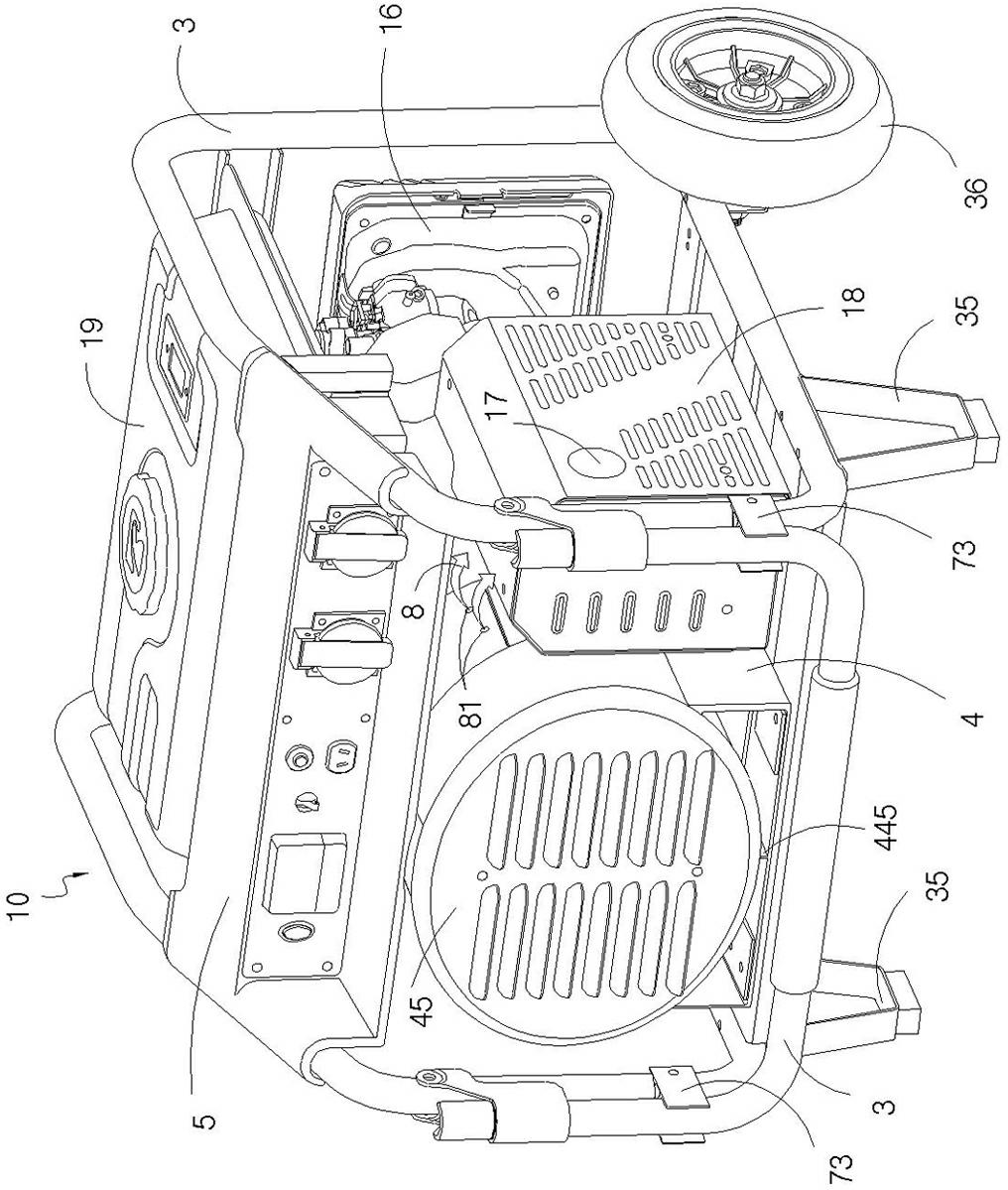

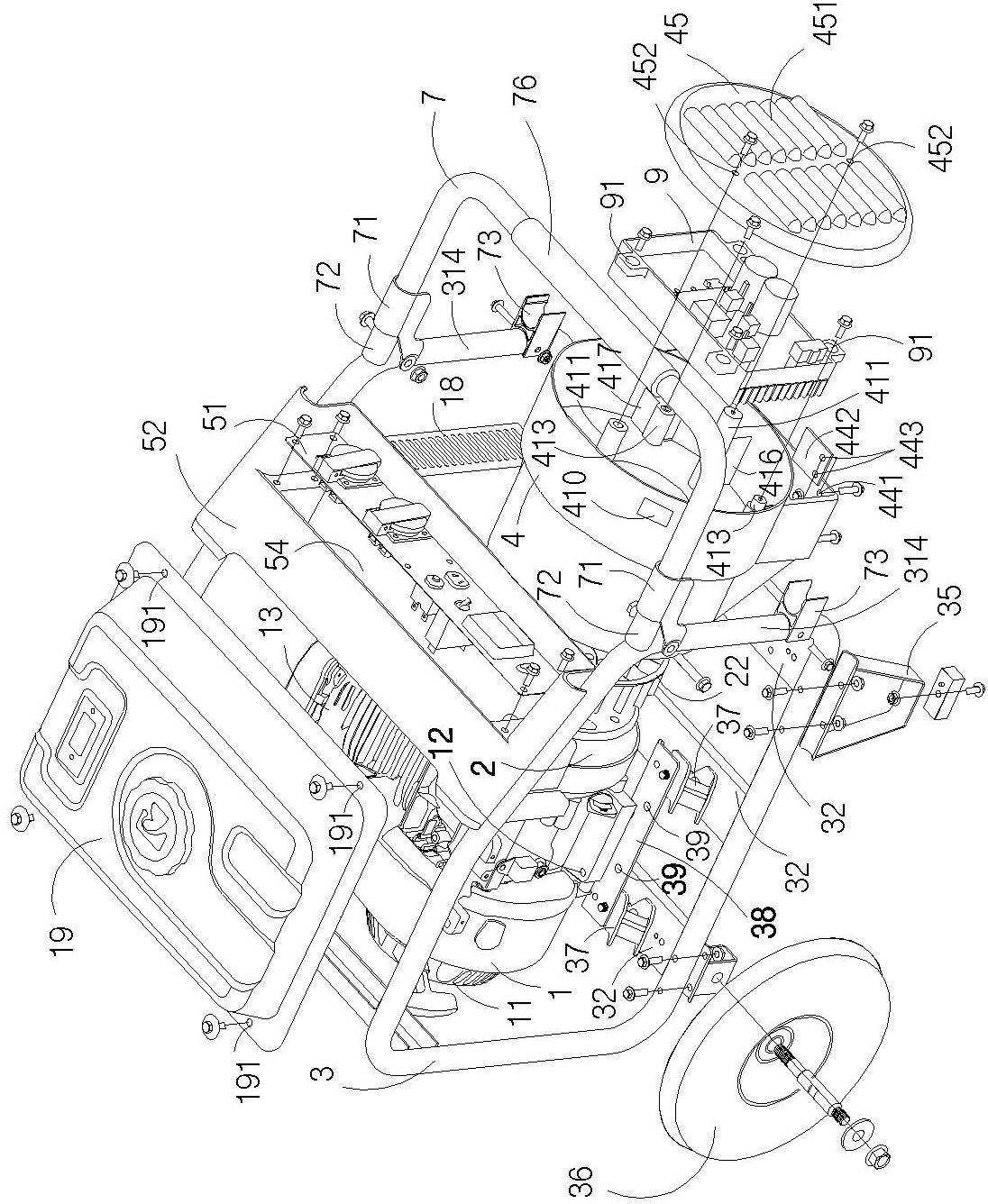

Engine-driven generator

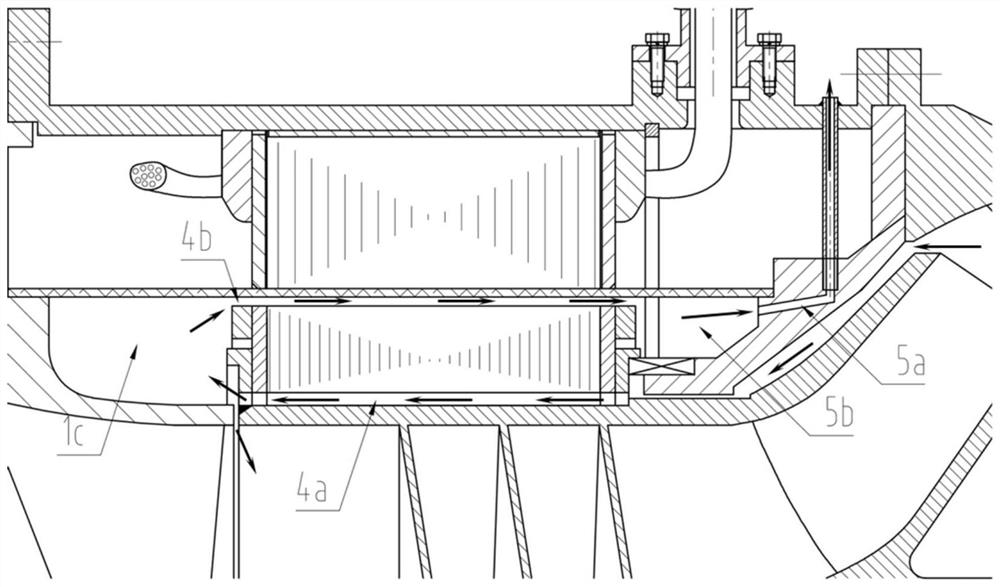

InactiveCN102588094ASimple structureReduce the amount of materialMachines/enginesCooling/ventillation arrangementEngineering

The invention provides an engine-driven generator, which is simple in structure, low in manufacturing cost, and capable of effectively solving the problem of radiation of an electrical unit and assisting in implementation of radiation of a silencer. The engine-driven generator comprises a generator, an engine, a motor fan, a frame, the electrical unit and a cooling shell arranged on the frame to form a first air passage, and the electrical unit and the generator are cooled by means of operation of the motor fan. The cooling shell comprises a cylindrical front shell, an end cover covering the front shell, a circular cylindrical rear shell, a first air outlet and a partition, wherein the front shell is provided with a front space for containing the electrical unit, the end cover is provided with a cooling air inlet, the circular cylindrical rear shell is integrally connected with the front shell and provided with a rear space for containing the generator and the motor fan, the first air outlet is formed by a gap between a rear-end opening of the rear shell and the generator, the partition is integrally arranged between the front space and the rear space, and the front space and the rear space are communicated with each other through a round transitional air port on the partition.

