Traction drive multi-car shared multi-hoistway circular operation elevator

A cycle operation, multi-car technology, applied to elevators, transportation and packaging, elevators, etc. in buildings, can solve the problem of low utilization efficiency of single-car elevator shafts, improve shaft utilization efficiency, reduce the number and number of shafts The effect of occupying an area and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

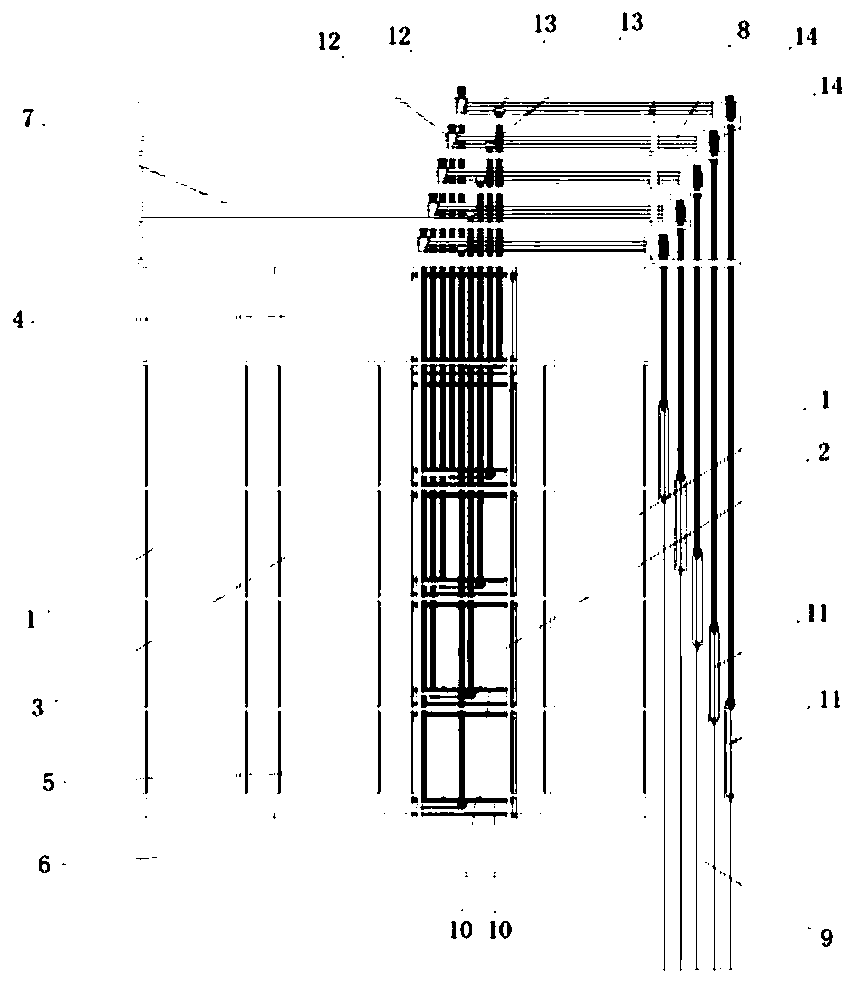

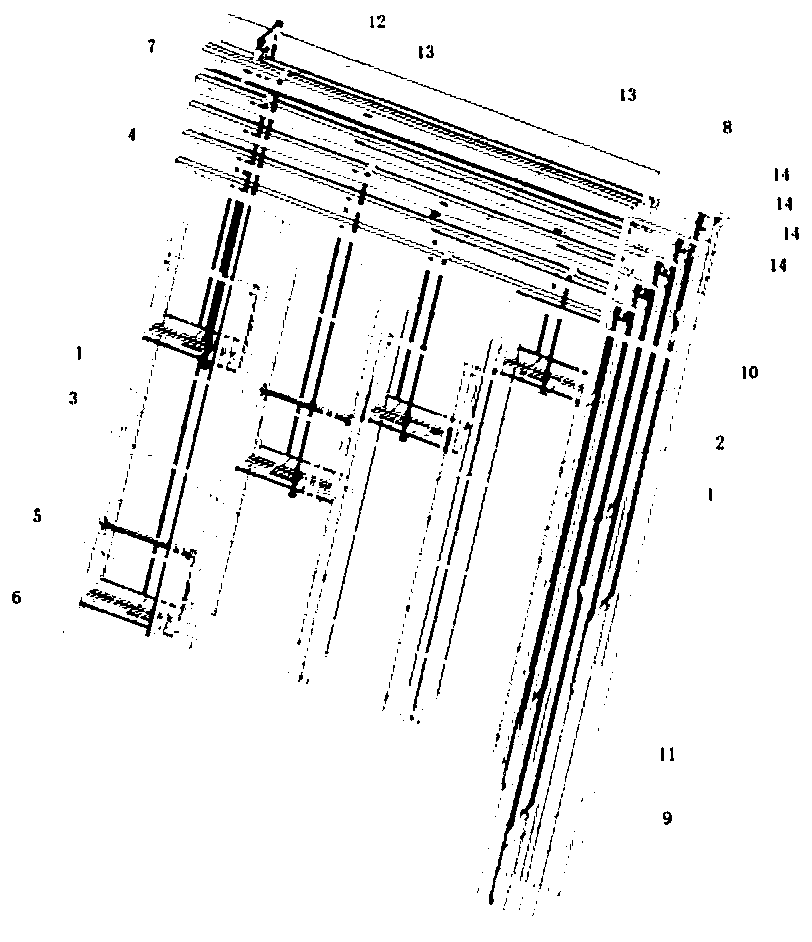

[0120] Such as figure 1 Shown is the front view of the multi-shaft structure and the position of the car in the initial running state of this embodiment. The multi-shaft structure described in the figure consists of two vertically ascending working shafts 1 (abbreviated as shaft 1) and vertically descending working shaft 2 of the car. (abbreviated as shaft 2), car vertical downward working aisle 3 (abbreviated as shaft 3), translational shaft 4 on the car (abbreviated as shaft 4), translational shaft 5 under the car (abbreviated as shaft 5), elevator shaft bottom pit 6, and more The support frame 7 (referred to as the support frame 7) of the layer guide wheel and the car rope head firmware translation drive, the multi-layer traction machine and the support frame 8 (referred