Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98results about How to "Save ink" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

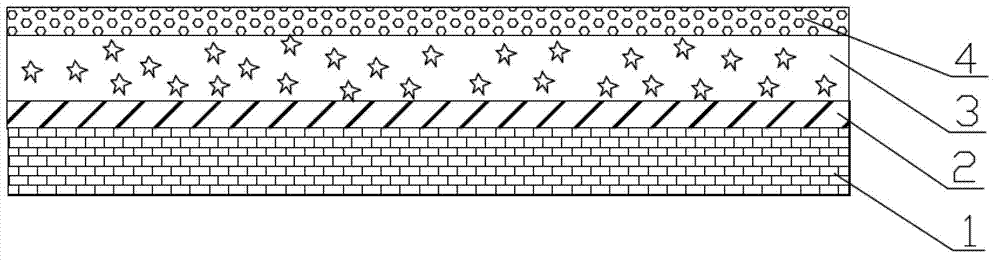

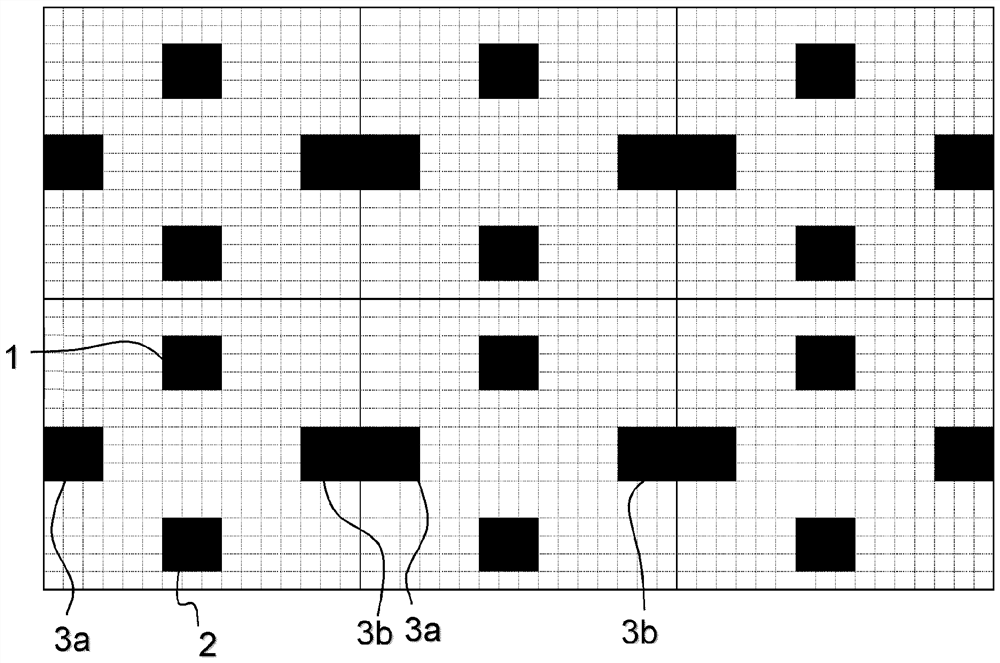

Thermal sublimation and transfer digital paper with high ink suction amount

ActiveCN103397576AIncrease ink absorptionQuick ink absorptionSurface covering paperCoatingsCalcium carbonatePolyacrylamide

The invention belongs to the field of transfer paper and particularly relates to a piece of thermal sublimation and transfer digital paper with high ink suction amount. The thermal sublimation and transfer digital paper comprises a piece of substrate paper, a hydrophobic layer coated on the surface of the substrate paper, an ink suction layer coated on the surface of the hydrophobic layer, and a surface layer on the upper surface of the ink suction layer. In terms of calculation by weight, the ink suction layer is a composite material of an inorganic material and cationic polyacrylamide cellulose interpenetrating network resin, wherein the inorganic material is one or a combination of two of porous silicon dioxide or porous calcium carbonate or porous alumina. The hydrophobic layer is organosilicone modified acrylic resin. According to the thermal sublimation and transfer digital paper, the composition material which is one or the combination of two of the porous silicon dioxide or the porous calcium carbonate or the porous alumina is added into the ink suction layer, the solid porous structure can rapidly and sufficiently absorb dye molecules, and the ink suction amount of the thermal sublimation and transfer digital paper is remarkably increased.

Owner:杭州华大海天科技股份有限公司

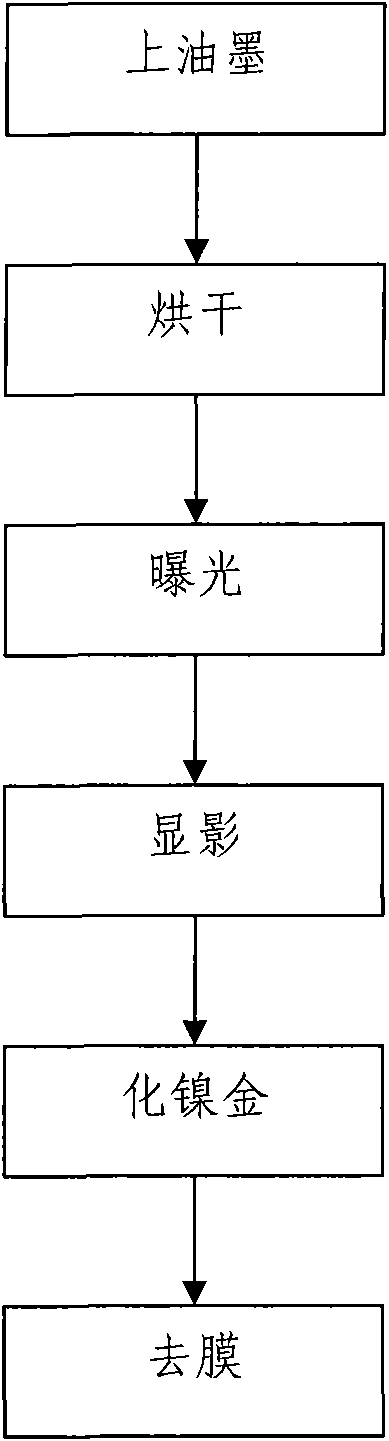

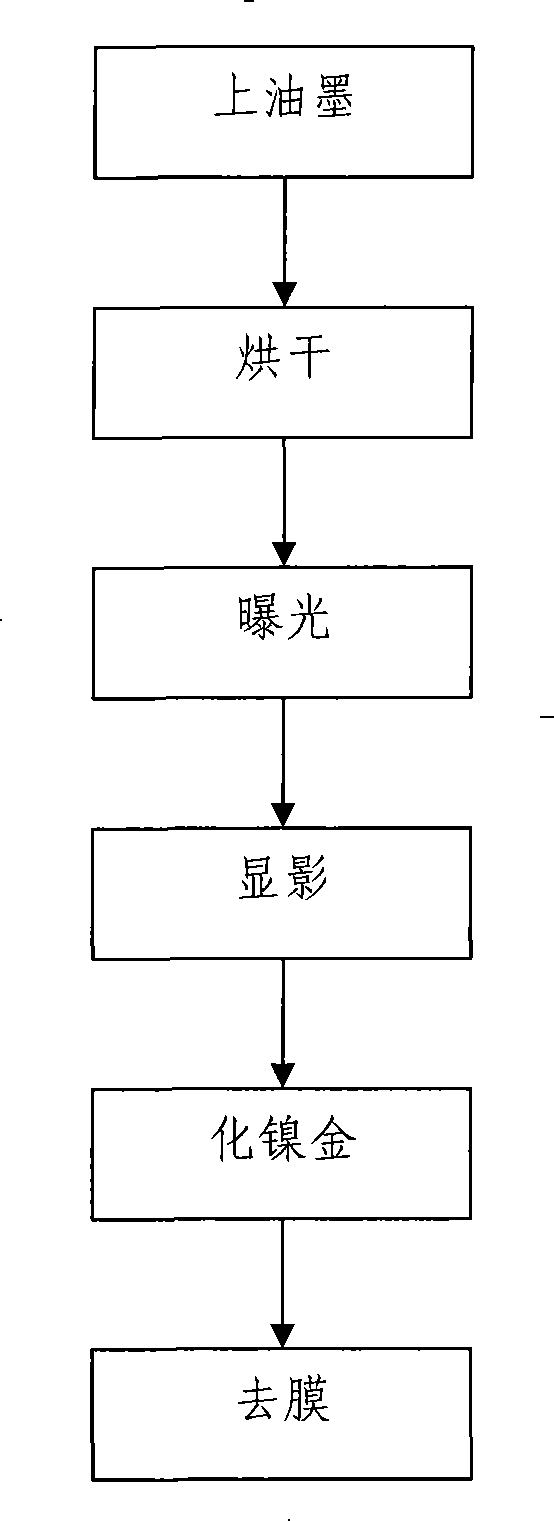

Method for melting nickel alloy by selective ink instead of dry film

InactiveCN101562943AEmission reductionImprove protectionConductive material chemical/electrolytical removalScreen printingEcological environment

The invention discloses a method for melting a nickel alloy by a selective ink instead of a dry film, which comprises the following steps: (1) selectively coating ageing resistant nickel alloy ink on a circuit board by a screen printing technology to form a wet film; (2) drying the ink; (3) exposing the ink; (4) developing the wet film so as to expose the required copper surface; (5) performing nickel alloy melting on the circuit board; and (6) removing the wet film. The selective ink instead of the dry film is used for selective nickel alloy melting, so the cost is greatly reduced, and the combination effect of the wet film and the board surface is superior to the combination effect of the dry film and the board surface, unfavorable phenomena such as diffusion coating and the like can beeffectively prevented, the defective rate of production is reduced and the quality of products is ensured. In addition, the method simplifies the manufacturing flow, saves the ink, greatly reduces theemission of pollutants, saves the expenses of wastewater treatment and is simultaneously favorable for the protection of ecological environment.

