Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Sharp particle size distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

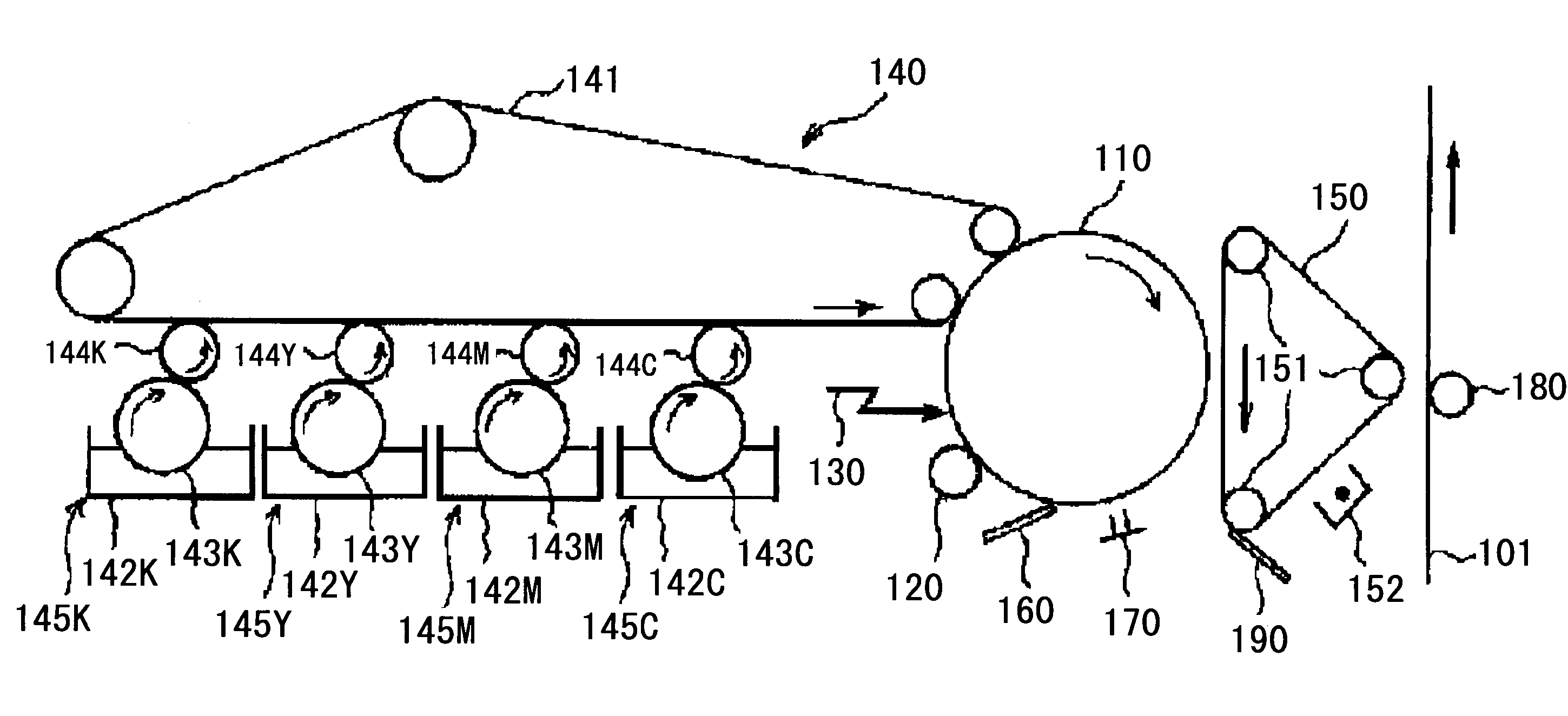

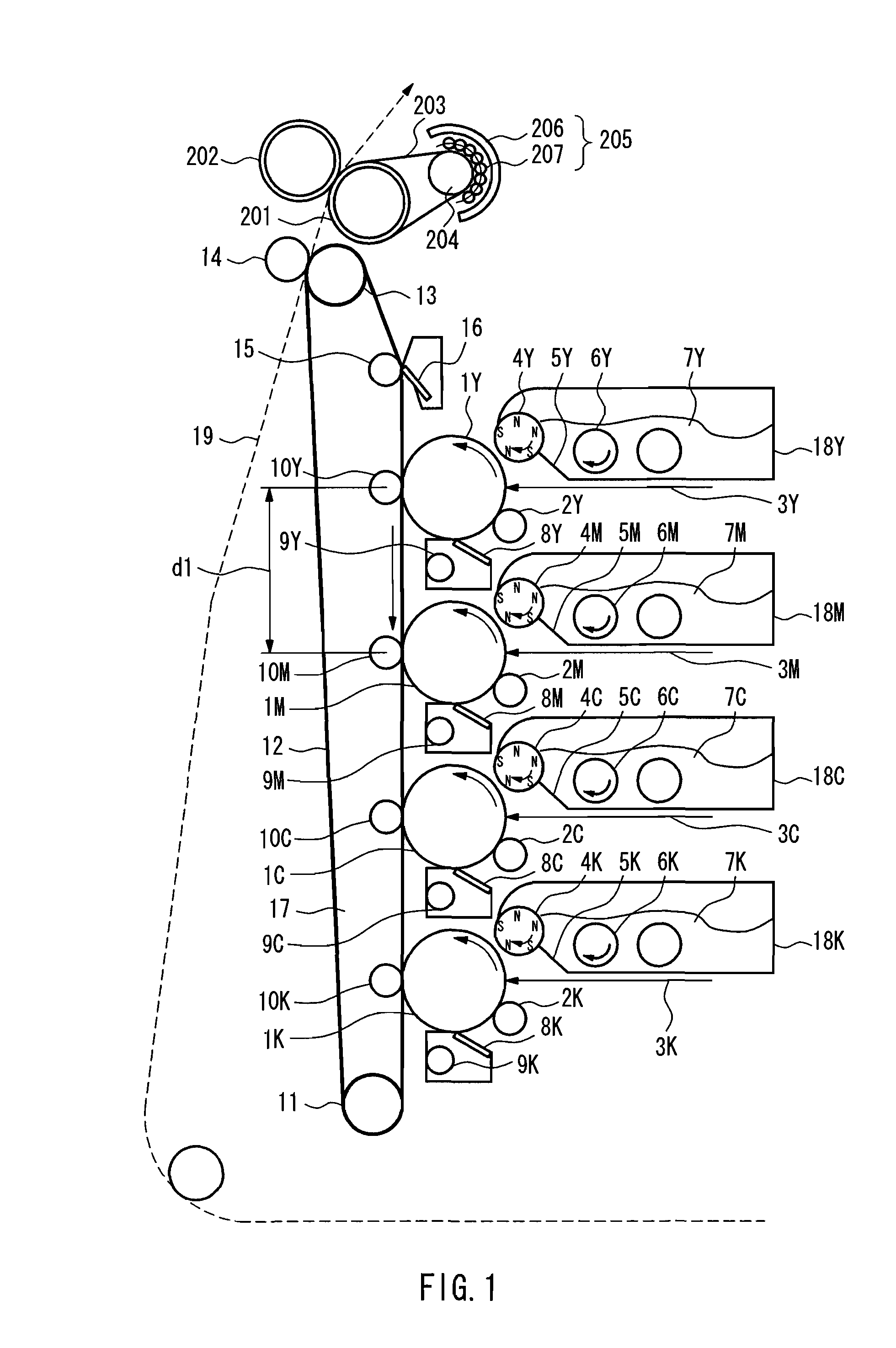

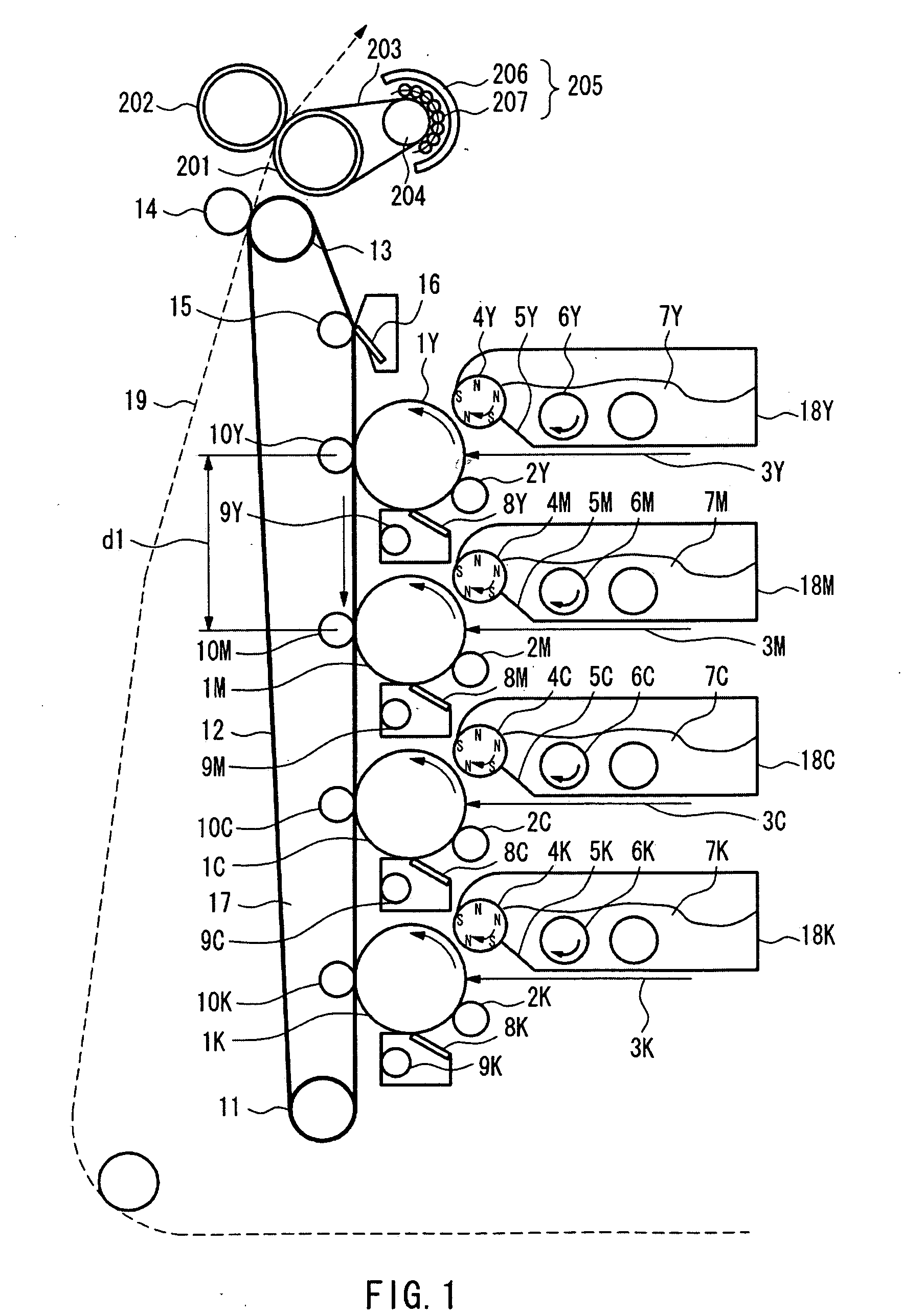

Toner for electrophotography and image forming apparatus

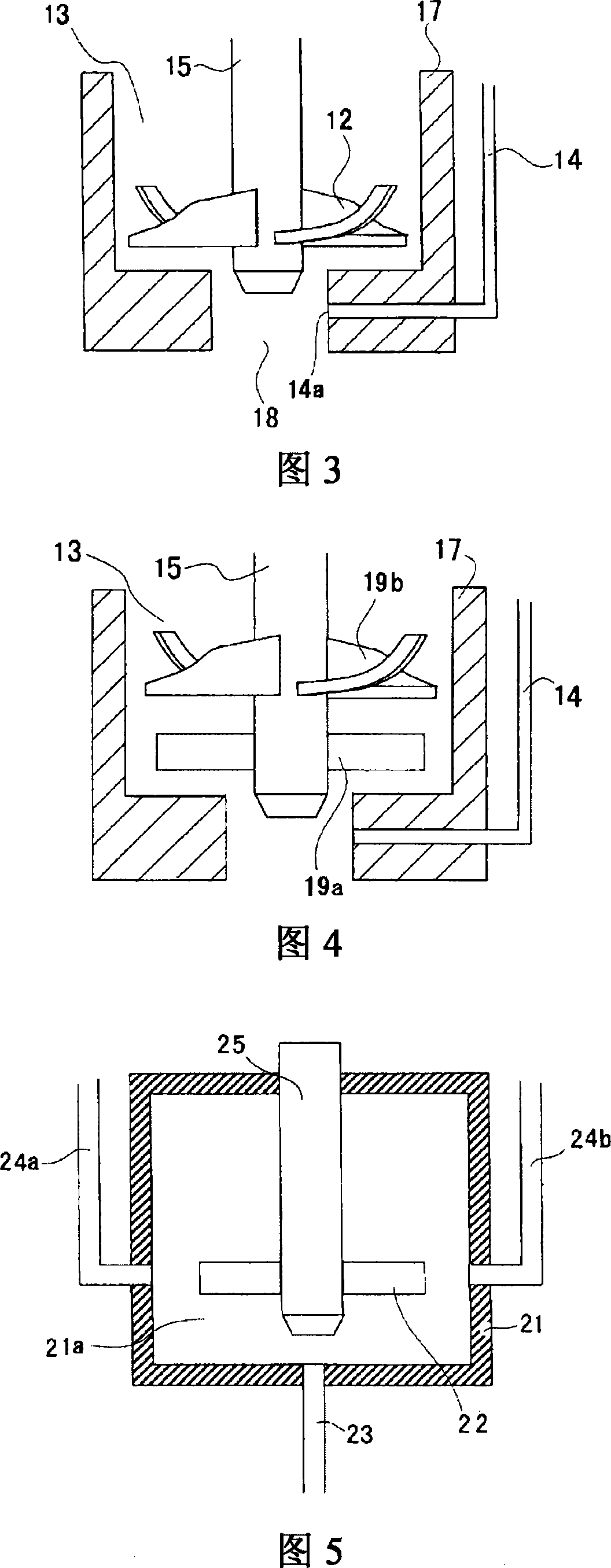

The object of the present invention is to provide a developer having a sharp charge amount distribution and bringing out high-quality image without substantially smearing a charging unit, developing units, a photoconductor, and an intermediate transferring member by the developer, namely, a developer capable of providing an appropriate image density and exhibiting extremely little background smear even when used over a long period of time and repeatedly used for a number of sheets of paper as well as to provide an image forming apparatus for electrophotography using the developer.

Owner:RICOH KK

Electrophotography and image forming apparatus

The object of the present invention is to provide a developer having a sharp charge amount distribution and bringing out high-quality image without substantially smearing a charging unit, developing units, a photoconductor, and an intermediate transferring member by the developer, namely, a developer capable of providing an appropriate image density and exhibiting extremely little background smear even when used over a long period of time and repeatedly used for a number of sheets of paper as well as to provide an image forming apparatus for electrophotography using the developer.

Owner:RICOH KK

Method of producing toner

Owner:CANON KK

Resin particle and method of producing the resin particle, and toner and method of producing the toner