Owner:CHONGQING RATO POWER

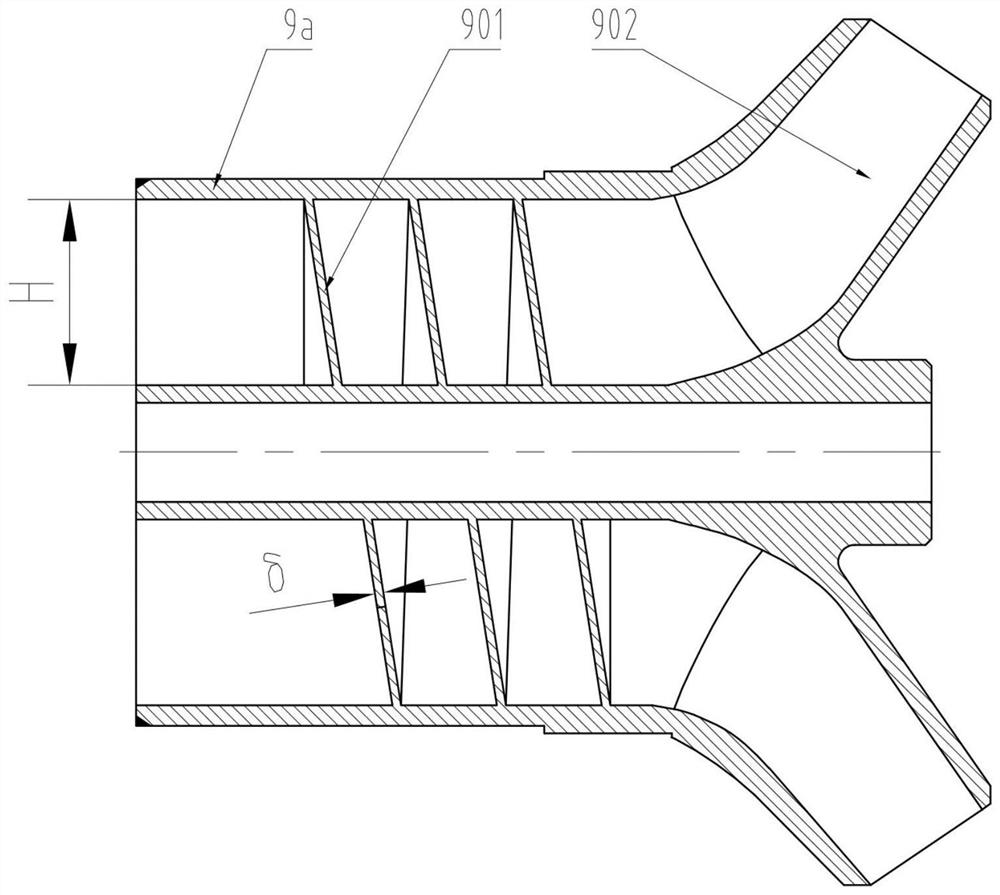

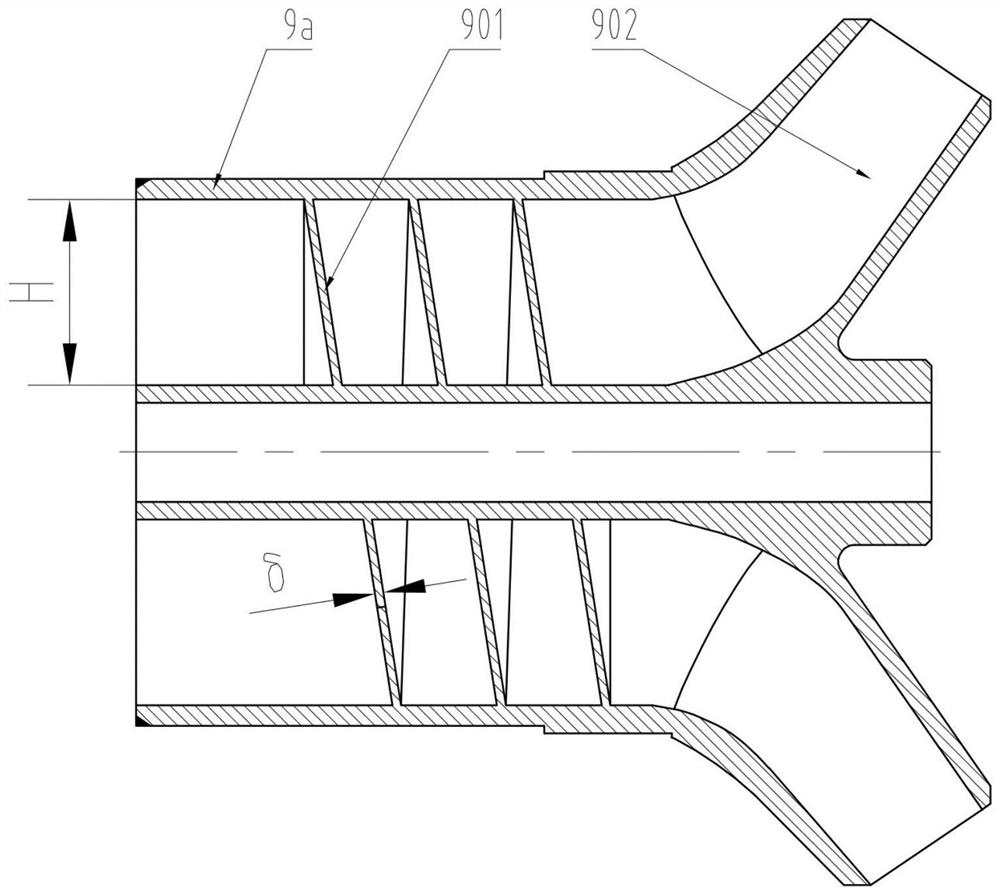

Efficient long-runner impeller low-specific-speed centrifugal pump

PendingCN113586513AImprove work efficiencyUniform change in flow areaPump componentsPumpsCircular discDrive shaft

The invention discloses an efficient long-runner impeller low-specific-speed centrifugal pump. The efficient long-runner impeller low-specific-speed centrifugal pump comprises a centrifugal impeller, an inducer, a transmission shaft, a centrifugal pump shell and sealing structures; the centrifugal impeller and the inducer are in rigid connection; the centrifugal impeller and the inducer are coaxial with the transmission shaft; the centrifugal impeller comprises a front cover plate and a rear cover plate which are in single-arc transition; and the sealing structures are arranged on the outer side of the front cover plate and the outer side of the rear cover plate correspondingly. According to the efficient long-runner impeller low-specific-speed centrifugal pump, the axial length is properly increased, the blade angle distribution of the centrifugal impeller is smoother, the inlet impact loss of the centrifugal impeller is reduced, the work efficiency of the low-specific-speed centrifugal pump is obviously improved, and the problem that due to the long and narrow runner characteristic of the low-specific-speed centrifugal pump, the impeller disc friction loss and the inlet impact loss of the low-specific-speed centrifugal pump are large, and consequently the efficiency of the low-specific-speed centrifugal pump is low is solved.

