Diode color ring roll printing device and roll printing method

A diode and printing device technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of difficult control of position and density, unfavorable color ring connection, uneven color ring thickness, etc., to achieve easy operation and wide application range , the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

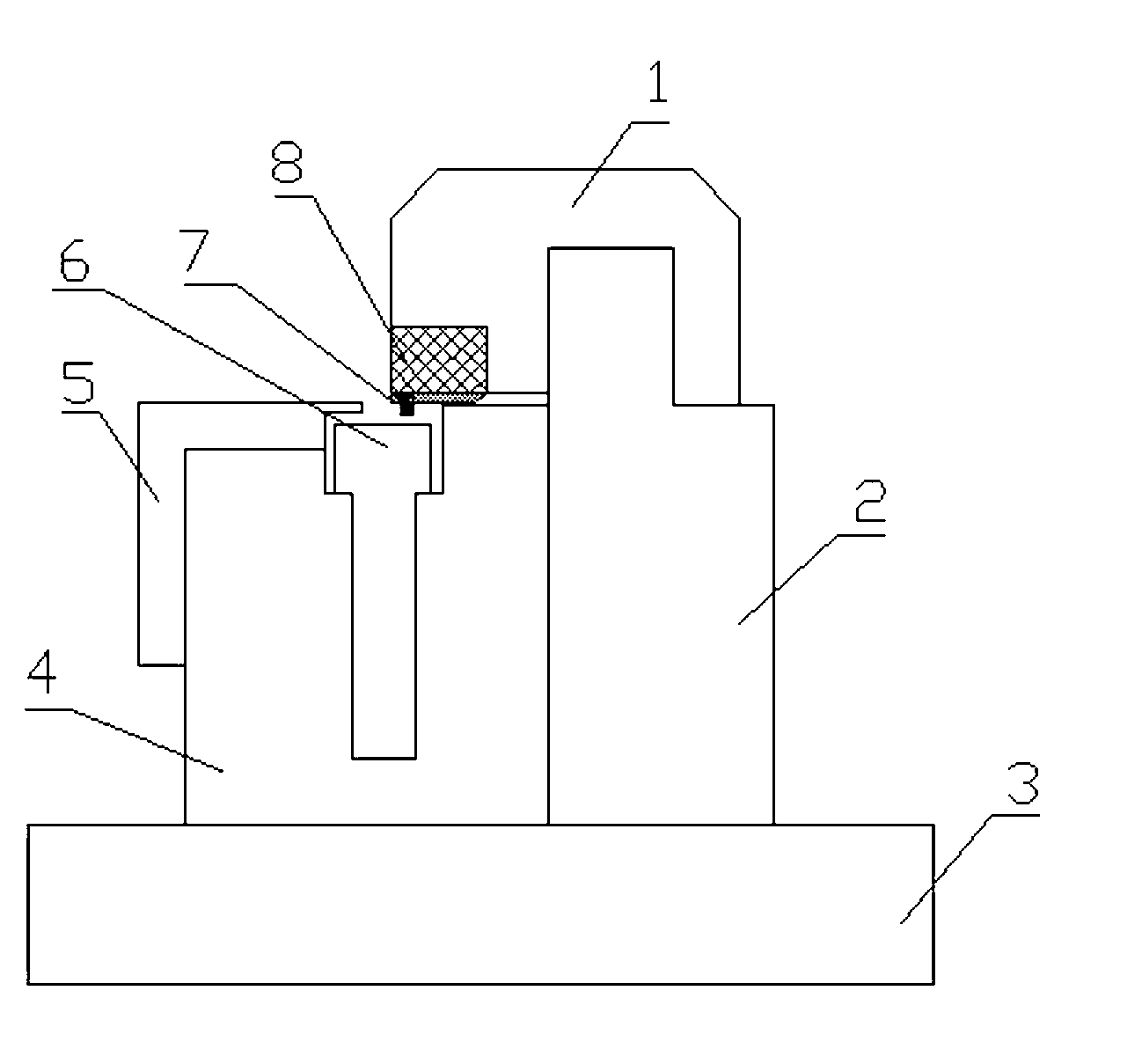

[0022] Such as figure 1 A diode color ring rolling printing device shown includes a printing block 1 , a linear guide rail 2 , a bottom plate 3 , a mold carrier 4 , a pressing plate 5 , a mold 6 , a color ring stamp mold 7 and a decompression pad 8 .

