Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Same itinerary" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

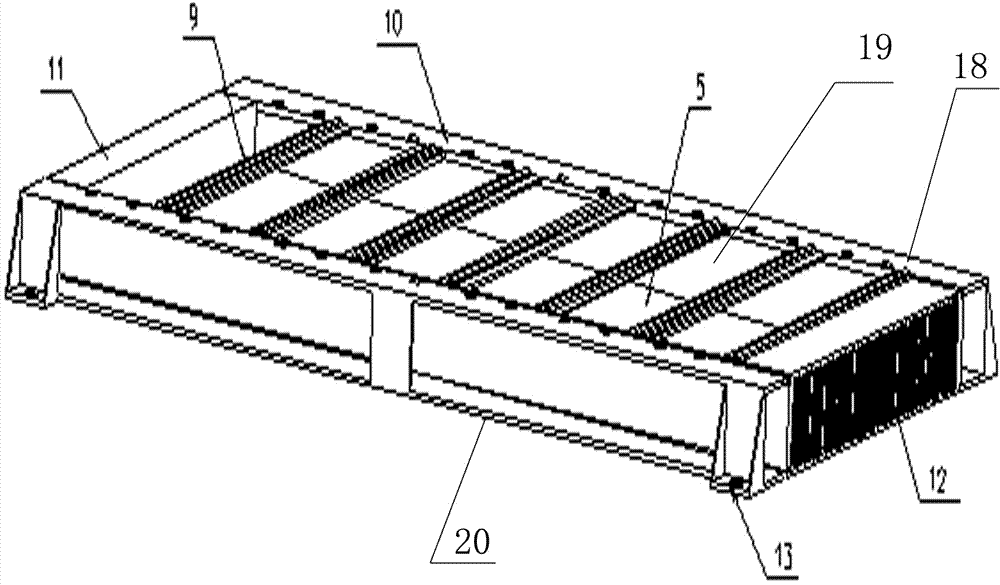

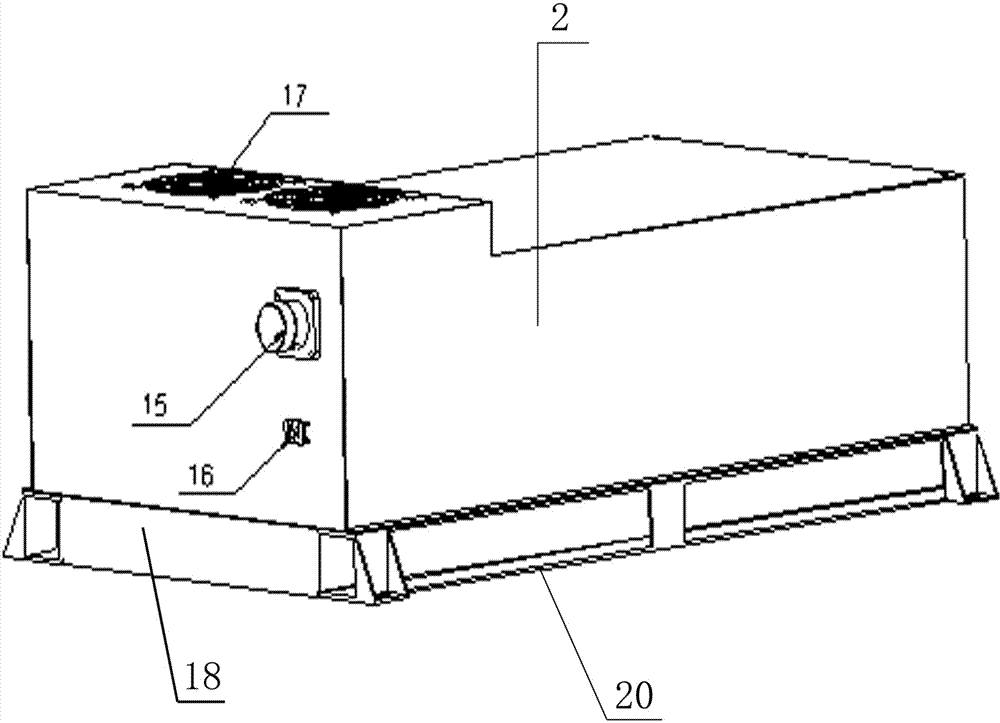

Motive power battery box with balanced heat radiation structure

ActiveCN102956850AGuaranteed uniformitySame itinerarySecondary cellsCell component detailsEngineeringMotive power

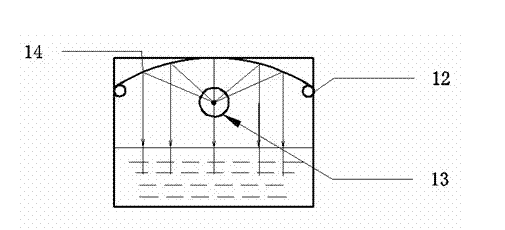

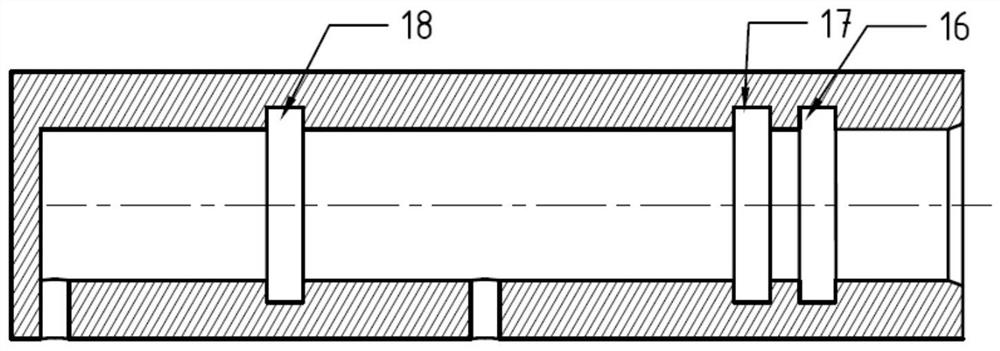

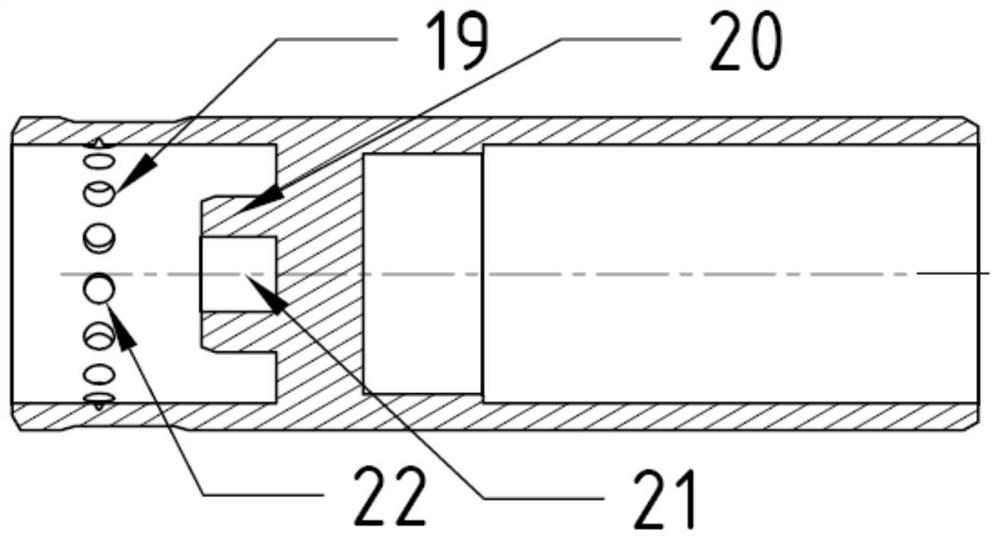

The invention discloses a motive power battery box with a balanced heat radiation structure. One end of a framework (18) is provided with an air inlet plate (12), gaps (19) are formed among connecting plates (9) longitudinally distributed at the upper part of the framework (18), an air guide plate (5) is positioned between the connecting plates (9) and a bottom plate (20), after the air guide plate (5) is upwards inclined, an included angle is formed between the air guide plate (5) and the upper part of the framework (18), an air guide groove is formed, an outer cover (2) is fixedly arranged on a bottom disc (1), a plurality of battery modules distributed in the outer cover (2) are arranged on the bottom disc (1), air inlets distributed in the air inlet plate (12) are communicated with a heat radiation air passage (21) arranged in the middle of each battery module in the outer cover (2) through the gaps formed between the air guide groove and the connecting plates (9), one side of the top of the outer cover (2) adjacent to an air outlet plate (4) is provided with an air outlet (22), the air outlet (22) is communicated with the inside of the outer cover (2), and an exhaust fan (6) is arranged at the air outlet (22) part.

