Winding mechanism of linen silk winding and strip forming device

A sliver forming device and flax silk technology, applied in winding mechanism, textile and paper making, fiber processing, etc., can solve problems such as unreasonable winding mechanism, avoid uneven winding, improve synchronization accuracy, and improve hot pressing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

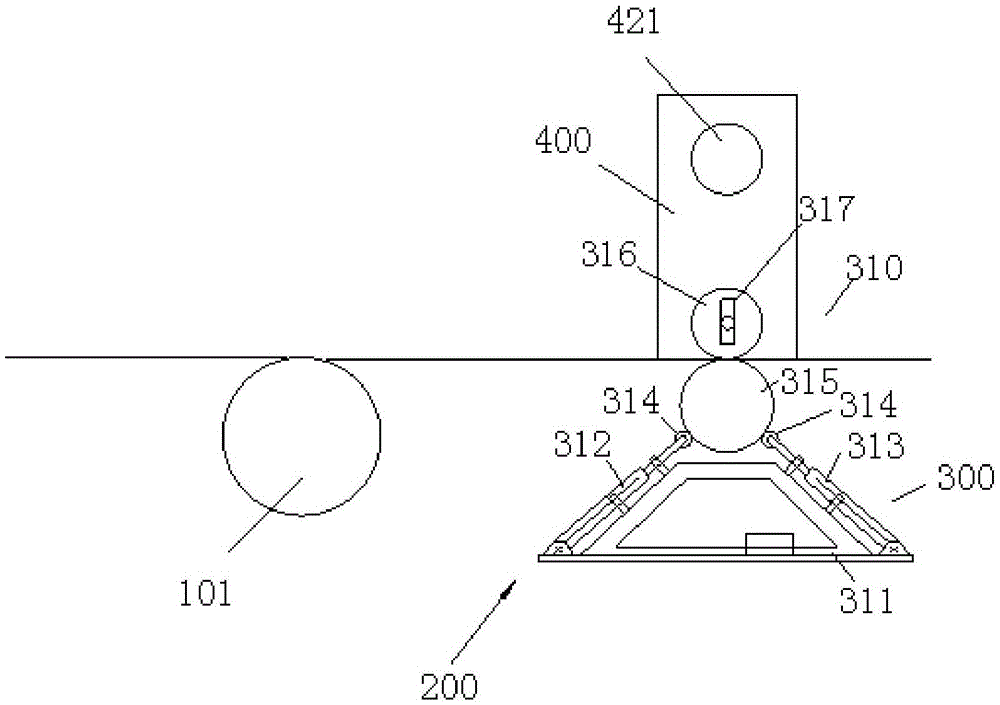

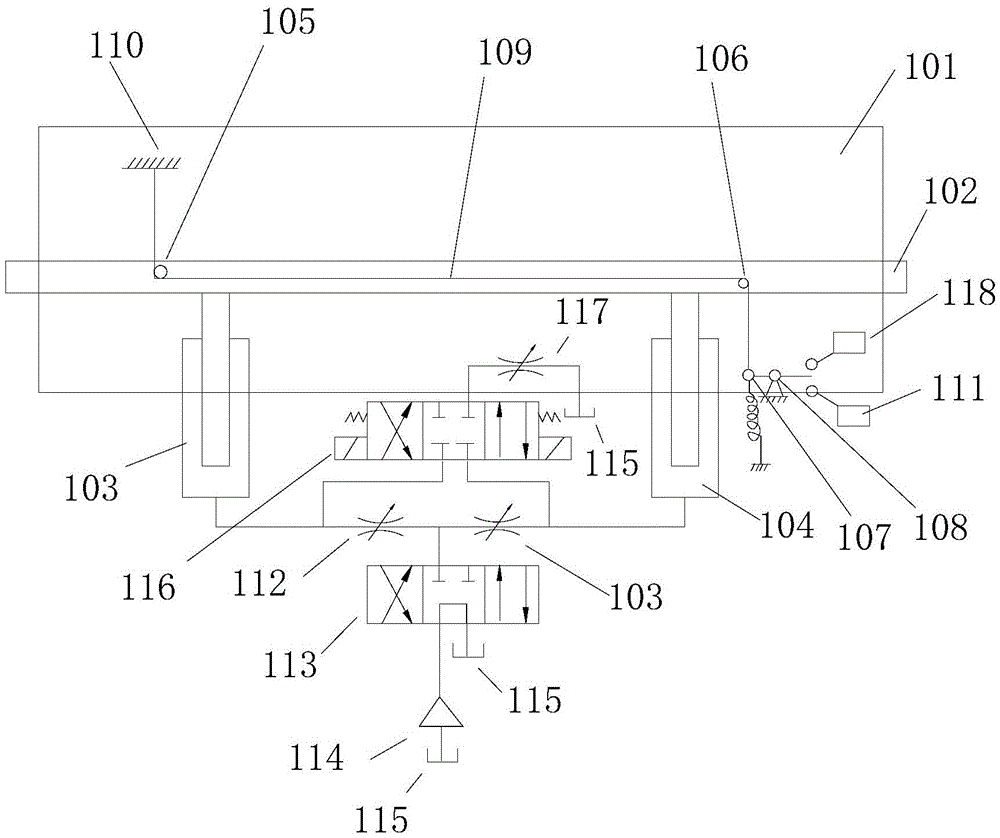

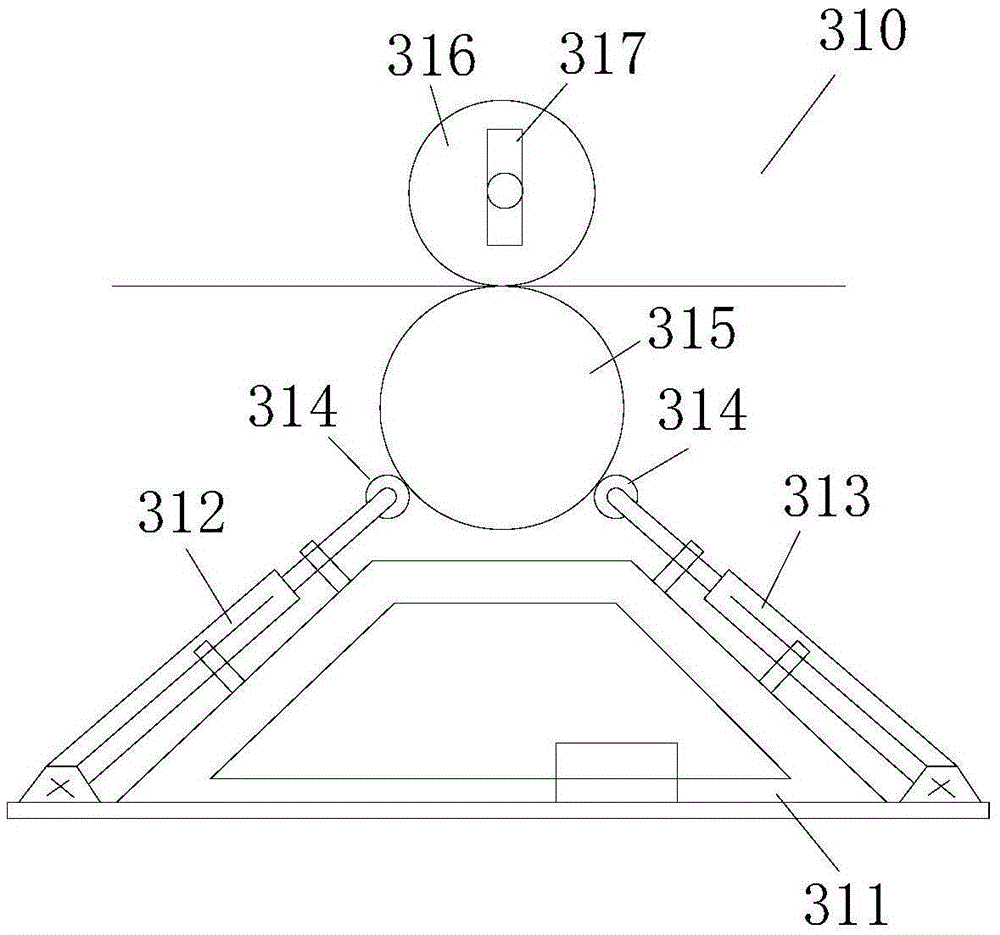

[0020] Embodiment: the winding mechanism of flax silk winding device, as attached figure 1 and figure 2 As shown, the reel 101 is included, the reel 101 is provided with a reel 102, one side of the reel 102 is connected with a first reel cylinder 103, and the other side of the reel 103 is connected with a second reel cylinder 104 The first winding cylinder 103 side of winding shaft 102 is provided with first fulcrum 105, the second winding cylinder 104 side of winding shaft 102 is provided with second fulcrum 106, and the second fulcrum 106 below is provided with moving fulcrum 107 and The hinge fulcrum 108, the first fulcrum 105 and the second fulcrum 106 are wound with a steel strip 109, the head of the steel strip 109 is fixed on the fixed part 110, and the steel strip 109 goes around the first fulcrum 105, the second fulcrum 106 successively, and moves The fulcrum 107 and the hinge fulcrum 108, the top of the end of the steel strip 109 is provided with a first microswitc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com