Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Save running energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

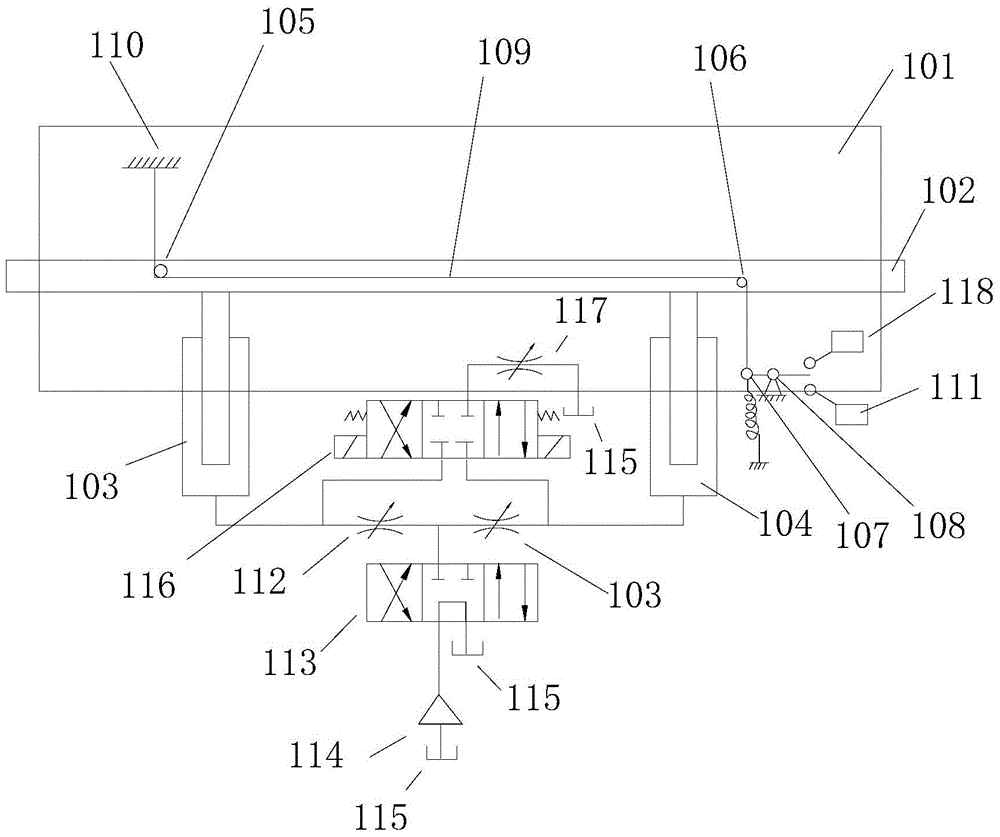

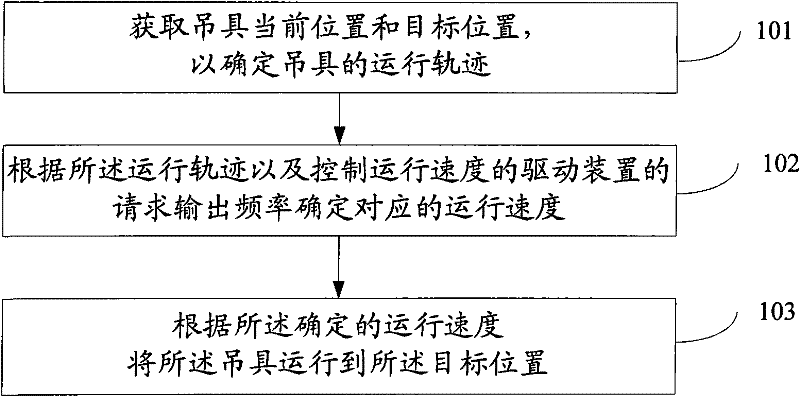

Control method of move track of crane container spreader, system and device

InactiveCN101665216AEasy to controlReduce running timeLoad-engaging elementsOperating energyControl theory

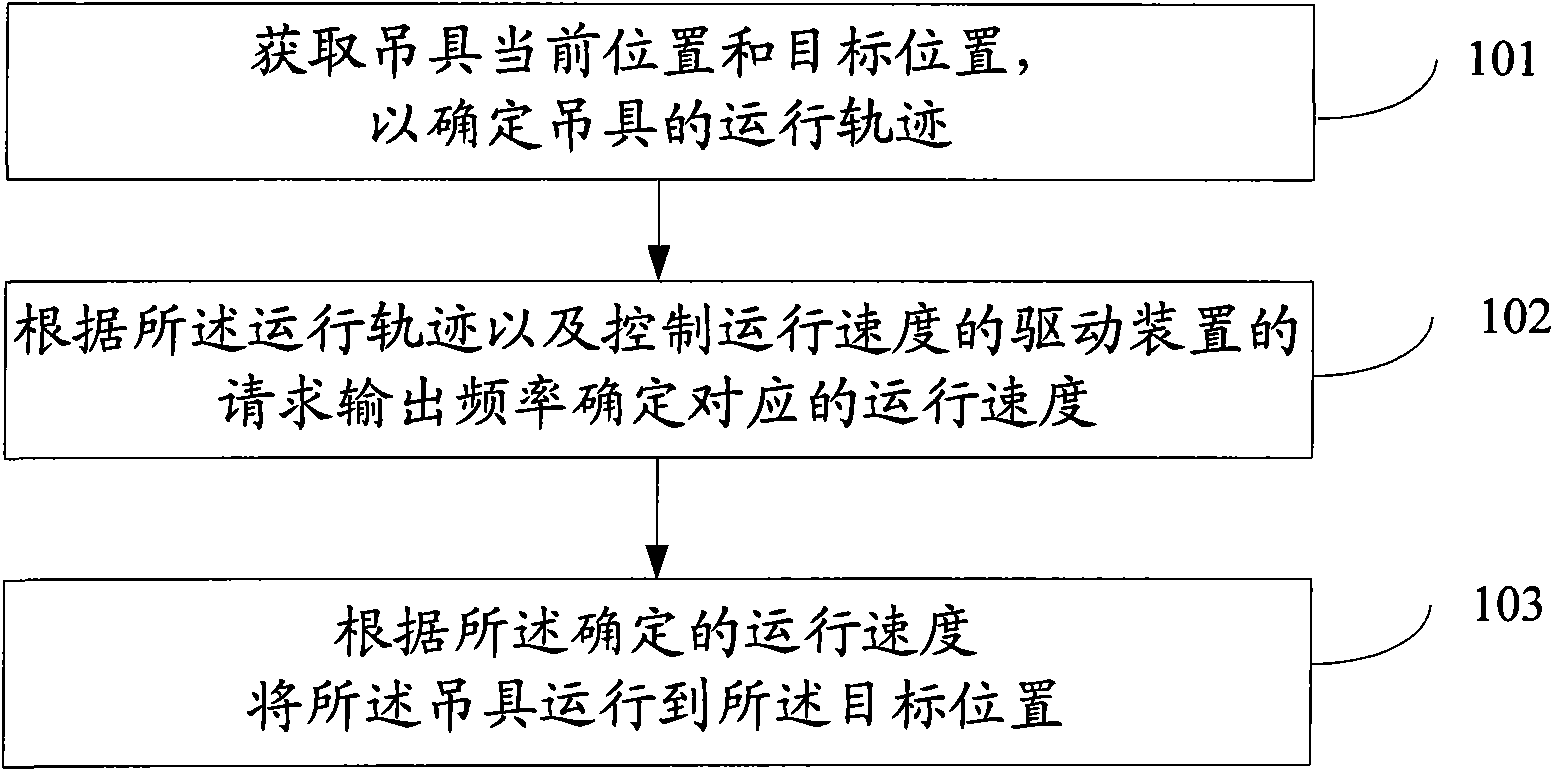

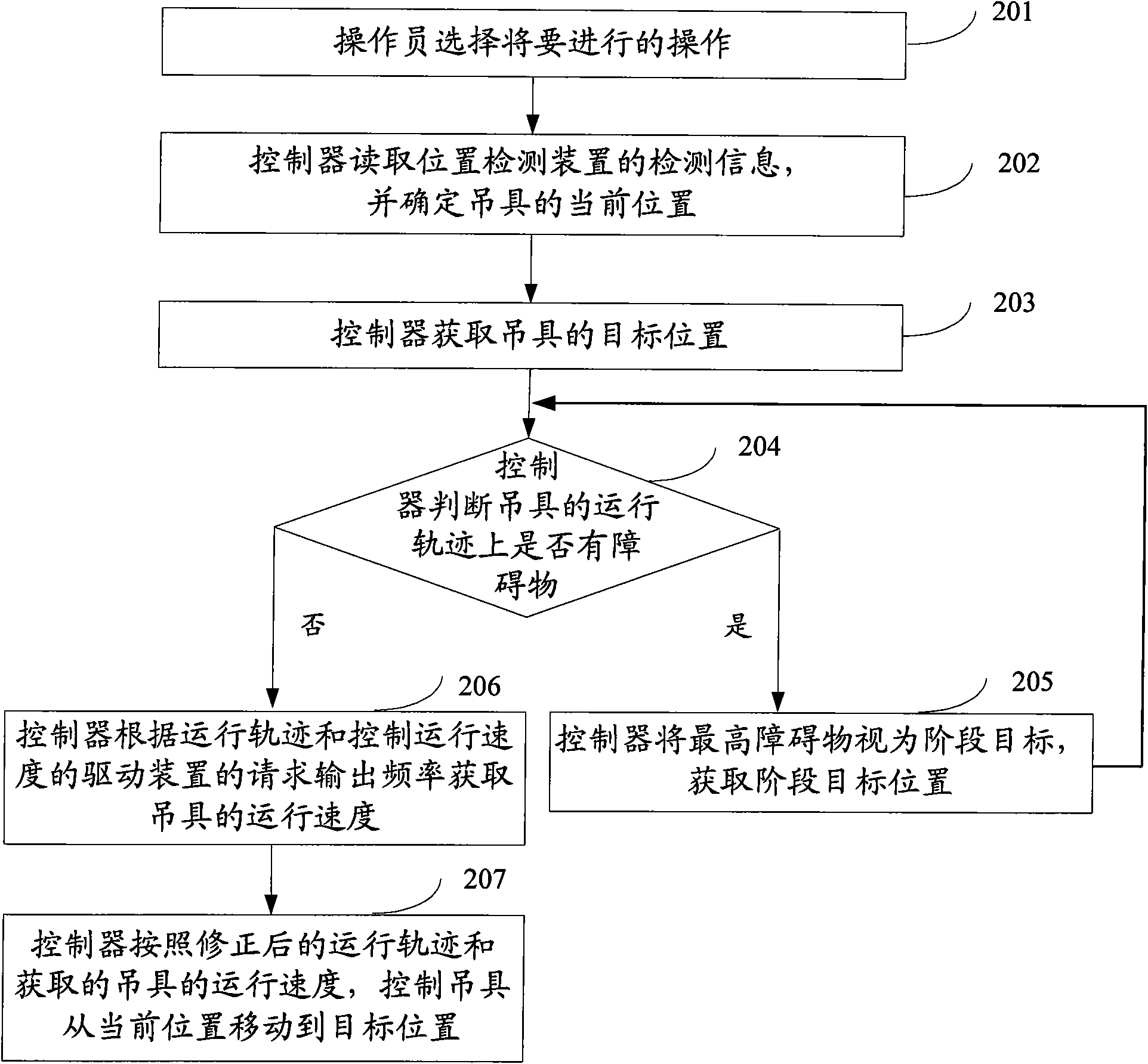

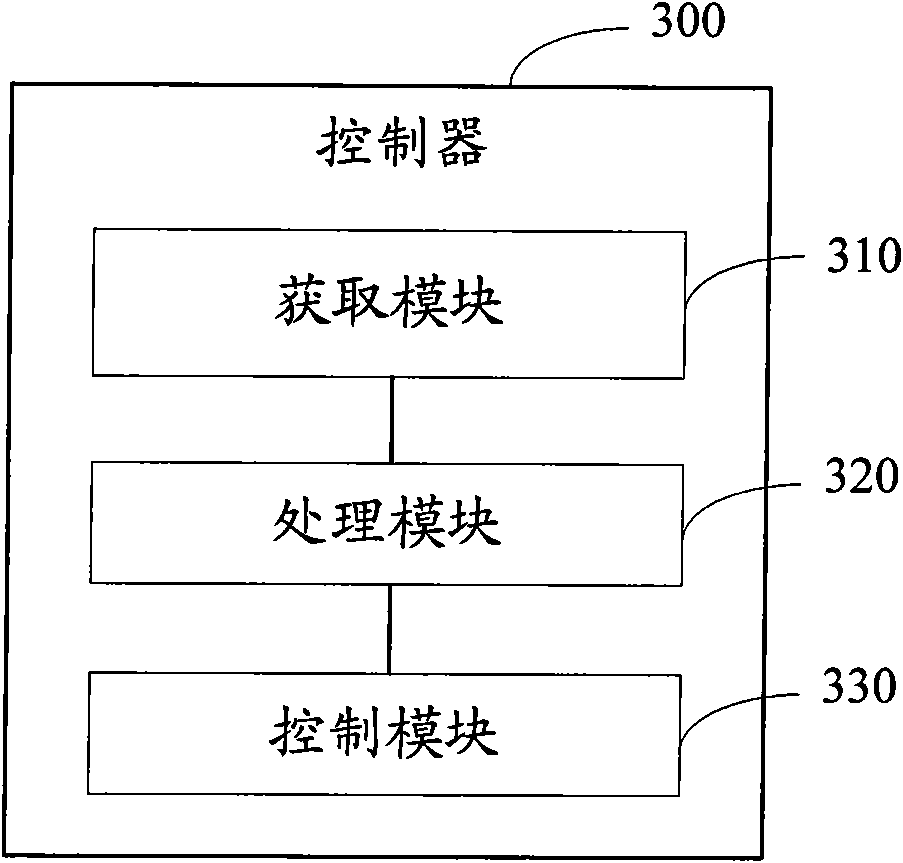

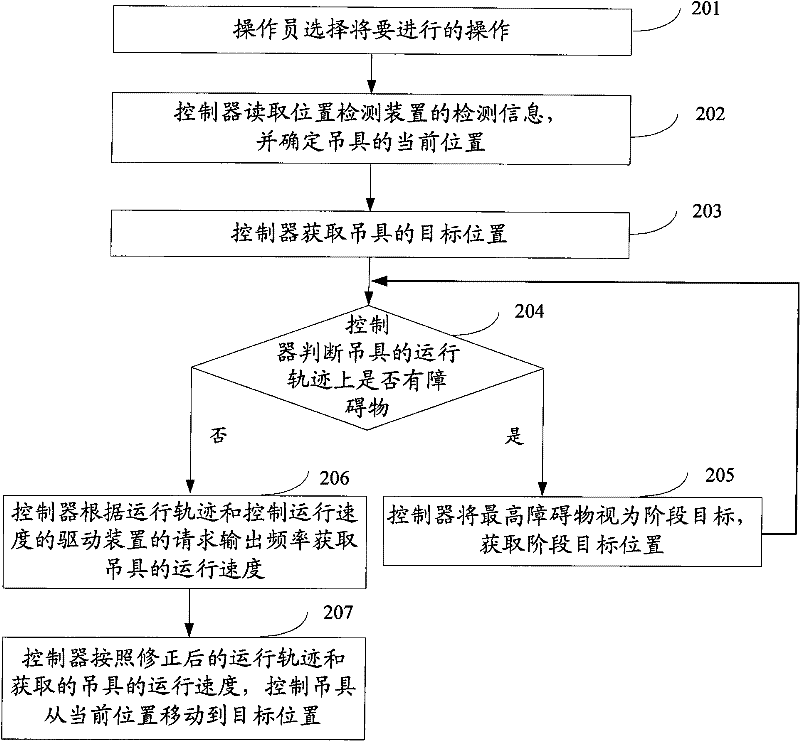

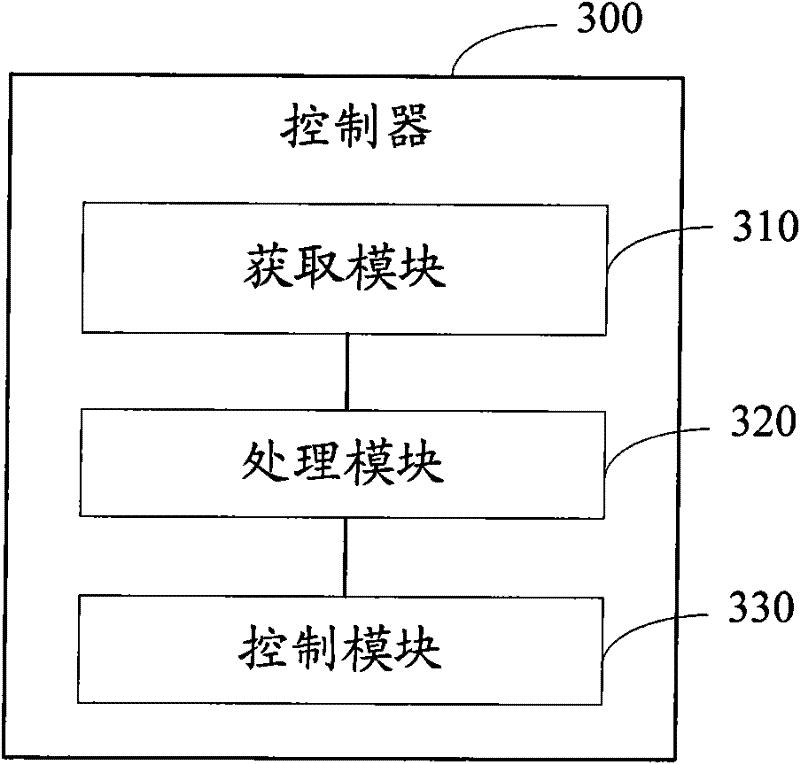

The embodiment of the invention discloses a control method of move track of a crane container spreader, a system and a device thereof; the method comprises a current position and a target position areobtained to determine the move track of a spreader; the position comprises a horizontal position and a vertical position, and the move track is liner; the corresponding operating speed is determinedaccording to the move track and requested output frequency of a driving device for controlling the operating speed; the operating speed comprises horizontal operating speed and vertical operating speed; the spreader is operated to the target position according to the determined operating speed. By adopting the invention, accurate control for operation of the spreader is realized, the operating time is shortened, the operating energy is saved and the accident rate is reduced.

Owner:SANY MARINE HEAVY IND

Traction drive multi-car shared multi-hoistway circular operation elevator

PendingCN110790111ASimple structureLow manufacturing costElevatorsBuilding liftsAutomotive engineeringTraction drive