Owner:ZHUHAI FOUNDER TECH MULTILAYER PCB +1

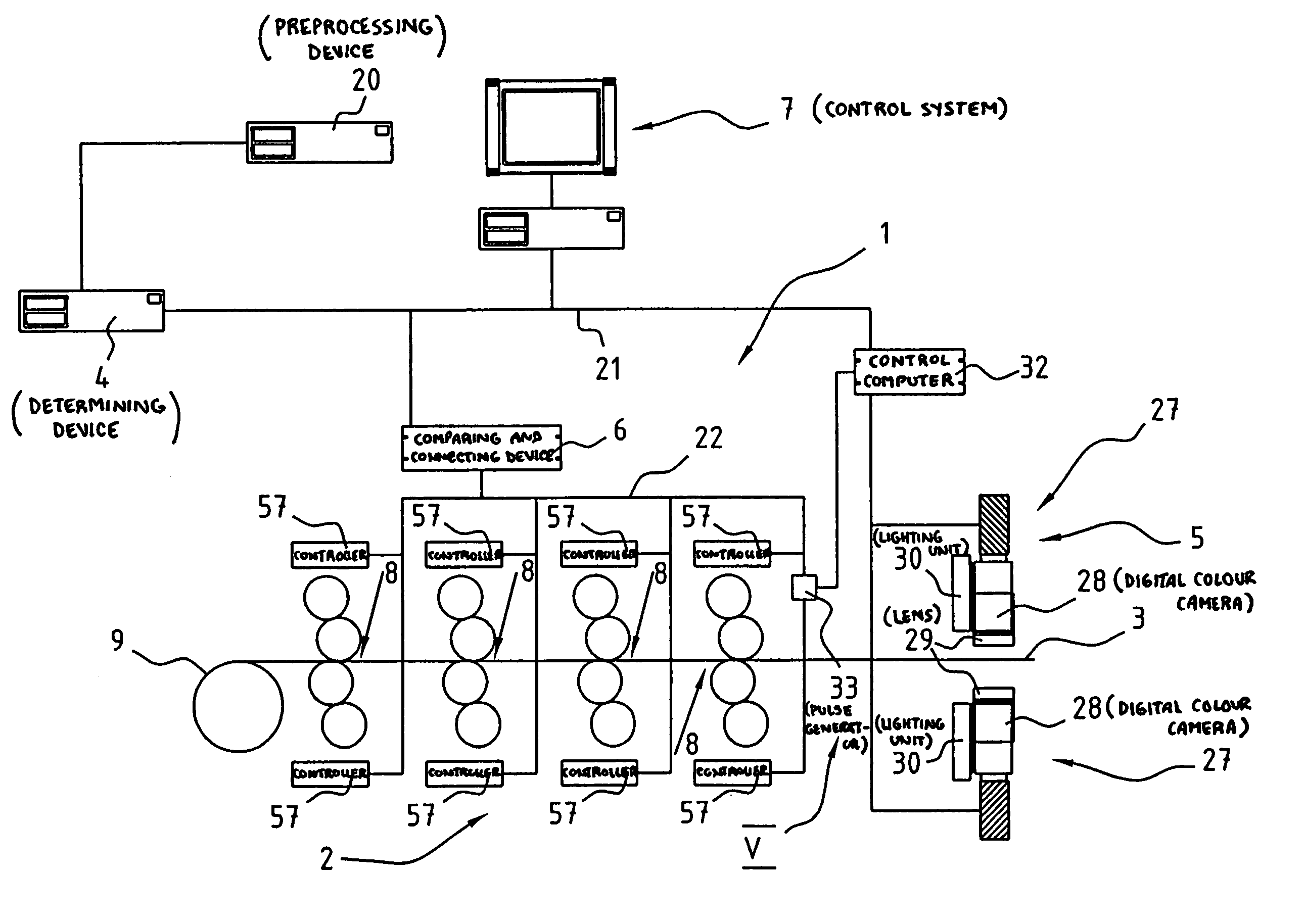

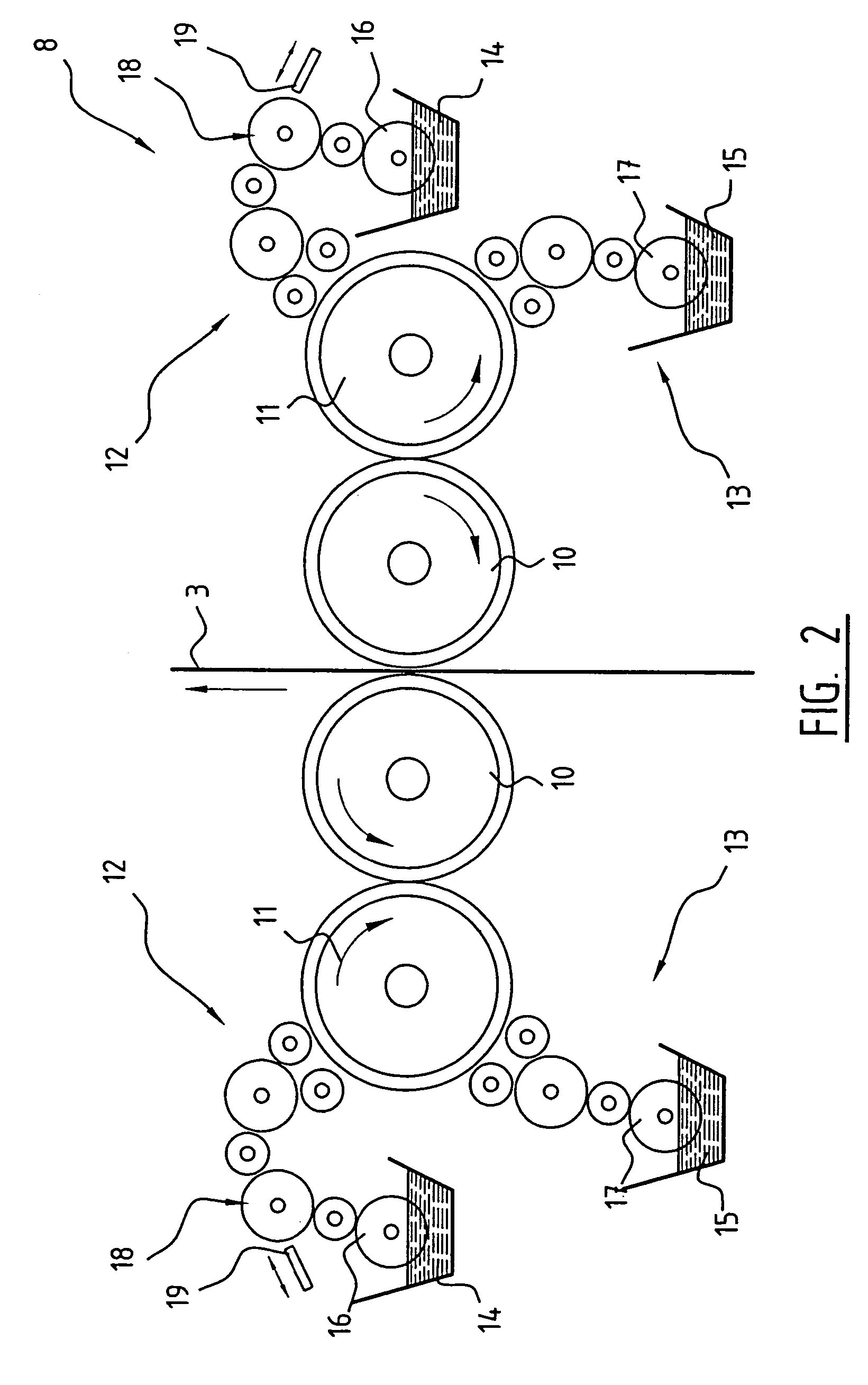

Method and system for monitoring printed material produced by a printing press

A method for monitoring printed material which is produced by a printing press and includes images printed on a paper web. The method includes the steps of determining, in an original, reference values for chosen parameters of the printed material, detecting the values of these parameters in the corresponding printed image, comparing the detected values to the reference values, and performing a correction when a difference in these values is found during the comparison. The chosen parameters may include the colours in the printed material, the location of the images in the printed material and / or the colour register of the printed material. A system for performing this method includes a reference value determining device, a detecting device and a comparing and correcting device connected to the reference value determining device and the detecting device.

Owner:Q I PRESS CONTROLS HLDG

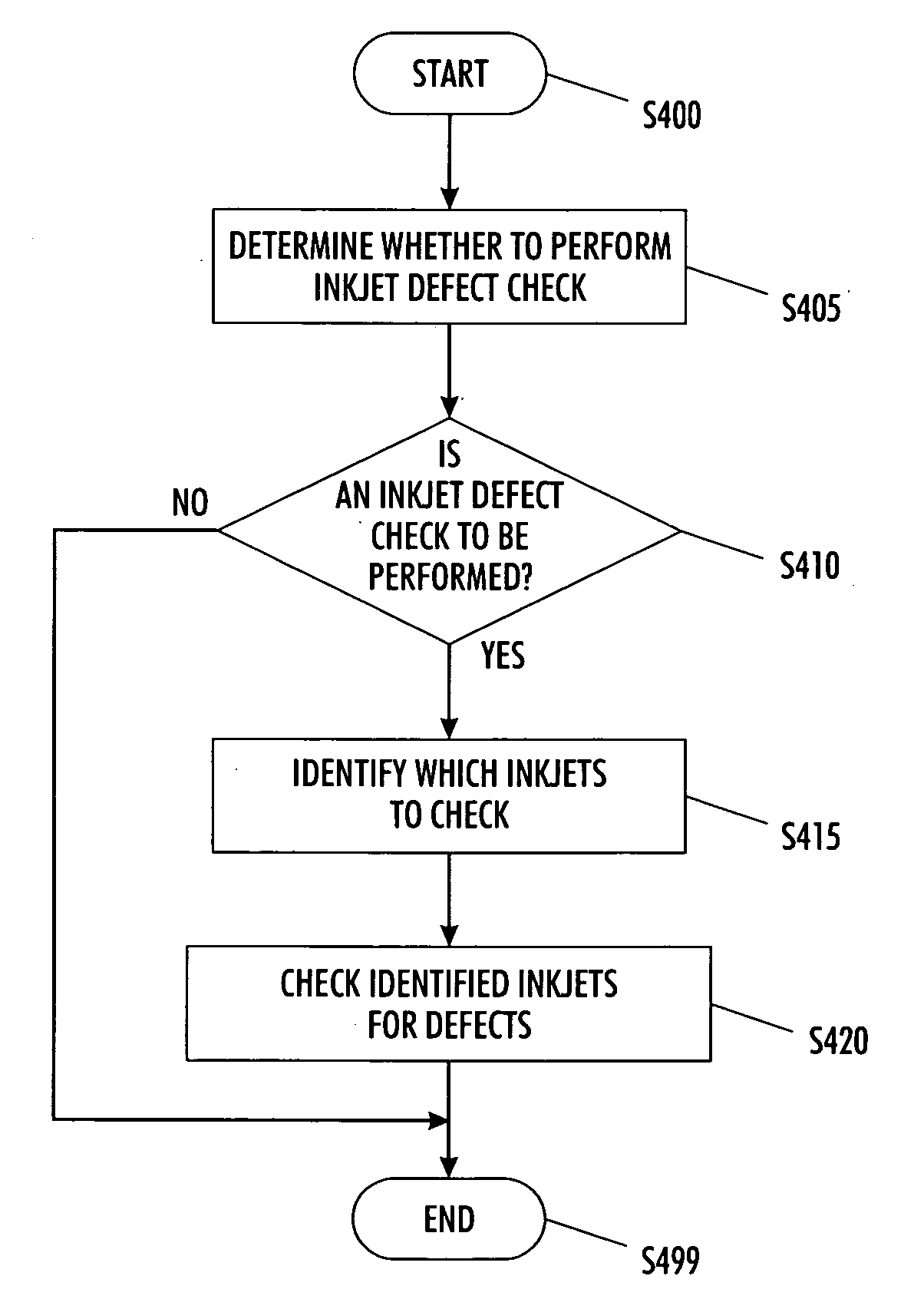

Systems and methods for detecting inkjet defects

ActiveUS20060098251A1Shorten the timeSave inkDigitally marking record carriersVisual representation by matrix printersInk printerImage sensor

A method for testing inkjets for defects in an inkjet device includes determining, based on the likelihood that one or more inkjets are defective, whether to perform an inkjet defect test, The method may also include, identifying, if it is determined to perform an inkjet defect test, which inkjets to test based on properties of the inkjets, the number of identified inkjets being less than a total number of inkjets in the inkjet device; and testing the identified inkjets for defects using an image sensor.

Owner:XEROX CORP

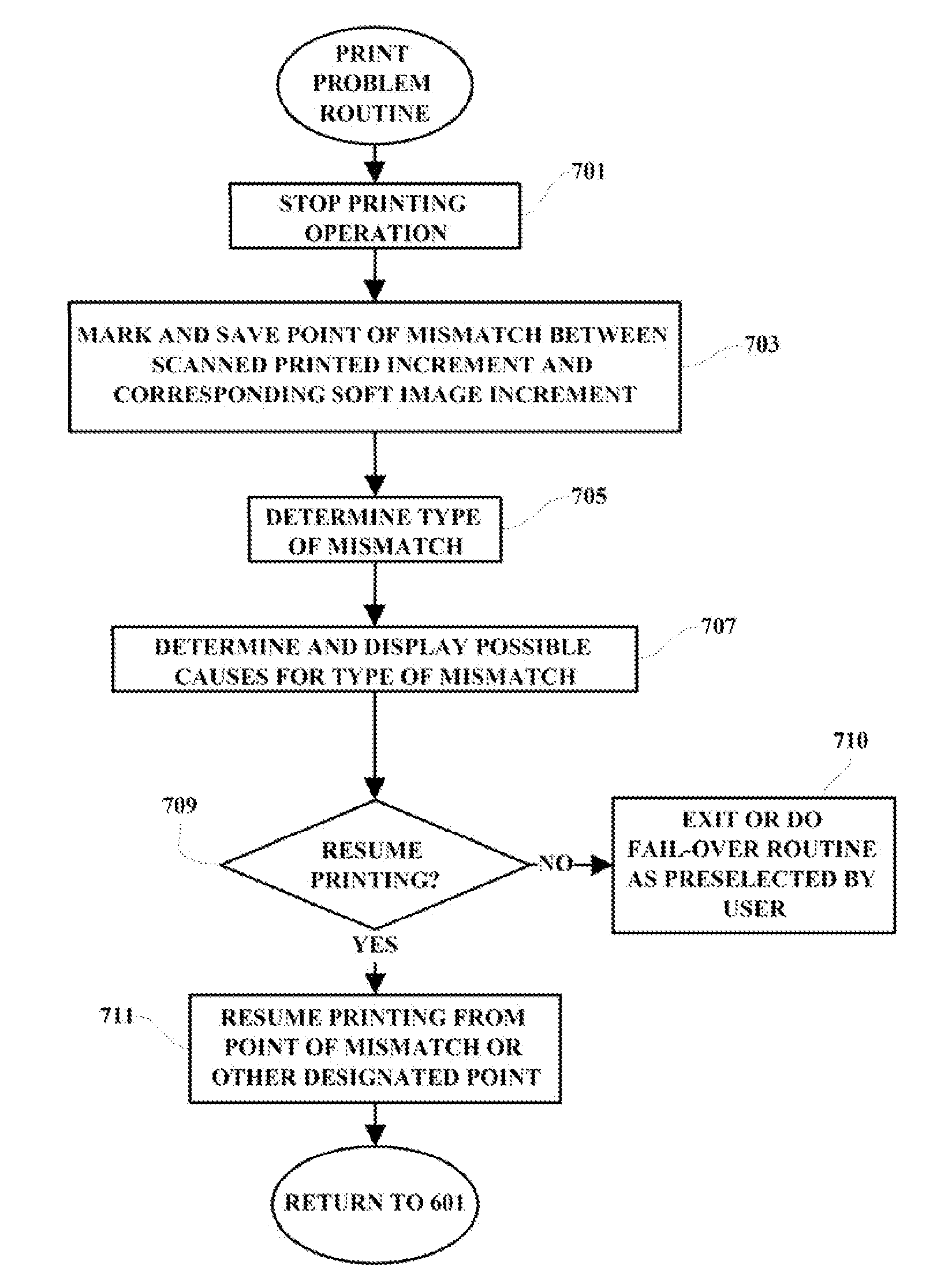

Print Quality Verification System

InactiveUS20120257917A1Save inkSave paperOther printing apparatusInput/output processes for data processingDocumentationVerification system

A method, programmed medium and system are disclosed which provide for an in-line scanner used to dynamically scan a document or image, real-time as it is being printed within a printer unit and before the printed document exits the printer. The scanned image is compared to a stored electronically-generated image of the file being printed. When the comparison is determinative that there is a printing problem, the printing operation may be stopped quickly before the partially printed document or image has exited the printer. An error message may then be displayed, and the user is enabled to take appropriate action. A resume function enables a user to resume a print job at exactly the place where it had left off before detecting a print problem. In another embodiment, when the system detects a problem with a print job, the entire print job of the remainder of the print job is sent from the faulting printer to another printer where either the remainder of the print job or the entire print job is completed.

