Pneumatic vacuum offset ink container

A technology of vacuum pneumatic glue and ink, which is applied in packaging, printing, and printing machines under vacuum/special atmosphere, which can solve the problems of ink adhesion, difficult operation, and high labor intensity of ink, and achieve the effect of saving ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

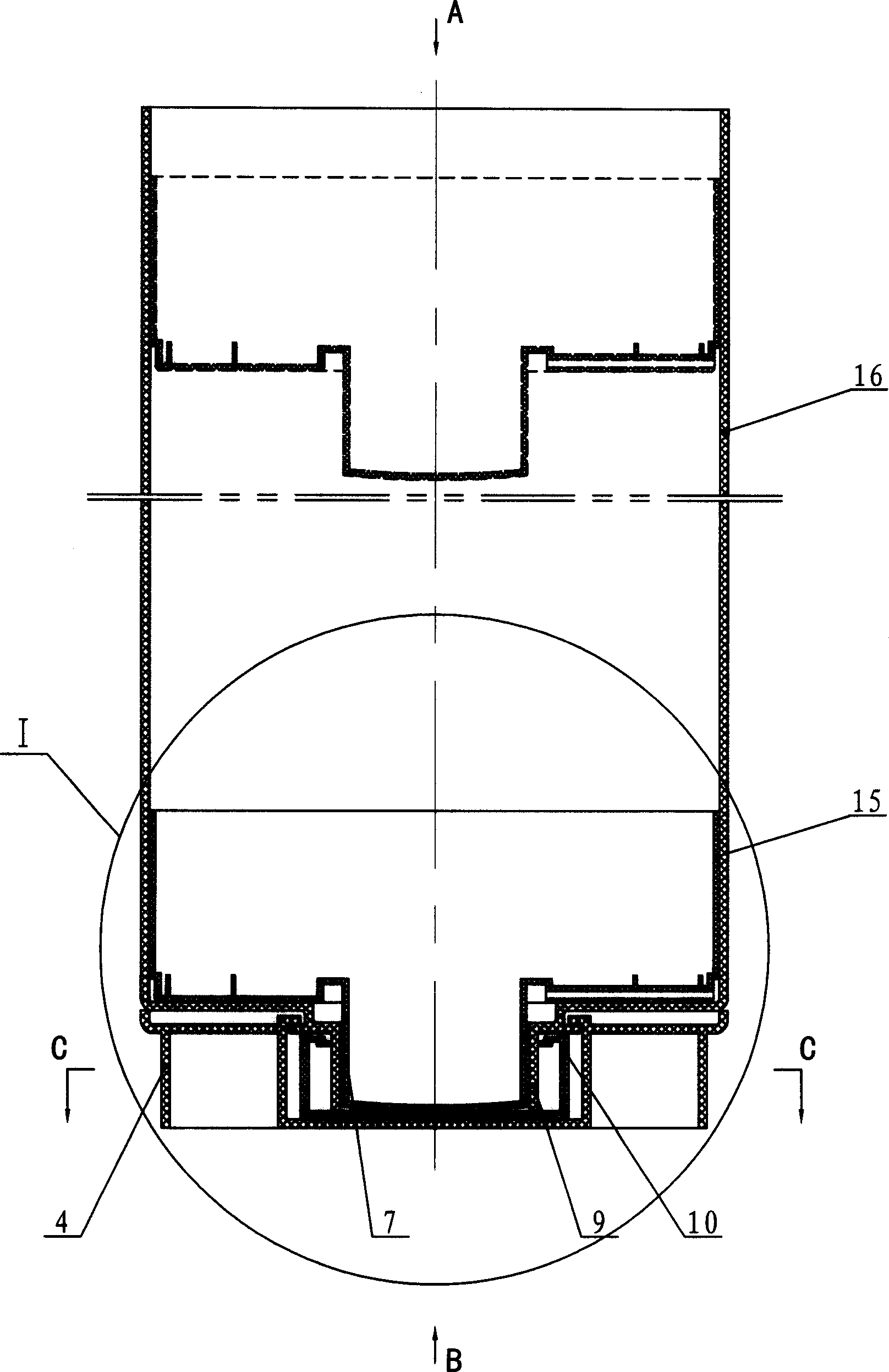

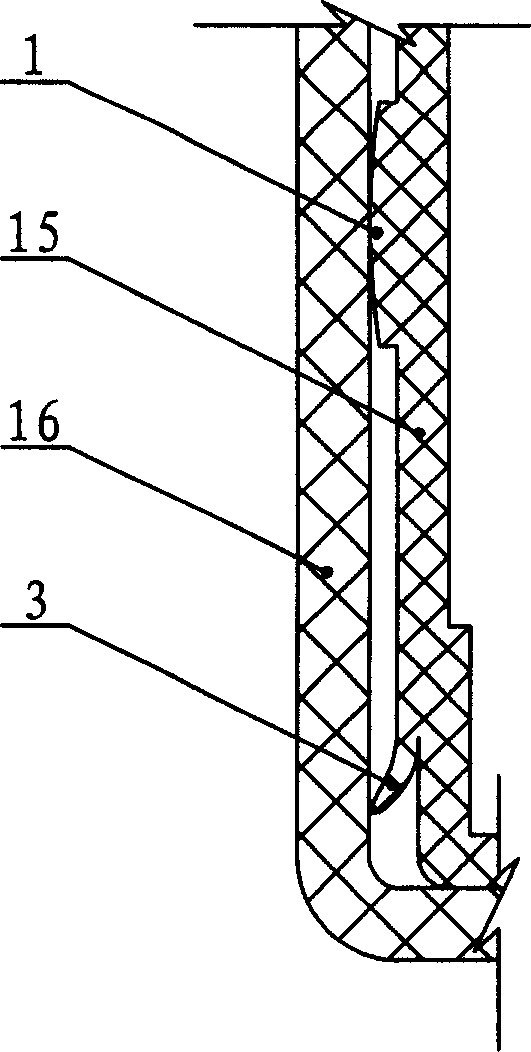

[0027] The specific implementation of the vacuum pneumatic offset printing ink container of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0028] refer to Figure 1 to Figure 6 The vacuum pneumatic offset printing ink container of the present invention includes a cylinder body 16 and a piston 15 located therein, the ink is vacuum-packed in the space defined by the cylinder body 16 and the piston 15 , and the rear end is closed by the piston 15 . The front end of cylinder body 16 is provided with ink outlet 9, and inner cover 10 and outer cover 4 are housed on it. The front end surface of the piston 15 is provided with a boss 7 matching the inner hole of the ink outlet 9. When the printing machine needs to add ink, push the piston 15 to slide towards the ink outlet 9 and keep the ink container empty. 15 can not only scrape the ink off the inner wall surface of the cylinder 16 conveniently, but also when the pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com