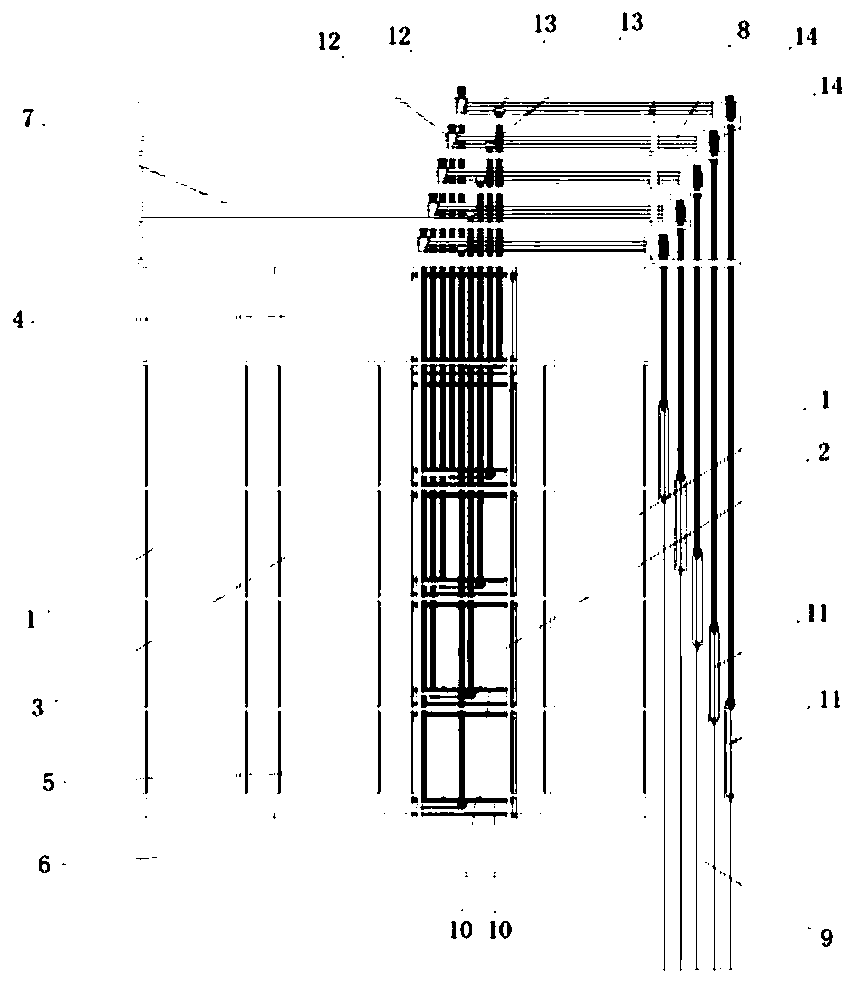

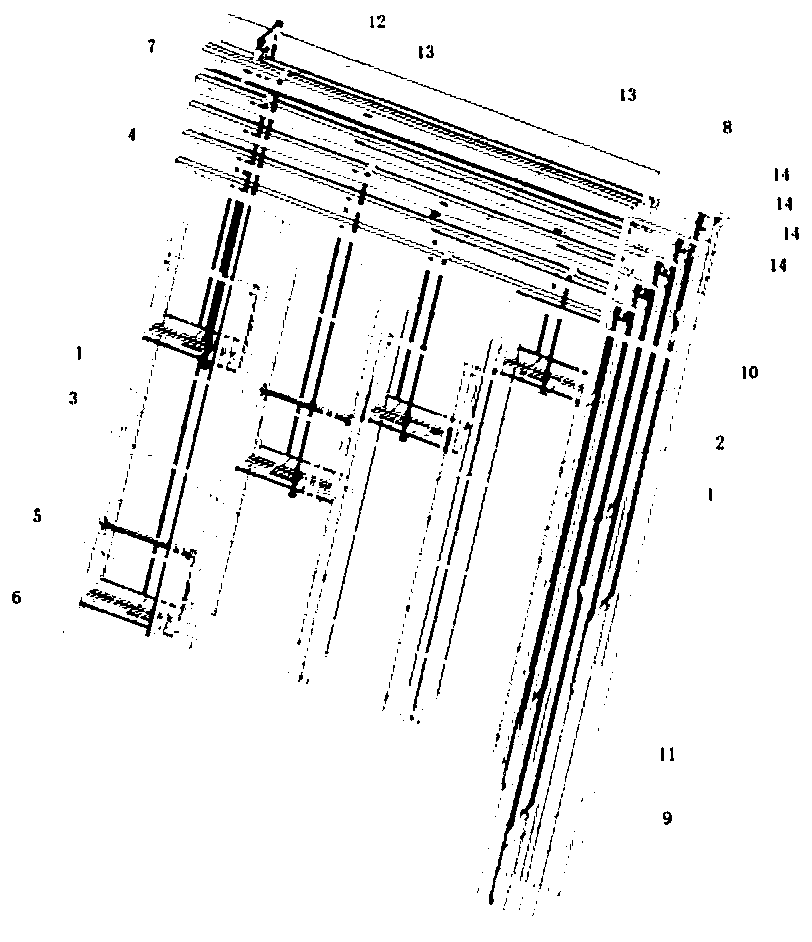

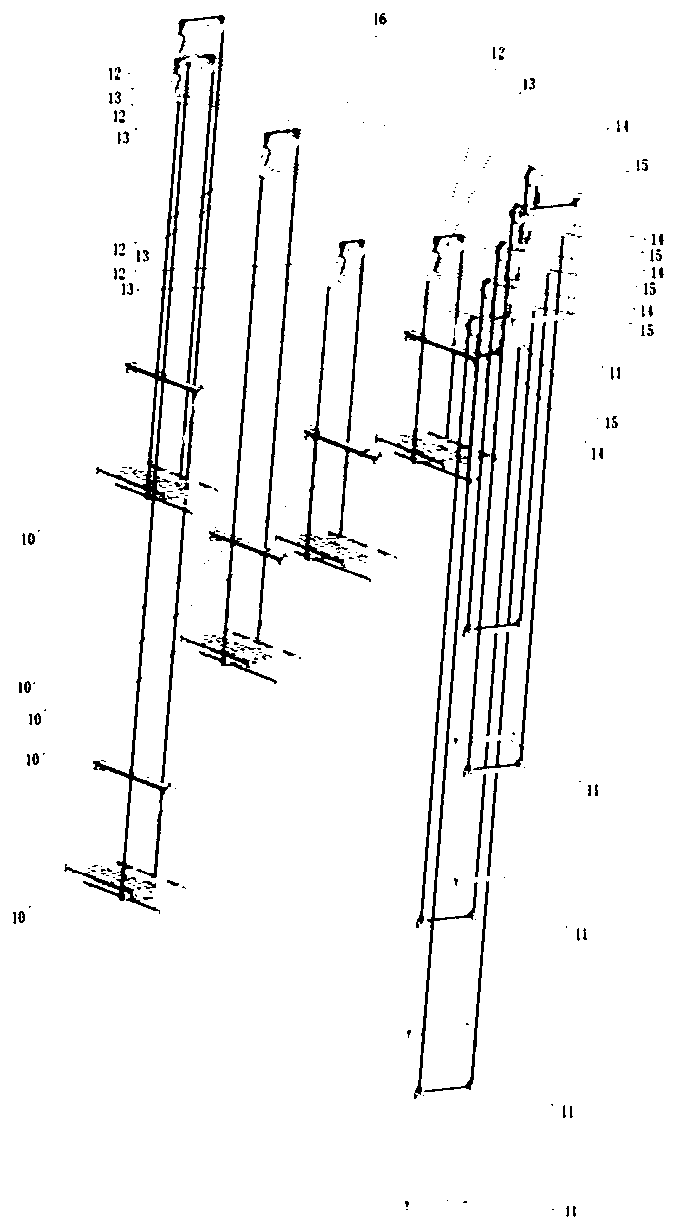

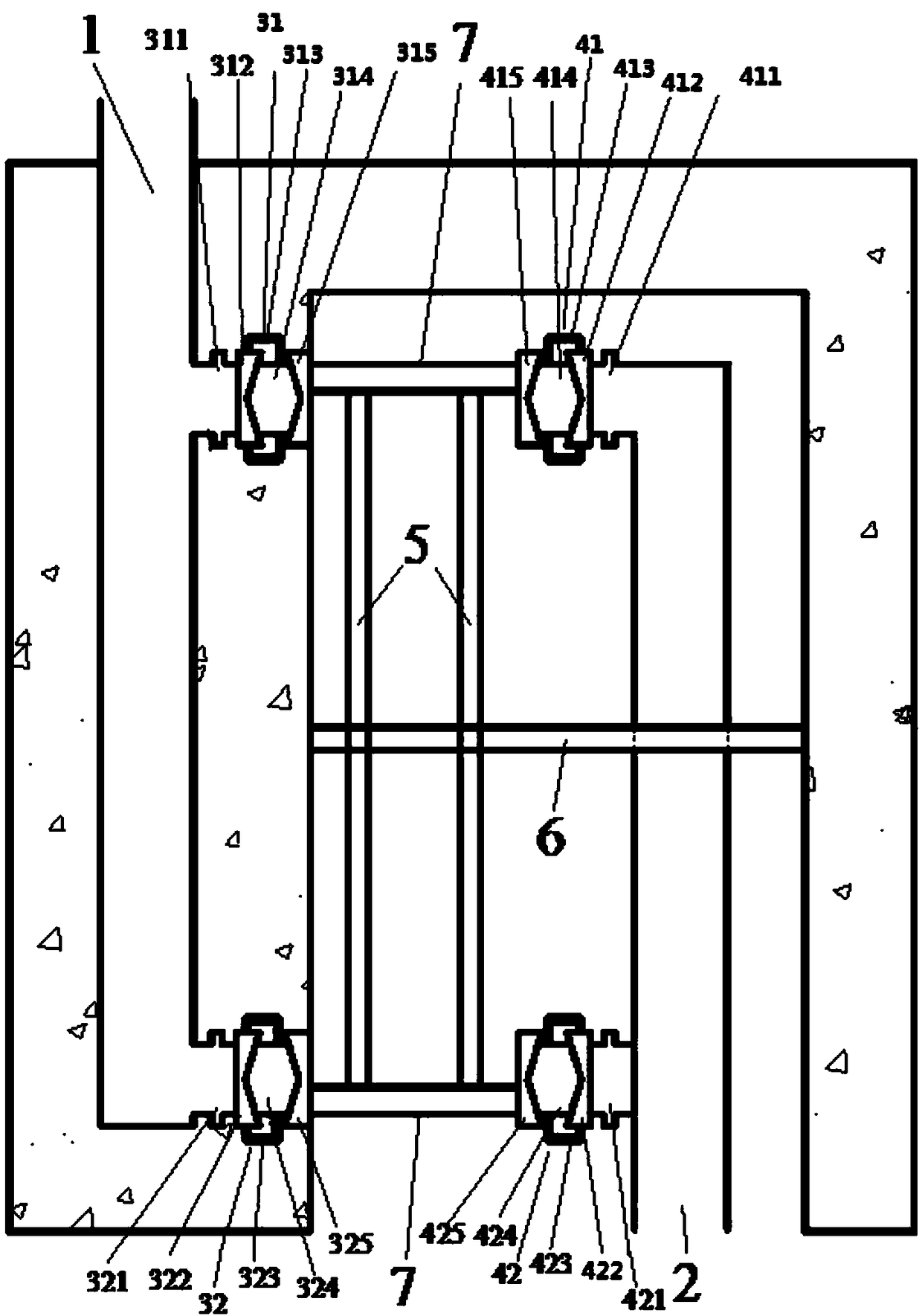

The invention discloses a traction drive multi-car shared multi-hoistway circular operation elevator. The elevator is composed of a multi-hoistway structure, multiple independent operation cars, multi-layer stacked traction rope guide wheel translation driving parts, multi-layer stacked car rope hitch firmware translation driving parts, multi-layer stacked traction machines and multiple counterweight rope hitch firmwares, wherein the multi-hoistway structure comprises four vertical operation hoistways, one upper translation hoistway, one lower translation hoistway, multiple independent counterweight vertical up-and-down movement spaces, a multi-layer guide wheel and car rope hitch firmware translation driving part supporting frame and a multi-layer traction machine and counterweight rope hitch firmware supporting frame. According to the elevator, all the cars are driven by the traction machines and translation driving devices to do vertical and upper and lower translation operation, guide wheels of the translation driving parts and traction ropes on the rope hitch firmwares are driven to do horizontal and longitudinal translation through horizontal translation driving devices and longitudinal translation driving devices, so that multiple cars can share the hoistways for circular operation, the elevator is a multi-hoistway circular operation elevator capable of integrating existing technologies, and the hoistway utilization rate can be increased.

Owner:胡杰

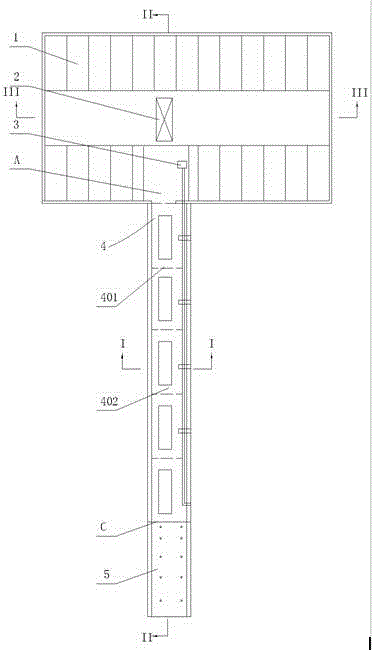

Production device for coiling silks into strips

InactiveCN105696121AHigh synchronization accuracyGuaranteed synchronous deliveryServomotor componentsFilament handlingEngineeringMechanical engineering

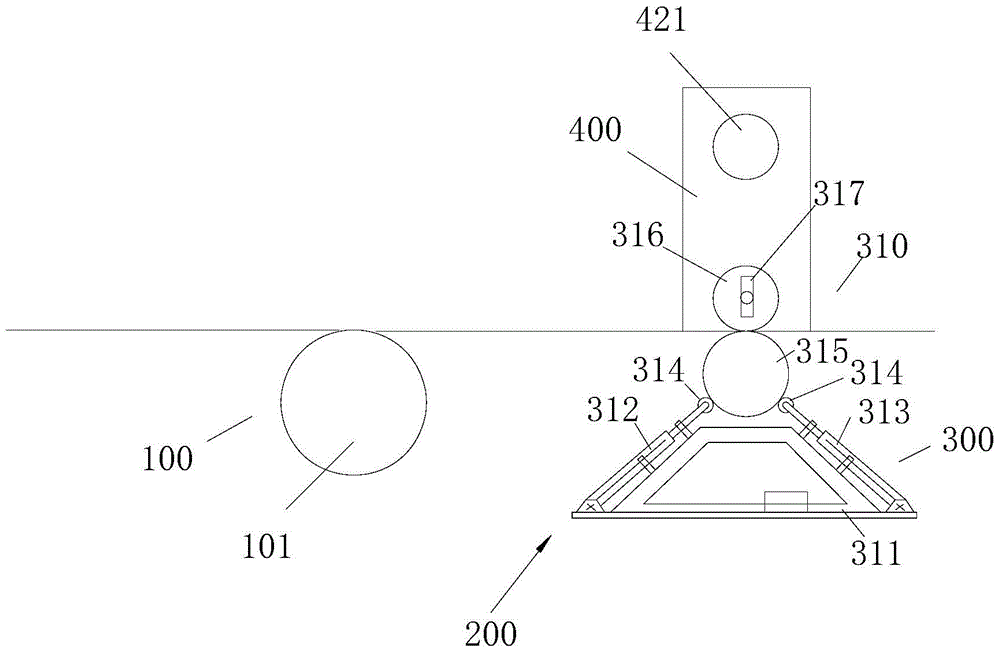

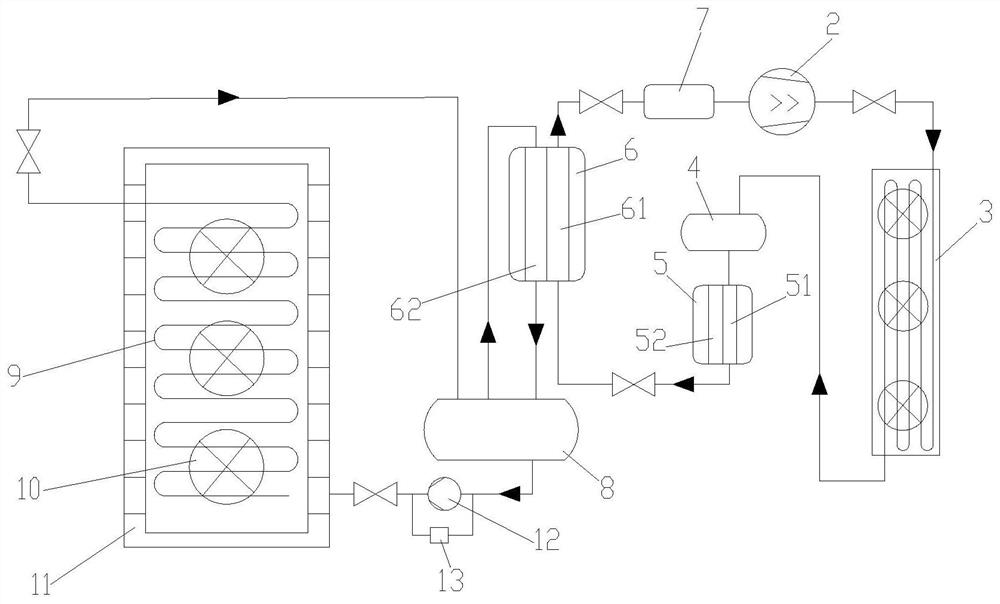

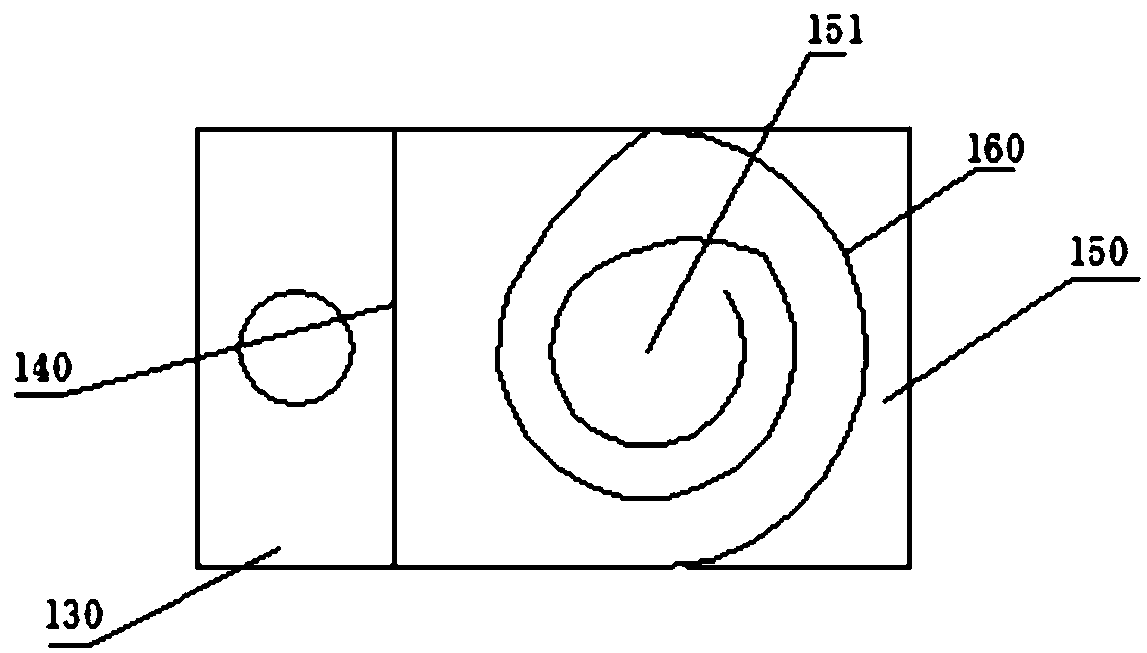

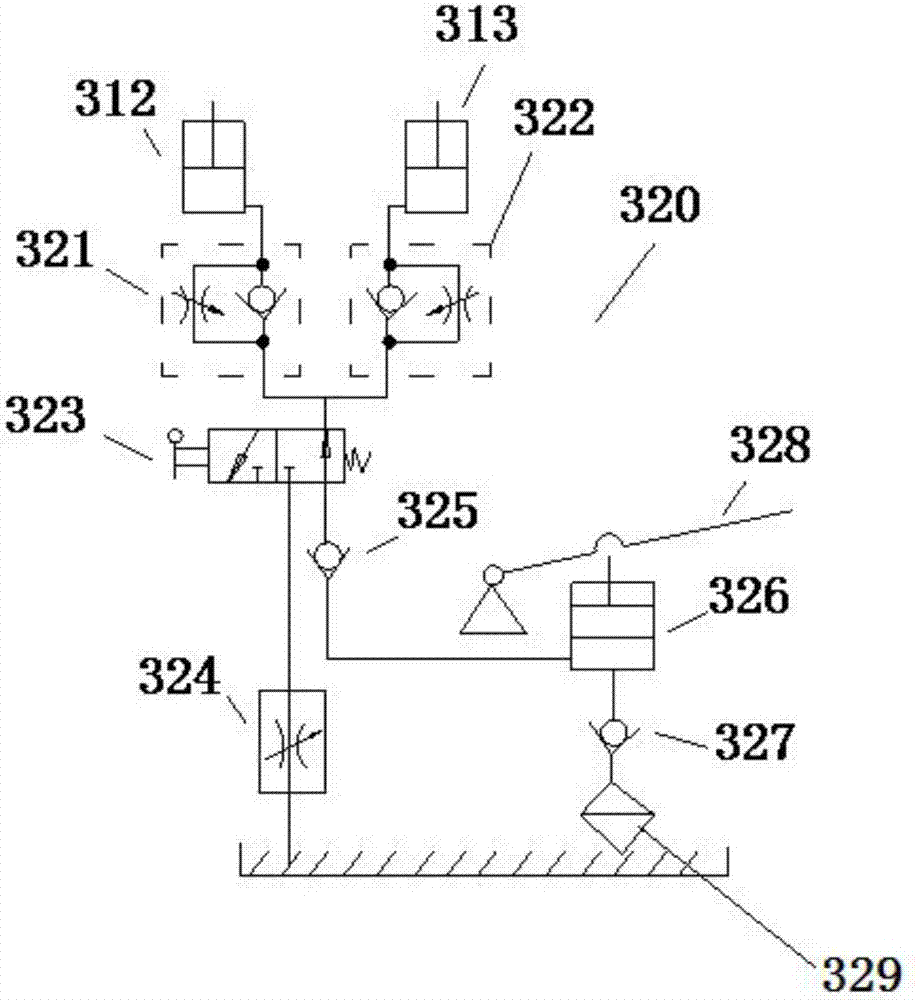

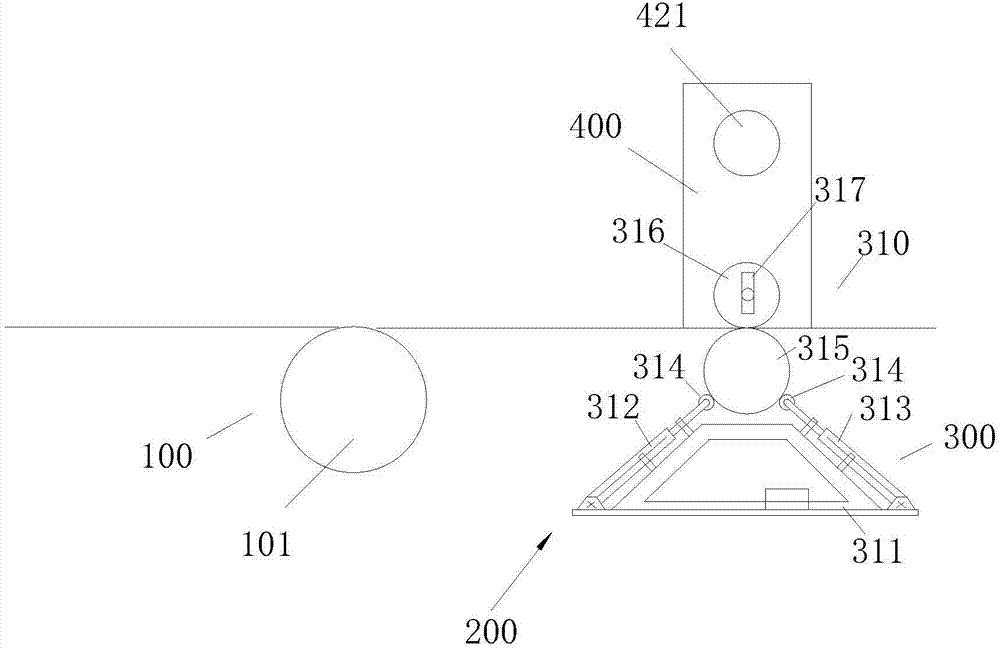

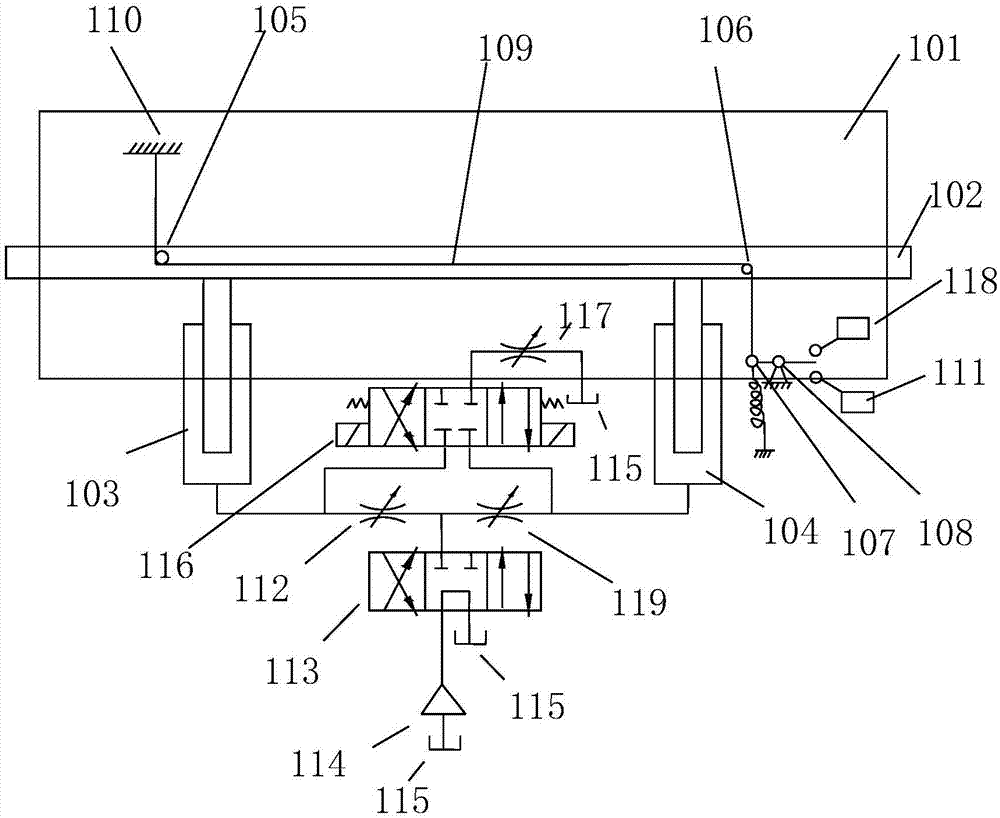

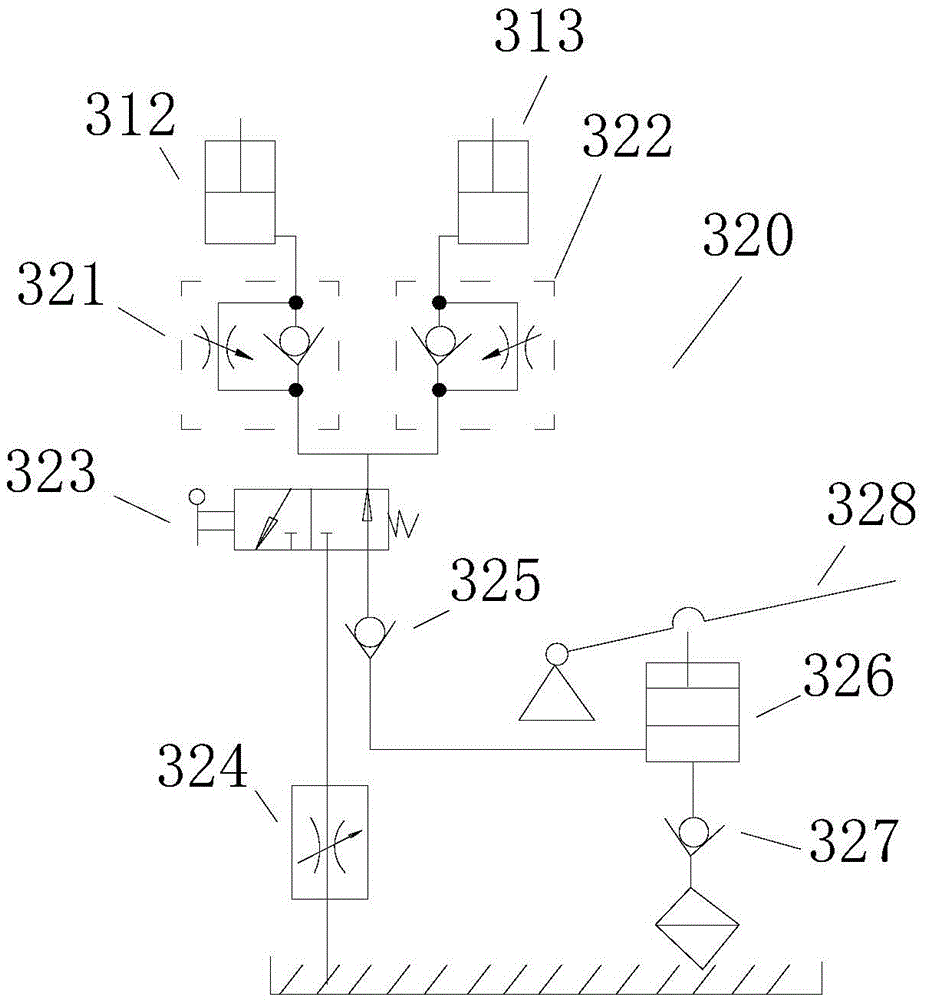

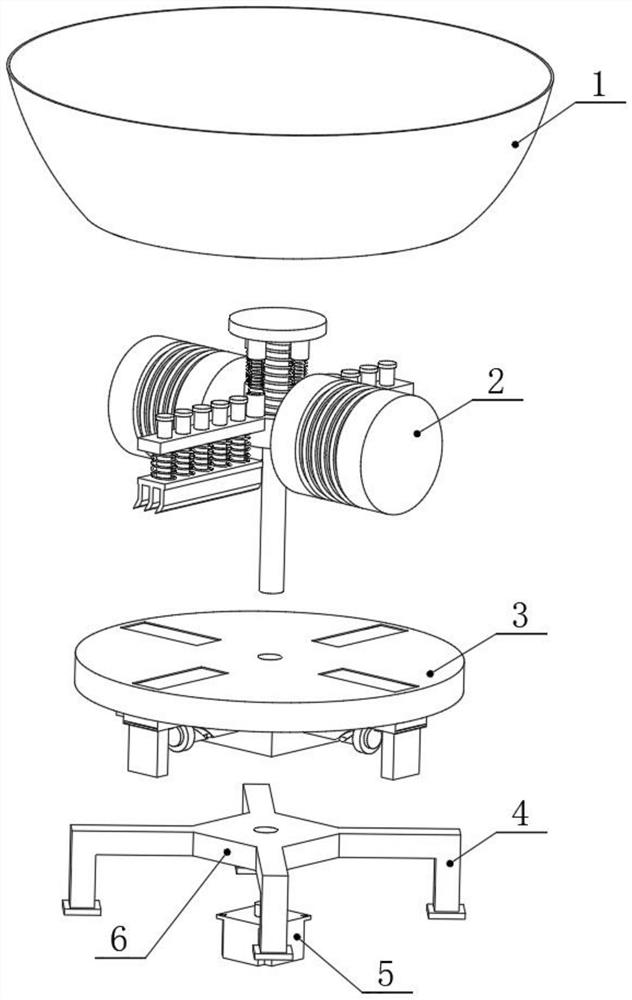

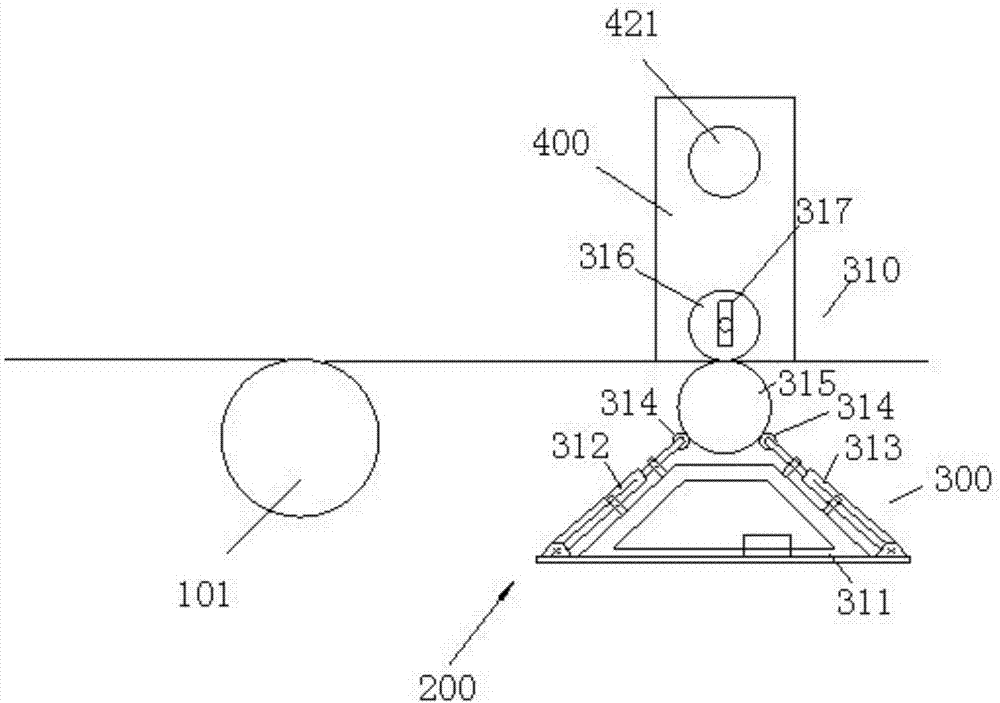

The invention discloses a production device for coiling silks into strips. The production device comprises a coiling mechanism (100), and a hot-pressing mechanism (200) is arranged behind the coiling mechanism (100); the hot-pressing mechanism (200) comprises a hot-pressing unit (300) and a silk coiling unit (400); the hot-pressing unit (300) comprises a hot-pressing mechanical part (310) and a hot-pressing hydraulic part (320), and the silk coiling unit (400) comprises a silk coiling hydraulic part (410) and a silk coiling mechanical part (420). By means of the production device, synchronous silk conveying can be guaranteed in real time, and uneven coiling caused by inclination of a coiling barrel is avoided; besides, a pressing roller and a hot pressing roller can be in close fit, and thus the hot pressing effect of silks is improved; a closed circuit adopting volumetric speed regulation is utilized, valve compensating oil is sucked in a vacuum mode, the oil path is simple, the structure is compact, the speed regulation range is wide, and operation energy is low.