Owner:BAILE ELECTROTHERMIC ELECTRIC APPLIANCE JIANGSU

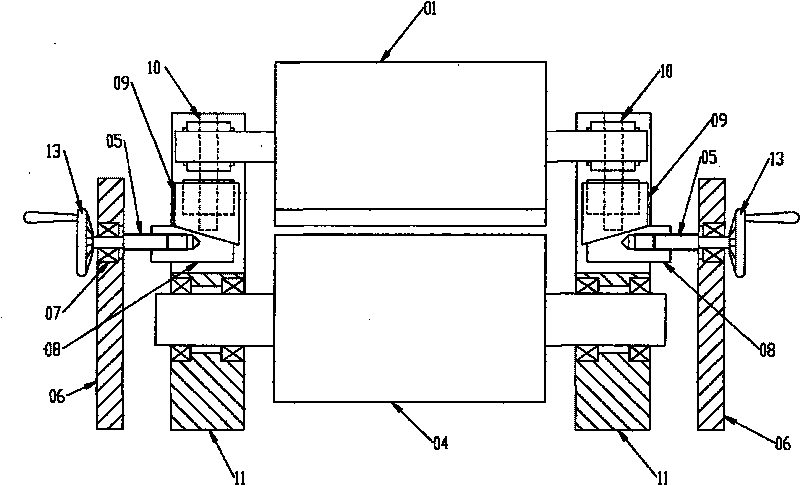

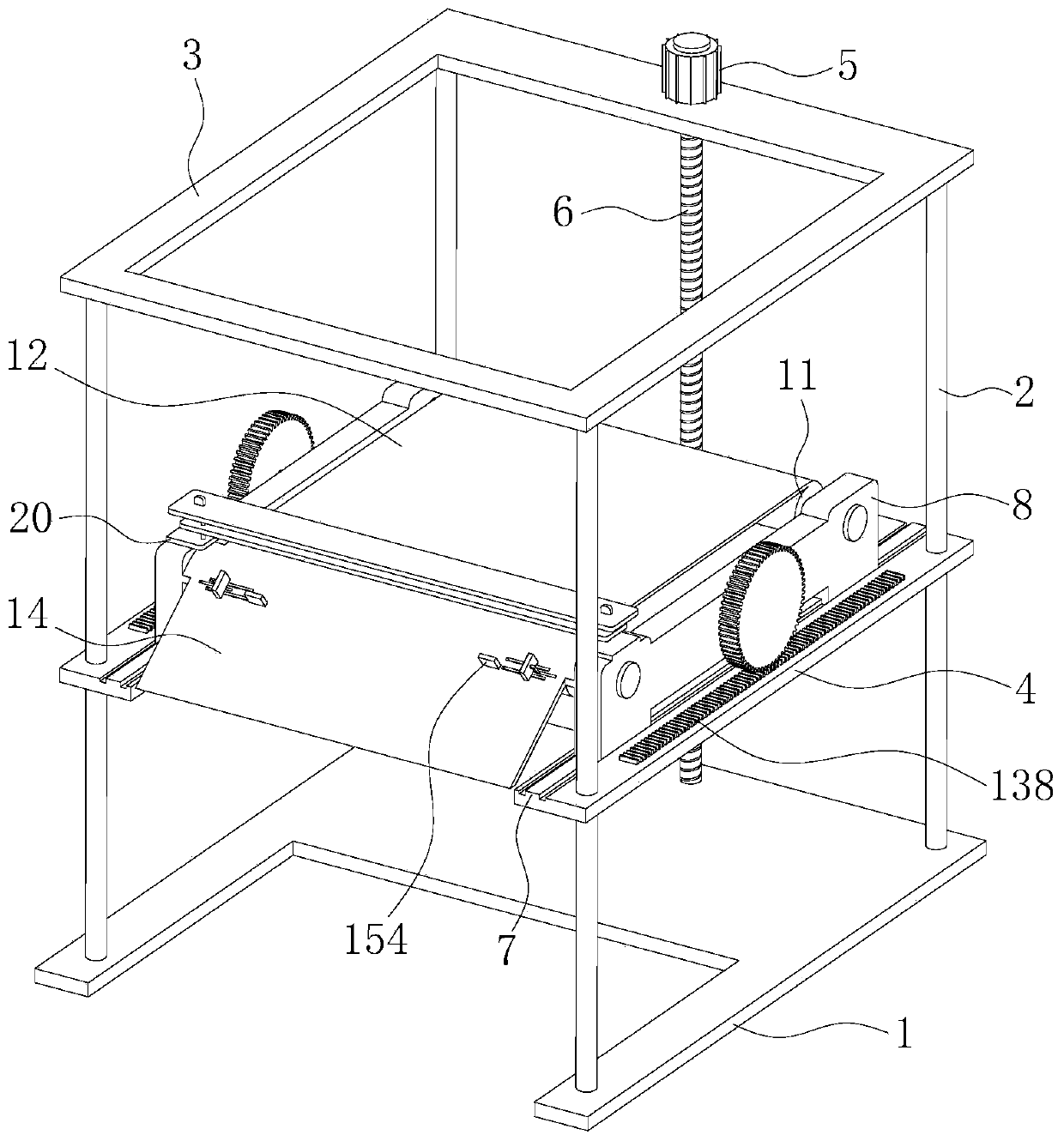

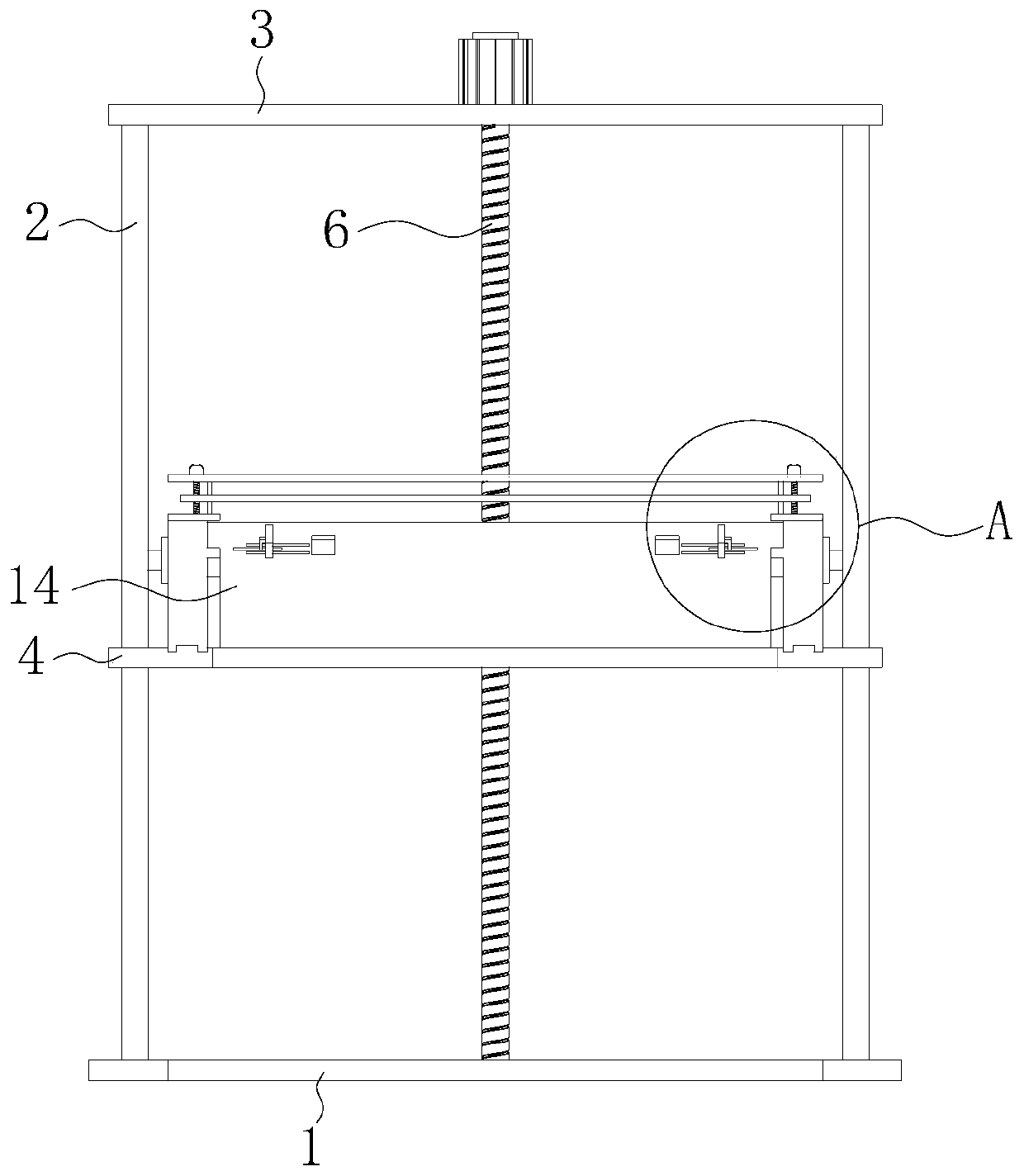

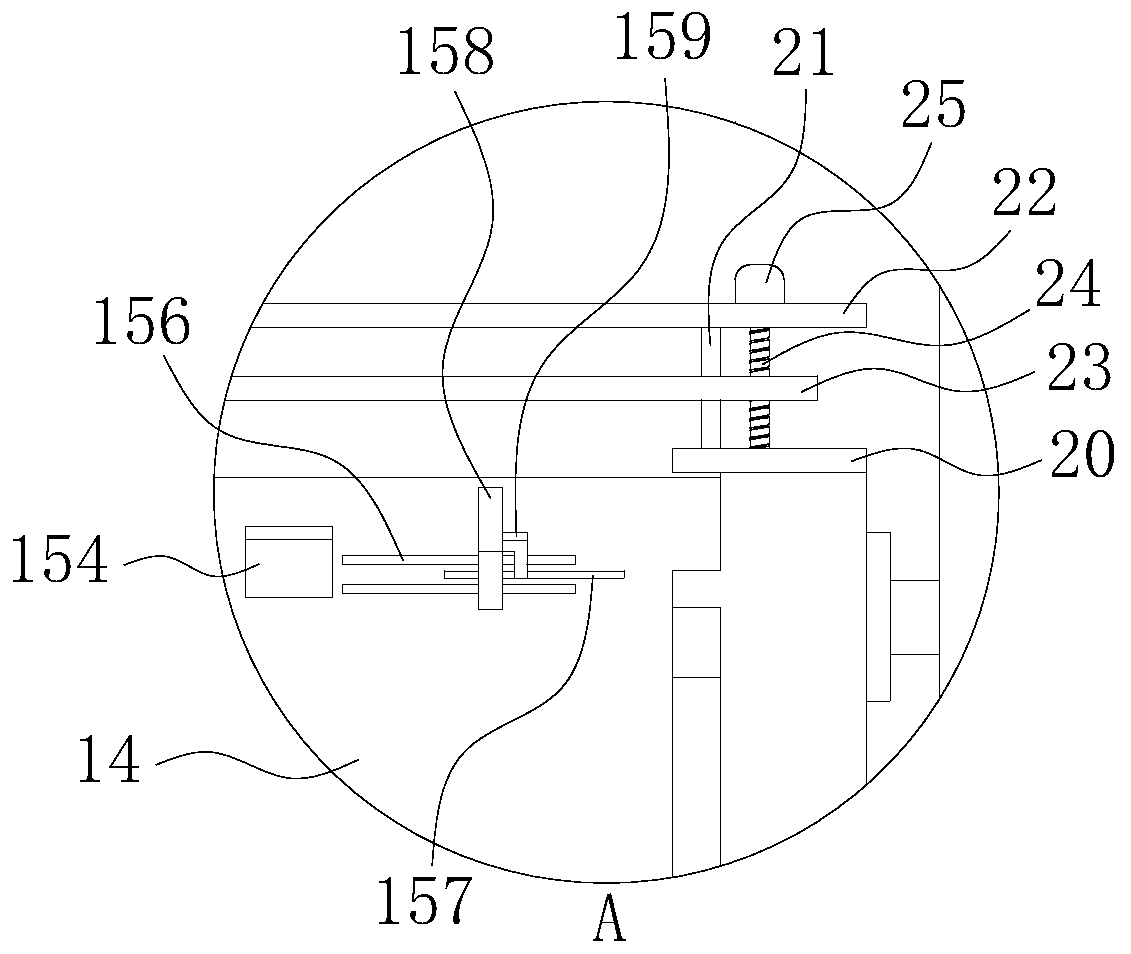

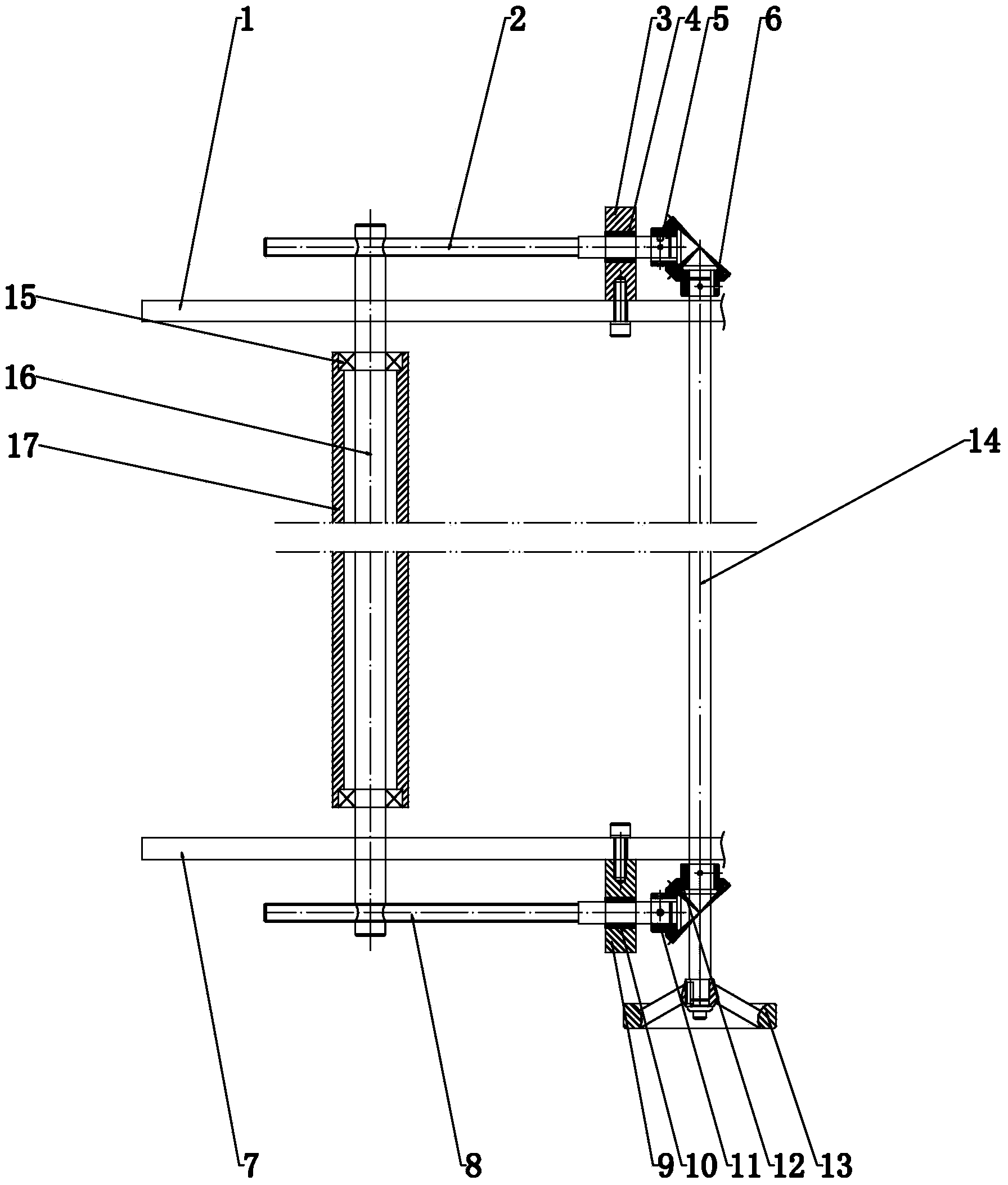

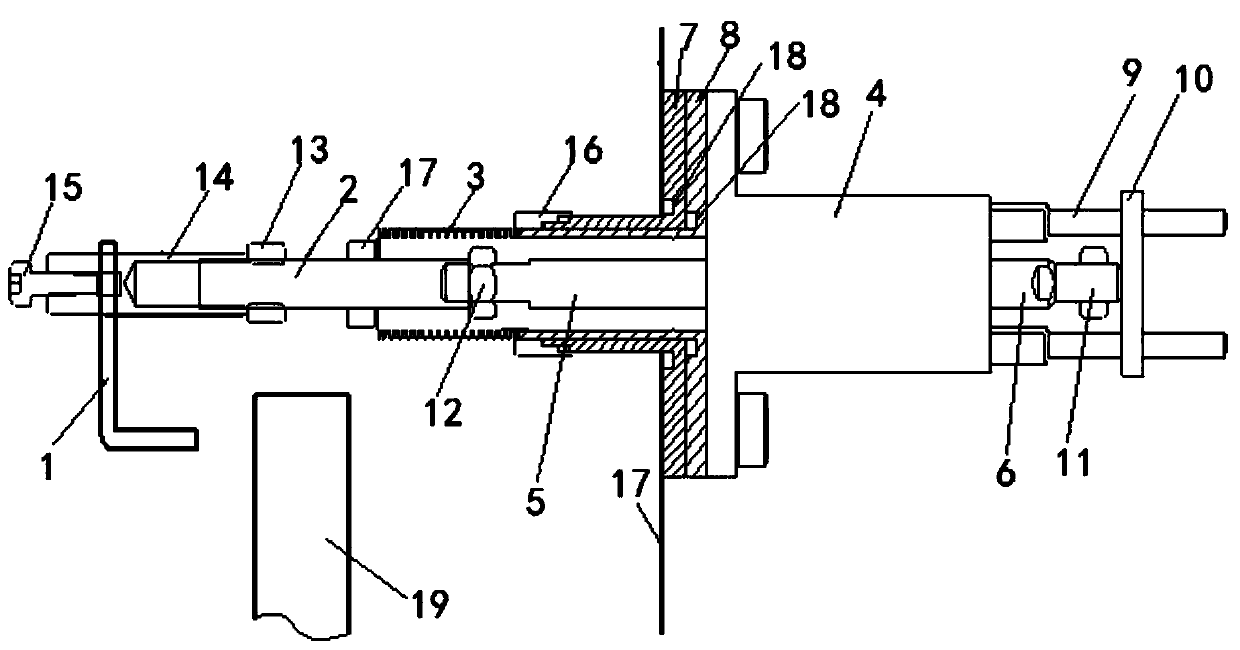

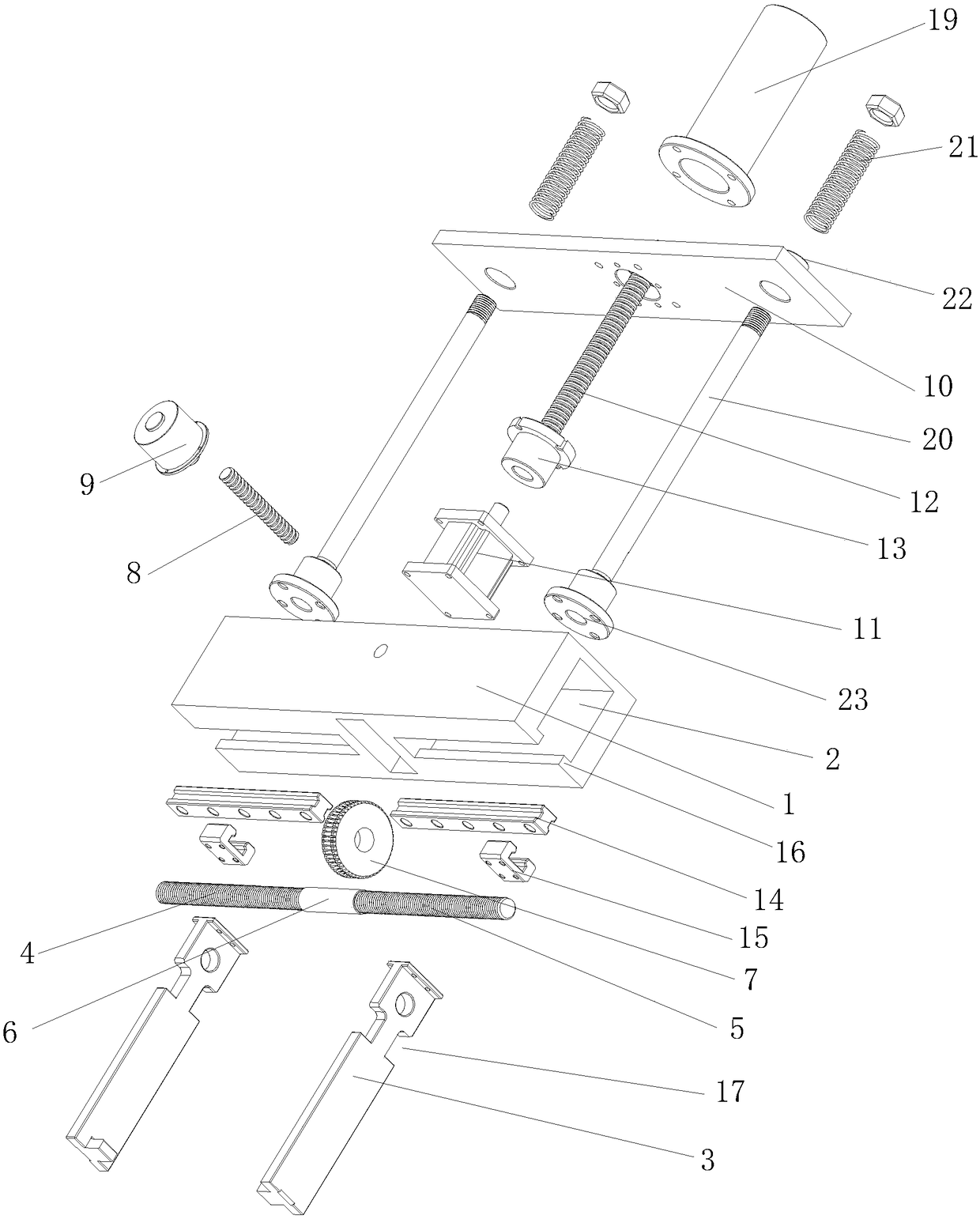

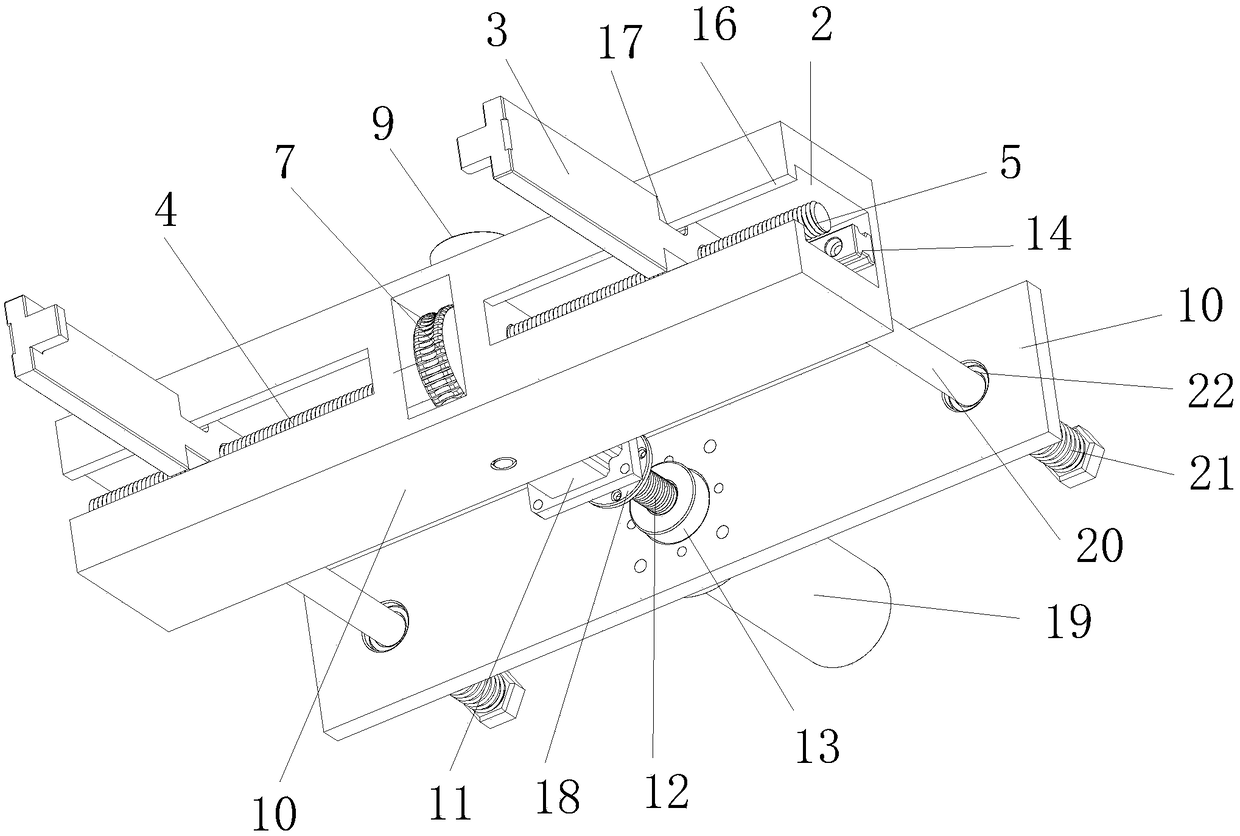

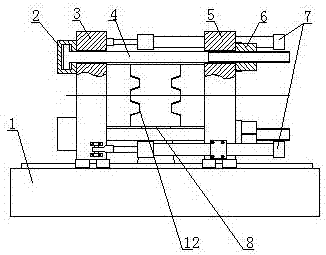

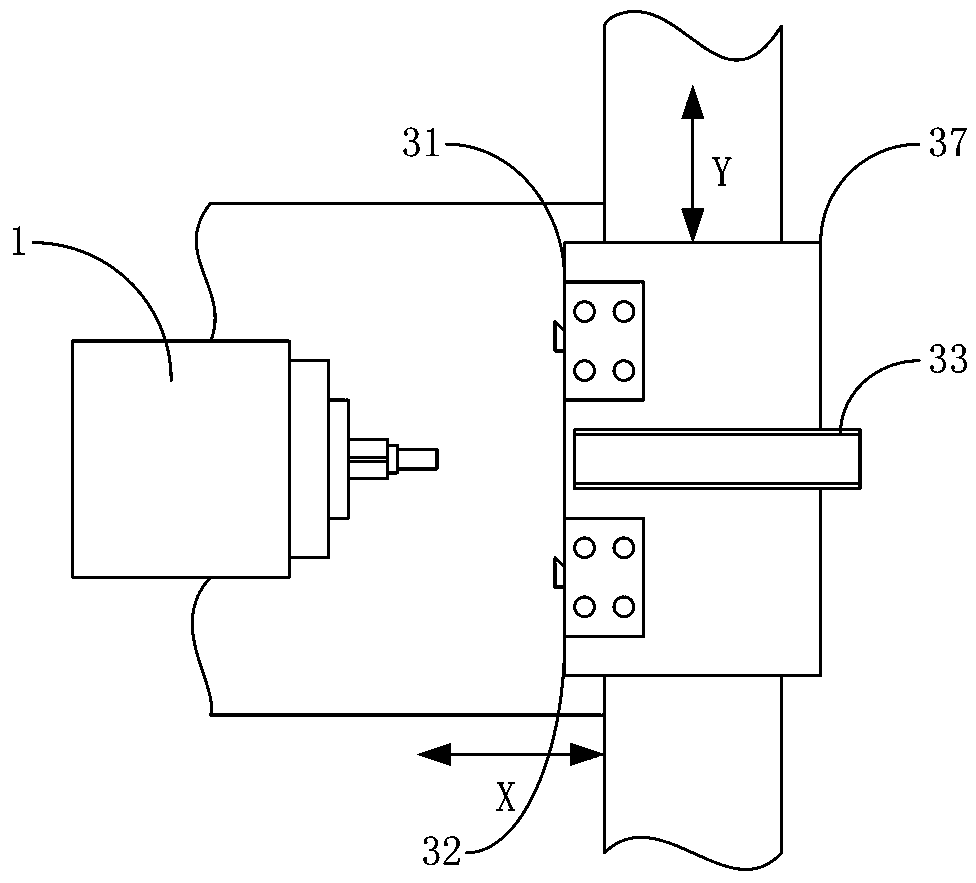

Device capable of automatically adjusting coating machine scraper gap

InactiveCN101712021AEasy to adjustRegulation stabilityLiquid surface applicatorsElectrode manufacturing processesAuto regulationCoupling

The invention discloses a device capable of automatically adjusting coating machine scraper gap, comprising a scraper, a coating roll, a screw, a stationary inclined block, a movable inclined block and a linear guide. The device is characterized in that the device is provided with two servo motors which are respectively connected with the movable inclined blocks at two ends of the scraper by a coupler, a bearing, a screw base and the screw; two servo motors adopt the same PLC to intensively control; the stationary inclined block is also provided with a high-precision displacement transducer and is connected with the PLC; the high-precision displacement transducer collects and adjusts gap feedback information in due time and sends the gap feedback information to the PLC control center to form a closed loop control system. The invention has the beneficial effect that the device adopts the closed loop control system to adjust the height of a scraper; the minimum effective stroke for adjustment is small, so that the gap precision can be accurately controlled; the servo motor operation consistency effectively avoids the problem of inconsistent adjustment height of two ends of the scraper.

Owner:东莞市九州浩德新能源设备有限公司

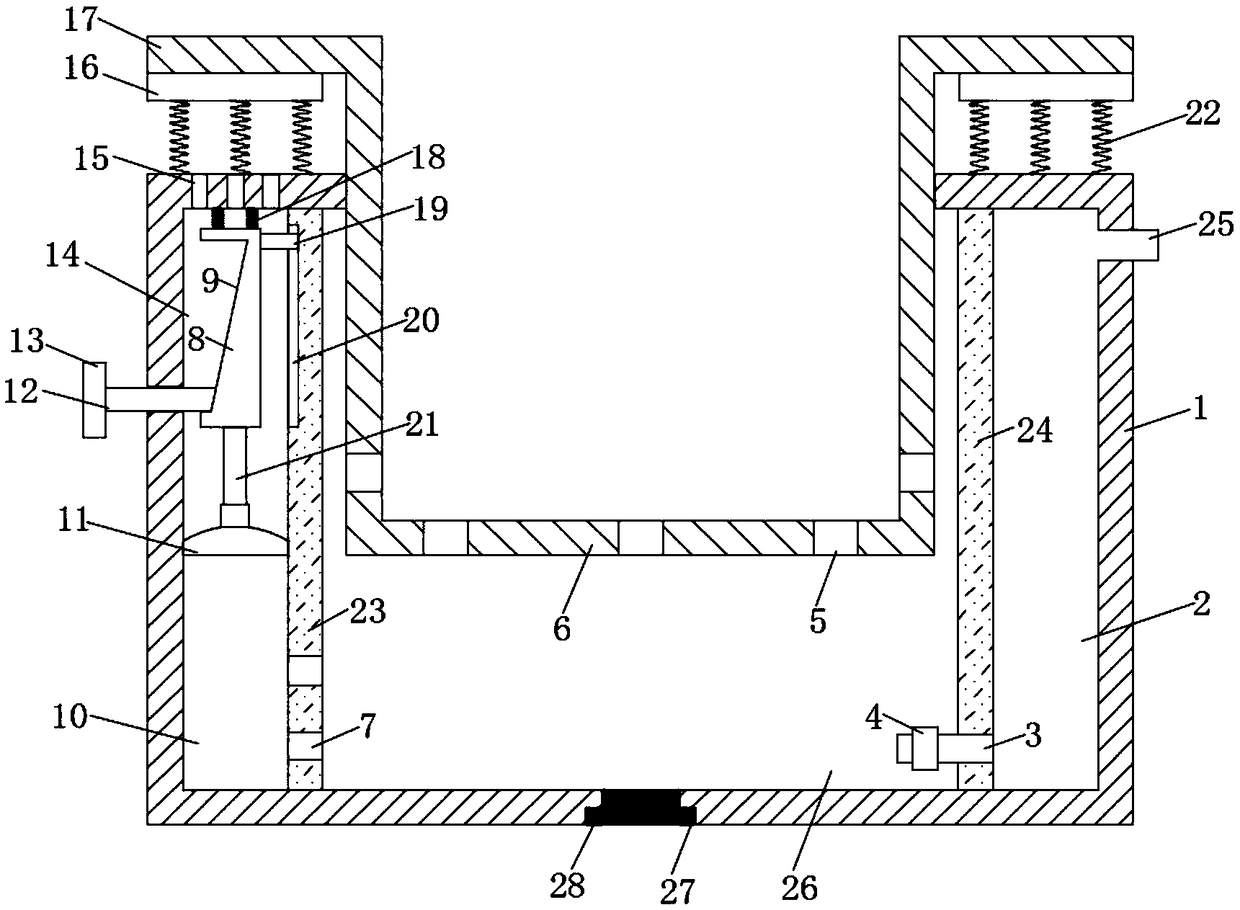

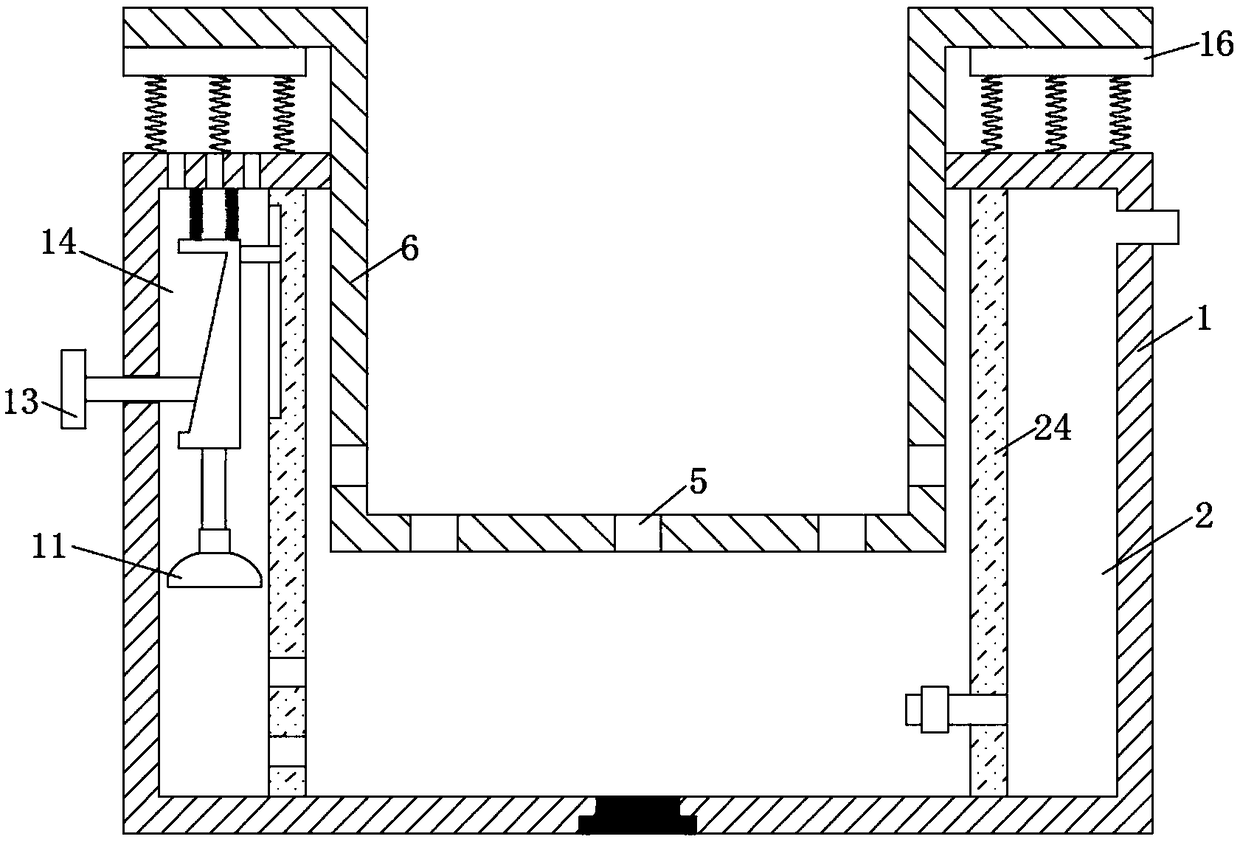

Irrigating planting pot used for non-hydrophile plants

ActiveCN109041892ASame itineraryEasy to moveSelf-acting watering devicesReceptacle cultivationWater storageHydrophile