ActiveUS9857713B2Increased durabilitySharp particle size distributionDevelopersOrganic solventCore shell

Provided is a toner, comprising a toner particle having a core-shell structure composed of a core particle and a shell phase on a surface of the core particle, the core particle containing a resin X and a colorant, the shell phase being derived from a resin fine particle containing a resin Y, in which a relationship among a SP value of the resin X, a SP value of the resin Y, and a SP value of an organic solvent falls within a specific range, and a relationship between a number-average particle diameter of the resin fine particle when the resin fine particle is dispersed in water and a number-average particle diameter of the resin fine particle when the resin fine particle is dispersed in the organic solvent falls within a specific range.

Owner:CANON KK

Dispersion stabilizer

ActiveUS20090111940A1Improve polymerization stabilityThe polymerization process is stableTransportation and packagingMixingPolymer scienceSide chain

The aforementioned problems can be solved by a dispersion stabilizer composed of a polyvinyl alcohol polymer (B) having a double bond in its side chain. The polyvinyl alcohol polymer (B) is obtained by esterifying a polyvinyl alcohol polymer (A) with a carboxylic acid having an unsaturated double bond or a salt thereof. Furthermore, the aforementioned problems can be solved with a dispersion stabilizer composed of a carboxylic acid-modified polyvinyl alcohol polymer (C) that is obtained by esterifying a polyvinyl alcohol polymer (A) with aliphatic carboxylic acid and / or aromatic carboxylic acid containing no olefinically unsaturated bond in the molecule or a salt thereof.