Owner:湖州南浔中兴丝织有限公司

Small lever type energy-saving ship lift and operation method thereof

InactiveCN108086281ASolve the problem of energy consumptionSolve the economyDry-docksClimate change adaptationDrive shaftMarine engineering

The invention discloses a small lever type energy-saving ship lift and an operation method thereof. The small lever type energy-saving ship lift is applicable to ship navigation of small water retaining structures. The ship lift comprises an upstream approach channel, an upper lock head, a ship chamber section, a lower lock head and a downstream approach channel which are sequentially intercommunicated with one another from upstream to downstream. The ship lift is characterized in that the ship chamber section comprises a lever, a transmission shaft and two cylindrical type ship bearing chambers, wherein the transmission shaft is of a driving braking structure, and two ends of the transmission shaft are connected to a dam body or a firm foundation rock; the transmission shaft is rigidly connected to the middle part of the lever; the two cylindrical ship bearing chambers are correspondingly connected to two ends of the lever. The ship lift is applicable to one-way navigation or two-waynavigation of a ship, so that the ship navigation efficiency is improved; moreover, the gravitational potential energy of ships at the upstream and the downstream can be converted with each other based on the lever principle, so that the transferring energy consumption is greatly reduced.

Owner:HOHAI UNIV

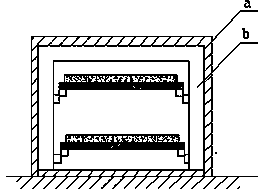

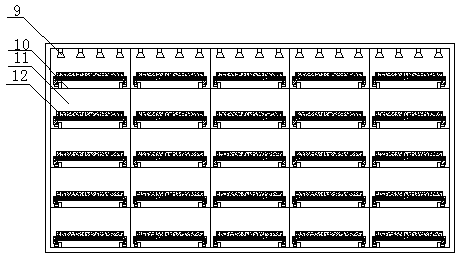

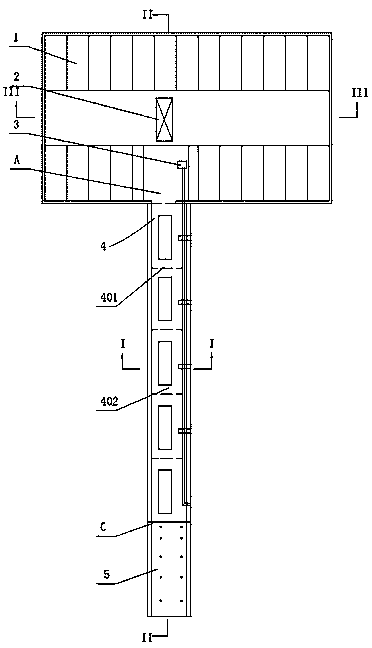

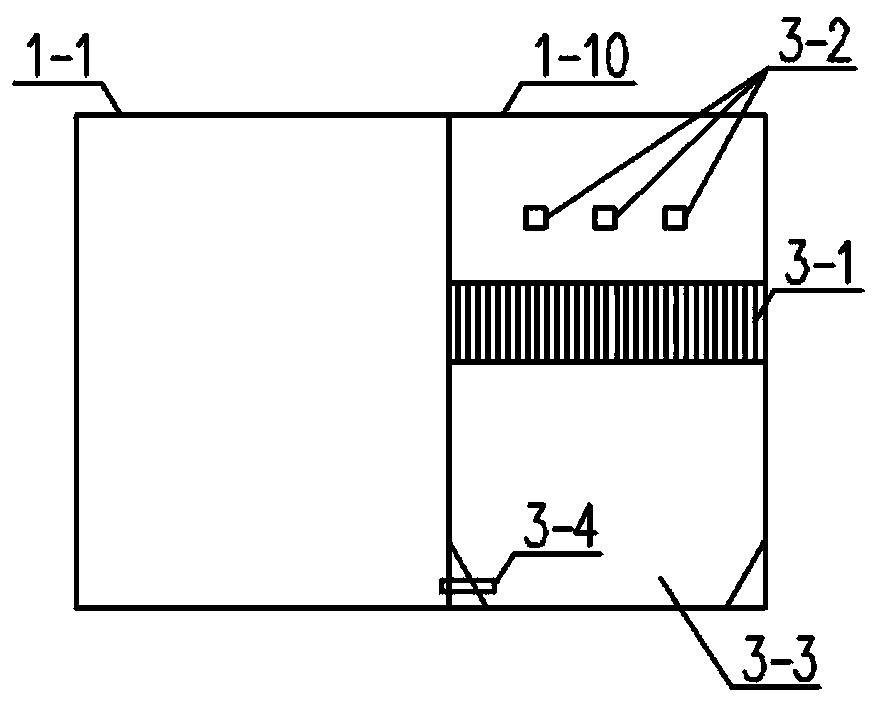

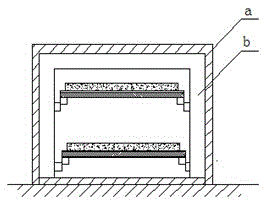

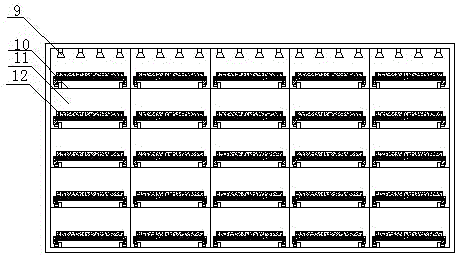

Low-energy-consumption concrete member curing kiln arranged on access way in upper and lower layer mode

ActiveCN104191512AFacilitate heat exchangeTemperature does not dropCeramic shaping apparatusEngineeringKiln

The invention provides a low-energy-consumption concrete member curing kiln arranged on an access way in an upper and lower layer mode. The low-energy-consumption concrete member curing kiln comprises a warming kiln body, a constant temperature kiln body and a cooling kiln body. The warming kiln body and the cooling kiln body are arranged in one kiln body in an upper and lower layer mode. A heat exchange device is arranged between the warming kiln body and the cooling kiln body. The end, away from the constant temperature kiln body, of the warming kiln body is provided with an entrance. The end, away from the constant temperature kiln body, of the cooling kiln body is provided with an exit. The constant temperature kiln body is provided with an entrance and an exit, the entrance is communicated with the warming kiln body and provided with an entrance air screen, and the exit is communicated with cooling kiln body and provided with an exit air screen. A middle way area and maintenance frames located on the two sides of the middle way area are arranged in the constant temperature kiln body. The maintenance frames comprise a plurality of maintenance rooms which are arranged up and down in a layered mode, and a lifting movement device is arranged on the middle way area.

Owner:SHANDONG LIANFANG INFORMATION TECH CO LTD

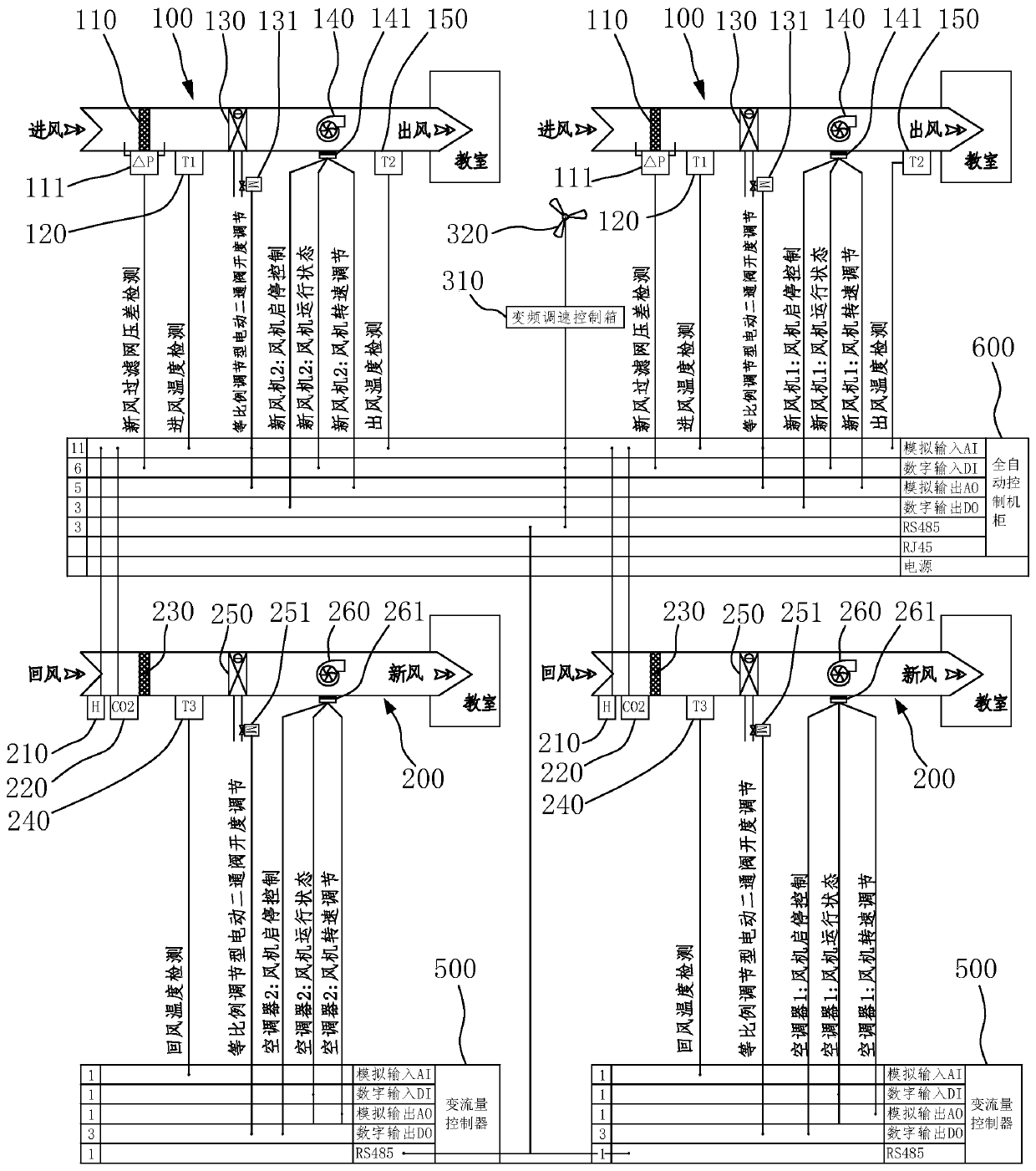

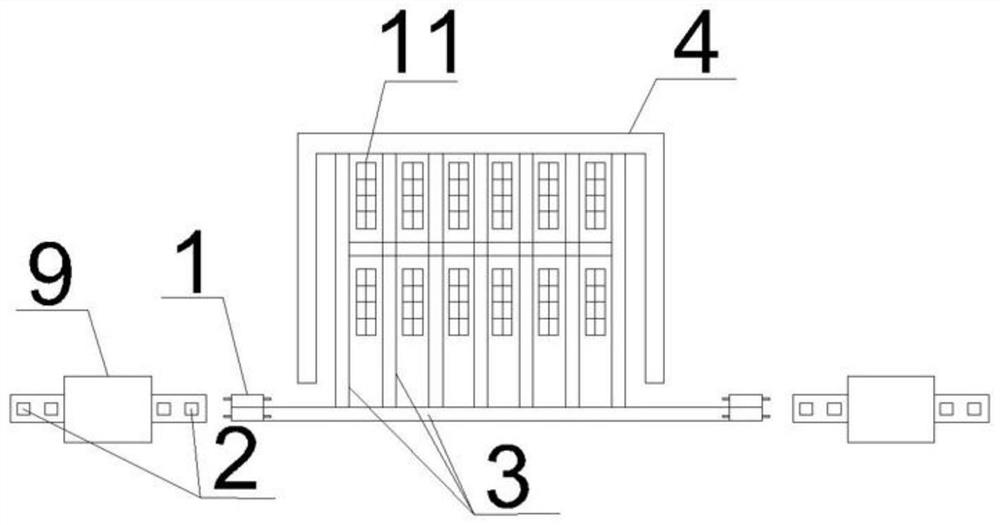

Automatic optimization energy-saving control system based on human body thermal comfort level and people number optimization grouping

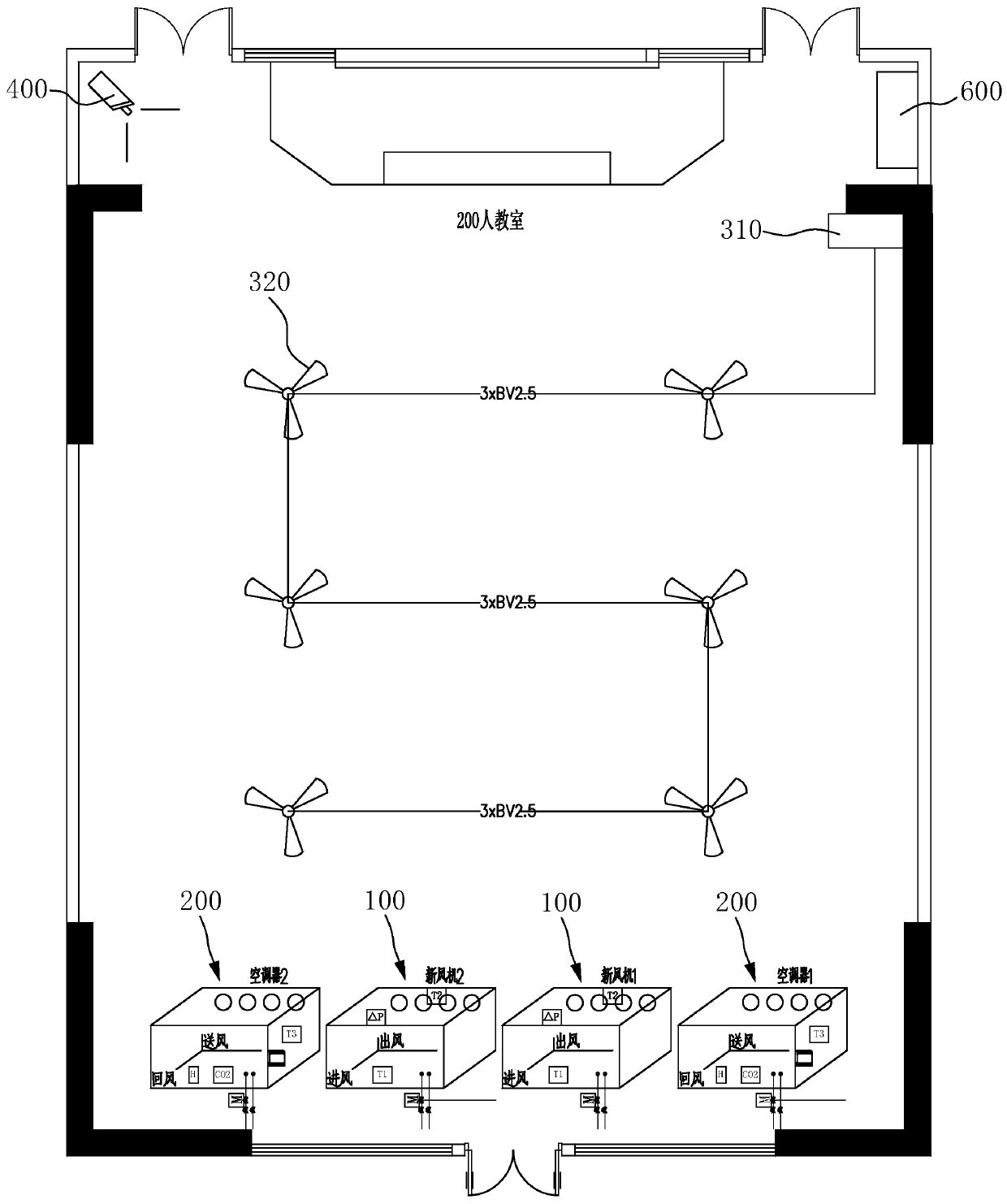

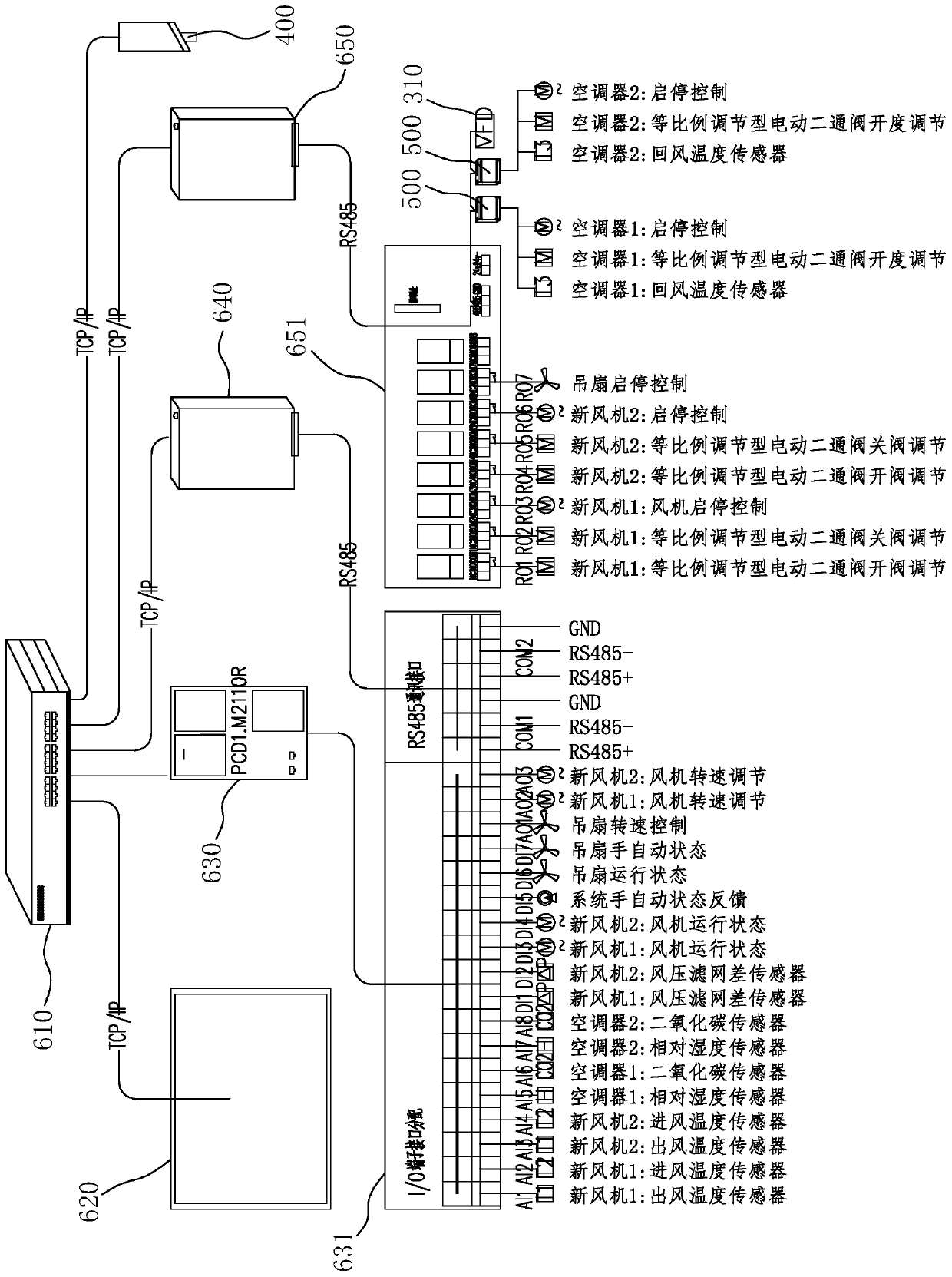

PendingCN111121258ASave running energySave on running energyMechanical apparatusSpace heating and ventilation safety systemsAutomatic controlControl system

The invention discloses an automatic optimization energy-saving control system based on the human body thermal comfort level and people number optimization grouping. The system comprises a fresh air ventilator, an air conditioner, a fan, a variable frequency speed regulation control box, an image camera, a laser matrix multipoint temperature detector, a variable flow controller and a full-automatic control cabinet. The fresh air ventilator is provided with an air inlet temperature sensor, a fresh air cold water coil, a fresh air stepless speed regulation fan and an air outlet temperature sensor. The air conditioner is provided with a relative humidity sensor, a carbon oxide sensor, an air return temperature sensor, an air conditioner cold water coil and an air conditioner stepless speed regulation fan. The image camera is used to recognize the number of people in an area. The laser matrix multipoint temperature detector is used to detect the shell temperature of a human body. The variable flow controller is connected to the air return temperature sensor, the air conditioner cold water coil and the air conditioner stepless speed regulation fan. The full-automatic control cabinet isconnected to the air inlet temperature sensor, the fresh air cold water coil, the fresh air stepless speed regulation fan, the air outlet temperature sensor, the relative humidity sensor, the carbon oxide sensor, the variable frequency speed regulation control box, the image camera, the laser matrix multipoint temperature detector and the variable flow controller.