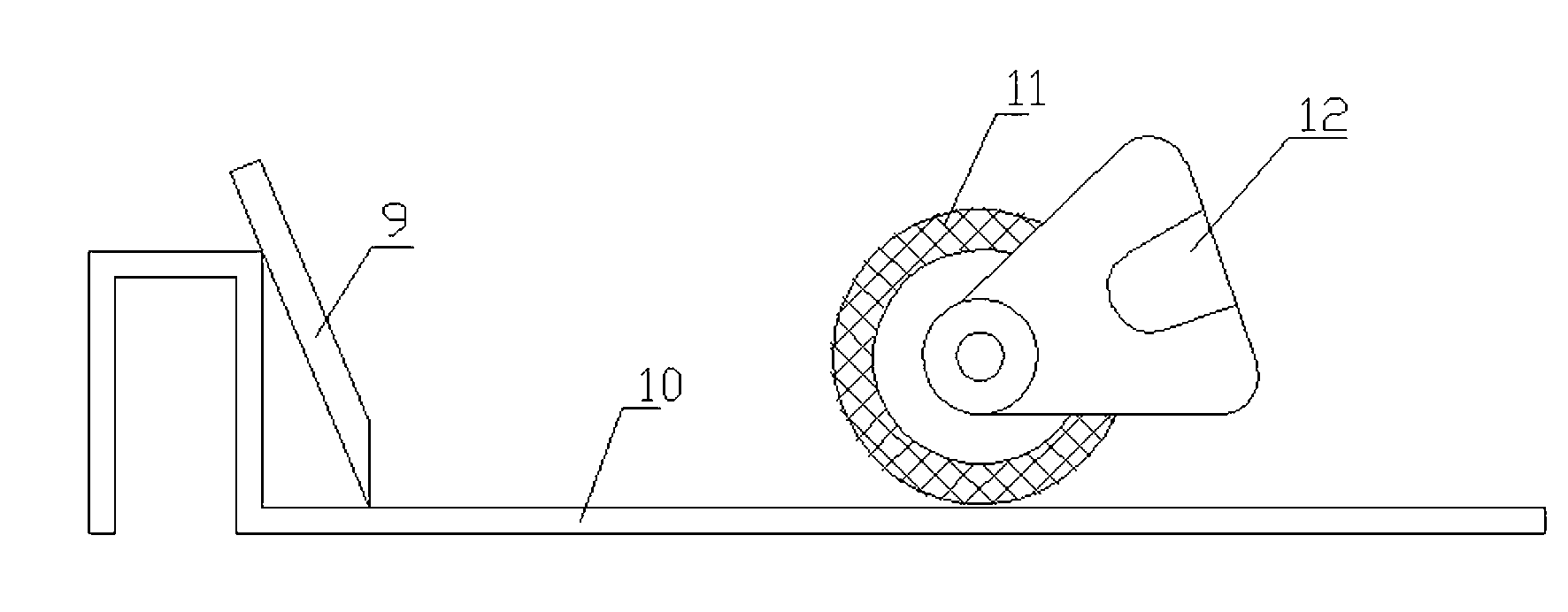

[0023] Such as figure 2 As shown, the mold 6 is a T-shaped block with a certain length, and the top surface of the mold 6 is provided with a plurality of arc-shaped grooves 6-1 that can accommodate a glass bulb 15 of a diode, and the arc-shaped grooves 6-1 run through Mold 6, the length of the arc groove 6-1 is less than the distance between the two terminals of the diode, there is a T-shaped groove on the mold carrier 4, and the mold 6 is inserted in the T-shaped groove on the mold carrier 4, the mold 6 There is a certain gap between both sides of the upper end and the mold carrier 4, forming a space that can accommodate the terminals of the rolling diodes, and the guiding direction of the linear guide rail 2 is perpendicula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com