Percolate and kitchen wastewater MBR system and process thereof

A kitchen wastewater and leachate technology, which is applied in the leachate and kitchen wastewater MBR system and process field, can solve the problems of aggravated membrane filter layer damage, difficult treatment, and high energy consumption in operation, so as to save equipment investment and The effect of operating energy consumption, reducing environmental pollution equivalent, and reducing operating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

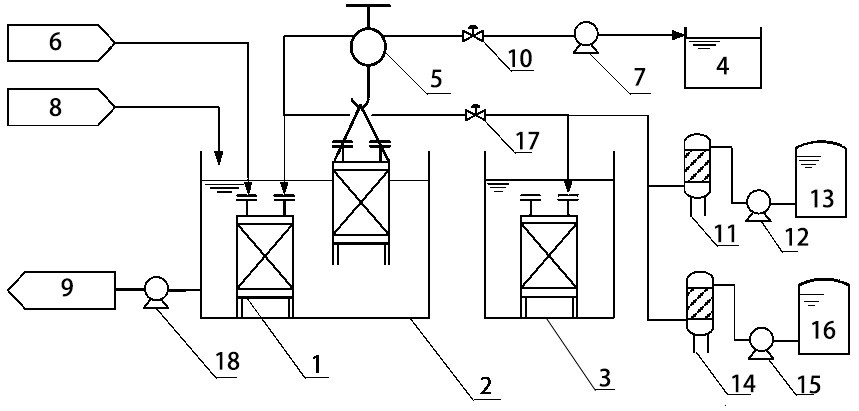

[0036] Such as figure 1 , the present embodiment proposes a leachate and kitchen waste water MBR system, including a water production system, a backwash system, and an air explosion system 6. The water production system includes a membrane box 1, a membrane pool 2, a membrane cleaning pool 3, a production Water tank 4, electric hoist 5 and cleaning equipment, the membrane box 1 includes an air inlet and a water production port, the air inlet is connected to the explosion system 6, and the water production port is connected to the water production tank 4 and the backwashing system through a water production pipeline , and connect the cleaning equipment through the cleaning pipeline, the water production pipeline is provided with a water production pump 7, the electric hoist 5 is connected to the membrane box 1, and the membrane box 1 is connected between the membrane pool 2 and the membrane cleaning pool 3 through the electric hoist 5 The membrane pool 2 includes a water inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com