The invention discloses an irrigating planting pot used for non-hydrophile plants. The irrigating planting pot comprises an outer pot body, multiple connecting springs are symmetrically arranged on the upper surface of the outer pot body, abutting-against plates are installed at the upper ends of the connecting springs together, a limiting base is placed at the upper ends of the abutting-against plates and provided with an inner pot body, multiple water inlet holes are uniformly formed in the lower surface and the side wall of the inner pot body, the interior of the outer pot body is divided into an equipment region, a water storage region and a water inlet region through a first partitioning plate and a second partitioning plate, multiple air pressure holes are formed in the first partitioning plate, a water inlet pipe is communicated with the side wall of the outer pot body, and a water drainage pipe is communicated with the second partitioning plate. The irrigating planting pot hasthe advantages of being ingenious in structure and convenient to use; based on the ingenious principle that air pressure is changed, the water level inside the water storage region is increased, thenwater is supplied to soil and plants in the inner pot body, under the condition of the same water level, the contact areas of the plants with different weights and water are different, and adsorbed moisture is different.

Owner:FUNAN NATURE ARTS & CRAFTS

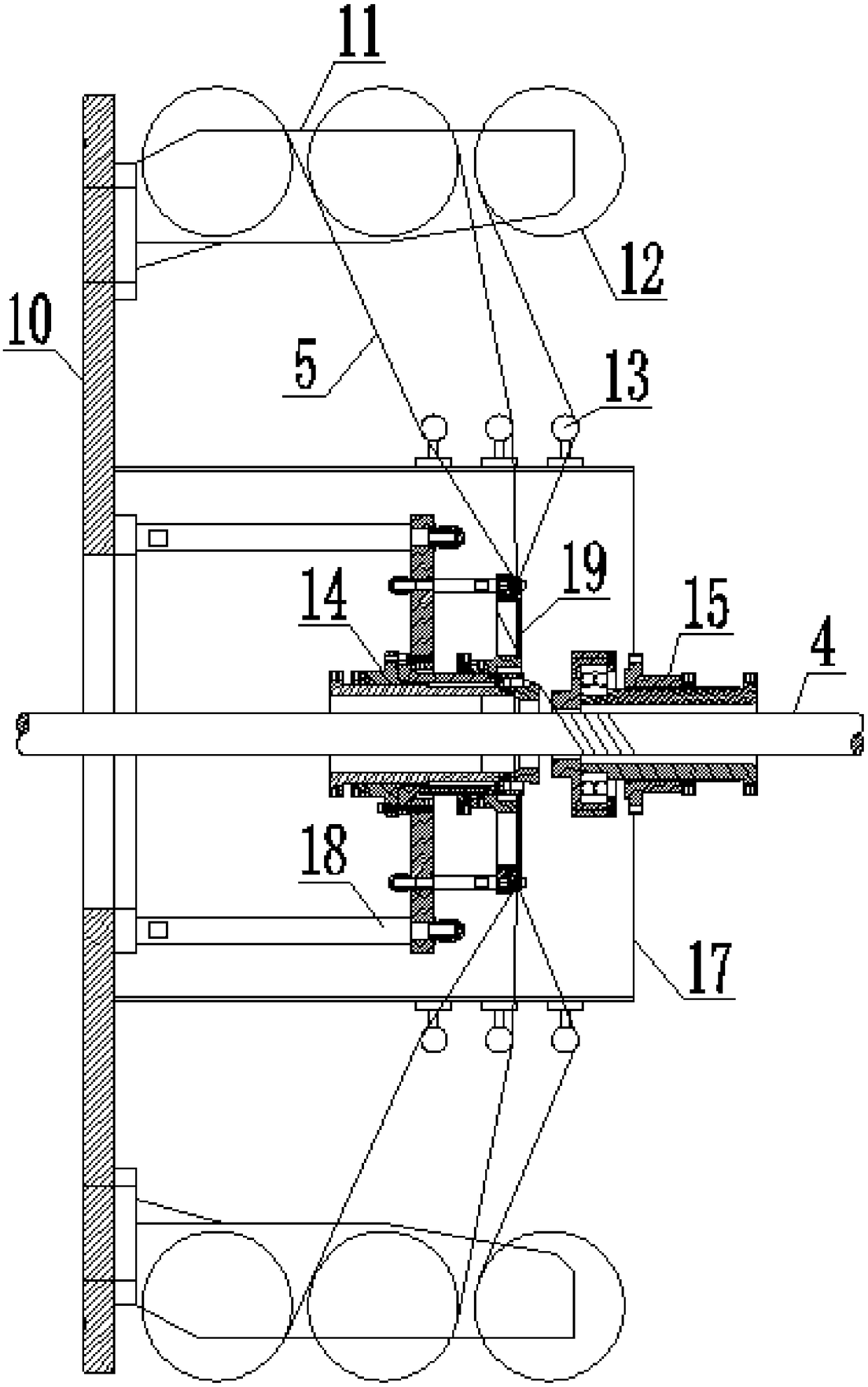

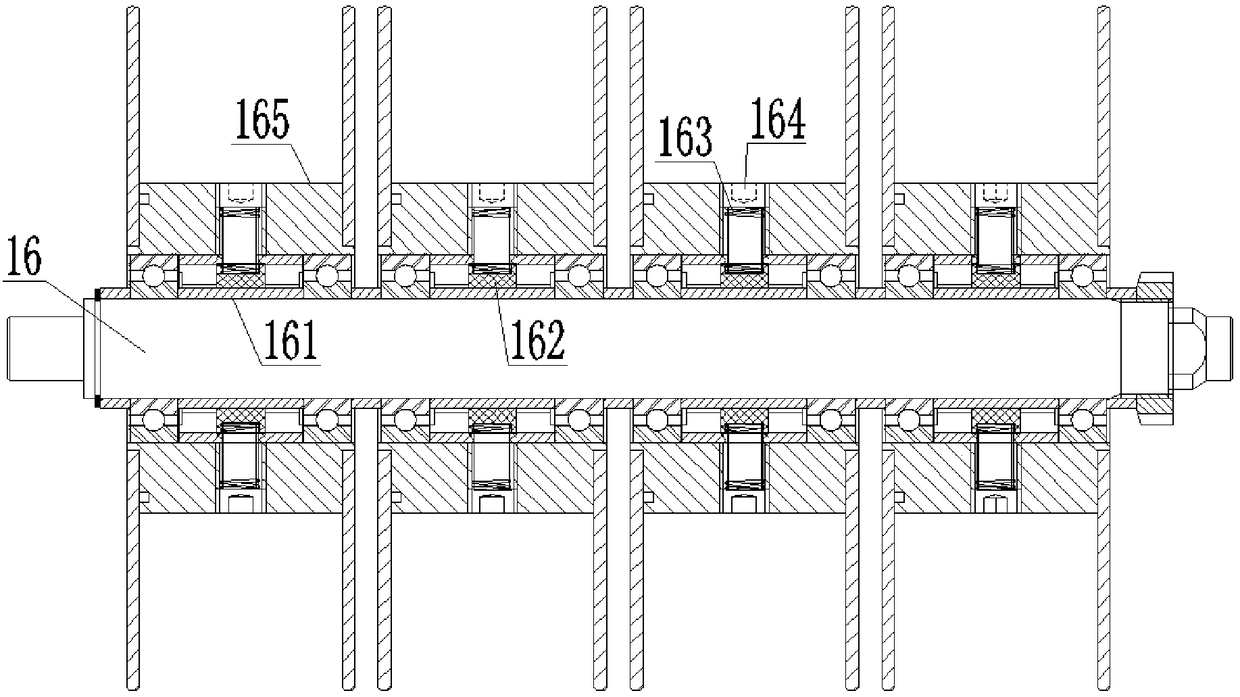

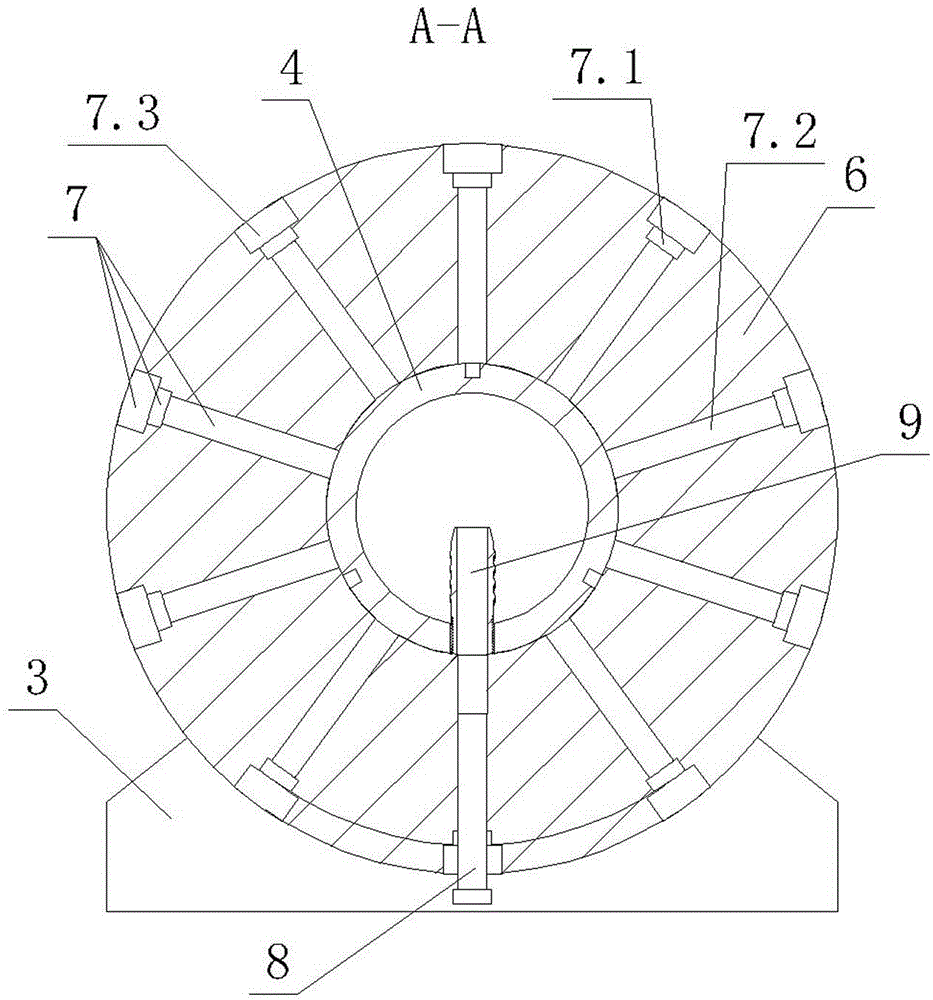

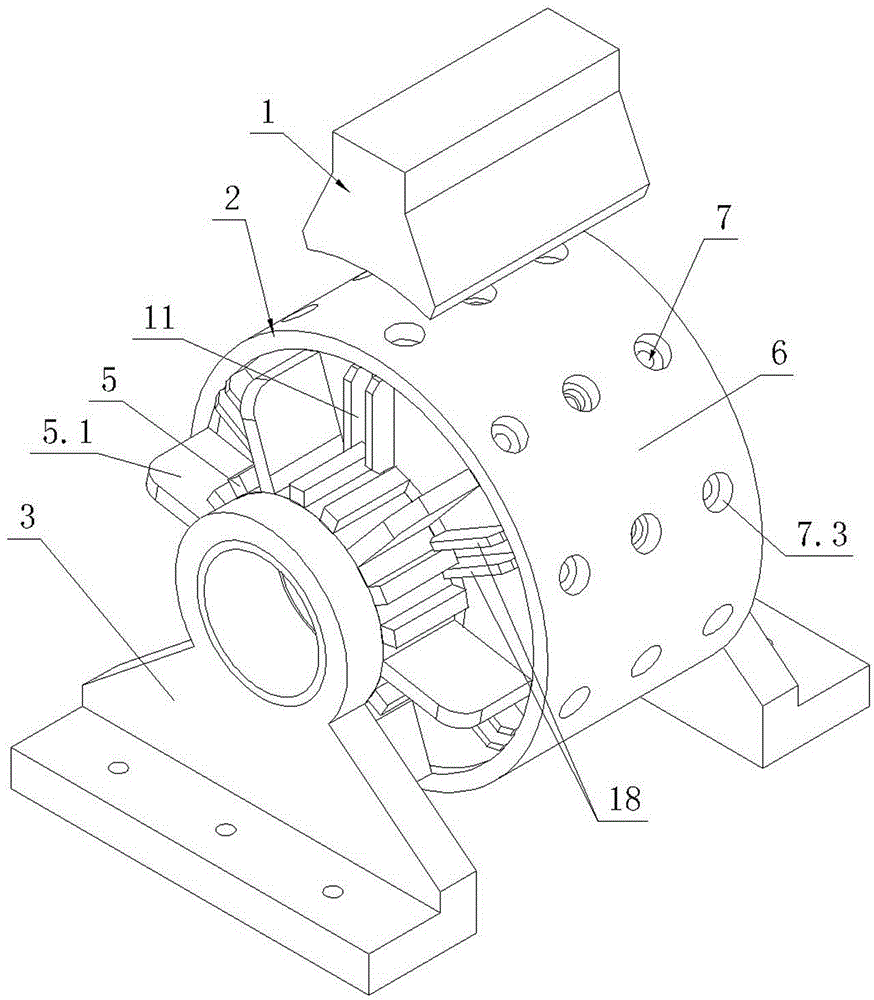

Full-automatic intelligent steel wire winding equipment

The invention relates to full-automatic intelligent steel wire winding equipment. The full-automatic intelligent steel wire winding equipment comprises at least one a steel wire pre-forming machine for winding a steel wire to a pipe blank and a traction machine which drives the pipe blank to move linearly, wherein a revolving disc provided with a plurality of winding wheels is arranged on the steel wire pre-forming machine; a pre-forming device capable of adjusting the straightening degree of the steel wire is arranged on the revolving disc; and the steel wire drives the pipe blank to move linearly through the traction machine and winds the pipe blank with a same stroke and an equal ring diameter by combining the rotating motions of the revolving disc and the winding wheels. The straightening degree of the steel wire is adjusted through axial motions of an external adjusting sleeve, an outer forming ring and an inner forming ring arranged on the revolving disc to achieve the stable tension of the pre-wound steel wire, so that the ring diameter and the stroke of the steel wires wound on the pipe blank are consistent, and the error is control to be within + / -8%, the demand of controlling the standard error within + / -15% is totally met, and defects that a product produced by conventional equipment is likely to be unstable in specification, be shortened, shrunk and loosened in headand the like are overcome.