Owner:KURARAY CO LTD

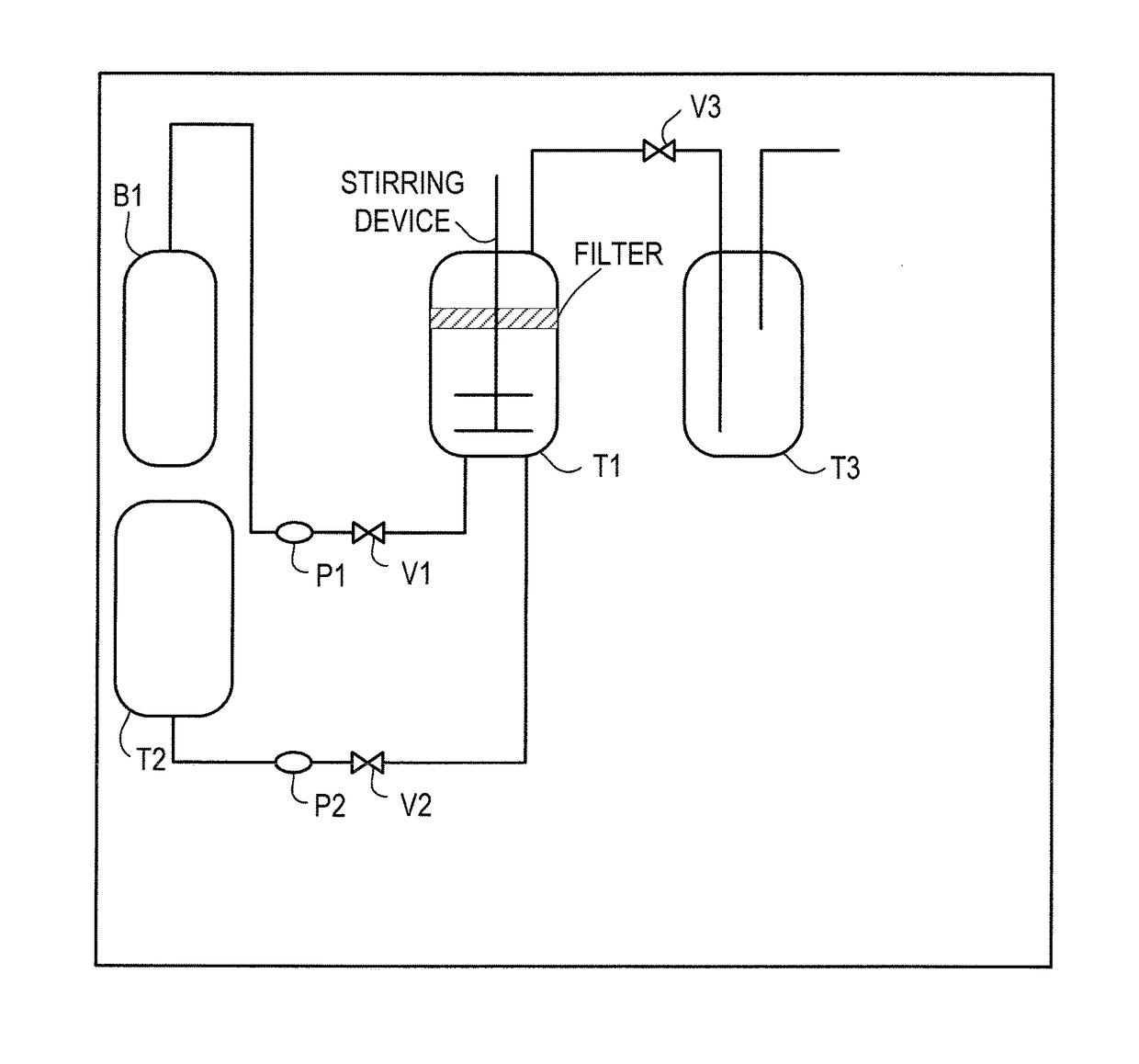

Resin fine particles, method of producing resin fine particles, method of producing resin particles, and method of producing toner

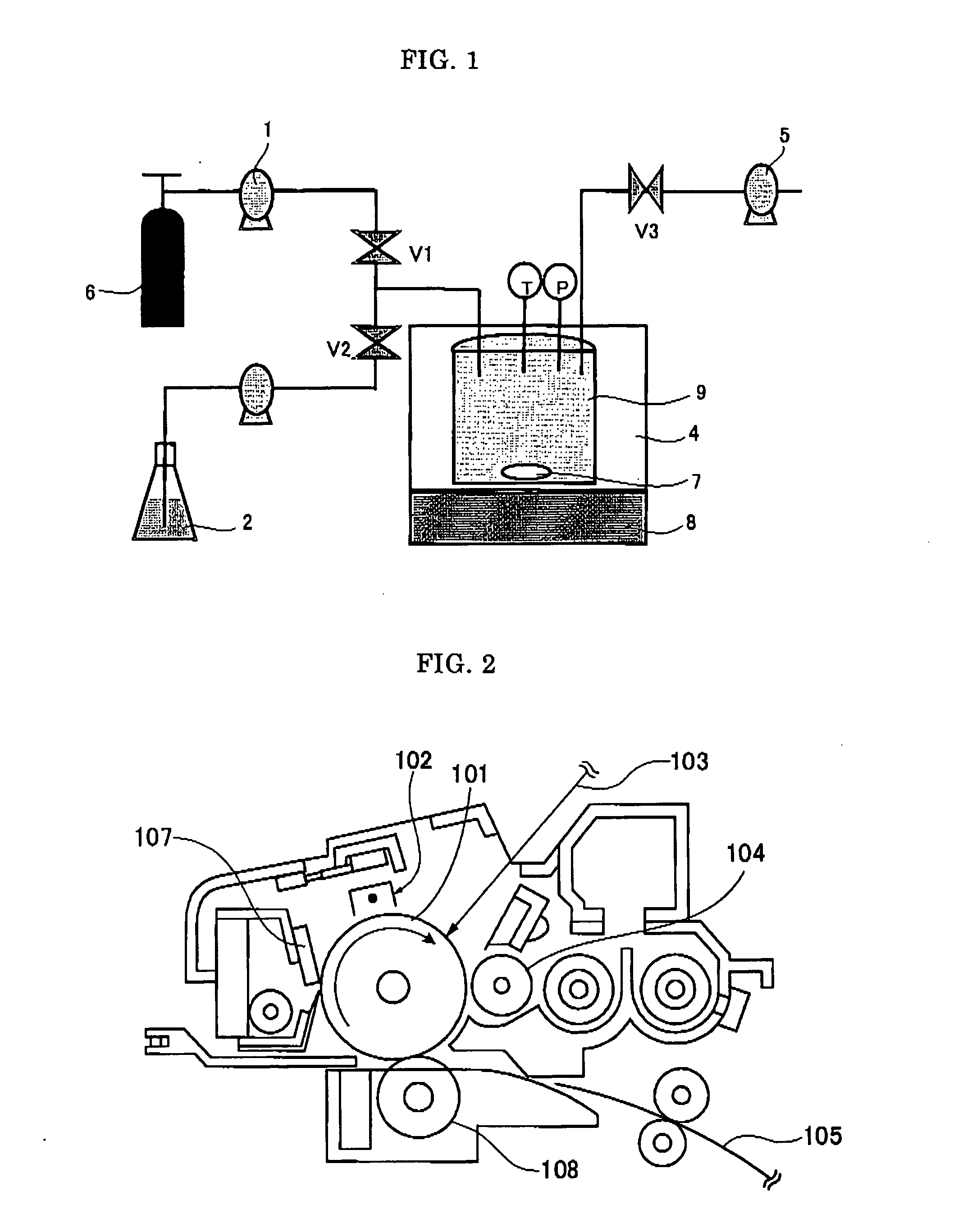

A method of producing a toner including the steps of: mixing resin fine particles, an organic solvent, and a resin R with a dispersion medium containing carbon dioxide, to prepare a dispersion of resin R-containing droplets; and removing the organic solvent by flowing carbon dioxide, wherein the resin fine particles contain one or more resins that have a partial structure A, B, and C, and are soluble in chloroform; the SP value of the partial structure A, the resin R, and the partial structure B satisfy particular relationships; a resin A constituted of the partial structure A and a resin B constituted of the partial structure B are soluble in the organic solvent; and a resin C constituted of the partial structure C is insoluble in the organic solvent.

Owner:CANON KK

Toner, method for producing the same, and image-forming method using the same

InactiveUS20070059628A1Sharp particle size distributionLittle waste solutionDevelopersBulk chemical productionImage formationFluorine containing

To provide a method for producing a toner in which at least monomers are polymerized in at least one of a supercritical fluid and a subcritical fluid to thereby produce toner particles, wherein at least one of the supercritical fluid and the subcritical fluid contains a fluorine-containing surfactant, and a polymer resulted from polymerization of the monomers is insoluble in at least one of the supercritical fluid and the subcritical fluid, and provide a toner produced by the method for producing the toner.

Owner:RICOH KK

Organic nano particle and dispersive combination, photo-sensitive resin combination, trans-printing material, filter, liquid display device and CCD device

InactiveCN101081941ASharp particle size distributionParticle Size Distribution ControlOptical filtersNanoopticsDisplay deviceOrganic chemistry

Provided are an organic nano-particle which has nano-size and its particle distribution is sharp; and an organic nano-particle dispersion composition having stable and excellent dispersion property, flow behavior. Besides, provided are a color filter made of them, which has high contrast and perform excellent display property; a liquid crystal device and a CCD device by using them; and a colored photosensitive resin composition and a photosensitive resin transcription material by using them. An organic nano-particle which is consisting of organic material, its amount average particle size is 50 nm or less, and the ratio of (volume average particle size) / (amount average particle size) is 1.0~2.0.