Owner:IBM CORP

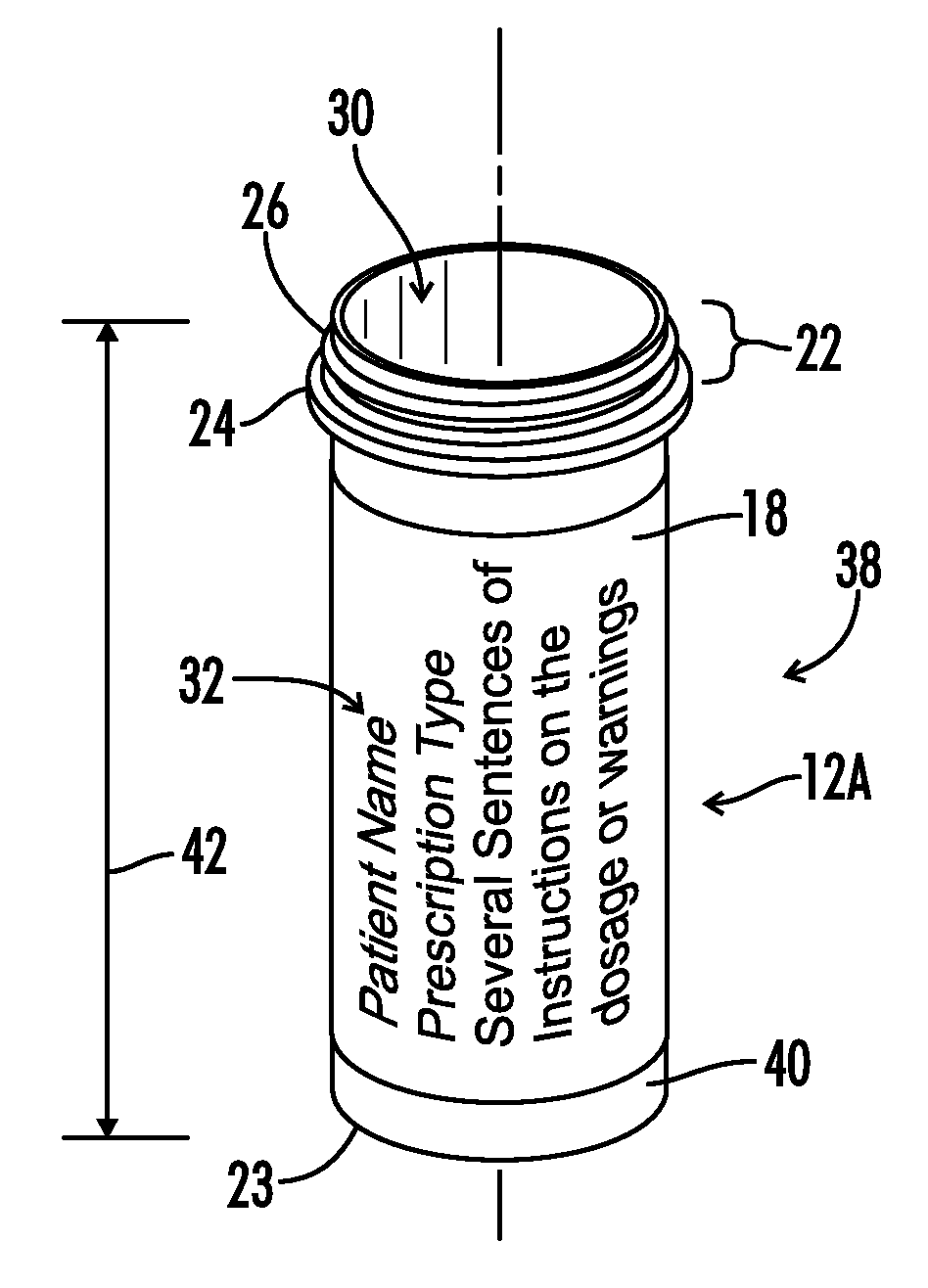

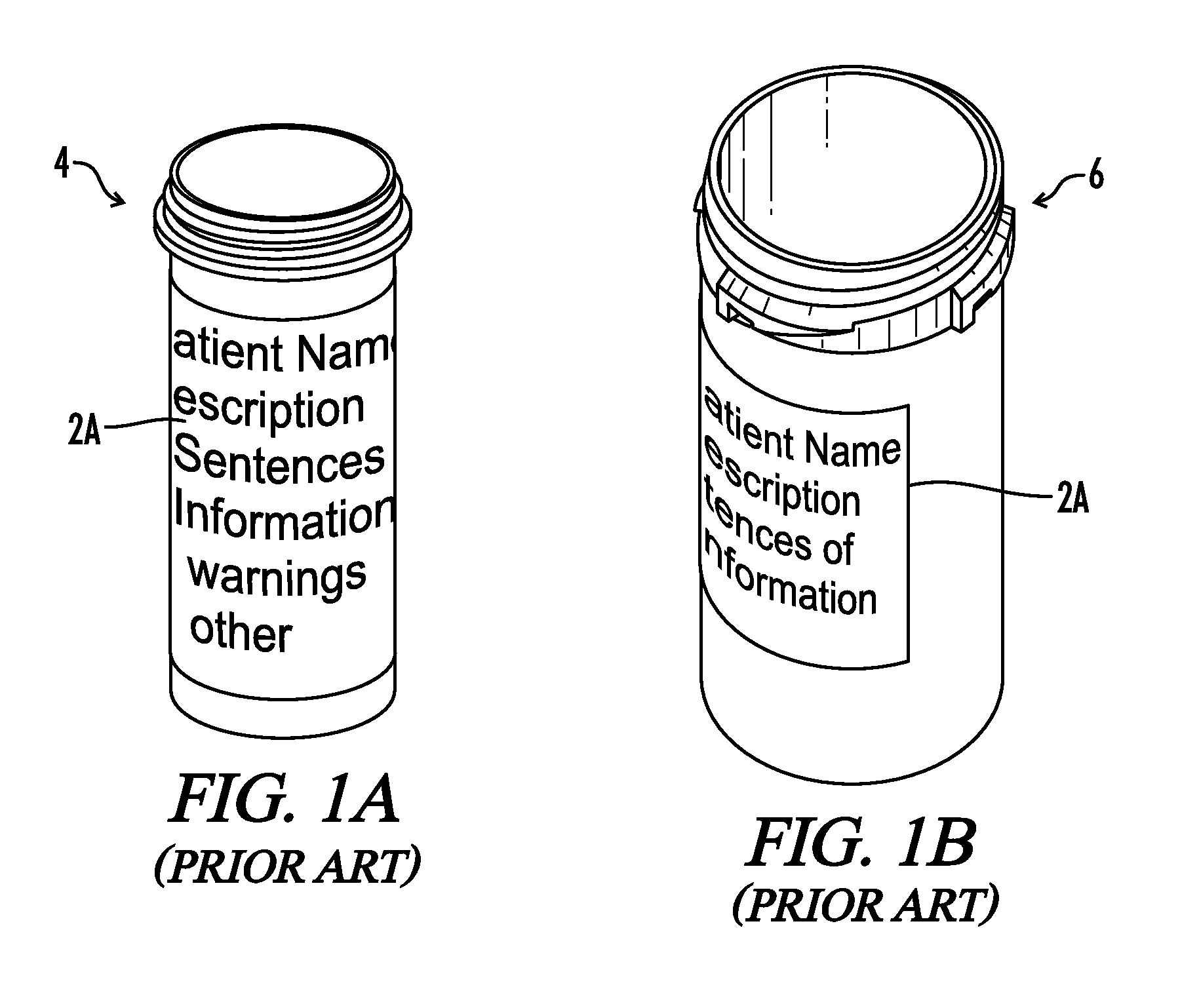

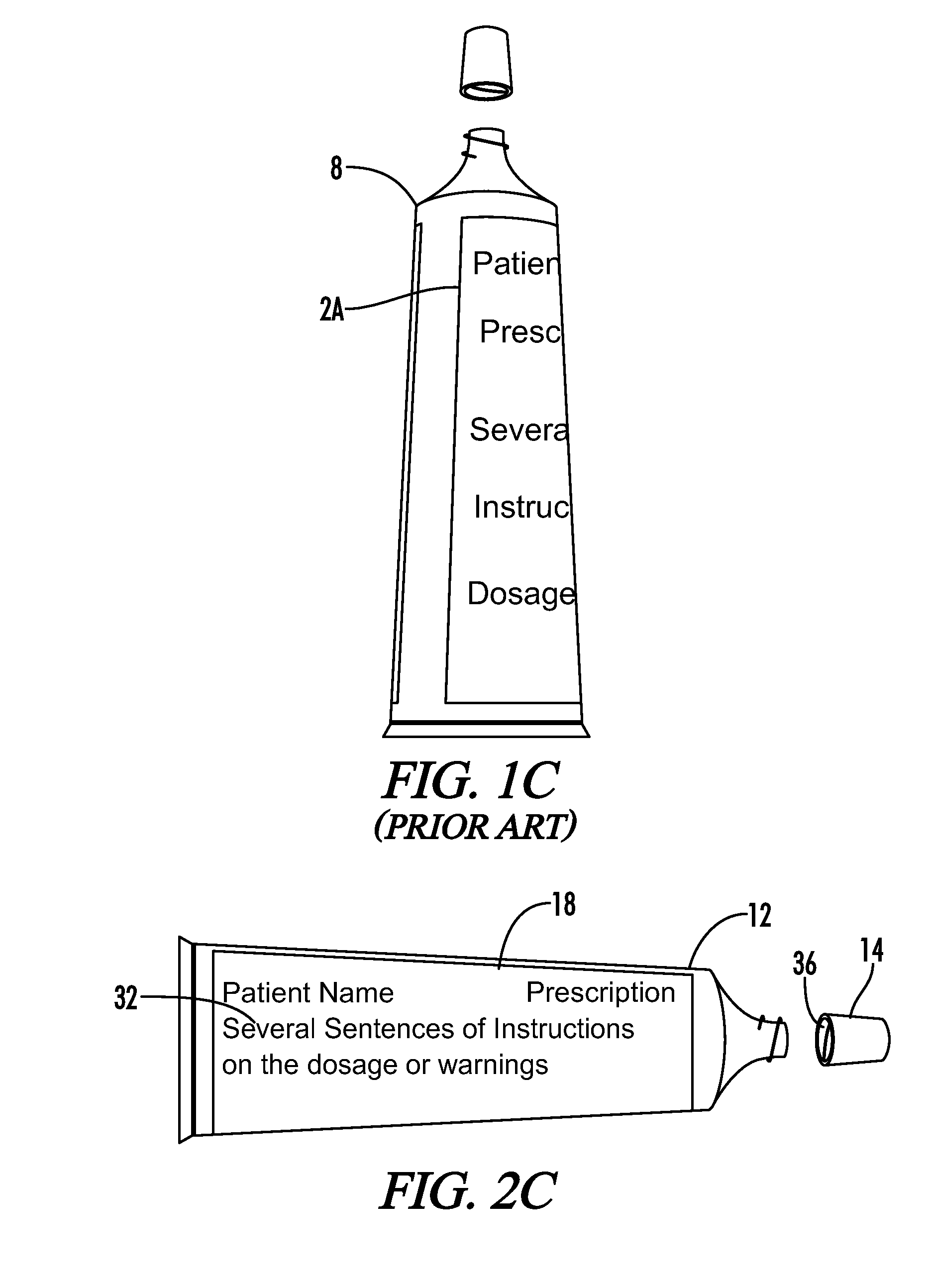

Labels With Multiple Designs For Prescription Containers

ActiveUS20100252474A1Maximize amount of informationMaximize readabilityStampsSmall article dispensingEngineeringMedical prescription

A system for labels that are positioned on a pharmaceutical container. The system can vary the choices for design and size of the labeling with respect to several types of container in which pharmaceuticals are positioned. The system increases the readability of information positioned on the pharmaceutical container by coordinating a label to the type and size of the container.

Owner:TRI STATE DISTRIBUTION

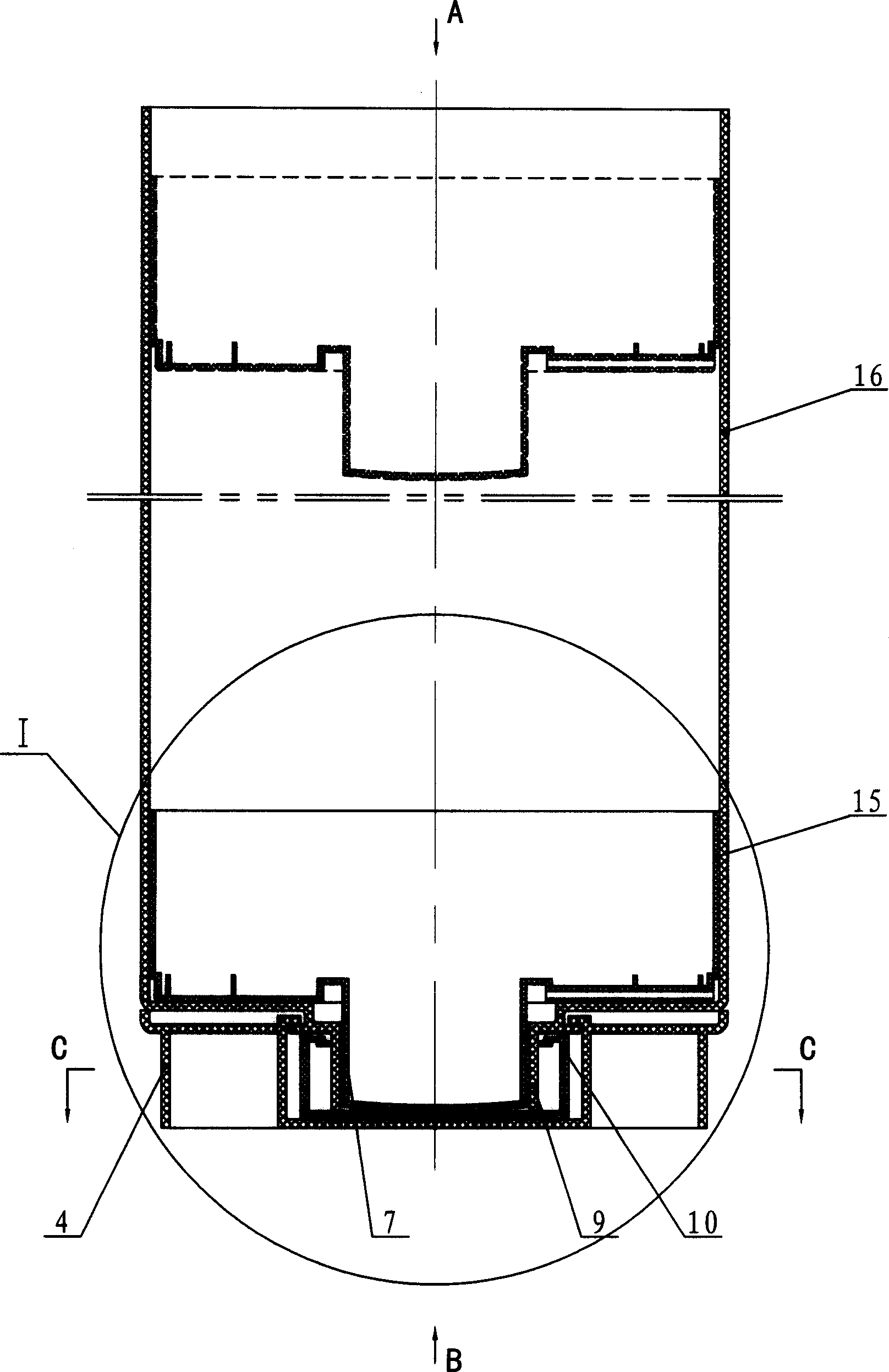

Pneumatic vacuum offset ink container

InactiveCN1803452ASave inkAchieve storageDispensing apparatusPackaging under vacuum/special atmospherePistonEngineering

The invention discloses a vacuum pneumatic offset ink container, which consists of cylinder and piston in the cylinder, wherein the ink outlet is opened on the front end of cylinder with inner lid on the ink outlet; the projected-column is set on the front end of piston to match the ink outlet; the air guide hole is set in the front end wall of piston; the inlet of air guide hole lies on the front end of piston and the outlet lies on the peripheral side face of piston. The container can adjust the ink, which realizes vacuum package and storage due to draining the air between piston and ink.

