Automatic positioning code printer

An automatic positioning and coding technology, applied in the direction of power transmission device, printing device, printing, etc., can solve the problems of wrong material use, chaotic operation, low position accuracy, etc. The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

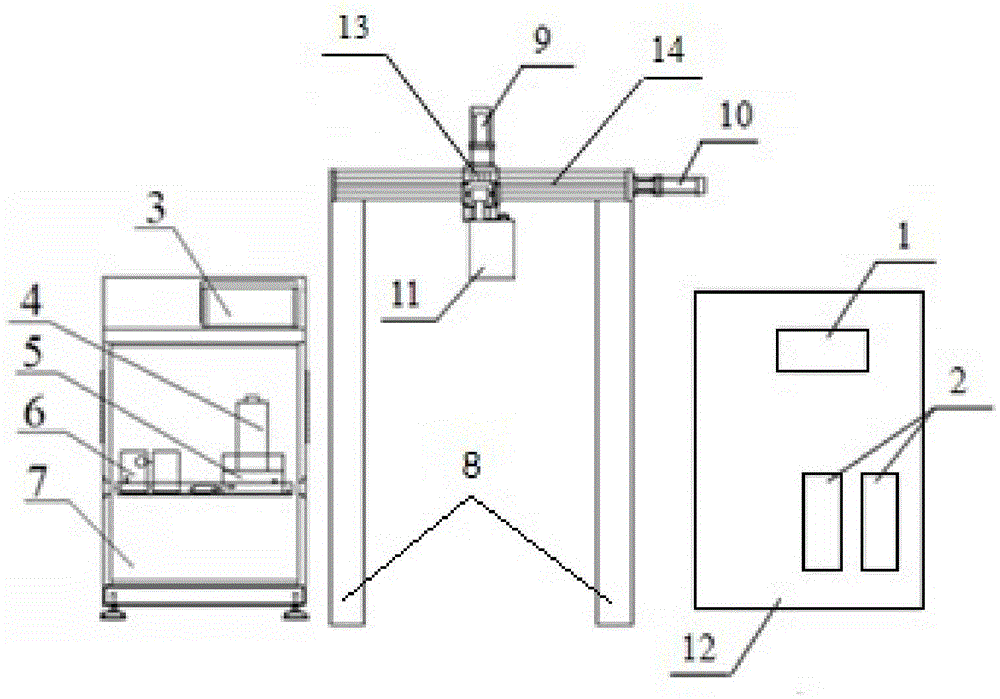

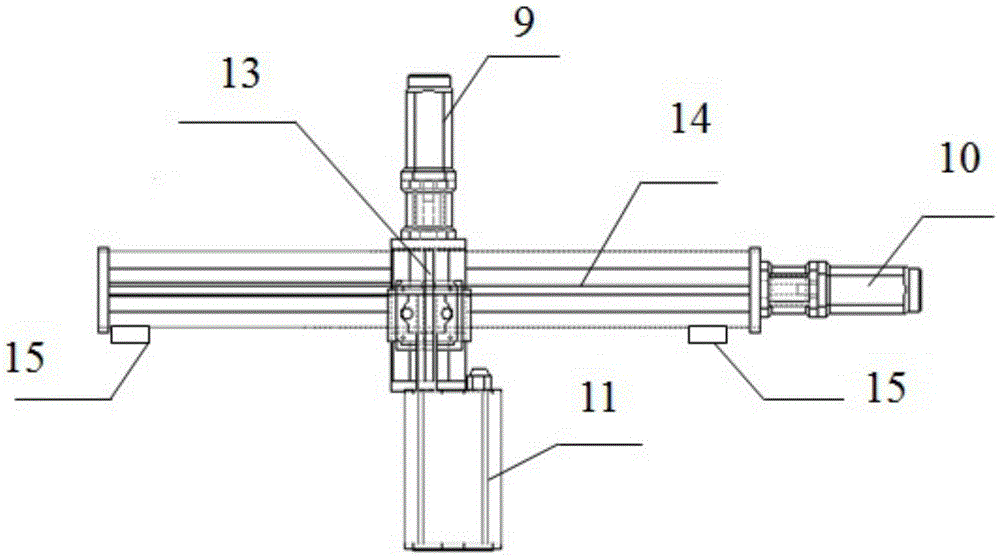

[0032] An automatic positioning inkjet device, such as figure 1 As shown, it includes a frame 8, a control assembly, an ink supply assembly, a nozzle 11 and a nozzle moving assembly. The nozzle 11 and the nozzle moving assembly are respectively connected to the control assembly. The transmission mechanism is arranged on the frame 8, the Y-axis transmission mechanism is arranged on the X-axis transmission mechanism, and the nozzle 11 is arranged on the Y-axis transmission mechanism. Limiter, a photoelectric switch for sensing the product to be coded, a code control photoelectric switch for controlling the opening and closing of the nozzle, and a distance sensing photoelectric switch for controlling the distance between the nozzle and the product to be coded.

[0033] Wherein, the X-axis transmission mechanism includes the first lead screw 14 and the first servo motor 10 that controls the rotation of the first lead screw 14, the first lead screw 14 is rotatably connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com