to as the support frame 8) of the counterweight rope head firmware, and multiple counterweight vertical Up and down moving space 9 (space 9 for short), in which: shaft 4 is leveled with the top end station ...

Embodiment 2

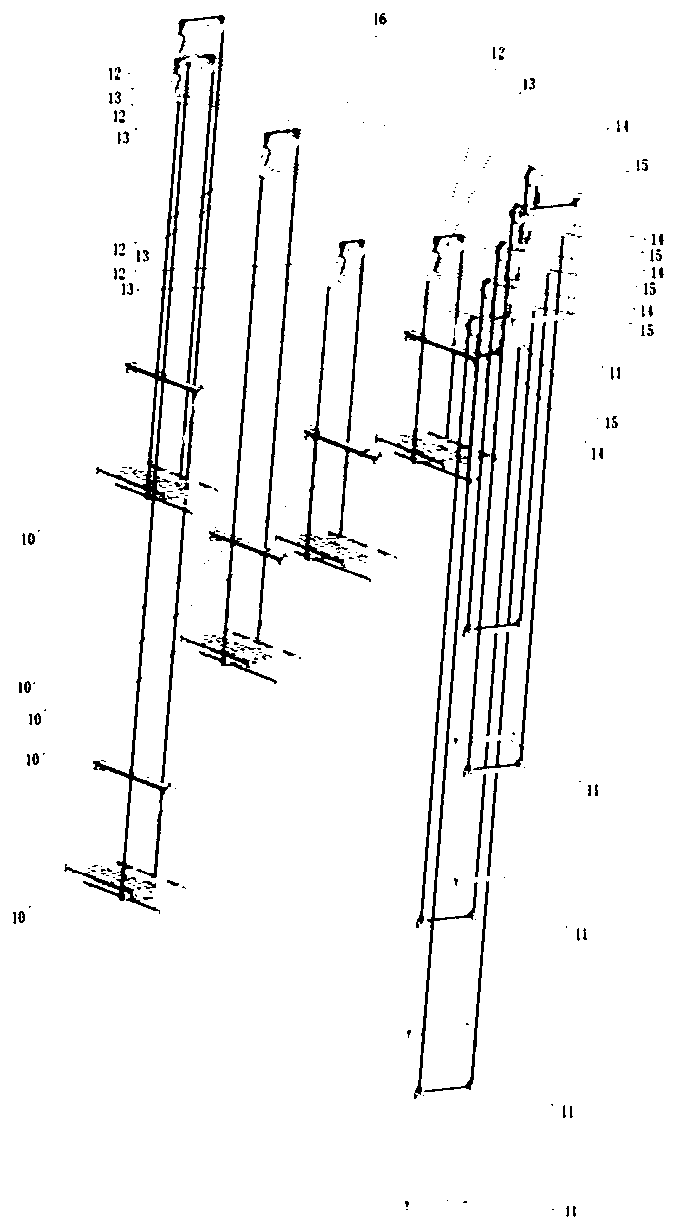

[0144] Such as Figure 17Shown is the schematic diagram of the car, the running shaft, the translation drive and the support frame in this embodiment. In this embodiment, the car rope head firmware translation drive 13 and the car frame 10 have different structures from those of Embodiment 1, while other structures are the same. In the same way as in Embodiment 1, the independent translation driving device of each layer of the support frame 7 can drive the translation driving member 12 and the translation driving member 13 of each layer to perform translational movement, thereby driving the traction rope 16 of the car to translate, as shown in Fig. The car frame 10 driven by the traction drive system of each floor mentioned in the above mentioned is parked at each elevator floor station from the bottom to the top floor of the hoistway after the hoistway 1 goes up. Cycle operation, the cycle operation is independently driven by the independent traction drive system of each laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com