Integrated main speed reducer

A main reducer, integrated technology, applied in the field of auto parts, can solve the problems of large axial space and heavy weight, and achieve the effects of reducing the number of parts, improving life, and short axial distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

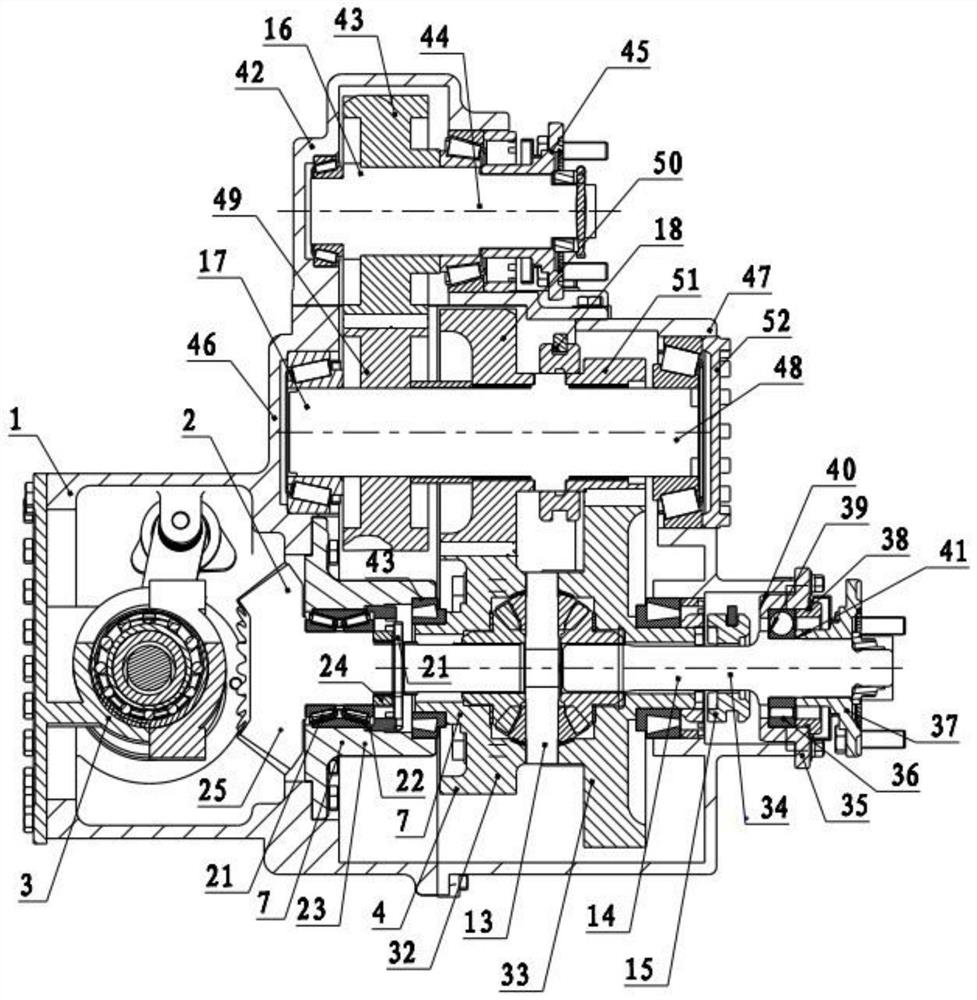

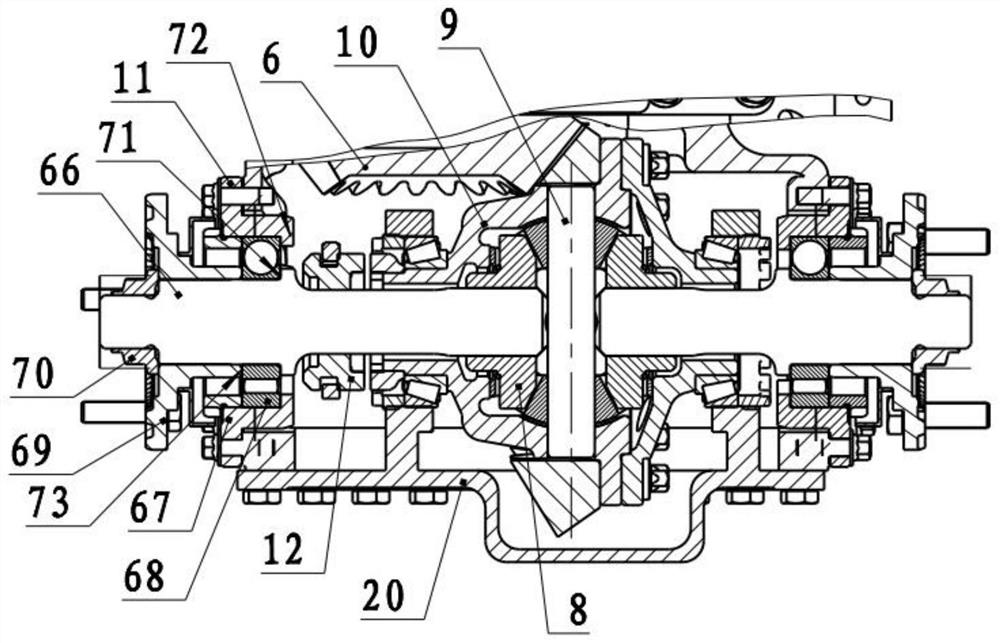

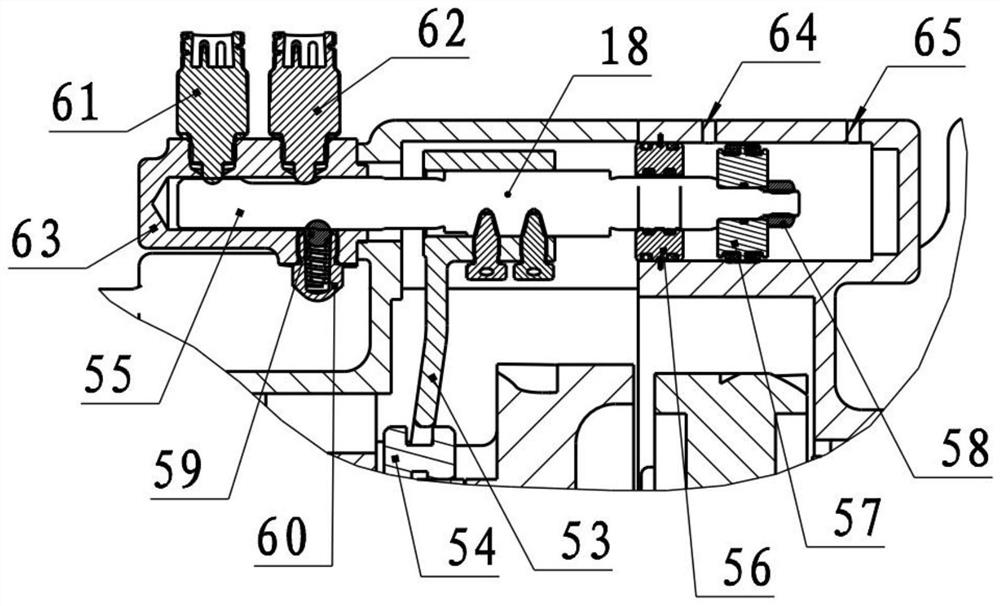

[0032] Embodiment 1: The structure of the main reducer according to the present invention, including the housing assembly 1, the main reducer assembly 2, the inter-wheel differential assembly 3, the inter-axle differential assembly 4, the transfer case assembly into; the final drive assembly 2, the inter-wheel differential assembly 3, the inter-axle differential assembly 4, and the transfer case assembly are all installed inside the shell assembly 1.

[0033] The housing assembly 1 is a structure in which the back cover and tile cover are designed as one, forming the back cover 20, which is beneficial to shorten the axial distance and reduce the space requirement.

[0034] The main reducer assembly 2 includes a bevel gear pair 6, a main cone bearing assembly 7, the main cone bearing assembly 7 is assembled in the inner cavity of the housing assembly 1, and the main cone bearing assembly 7 is connected with the housing Adjusting washers are used between the assembly surfaces of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com