Owner:谭慈源

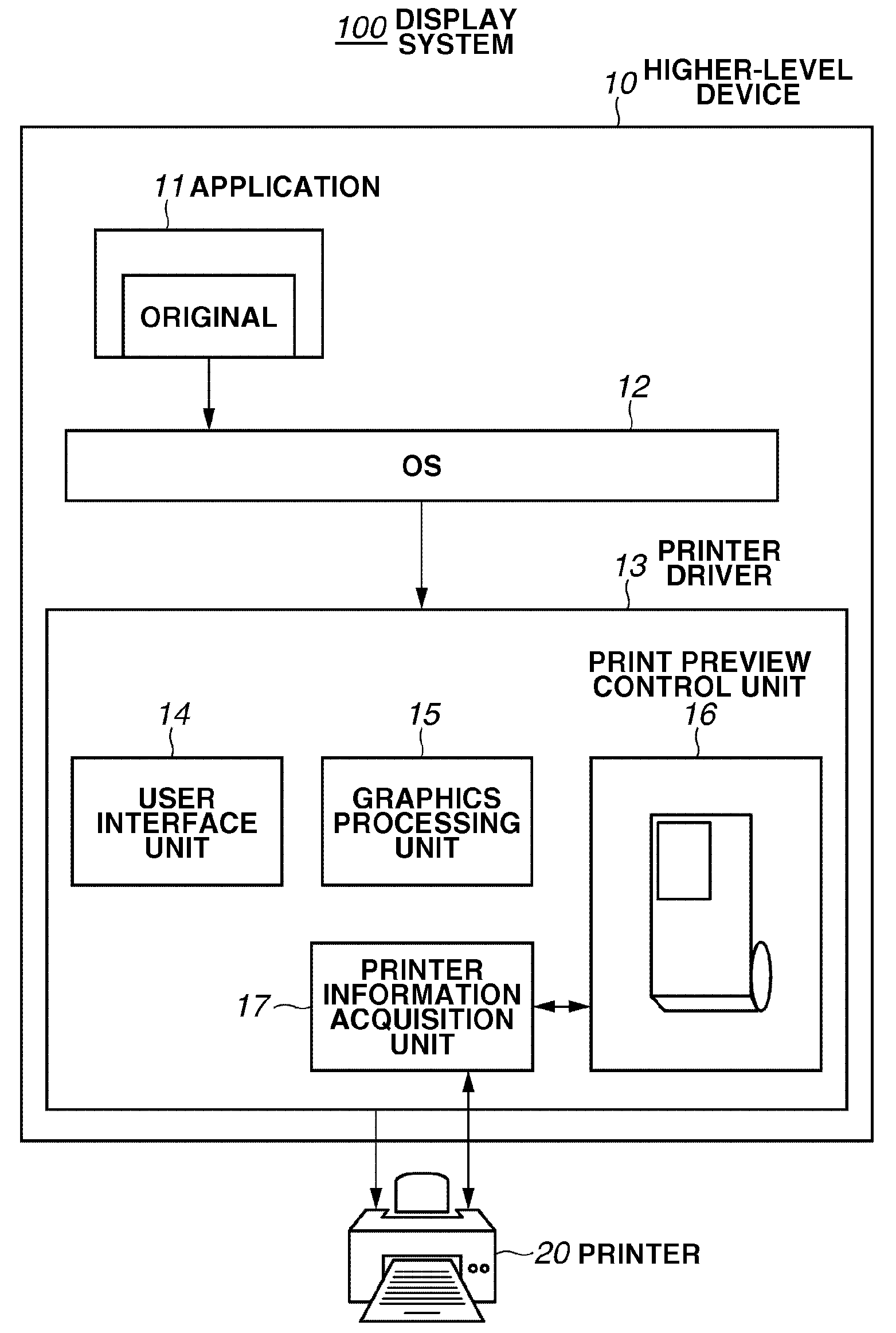

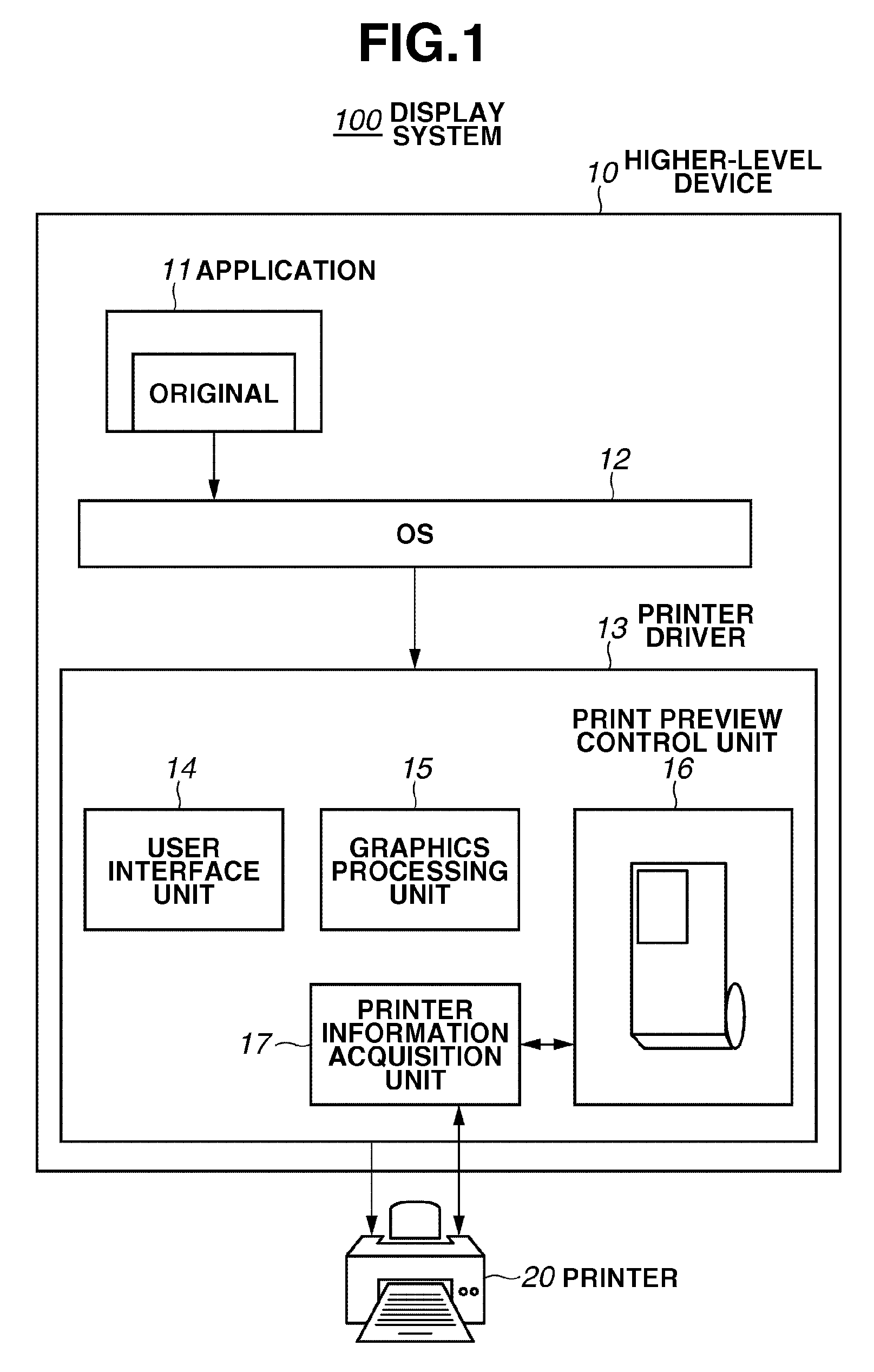

Display system, display method, and storage medium storing display program

InactiveUS20090059289A1Easy to findReduce failureDigital computer detailsDigital output to print unitsControl unitComputer engineering

A display system configured to display a print preview of a roll paper image and a print area includes an acquisition unit configured to acquire a roll paper width, and a horizontal length of a set paper size, a print-area determination unit for determining a print area based on the acquired roll paper width and horizontal length, a determination unit configured to determine whether the determined print area is displayable in a preview area, a calculation unit configured to calculate a scaling required to display the entire print area in a preview according to a vertical length of the print area, and a display control unit configured to, if it is determined by the determination unit that the entire print area is not displayable, preview a roll paper image and a print area based on the scaling calculated by the calculation unit.

Owner:CANON KK

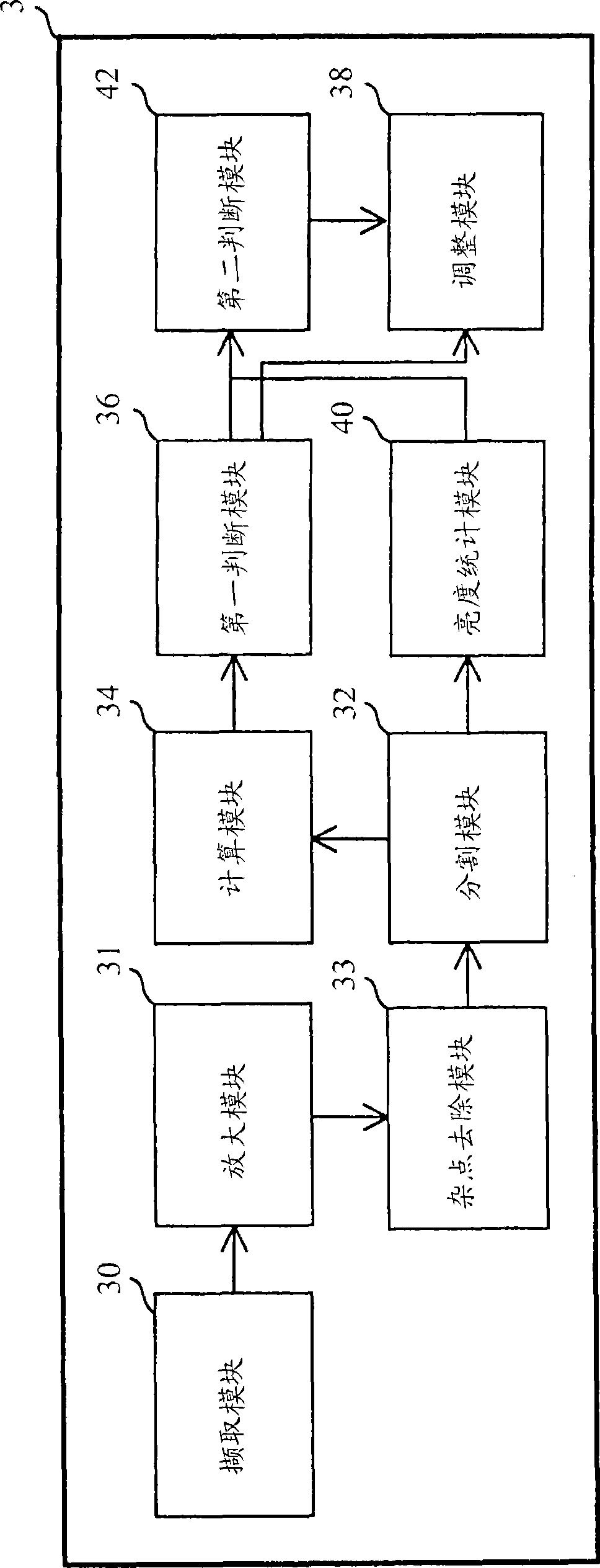

Image processing device and image processing method

ActiveCN101500063AImprove unevenness of light and shadeAdjust average brightnessPictoral communicationImaging processingImage segmentation

The invention provides an image processing device, which comprises a partitioning module, a first judge module and an adjusting module, wherein the partitioning module is used for partitioning an image into a plurality of sub-images; the first judge module comprises a brightness statistical unit and a judge unit; the brightness statistical unit is used for generating a brightness statistical result of the image and determining a brightness critical value according to the brightness statistical result; the judge unit is used for judging whether the average brightness of a target sub-image of the sub-images is larger than the brightness critical value or not; and if so, the adjusting module adjusts the average brightness of the target sub-image.

Owner:QUANTA COMPUTER INC

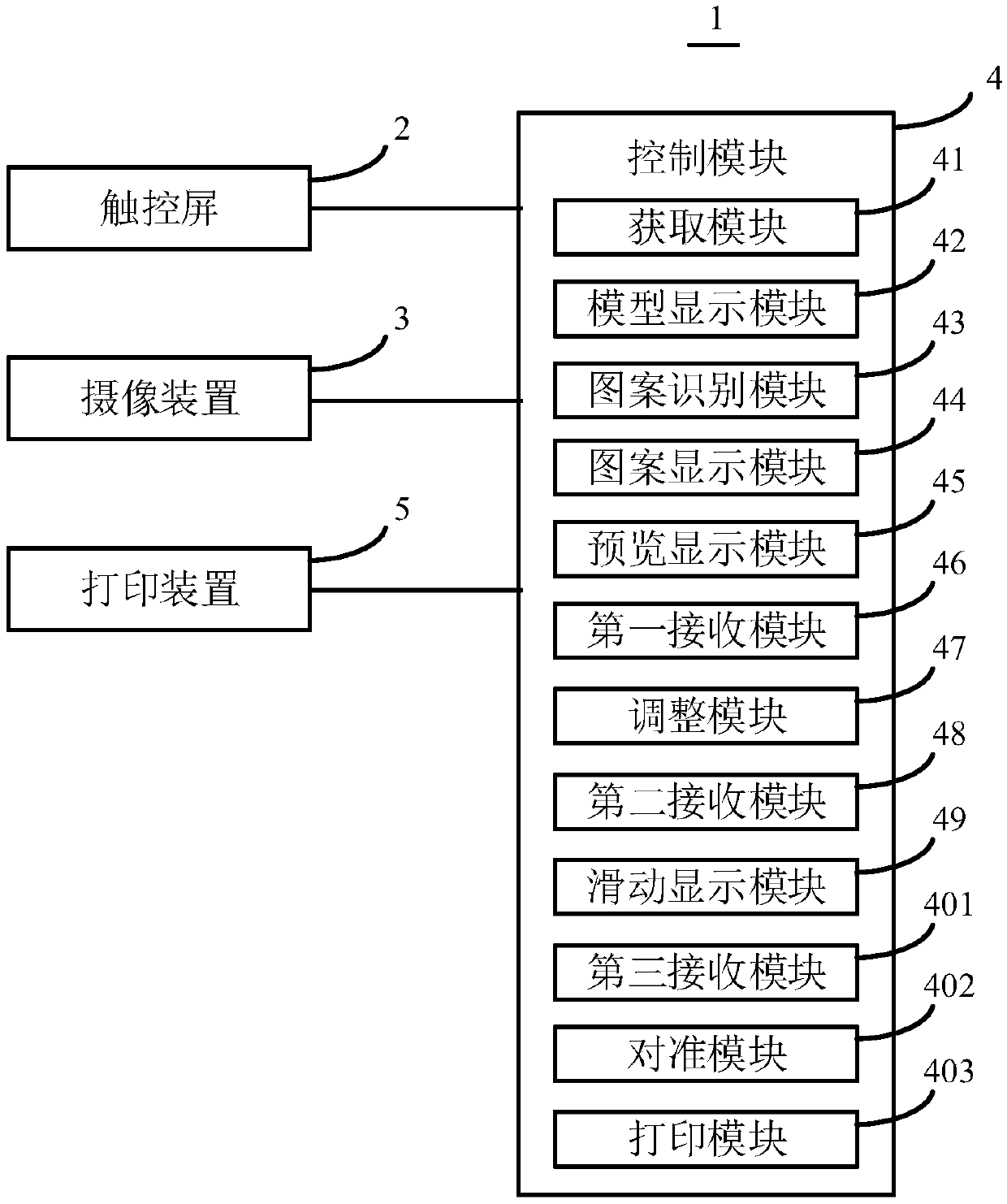

Printing method and system of nail beautifying device, nail beautifying equipment and medium

The embodiment of the invention relates to the field of nail beautifying, in particular to a printing method and system of a nail beautifying device, nail beautifying equipment and a medium. The nailbeautifying device comprises a touch screen; the touch screen is used for displaying a first interface; the first interface comprises a first area and a second area; and the first area comprises a plurality of first patterns. The printing method of the nail beautifying device comprises the following steps of displaying a user nail model on the second area; displaying a second pattern on the secondarea, wherein the user nail model is superposed with the second pattern partially, and the superposed part pattern of the second pattern and the user nail model serves as a printing pattern; and printing the printing pattern according to a printing instruction. Patterns to be printed are reduced, ink is saved, the service time of an ink box is prolonged, and the cost is reduced; furthermore, twoprocesses of coating with anti-overflowing glue before printing and cleaning the anti-overflowing glue after printing are reduced, and the nail beautifying efficiency is improved.