Owner:XI AN JIAOTONG UNIV

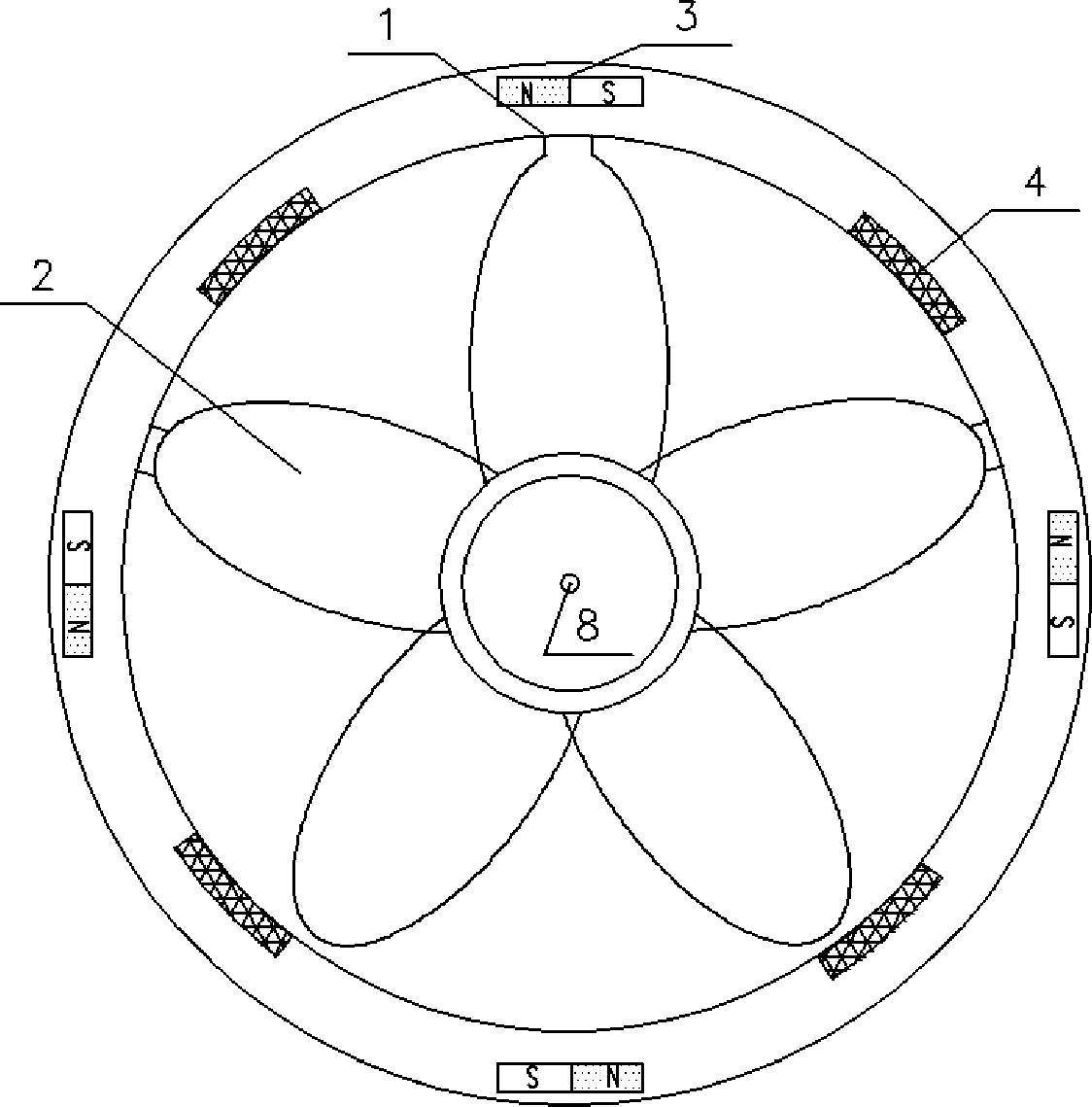

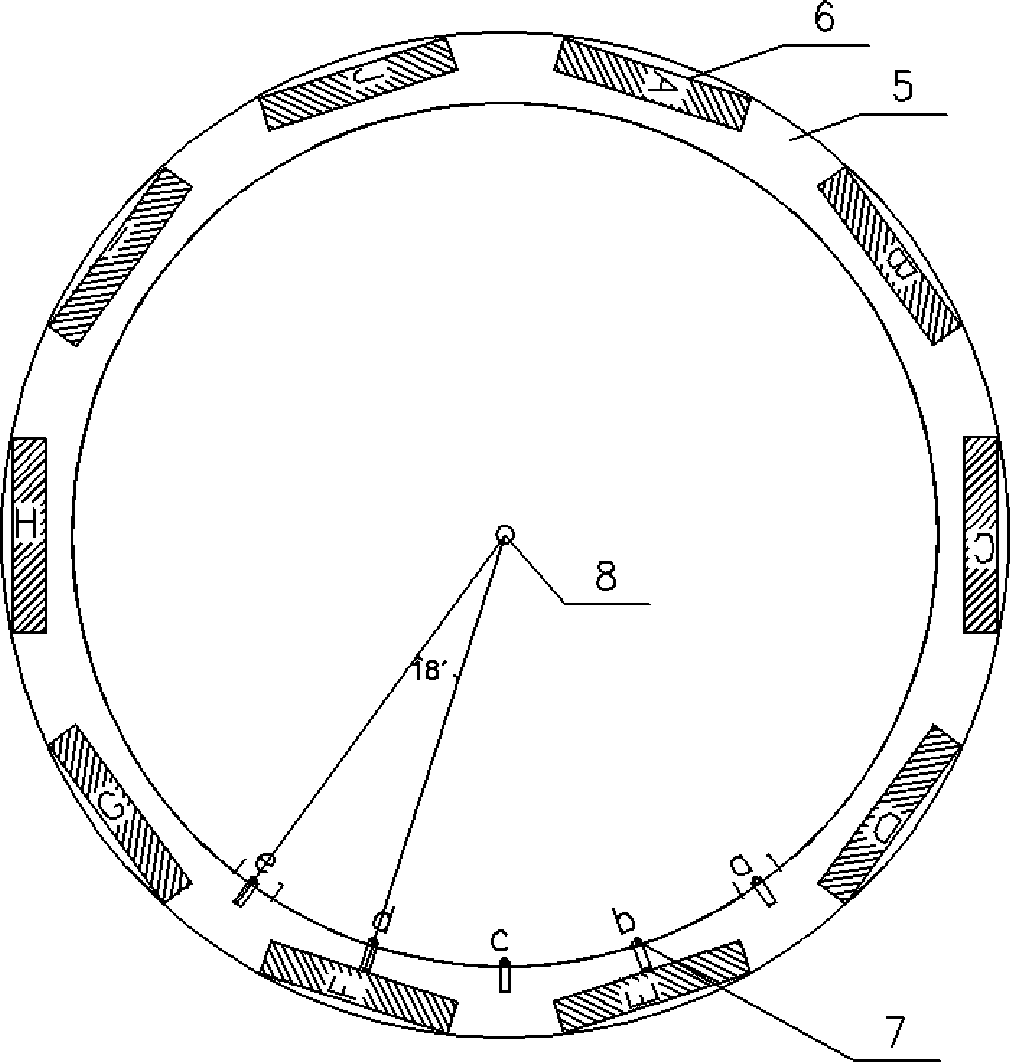

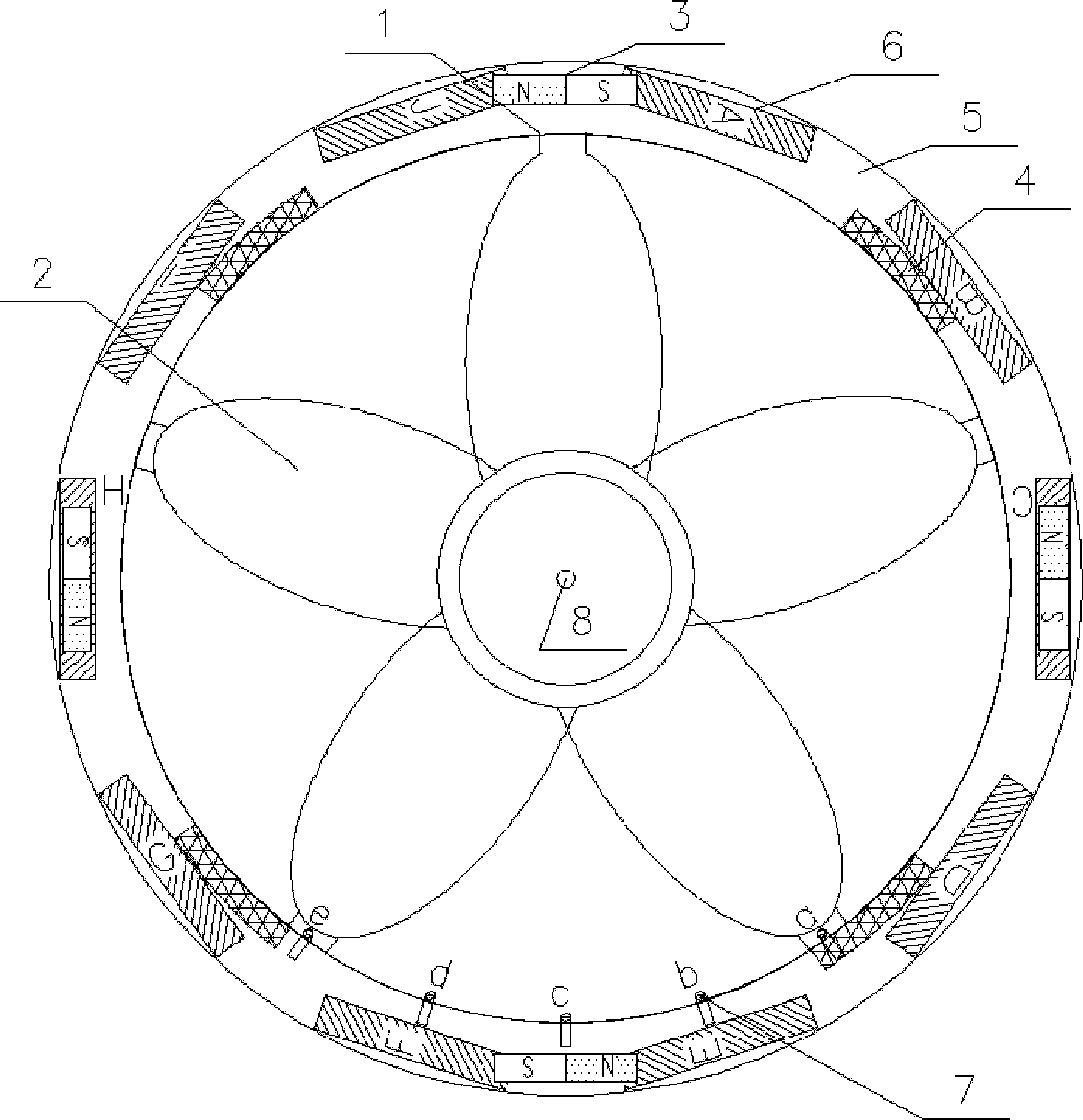

Wheel-type fan driving method and wheel-type fan

InactiveCN102635563AReduce reflectionIncrease forcePump installationsNon-positive displacement fluid enginesImpellerEngineering

The invention provides a wheel-type fan driving method and a wheel-type fan. The method comprises the following steps of: arranging a permanent magnet block and a light reflecting region on a ring provided with an impeller; arranging electromagnetic coil sets and an optoelectronic switch on a base, and connecting the optoelectronic switch with the electromagnetic coil sets in series; rotatably connecting the ring with the base by virtue of a rotating shaft; and starting up the fan, and switching on the optoelectronic switch meeting with the light reflecting region, so that the electromagnetic coils are electrified, and the fan is driven. The wheel-type fan comprises the ring, the impeller, the base and the rotating shaft, wherein the impeller is arranged in the ring, and the permanent magnet block and the light reflecting region are arranged on the ring; the electromagnetic coil sets and the optoelectronic switch are arranged on the base, and the optoelectronic switch is connected with each electromagnetic coil set in series; the impeller is rotatably connected with the base by virtue of the rotating shaft; and after each series loop is electrified and the fan is started up, the light reflecting region meets with the optoelectronic switch, the optoelectronic switch is switched on, and the electromagnetic coils on the corresponding series loops are electrified to drive the fan.