Owner:LUOHE HENGFENG MACHINERY MOLD

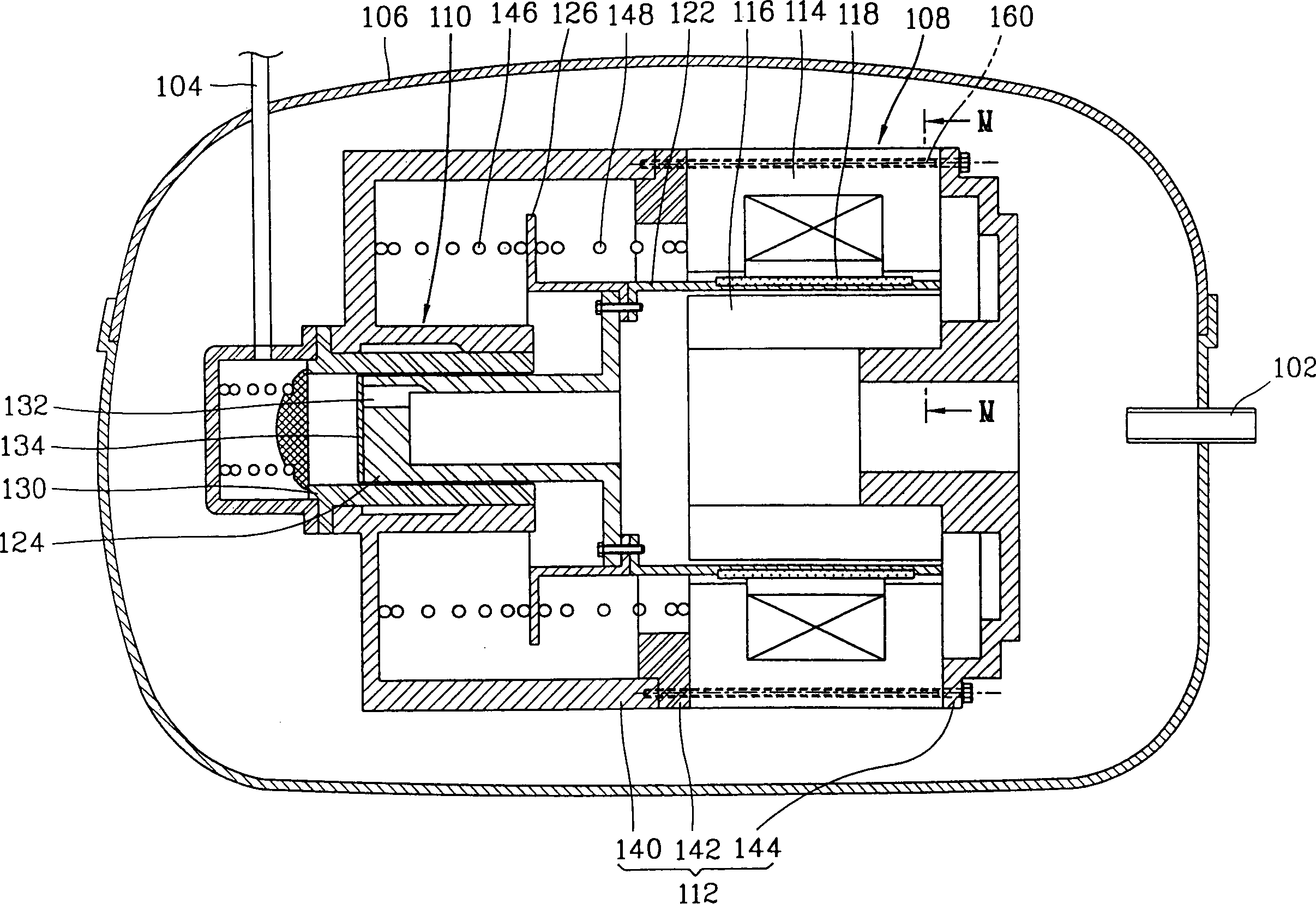

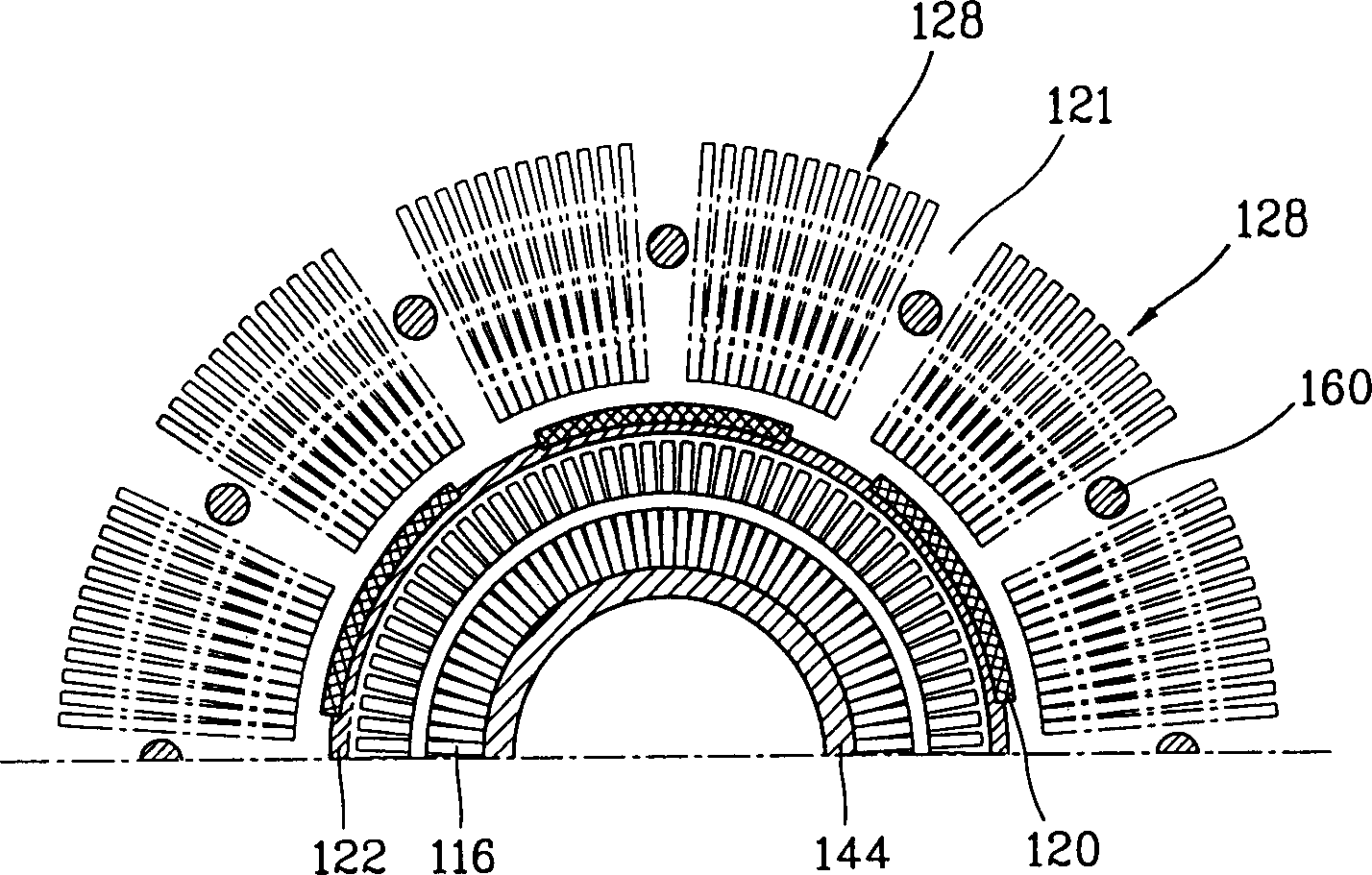

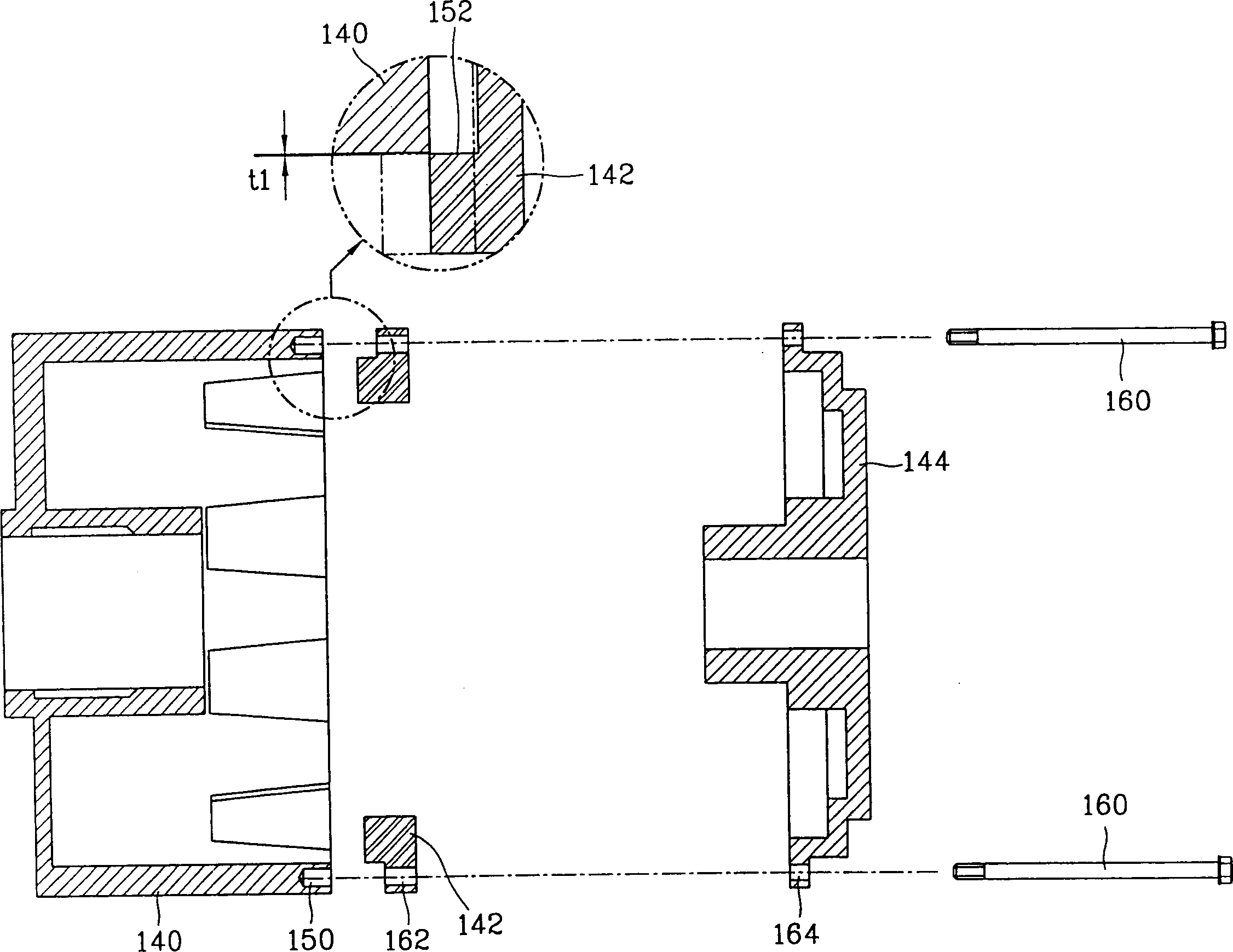

Reciprocating compressor

InactiveCN1427151AReduce manufacturing costSimplify the installation processPositive displacement pump componentsPiston pumpsManufacturing cost reductionEngineering

In a reciprocating compressor including a first frame for supporting a cylinder of a compressing unit, a second frame for supporting a side of an outer stator of a motor unit and a third frame for supporting the other side of the outer stator and an inner stator of the motor unit, wherein the motor unit is arranged between the second and third frames, they are combined with each other, and the assembly is combined with the first frame. Accordingly, a reciprocating compressor is capable of reducing a fabrication cost by eliminating precise processing of construction parts and simplifying an assembly process by constructing a reciprocating motor as one assembly and combining it with a compressing unit.