Owner:WUYI UNIV +1

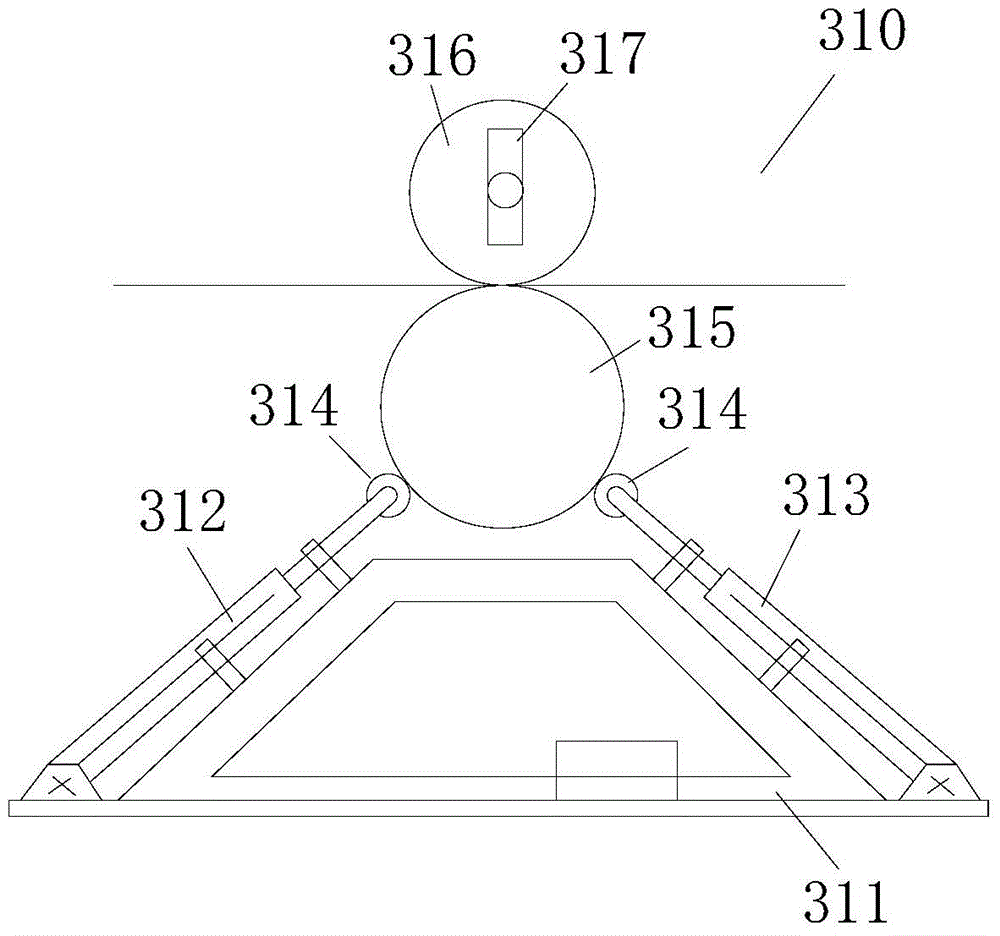

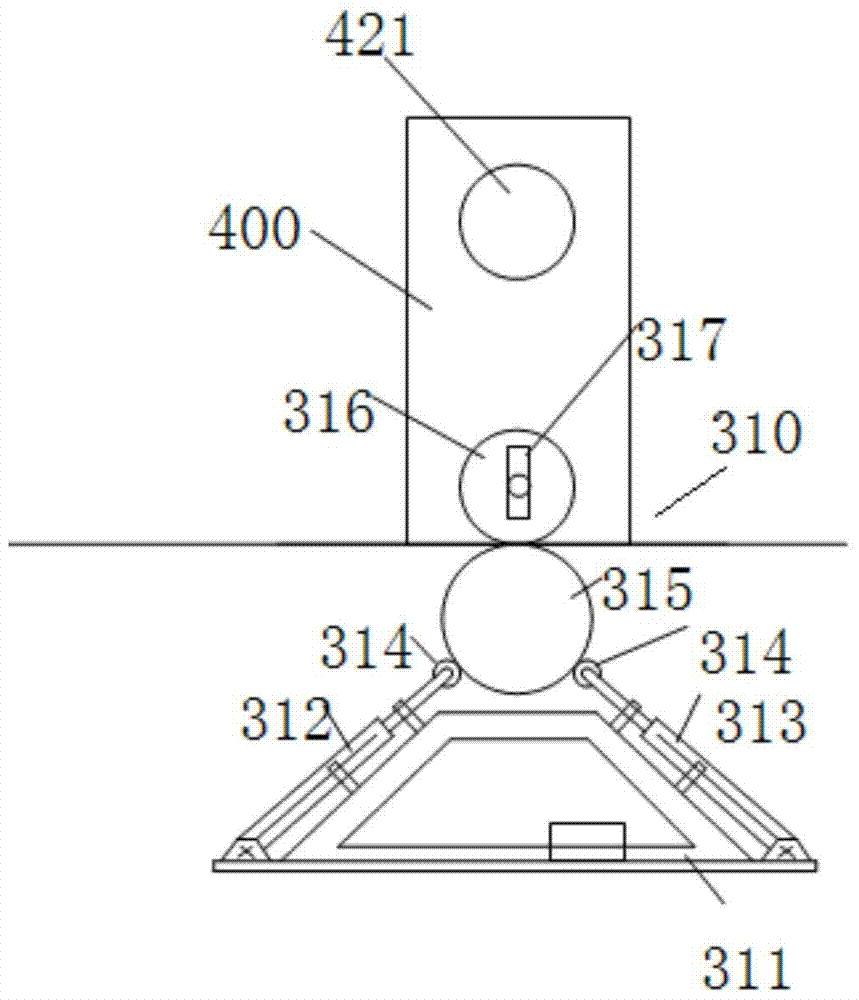

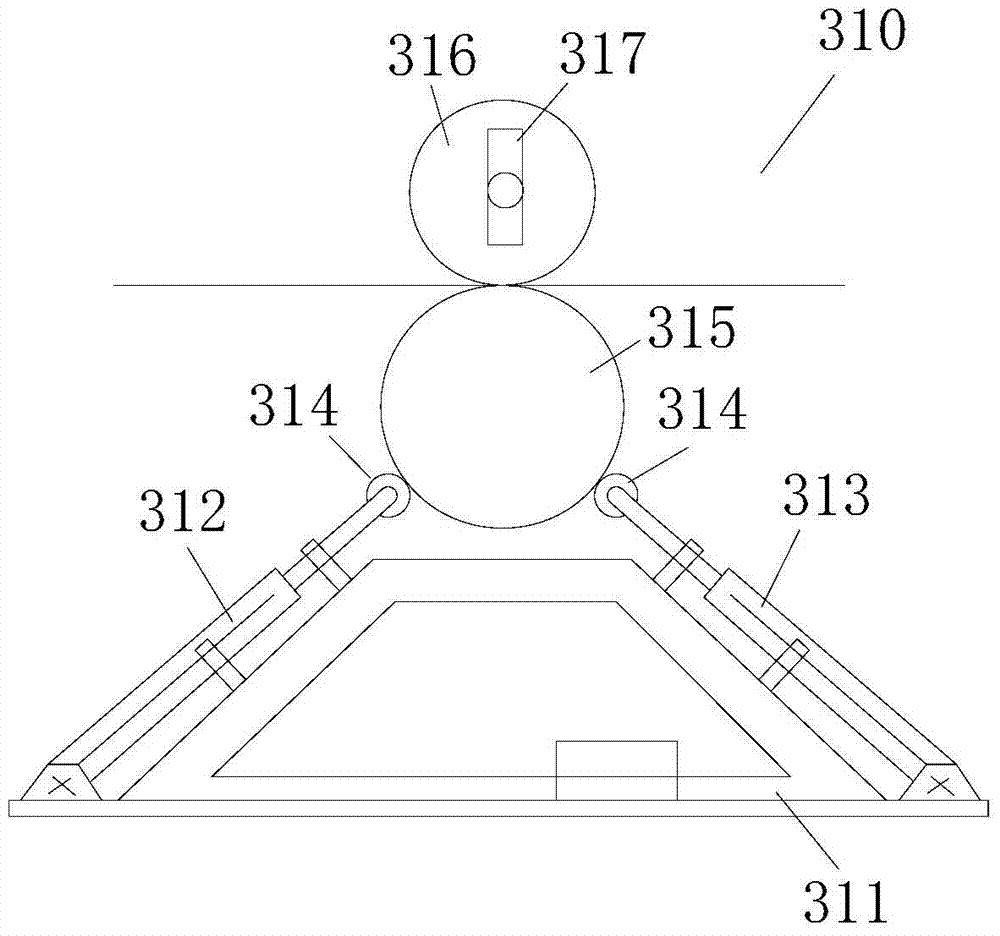

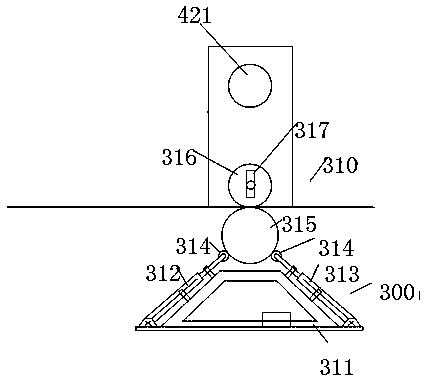

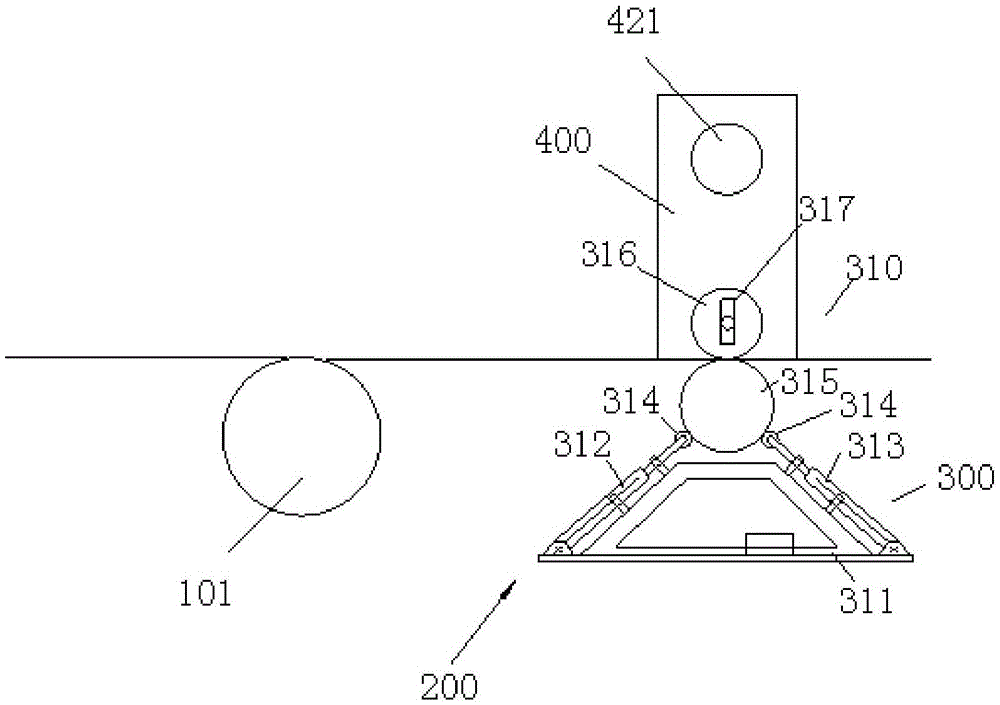

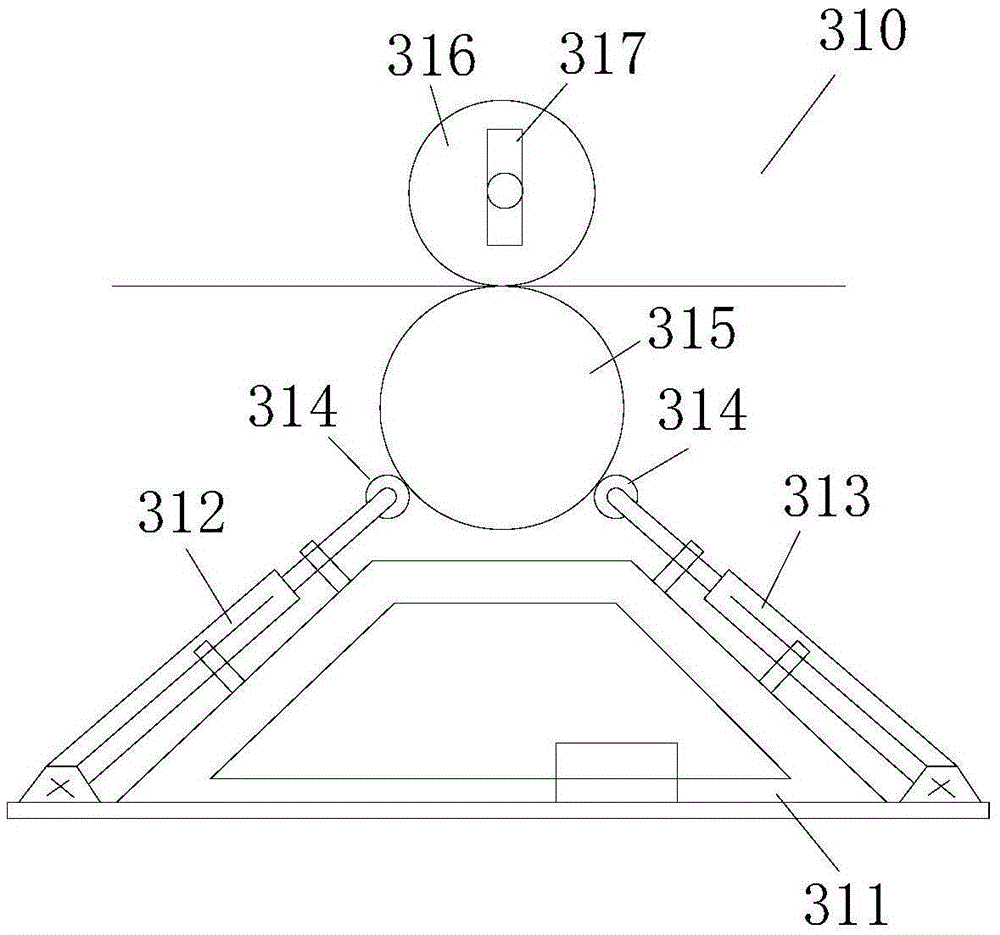

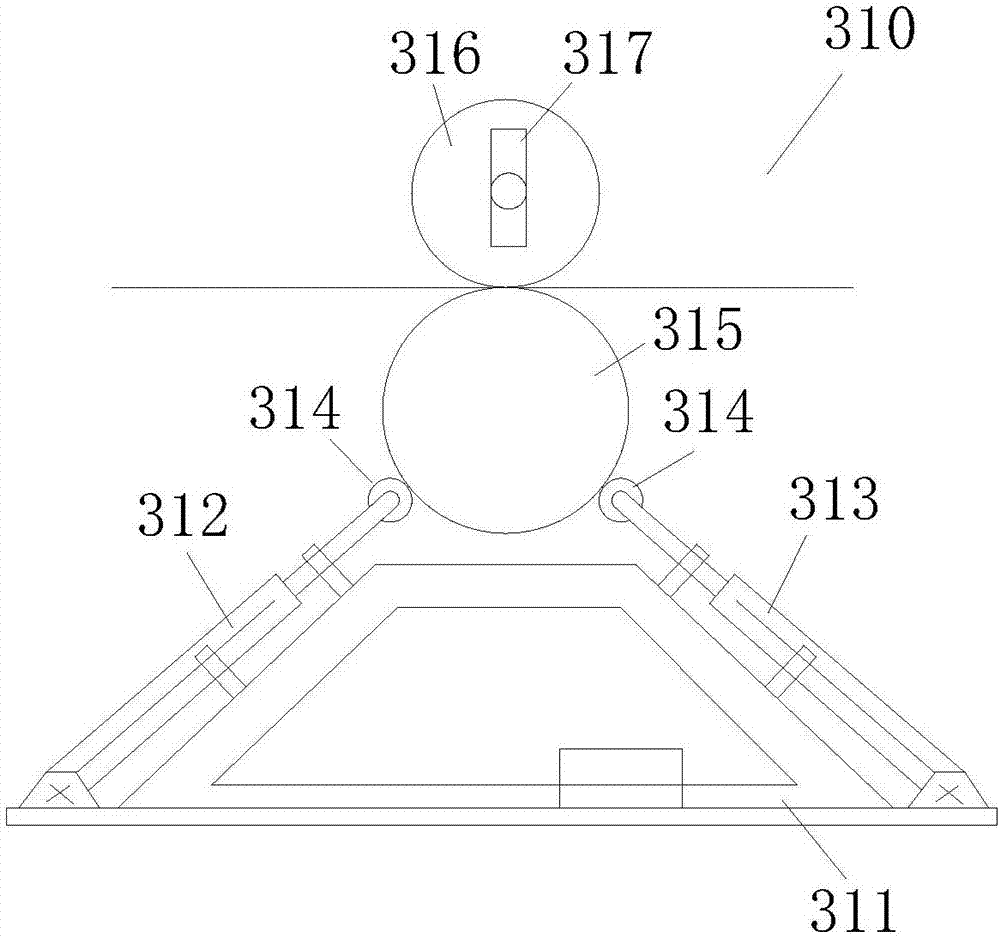

Hot press unit of silk winding and strip forming production device

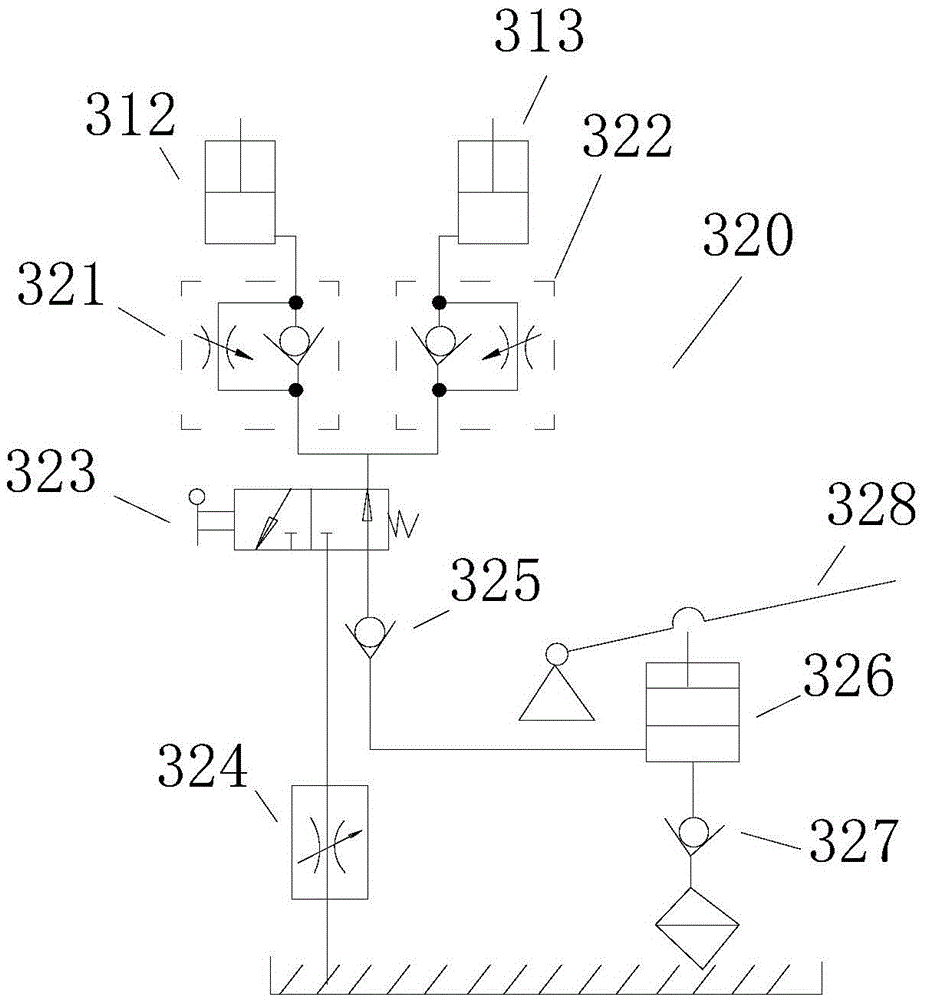

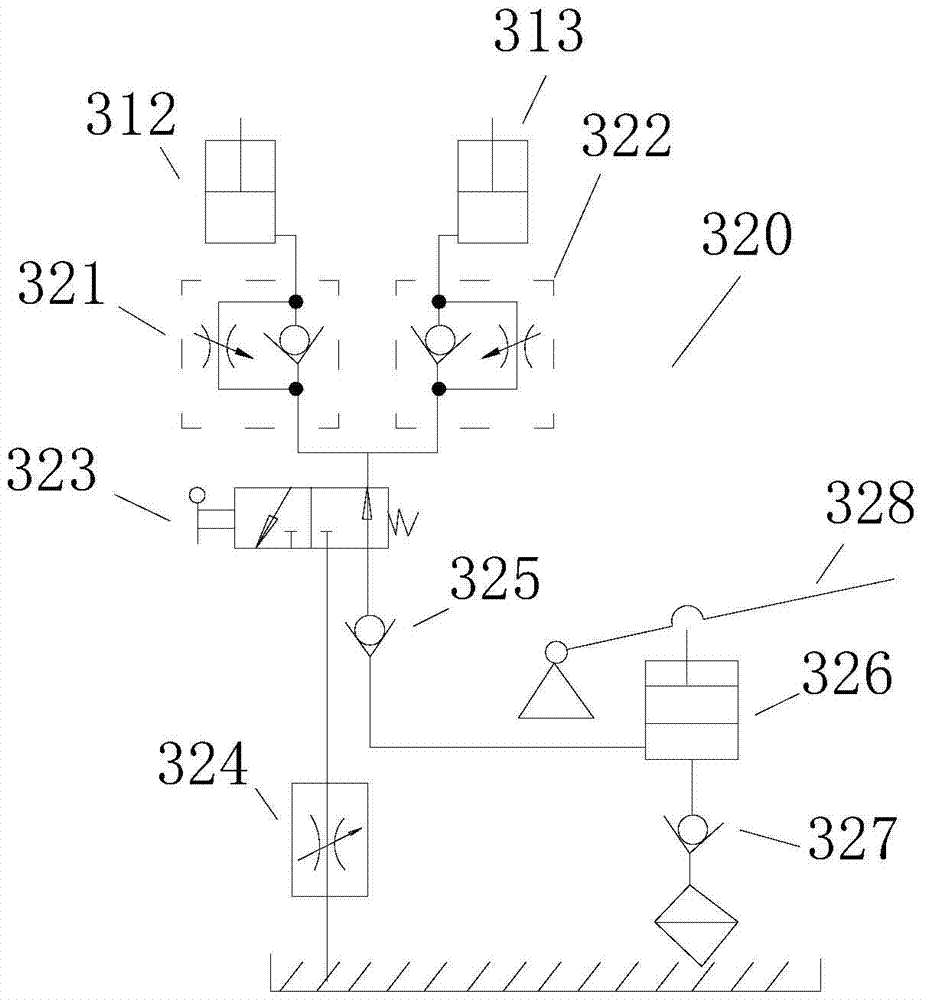

InactiveCN105483871AImprove the effect of hot pressingFit tightlyServomotor componentsServomotorsConductor CoilMobile device

