Internet-of-Things based preparation method and preparation system of light green gold alloy for jewelry and horologe industry

A preparation system and Internet of Things technology, applied in the field of preparation method and preparation system of light green gold alloy, can solve problems such as use restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

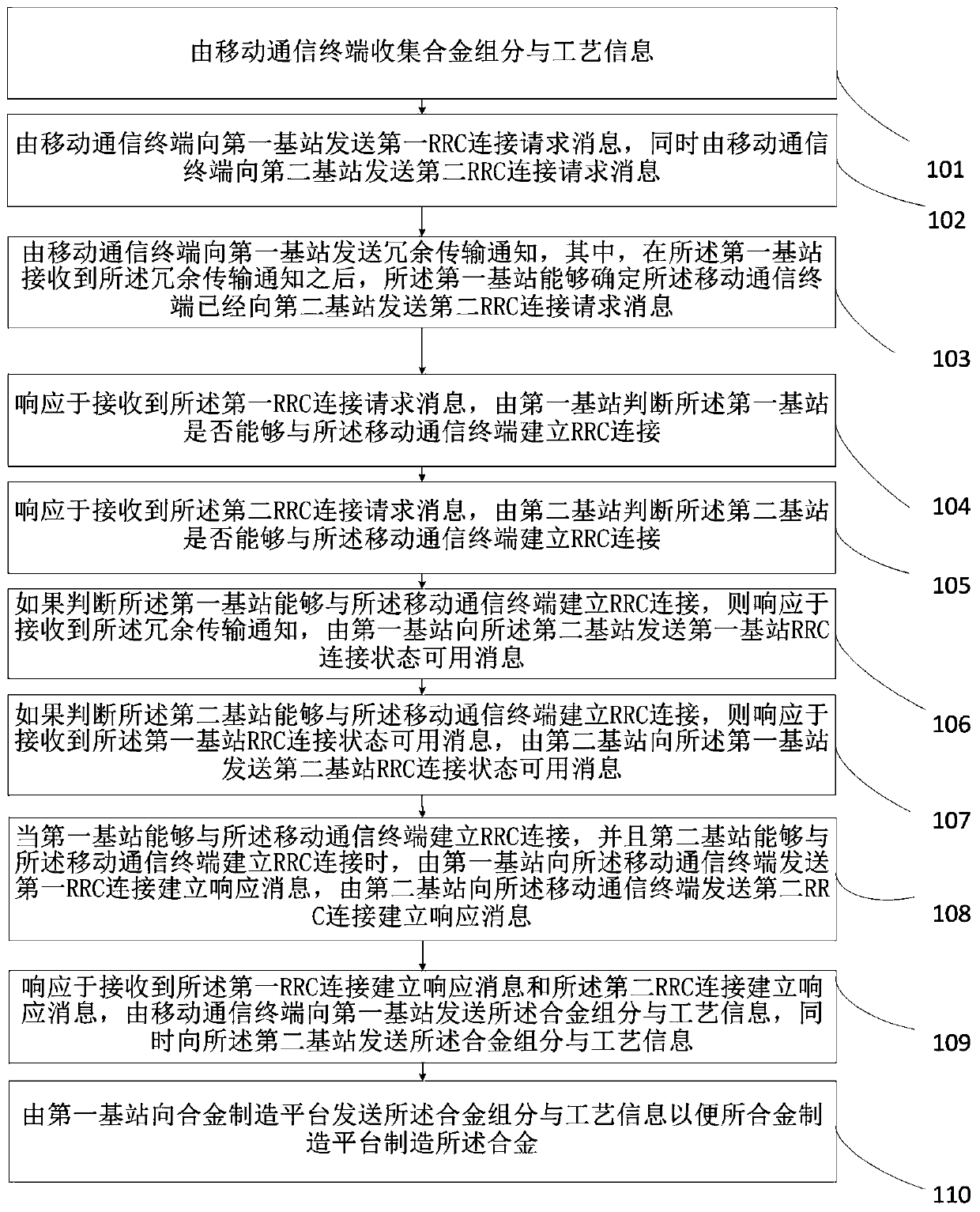

[0021] figure 1 is a flow chart of the preparation method according to one embodiment of the present invention. As shown in the figure, the preparation method of the light green gold alloy for jewelry and watch industry based on the Internet of Things of the present invention comprises the following steps:

[0022] Step 101: collecting alloy composition and process information by the mobile communication terminal;

[0023] Step 102: sending a first RRC connection request message to the first base station by the mobile communication terminal, and sending a second RRC connection request message to the second base station by the mobile communication terminal at the same time;

[0024] Step 103: The mobile communication terminal sends a redundant transmission notification to the first base station, wherein, after the first base station receives the redundant transmission notification, the first base station can determine that the mobile communication terminal has sent a second RR...

Embodiment 1

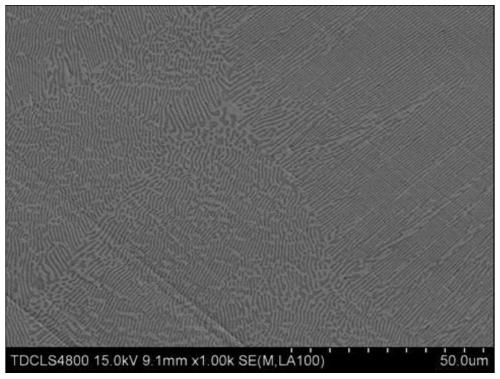

[0045] The alloy manufacturing platform prepares the alloy according to the following weight percentages, the content of silver (Ag) is 5.5%, the content of copper (Cu) is 8.5%, the content of zinc (Zn) is 6%, the content of cobalt (Co) is 0.05%, and the content of silicon (Si) is 200, and the balance is gold. Melting under the protection of inert gas or reducing gas, the melting temperature is 1050℃. Invert the mold according to the well-known methods in the jewelry industry and the watch industry, and then undergo follow-up treatments such as grinding and polishing to obtain 18K light green gold alloy ornaments. Repeat the above process to get ten sets of samples, the obtained 18K light green gold alloy CIElab value a*:-1.5--1.6, b*: 19-20, showing light green, hardness Hv175-177, after 300 ℃, protective atmosphere insulation 1 The hardness Hv190-192 after 1-hour aging treatment, and the average manufacturing cost is 1 (because the actual cost value involves the applicant's...

Embodiment 2

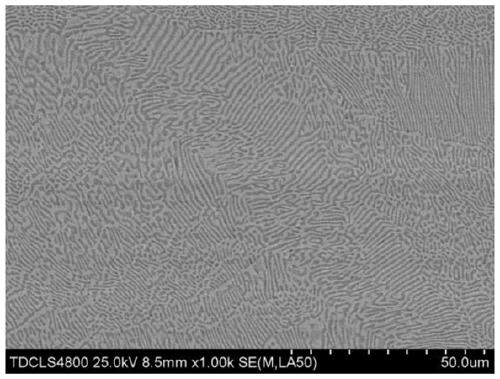

[0047] The alloy fabrication platform formulates alloys in the following weight percentages. Silver (Ag) content is 7.5%, copper (Cu) content is 12%, zinc (Zn) content is 10%, cobalt (Co) content is 0.35%, silicon (Si) content is 400ppm, iridium (Ir) content is 150ppm , the boron (B) content is 120ppm, the phosphorus (P) content is 50ppm, and the balance is gold. Melting under the protection of inert gas or reducing gas, the melting temperature is 1150℃. Invert the mold according to the well-known methods in the jewelry industry and the watch industry, and then undergo follow-up treatments such as grinding and polishing to obtain 18K light green gold alloy ornaments. Repeat the above process to get ten sets of samples, the prepared 18K light green gold alloy CIElab value a*:-3.0--2.9, b*: 25-26, showing light green, hardness Hv200-201, after 350 ℃, protective atmosphere heat preservation The hardness Hv255-256 after 1-hour aging treatment, and the average manufacturing cost ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com