Owner:徐荻明

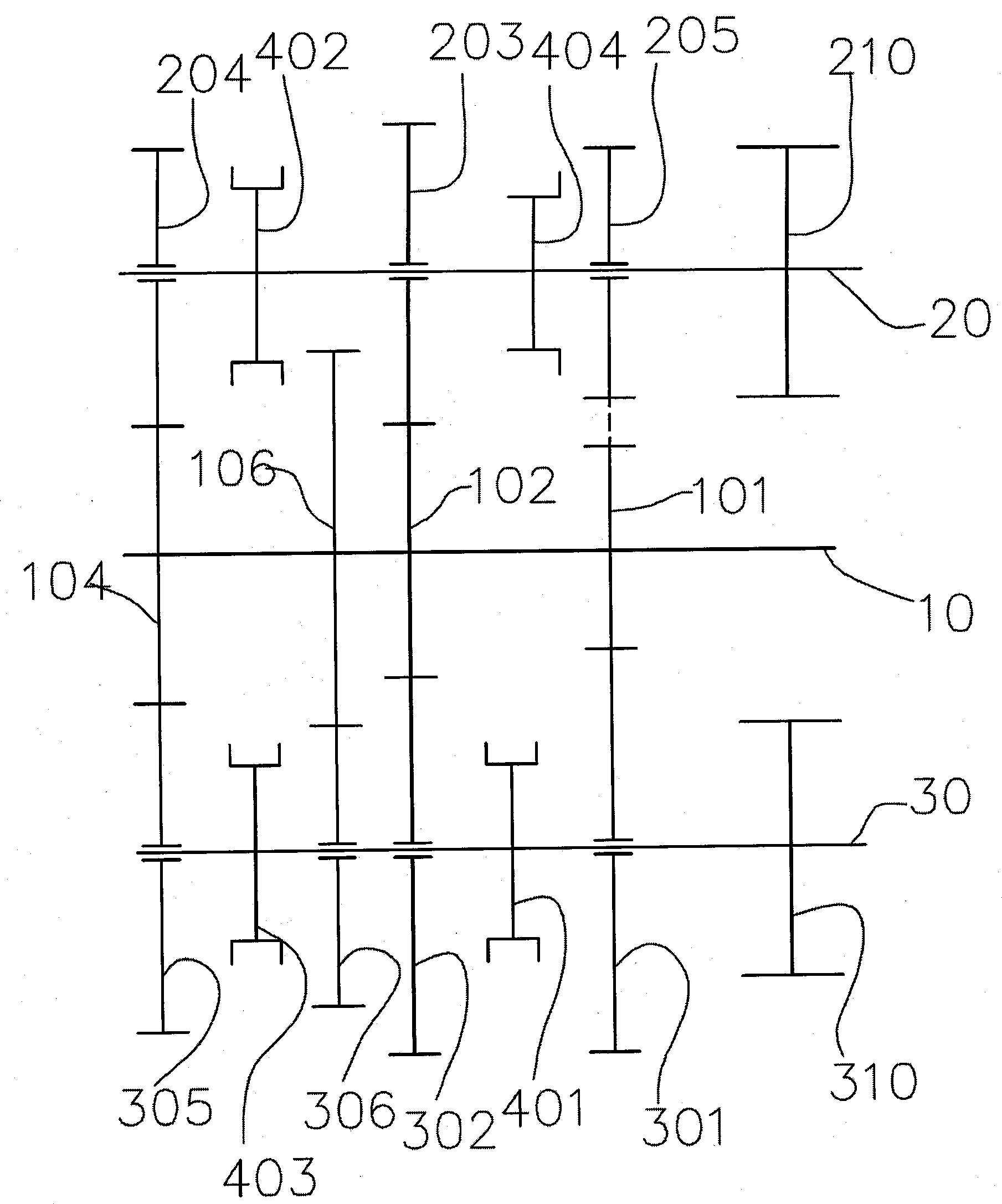

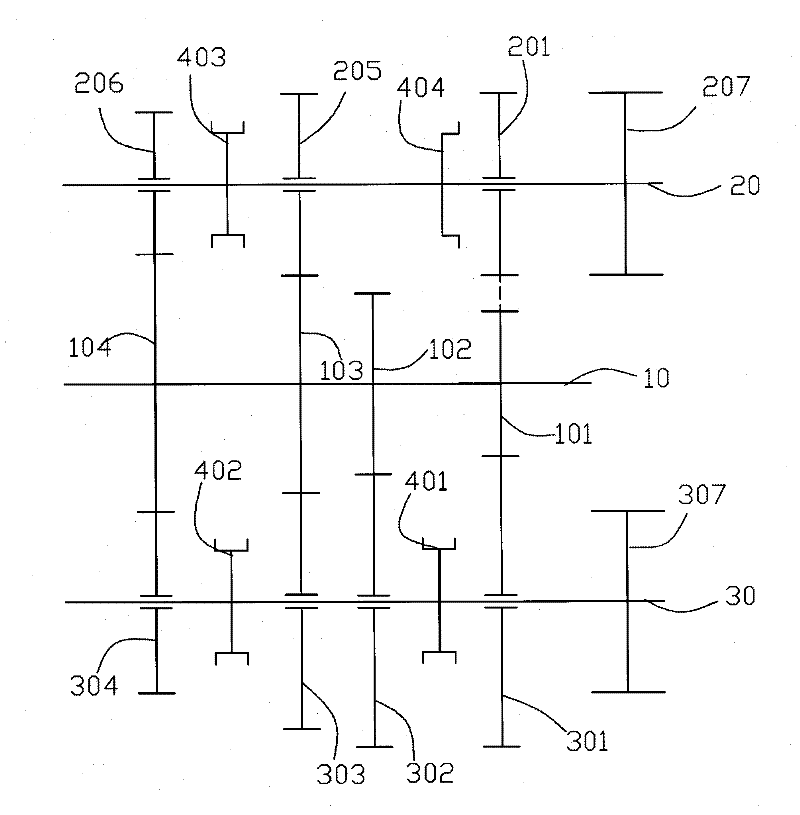

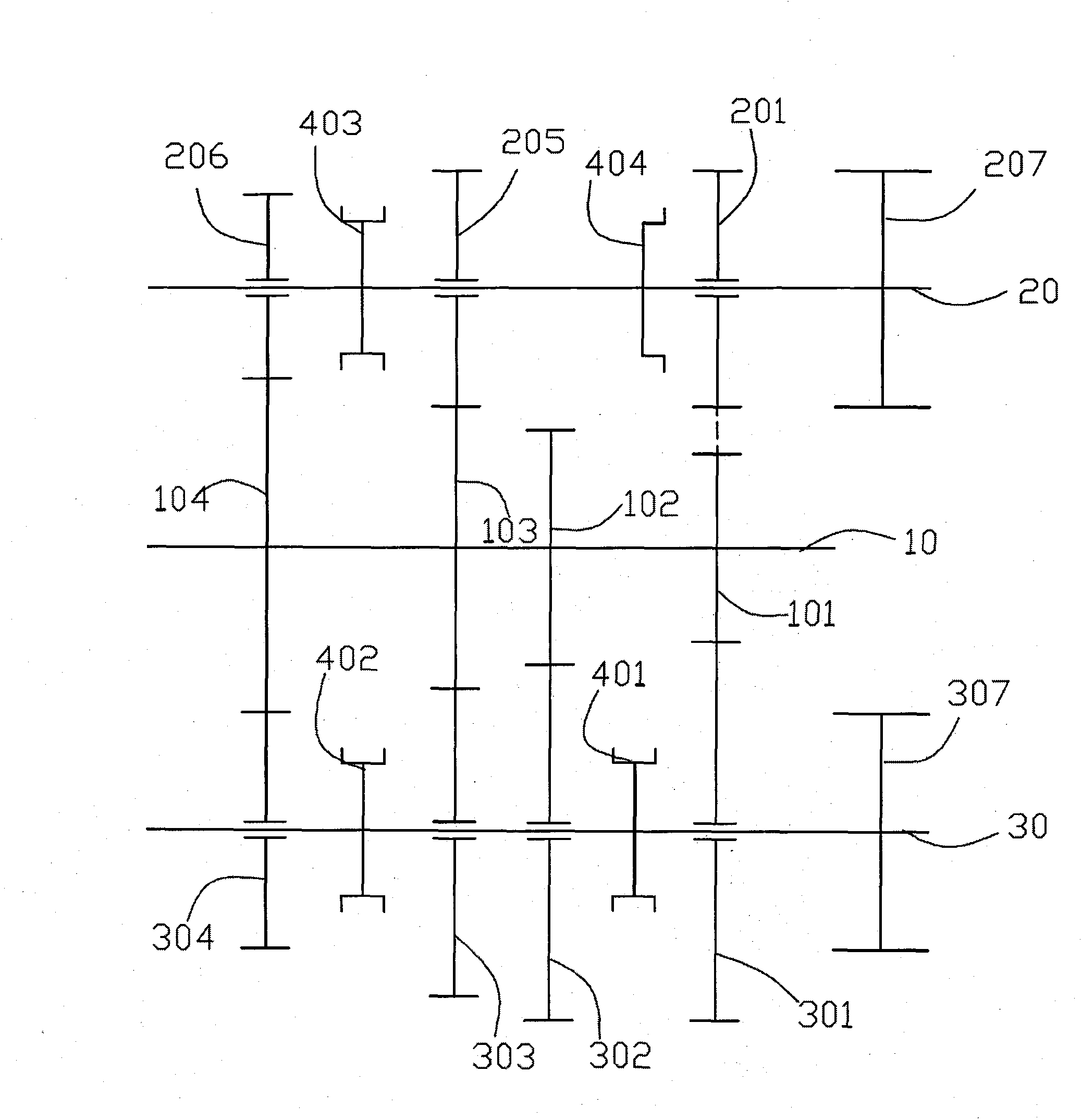

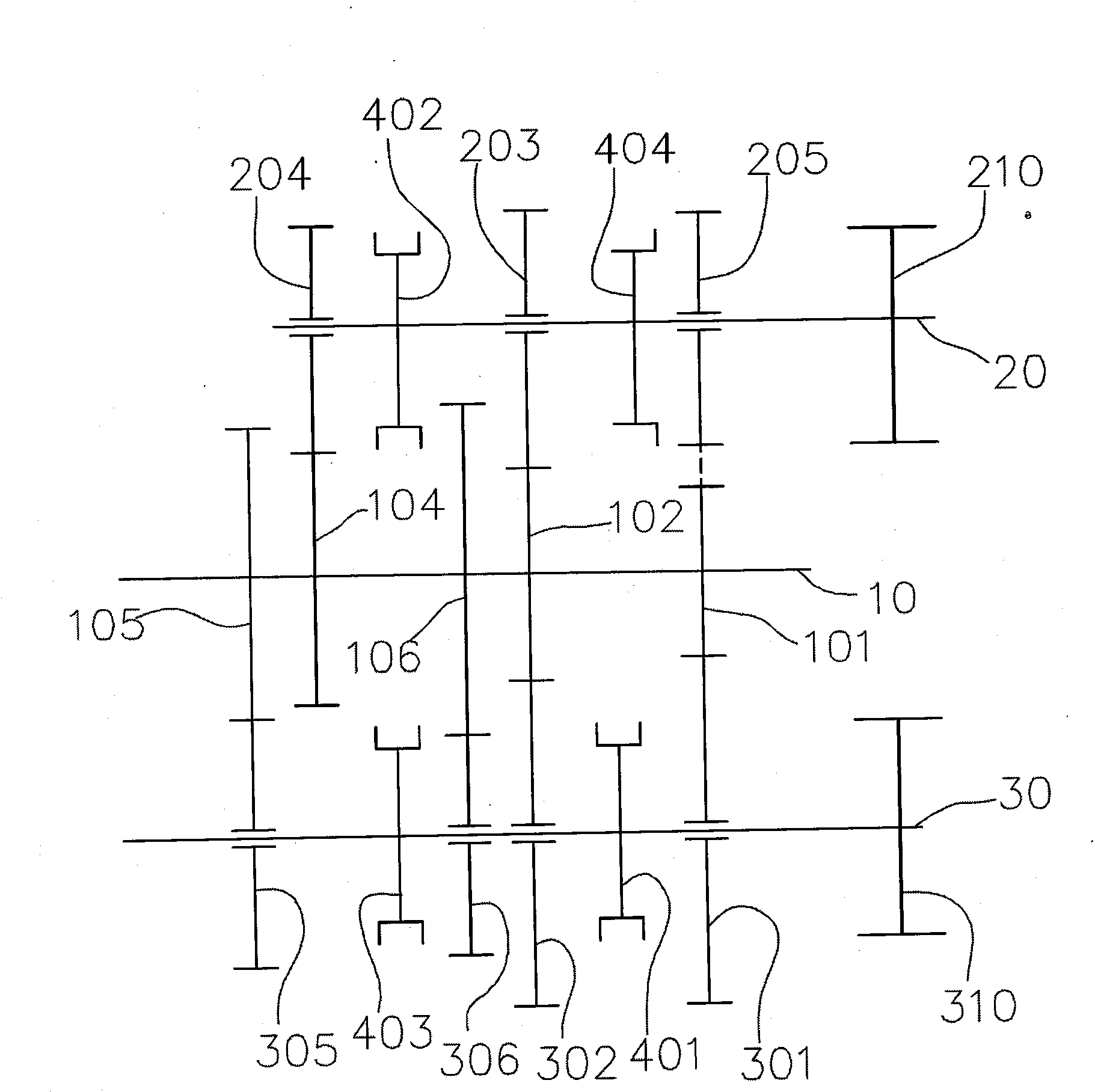

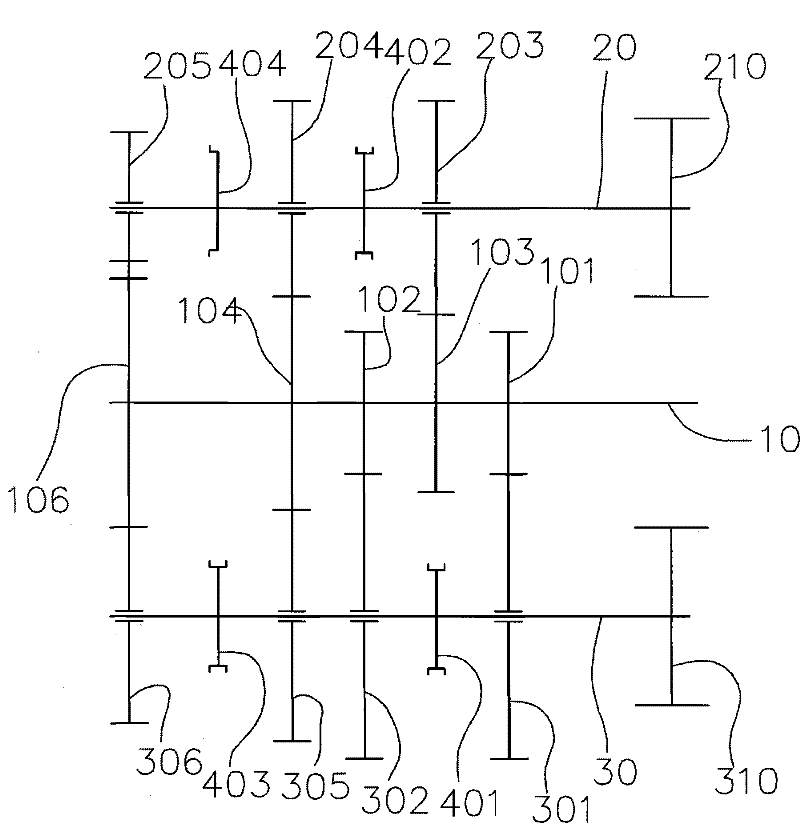

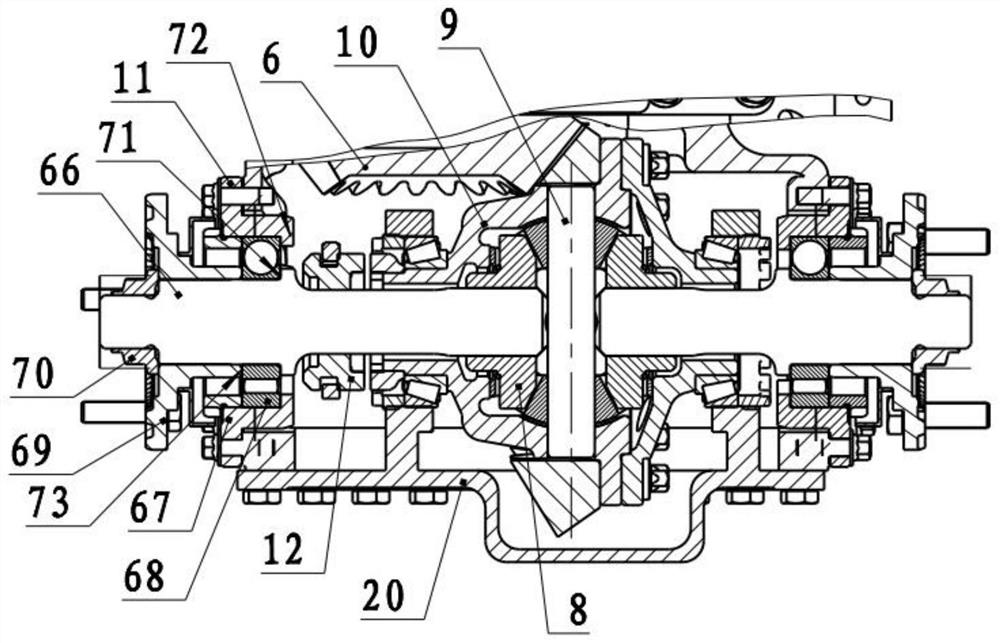

Arrangement structure of gear shaft system of gearbox

ActiveCN102269240BBalanced and reasonable space layoutImprove matchToothed gearingsInterior spaceGear wheel

The invention relates to an arrangement structure of a gear shaft system of a gearbox. The arrangement structure comprises an input shaft as well as a first output shaft and a second output shaft which are in parallel with the input shaft and are arranged at the two sides of the input shaft, wherein driving gears are fixed on the input shaft; driven gears are sleeved on the output shafts in an idle manner; the driving gears are meshed with corresponding driven gears and drive the driven gears to rotate; at the same time, the first and second output shafts are provided with joint devices which are matched with the driven gears and are used for switching gears; and the first and second output shafts are driven by the joint devices to rotate to output power. Compared with the prior art, the arrangement structure has the following beneficial effects: the arrangement of the inner space of the gearbox is balanced and reasonable; the number ratio is easy to match; and the axial distance is shorter.