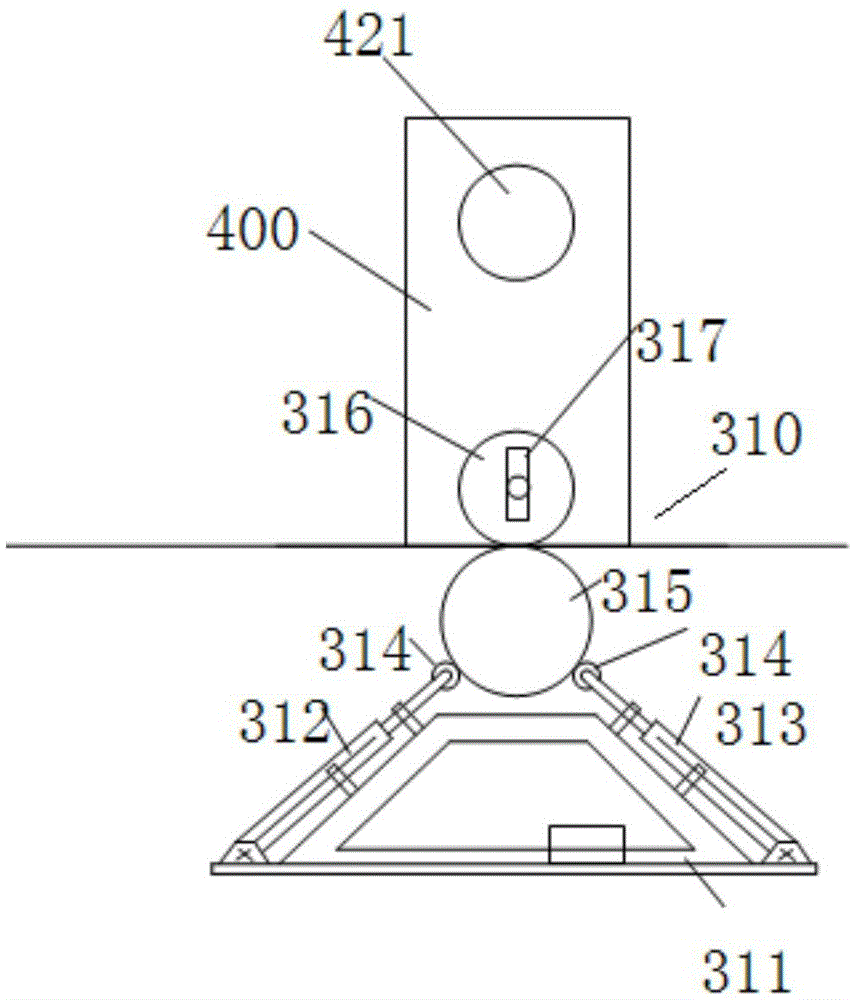

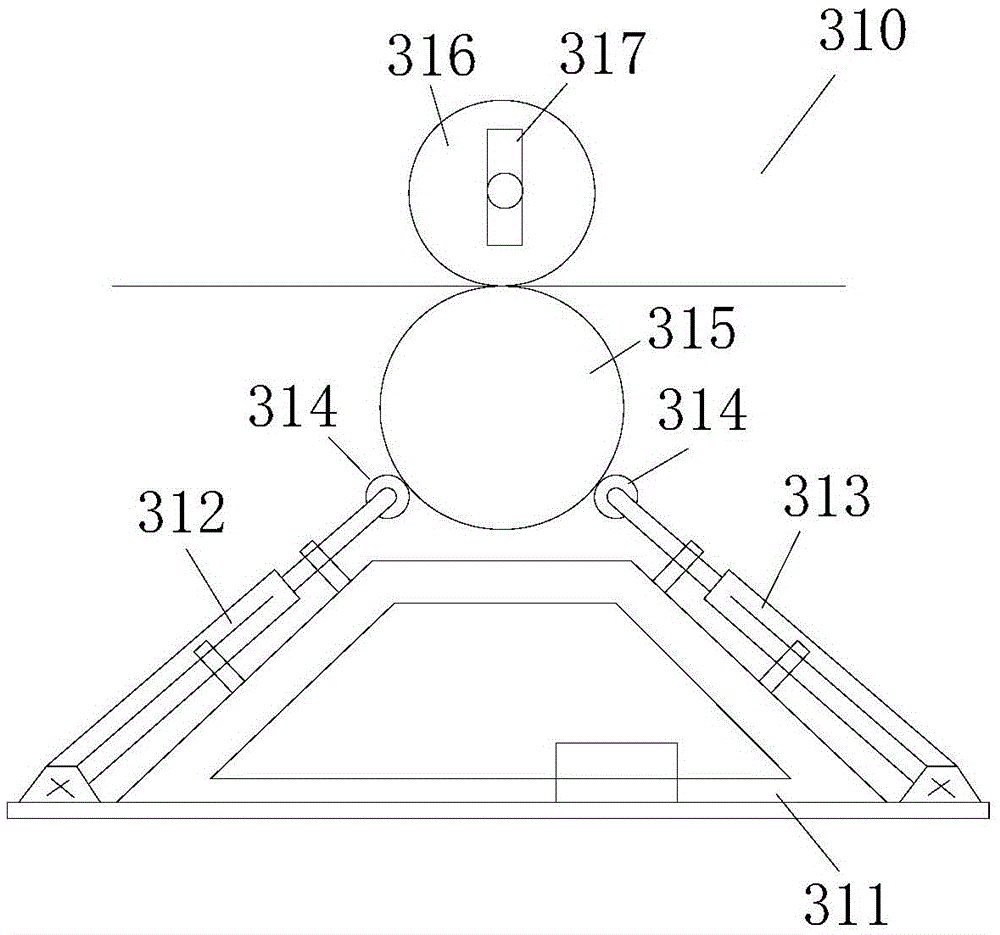

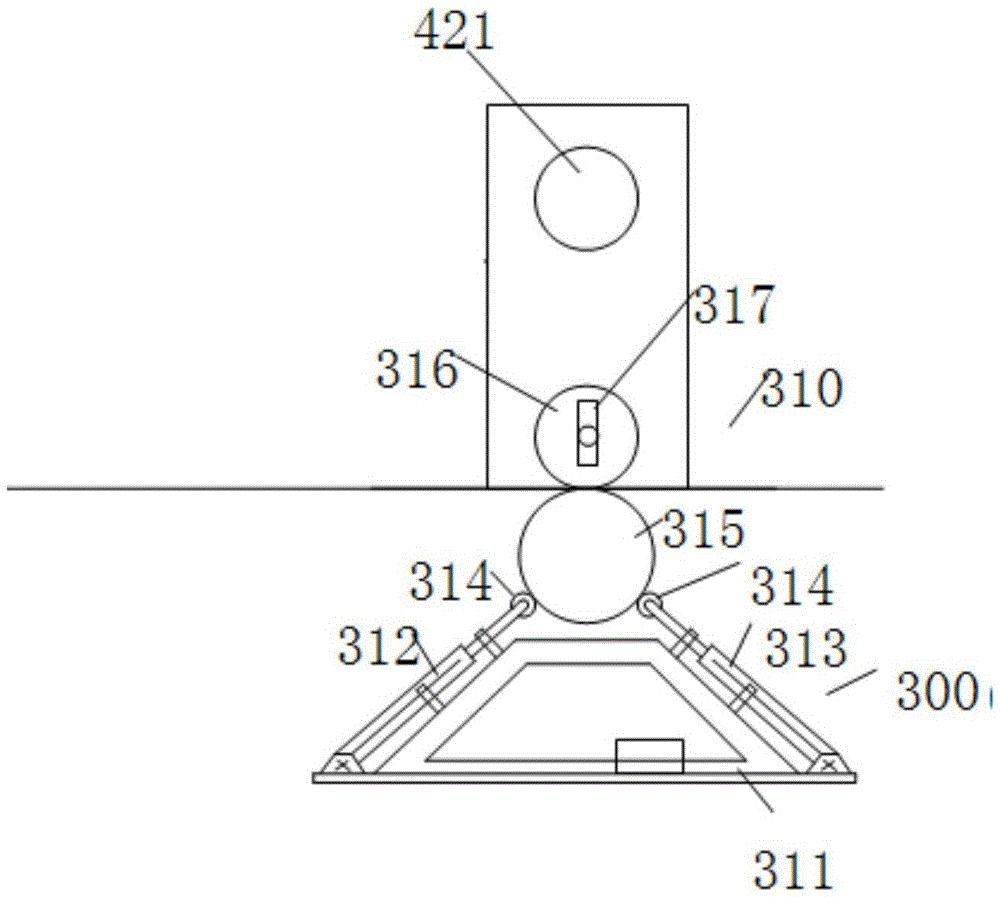

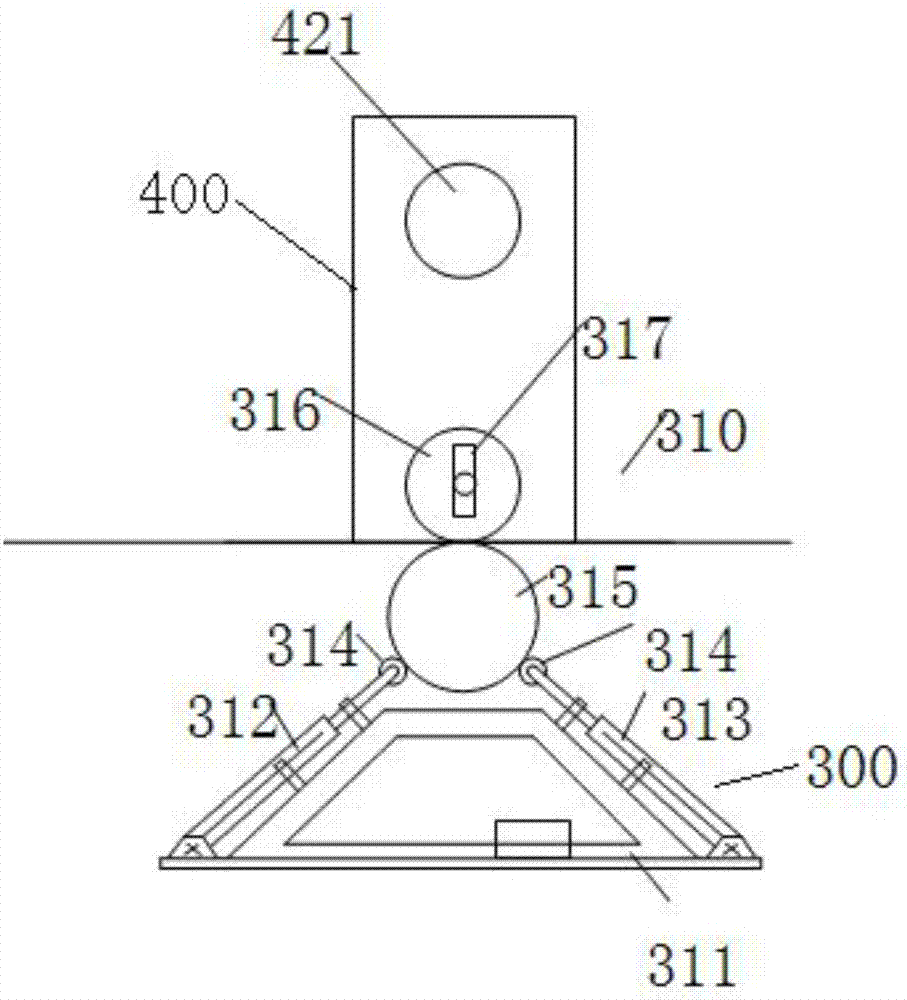

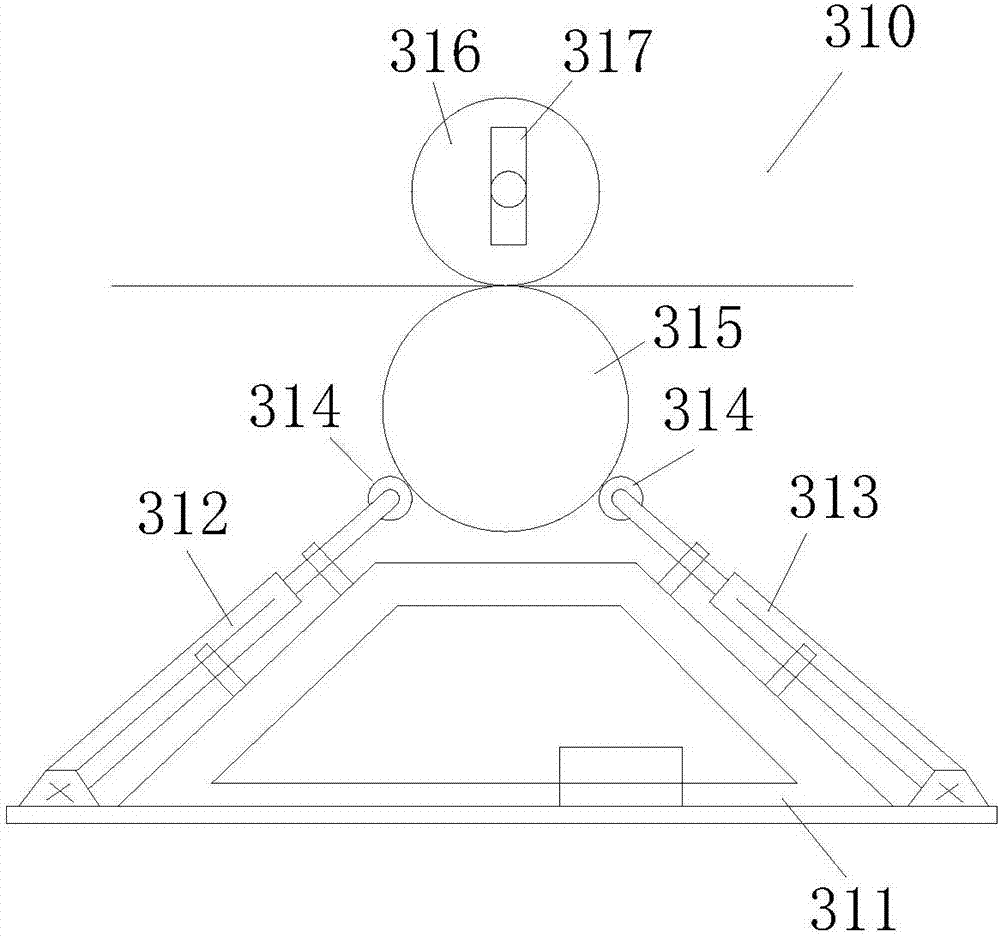

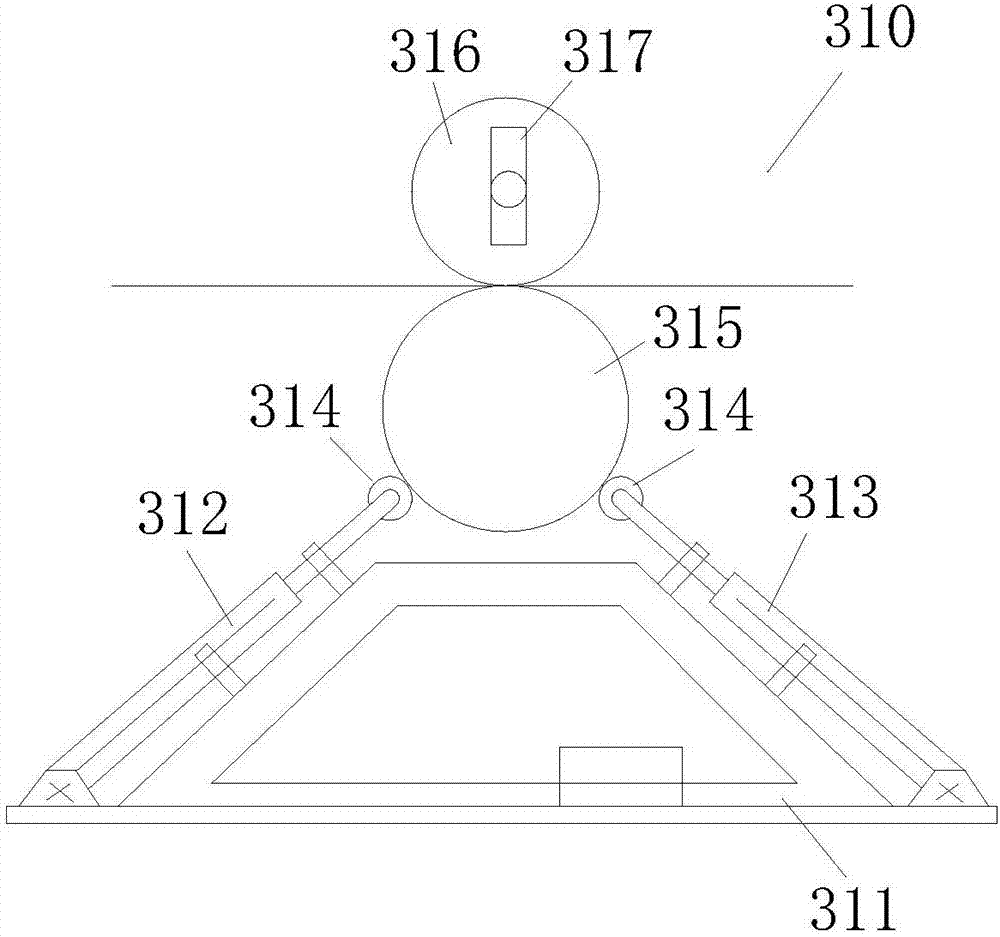

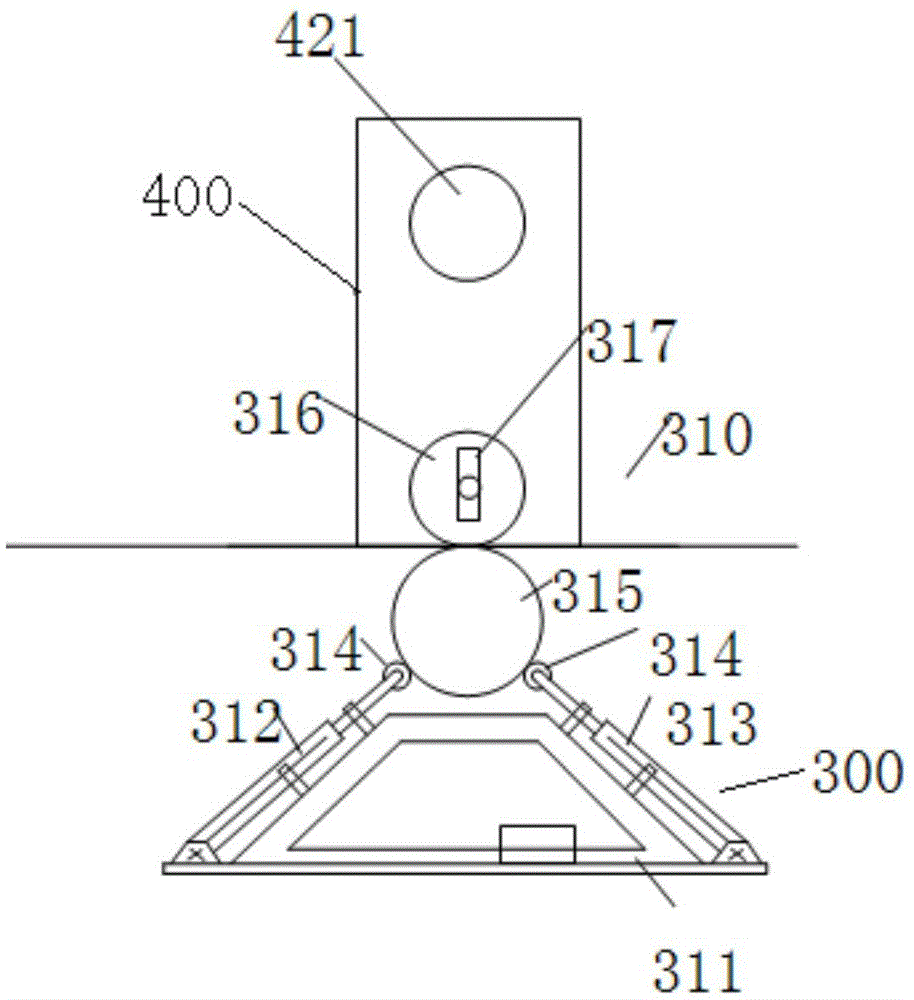

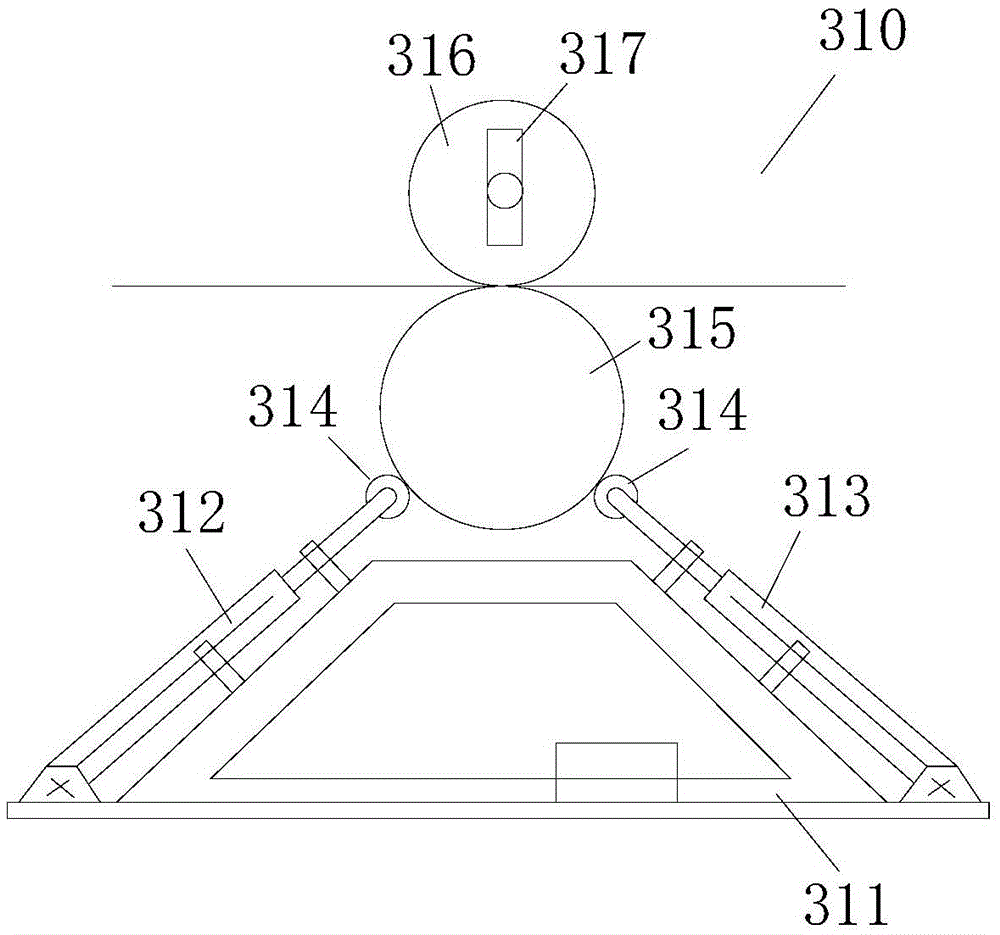

The invention discloses a hot press unit of a silk winding and strip forming production device. The hot press unit comprises a hot press mechanical part (310) and a hot press hydraulic part (320), wherein the hot press mechanical part (310) comprises a trapezoid base (311), a first lifting cylinder (312) and a second lifting cylinder (313) are arranged on two side surfaces of the base (311), rollers (314) are arranged at extending ends of the first lifting cylinder (312) and the second lifting cylinder (313), a compressing roller (315) is arranged above the rollers (314), a hot press roller (316) is arranged above the compressing roller (315), and mobile devices (317) are arranged at two shaft ends of the compressing roller (315). After silk enters a hot press mechanism, a treadle is stepped with corresponding amplitude according to different thicknesses of silk bundles, and then the compressing roller and the hot press roller can be tightly attached, so that the hot press effect of the silk is improved.

Owner:湖州南浔中兴丝织有限公司

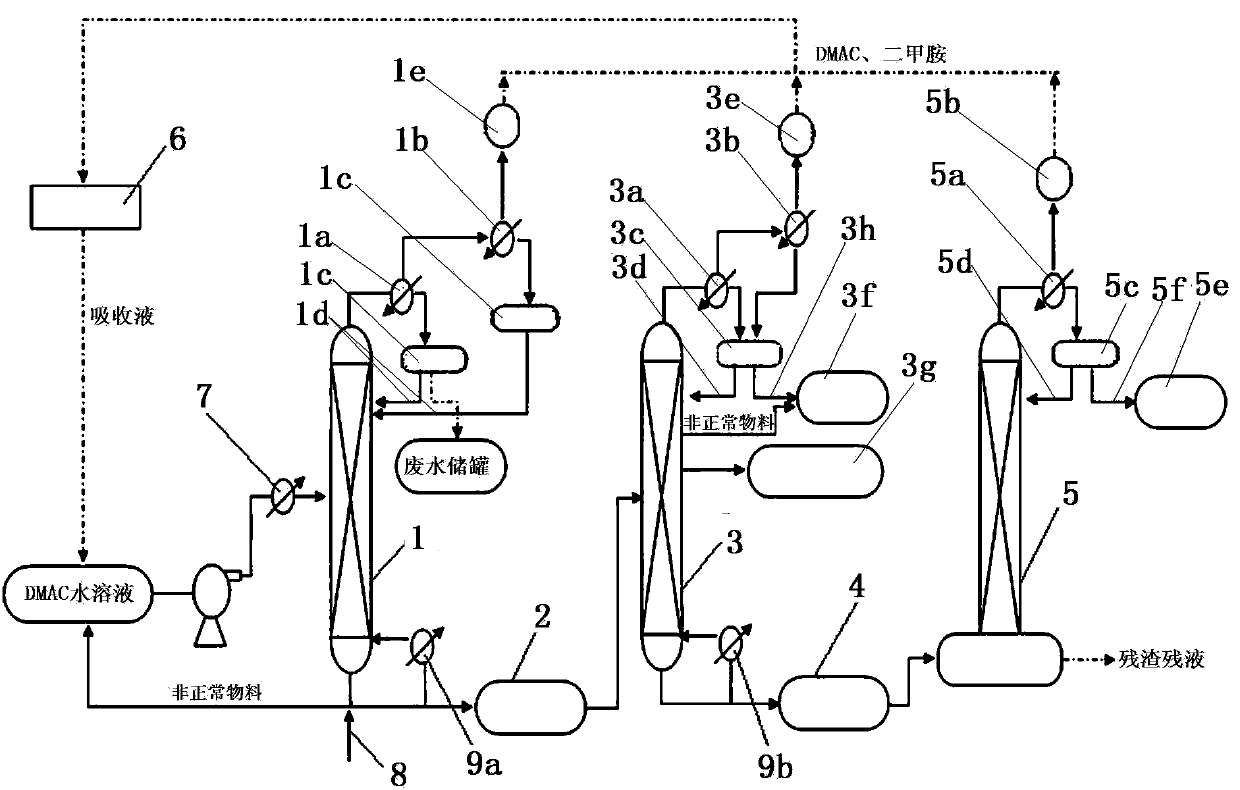

Physical index optimizing system for recycling DMAC (dimethylacetamide)

ActiveCN104043260AGood yieldAchieve recyclabilityCarboxylic acid amide separation/purificationFractional distillationDistillationPulp and paper industry

The invention relates to a physical index optimizing system for recycling DMAC (dimethylacetamide), which belongs to the technical field of spandex production. The physical index optimizing system for recycling DMAC comprises a dehydrating tower, a coarse solvent tank, a refining tower, a distillation still supplying tank and a recovery tower, wherein the dehydrating tower is connected with a feed pipe, the bottom of the dehydrating tower is communicated to the middle of the refining tower through the coarse solvent tank, and the bottom of the refining tower is communicated with the bottom of the recovery tower through the distillation still supplying tank; a preheater is connected to the middle of the dehydrating tower, and a No.1 condenser and a No.1 chiller are connected to the top of the dehydrating tower; a No.2 condenser and a No.2 chiller are connected to the top of the refining tower; a No.3 condenser is arranged on the top of the recovery tower, a No.3 condensate receiving tank is arranged on the No.3 condenser, and a No.3 vacuum pump is arranged on the top of the No.3 condenser. By adopting the physical index optimizing system to recycle DMAC in the process of spandex production, normal operation of a DMAC distillation system is guaranteed, and the yield and physical indexes of the recycled DMAC are greatly increased.