Owner:INTELLECTUAL DISCOVERY CO LTD

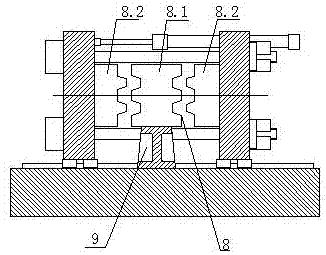

Punching die

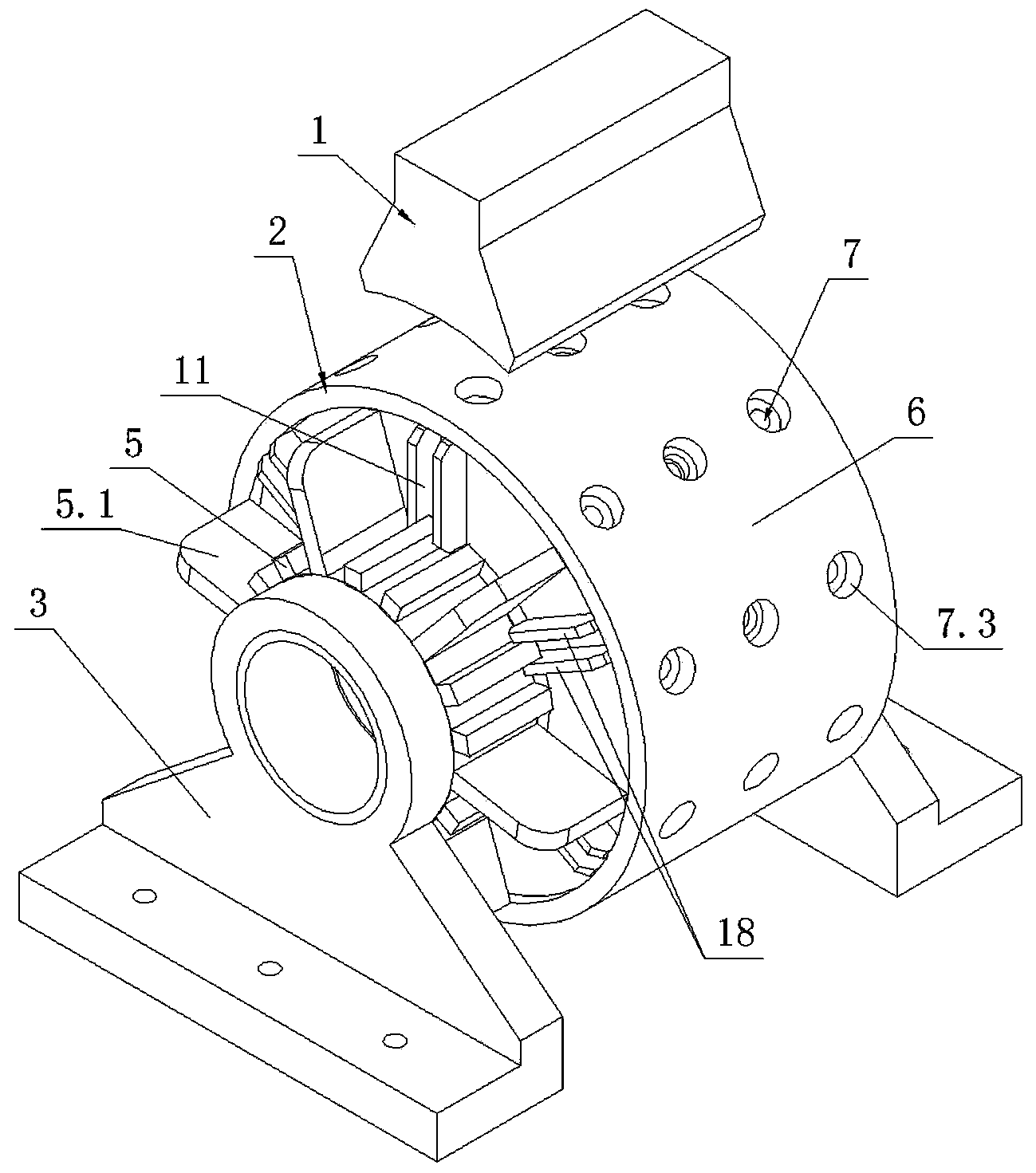

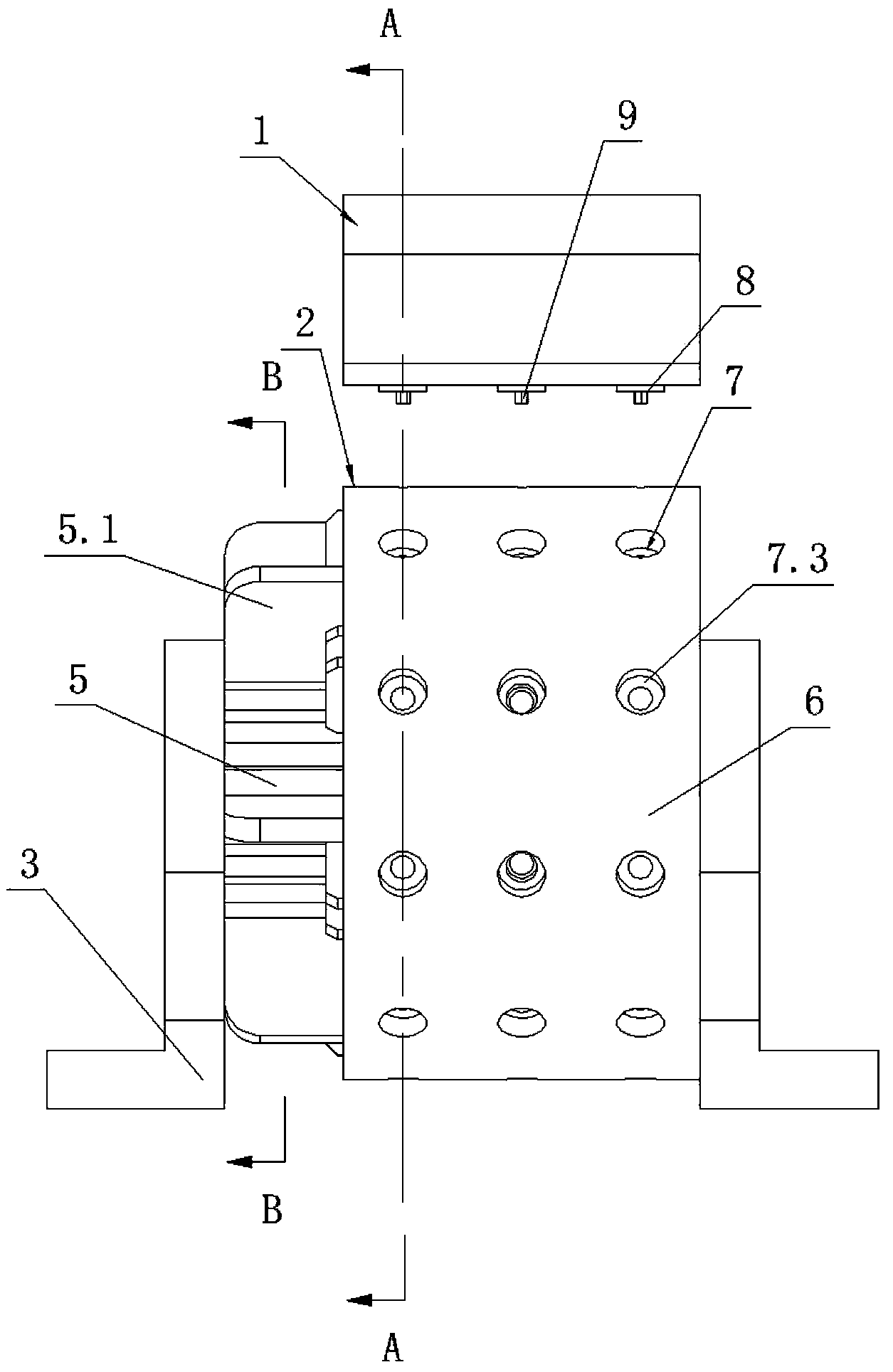

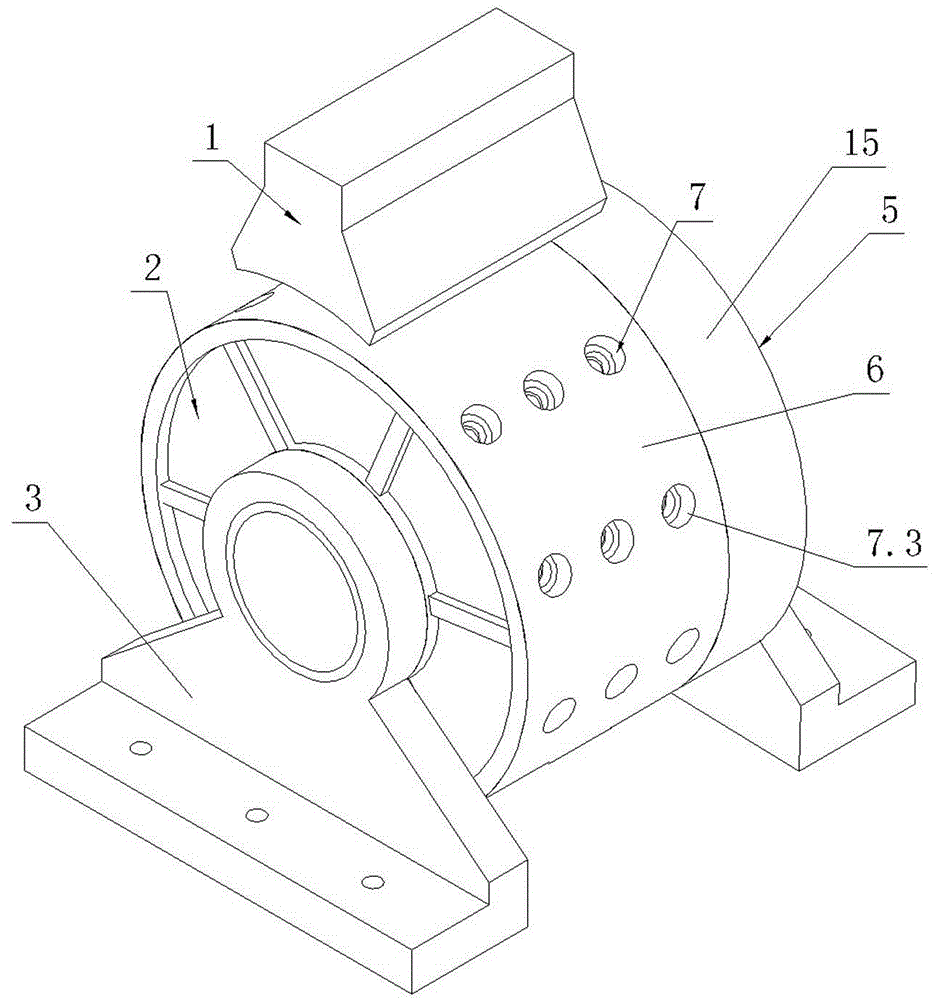

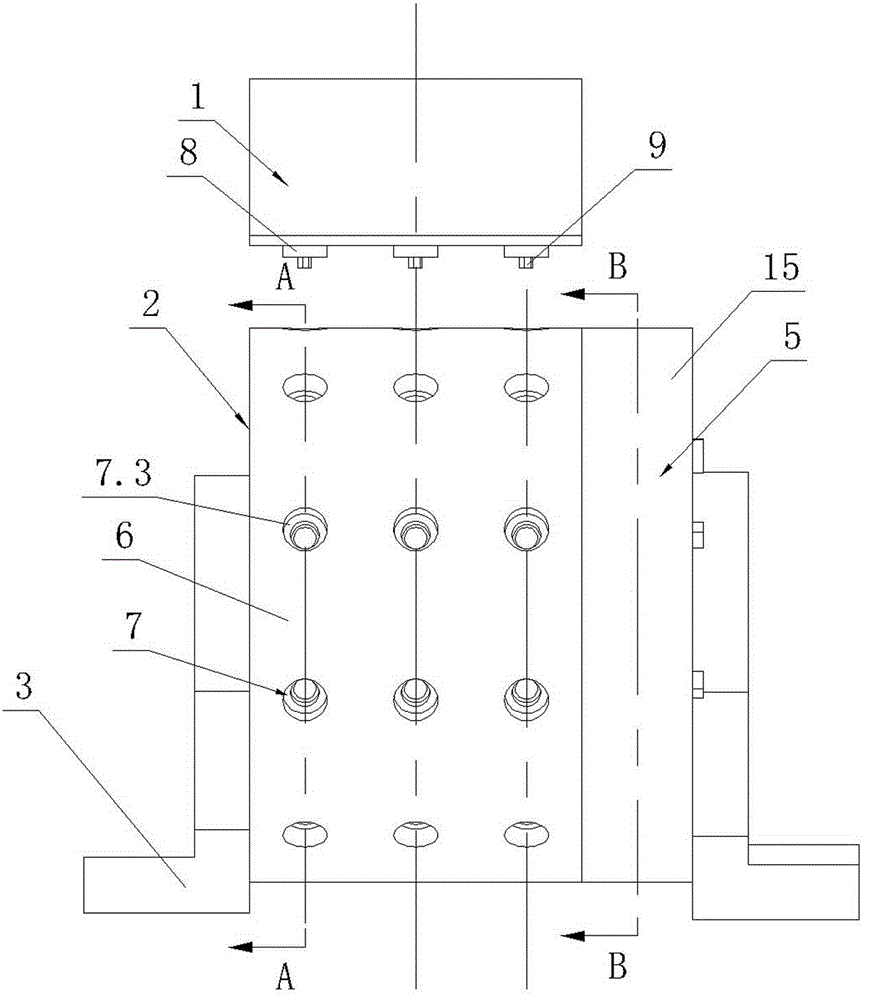

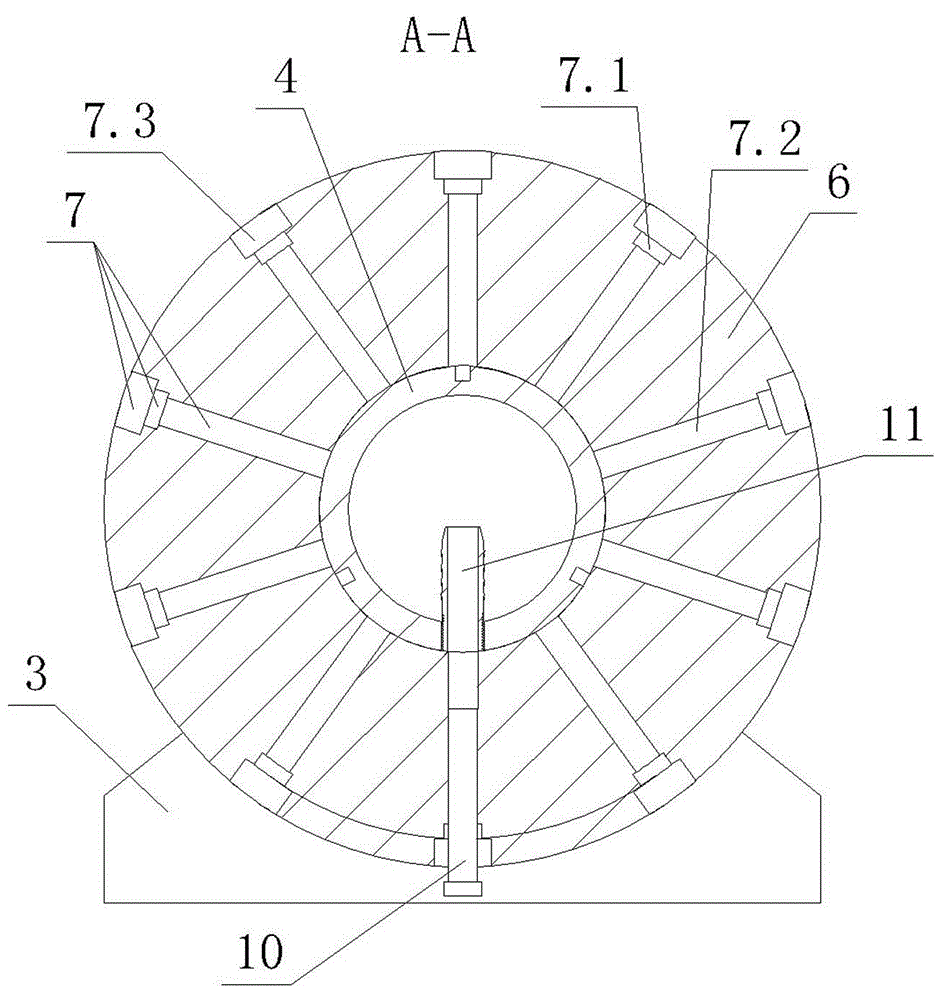

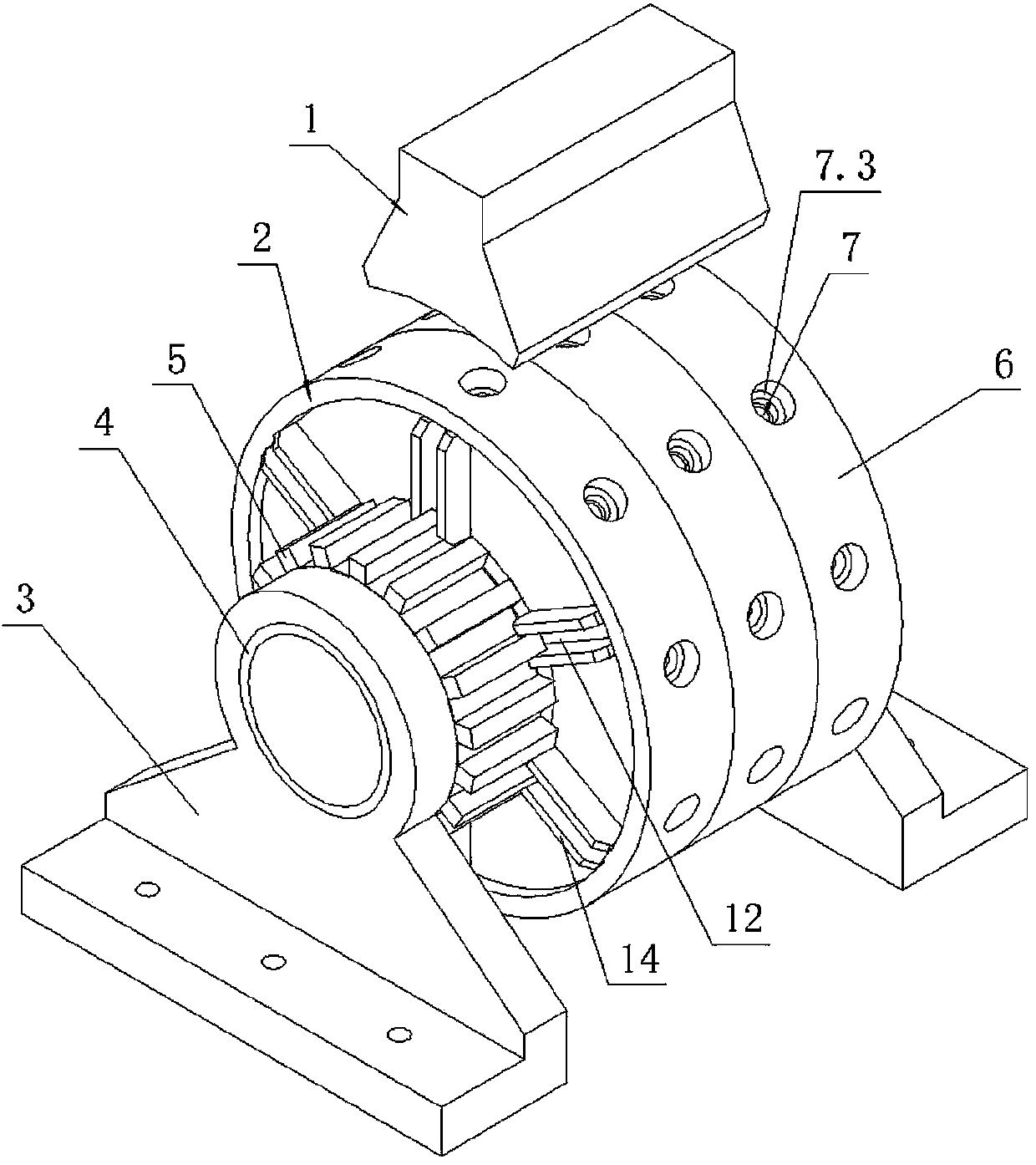

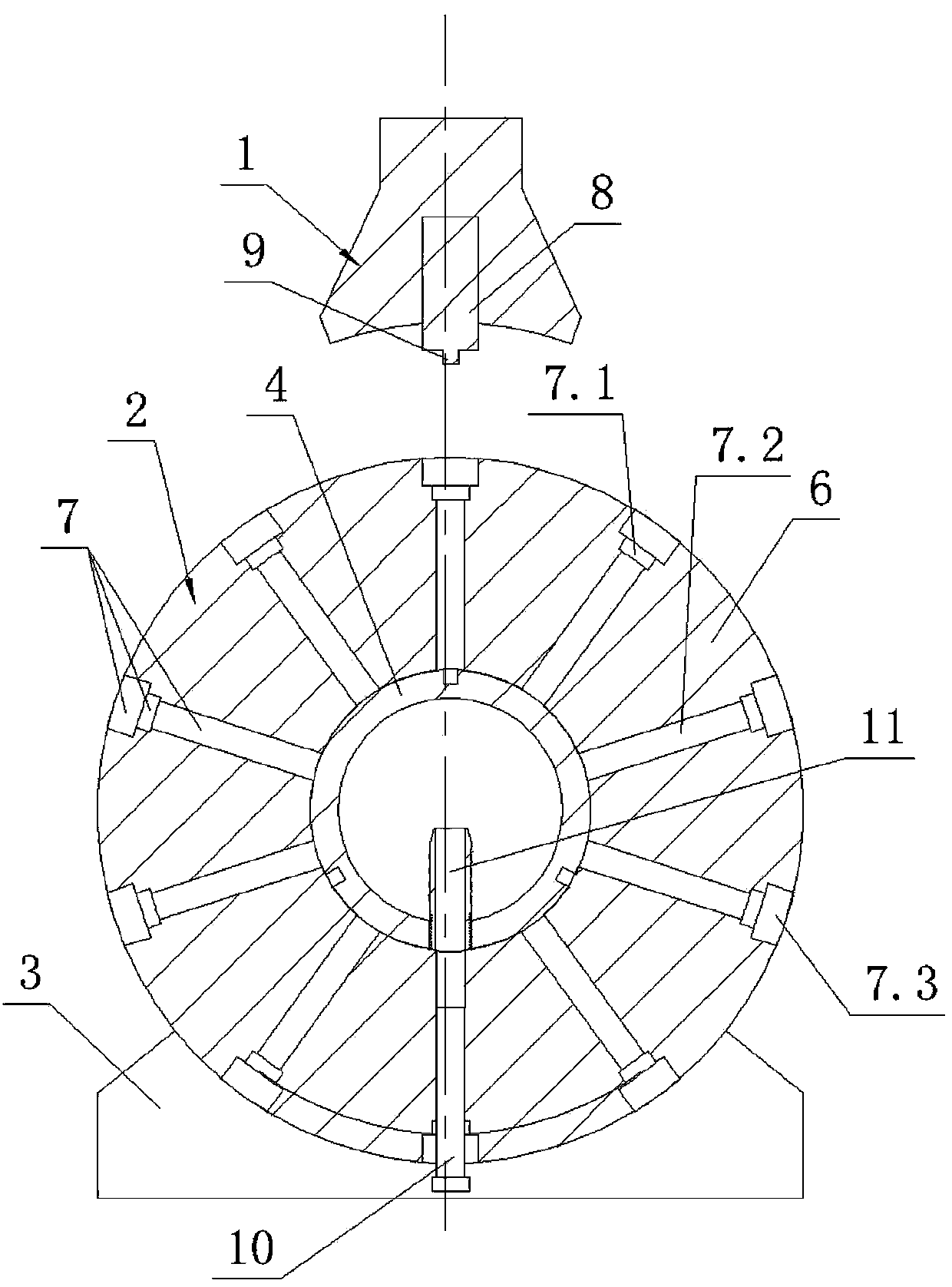

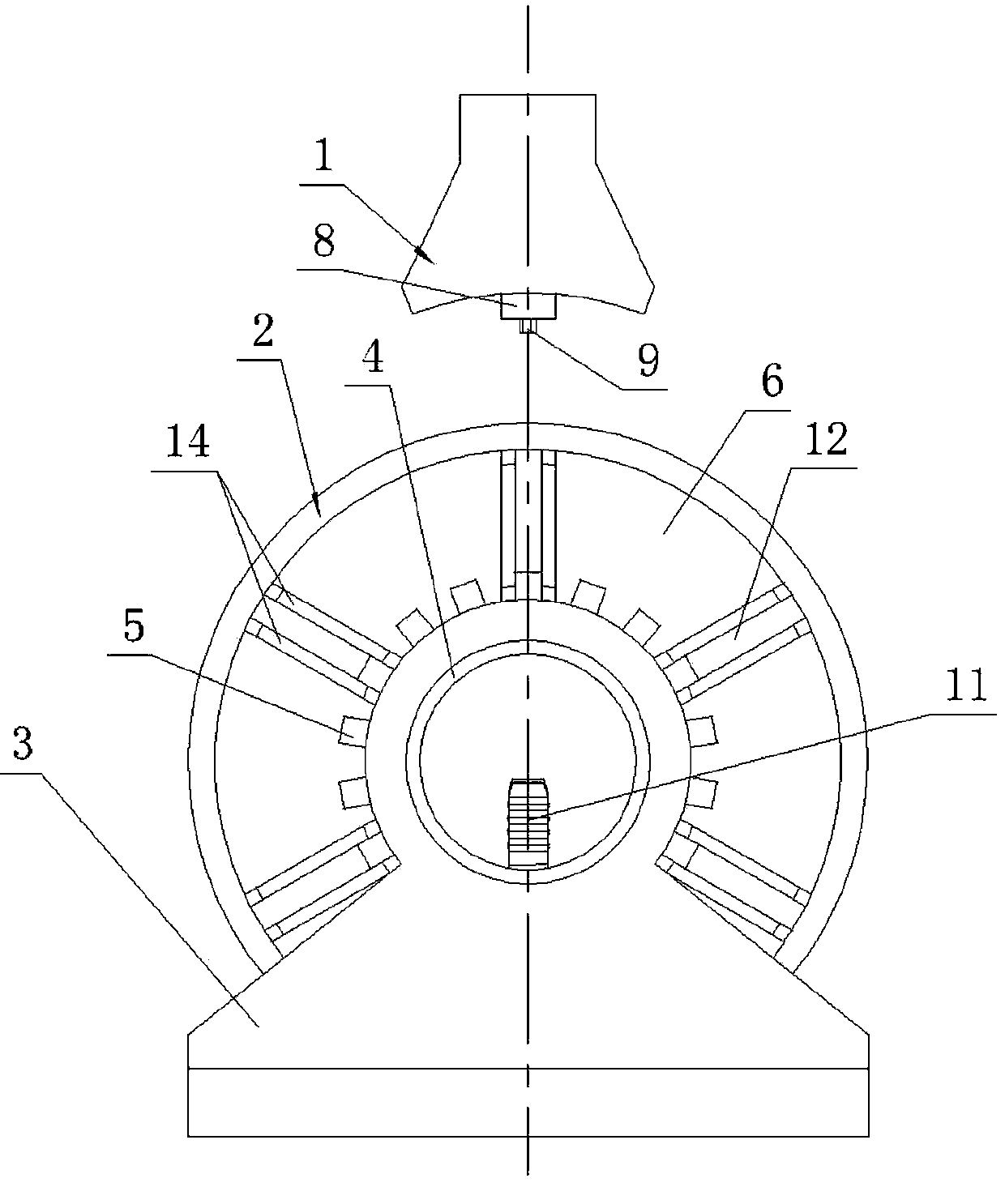

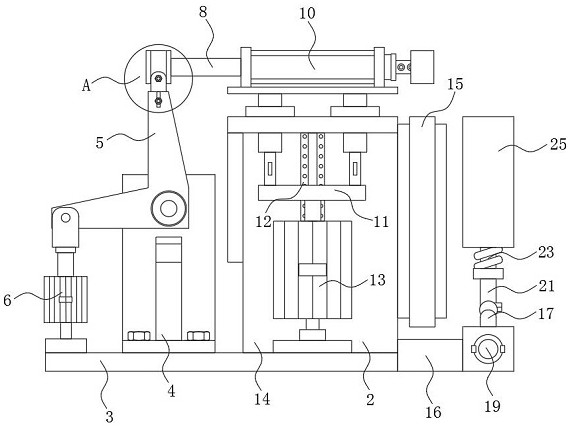

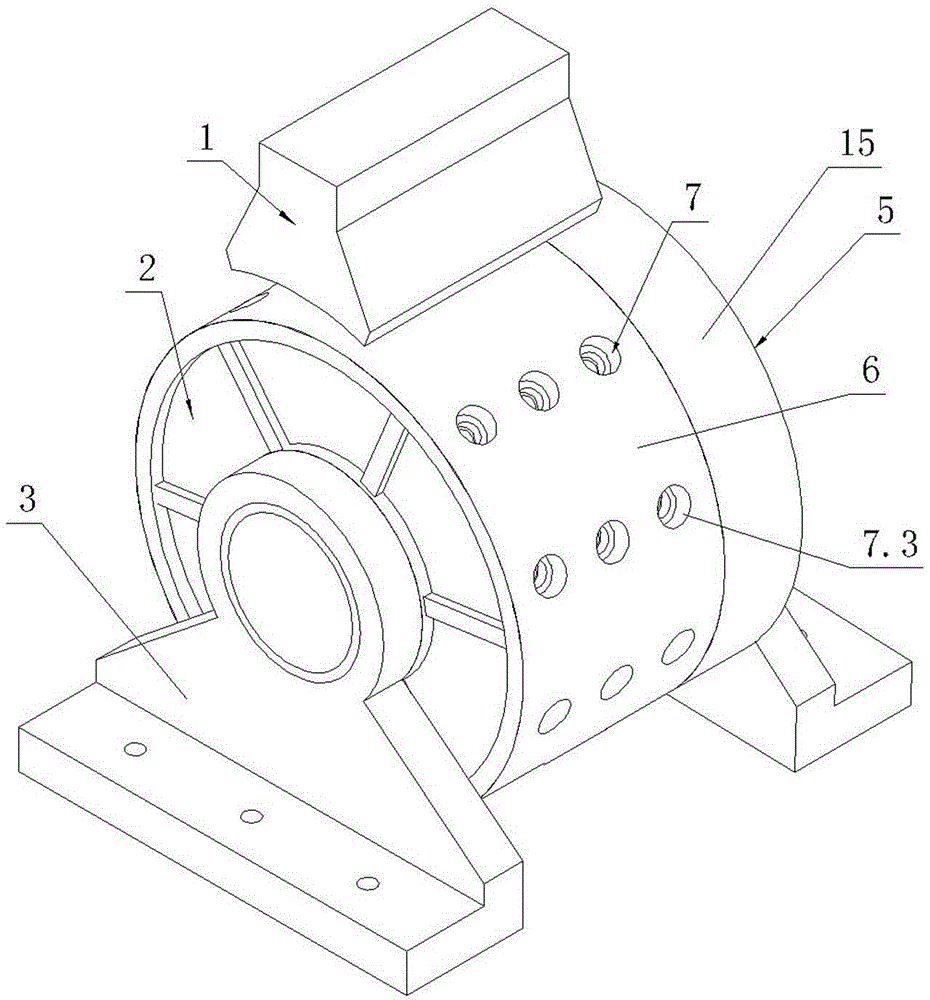

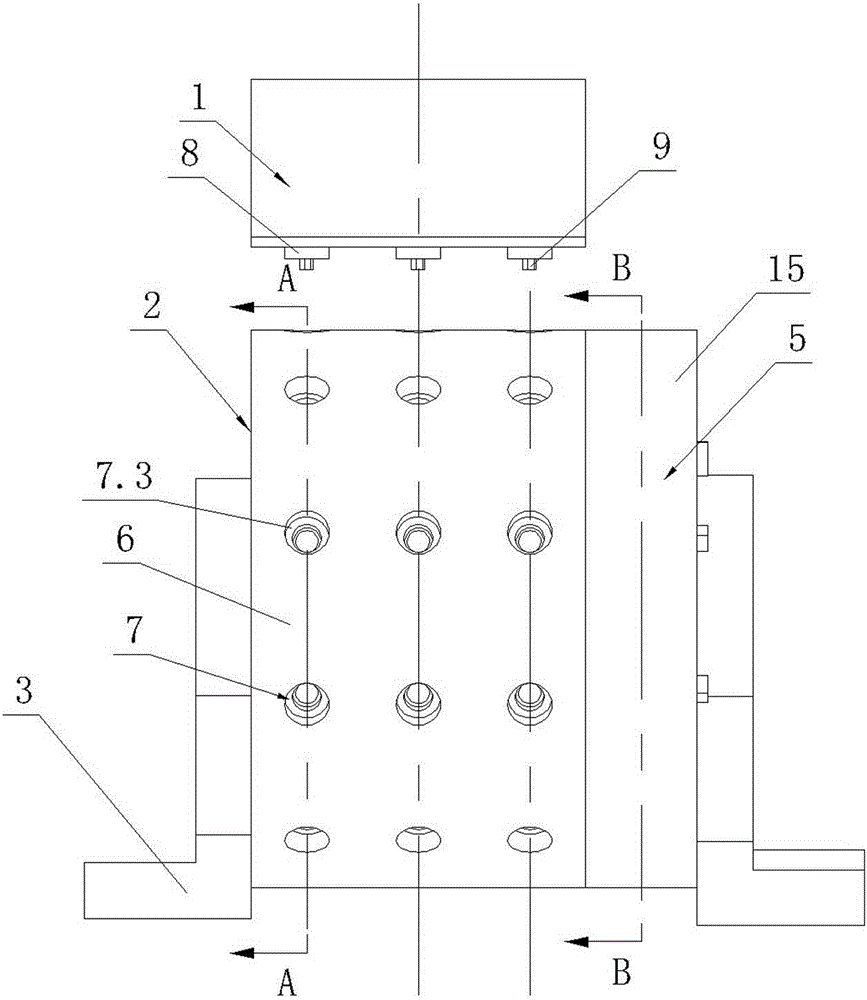

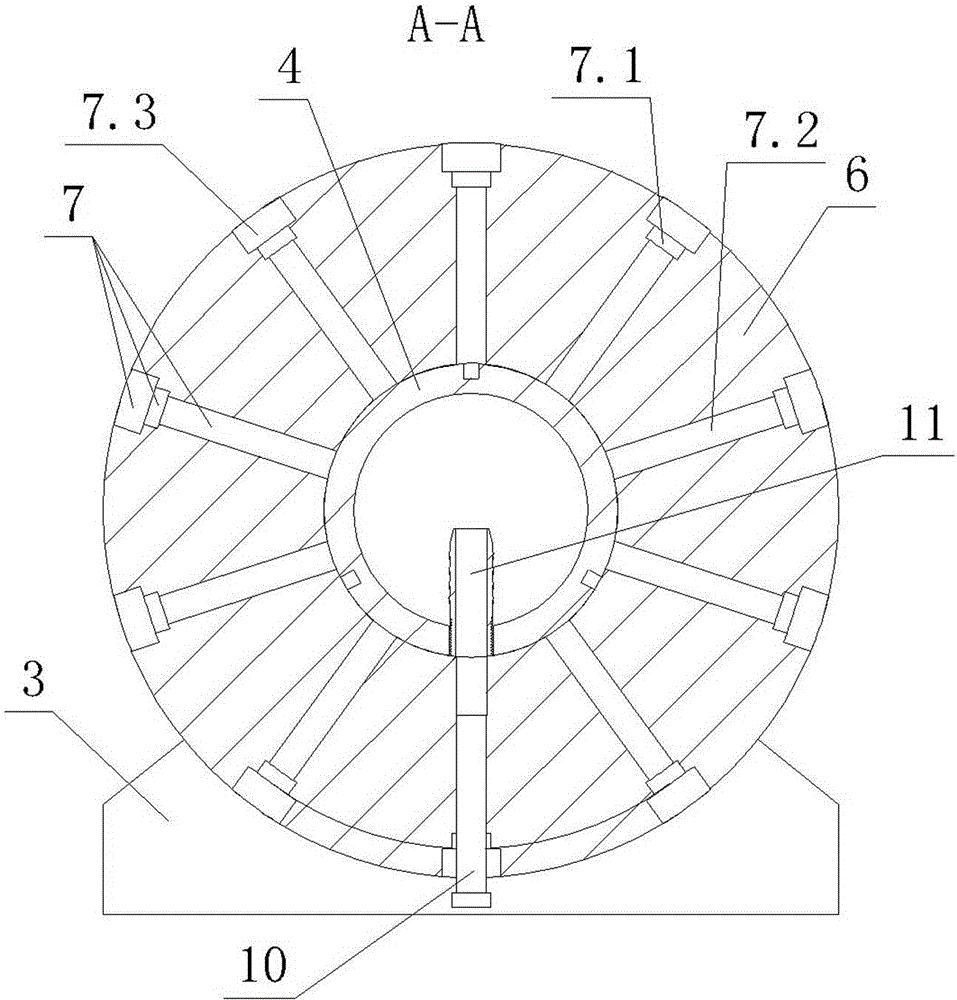

InactiveCN103480732AShort tripPut an end to the safety hazard of smashing and injuring people's handsShaping toolsNutsPunchingGear wheel