Owner:GIF RES CENT CHINA

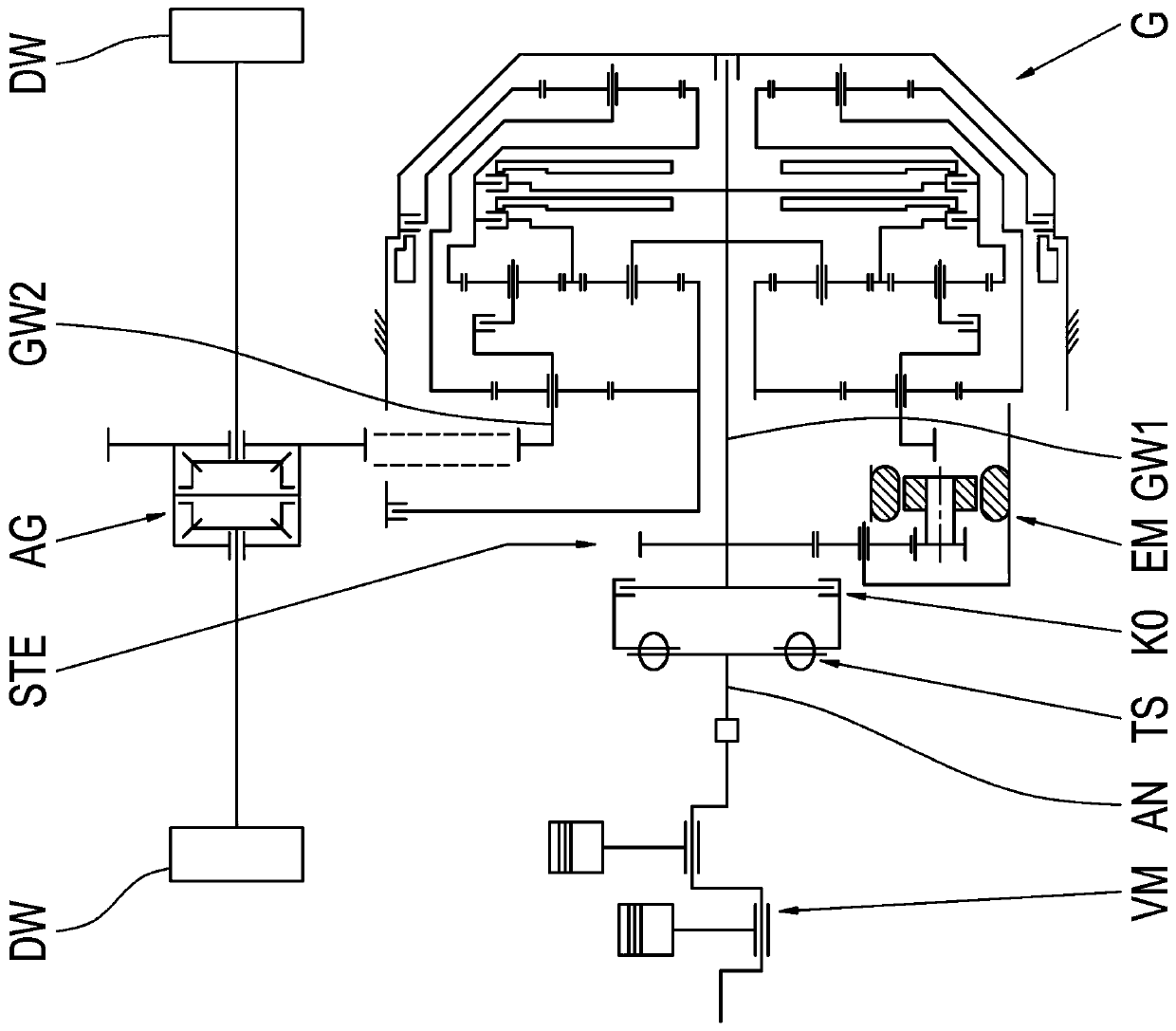

Transmission for a motor vehicle

InactiveCN109906323ASmall cross sectionAxially compactToothed gearingsTransmission elementsGear wheelAxial distance

Owner:ZF FRIEDRICHSHAFEN AG

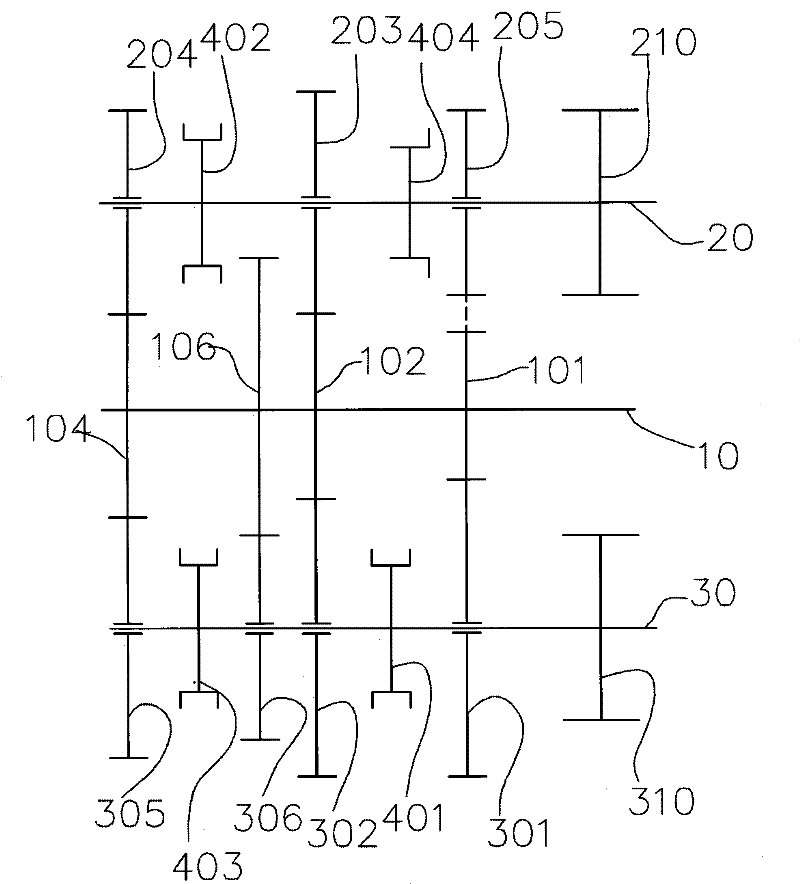

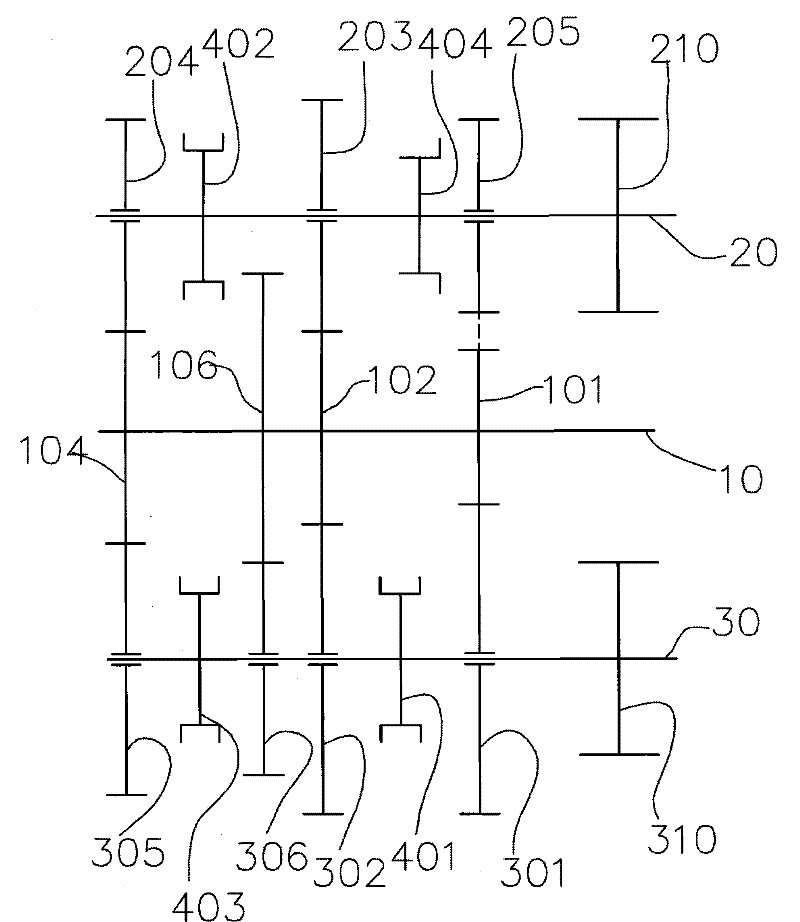

Arrangement structure of transmission gear shaft system

ActiveCN102269245AStructural layout balanceShort axial distanceToothed gearingsMechanical engineeringAxial distance

The invention relates to an arrangement structure of a gearbox gear shaft system. The structure comprises an input shaft, and two output shafts which are parallel to the input shaft and are positioned on the two sides of the input shaft, wherein the input shaft is fixedly provided with driving gears; driven gears are sleeved on the output shafts and are meshed with the driving gears; a fourth driven gear and a sixth driven gear are meshed with a fourth and sixth driving gear simultaneously; a third driven gear and a fifth driven gear are meshed with a third and fifth driving gear simultaneously; and a reverse gear connecting device is arranged on one output shaft. Through the structure, an inner space is reasonably utilized, a synchronous connecting device has enough installation space, axial positions are approximately the same, the structure has a balanced layout, and the axial distance is short.