Owner:SHENZHEN NEARBYEXPRESS TECH DEV CO LTD

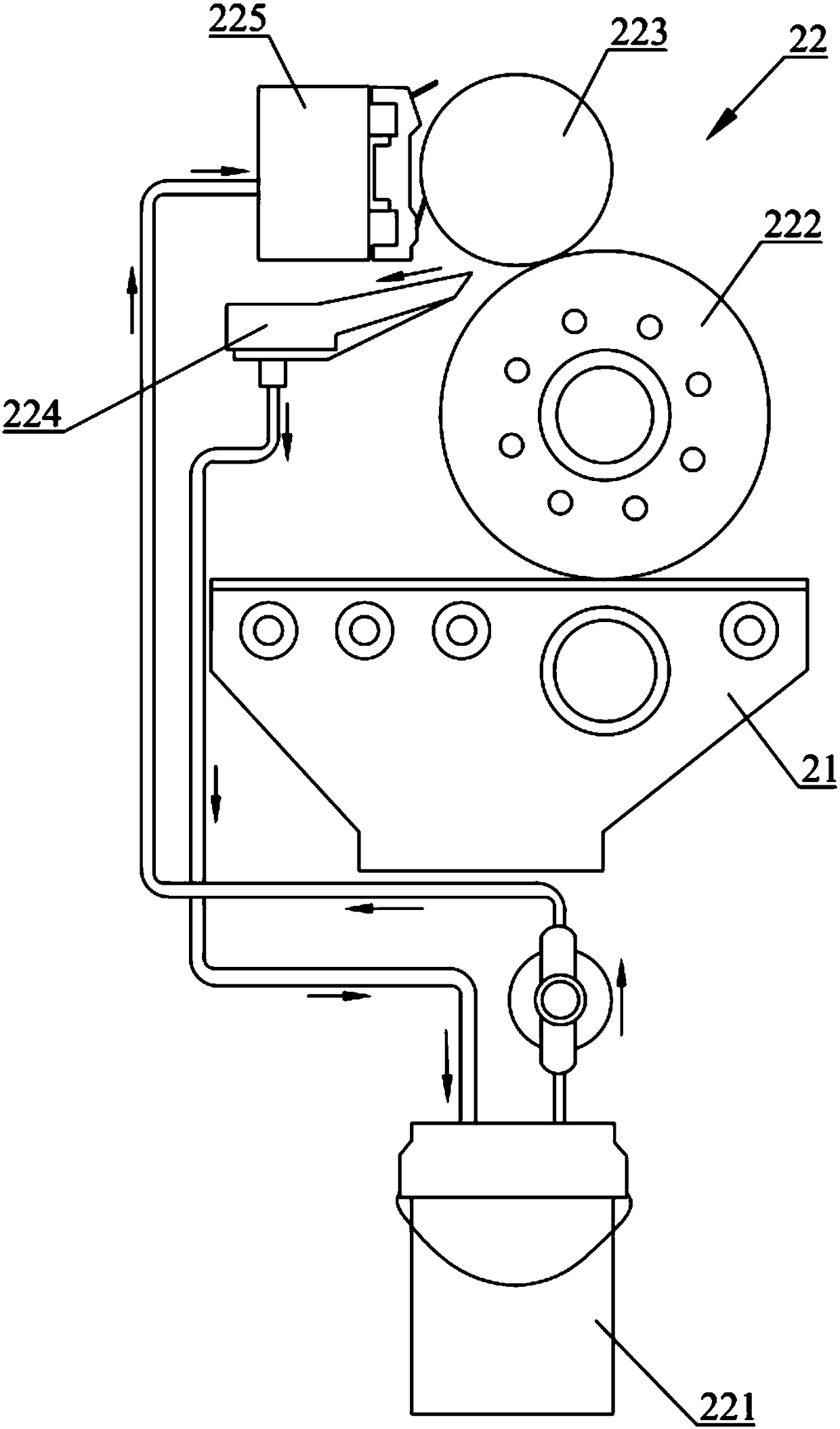

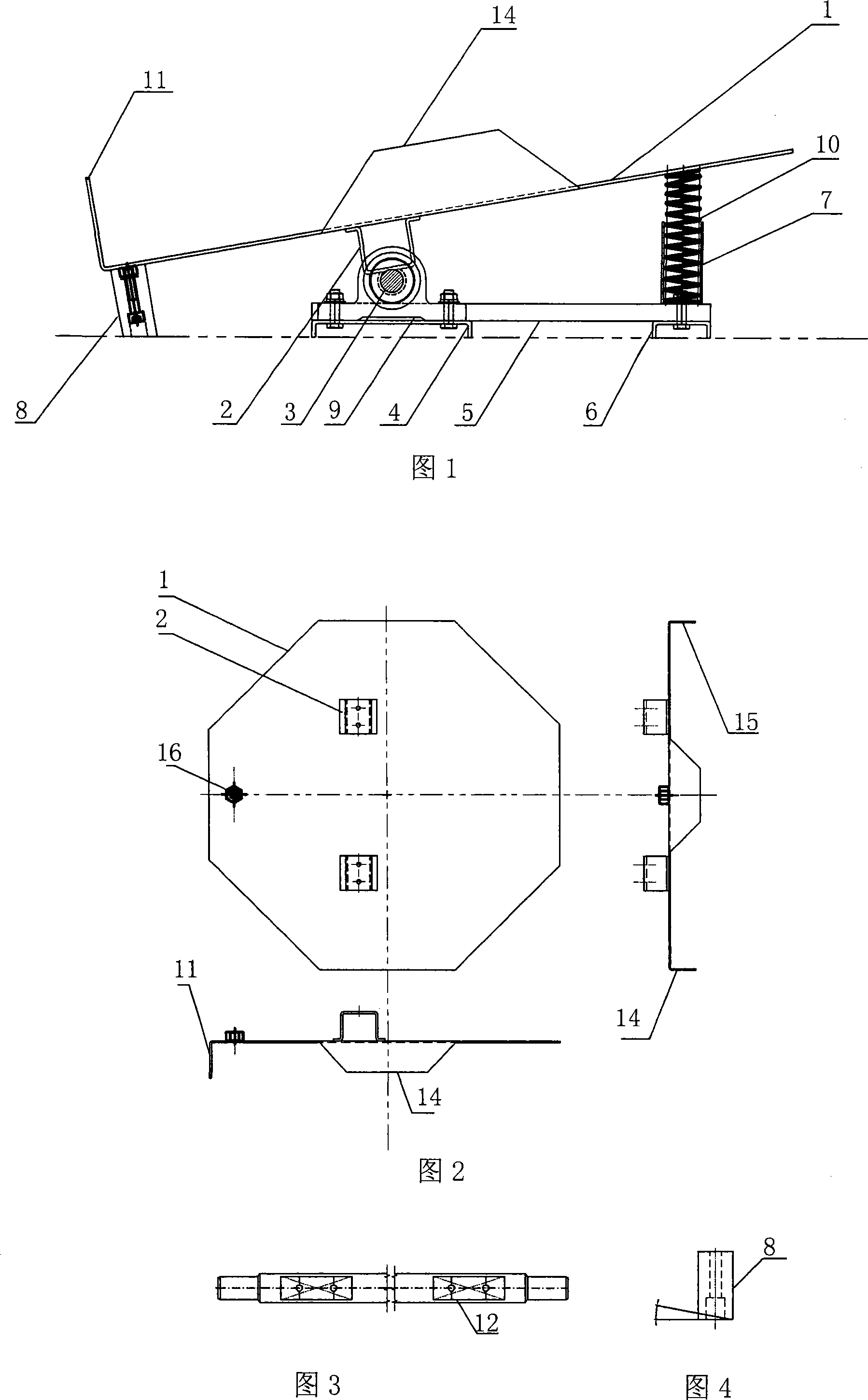

Corrugated board printing production line with environmental protection and energy saving functions

InactiveCN108394172ARealize continuous processingIncrease productivityRotary pressesMetal working apparatusProduction lineStack machine

The invention discloses a corrugated board printing production line with environmental protection and energy saving functions, and belongs to the technical field of corrugated board manufacturing. Thecorrugated board printing production line comprises a machine frame, a paper feeding mechanism, a printing mechanism, a slotting mechanism, a die cutting mechanism and an automatic stacking machine,wherein the paper feeding mechanism, the printing mechanism, the slotting mechanism, the die cutting mechanism and the automatic stacking machine are sequentially arranged on the machine frame. The printing mechanism comprises a printing portion, and the printing portion comprises an ink barrel, a plate cylinder, an anilox roller, an air bag type scraper and an ink fountain under the anilox rollerand the air bag type scraper. The plate cylinder and the anilox roller are rotatably connected to the machine frame, and the plate cylinder is pressed against a corrugated board. The anilox roller ispressed against the plate cylinder, the air bag type scraper communicates with the ink barrel and is in contact with the edge of the anilox roller, and the ink fountain communicates with the ink barrel. The corrugated board is subjected to paper feeding, printing, slotting and die-cutting, and finally, corrugated boards are neatly stacked by the automatic stacking machine. The air bag type scraper scrapes ink on the anilox roller, the amount of the ink is saved, and an ink layer is dried quickly; and the running speed of a machine is improved, the power consumption and labor cost are saved, and energy saving and environmental protection are achieved.

Owner:合肥丹盛包装有限公司

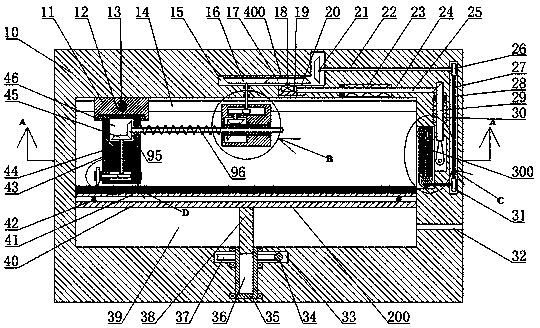

Automatic paper lace printing equipment

InactiveCN110171210AAutomatic printingSimple structureTypewritersPower drive mechanismsPulp and paper industryPrinting ink

The invention relates to the field of printing, in particular to automatic paper lace printing equipment. The equipment comprises a machine body and an operating cavity arranged in the machine body, wherein a rotating frame is rotationally arranged in the operating cavity, and the rotating frame rotates to drive a supporting block arranged on the left side of the rotating frame to move along a rectangular track so as to drive the rotating block arranged on the bottom wall of the supporting block to move along the rectangular track. The paper lace automatic printing equipment can realize automatic paper lace printing, and meanwhile, an automatic paper feeding device is arranged in the equipment so that paper can be printed one by one. The equipment is simple in structure and convenient to operate, printing ink is saved, the working efficiency is high, the functionality is high, the stability is good, and production and popularization are facilitated.

Owner:FOSHAN TUOXIN PACKAGING CO LTD

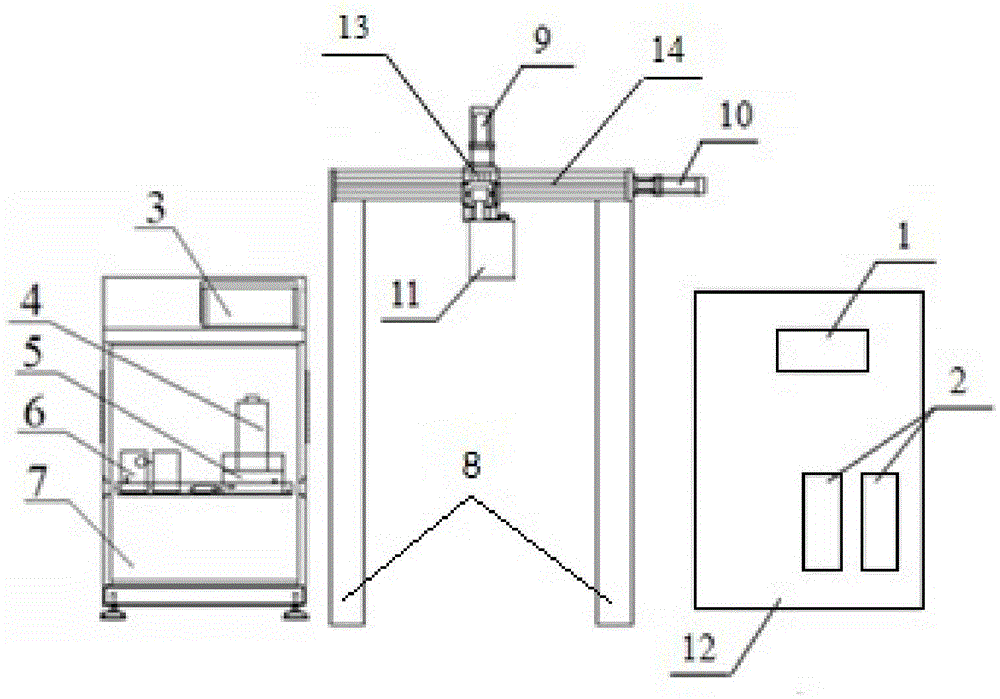

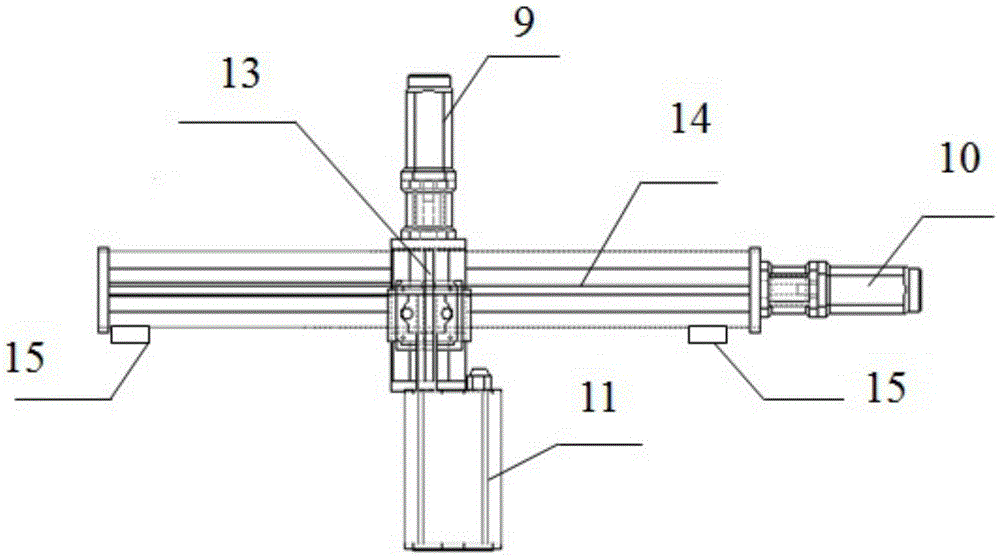

Automatic positioning code printer

The present invention relates to an automatic positioning code printer. The automatic positioning code printer comprises a frame, an ink supply assembly, a nozzle, a control assembly and a nozzle mobile assembly. The nozzle and the nozzle mobile assembly are connected with the control assembly; the nozzle mobile assembly includes an X-axis transmission mechanism and a Y-axis transmission mechanism; the X-axis transmission mechanism is arranged on the frame, the Y-axis transmission mechanism is arranged on the X-axis transmission mechanism, and the nozzle is installed on the Y-axis transmission mechanism. Compared with the prior art, the automatic positioning code printer is simple in structure, clear in printing, is able to print large characters and rapidly adapt the specifications of products with various printing codes, is accurate in printing code positioning, and greatly reduce the operators' labor intensity, etc.