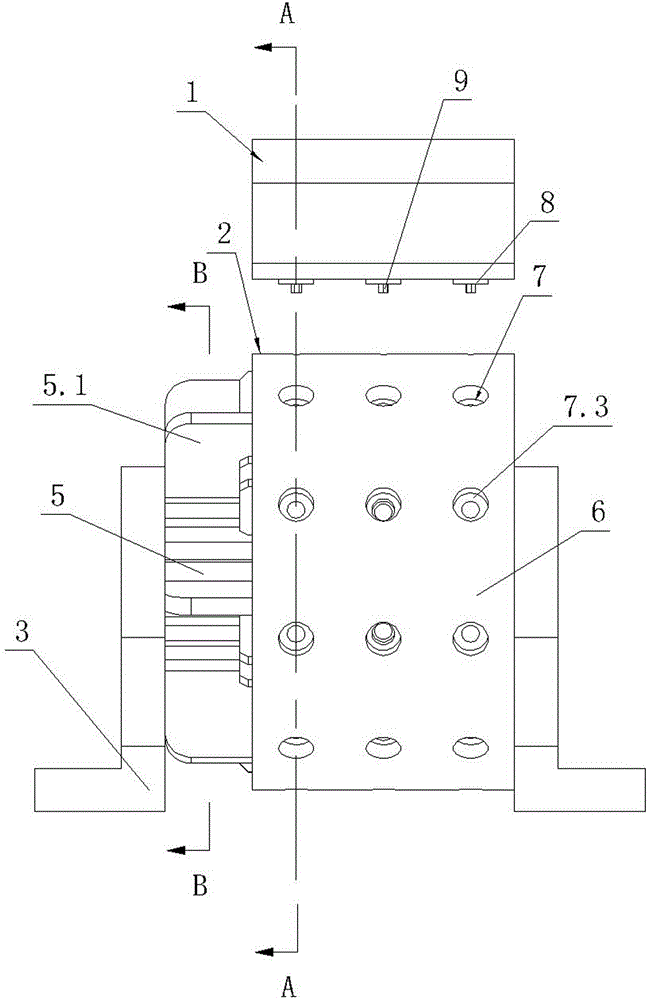

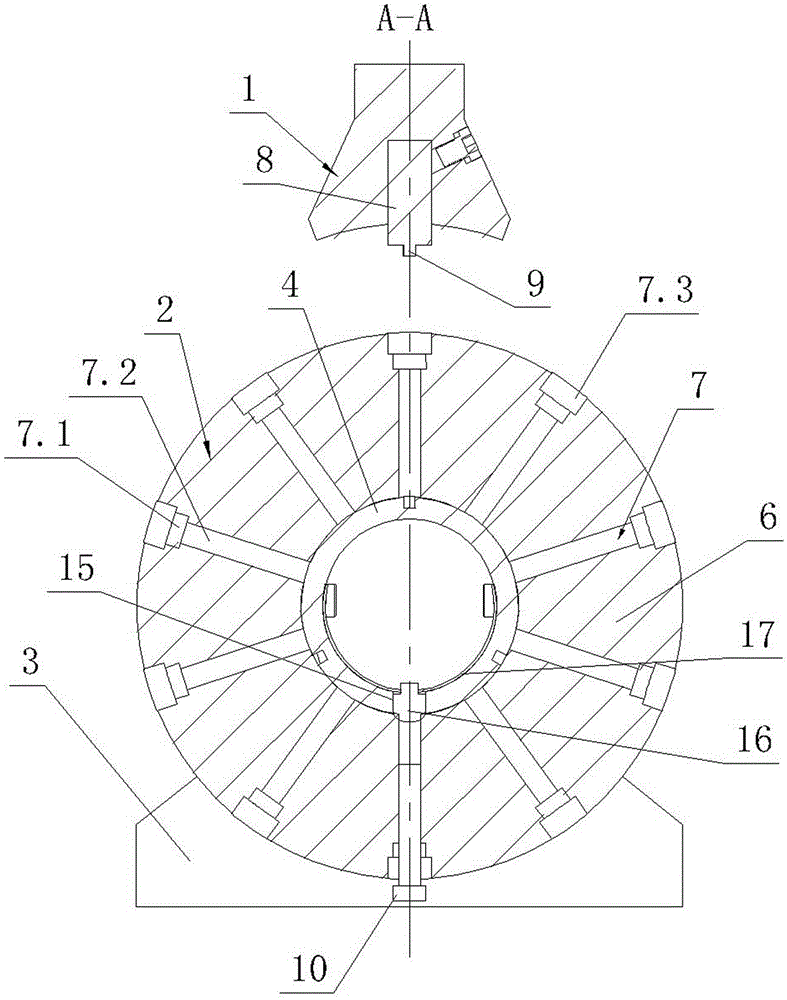

The invention discloses a punching die, which comprises a punch (1) and a die shell (2), wherein the die shell (2) comprises two supports (3), a rotating shaft (4), a shifting gear and a rotating barrel (6), the two ends of the rotating shaft (4) are fixed with the two supports (3), the shifting gear and the rotating shaft (4) are registered, a ratchet gear is arranged between the shifting gear and the rotating shaft (4), the rotating barrel (6) is rotatably registered on the rotating shaft (4), a plurality of radial through holes (7) are formed in the rotating barrel (6), the outer openings of the radial through holes (7) are arrayed in the outer circumferential surface of the rotating barrel (6) in rows along the axial direction, the punch (1) is provided with a plurality of rams (8), all of the row of rams (8) are over against the row of radial through holes (7) on the highest position of the rotating barrel (6), and the rotating shaft (4) is also provided with a device for releasing a punching forming screw (10) from the radial through holes (7) in an ejecting manner. The punching die enables the speed of a punching process to be high, the efficiency is high, and safety and convenience are realized.

Owner:TAIZHOU XINGYU SPORTS TACKLE

Stamping die

InactiveCN103599986AImprove work efficiencyFast punching speedShaping toolsNutsStamping processImpeller

The invention discloses a stamping die which comprises a punch and a formwork. The formwork comprises two supports (3), a spindle (4), a pneumatic disc and a rotating drum (6). Two ends of the spindle (4) are fixed with the two supports (3), the rotating drum (6) is provided with a center hole, the spindle (4) is rotatably sleeved with the rotating drum (6) through the center hole, the pneumatic disc comprises a disc casing and an impeller located in the disc casing, an end wall of the disc casing is fixed with the spindle (4), the spindle (4) is rotatably sleeved with the impeller and is in circumferential limitation with the rotating drum (6), the rotating drum (6) is provided with a plurality of radial through holes (7), the punch is provided with a plurality of punching columns, the lower end of every punching column is provided with a hexagonal prism protrusion, all the punching columns are distributed in a row, the whole row of punching columns are opposite to a row of radial through holes (7) at the highest position of the rotating drum (6), and a circumferential wall of the disc casing is provided with a first nozzle for blowing blades of the impeller. The stamping die is quick in speed in the stamping process, high in efficiency, safe and convenient.

Owner:XINGHUA TIEXIN ELECTRONICS ENG

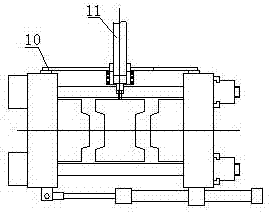

Stamping tool

InactiveCN103464644AShort tripPut an end to the safety hazard of smashing and injuring people's handsShaping toolsNutsEngineeringNozzle

The invention discloses a stamping tool comprising a punch (1) and a die shell (2). The die shell (2) comprises two supports (3), a rotary shaft (4), a transmission gear and at least two rotary plates (6). Two ends of the rotary shaft (4) are fixed to the two supports (3) respectively. The transmission gear and all rotary plates (6) are rotatably fitted to the rotary shaft (4) in a sleeving manner. The outer peripheral surface of the each rotary plate (6) is provided with a plurality of radial through holes (7). The punch (1) is provided with at least two stamping posts (8) as many as the rotary plates (6). The stamping posts (8) are arranged in a row and right face a highest row of radial through holes (7) in the rotary plates (6). The rotary shaft (4) is further connected with a nozzle (11). The stamping tool is high in stamping speed, efficient, safe, and handy.

Owner:泰州市凌峰机电设备有限公司

Intelligent wood stacking wood-working machine

ActiveCN110937385AReduce labor intensityImprove efficiencyConveyorsStacking articlesAgricultural engineeringWoodworking machine

The invention belongs to the technical field of wood manufacturing, and particularly relates to an intelligent wood stacking wood-working machine. The wood-working machine comprises a bottom plate, and is characterized in that guide columns and a top plate are mounted on the bottom plate; a sliding plate slides on the guide columns; a rotating motor is mounted on the top plate and fixedly connected with a first lead screw, and n-shaped notches are formed in the bottom plate and the sliding plate; mutually parallel guide rails are mounted on the sliding plate, and vertical mounting plates are arranged on the guide rails in a sliding fit mode; a horizontal mounting plate, a driving roller and a driven roller are mounted between the vertical mounting plates, and the driving roller and the driven roller are rotationally matched with a conveying belt; a power mechanism is mounted on the horizontal mounting plate; and a conveying plate is fixedly mounted between the vertical mounting plates,and an adjusting mechanism is mounted on the conveying plate. After the intelligent wood stacking woodworking machine is adopted for stacking wood, the wood is parallel to each other, gaps between the wood are eliminated, two ends of the wood are aligned, and the stacking stability is improved.

Owner:广州市升晖木业有限公司

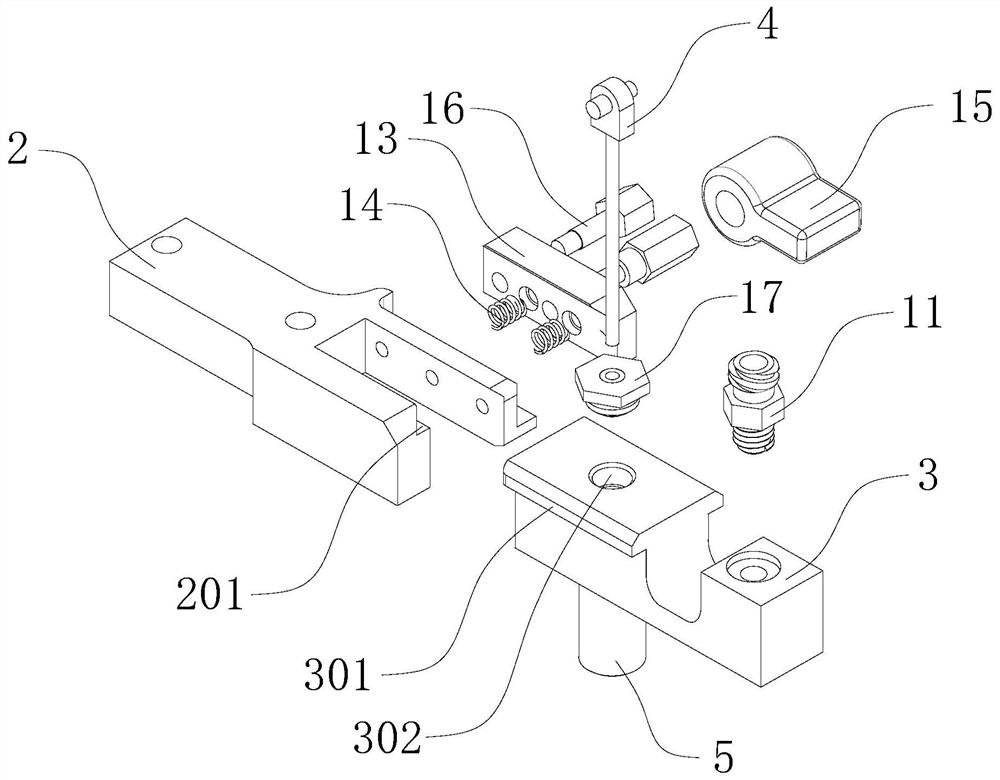

Opposite-cutting adjusting device for bag making machine

The invention relates to an adjusting device, particularly relates to an opposite-cutting adjusting device for a bag making machine, and belongs to the technical field of bag making machines. The opposite-cutting adjusting device for the bag making machine comprises a right connecting plate support and a left connecting plate support, wherein a second right fan-shaped gear and a second left fan-shaped gear are arranged on an adjusting strut; the outer side of the left connecting plate support is connected with a left supporting plate through a bolt; the inside of the left supporting plate is slidably connected with a left adjusting screw; one end of the left adjusting screw is provided with a first left fan-shaped gear which is meshed with the second left fan-shaped gear; and the other end of the left adjusting screw is in threaded connection with the left end of a supporting shaft. The outer side of the right connecting plate support is connected with a right supporting plate through a bolt; the inside of a right supporting plate is slidably connected with a right adjusting screw; one end of the right adjusting screw is provided with a first right fan-shaped gear meshed with the second right fan-shaped gear; and the other end of the right adjusting screw is connected with the right end of the supporting shaft through a bolt. The travel of an upper film and the travel of a lower film can be adjusted to be consistent; the production efficiency and the bag making quality are improved; and adjustment is convenient, quick and effective.

Owner:WUXI KING MO MACHINERY

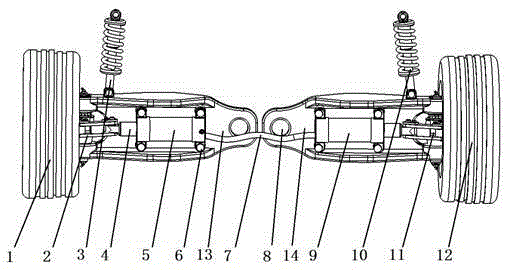

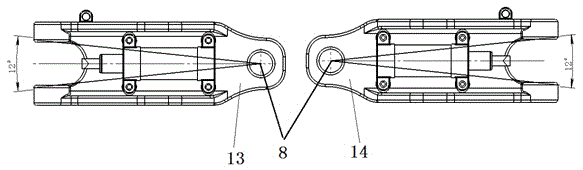

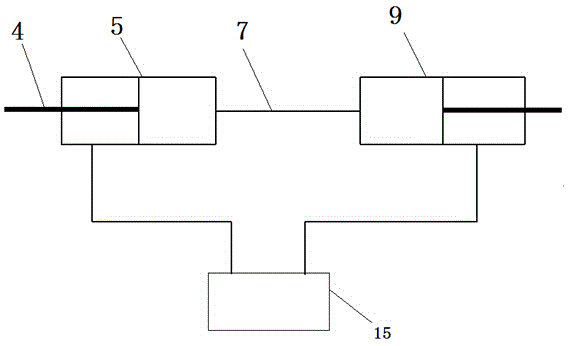

Live forklift steering axle with series oil cylinders

The invention provides a live forklift steering axle with series oil cylinders. The live forklift steering axle with the series oil cylinders comprises a left steering knuckle assembly, a right steering knuckle assembly and a steering axle body, wherein the left steering knuckle assembly is connected with a left rear wheel; the right steering knuckle assembly is connected with a right rear wheel; the steering axle body is arranged between the left steering knuckle assembly and the right steering knuckle assembly; the left steering knuckle assembly is hinged with a piston rod of a left oil cylinder; the right steering knuckle assembly is hinged with a piston rod of a right oil cylinder; cavities, without rods, of the left oil cylinders and the right oil cylinders are connected with each other through soft oil pipes; the steering axle body is divided into a left axle body and a right axle body; axle body mounting holes connected with a forklift body are formed in both the left axle body and the right axle body; a left suspension of a suspended forklift body is arranged on the left axle body; and a right suspension of the suspended forklift body is arranged on the right axle body; the left oil cylinder is fixedly arranged on the left axle body; and the right oil cylinder is fixedly arranged on the right axle body. Under a bumping working condition, the left axle body and the right axle body respectively swing so as to improve the stability of a whole vehicle; and moreover, the travels of the left oil cylinder and the right oil cylinder are consistent with each other so as to ensure that steering angles of the left wheel and the right wheel have relation to each other.

Owner:ANHUI HELI CO LTD

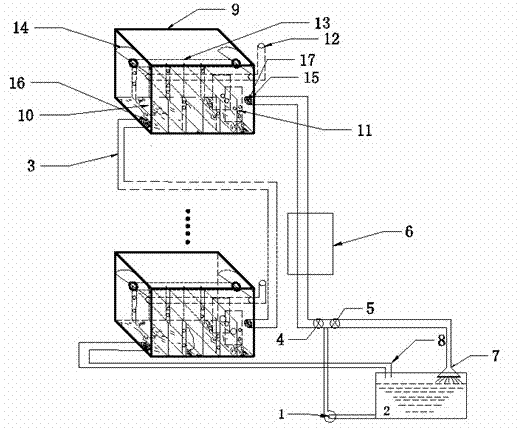

Water treatment device based on mechanism of photocatalysis reaction of nano-crystalline titanium dioxide fiber

InactiveCN102583638AReduce light absorption barrierImprove catalytic effect and efficiencyWater/sewage treatment by irradiationWater/sewage treatment by oxidationBody typeWater pipe

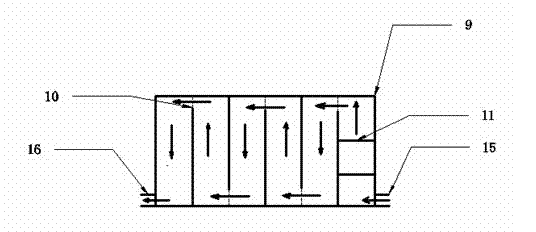

The invention discloses a water treatment device based on a mechanism of a photocatalysis reaction of nano-crystalline titanium dioxide fiber. The water treatment device comprises photocatalysis reactors of the nanocrystalline titanium dioxide fiber, a water storage tank, a water pump, a first valve, a second valve, a flow meter, a spraying and aerating head, a water outlet pipe and a connecting pipe. The water treatment device has the advantages that multiple stages of square body type reactors are stacked together to realize equal-path parallel circulating water treatment, the number of thereactors can be conveniently increased and reduced, the efficiency of a photocatalysis circulating water treatment is high due to the adoption of a parallel mechanism, and the continuity is strong; ultraviolet lamps are horizontally placed above the reactors and parabola-shaped lampshades are adopted, so that light can be vertically incident into liquid levels to the maximal extent; as parallel clapboards are arranged, the flow rates of water flows in the reactions are obviously reduced, breakage and loss of the fiber, which are caused by overlarge impact of the water flows, are effectively avoided, and the strokes of the water flows in different time segments are uniform; and the water treatment device can be applied to large-flow dynamic continuous water treatment, makes large-scale treatment of industrial wastewater containing organic pollutants possible, has a simple structure, requires a low cost and has a broad prospect.