Owner:GIF RES CENT CHINA

A three-channel microwave rotary joint

The invention discloses a three-channel microwave rotary joint which comprises a single-waveguide rotor, a double-waveguide rotor, a double-waveguide stator, a single-waveguide stator, a first bearing, a second bearing, a first connection arm, a second connection arm, a first inner conductor, a second inner conductor and a third inner conductor. According to the three-channel microwave rotary joint, the axial distance is short, the signal transmission loss is reduced, the problem of multi-channel Ka frequency band signal transmission is solved, the transmit-receive insulation degree is good, double-bearing design is adopted, coaxiality is guaranteed through precise machining and assembling, electrical performance fluctuation generated in the rotating process is greatly lowered, and the reliability of spacecraft moving components is improved.

Owner:BEIJING RES INST OF TELEMETRY +1

A high-speed centrifugal pump with built-in impeller

ActiveCN112460031BBalance axial forceOptimize layoutSpecific fluid pumpsPump componentsJet propulsionElectric machine

The invention provides a high-speed centrifugal pump with built-in impeller, comprising a casing and a runner, the runner being rotatably installed in the casing, and characterized in that it also includes a motor stator and a motor rotor, and the motor stator is installed in the casing On the body, the motor rotor is fixedly connected with the runner, the runner includes an inducer and a centrifugal impeller, the outer edge of the inducer is provided with an outer ring, and the outer ring of the inducer is connected to the inner ring of the motor rotor. The circle is fixedly connected; electricity is obtained from the motor stator to make the motor rotor rotate; the centrifugal impeller and the inducer rotate synchronously; the rotational speed of the runner is not lower than 2800r / min. The invention overcomes the problem that the water outlet direction of the traditional centrifugal pump is perpendicular to the rotation axis of the pump, and at the same time reduces the structural size of the traditional centrifugal pump, reduces the axial force of the rotor, and can meet the requirements of high-speed sailing devices such as torpedoes for the high-lift, large-capacity water-jet propulsion pump. flow, stable operation and compact structure.

Owner:JIANGSU UNIV

Arrangement structure of gearbox gear shaft system

ActiveCN102269245BSufficient installation spaceStructural layout balanceToothed gearingsGear wheelEngineering

The invention relates to an arrangement structure of a gearbox gear shaft system. The structure comprises an input shaft, and two output shafts which are parallel to the input shaft and are positioned on the two sides of the input shaft, wherein the input shaft is fixedly provided with driving gears; driven gears are sleeved on the output shafts and are meshed with the driving gears; a fourth driven gear and a sixth driven gear are meshed with a fourth and sixth driving gear simultaneously; a third driven gear and a fifth driven gear are meshed with a third and fifth driving gear simultaneously; and a reverse gear connecting device is arranged on one output shaft. Through the structure, an inner space is reasonably utilized, a synchronous connecting device has enough installation space, axial positions are approximately the same, the structure has a balanced layout, and the axial distance is short.

Owner:GIF RES CENT CHINA

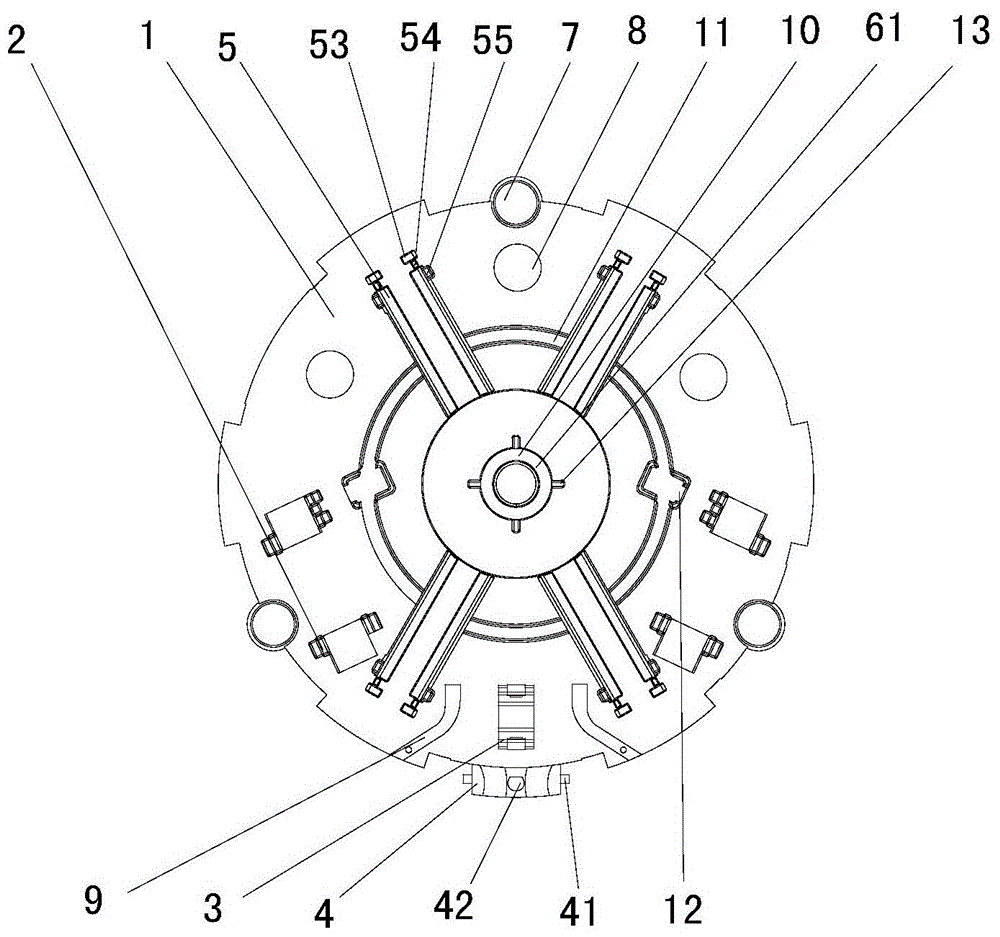

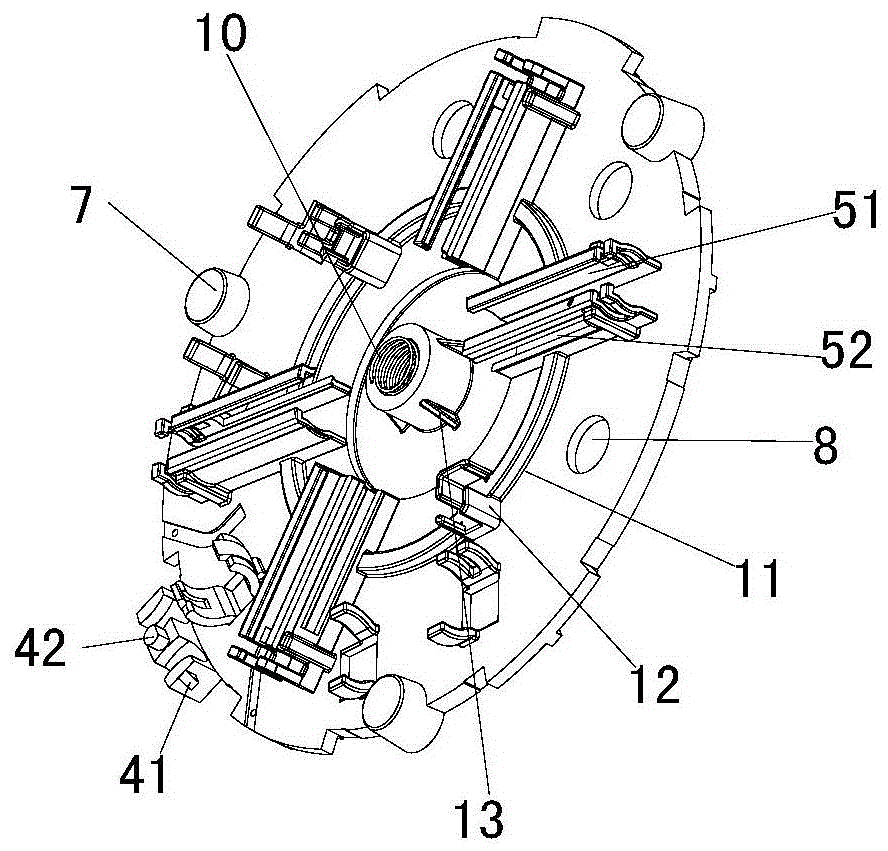

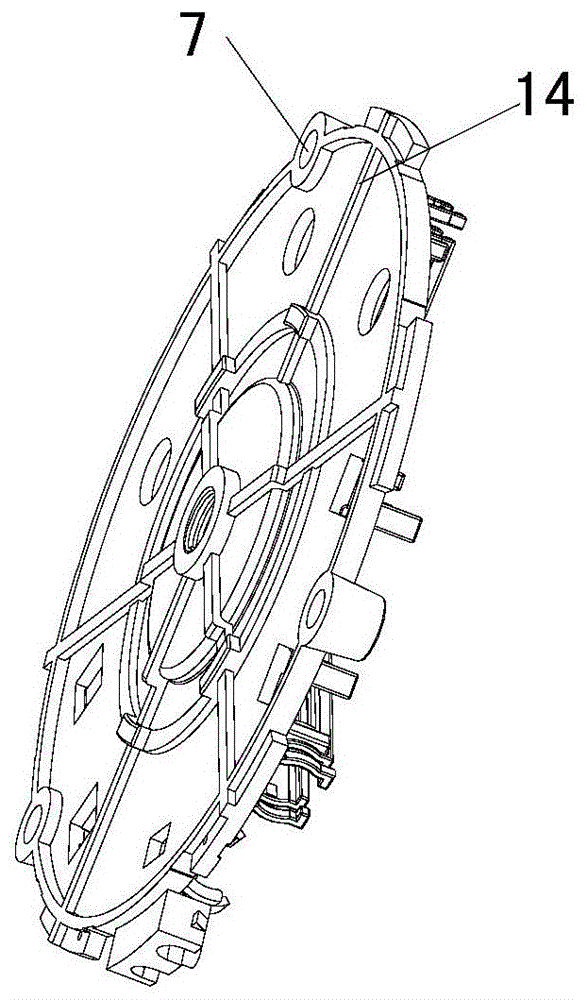

Integrated motor endshield

An integrated motor end cover comprises an end cover body and further comprises two groups of inductor fixing clamps integrally formed with the end cover body, a wire outlet clamp and four groups of concave guide rails for installing electric brushes. The middle of the end cover body is provided with a fixing column or a bearing chamber for fixing a motor shaft, the circumference of the end cover body is provided with three hole columns for penetrating mounting screws, the end cover body is provided with a plurality of heat dissipation holes, a plurality of reinforcing ribs and two grooves for installing grounding pieces, the fixing column is provided with reinforcing ribs, a spring is embedded in the fixing column, strength of the position is improved, and the risk of cracking of plastic entering a shaft can be reduced. The integrated motor end cover has the advantages of high integration degree, less parts and materials, light weight, small size, short axial distance, good heat dissipation, high reliability and long service life.

