Non-ferrous metal gas fully shielded welding workshop and its operation method

A welding workshop, non-ferrous metal technology, applied in separation methods, welding equipment, auxiliary welding equipment, etc., can solve the problems of high operating requirements, environmental conditions, high protection mold costs, etc., to save system operation energy, The effect of ensuring work safety and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

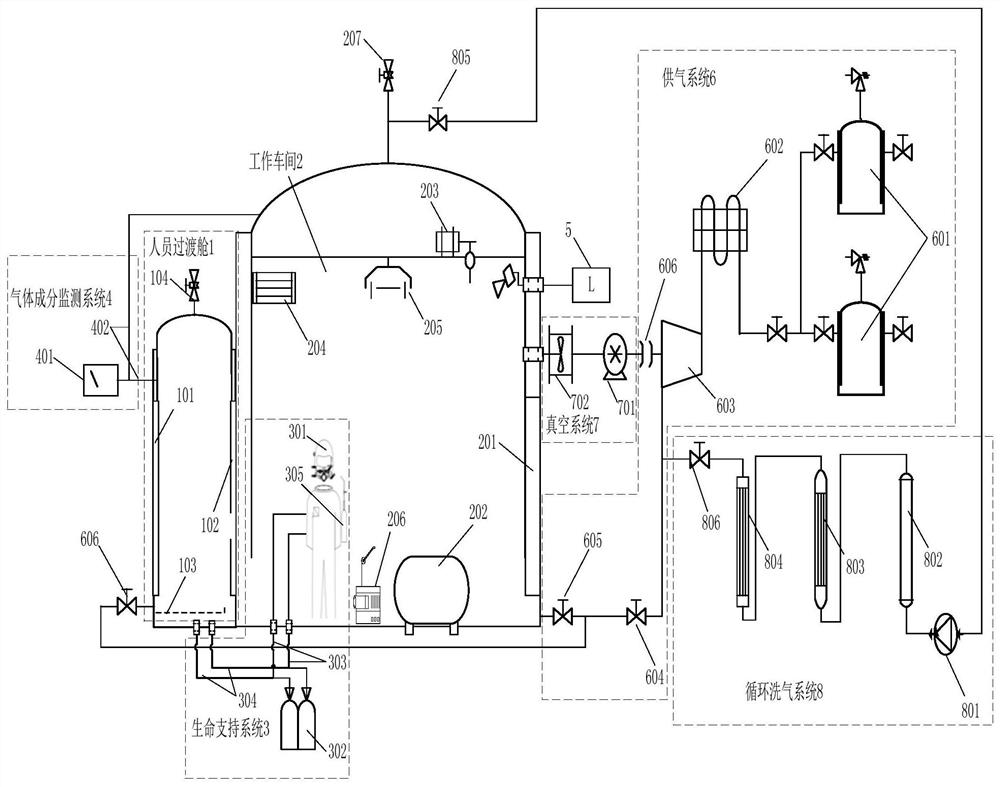

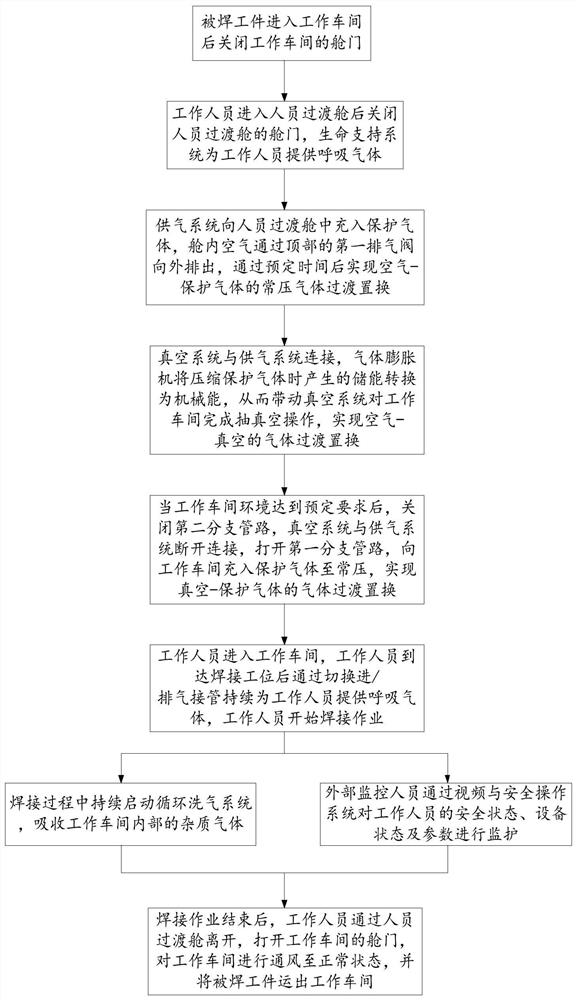

[0037] The present application discloses a non-ferrous metal gas full protection welding workshop, and its principle block diagram is as follows figure 1 As shown, it includes personnel transition cabin 1, work workshop 2, life support system 3, gas supply system 6, vacuum system 7 and circulating gas washing system 8, and optionally, also includes gas composition monitoring system 4 and video and safety control system 5. The personnel transition cabin 1 is connected to the workshop 2 and the external space respectively. The staff enters the workshop 2 through the personnel transition cabin 1 to perform welding operations. The workshop 2 is connected to the external space, and the workpieces to be welded enter the workshop 2 for welding. The life support system 3 connect the personnel transition cabin 1 and the work shop 2 respectively and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com