Owner:苏州圣瑞赛标识科技有限公司

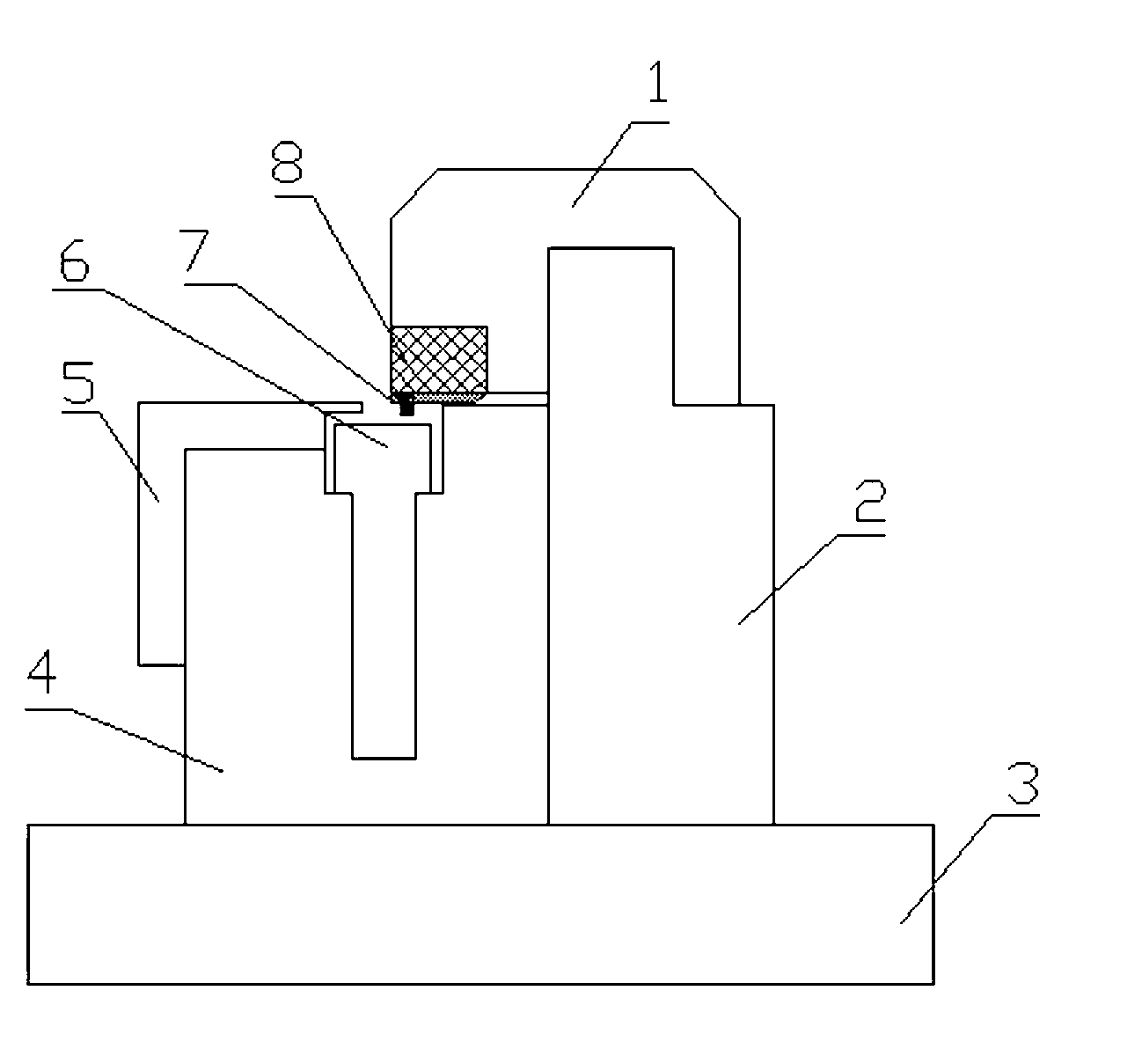

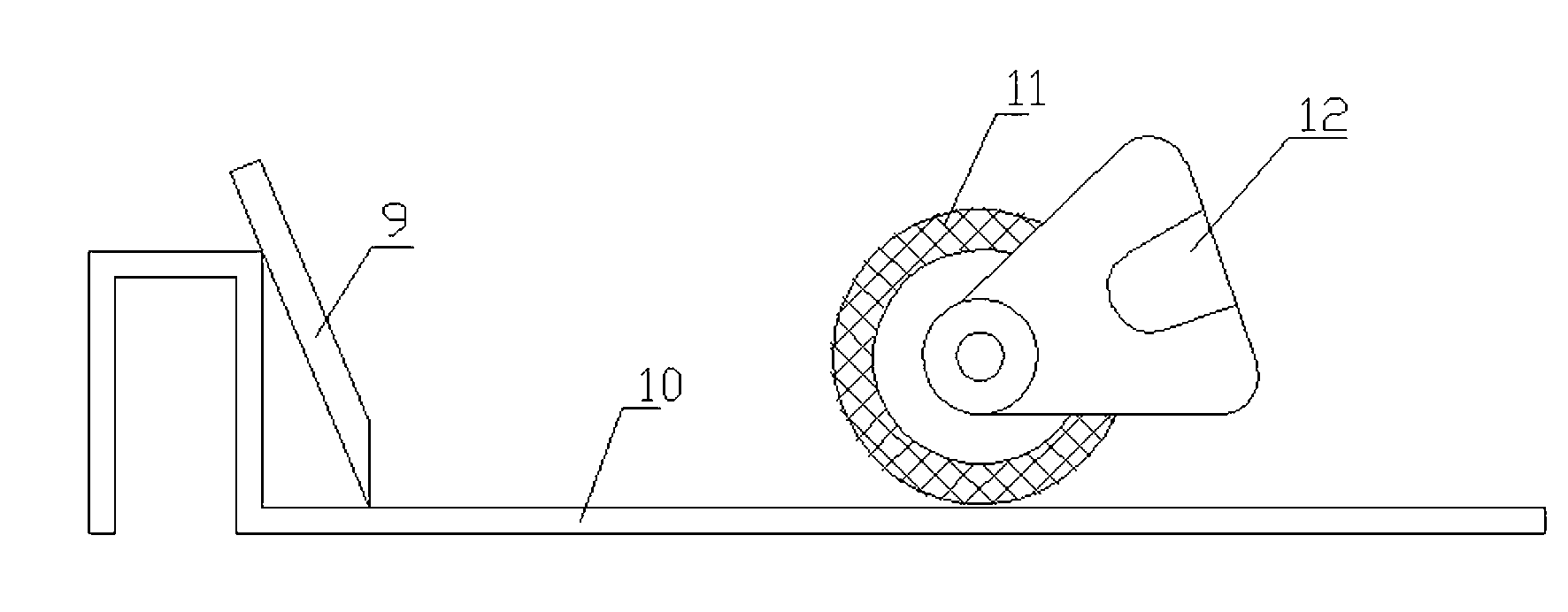

Diode color ring roll printing device and roll printing method

The invention discloses a diode color ring roll printing device and a roll printing method. At least one glass-bulb arc-shaped groove capable of containing one diode is formed in the top face of a die, the arc-shaped groove penetrates through the die, the length of the arc-shaped groove is smaller than the distance between two wiring terminals of the diode, the die is arranged on a die carrier, space for containing the wring terminals of the rolling diode is formed in the two sides of the arc-shaped groove and outside the die, the guiding direction of a linear guiding rail is perpendicular to the axial direction of the arc-shaped groove, and the printing device is arranged on the linear guiding rail in a sliding mode. According to the roll printing method, the diode color ring roll printing device is adopted. Before the diode color ring roll printing device performs roll printing, the diode is only needed to be installed in the arc-shaped groove, and the two wiring terminals of the diode are located outside the groove; the roll printing method, the diode color ring roll printing device can be adopted for both a round leading wire diode and a square leading wire diode to perform the roll printing, and material of leading wires is not limited.

Owner:JINAN JINGHENG ELECTRONICS

Aluminum foil double-face fast coating device and method

InactiveCN107159524ASave spaceFast coatingPretreated surfacesCoatingsEngineeringStructural engineering

The invention provides an aluminum foil double-face fast coating device. The aluminum foil double-face fast coating device comprises a first frame, an unwinding mechanism, a feeding drawing mechanism, a coating mechanism, a drying oven, a discharging drawing mechanism and a winding mechanism, wherein the unwinding mechanism, the feeding drawing mechanism, the coating mechanism, the drying oven, the discharging drawing mechanism and the winding mechanism are arranged on the first frame. The coating mechanism is a double-face ladder type coating mechanism which comprises a front side coating mechanism body and a back side coating mechanism body. The drying oven is a suspension drying oven. Aluminum foil sequentially passes through the unwinding mechanism, the feeding drawing mechanism, the coating mechanism, the drying oven, the discharging drawing mechanism and the winding mechanism, and then double-face coating is completed. An aluminum foil double-face fast coating method sequentially comprises the steps of unwinding, front side coating, back side coating, double-face drying and winding. According to the aluminum foil double-face fast coating device and method, through the ladder type one-time front side and back side coating and one-time double-face drying technologies, the material conveying path is greatly shortened, fast coating is achieved, the coating speed can reach 150m / min, in addition, the double faces are dried at a time after being coated, the space of the drying oven is saved, the manufacturing cost is reduced, meanwhile, energy is saved by about 160KW / h, and the aluminum foil double-face fast coating device and method are suitable for gravure coating and reverse kiss coating.

Owner:XIAN XINDA MACHINERY

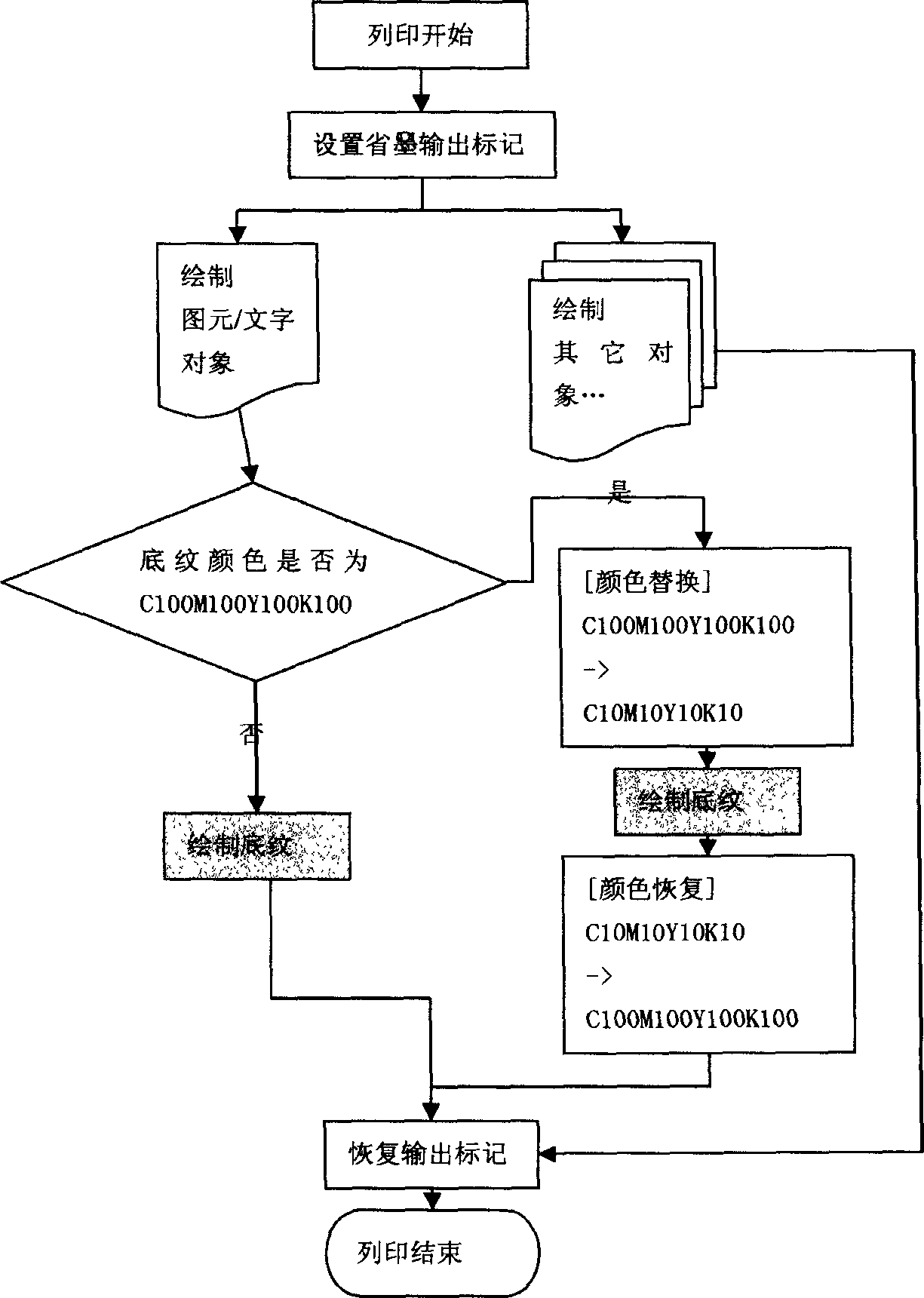

Column printing method for saving ink

InactiveCN1820959AWill not affect browsingSave inkOther printing apparatusPrinting inkPulp and paper industry

The present invention relates to a kind of train printing method capable of saving ink, and belongs to the field of printing technology. Before train printing, the targets containing colorplate colors C100M100Y100K100 is specially treated and replaced into C10M10Y10K10 before drawing, and after drawing the color values are restored. The said train printing method can express the color of target, show the typesetting effect in paper, save printing ink and lower production cost.