Owner:SHANGHAI MALU RI YONG JEA GATE ELECTRIC +2

Arrangement structure of gear shaft system of gearbox

The invention relates to an arrangement structure of a gear shaft system of a gearbox. The arrangement structure comprises an input shaft as well as a first output shaft and a second output shaft which are in parallel with the input shaft and are arranged at the two sides of the input shaft, wherein driving gears are fixed on the input shaft; driven gears are sleeved on the output shafts in an idle manner; the driving gears are meshed with corresponding driven gears and drive the driven gears to rotate; at the same time, the first and second output shafts are provided with joint devices which are matched with the driven gears and are used for switching gears; and the first and second output shafts are driven by the joint devices to rotate to output power. Compared with the prior art, the arrangement structure has the following beneficial effects: the arrangement of the inner space of the gearbox is reasonable; the number ratio is easy to match; and the axial distance is shorter.

Owner:GIF RES CENT CHINA

Arrangement structure of transmission gear shaft system

ActiveCN102269240ABalanced and reasonable space layoutImprove matchToothed gearingsAxial distanceControl theory

The invention relates to an arrangement structure of a gear shaft system of a gearbox. The arrangement structure comprises an input shaft as well as a first output shaft and a second output shaft which are in parallel with the input shaft and are arranged at the two sides of the input shaft, wherein driving gears are fixed on the input shaft; driven gears are sleeved on the output shafts in an idle manner; the driving gears are meshed with corresponding driven gears and drive the driven gears to rotate; at the same time, the first and second output shafts are provided with joint devices which are matched with the driven gears and are used for switching gears; and the first and second output shafts are driven by the joint devices to rotate to output power. Compared with the prior art, the arrangement structure has the following beneficial effects: the arrangement of the inner space of the gearbox is balanced and reasonable; the number ratio is easy to match; and the axial distance is shorter.

Owner:GIF RES CENT CHINA

An external rotor submersible tubular pump

ActiveCN106837816BSmall outer diameterAvoid the defect of large friction lossPump componentsPump installationsImpellerEngineering

The invention discloses an outer-rotor submersible tubular pump which comprises a guide vane body, an impeller housing, an outer rotor, a water filling type submersible motor stator and a water sucking chamber. The outer rotor is of an integrated structure and comprises a water filling type submersible motor rotor, a hub body and an impeller. An impeller is welded and fixed to the water filling type submersible motor rotor, and the water filling type submersible motor rotor is rigidly connected with the hub body to form a whole. The water filling type submersible motor stator is built in the inner cavity of the outer rotor. The whole structure of the pump has the advantages of being short in axial distance, compact in structure, light in weight, safe, reliable and the like, the water filling type submersible motor stator is creatively built in the inner cavity of the motor rotor, meanwhile the phenomenon that rotation of an integrated rotor of a submersible electric pump with a built-in impeller in water causes larger frictional loss is avoided, and the water pumping efficiency is greatly improved.

Owner:HEFEI HENGDAJIANGHAI PUMP IND CO LTD

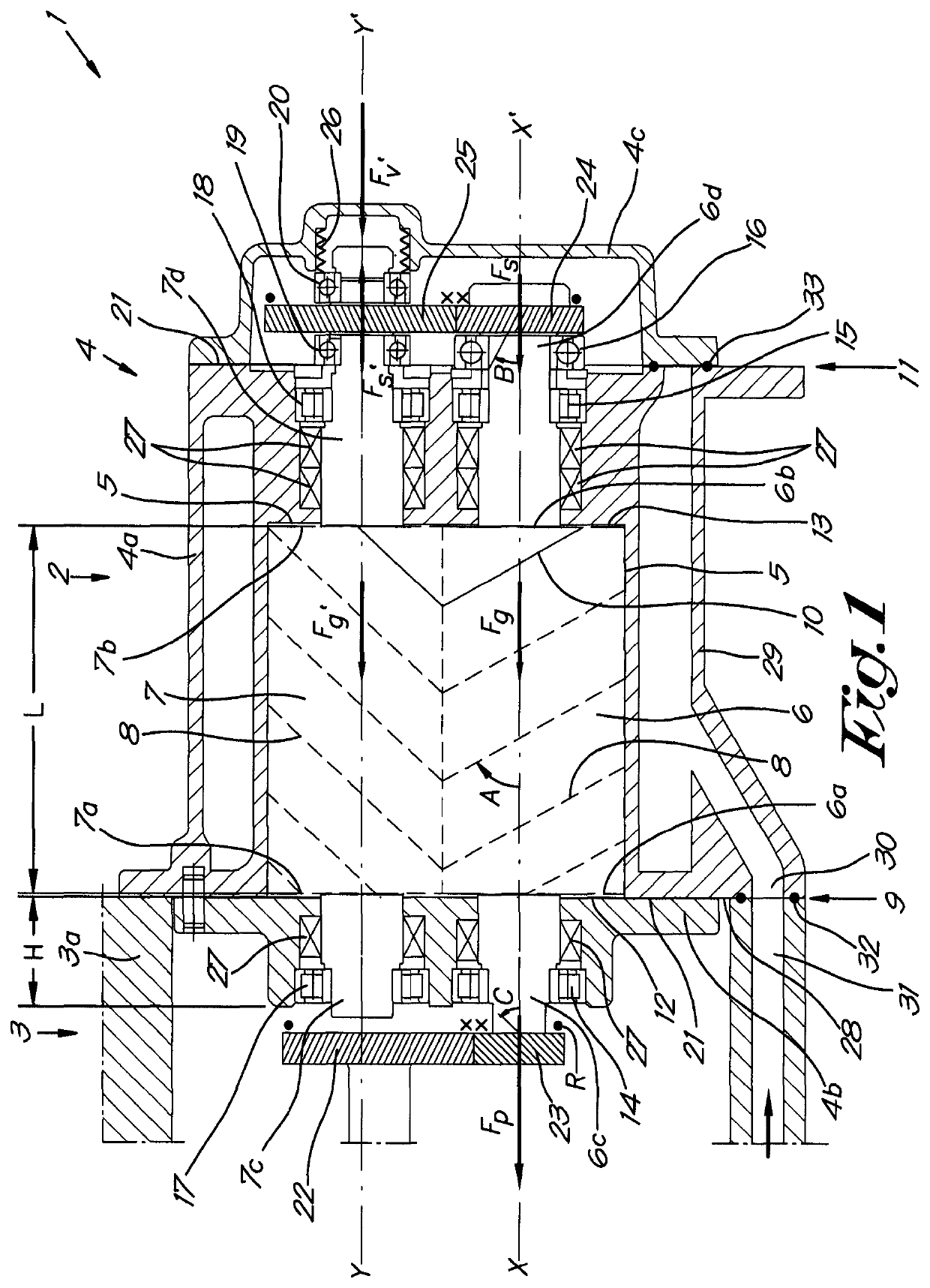

Compressor element for a screw compressor and screw compressor in which such a compressor element is applied

ActiveUS10760574B2For direct connectionMounting is preventedOscillating piston enginesEngine of intermeshing engagement typeGear wheelEngineering

A compressor element of a screw compressor inlet side and an outlet side and two helical rotors, respectively a male rotor with a drive for the male rotor and a female rotor that is driven by the male rotor by means of synchronisation gearwheels with at least one synchronisation gearwheel on the male rotor, wherein the drive and synchronisation gearwheels of the male rotor are chosen such that, upon being driven with acceleration of the rotors without gas forces, the resulting mechanical drive force that is exerted by this drive and by this synchronisation gearwheel on the male rotor has an axial component that is directed from the outlet side to the inlet side and that the movement of the male rotor in the axial direction from the outlet side to the inlet side is fixed by means of a single axial single-acting or double-acting bearing.

Owner:ATLAS COPCO AIRPOWER NV

Arrangement structure of transmission gear shaft system

InactiveCN102269242AReasonable space layoutShort axial distanceToothed gearingsGear driveEngineering

The invention relates to an arrangement structure of a transmission gear shaft system, which includes an input shaft, a first output shaft and a second output shaft parallel to the input shaft and located on both sides of the input shaft, and fixed on the input shaft A driving gear is provided, and driven gears are sheathed on the output shaft, wherein each driving gear meshes with a corresponding driven gear to drive the driven gears to rotate, and at the same time, the first output shaft and the The second output shaft is also provided with an engaging device that cooperates with the driven gear and is used to switch gears, and the first output shaft and the second output shaft are driven to rotate through the engaging device to output power. Compared with the prior art, the beneficial effect of the present invention is that the interior space of the gearbox is arranged reasonably, the number ratios are well matched, and the axial distance is relatively short.