Owner:ZHEJIANG KAIPUTE SPANDEX

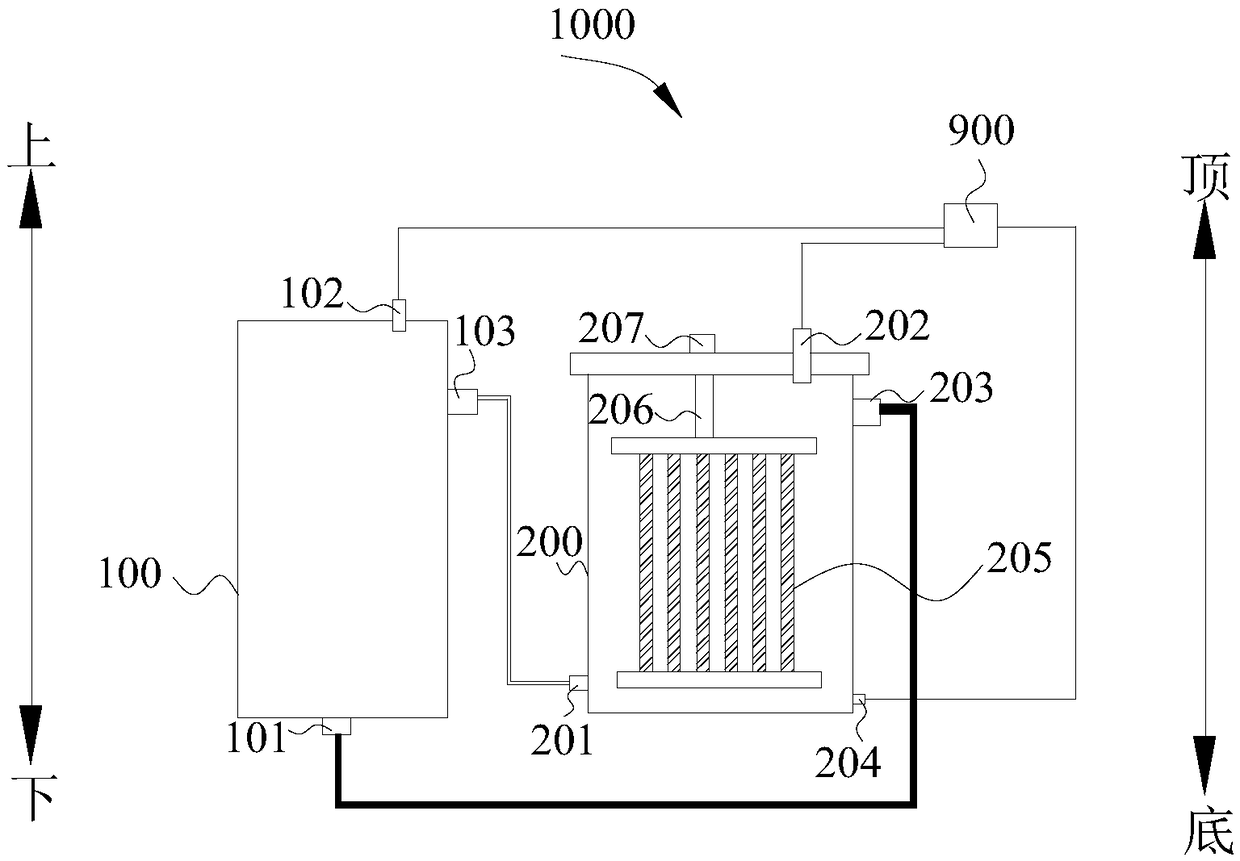

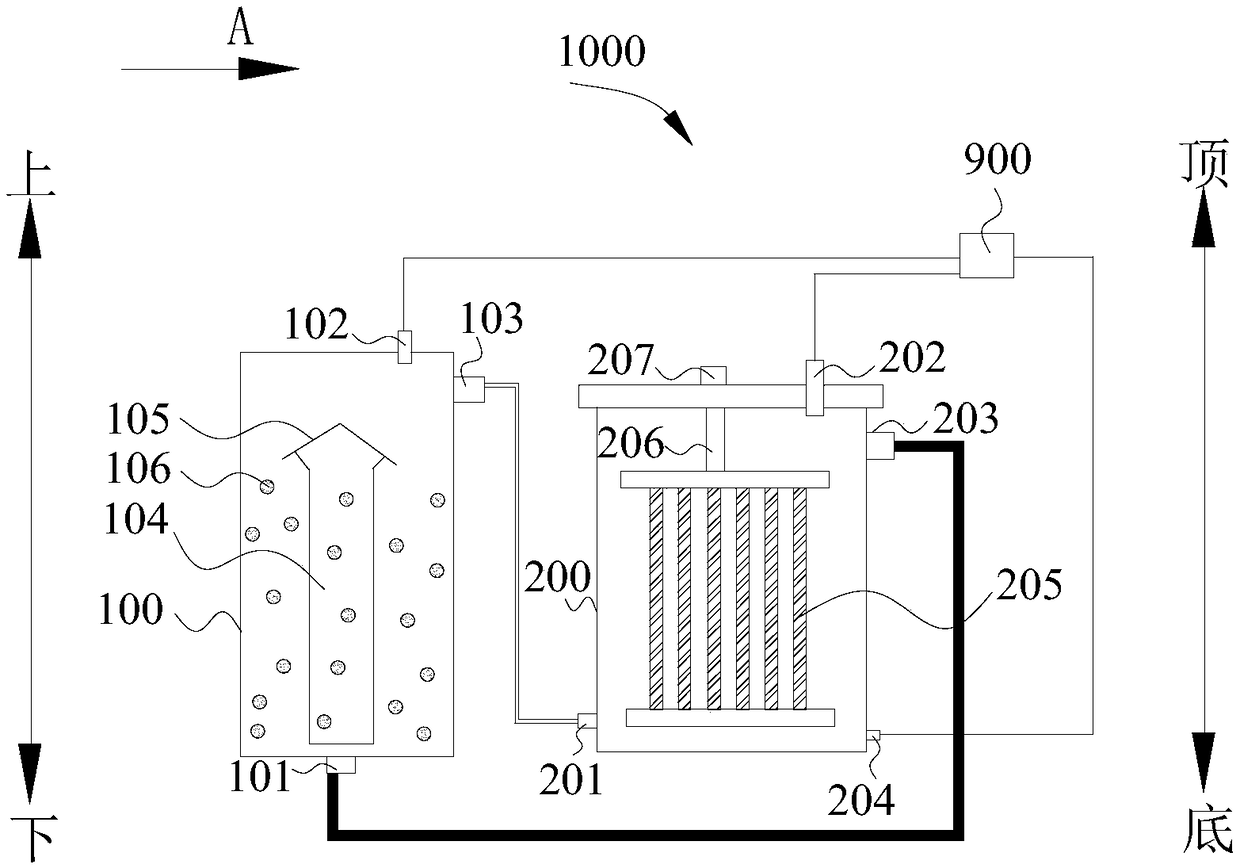

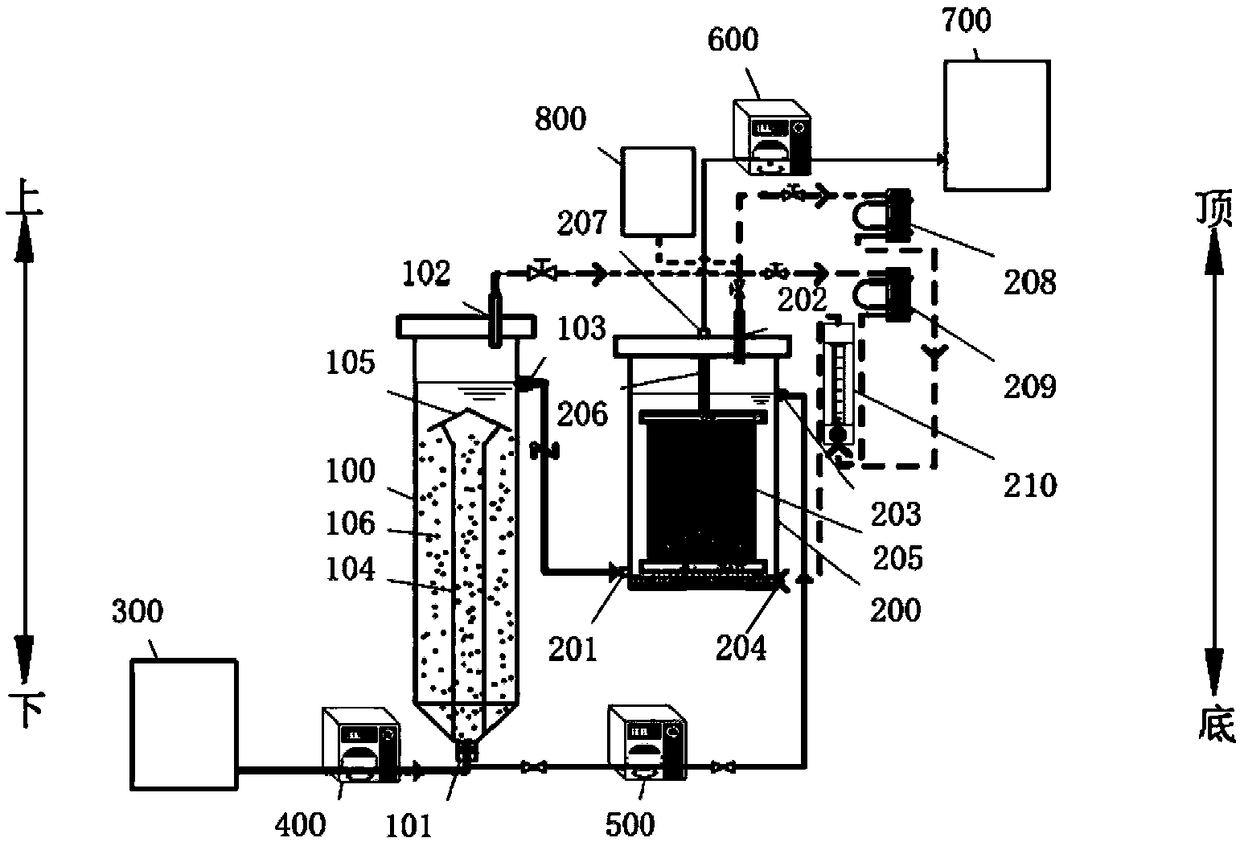

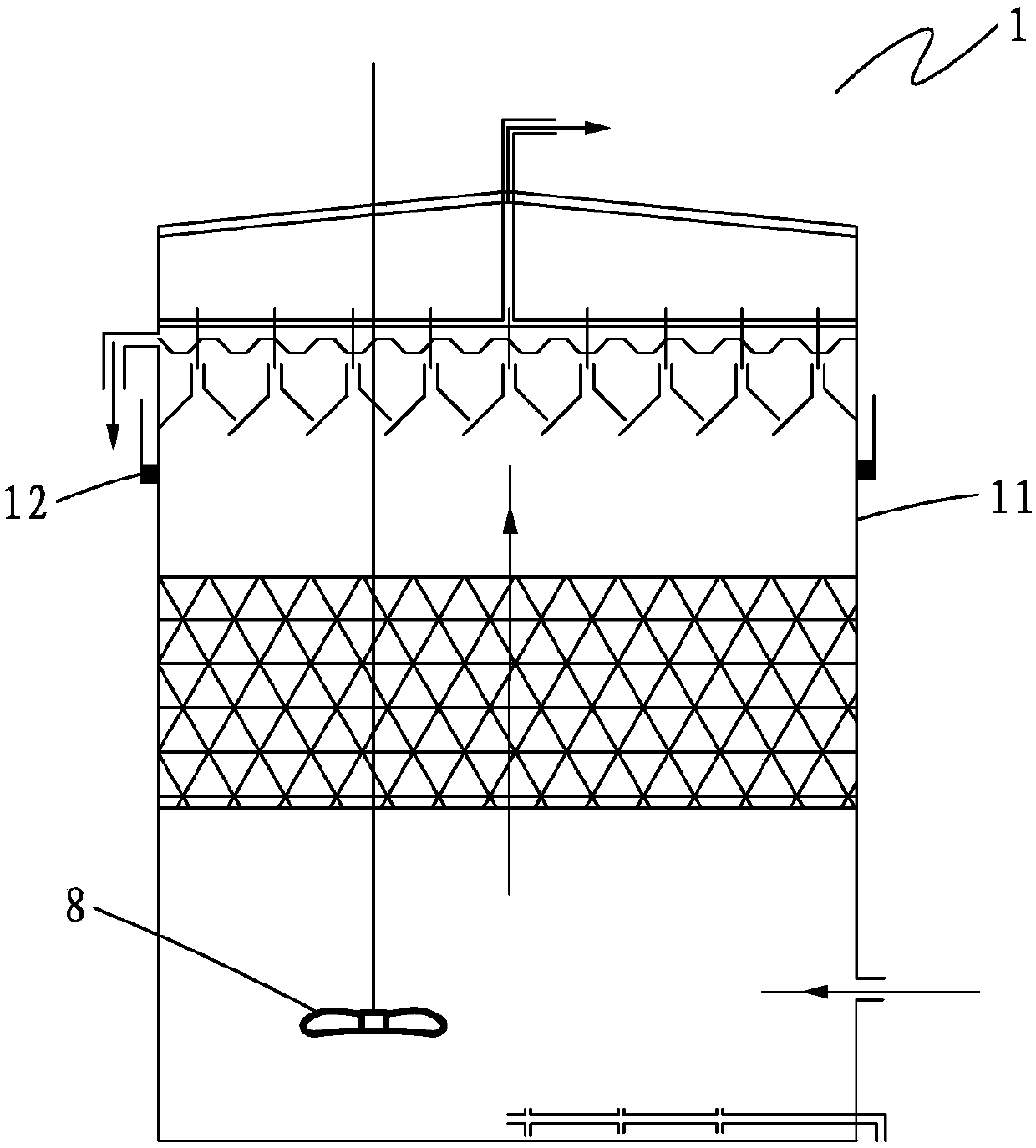

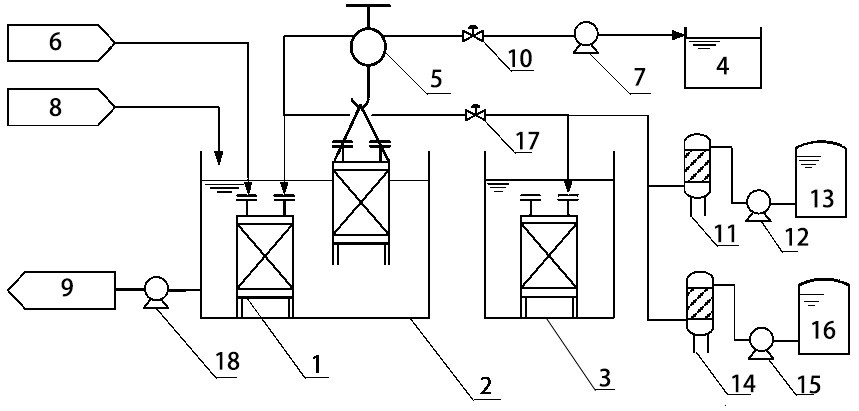

Sewage treatment device and sewage treatment method

PendingCN109052815AFluidized state is goodSave running costSpecific water treatment objectivesWater/sewage treatment bu osmosis/dialysisFluidized bedOperating energy

The invention discloses a sewage treatment device and a sewage treatment method. The sewage treatment device provided by the invention specifically comprises: an anaerobic fluidized bed having a firsthousing, the lower part of the first housing having a first water inlet port, the upper part of the first housing having a first water outlet port and a first gas outlet; a membrane filtration processing unit having a second housing, the lower part of the second housing having a second water inlet port and an aeration port, the upper part of the second housing having a second water outlet port and a second gas outlet, the second water inlet port being connected to the first water outlet port, a filter membrane component being arranged in the second housing, a water outlet port being arrangedat the top part of the filter membrane component, the water outlet port being connected to the second water outlet port, a return port being arranged at the side wall of the second housing, the returnport being arranged between the filter membrane component and the top part of the second housing, and the return port being communicated with the first water inlet port; and a biogas circulation unitrespectively connected to the first gas outlet and the second gas outlet, the unit being able to continuously supply gas to the aeration port. The sewage treatment device can reduce membrane pollution and reduce operating energy consumption.

Owner:TSINGHUA UNIV

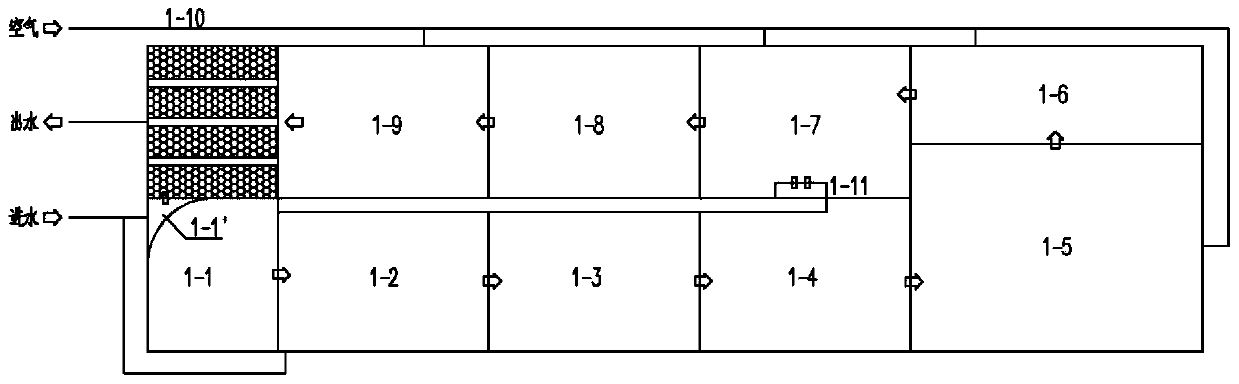

Biochemical treatment system for enhancing total nitrogen removal

PendingCN110734140AIncrease profitIncrease solid contentWater treatment parameter controlWater contaminantsOxygen tankSludge

The invention discloses a biochemical treatment system for enhancing total nitrogen removal. The biochemical treatment system comprises an anaerobic tank, an anoxic tank, an aerobic tank, a rear anoxic tank, a rear aerobic tank and a precipitation and concentration tank which are sequentially communicated. In a treatment method, sewage is introduced into the system from the anaerobic tank, is sequentially delivered through the anoxic tank, the aerobic tank, a slightly-dissolved oxygen tank, a buffer tank, the rear anoxic tank, the rear aerobic tank and the precipitation and concentration tankto be treated and then is discharged; wherein an oxygen elimination tank is arranged in the anaerobic tank, sewage is introduced into the system through the oxygen elimination tank of the anaerobic tank; a sludge reflux pump is arranged at the bottom of the precipitation and concentration tank, and an outlet of the sludge reflux pump is communicated to the oxygen elimination tank in the anaerobictank through a sludge discharge pipe and is used for refluxing sludge at the bottom of the precipitation and concentration tank to the oxygen elimination tank in the anaerobic tank for recycling; a mixed liquid reflux pump is arranged at the tail end of the aerobic tank, and an outlet of the mixed liquid reflux pump is communicated to the front end of the anoxic tank through a reflux channel and is used for refluxing mixed liquid at the tail end of the aerobic tank to the anoxic tank to be quickly mixed with sewage introduced into the anoxic tank.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

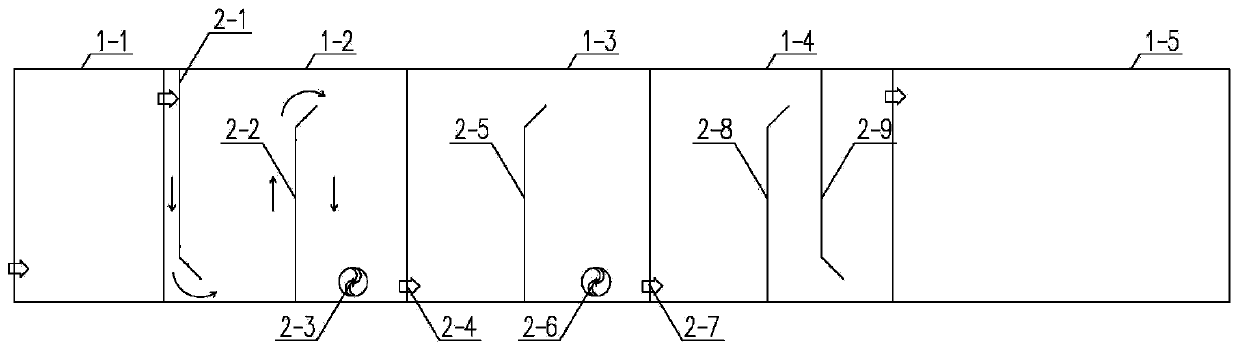

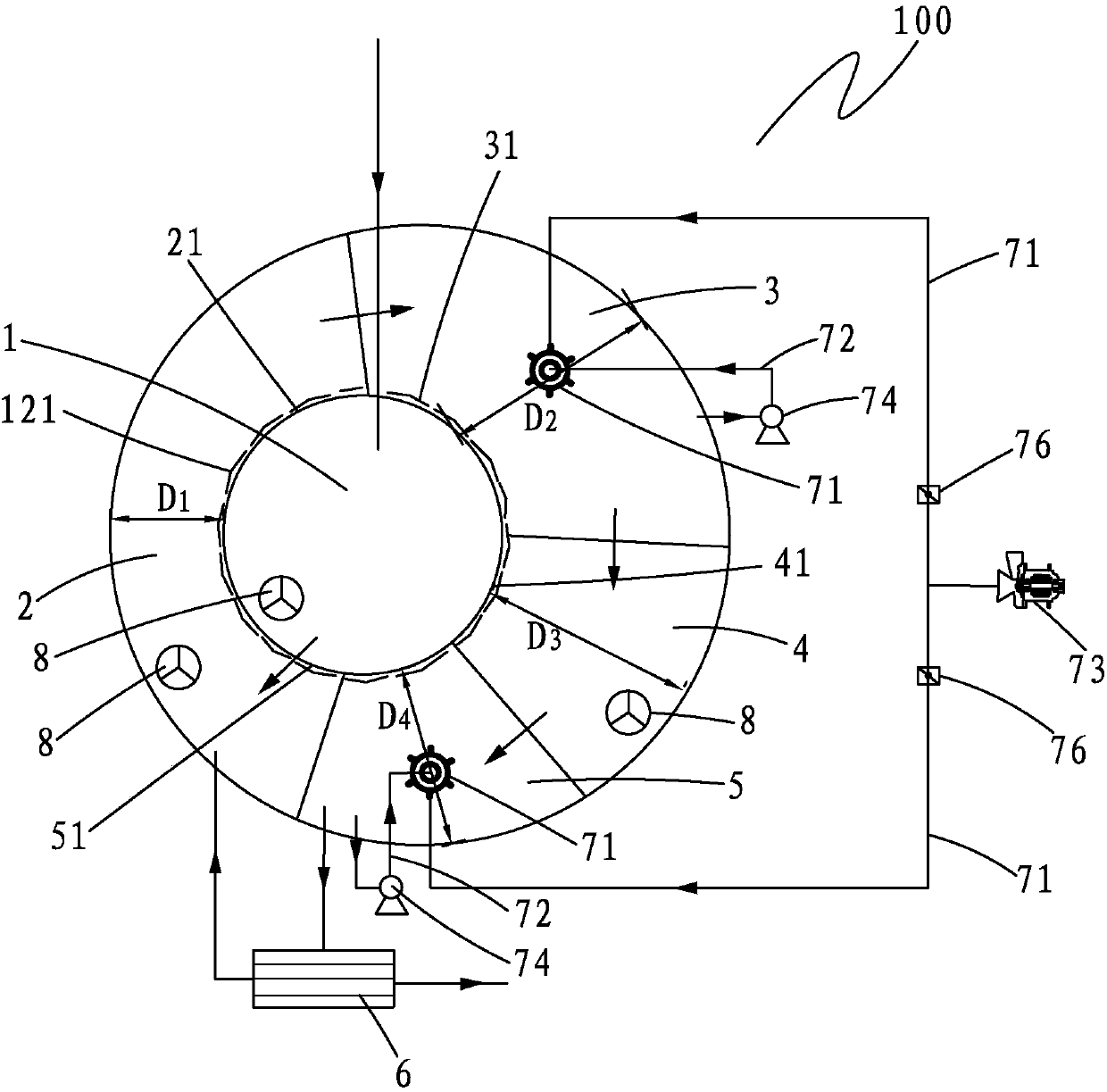

Landfill leachate biochemical treatment system

PendingCN107902853AWell mixedAvoid short circuitWater/sewage treatmentMultistage water/sewage treatmentWater flowEnvironmental engineering

The invention provides a landfill leachate biochemical treatment system. The system comprises an anaerobic reactor, a first-level denitrification pool, a first-level nitrification pool, a second-leveldenitrification pool, a second-level nitrification pool and an ultrafiltration device, wherein the first-level denitrification pool, the first-level nitrification pool, the second-level denitrification pool and the second-level nitrification pool are each attached to the anaerobic reactor, the first-level denitrification pool, the first-level nitrification pool, the second-level denitrification pool, and the second-level nitrification pool are circularly distributed with the anaerobic reactor as a center, so as to form an eccentric circle structure, the width of the center of the first-leveldenitrification pool is smaller than the center of any other nitrification pool, a tank of the anaerobic reactor is a heat conduction tank, and attachment surfaces between the denitrification pools aswell as the nitrification pools and the anaerobic reactor are all heat conduction surface layers. The landfill leachate biochemical treatment system lowers the probability of water flow dead ends, ensures that leachate is mixed fully, prevents water short circuit, has a better treatment effect of organic matters and total nitrogen, and reduces investment costs and running energy consumption.

Owner:GARDEN ENVIRONMENTAL PROTECTION

A method, system and device for controlling the running track of a quay crane container spreader

InactiveCN101665216BEasy to controlReduce running timeLoad-engaging elementsControl theoryMechanical engineering

Embodiments of the present invention disclose a method, system and device for controlling the running trajectory of a container spreader on a quayside crane. The method includes: acquiring a current position and a target position of the spreader to determine the running trajectory of the spreader; the position includes a horizontal direction position and vertical direction position, the running track is a straight line; the corresponding running speed is determined according to the running track and the requested output frequency of the driving device that controls the running speed; the running speed includes the horizontal running speed and the vertical running speed; according to The determined operating speed operates the spreader to the target position. Through the invention, the accurate control of the operation of the spreader is realized, the operation time is shortened, the operation energy is saved, and the accident rate is reduced.

Owner:SANY MARINE HEAVY IND

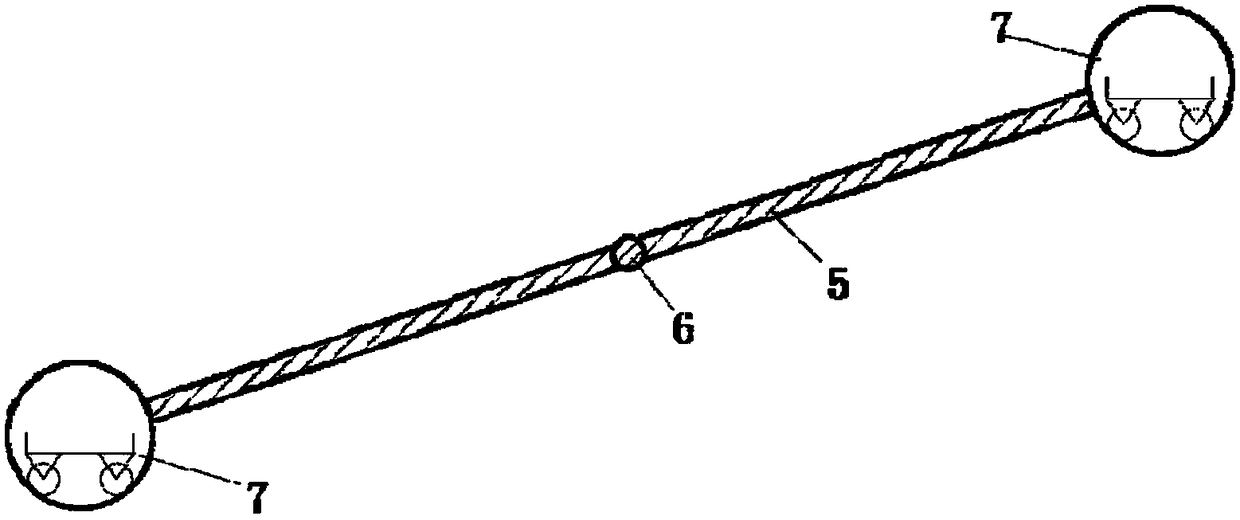

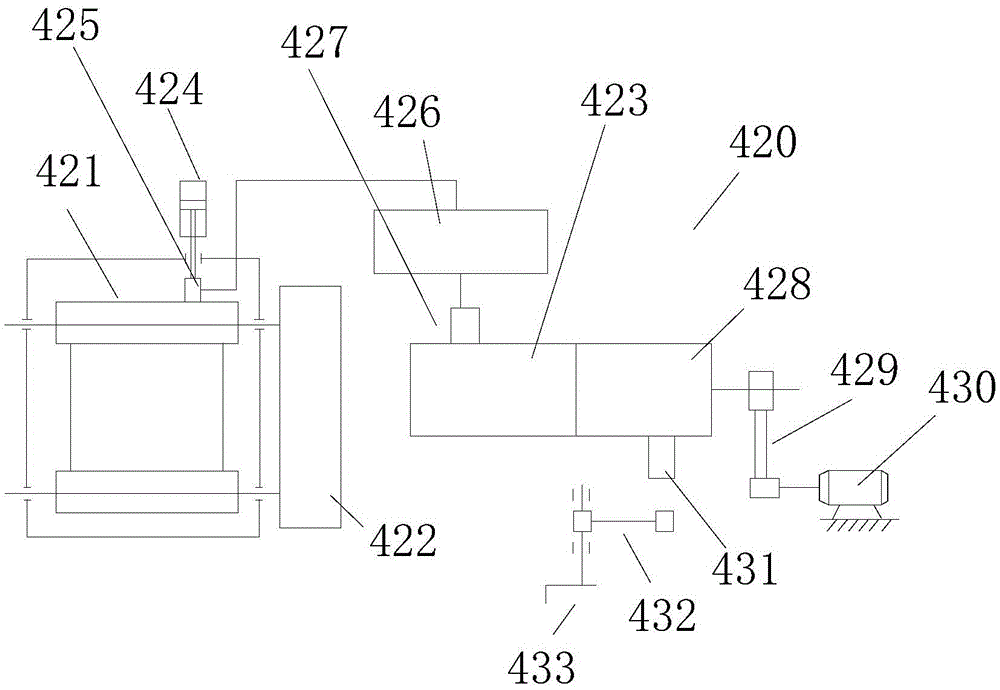

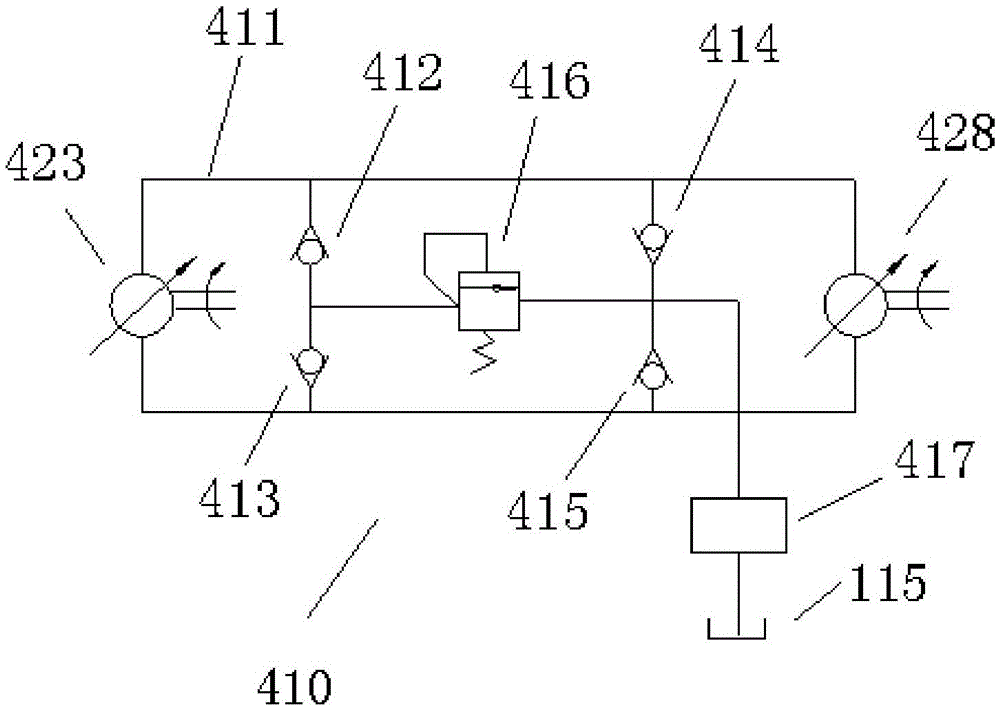

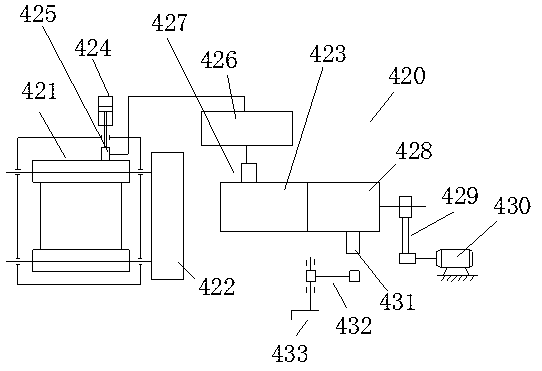

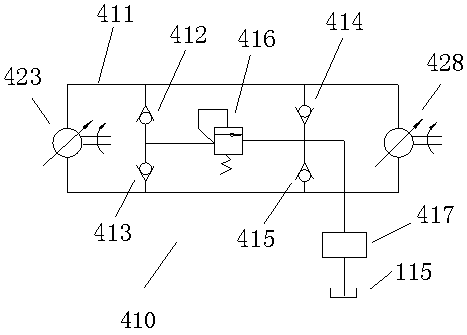

Silk winding unit of silk winding and strip forming production device

InactiveCN105483869ASave running energyCompact structureServomotor componentsServomotorsHydraulic motorClosed loop

The invention discloses a silk winding unit of a silk winding and strip forming production device. The silk winding unit comprises a silk winding hydraulic part (410) and a silk winding mechanical part (420), wherein the silk winding mechanical part (420) comprises a hot press roller (316), a rubber roller (421) is arranged beside the hot press roller (316), shafts of the rubber roller (421) and the hot press roller (316) are connected with a first transmission part (422), and the first transmission part (422) is connected with a silk winding hydraulic motor (423) through an output shaft. The silk winding unit adopts a volume-speed-control closed loop, realizes oil supplementation through a vacuum suction valve, adopts a simple oil line, and is compact in structure, large in speed regulating range and low in operation energy.