Owner:NANJING UNIV OF SCI & TECH

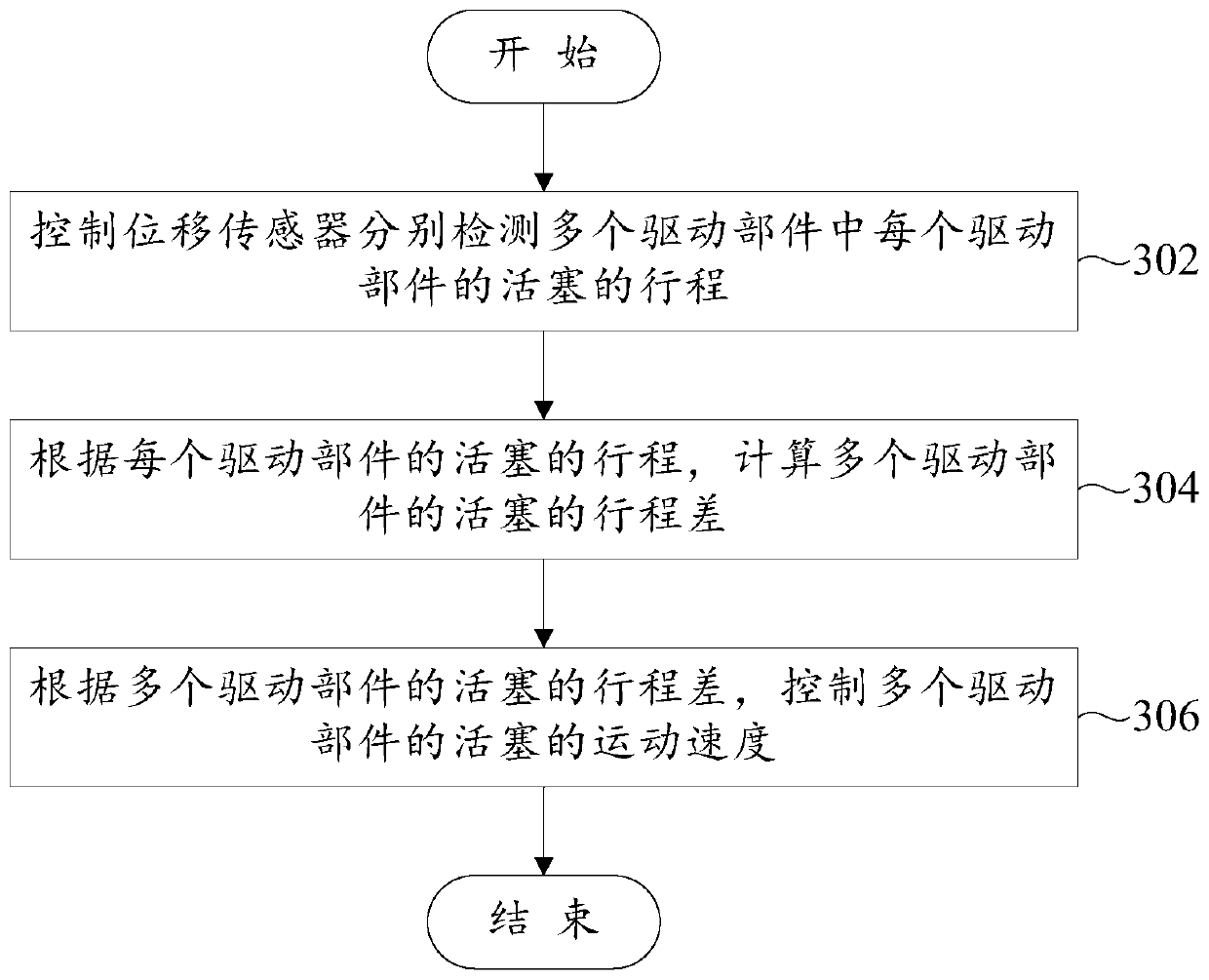

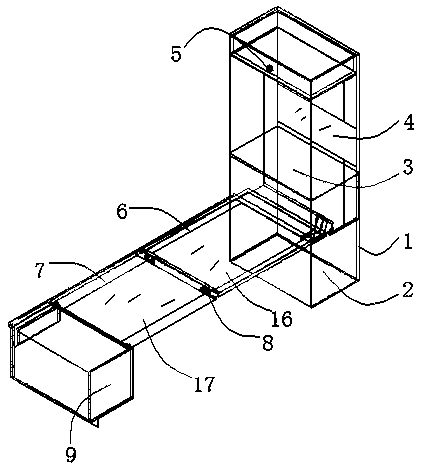

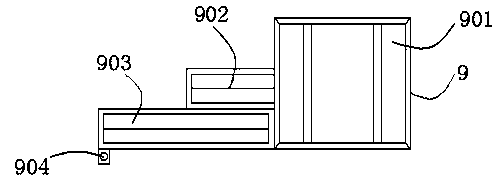

Lifting assembly, tunneling machine and control method of lifting assembly

PendingCN110422788AAvoid leaningSame itinerarySafety devices for lifting equipmentsServomotorsTunnel boring machineCylinder block

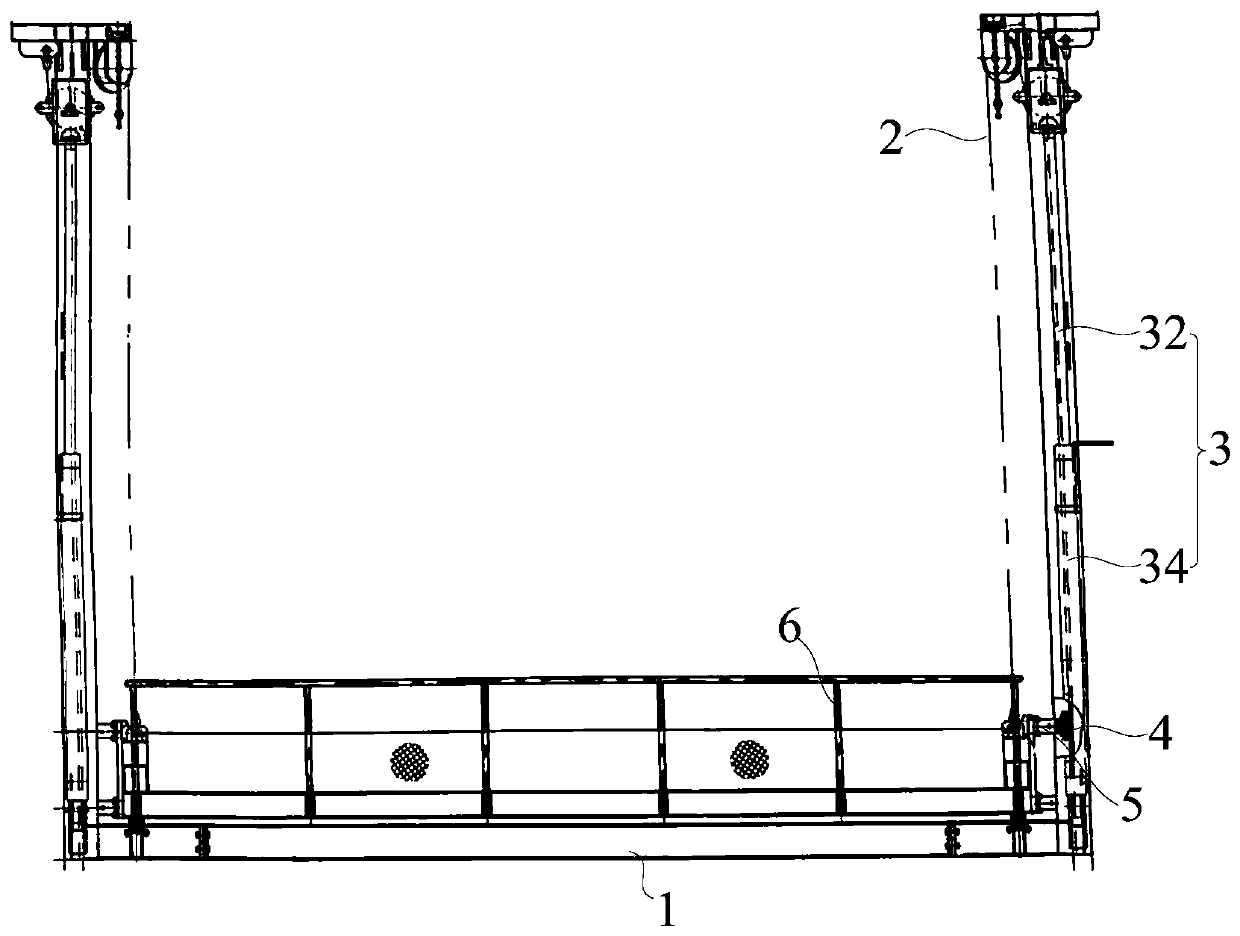

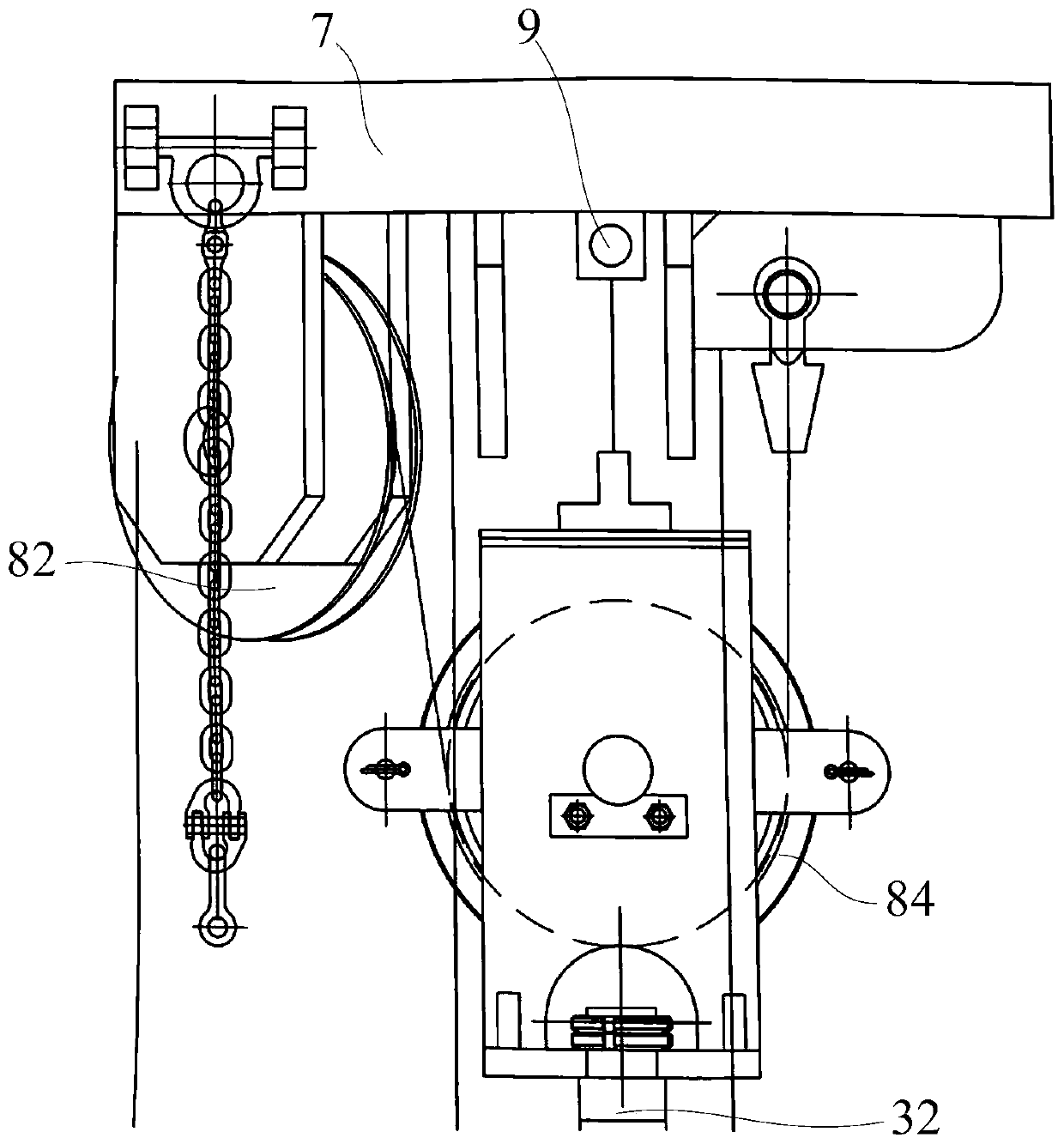

The invention provides a lifting assembly, a tunneling machine and a control method of the lifting assembly. The lifting assembly is used for the tunneling machine. The tunneling machine comprises a body. The lifting assembly comprises a platform, lifting ropes, multiple drive components, displacement sensors and a control device. The lifting ropes are connected with the platform. Any one in the multiple drive components comprises a cylinder body and a piston. The cylinder bodies are mounted on the body, the pistons can slide relative to the cylinder bodies, and the pistons drive the platformto ascend or descend through the lifting ropes. The displacement sensors are connected with the pistons and are used for detecting the stroke of the pistons. The control device is in communication with the displacement sensors and is used for controlling the running speed of the pistons according to the stroke of the pistons. According to the lifting assembly, the motion speed of each piston is controlled according to the stroke of each piston, then it is ensured that the stroke of each piston keeps consistent, the platform is prevented from inclining, then workpieces on the platform are prevented from sliding down, and safety of the construction process is ensured.

Owner:RAILWAY CONSTR HEAVY IND XINJIANG CO LTD +1

Guiding vehicle type plate turnover machine with extensible ladder

InactiveCN109339690ALighten the supportFast folding workStep stoolsLaddersAgricultural engineeringVehicle type

The invention discloses a guiding vehicle type plate turnover machine with an extensible ladder and relates to the technical field of plate turnover machines. The guiding vehicle type plate turnover machine with an extensible ladder comprises a machinery room and a rear turnover plate, a driving mechanism is arranged on the lower part of the interior of the machinery room, a seat bench is arrangedon the middle part of the inside of the machinery room, the rear turnover plate is arranged on the one side of the machinery room, and a dressing mirror is installed on the inner wall of the inside of the machinery room, a controlling assembly is arranged on the upper part of the inner side of the machinery room, and one end of the rear turnover plate is connected with a front turnover plate. Theguiding vehicle type plate turnover machine with the extensible ladder has the beneficial effects that through arrangement of a first tow rod, the front turnover plate, a second movable shaft and a first movable shaft, and a moving structure composed by the first tow rod through the second movable shaft and a second electric pushing rod, when the second electric pushing rod is started, the firsttow rod drives the front turnover plate to move downward through a second tow rod, the front turnover plate is made to rotate along the outer side of a hinge and convenient for being folded with the rear turnover plate, and the speed of achieving that a turnover plate is taken in the machinery room is increased.

Owner:孟东昕

Arc striking device for ion plating and ion plating device

PendingCN110565055AImprove sealingSame itineraryVacuum evaporation coatingSputtering coatingEngineeringVacuum chamber

The invention discloses an arc striking device for ion plating and an ion plating device, and relates to the technical field of ion plating. The arc striking device comprises an arc striking hook, a connecting rod, a corrugated pipe, a drive device and a sealing insulating part. A mounting hole is formed in the side wall of a vacuum chamber of the ion plating device, the sealing insulating part isfixed into the mounting hole and connected with the mounting hole in a sealed manner, an output shaft of the drive device penetrates through the sealing insulating part to be fixedly connected with one end of the connecting rod, the drive device can drive the connecting rod to reciprocate in the axial direction, one end of the corrugated pipe is fixedly connected with one end of the sealing insulating part, the other end of the corrugated pipe fixedly sleeves the connecting rod and is connected with the connecting rod in a sealed manner, and the connecting rod penetrates through the corrugated pipe to be fixedly connected with the arc striking hook. The ion plating device comprises the vacuum chamber and the arc striking device for ion plating. The drive device drives the arc striking hook to move, acting force is large, hook adhesion is not easily caused, the corrugated pipe is arranged for static sealing, the sealing performance of the vacuum chamber is good, and vacuum is not easily damaged.

Owner:BEIJING TECHNOL SCI

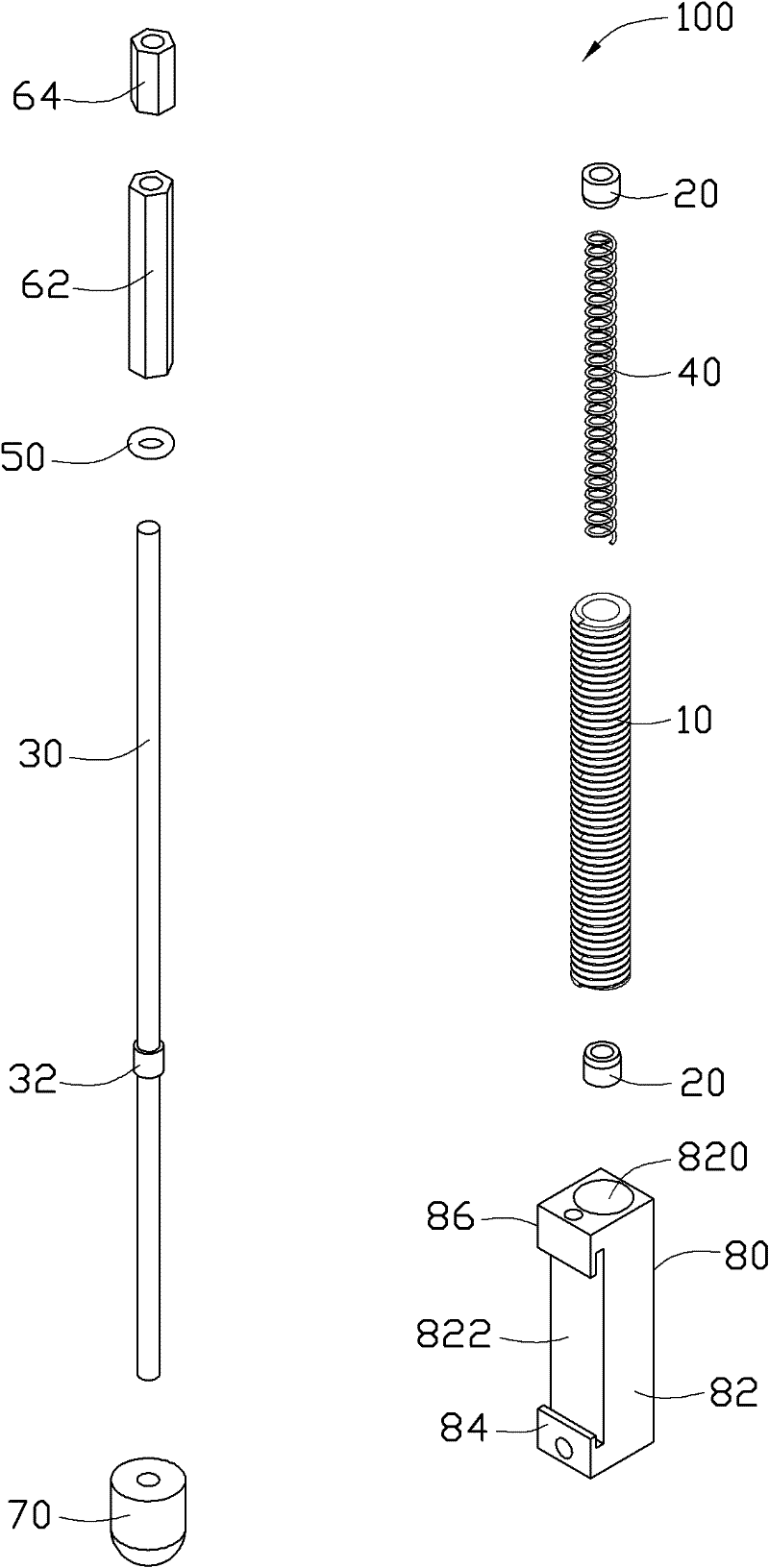

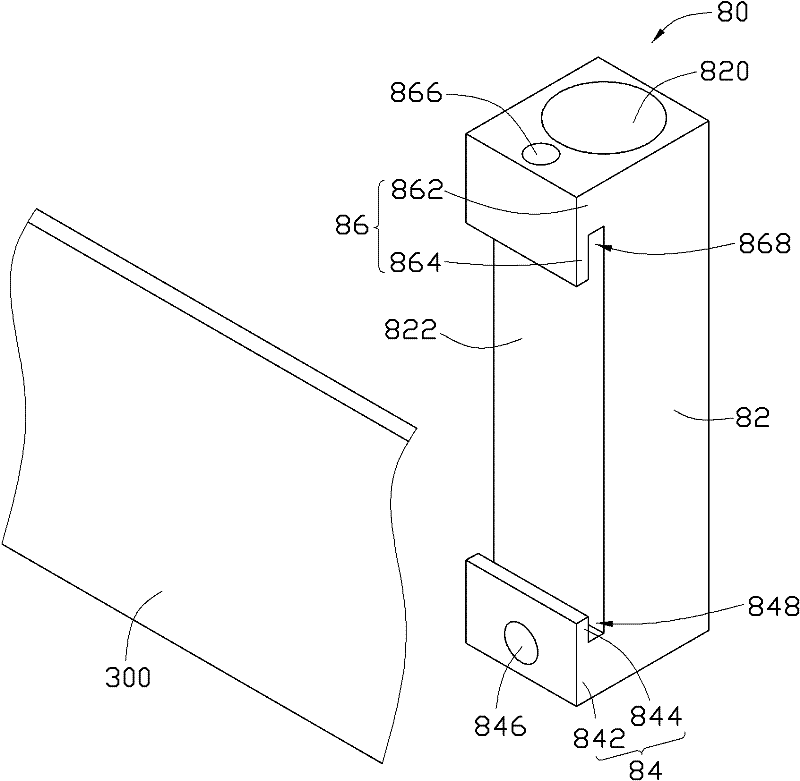

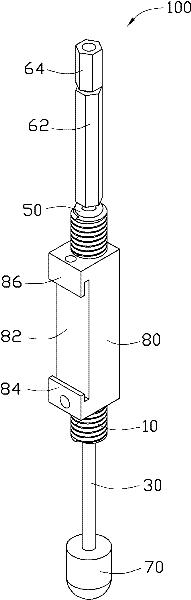

Testing device

InactiveCN102650680AEasy level adjustmentConsistent levelElectrical measurement instrument detailsCircuit interrupters testingBiomedical engineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