Owner:GIF RES CENT CHINA

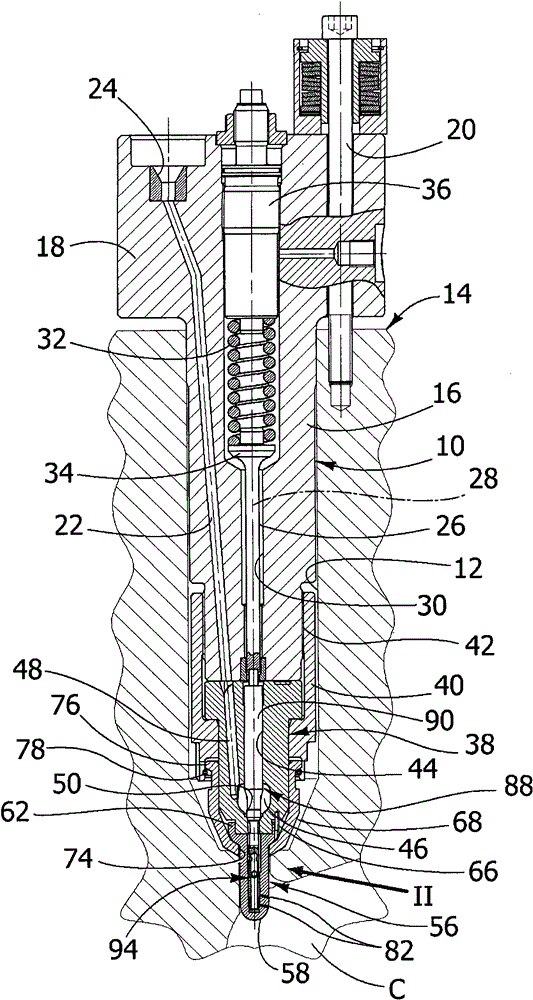

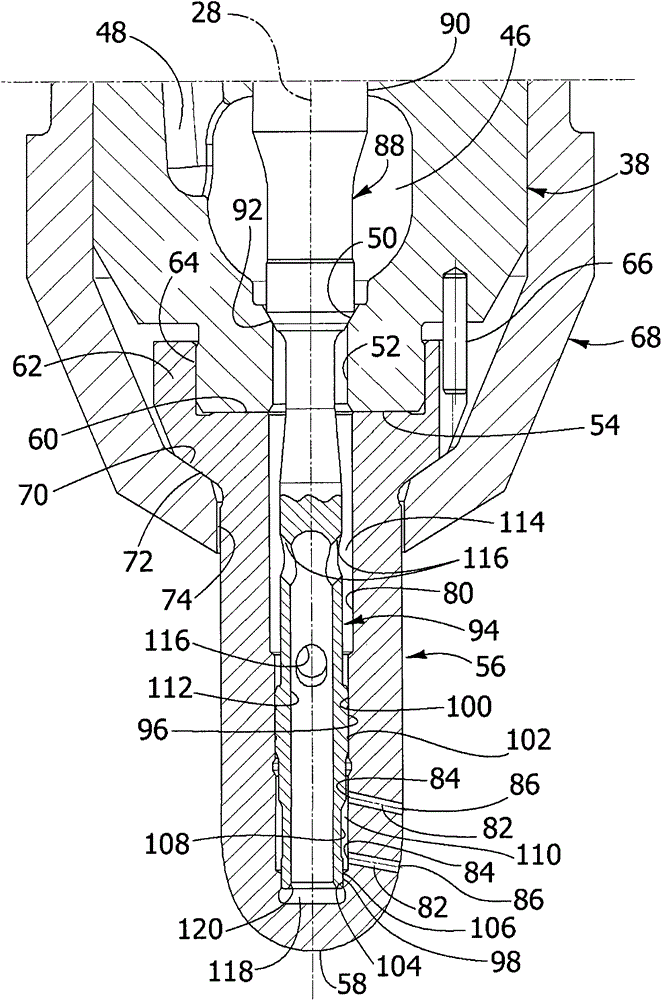

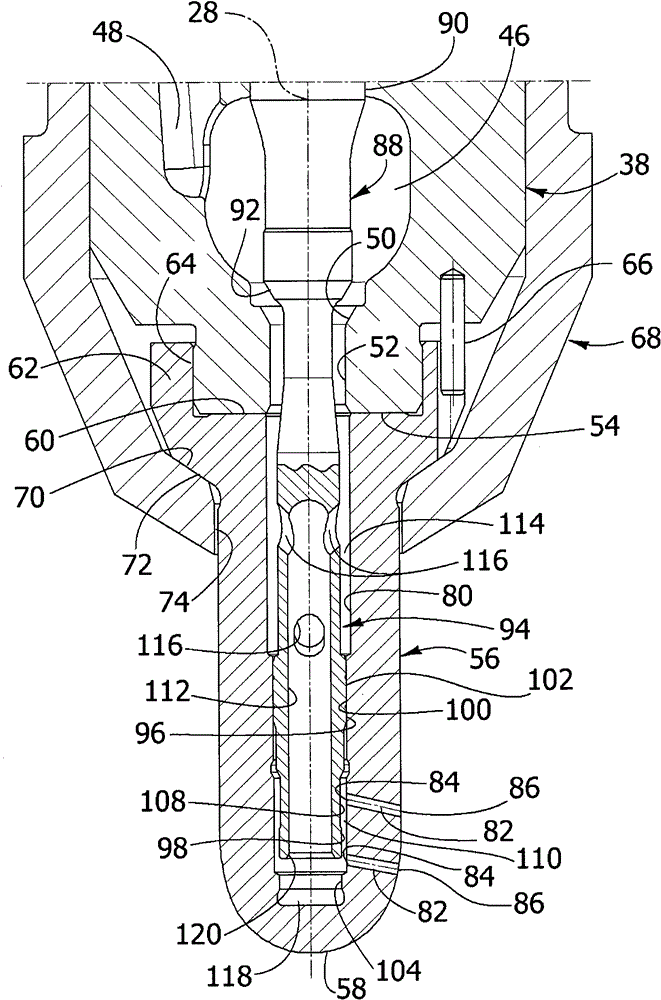

A fuel injector for internal combustion engines

ActiveCN101852157BMany degrees of freedomImprove spray qualityFuel injection apparatusMachines/enginesCombustionExternal combustion engine

A fuel injector for internal combustion engines, comprising: - a housing (16), - a valve guide (38) fixed at a lower end of said housing (16), the valve guide (38) having a longitudinal guide bore (44) and a chamber (46) provided with a valve seat (50), said chamber (46) being connected to a fuel supply duct (22,48); - an atomizer (56) fixed at a lower end of said valve guide (38), the atomizer (56) having a longitudinal bore (80) in flow connection with said chamber (46), the atomizer having a plurality of nozzle bores (82) having inlet openings (84) facing into said longitudinal bore (80); - a spindle (88) having a valve portion (92) cooperating with said valve seat (50), and a cut-off element (94) extending into said longitudinal bore (80) of the atomizer (56), wherein an upper cut-off section (102) and a lower cut-off section (106) axially spaced apart from each other are defined between the outer surface of the cut-off element (94) and the inner surface of the longitudinal bore (80), cut-off sections (102,106) being both closed in the closed position of the spindle (88), the cut-off element (94) having a central duct (112) in flow connection with the longitudinal bore (80) of the atomizer (56) both above the upper cut-off section (102) and below the lower cut-off section (106).

Owner:WAERTSILAE SWITZERLAND

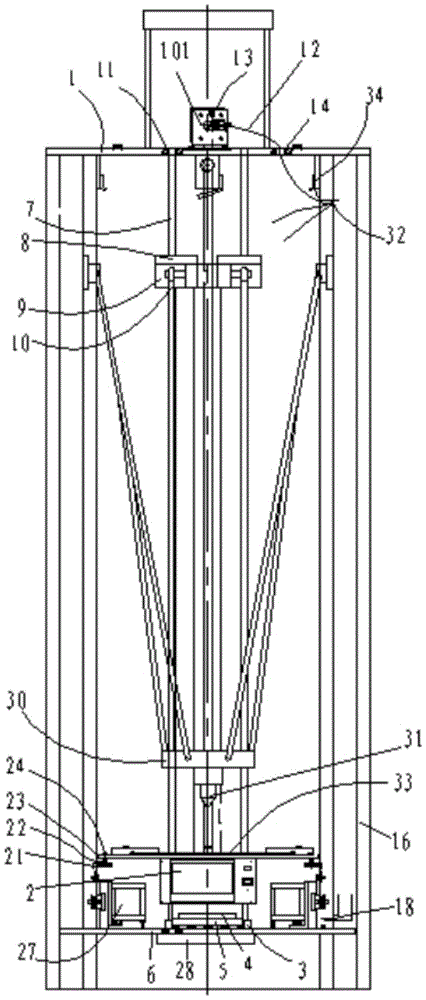

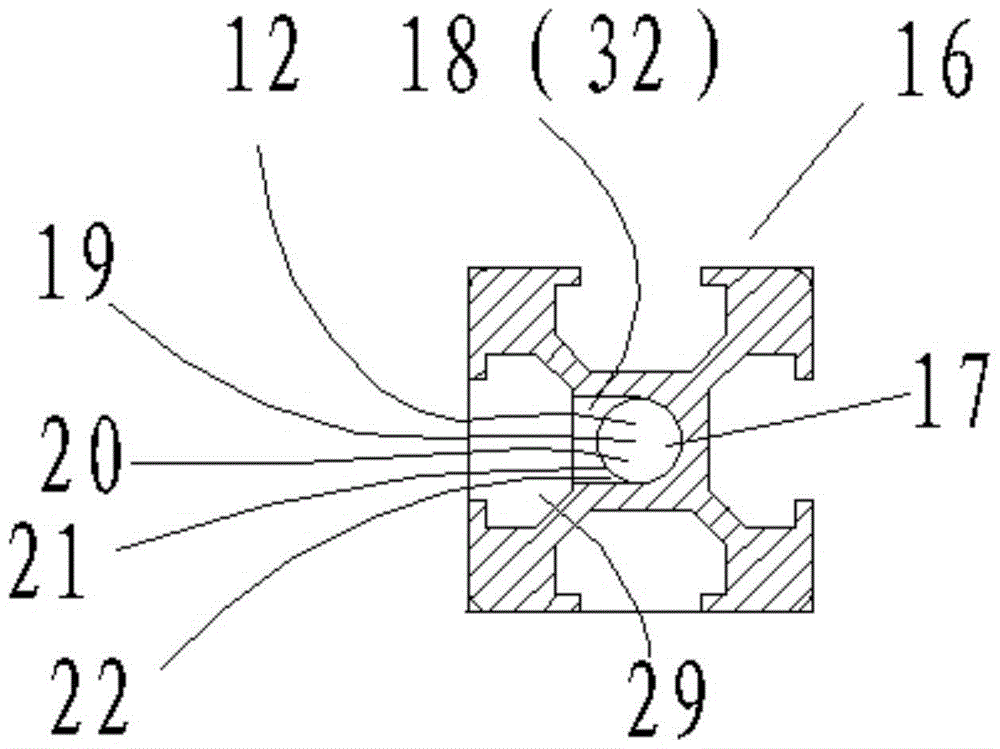

Delta 3d printer

InactiveCN105415684BImprove versatilityEasy to observeManufacturing platforms/substrates3D object support structuresDrive motorEngineering

The invention discloses a delta 3D printer. The delta 3D printer comprises three vertical columns with sectional material structures, a control panel, a switching power supply, a display screen and a printed finished product connection seat, wherein an upper support plate is arranged at the upper ends of the vertical columns with the sectional material structures; a lower support plate is arranged on the lower parts of the vertical columns with the sectional material structures; a wire feeding motor is arranged on the upper support plate; printing head drive motors are arranged on the upper end surface of the lower support plate; each printing head drive motor is connected with a printing head connection disc; each printing head connection disc is connected with a slide block with linear bearings through parallel arms; each linear bearing is matched with a vertical polished rod; the upper end of each vertical polished rod is connected with the upper support plate, and the lower end of each vertical polished rod is connected with the lower support plate; a support with a bent structure is arranged on the upper end surface of the lower support plate; the control panel is horizontally connected with the support; the display screen is connected with the support; and the printed finished product connection seat is connected with the vertical columns with the sectional material structures. The delta 3D printer disclosed by the invention is low in manufacturing and maintenance costs, convenient to disassemble and assemble, convenient to adjust and repair, high in use safety and reliability, and easy to ensure the quality of the printed products.

Owner:UNIV OF JINAN

Integrated main speed reducer

PendingCN112483630AImprove transmission efficiencyAxial space savingGearing detailsTransfer caseReduction drive

The invention relates to an integrated main speed reducer which comprises a shell assembly. The shell assembly comprises a speed reducer shell and a gap bridge box. A main speed reducer assembly, an inter-wheel differential mechanism assembly, an inter-axle differential mechanism assembly and a transfer case assembly are installed in an inner cavity of the shell assembly, and the transfer case assembly comprises a second axle system assembly. The second axle system assembly is mounted above the inter-axle differential mechanism assembly and engaged with the inter-axle differential mechanism assembly through a second-stage low-gear driving cylindrical gear, and the main speed reducer assembly is mounted at the front end of the inter-axle differential mechanism assembly. An inter-wheel differential mechanism is mounted in the main speed reducer assembly. According to the integrated main speed reducer, the problems that in the prior art, most of a main speed reducer assembly and a transfer case assembly are two independent assemblies, the axial space is large, and the weight is large are solved.

Owner:SHAANXI HANDE AXLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com