Owner:FUJIFILM CORP

Process for producing powdery linear polymer having improved powder properties

InactiveUS20050049332A1Avoid cloggingPreventing excessive coagulationSynthetic resin layered productsCellulosic plastic layered productsVitrificationPolymer science

A powdery linear polymer having a narrow particle size distribution with little dusting and excellent in anti-blocking property is recovered from a latex of a linear polymer containing a large proportion (35-75 wt. %) of soft polymer (S) component through a two-step coagulation process including a first (moderate coagulation) step causing 70-98 wt. % of the coagulation. The linear polymer in the latex has a multilayer structure comprising a linear polymer (S) having a glass transition temperature below 40° C. and a linear polymer (H) having a higher glass transition temperature disposed in totally at least two layers and containing 35-75 wt. %, as a whole, of the linear polymer (S) with the proviso that the linear polymer (S) cannot be contained in excess of 30 wt. % in an outermost layer of the multilayer structure.

Owner:ROHM & HAAS CO

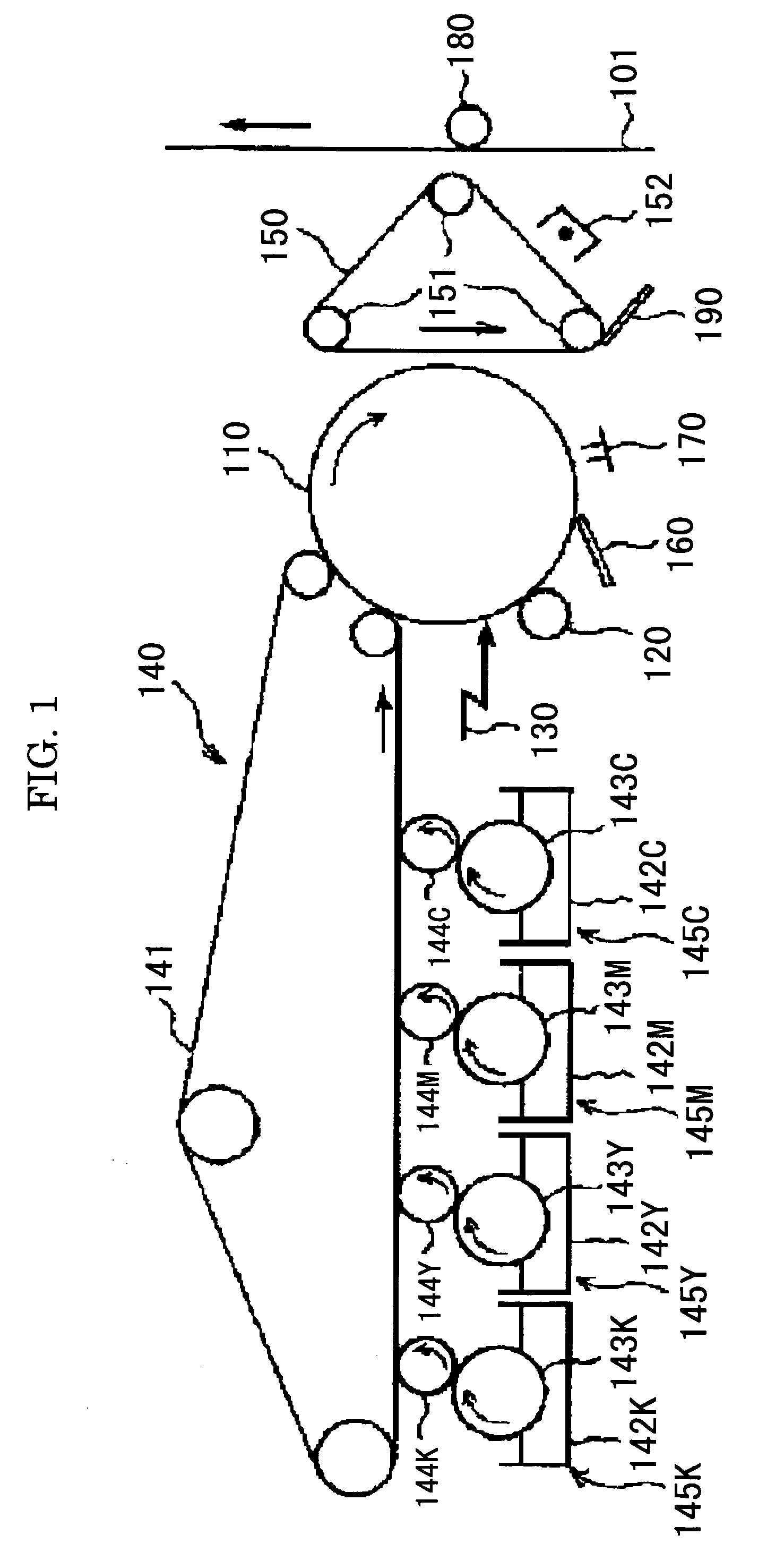

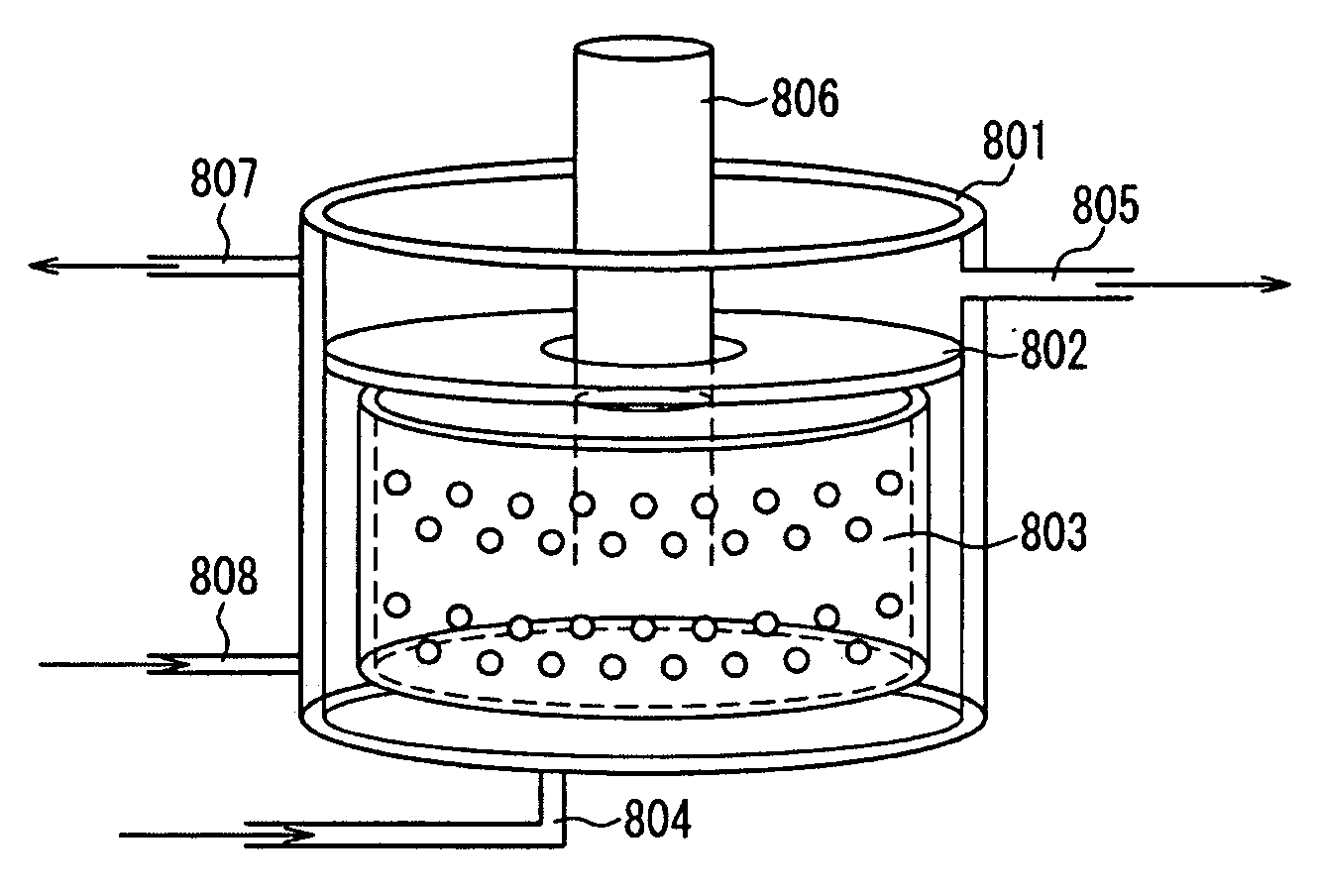

Nickel-cobalt compound hydroxide and method and device for producing same, positive electrode active substance for nonaqueous electrolyte secondary cell and method for producing same, and nonaqueous electrolyte secondary cell