Owner:湖州南浔中兴丝织有限公司

Percolate and kitchen wastewater MBR system and process thereof

PendingCN113003713AMBR process integratedSave investmentSpecific water treatment objectivesSustainable biological treatmentAeration systemWater production

The invention discloses a percolate and kitchen wastewater MBR system and a process thereof, the percolate and kitchen wastewater MBR system comprises a water production system, a backwashing system and an aeration system, the water production system comprises a membrane box, a membrane pool, a membrane cleaning water pool, a water production tank, an electric hoist and a cleaning device. According to the invention, the combination mode of the biochemical system and the membrane system is optimally designed, so that the MBR process is more integrated; the curtain type membrane is directly arranged in the biochemical aeration tank, the aeration system not only performs oxygenation aeration on the biochemical tank, but also performs disturbance aeration on curtain type membrane filaments, and meanwhile, the surface of the curtain type membrane is self-cleaned and dredged by utilizing the action of transverse water flow, so that the equipment investment and the operation energy consumption are saved.

Owner:江苏激扬环境科技有限公司

Hot pressing unit of silk coiling and sliver production equipment

InactiveCN105483871BImprove the effect of hot pressingFit tightlyServomotor componentsServomotorsThermal compressionEngineering

The invention discloses a hot press unit of a silk winding and strip forming production device. The hot press unit comprises a hot press mechanical part (310) and a hot press hydraulic part (320), wherein the hot press mechanical part (310) comprises a trapezoid base (311), a first lifting cylinder (312) and a second lifting cylinder (313) are arranged on two side surfaces of the base (311), rollers (314) are arranged at extending ends of the first lifting cylinder (312) and the second lifting cylinder (313), a compressing roller (315) is arranged above the rollers (314), a hot press roller (316) is arranged above the compressing roller (315), and mobile devices (317) are arranged at two shaft ends of the compressing roller (315). After silk enters a hot press mechanism, a treadle is stepped with corresponding amplitude according to different thicknesses of silk bundles, and then the compressing roller and the hot press roller can be tightly attached, so that the hot press effect of the silk is improved.

Owner:湖州南浔中兴丝织有限公司

Movable integrated carbon dioxide precooler

InactiveCN111981721AMeet the needs of the first pre-coolingCompact structureCompression machinesFluid circulation arrangementVapor–liquid separatorEngineering

The invention discloses a movable integrated carbon dioxide precooler, and relates to the technical field of refrigeration equipment. The system comprises a heat preservation box body, and a compressor, an air-cooled condenser, a first liquid storage device, a first heat exchanger, a gas-liquid separator, a second heat exchanger, a second liquid storage device, an evaporator, a first fan and a material conveying belt which are arranged in the heat preservation box body; the material conveying belt extends from the feeding hole to the discharging hole; the compressor, the air-cooled condenser,the first liquid storage device, the first channel, the third channel and the gas-liquid separator are sequentially communicated, and the liquid outlet end of the gas-liquid separator is communicatedwith the liquid inlet end of the compressor to form refrigerant flowing circulation; and the fourth channel is communicated with the second liquid storage device, and the second liquid storage deviceis communicated with the evaporator to form carbon dioxide flow circulation. The integrated design is adopted, the structure is compact, moving and transporting are convenient, the requirement for rapid pre-cooling of fruits and vegetables can be met, a carbon dioxide refrigerant is environmentally friendly, the refrigerating capacity per unit volume is high, the refrigerating efficiency can be improved, energy consumption is reduced, and the equipment size is reduced.

Owner:浙江英诺绿能科技有限公司

Automatic waste storage system based on unmanned forklift

PendingCN114004561ASave running energyLow running costEnergy industryForecastingStorage managementMechanical engineering

An automatic waste storage system based on an unmanned forklift, disclosed by the present invention comprises an electric forklift, a hazardous waste containing box, a forklift track, an automatic storage warehouse and a storage management unit, an RFID tag is arranged on the hazardous waste containing box, and an RFID reader-writer is arranged on the electric forklift; a wireless signal transmitter is arranged in the RFID reader-writer, and the storage management unit is connected with a wireless signal receiver; the storage management unit comprises a processing module, a storage module and a circuit control module, the automatic storage warehouse is composed of a storage goods shelf and a storage area, the storage module stores a waste type storage table, and the processing module is used for calculating a path from the starting position of the electric forklift to the automatic storage warehouse; the circuit control module is used for controlling the advancing direction of the electric forklift on the forklift track. According to the present invention, a large amount of operation energy of the electric forklift is saved, it is ensured that the operation cost of the whole system is reduced to the minimum, and the operation efficiency of the whole system is improved.

Owner:上海詹知信息科技有限公司

Treatment device for removing sulfur and organic matters from industrial sewage

InactiveCN106830413AGood removal effectEasy to handleWater contaminantsMultistage water/sewage treatmentSulfur containingPollution

The invention belongs to an industrial sewage treatment technology, and relates to a treatment device for removing sulfur and organic matters from industrial sewage. Three stages of reaction tanks and three solid-liquid separation tanks are connected in sequence in a spacing manner; chlorine is fed into the first and second stages of reaction tanks; hydrogen chloride gas is fed into the third stage of reaction tank; under a condition of continuous stirring, chlorine is fed into the reaction tank with sulfur-containing waste water; the waste water is subjected to solid-liquid separation after being subjected to oxidization treatment of the chlorine, so that solid residues and filtrate are obtained; during third-stage treatment, the hydrogen chloride gas is fed; salt is separated out of chlorine salt-containing waste water. Non-reacted chlorine is absorbed by alkaline liquid, so as to prevent secondary pollution; the solid residues are washed with water to obtain elemental sulfur. The treatment device can work under normal pressure, and also can separate and recycle the produced elemental sulfur when efficiently removing sulfides and organic matters from the industrial waste water.

Owner:天津德人生态环境科技集团有限公司

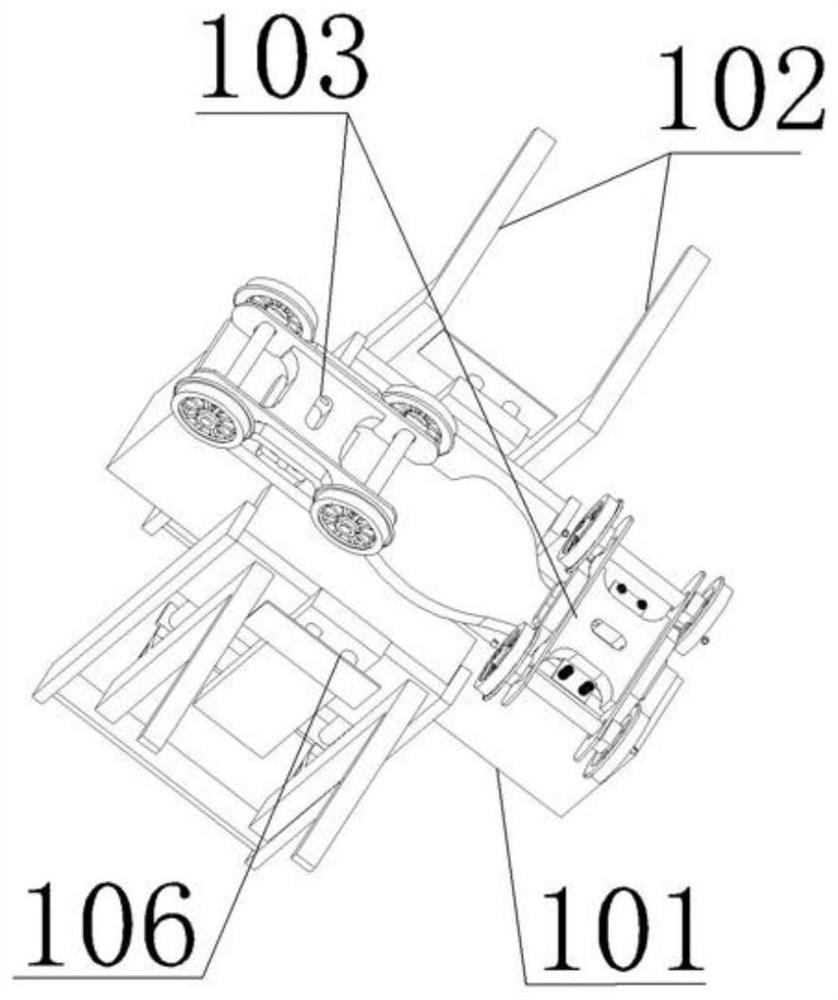

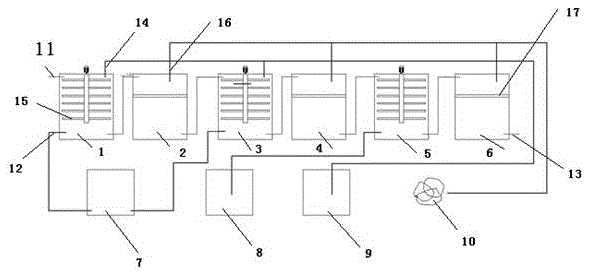

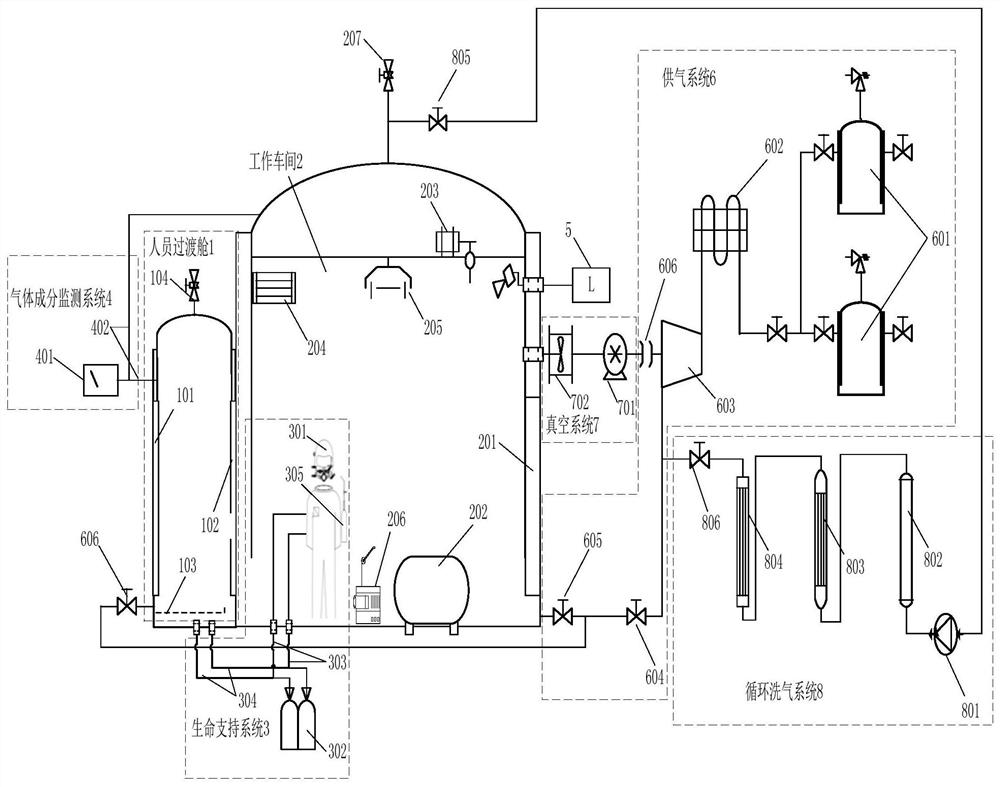

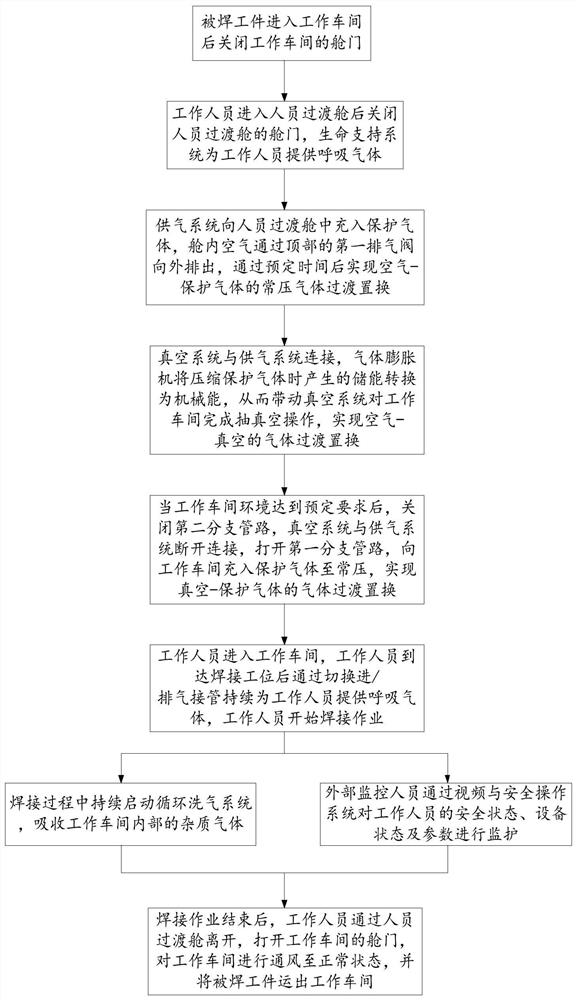

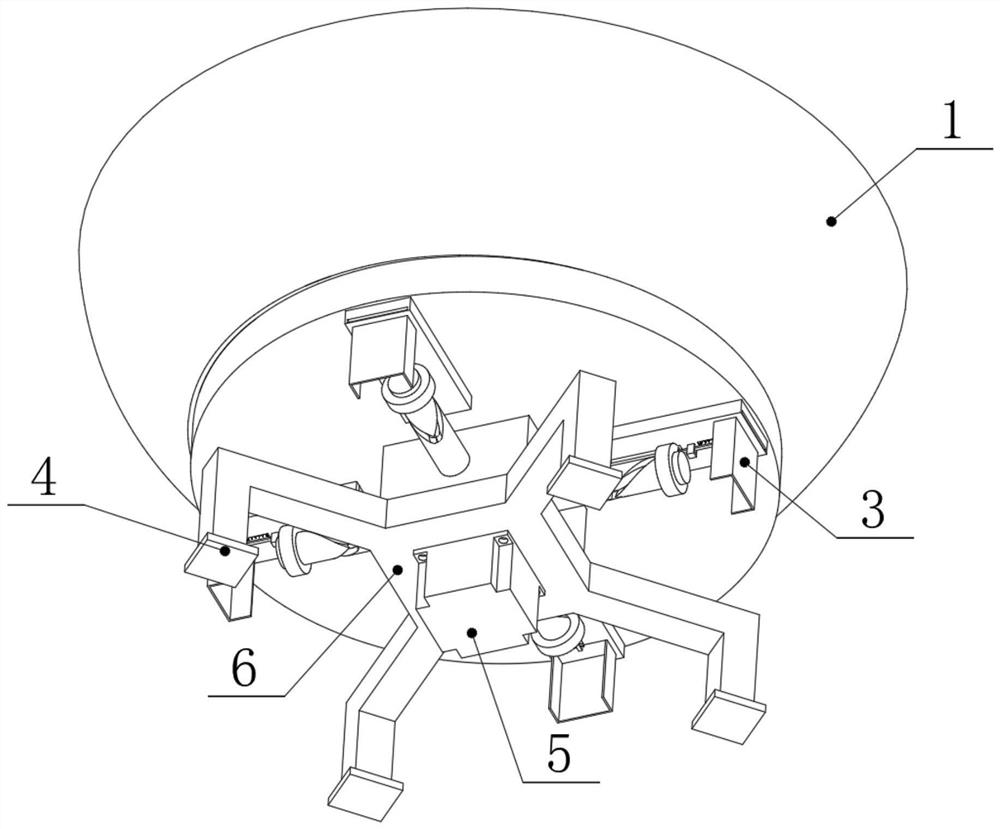

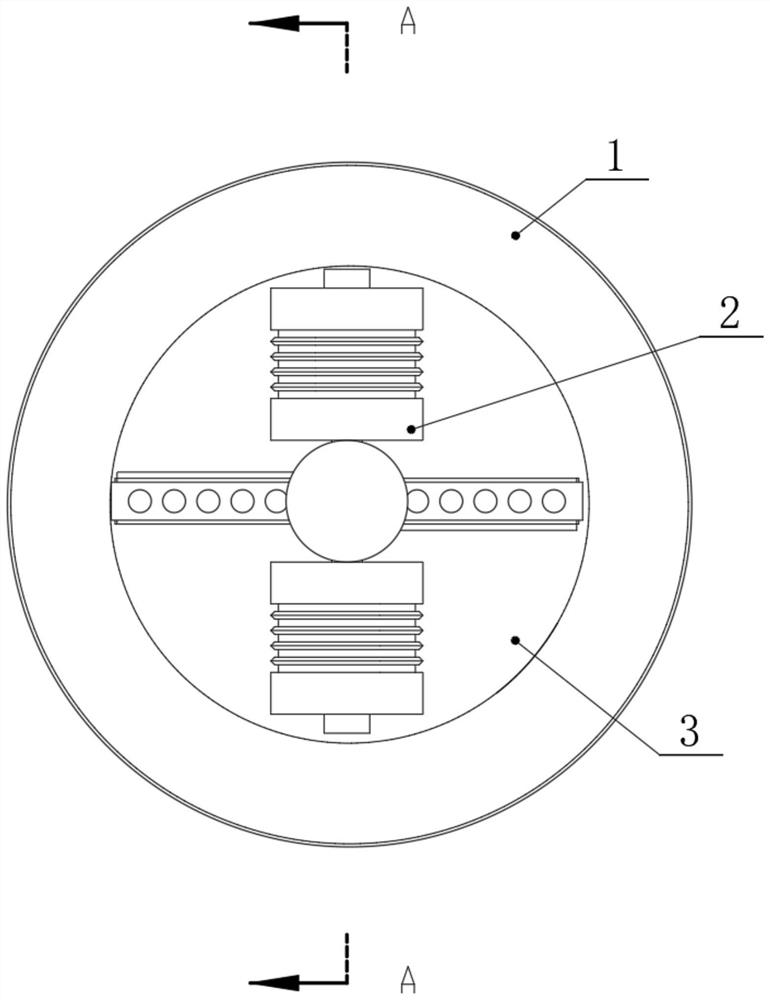

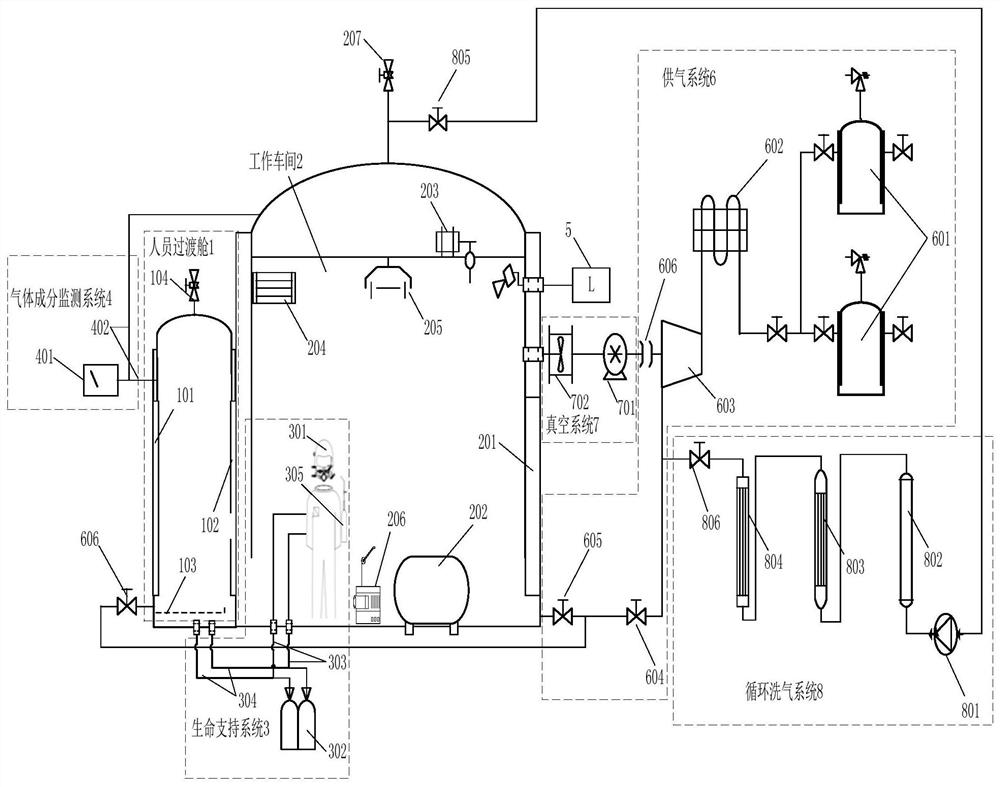

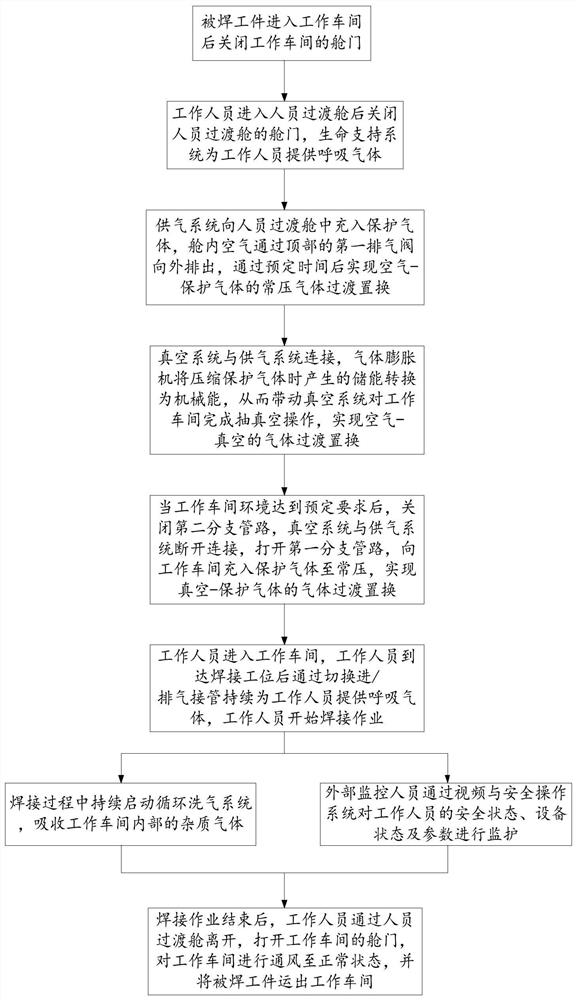

Non-ferrous metal gas fully shielded welding workshop and its operation method

ActiveCN111791002BGuarantee job securityGuaranteed purityWithdrawing sample devicesDispersed particle separationShielding gasIndustrial engineering

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

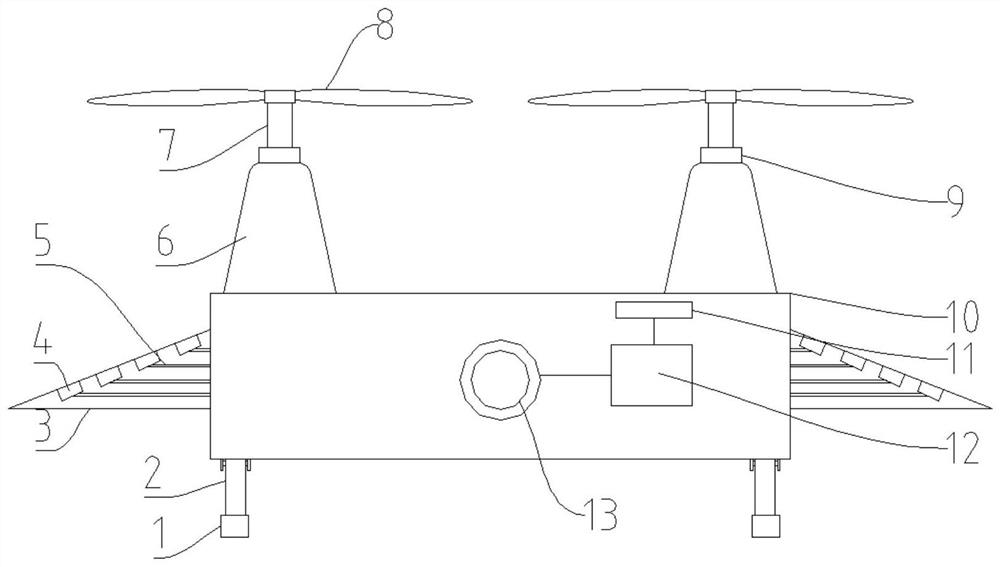

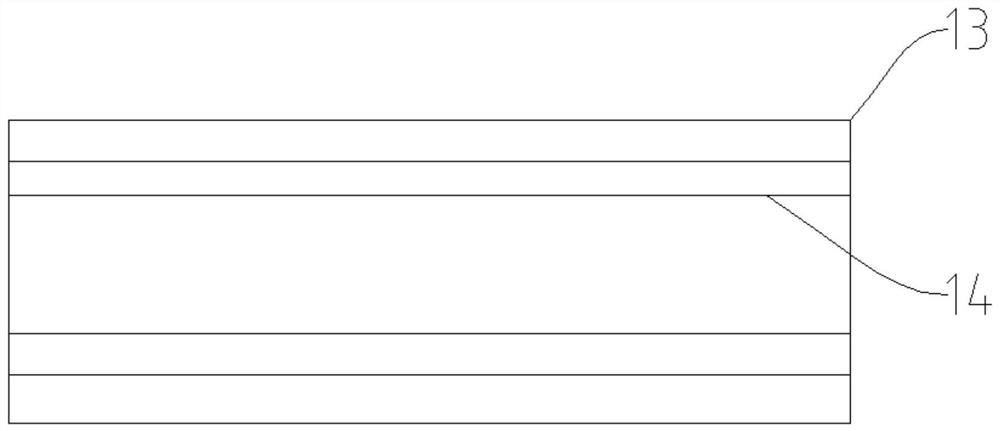

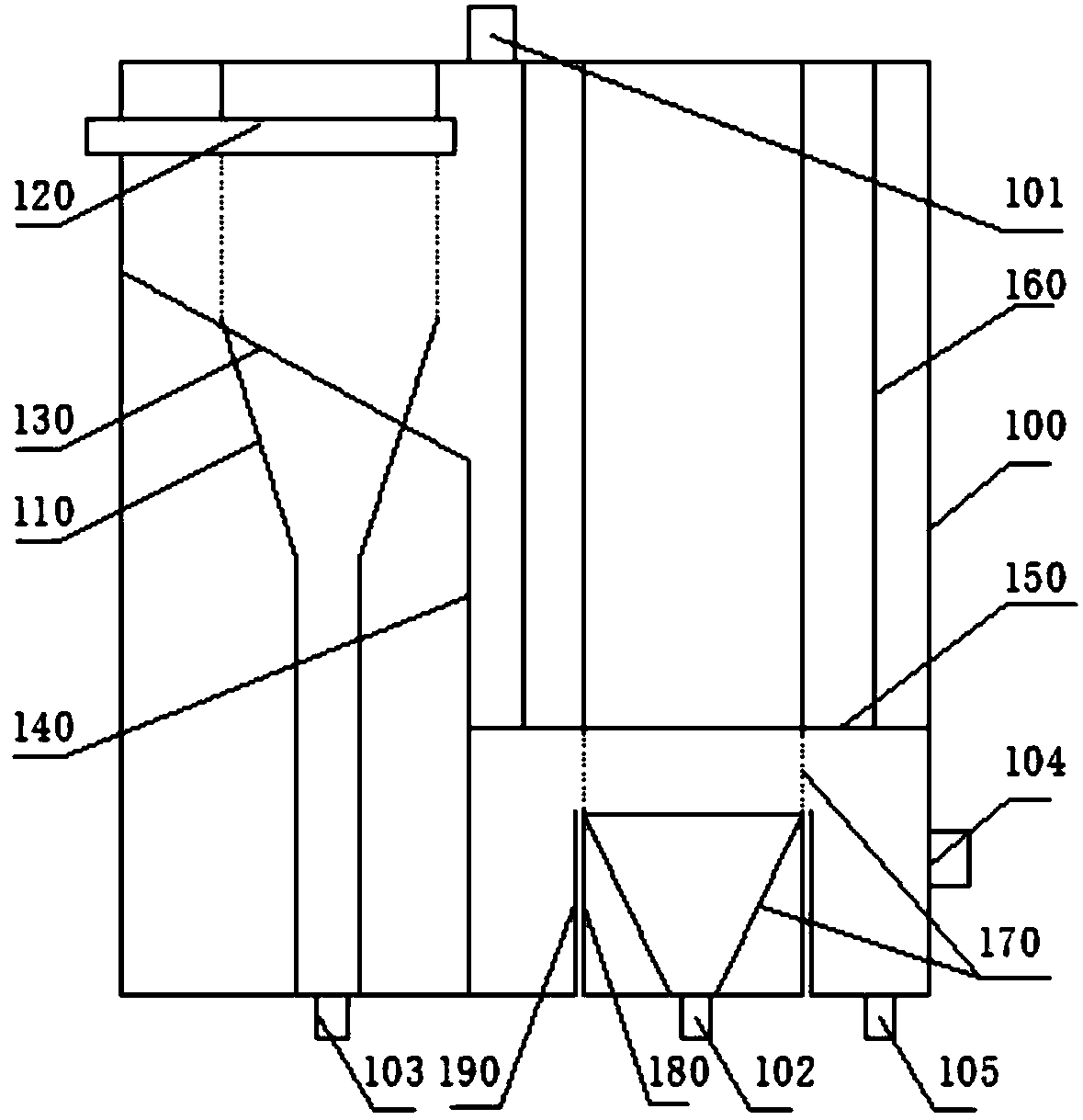

A drone that can self-balance according to the wind direction

ActiveCN108438206BSave running energyExtended flight timeAircraft controlRotocraftMicrocontrollerHigh energy

The invention discloses an unmanned aerial vehicle capable of self-adjusting and balancing according to the wind direction, which comprises a bottom shock pad, an adjustment web, a mechanical rotor and a micro-controller, and a foldable outrigger is installed above the bottom shock pad. A web steering rod is arranged above the adjustment web, the mechanical rotor is connected above the telescopic adjustment shaft, the shaft protection bearing is installed under the mechanical rotor, and a full metal protective shell is installed under the shaft protection bearing , a signal receiver is connected under the all-metal protective shell, the microcontroller is installed above the signal receiver, a holographic camera is installed under the microcontroller, and a telescopic lens is installed inside the holographic camera, A high-energy lithium battery is installed inside the all-metal protective case. The invention can adjust the flying direction of the drone according to the wind direction, greatly saves the running energy of the drone, and the flying time of the drone is longer.