Owner:BEIJING FOUNDER ELECTRONICS CO LTD +1

Raised Pad manufacturing method

ActiveCN111511120AOmit the preparation processSimple processPrinted circuit liquid treatmentPrinted circuit secondary treatmentCopper platingElectrical conductor

The invention relates to a Raised Pad manufacturing method, which comprises the steps of manufacturing an outer layer circuit, and the manufacturing of the outer layer circuit comprises the followingsteps of: S1, drilling the inner layer circuit of a PCB, entering a board electrical process, electroplating the whole board in an electroplating mode, and plating a layer of copper on the whole boardsurface and the wall of a drilled hole; S2, pressing a layer of photosensitive anti-corrosion film on the board surface subjected to plate electrification by using a hot roller film pressing machineto ensure the copper plating thickness; S3, manufacturing an outer layer circuit by adopting a developing machine, an etching machine and a film removing machine; S4, depositing a thin copper layer onthe independent units of the outer-layer circuit through copper deposition wires to enable the independent units to be connected together, and providing a conductor for subsequent electroplating; S5,pressing a layer of photosensitive anti-corrosion film on the board surface subjected to plate electrification by using a hot roller film pressing machine for manufacturing a PAD pattern for electroplating; and S6, placing the treated board on a copper plating wire to be subjected to copper plating operation, and obtaining the Raided Pad. The Raised Pad manufacturing method has the advantages ofthe simple process, low cost, high efficiency, the good product yield and the like.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

Method for manufacturing color filters

InactiveUS20060210707A1Improve production efficiencyReduce manufacturing costOptical filtersPretreated surfacesIndium tin oxideEngineering

A method for manufacturing a color filter includes the following steps: (a) forming a black matrix layer (240) on a substrate (210) by means of imprinting; (b) using a multi-head ink-jet array (MHIJA) (300) to color the black matrix layer, thereby forming a color layer (250) thereon; and (c) forming an indium-tin oxide (ITO) layer (260) on the color layer. The means of imprinting can form the black matrix layer quickly. This enhances a manufacturing efficiency and decreases a manufacturing cost. Furthermore, the multi-head ink-jet array can color the black matrix layer by jetting inks once. This enhances a manufacturing efficiency, saves the ink and decreases a manufacturing cost. Therefore, the method has an enhanced efficiency and a decreased cost.

Owner:HON HAI PRECISION IND CO LTD

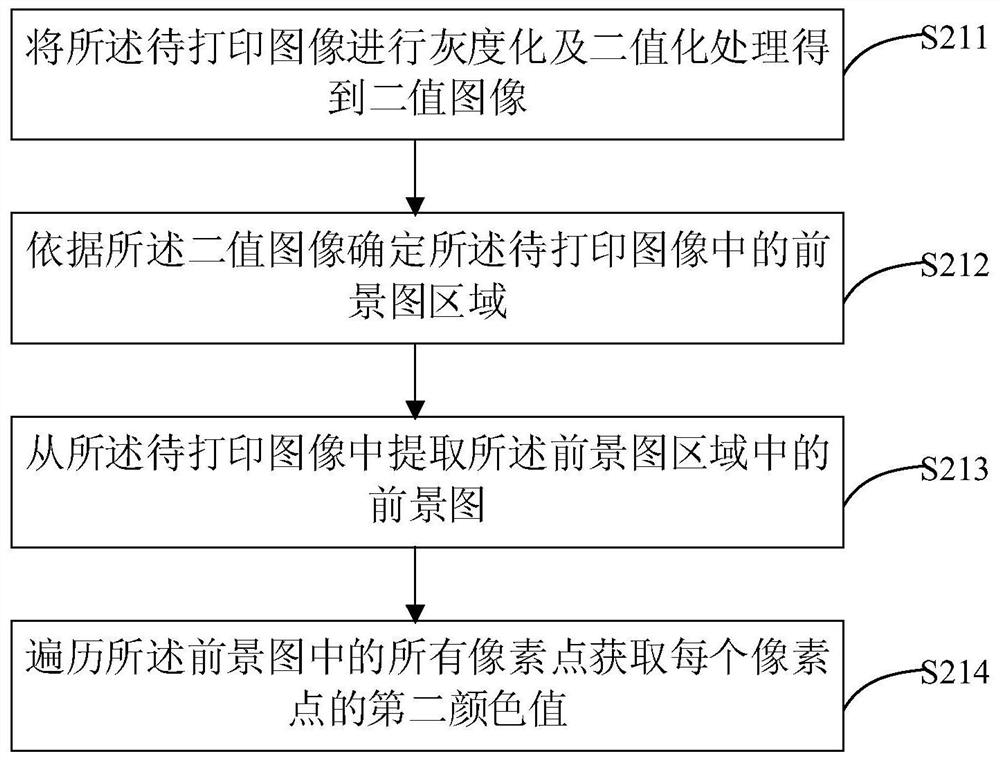

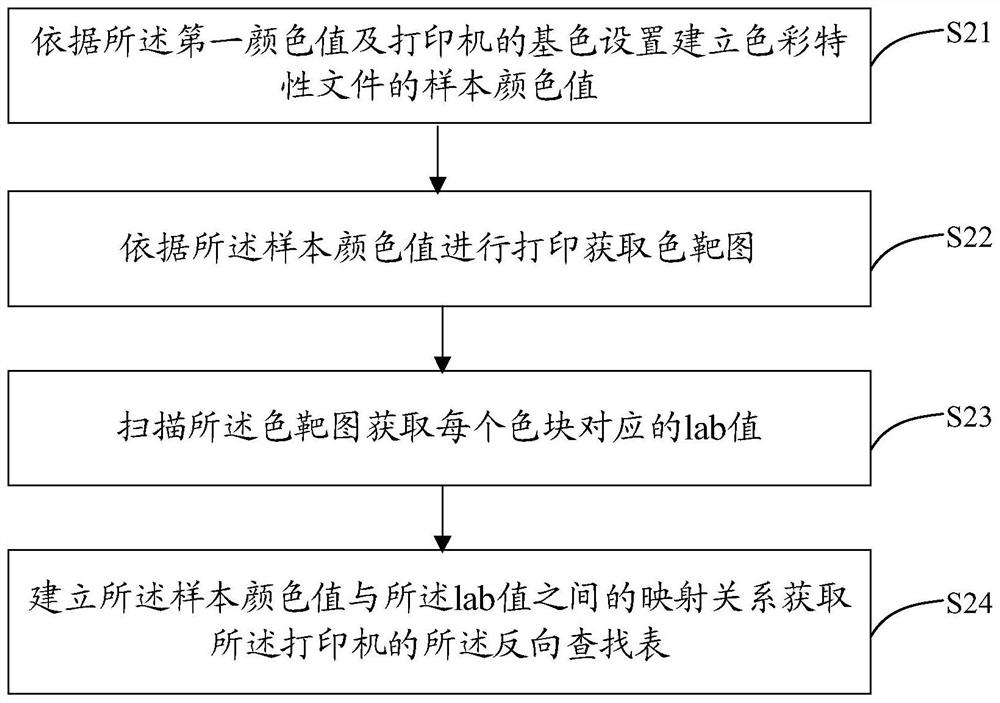

Image processing based printer ink quantity regulating method, device and equipment as well as medium

The invention discloses an image processing based printer ink quantity regulating method, device and equipment as well as a medium. The printer ink quantity regulating method comprises the following steps: obtaining a color value of the printing medium, and recording the color value as a first color value; obtaining a color value of all pixel points, with background images removed, in a to-be-printed image, and recording the color value as a second color value; obtaining a color difference value corresponding to each pixel point according to the first color value and the second color value; comparing the color difference value with a set color threshold value; and while the color difference value is smaller than the color threshold value, regulating data, in all color channels of a printer, of the pixel points corresponding to the color difference value as data for not discharging ink. The image processing based printer ink quantity regulating method, device and equipment as well as the medium can save ink amount, and reduces printing cost.

Owner:SENDA SHENZHEN TECH CO LTD

Spray method and spray device of electrostatic spraying circuit board

InactiveCN104438000ASave inkImprove qualityLiquid surface applicatorsCoatingsManufacturing cost reductionStructural engineering

The invention relates to the technical field of spray methods and discloses a spray method and a spray device of an electrostatic spraying circuit board. The method comprises the following steps: respectively clamping a plurality of circuit boards by clamps, wherein the circuit boards are in a same plane to form a circuit board set; respectively arranging pseudo plates in front of the circuit board set and on the back of the circuit board set and clamping the pseudo plates by using clamps, wherein the two pseudo plates and the circuit boards are located in a same plane and the pseudo plates and the circuit boards are arranged at intervals; grounding the clamps; and spraying the two board faces of the circuit boards by using a spraying machine respectively. The pseudo plates are respectively arranged in front of the circuit board set and on the back of the circuit board set, which is equivalent to extension of the plane formed by the circuit boards, so that oil gathering phenomenon on the left and right plates of the circuit boards can be avoided, printing ink on the circuit boards are relatively uniform, the circuit boards in the subsequent processing are prevented from polluting a conveyer, a film and an exposure machine and oil residues on the board surfaces of the circuit boards and board copper leakage are avoided, thereby greatly improving the quality of the circuit boards, saving the printing ink and greatly lowering the manufacturing cost.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

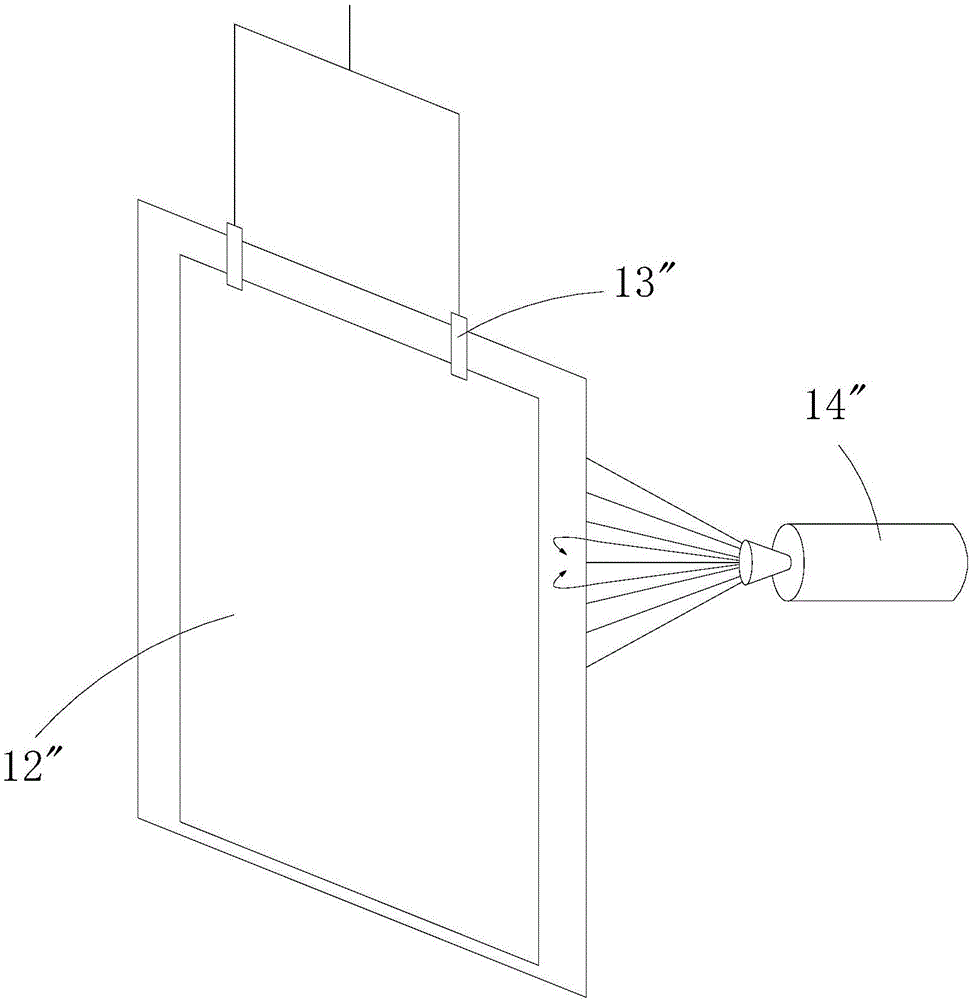

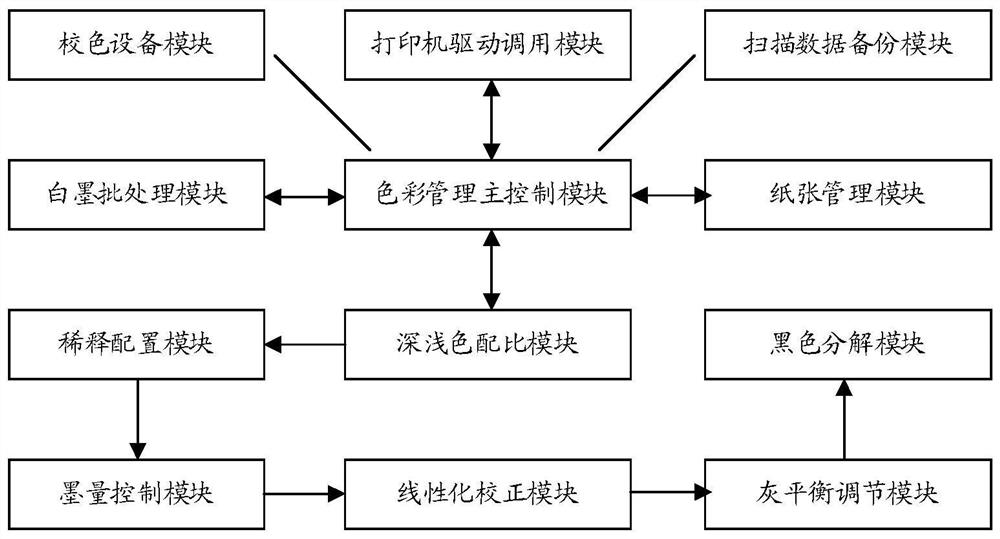

Color management based printer ink amount adjusting method and device, color management based printer ink amount adjusting equipment and medium

The invention discloses a color management based printer ink amount adjusting method and device, color management based printer ink amount adjusting equipment and a medium. The printer ink amount setting method comprises the following steps of acquiring a color value of a printing medium, and recording the color value as a first color value; establishing a color characteristic profile containing the first color value in color management of a printer according to the first color value; obtaining a color value of each pixel point in the to-be-printed image, and recording the color values as second color values; and obtaining a printing color value and a white ink amount value corresponding to each pixel point according to each second color value and the color characteristic file. According to the color management based printer ink amount adjusting method and device, the color management based printer ink amount adjusting equipment and the medium, the ink amount can be saved, and the printing cost is reduced.