ActiveCN104661963ASharp particle size distributionExcellent cycle characteristicsSecondary cellsChemical electrode manufacturingSlurryAqueous solution

[Problem] By obtaining a compound hydroxide that has a sharp particle diameter distribution, the present invention aims to improve the cycle properties of a nonaqueous electrolyte secondary cell obtained using the nickel-cobalt compound hydroxide as the precursor. [Solution] In the present invention, a slurry contains a nickel-cobalt compound hydroxide that is obtained by reacting and continuously feeding to a reactor an aqueous solution containing at least nickel and cobalt, an aqueous solution that serves as an ammonium ion donor, and an aqueous caustic alkali solution. The slurry is continuously extracted and the slurry is separated by grading into large particle diameter portions and small particle diameter portions. The small particle diameter portion is continuously circulated back to the reactor. The resulting nickel-cobalt compound hydroxide is represented by the general formula Ni1-x-yCoxMy (OH)2 (where 0.05 ≤ x ≤ 0.50, 0 ≤ y ≤ 0.10, 0.05 ≤ x + y ≤ 0.50, M is at least one metal element selected from Al, Mg, Mn, Ti, Fe, Cu, Zn, and Ga), wherein the correlations of (D50-D10) / D50 ≤ 0.30 and (D90-D50) / D50 ≤ 0.30 are established between D10, D50, and D90.

Owner:SUMITOMO METAL MINING CO LTD

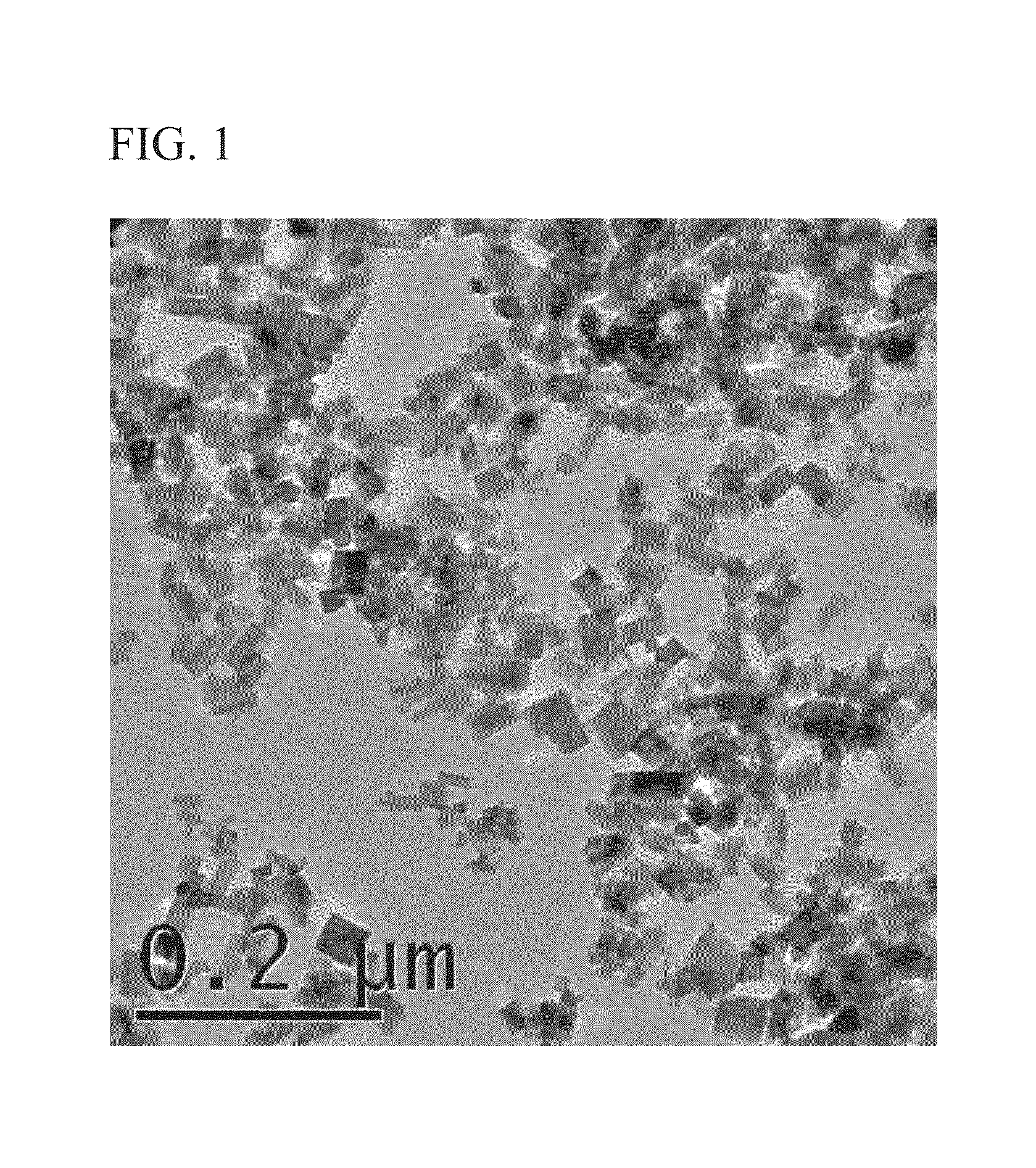

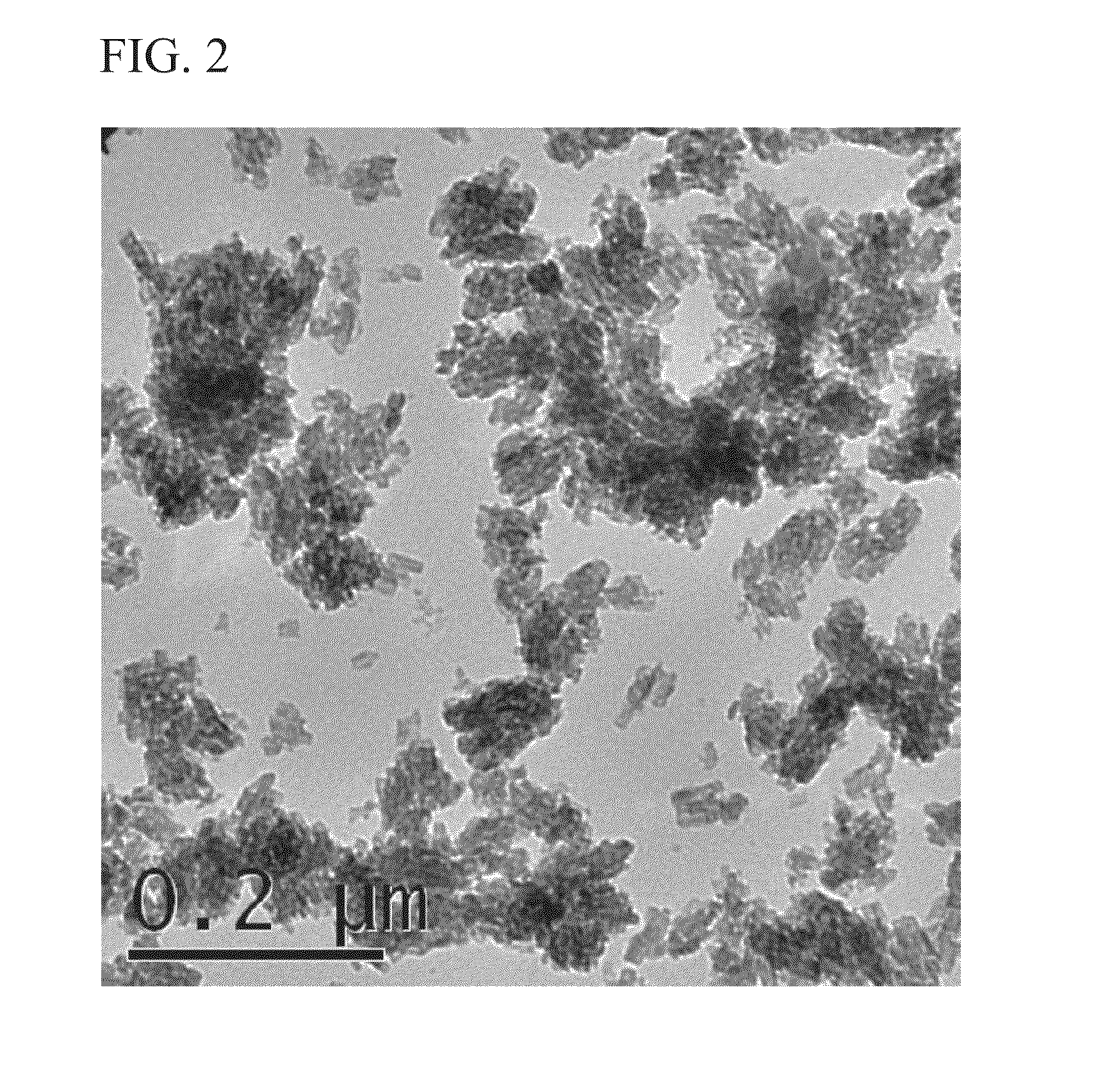

Inorganic fine particles, inorganic raw material powder, and method for production thereof