Owner:WUHU HAILIAN MACHINERY INSTALLATION

Device for removing pollutant in rainwater

InactiveCN109455843AReduce contentExtend the mixing timeTreatment involving filtrationMultistage water/sewage treatmentEngineeringStormwater

The invention discloses a device for removing a pollutant in rainwater. The device comprises a shell, a filtering device, a water inlet pipe, a guide plate and a first baffle plate, wherein the top ofthe shell is provided with a flocculating agent inlet opening; the bottom of the shell is provided with a mud discharge opening and a residue discharge opening; the side wall of the shell is providedwith a first water outlet opening; the upper part of the filtering device is provided with multiple first filtering holes; the bottom of the filtering device is communicated with the residue discharge opening; the water inlet pipe is connected into the upper part of the filtering device from one side of the upper part of the filtering device; the middle of the filtering device passes through theguide plate; the flocculating agent inlet opening is opposite to the guide plate; the first baffle plate is parallel to the side wall, in which the first water outlet opening is formed, of the shell;the top of the first baffle plate is fixedly connected with the guide plate; and the mud discharge opening is located between the first baffle plate and the side wall, in which the first water outletopening is formed, of the shell. The device can be used for carrying out effective separation on impurities in the rainwater, and further, has no mechanical agitating device; the running energy consumption and cost can be saved; meanwhile, the internal impurity removal is conveniently carried out; and the service life of the device is prolonged.

Owner:刘兴海

Hot-press mechanism of flax yarn coiling device

The invention discloses a hot pressing mechanism of a linen silk winding and strip forming device. The hot pressing mechanism comprises a hot pressing unit (300) and a silk winding unit (400), wherein the hot pressing unit (300) comprises a mechanical hot pressing part (310) and a hydraulic hot pressing part (320); the mechanical hot pressing part (310) comprises a trapezoid base (311), a first lifting cylinder (312) and a second lifting cylinder (313) are arranged on two side surfaces of the base (311), rollers (314) are arranged at extending-out ends of the first lifting cylinder (312) and the second lifting cylinder (313), a pressing roller (315) is arranged above the rollers (314), a hot pressing roller (316) is arranged above the pressing roller (315), and moving devices (317) are arranged at two shaft ends of the pressing roller (315). The pressing roller and the hot pressing roller can be tightly attached, so that the silk hot-pressing effect is improved.

Owner:湖州南浔中兴丝织有限公司

Silk winding and sliver production equipment

InactiveCN105696121BHigh synchronization accuracyGuaranteed synchronous deliveryServomotor componentsFilament handlingEngineeringMechanical engineering

The invention discloses a production device for coiling silks into strips. The production device comprises a coiling mechanism (100), and a hot-pressing mechanism (200) is arranged behind the coiling mechanism (100); the hot-pressing mechanism (200) comprises a hot-pressing unit (300) and a silk coiling unit (400); the hot-pressing unit (300) comprises a hot-pressing mechanical part (310) and a hot-pressing hydraulic part (320), and the silk coiling unit (400) comprises a silk coiling hydraulic part (410) and a silk coiling mechanical part (420). By means of the production device, synchronous silk conveying can be guaranteed in real time, and uneven coiling caused by inclination of a coiling barrel is avoided; besides, a pressing roller and a hot pressing roller can be in close fit, and thus the hot pressing effect of silks is improved; a closed circuit adopting volumetric speed regulation is utilized, valve compensating oil is sucked in a vacuum mode, the oil path is simple, the structure is compact, the speed regulation range is wide, and operation energy is low.

Owner:湖州南浔中兴丝织有限公司

Low-energy consumption concrete component curing kiln arranged on the upper and lower floors of the access passage

ActiveCN104191512BFacilitate heat exchangeTemperature does not dropCeramic shaping apparatusEngineeringKiln

The invention provides a low-energy-consumption concrete member curing kiln arranged on an access way in an upper and lower layer mode. The low-energy-consumption concrete member curing kiln comprises a warming kiln body, a constant temperature kiln body and a cooling kiln body. The warming kiln body and the cooling kiln body are arranged in one kiln body in an upper and lower layer mode. A heat exchange device is arranged between the warming kiln body and the cooling kiln body. The end, away from the constant temperature kiln body, of the warming kiln body is provided with an entrance. The end, away from the constant temperature kiln body, of the cooling kiln body is provided with an exit. The constant temperature kiln body is provided with an entrance and an exit, the entrance is communicated with the warming kiln body and provided with an entrance air screen, and the exit is communicated with cooling kiln body and provided with an exit air screen. A middle way area and maintenance frames located on the two sides of the middle way area are arranged in the constant temperature kiln body. The maintenance frames comprise a plurality of maintenance rooms which are arranged up and down in a layered mode, and a lifting movement device is arranged on the middle way area.

Owner:SHANDONG LIANFANG INFORMATION TECH CO LTD

Silk winding unit of silk winding and sliver production device

InactiveCN105483869BSave running energyCompact structureServomotor componentsServomotorsYarnHydraulic motor

The invention discloses a silk winding unit of a silk winding and strip forming production device. The silk winding unit comprises a silk winding hydraulic part (410) and a silk winding mechanical part (420), wherein the silk winding mechanical part (420) comprises a hot press roller (316), a rubber roller (421) is arranged beside the hot press roller (316), shafts of the rubber roller (421) and the hot press roller (316) are connected with a first transmission part (422), and the first transmission part (422) is connected with a silk winding hydraulic motor (423) through an output shaft. The silk winding unit adopts a volume-speed-control closed loop, realizes oil supplementation through a vacuum suction valve, adopts a simple oil line, and is compact in structure, large in speed regulating range and low in operation energy.

Owner:湖州南浔中兴丝织有限公司

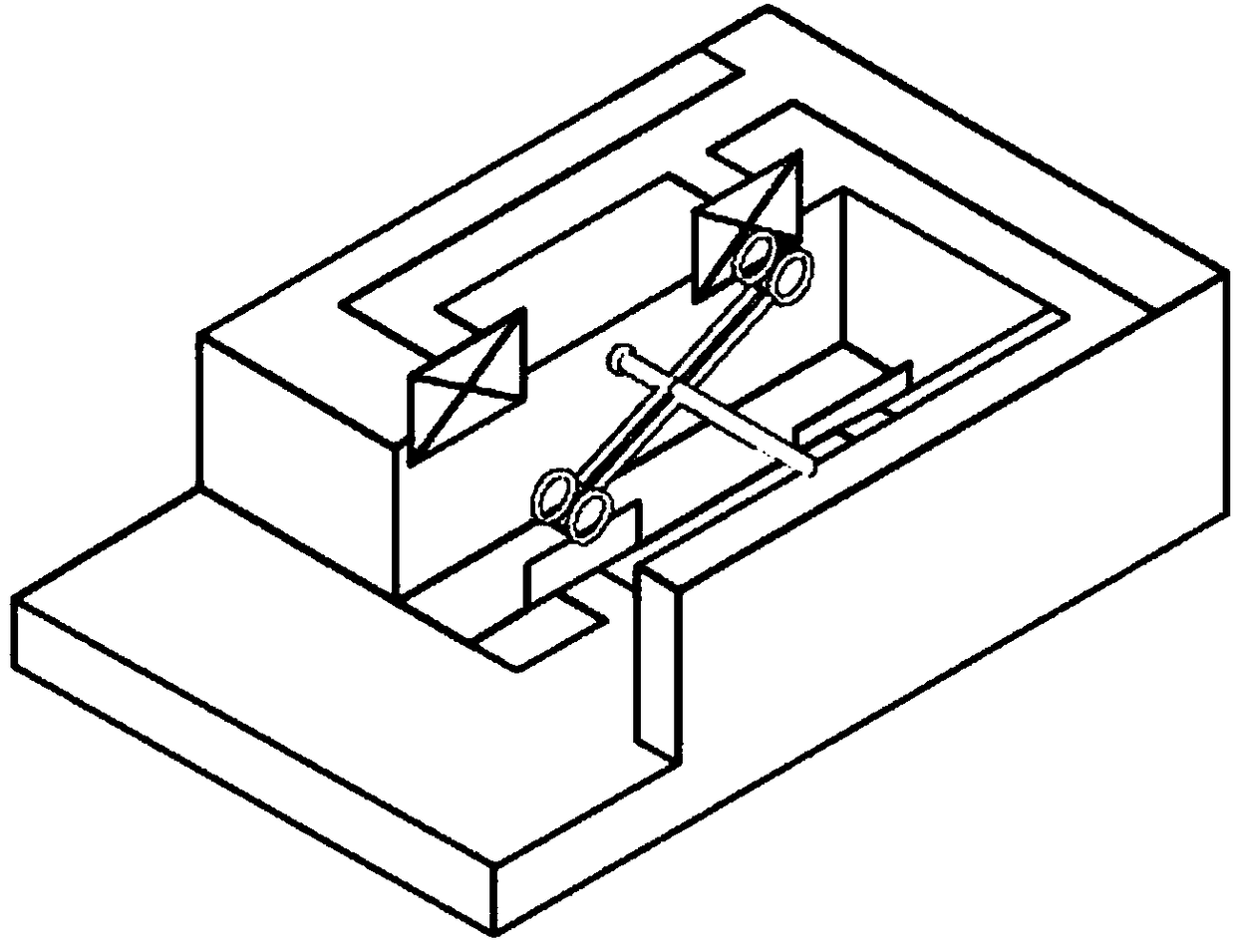

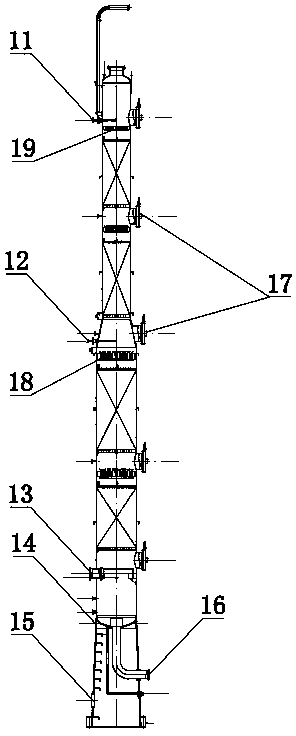

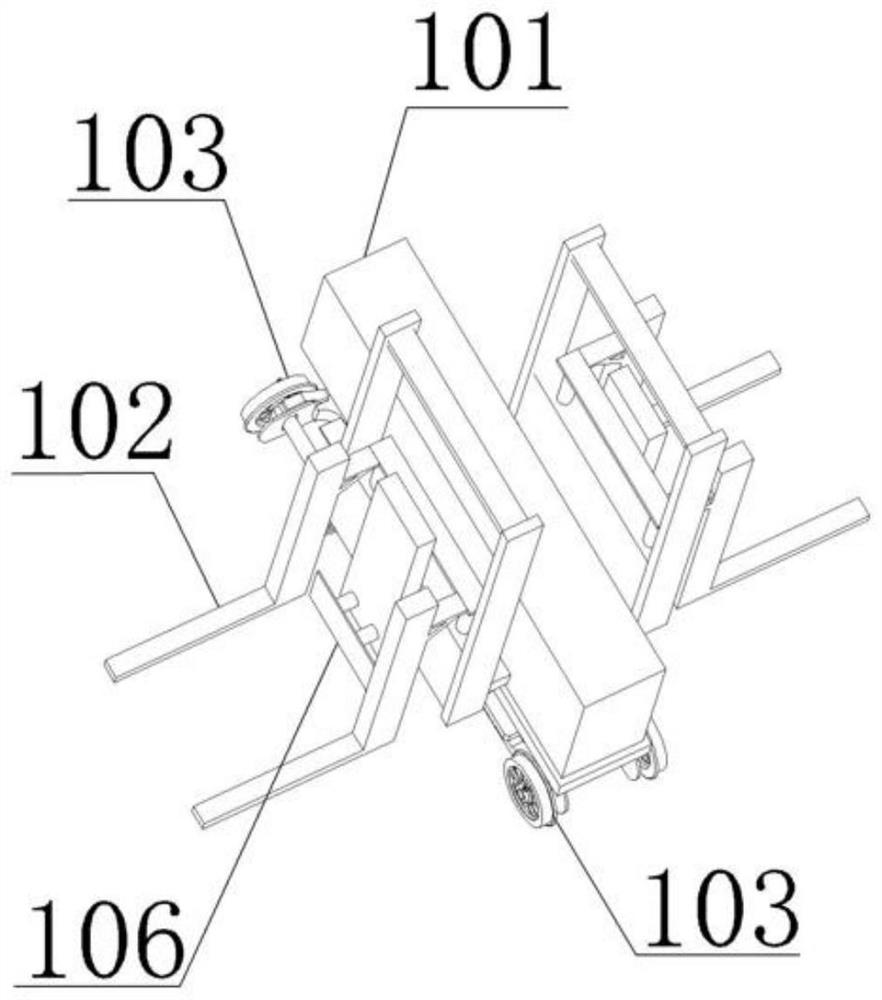

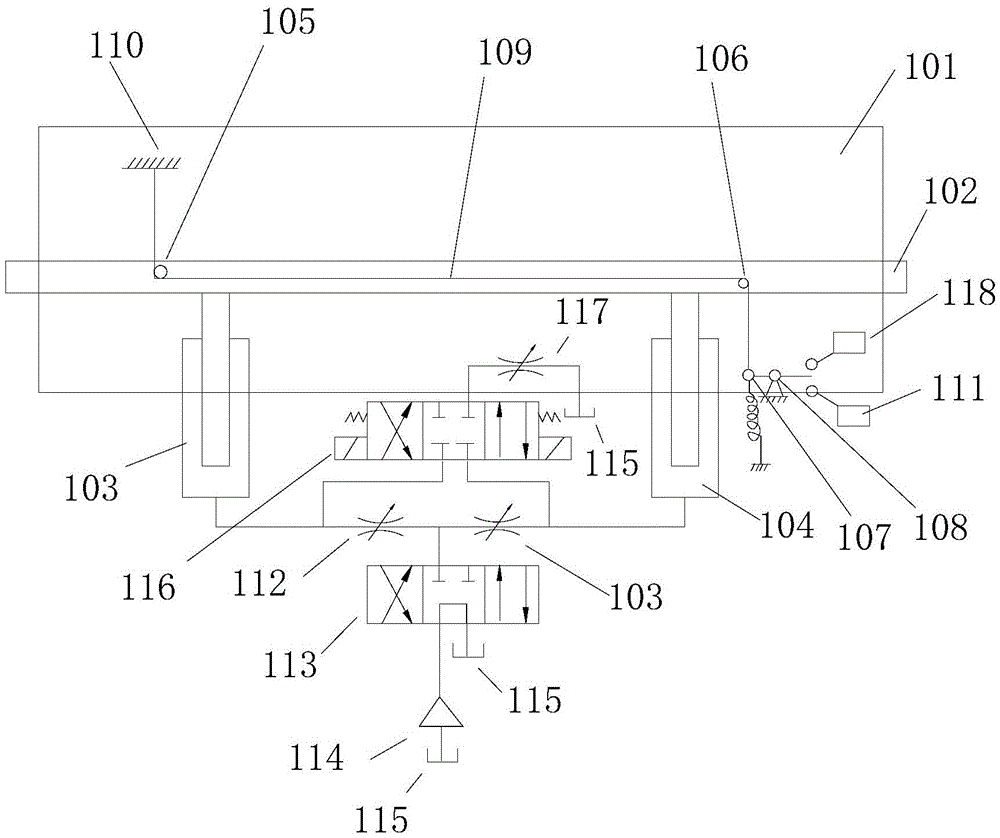

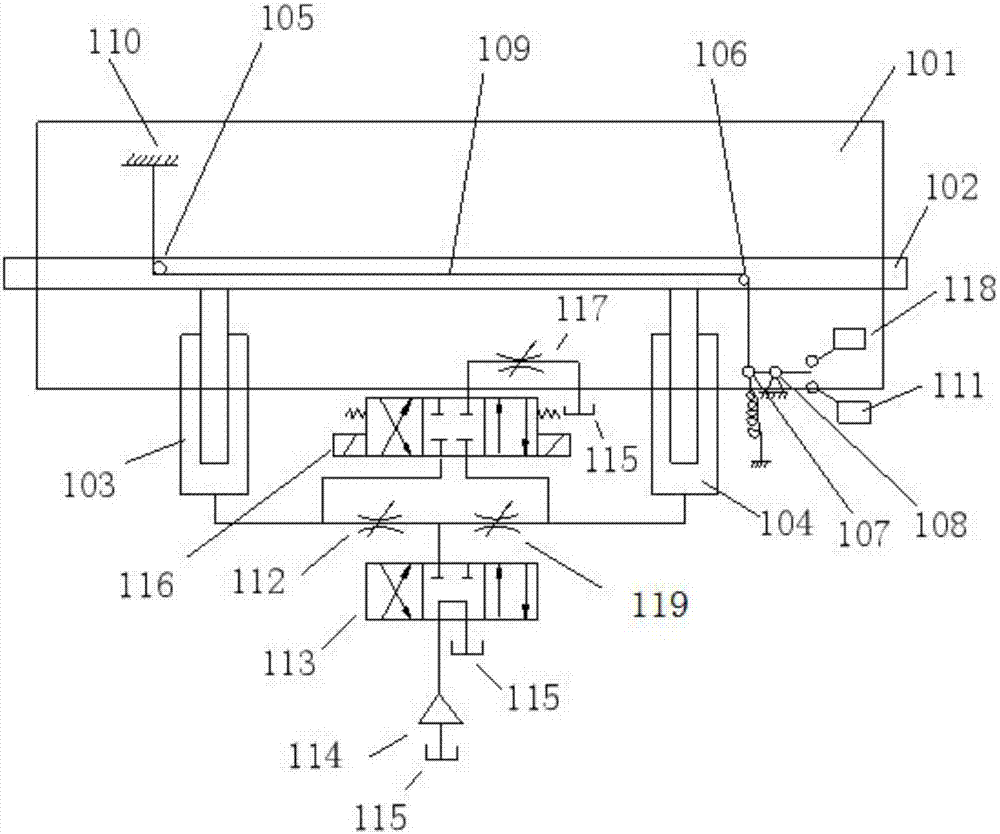

Winding mechanism of linen silk winding and strip forming device

InactiveCN105525394AHigh synchronization accuracyGuaranteed synchronous deliveryLap-winding devicesMechanical engineeringEnergy analysis

The invention discloses a winding mechanism of a linen silk winding and strip forming device. The winding mechanism comprises a winding mechanism body (100), wherein a hot pressing mechanism (200) is arranged behind the winding mechanism body (100) and comprises a hot pressing unit (300) and a silk winding unit (400); the hot pressing unit (300) comprises a mechanical hot pressing part (310) and a hydraulic hot pressing part (320); the silk winding unit (400) comprises a hydraulic silk winding part (410) and a mechanical silk winding part (420). The winding mechanism can guarantee synchronous silk conveying, and non-uniform winding caused by slant of a winding drum is avoided; besides, a pressing roller and a hot pressing roller can be tightly attached, so that the silk hot-pressing effect is improved; the winding mechanism adopts a volume speed-control closed circuit, oil is supplemented through a vacuum suction valve, an oil way is simple, the structure is compact, the speed regulation range is large, and operation energy is low.

Owner:湖州南浔中兴丝织有限公司

Hot pressing mechanism of linen silk winding and strip forming device

InactiveCN105525395AImprove the effect of hot pressingFit tightlyLap-winding devicesEngineeringConductor Coil

The invention discloses a hot pressing mechanism of a linen silk winding and strip forming device. The hot pressing mechanism comprises a hot pressing unit (300) and a silk winding unit (400), wherein the hot pressing unit (300) comprises a mechanical hot pressing part (310) and a hydraulic hot pressing part (320); the mechanical hot pressing part (310) comprises a trapezoid base (311), a first lifting cylinder (312) and a second lifting cylinder (313) are arranged on two side surfaces of the base (311), rollers (314) are arranged at extending-out ends of the first lifting cylinder (312) and the second lifting cylinder (313), a pressing roller (315) is arranged above the rollers (314), a hot pressing roller (316) is arranged above the pressing roller (315), and moving devices (317) are arranged at two shaft ends of the pressing roller (315). The pressing roller and the hot pressing roller can be tightly attached, so that the silk hot-pressing effect is improved.

Owner:湖州南浔中兴丝织有限公司

Environment-friendly and energy-saving solid waste treatment device and working method thereof

PendingCN114798075ACrushed fullyImprove processing efficiencyGrain treatmentsPressesWaste processingElectric machine

The invention discloses an environment-friendly and energy-saving solid waste treatment device and a working method thereof.The environment-friendly and energy-saving solid waste treatment device comprises a supporting guide base used for supporting, four sets of positioning supporting legs are evenly and fixedly installed on the outer end face of the supporting guide base at equal intervals, and a gear motor is fixedly connected to the center of the lower end face of the supporting guide base; a machining device is fixedly installed on the upper end face of the supporting guide base. By arranging the treatment device, when solid waste is treated, two groups of crushing compression rollers can fully crush the solid waste in the protective box body under the elastic pressing of four groups of spring guide shafts and spring clamping rings, and a cutting tool can crush various adhered wastes, so that the waste treatment efficiency is improved. And meanwhile, the three sets of positioning scrapers can turn over the crushed waste, through triple treatment operation, the waste treatment efficiency can be improved to the maximum extent, and the waste processing fineness degree is effectively improved.

Owner:王文超

Non-ferrous metal gas full-protection welding workshop and operation method thereof

ActiveCN111791002AGuarantee job securityGuaranteed purityWithdrawing sample devicesDispersed particle separationNonferrous metalShielding gas

The invention discloses a non-ferrous metal gas full-protection welding workshop and an operation method thereof, and relates to the field of non-ferrous metal welding. The non-ferrous metal gas full-protection welding workshop comprises a personnel transition cabin, a working workshop, a life support system, a gas supply system, a vacuum system and a circulating gas washing system. The personneltransition cabin is connected with the working workshop, work personnel enters the working workshop through the personnel transition cabin to carry out welding work, a welded workpiece enters the working workshop for welding, the life support system is respectively connected with the personnel transition cabin and the working workshop and provides breathing gas for the work personnel, the gas supply system is respectively connected with the personnel transition cabin and the working workshop and provides protective gas for welding, the vacuum system is connected with the working workshop and is used for vacuumizing the interior of the working workshop, and the circulating gas washing system is connected with the working workshop and is used for absorbing impurity gas in the working workshop in the welding process. According to the non-ferrous metal gas full-protection welding workshop, work personnel enter the working workshop filled with protective gas to carry out welding operation,and the welding quality can be improved through close-range fine operation.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

Winding mechanism of silk winding device

InactiveCN105525394BHigh synchronization accuracyGuaranteed synchronous deliveryLap-winding devicesConductor CoilMechanical engineering

The invention discloses a winding mechanism of a linen silk winding and strip forming device. The winding mechanism comprises a winding mechanism body (100), wherein a hot pressing mechanism (200) is arranged behind the winding mechanism body (100) and comprises a hot pressing unit (300) and a silk winding unit (400); the hot pressing unit (300) comprises a mechanical hot pressing part (310) and a hydraulic hot pressing part (320); the silk winding unit (400) comprises a hydraulic silk winding part (410) and a mechanical silk winding part (420). The winding mechanism can guarantee synchronous silk conveying, and non-uniform winding caused by slant of a winding drum is avoided; besides, a pressing roller and a hot pressing roller can be tightly attached, so that the silk hot-pressing effect is improved; the winding mechanism adopts a volume speed-control closed circuit, oil is supplemented through a vacuum suction valve, an oil way is simple, the structure is compact, the speed regulation range is large, and operation energy is low.

Owner:湖州南浔中兴丝织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com