Owner:SHENZHEN HOSONSOFT CO LTD

Method for melting nickel alloy by selective ink instead of dry film

InactiveCN101562943BEmission reductionImprove protectionConductive material chemical/electrolytical removalScreen printingEcological environment

The invention discloses a method for melting a nickel alloy by a selective ink instead of a dry film, which comprises the following steps: (1) selectively coating ageing resistant nickel alloy ink on a circuit board by a screen printing technology to form a wet film; (2) drying the ink; (3) exposing the ink; (4) developing the wet film so as to expose the required copper surface; (5) performing nickel alloy melting on the circuit board; and (6) removing the wet film. The selective ink instead of the dry film is used for selective nickel alloy melting, so the cost is greatly reduced, and the combination effect of the wet film and the board surface is superior to the combination effect of the dry film and the board surface, unfavorable phenomena such as diffusion coating and the like can be effectively prevented, the defective rate of production is reduced and the quality of products is ensured. In addition, the method simplifies the manufacturing flow, saves the ink, greatly reduces the emission of pollutants, saves the expenses of wastewater treatment and is simultaneously favorable for the protection of ecological environment.

Owner:ZHUHAI FOUNDER TECH MULTILAYER PCB +1

Print quality verification system for detecting a mismatch in a printed document

InactiveUS8804157B2Save inkSave paperVisual presentationOther printing apparatusVerification systemDocumentation

A method, programmed medium and system are disclosed which provide for an in-line scanner used to dynamically scan a document or image, real-time as it is being printed within a printer unit and before the printed document exits the printer. The scanned image is compared to a stored electronically-generated image of the file being printed. When the comparison is determinative that there is a printing problem, the printing operation may be stopped quickly before the partially printed document or image has exited the printer. An error message may then be displayed, and the user is enabled to take appropriate action. A resume function enables a user to resume a print job at exactly the place where it had left off before detecting a print problem. In another embodiment, when the system detects a problem with a print job, the entire print job of the remainder of the print job is sent from the faulting printer to another printer where either the remainder of the print job or the entire print job is completed.

Owner:INT BUSINESS MASCH CORP

Digital halftoning with clustered microdots

PendingCN112534801ASave inkPlate printingVisual presentationPattern recognitionComputer graphics (images)

A method of reproducing a continuous-tone image with a printing press comprises the step of making a printing plate having a halftone raster image comprising regularly tiled halftone cells which consist of a grid of image pixels and non-image pixels; the halftone cells are obtained by digital halftoning with a single threshold array and at least a portion of the halftone cells in the raster imagecomprise multiple image clusters, image clusters being defined as mutually separated groups of more than 4 adjacent image pixels; the image clusters allow to obtain a printed image of the same image density with less ink than with conventional screens wherein the image pixels are grouped into a single cluster.

Owner:YIKEFA CO LTD

Locker adopting NFC (Near Field Communication) identification technology

InactiveCN104361690ASave paperSave inkApparatus for meter-controlled dispensingElectromagnetic lockBarcode

The invention discloses a locker adopting an NFC (Near Field Communication) identification technology. The locker has a technical scheme that the NFC identification technology is utilized, the NFC of a specific individual is recorded and identified, and a normally closed circuit is disconnected when a signal is correct. A circuit is connected with an electromagnetic lock, and the electromagnetic lock is released when the circuit is disconnected so as to open the door of the locker. After depositing is finished, the door is artificially closed. The locker adopting the NFC identification technology can be effectively applied to various occasions of supermarkets, shopping malls, bathhouses, public changing rooms, amusement parks and the like to meet depositing requirements. Compared with a traditional paper tape barcode technology, the locker is more accurate and reliable, paper and stamping ink are saved, and the locker is a new-generation energy-saving environment-friendly storage cabinet.

Owner:ANHUI NEOFOUND TECH

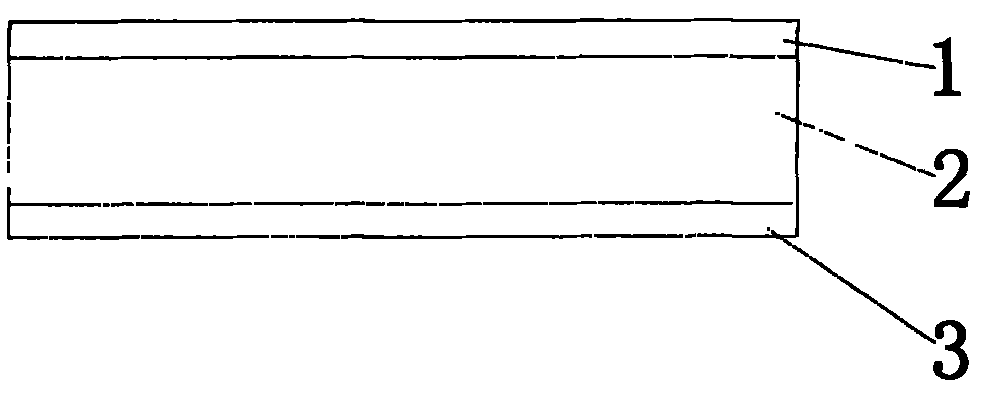

Modified polyolefins paper without plant fibre

InactiveCN101462387BOpaqueChemically resistantSynthetic resin layered productsHandwritingOrganic chloride compound

The invention discloses modified polyolefin paper without plant fiber. The modified polyolefin paper is formed by a first matrix layer without the plant fiber, a second matrix layer without the plant fiber and a third matrix layer without the plant fiber which are compounded into a whole, wherein the first matrix layer and the third matrix layer are respectively prepared by 20 to 30 percent of ethylene-acrylic acid modified copolymer EAA, 45 to 60 percent of metallocene high-density polyethylene mHDPE, and 20 to 25 percent of activated ultrafine inorganic powder by using an aluminate F-2 type coupling agent, and the second matrix layer is prepared by 60 to 90 percent of activated ultrafine inorganic powder, 2 to 5 percent of maleic anhydride and 8 to 35 percent of high-density polyethylene. The modified polyolefin paper has the advantages of good ink receptivity and softness. Therefore, the modified polyolefin paper can not only be used as industrial paper, packing paper and household paper, but also be used as cultural paper, and enlarges the use range. The modified polyolefin paper has higher foldability and rigidity, has the longitudinal and transverse tearing strength which are superior to those of plant fiber paper, has good surface flattening, good handwriting, and clear printing performance, saves printing ink, has simple production technology, protects forest resources, saves energy sources and water, reduces the discharge of organic chlorides and harmful gas, has no waste, and protects the environment.

Owner:宋旭

Multi-color screening printing method

The invention discloses a multi-color screening printing method. According to the method, the four kinds of colors including C, M, Y and K serve as main basic colors according to the number of color cells of a printing machine and the variety of colors of products, and three or less than three colors are selected from four colors including O, G, B and V to serve as auxiliary basic colors; a screening method is determined to be amplitude modulation screening, the screen line number is 133-200 L / inch, and the screening angle is that the four main basic colors including C,M,Y and K are distributed at 90 degrees and the screening angles of all the selected auxiliary basic colors are the same as that of the color K. The four main basic colors including C,M,Y and K and the three or less than three auxiliary basic colors selected from the four colors including O, G, B and V replace the four main basic colors including C, M, Y and K and special colors for multi-color screening printing, the special colors do not need to be made specially, viscosity adjustment does not need solvents in the printing process, and the method has the advantages of saving printing ink, reducing the number of workers and saving work hour and overcomes the defect of moire.

Owner:SHANGHAI ZIQUAN LABEL CO LTD

Automatic ink-saving device for ink barrel

The present invention relates to ink filling equipment for ink box of printer, and is especially one kind of automatic ink economizer for pouring from an ink barrel. The automatic ink economizer includes one ink barrel supporting board with two shaft brackets and nuts welded to the back side, one supporting board shaft, one bearing support, one connecting support, one spring support, one spring sleeve, one pouring support, bearing seats and springs assembled together. The present invention has obvious ink saving effect.

Owner:TIANJIN EPSON CO LTD

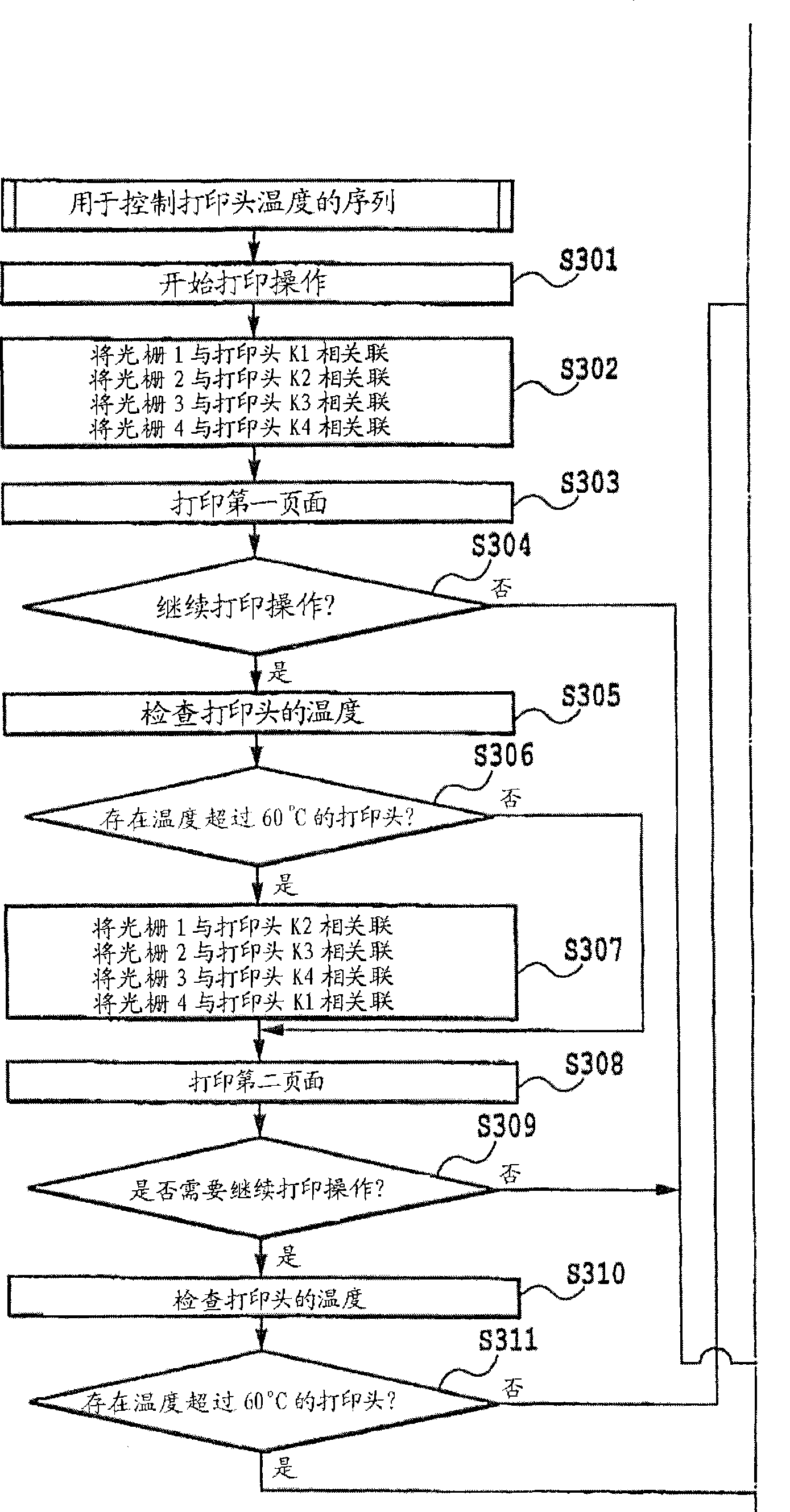

Image forming method and image forming apparatus

The invention provides an image forming method which prevents the temperatures of printing heads from exceeding a predetermined temperature. In this image forming method, its basic assignment is changed when any one of the temperatures detected by the respective temperature sensors (61 to 64) exceeds the predetermined temperature (for example, 60 DEG C). Specifically, each time the forming of an image on a printing medium (for example, a label) is completed, the temperatures of the respective printing heads (K1 to K4) are detected with the respective temperature sensors. When any one of the temperatures thus detected exceeds 60 DEG C, the association of raster line regions with ink ejection opening arrays (N1 to N4) (the association of rasters with the printing heads) under the basic assignment is shifted one-by-one.

Owner:COPYER

Roll paper perfecting press

PendingCN108749315AReduce human inputNot easy to damageRotary pressesPrinting press partsRolling paperEngineering

The invention discloses a roll paper perfecting press. The roll paper perfecting press comprises a paper supplying device, an ink supplying device, a printing device and a paper collecting device; thepaper supplying device comprises a paper supplying roller, a paper supplying supporting seat and a paper supplying table; the paper collecting device comprises a paper collecting roller, a paper collecting supporting seat and a paper collecting table; the ink supplying device comprises an ink duct, an ink roller, a first ink conveying roller, a first inking roller, a second ink conveying roller and a second inking roller, and the ink roller is suspended in the middle of the ink duct; the printing device comprise a first plate roller, a first impression roller, a second plate roller and a second impression roller, and the upper portions of the first plate roller and the second plate roller are provided with ink scraping devices; and the upper portion of the paper collecting device is provided with a drying device. According to the roll paper perfecting press, compared with the prior art, one ink duct is provided and can provide ink for the printing device with two systems at the same time, turning operation does not need to be conducted on printed paper, and the roll paper perfecting press has the advantages of being simple in structure, convenient to operate, not prone to damagingthe printed paper, capable of saving printing ink and manpower and improving the printing quality, and the like.

Owner:芜湖市华美工艺包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com