Intelligent calculation method for mechanical arm movement planning group

A technology of swarm intelligence and motion planning, applied in the direction of instruments, adaptive control, control/regulation systems, etc., can solve problems such as error safety accidents and limited vision of robotic arms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

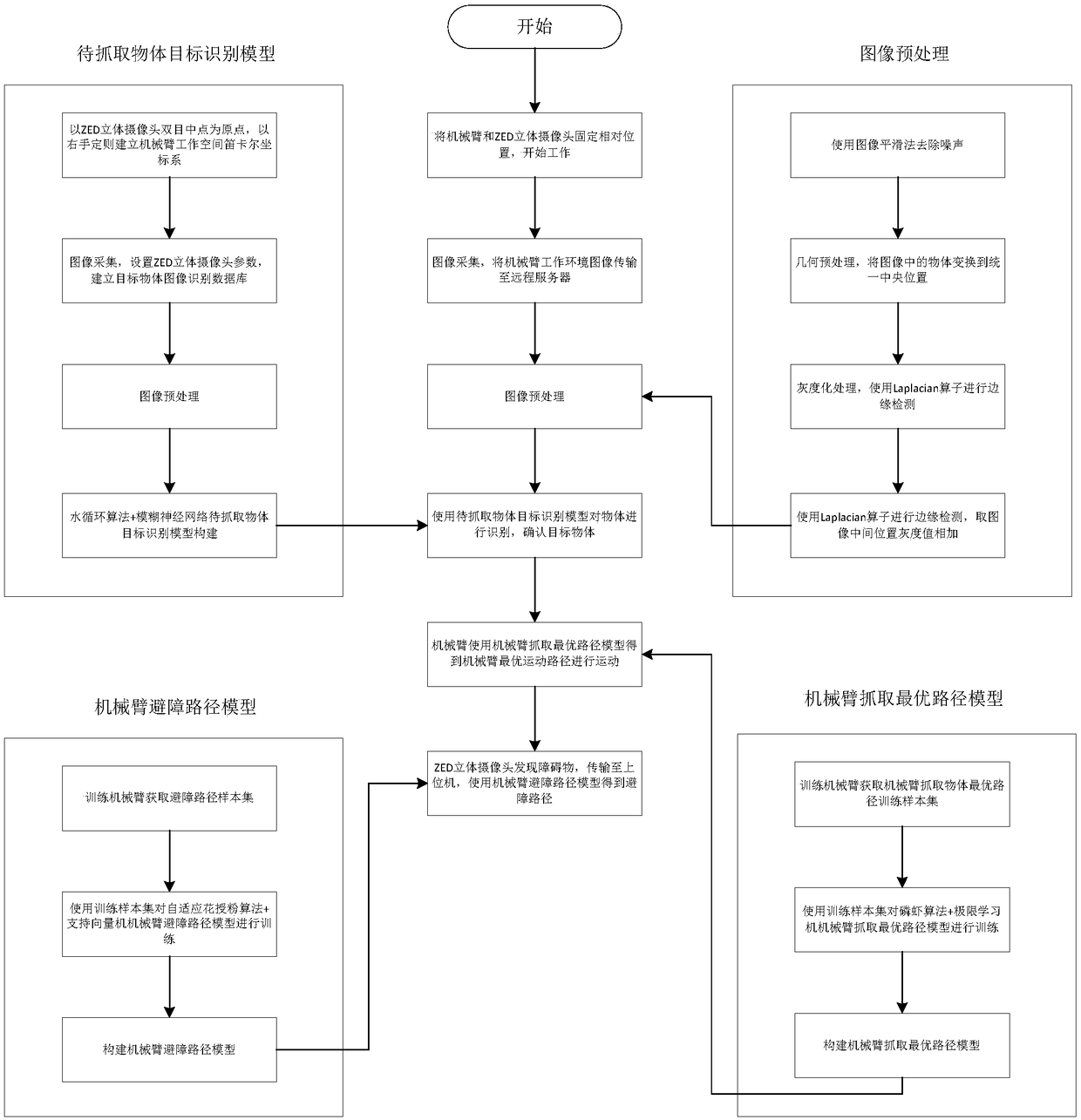

[0078] Such as figure 1 As shown, a swarm intelligence calculation method for manipulator motion planning includes the following steps:

[0079] Step 1: Construct the three-dimensional coordinate system of the working space where the manipulator is located;

[0080] Use the image acquisition area to cover the entire working space of the robot arm to grab the target object. The midpoint of the line connecting the left and right cameras of the binocular ZED camera is taken as the origin, and the line connecting the center of the right camera of the binocular ZED to the center of the left camera of the binocular ZED is the positive y-axis. According to the right-hand rule, the three-dimensional coordinate system of the working space of the manipulator is established;

[0081] Step 2: Construct a fuzzy neural network-based target recognition model for obj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com