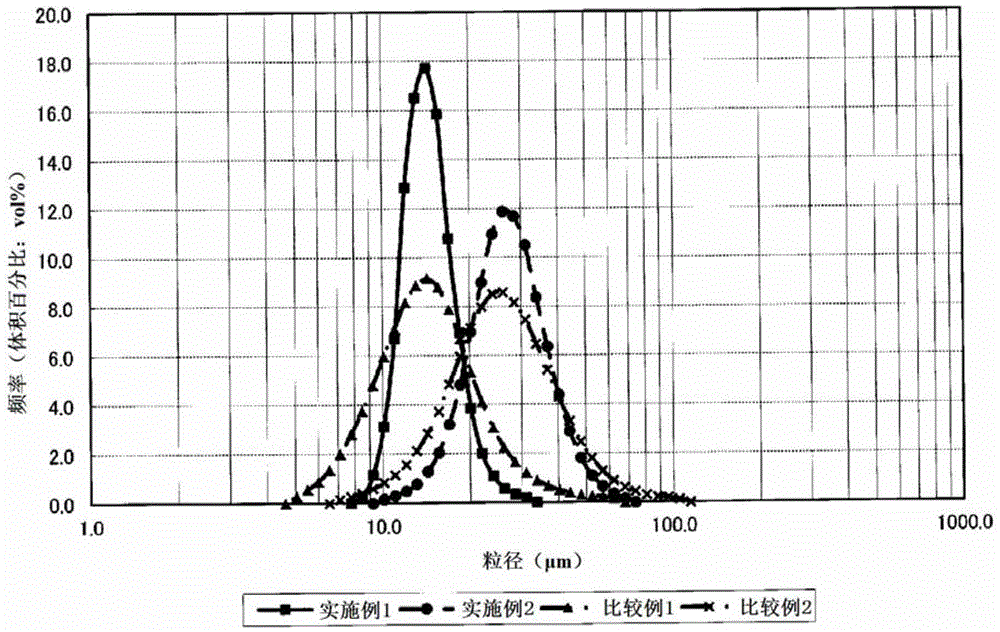

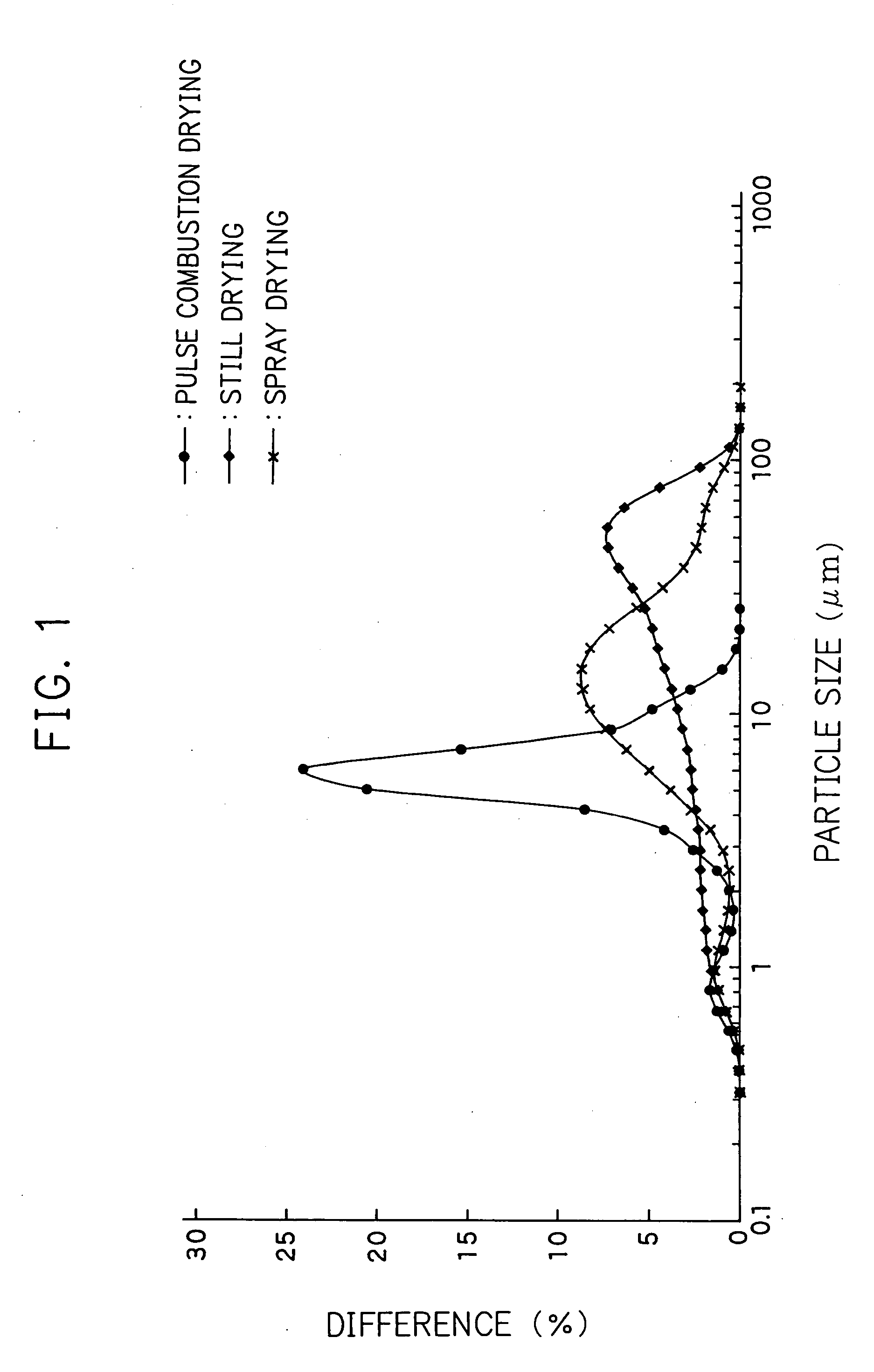

InactiveUS20060051288A1Suppress agglomeration actionShort timeMaterial nanotechnologyDrying solid materials with heatChemical structureSlurry

The present invention provides new process for preparing inorganic fine particles, which suppresses agglomeration and adhesion of particles due to heat when preparing powder from a raw material liquid such as a slurry of zirconia hydrate fine particles in order to obtain inorganic raw material powder having sharp particle size distribution. Furthermore, the present invention provides a new process for preparing inorganic fine particles, which can make the chemical structure homogenous among the produced particles and inside the particles even in a multi-component system. The present invention provides a process for preparing inorganic fine particles, which comprises heating and applying impulse waves to a raw material liquid.

Owner:DAI ICHI KOGYO SEIYAKU CO LTD +2

Highly crystalline silver powder and process for production of the same

InactiveCN101218051AExcellent heat shrinkage resistanceSmooth surface roughnessTransportation and packagingMetal-working apparatusFiltrationMicroparticle

The invention aims at providing a process for the production of highly crystalline silver powder which comprises silver particles falling within the fine particle region and has an excellent particle size distribution and highly crystalline silver powder obtained by the process. The aim is attained by a process for the production of highly crystalline silver powder which is characterized by preparing the first aqueous solution containing gelatin, silver nitrate and nitric acid and having a temperature of 45 to 55 C and the second aqueous solution containing erythorbic acid and / or ascorbic acid and a water-soluble organic acid, adding the second aqueous solution mildly to the first aqueous solution, stirring the mixed solution after the completion of the addition to form silver particles through particle growth, allowing the resulting system to stand to settle the silver particles, removing the supernatant, and then subjecting the remainder to filtration and washing to recover the silver particles.

