Treatment device for removing sulfur and organic matters from industrial sewage

A technology for treatment devices and industrial sewage, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, water pollutants, etc. It can solve problems such as low efficiency and complicated operation, and achieve simple process flow and treatment efficiency. High and good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

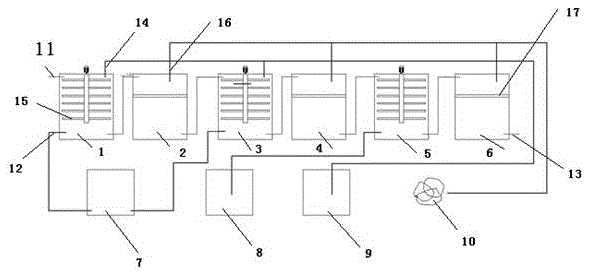

[0018] An industrial sewage desulfurization and organic matter removal device, which includes three-stage reaction tanks 1, 2, 3, three solid-liquid separation tanks 4, 5, 6, chlorine gas storage tank 7, hydrogen chloride storage tank 8, tail gas recovery tank 9 and solid Recovery device 10; the three-stage reaction tank is respectively provided with a water inlet pipe 11, an air inlet pipe 12 and an outlet pipe 13, the water inlet pipe 11 is arranged at the upper end of one side of the reaction tank, the air inlet pipe 12 is arranged at the lower end of one side of the reaction tank, and the water outlet pipe 13 is arranged on the lower end of the other side of the reaction tank, the top of the primary and secondary reaction tanks is provided with an air outlet pipe 14, and the stirring device 15 is arranged in the reaction tank; the upper end of one side of the solid-liquid separation tank is provided with a water inlet pipe 11, and the The lower end is provided with an outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com