Owner:MITSUI MINING & SMELTING CO LTD

Toner

ActiveUS7794909B2Excellent low temperature fixabilityIncrease resistanceDevelopersPolyesterPolymer science

An object of the present invention is to provide a spherical toner that has a sharp particle size distribution and a small particle diameter. This is a capsule-type toner that exhibits an excellent low-temperature fixability, while at the same time having a high offset resistance and excellent charging properties and having the ability to provide a high-quality image in which the characters, lines, and dots are precisely defined. The object is achieved by a toner comprising a toner particle that comprises at least (a) resin having polyester as the main component, colorant, wax, and (b) urethane resin, wherein the hydroxyl value per specific surface area of the toner particle is fall into the specific range, and wherein a Tg(0.5) and a Tg(4.0)-Tg(0.5) of the toner fall into specific range.

Owner:CANON KK

Indium tin oxide powder, method for producing same, dispersion, paint, and functional thin film

InactiveUS20130187104A1Small particle sizeSatisfactory dispersibilityMaterial nanotechnologyPigmenting treatmentIndium(III) hydroxideLiquid temperature

This indium tin oxide powder has a median diameter of 30 nm to 45 nm and a D90 value of 60 nm or less in a particle size distribution. This method for producing an indium tin oxide powder includes, in series: a step (A) of coprecipitating an indium tin hydroxide by using a tin (Sn2+) compound under conditions where a pH is in a range of 4.0 to 9.3 and a liquid temperature is in a range of 5° C. or higher, wherein the indium tin hydroxide has a color tone ranging from bright yellow to color of persimmon in a dried powder state; a step (B) of drying and calcining the indium tin hydroxide, and thereby, obtaining indium tin oxide; and a step (C) of dry pulverizing the obtained indium tin oxide in a nitrogen atmosphere.

Owner:MITSUBISHI MATERIALS CORP +1

Method for producing gold colloid and gold colloid

ActiveUS8048193B2Control concentrationSuitable for useMaterial nanotechnologyOther chemical processesGold ColloidCITRATE ESTER

It is an object of the present invention to provide a method for producing gold colloid having a targeted particle size, a sharp particle size distribution and a uniform and perfect spherical shape. The present invention relates to a method for producing gold colloid including a nucleation step of forming nuclear colloidal particles by adding a first reducing agent to a first gold salt solution; and a growth step of growing nuclear colloid by adding a second gold salt and a second reducing agent to the solution of the nuclear colloidal particles, characterized in that the growth step is performed at least once; a citrate is used as the first reducing agent and an ascorbate is used as the second reducing agent; and the addition of the ascorbate in the growth step is performed simultaneously with addition of the second gold salt. According to the method for producing gold colloid of the present invention, gold colloid having a sharp particle size distribution and a uniform and perfect spherical shape can be obtained.

Owner:TANAKA PRECIOUS METAL IND

Toner, production process for the same, and image forming method

InactiveUS7390607B2Quality improvementSharp particle size distributionDevelopersElectrographic processes using charge patternMonomerSupercritical fluid

Owner:RICOH KK

Dispersion stabilizer for suspension polymerization, production method for vinyl-based polymer, and vinyl chloride resin

ActiveUS20170198068A1Improve performanceReduce adhesionTransportation and packagingMixingSide chainPlasticizer

Provided is a dispersion stabilizer which exhibits an excellent polymerization stability when used in suspension polymerization for a vinyl chloride-based resin, and gives a vinyl chloride-based resin having few coarse particles, few fish eyes after resin molding, an excellent plasticizer absorption, and an excellent hue. Also provided is a high-quality vinyl chloride-based resin produced using the dispersion stabilizer. The present invention is a dispersion stabilizer for suspension polymerization containing a polyvinyl alcohol-based polymer (B) which has a double bond in a side chain and which is obtainable by acetalization of a polyvinyl alcohol-based polymer (A) with a monoaldehyde having an olefinic unsaturated double bond.

Owner:JAPAN VAM & POVAL

Yellow toner

A yellow toner is provided which can form high-quality images and has high offset resistance and excellent charging performance while being a capsule-type toner having excellent low-temperature fixability. The yellow toner satisfies, in DSC measurement, 40.0≦Tg(0.5)≦60.0 and 2.0≦Tg(4.0)−Tg(0.5)≦10.0, wherein when the concentration of the yellow toner in an ethyl acetate dispersion is Cy1 (mg / ml) and the light absorbance at a wavelength of 422 nm of the dispersion is A(ethyl acetate)422, the relationship between Cy1 and A(ethyl acetate)422 satisfies A(ethyl acetate)422 / Cy1<0.45, and when the concentration of the yellow toner in a chloroform solution is Cy2 (mg / ml) and the light absorbance at a wavelength of 422 nm of the solution is A(chloroform)422, the relationship between Cy2 and A(chloroform)422 satisfies 6.00<A(chloroform)422 / Cy2<14.4.

Owner:CANON KK

Process for producing toner particles, and toner

InactiveUS7153625B2Easy to chargeGood transfer performance and anti-fogging propertyDevelopersMonomer compositionAlcohol

In a process for producing toner particles by dispersing in an aqueous medium a polymerizable monomer composition containing at least a polymerizable monomer and a colorant and carrying out polymerization by the use of a polymerization initiator, the concentration of alcohol having 4 to 6 carbon atoms in the aqueous medium is so adjusted as to be from 500 ppm to 2,000 ppm when the polymerization conversion of the polymerizable monomer composition is 30%, and to be from 2,300 ppm to 10,000 ppm when the polymerization conversion of the polymerizable monomer composition is 97%.

Owner:CANON KK

Toner and Process for Producing the Same

The present invention provides toner containing core particles prepared by mixing and aggregating in an aqueous medium at least a first resin particle dispersion in which first resin particles are dispersed, a colorant particle dispersion in which particles of colorant are dispersed and a wax particle dispersion in which particles of wax are dispersed. The colorant contains carbon black having a DBP oil absorption of 45 to 70 (ml / 100 g) and the wax contains a wax having an endothermic peak temperature (referred to as melting point Tmw1 (° C.)) according the DSC method of 50 to 90° C. It is thus possible to prepare toner that has a small particle size and a sharp particle size distribution without requiring a classification process and that can prevent transfer void and toner scattering during transfer and obtain high transfer efficiency. The present invention provides also a method for producing the toner.

Owner:PANASONIC CORP

Toner and process for producing the same

InactiveUS20100167197A1Small particle sizeSharp particle size distributionDevelopersWaxAqueous medium

A toner includes aggregated particles produced by preparing in an aqueous medium a mixed dispersion including at least a first resin particle dispersion in which first resin particles are dispersed, a colorant particle dispersion in which colorant particles are dispersed, and a wax particle dispersion in which wax particles are dispersed, heating the mixed dispersion so that at least part of the wax particles is melted, and aggregating the first resin particles, the colorant particles, and the wax particles at least part of which is melted by the addition of an aqueous solution containing an aggregating agent. Thus, the toner can have a smaller particle size and a sharp particle size distribution without requiring a classification process. Moreover, the toner can achieve a longer life and suppress transfer voids or scattering during transfer.

Owner:PANASONIC CORP

Toner, method for producing the same, and image-forming method using the same

InactiveUS7396625B2Sharp particle size distributionAvoid serious impactDevelopersBulk chemical productionImage formationFluorine containing

To provide a method for producing a toner in which at least monomers are polymerized in at least one of a supercritical fluid and a subcritical fluid to thereby produce toner particles, wherein at least one of the supercritical fluid and the subcritical fluid contains a fluorine-containing surfactant, and a polymer resulted from polymerization of the monomers is insoluble in at least one of the supercritical fluid and the subcritical fluid, and provide a toner produced by the method for producing the toner.

Owner:RICOH KK

Coloring composition for color filter containing colorant and color filter using the same

InactiveUS7094814B2Good dispersionGood light fastnessMaterial nanotechnologyDiffusing elementsInorganic particleInorganic particles

A coloring composition for a color filter composed of composite particles having an average particle diameter of 0.00 1 to 1.0 μm, and containing white inorganic particles, a glue coating layer formed on the surface of the white inorganic particle and an organic pigment coat formed on the glue. A dispersant, binder resin, monomer as a reactive diluent, a polymerization initiator and a solvent are also present. The colorant provides not only a sharp particle size distribution but also excellent light resistance.

Owner:TODA IND

Process for producing toner particles, and toner

InactiveUS20060204876A1Easy to chargeGood transfer performance and anti-fogging propertyDevelopersMonomer compositionAlcohol

In a process for producing toner particles by dispersing in an aqueous medium a polymerizable monomer composition containing at least a polymerizable monomer and a colorant and carrying out polymerization by the use of a polymerization initiator, the concentration of alcohol having 4 to 6 carbon atoms in the aqueous medium is so adjusted as to be from 500 ppm to 2,000 ppm when the polymerization conversion of the polymerizable monomer composition is 30%, and to be from 2,300 ppm to 10,000 ppm when the polymerization conversion of the polymerizable monomer composition is 97%.

Owner:CANON KK

Nickel-cobalt compound hydroxide and method and device for producing same

ActiveCN107021528ASharp particle size distributionExcellent cycle characteristicsSecondary cellsChemical electrode manufacturingSlurryLarge particle

The present invention aims to improve the cycle properties of a nonaqueous electrolyte secondary cell obtained using the nickel-cobalt compound hydroxide as the precursor. In the present invention, a slurry contains a nickel-cobalt compound hydroxide that is obtained by reacting and continuously feeding to a reactor an aqueous solution containing at least nickel and cobalt, an aqueous solution that serves as an ammonium ion donor, and an aqueous caustic alkali solution. The slurry is continuously extracted and the slurry is separated by grading into large particle diameter portions and small particle diameter portions. The small particle diameter portion is continuously circulated back to the reactor. The resulting nickel-cobalt compound hydroxide is represented by the general formula Ni1-x-yCoxMy (OH)2 (where 0.05 <= x <= 0.50, 0 <= y <= 0.10, 0.05 <= x + y <= 0.50, M is at least one metal element selected from Al, Mg, Mn, Ti, Fe, Cu, Zn, and Ga), wherein the correlations of (D50-D10) / D50 <= 0.30 and (D90-D50) / D50 <= 0.30 are established between D10, D50, and D90.

Owner:SUMITOMO METAL MINING CO LTD

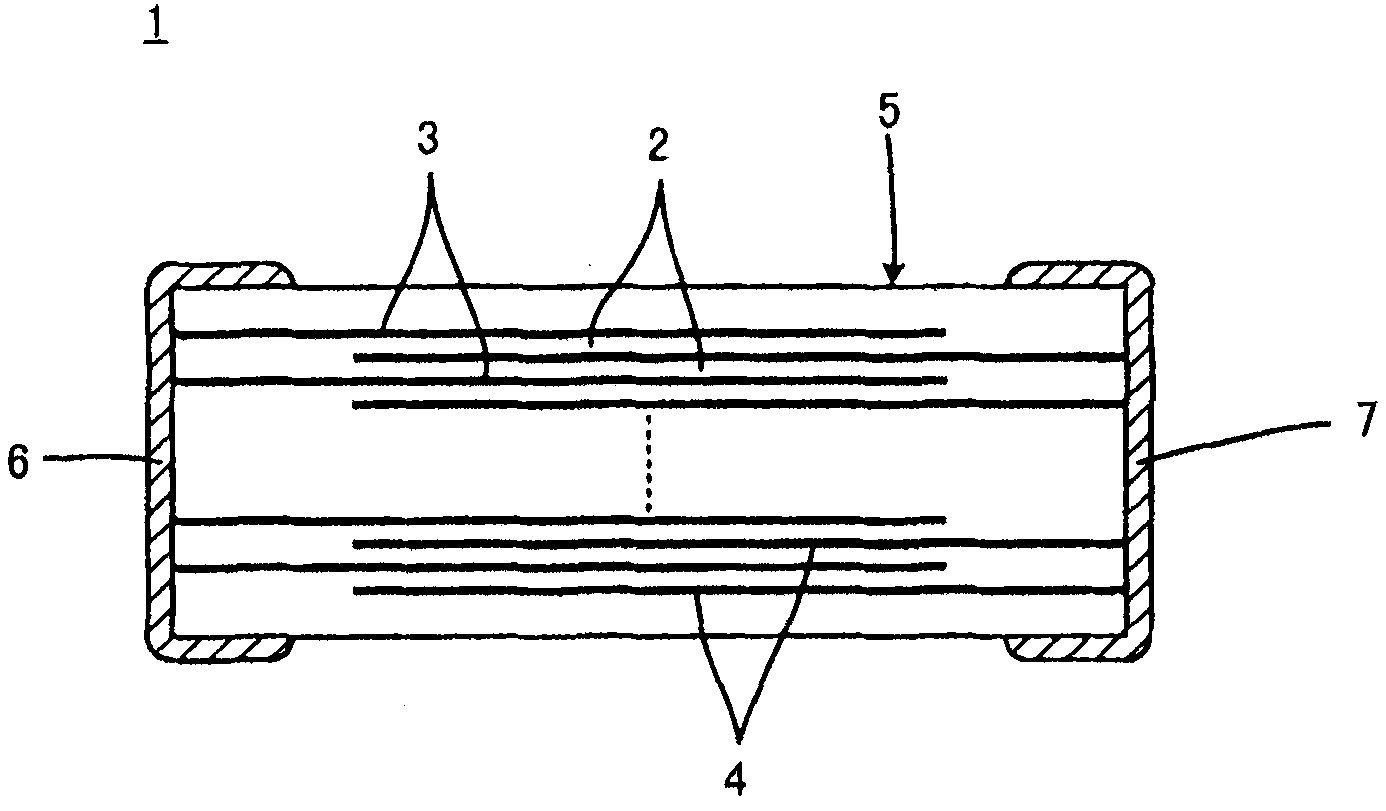

Barium titanate powder, process for producing the same, dielectric ceramic, and laminated ceramic capacitor

InactiveCN101857431AImproved failure life characteristicsIntegral width becomes smallerFixed capacitor dielectricStacked capacitorsElectricityParticle-size distribution

The aim of the invention is to reduce inferior insulation of laminated ceramic capacitor and improve failure lifetime characteristic in load test. The barium titanate powder which is used for obtaining dielectric ceramic of a dielectric layer 2 in the laminated ceramic capacitor 1 has sharp particle size distribution and satisfies the following states: the average particle diameter D1 is 10-200nm; 1.0<D2 / D1< / =2.0 and 0.5< / =D3 / D1<1.0 when a maximum particle diameter is set to D2 and a minimal particle diameter is set to D3. Therefore, the barium titanate powder has the following advantages: greatly improving the dispersivity in ceramic slurry, realizing density increase and surface smoothing of the dielectric ceramic layer 2 in the laminated ceramic capacitor 1, reducing inferior insulation and improving failure lifetime characteristic of load test.

Owner:MURATA MFG CO LTD

Copper powder for conductive paste and method for producing same

ActiveUS20130177471A1Stable productionThinnerMaterial nanotechnologyTransportation and packagingConductive pasteCopper

There are provided a copper powder for conductive paste, which comprises monodisperse and spherical fine copper particles having a sharp particle size distribution and containing no coarse particles and which can form a thinner electrode film while avoiding a bad influence on electric characteristics thereof, and a method for stably producing such a copper powder for conductive paste. After copper is complexed by adding a complexing agent to an aqueous solution containing copper while blowing air into the solution, the blowing of air is stopped, and then, a reducing agent is added to the solution to deposit copper particles by reduction.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Copper powder for conductive paste and method for producing same

ActiveUS9248504B2Thinner electrode filmReduce adverse effectsMaterial nanotechnologyTransportation and packagingConductive pasteElectricity

There are provided a copper powder for conductive paste, which comprises monodisperse and spherical fine copper particles having a sharp particle size distribution and containing no coarse particles and which can form a thinner electrode film while avoiding a bad influence on electric characteristics thereof, and a method for stably producing such a copper powder for conductive paste. After copper is complexed by adding a complexing agent to an aqueous solution containing copper while blowing air into the solution, the blowing of air is stopped, and then, a reducing agent is added to the solution to deposit copper particles by reduction.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Magenta toner

A magenta toner characterized by satisfying, in DSC measurement, 40.0≦Tg(0.5)≦60.0 and 2.0≦Tg(4.0)−Tg(0.5)≦10.0, wherein when preparing a solution of which the magenta toner is dissolved in ethyl acetate, and defined the concentration of the thereof as Cm1 (mg / ml), and the light absorbance thereof at a wavelength of 538 nm as A(ethyl acetate)538, the ratio of A(ethyl acetate)538 to Cm1 satisfies the formula, A(ethyl acetate)538 / Cm1<0.15, and, when preparing a solution of which the magenta toner is dissolved in chloroform, and defined the concentration of the thereof as Cm2 (mg / ml), and the light absorbance thereof at a wavelength of 538 nm as A(chloroform)538, the ratio of A(chloroform)538 to Cm2 satisfies the formula, 2.00<A(chloroform)538 / Cm2<6.55.

Owner:CANON KK

Resin particle and method of producing the resin particle, and toner and method of producing the toner

ActiveUS20160187797A1Increased durabilitySharp particle size distributionDevelopersOrganic solventMicroparticle

Provided is a toner, comprising a toner particle having a core-shell structure composed of a core particle and a shell phase on a surface of the core particle, the core particle containing a resin X and a colorant, the shell phase being derived from a resin fine particle containing a resin Y, in which a relationship among a SP value of the resin X, a SP value of the resin Y, and a SP value of an organic solvent falls within a specific range, and a relationship between a number-average particle diameter of the resin fine particle when the resin fine particle is dispersed in water and a number-average particle diameter of the resin fine particle when the resin fine particle is dispersed in the organic solvent falls within a specific range.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com