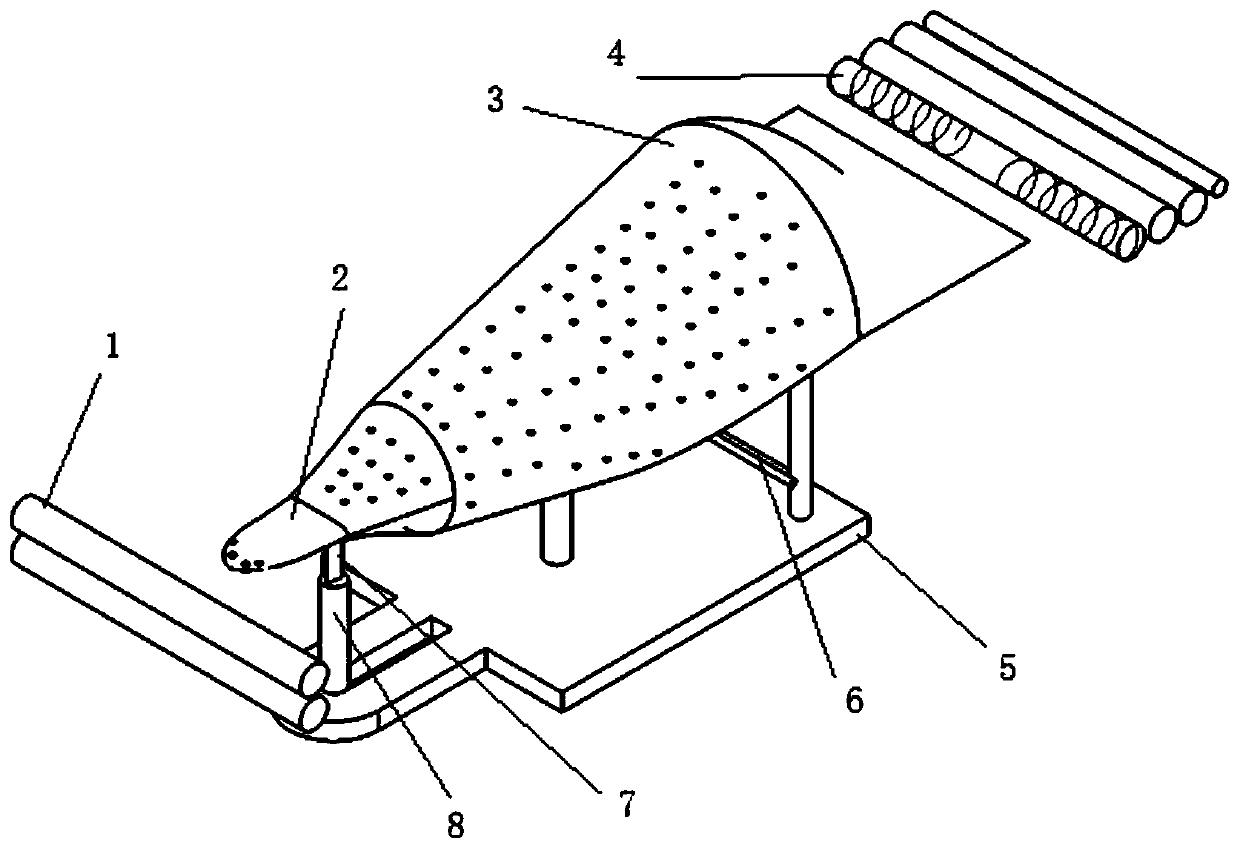

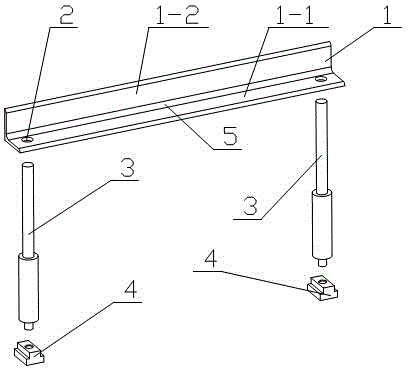

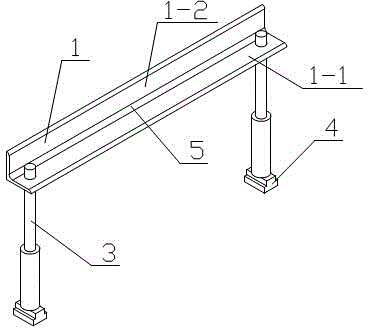

Plastic film unfolding frame

The invention discloses a plastic film unfolding frame. The plastic film unfolding frame is mainly composed of an opening device, a cutter, a cutter supporting column, a circular truncated cone unfolding device, an air inlet pipe, a supporting frame, an unrolling roller and a rolling roller all of which are arranged in a line shape. The cutter is located at the middle position of the opening device. The opening device is in a tongue shape and is fixedly connected with the circular truncated cone unfolding device. The front end of the opening device is provided with air holes, and the surface of the circular truncated cone unfolding device is provided with air holes. The circular truncated cone unfolding device is fixed to the supporting frame. The supporting frame is provided with slidingrails. The air inlet pipe is connected to the rear part of the unfolding device. The unrolling roller is located in front of the opening device and is parallel to the opening device and guides a plastic film to enter the unfolding frame, and the purpose of blowing the double-layer film can be achieved through ventilation of the air holes in the front end. By means of the plastic film unfolding frame, same journey in the unfolding process of the film parts can be guaranteed, meanwhile, the contact area of the film and the unfolding frame is reduced through an air film, the problem caused by being pulled of the film in the process is avoided, and the quality level of the film is improved.

Owner:BEIJING UNIV OF CHEM TECH +1

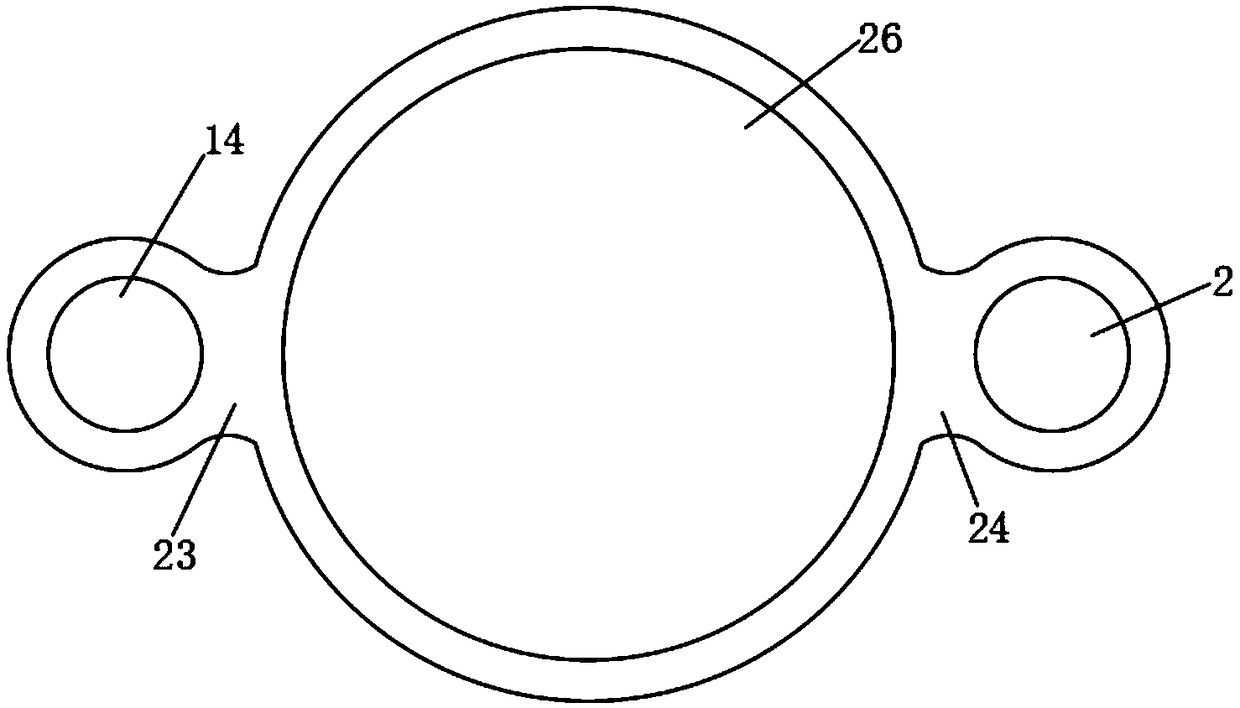

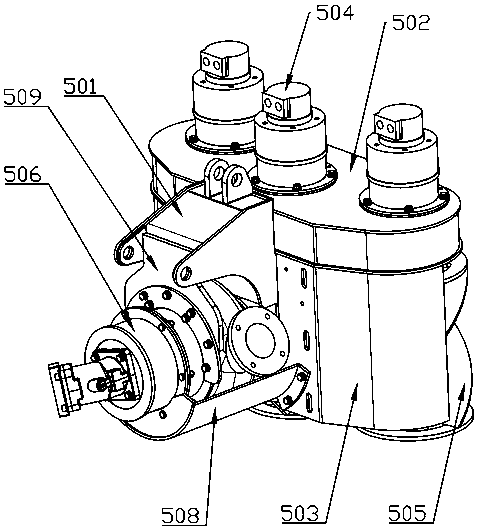

Gearbox shell grabbing manipulator for new-energy automobiles

The invention relates to the technical field of gearbox production equipment for new-energy automobiles, in particular to a gearbox shell grabbing manipulator for the new-energy automobiles. The gearbox shell grabbing manipulator comprises a clamping jaw seat, clamping jaws, a threaded shaft, a worm gear, a worm, a worm driving motor, a connecting plate, a servo motor, a ball screw and a screw nut, wherein the clamping jaw seat is provided with a sliding groove, and the clamping jaws slide in the sliding groove; and when the threaded shaft rotates, the two clamping jaws are driven to move oppositely, and the worm gear is engaged with the worm. According to the gearbox shell grabbing manipulator, each clamping jaw is arranged on the clamping jaw seat through a sliding part, so that the resistance is reduced to the minimum when the clamping jaws slide, and quick clamping is achieved; the clamping jaws are arranged to move oppositely after being driven by the threaded shaft, and due to the fact that the threaded engagement force of threaded connection is large, a gearbox shell with a large weight can be clamped; and the driving mode of the threaded shaft enables the moving speed and the stroke of the two clamping jaws to be consistent, so that the clamped gearbox shell is in a balanced state, and the situation that assembly is affected due to shake cannot occur.

Owner:安徽航科自动化设备有限公司

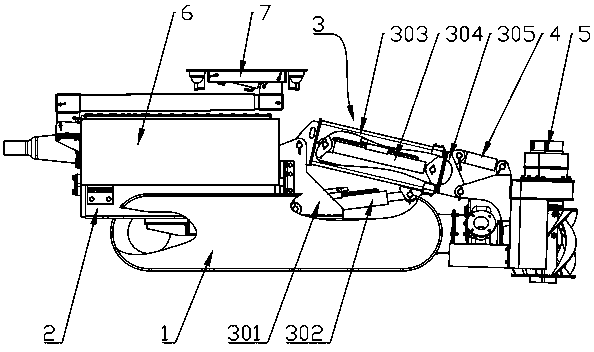

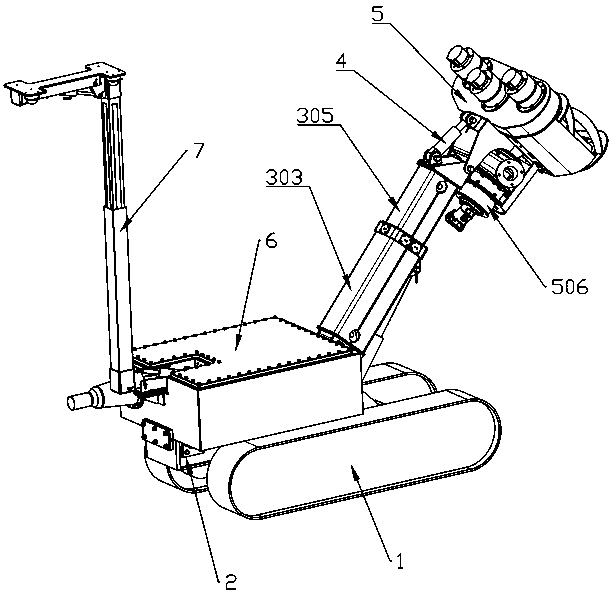

Stirring-sucking dredging robot suitable for multiple working conditions

PendingCN110952611AEasy to cleanImprove convenienceMechanical machines/dredgersHydraulic motorControl engineering

The invention discloses a stirring-sucking dredging robot suitable for multiple working conditions. The stirring-sucking dredging robot comprises a crawler travelling mechanism, a lifting mechanism, adredging actuator, a counterweight module and a sealed box are mounted on the crawler travelling mechanism, the lifting mechanism comprises a large arm seat, a large arm lifting cylinder, a first-stage large arm, a large arm telescopic cylinder and a second-stage large arm, the dredging actuator comprises a connecting block, a mounting plate, a collecting plate, a hydraulic motor, a stirring head, and a sand pump, and the connecting block is hinged to the lower side of the front end of the second-stage large arm; and an overturning oil cylinder is hinged to the upper part of the connecting block, the other end of the overturning oil cylinder is hinged to the upper side of the front end of the second-stage large arm, the mounting plate and the collecting plate are fixed on the connecting block, the hydraulic motor is fixed on the mounting plate, the output end of the hydraulic motor is connected with the stirring head, the collecting plate is arranged on one side of the stirring head,a mud outlet is formed in the middle of the collecting plate, and the sand pump is fixed on the side, away from the stirring head, of the collecting plate. The stirring-sucking dredging robot can apply to a wider underground pipe network, a mine pit, a pump station and other working conditions with different water depths.

Owner:湖南中科恒清环境管理有限责任公司

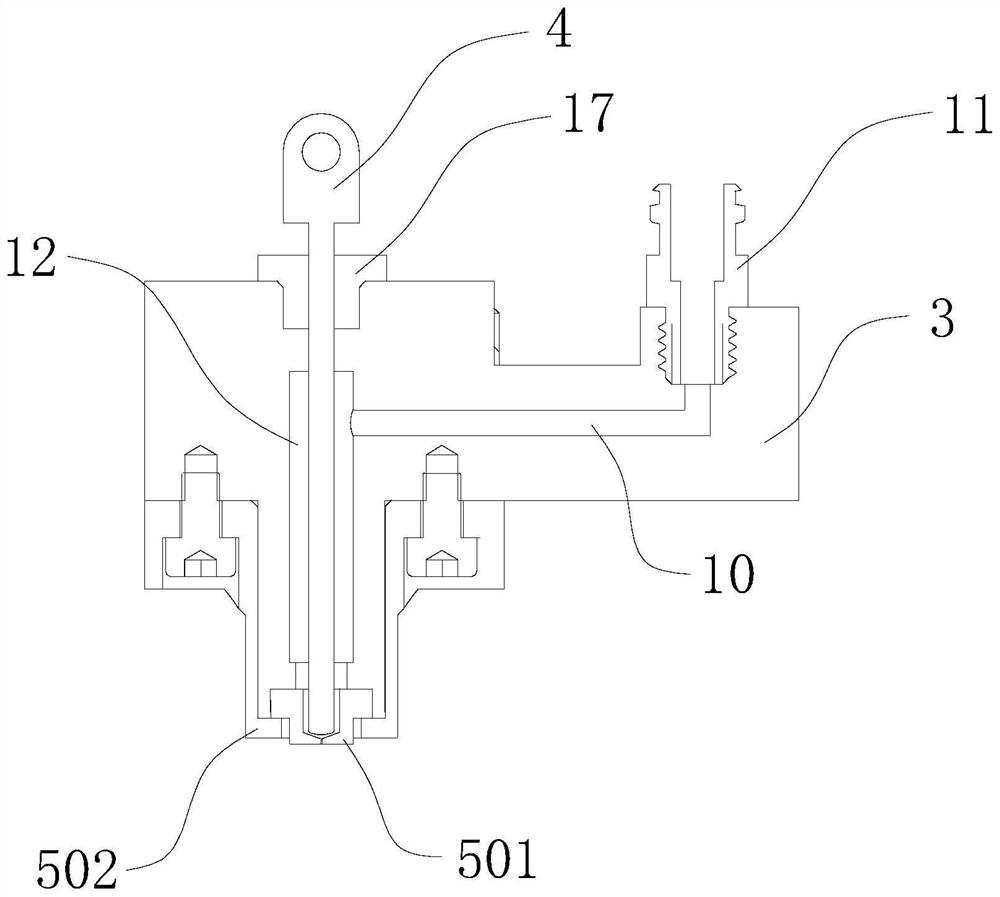

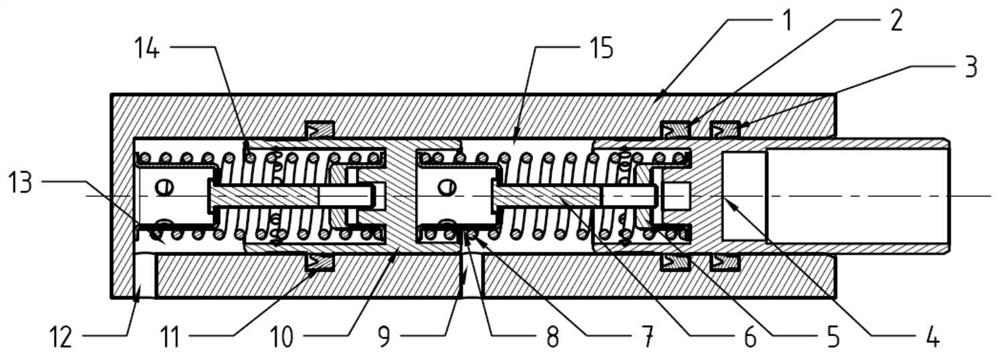

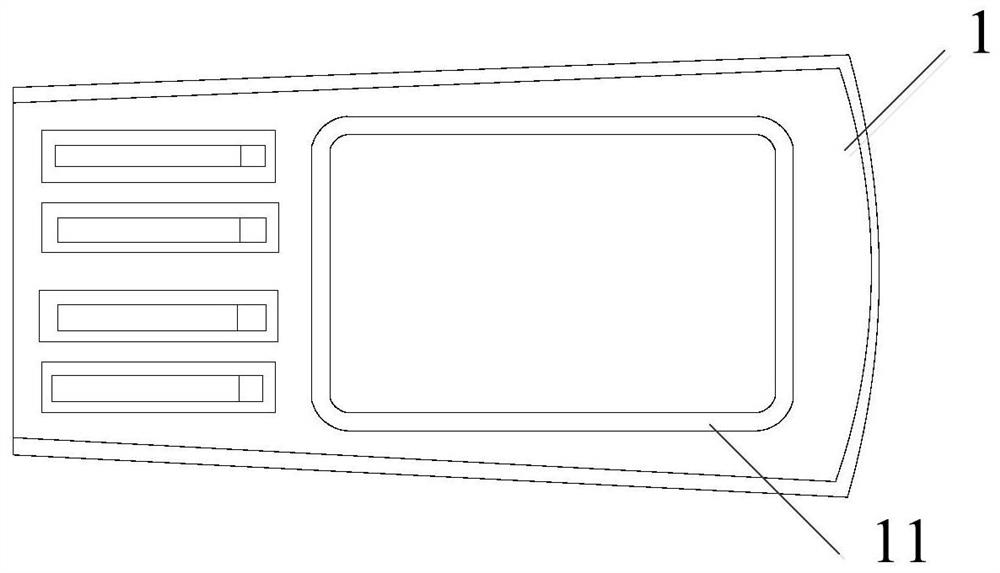

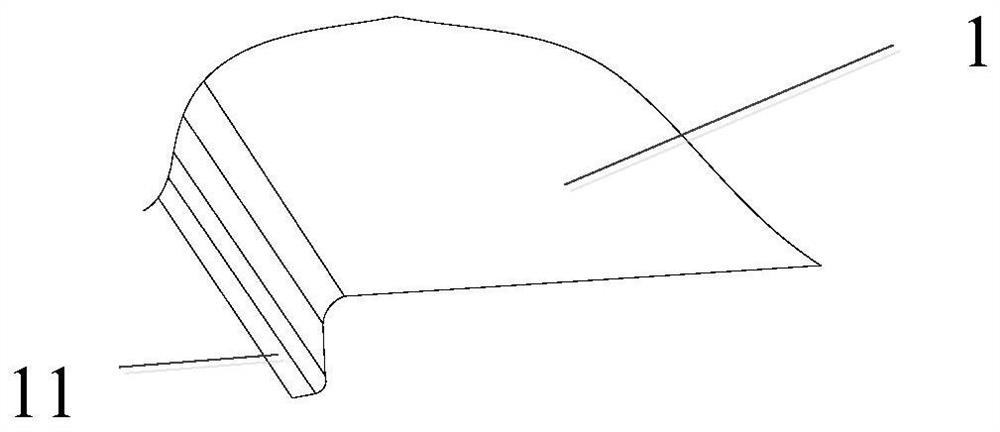

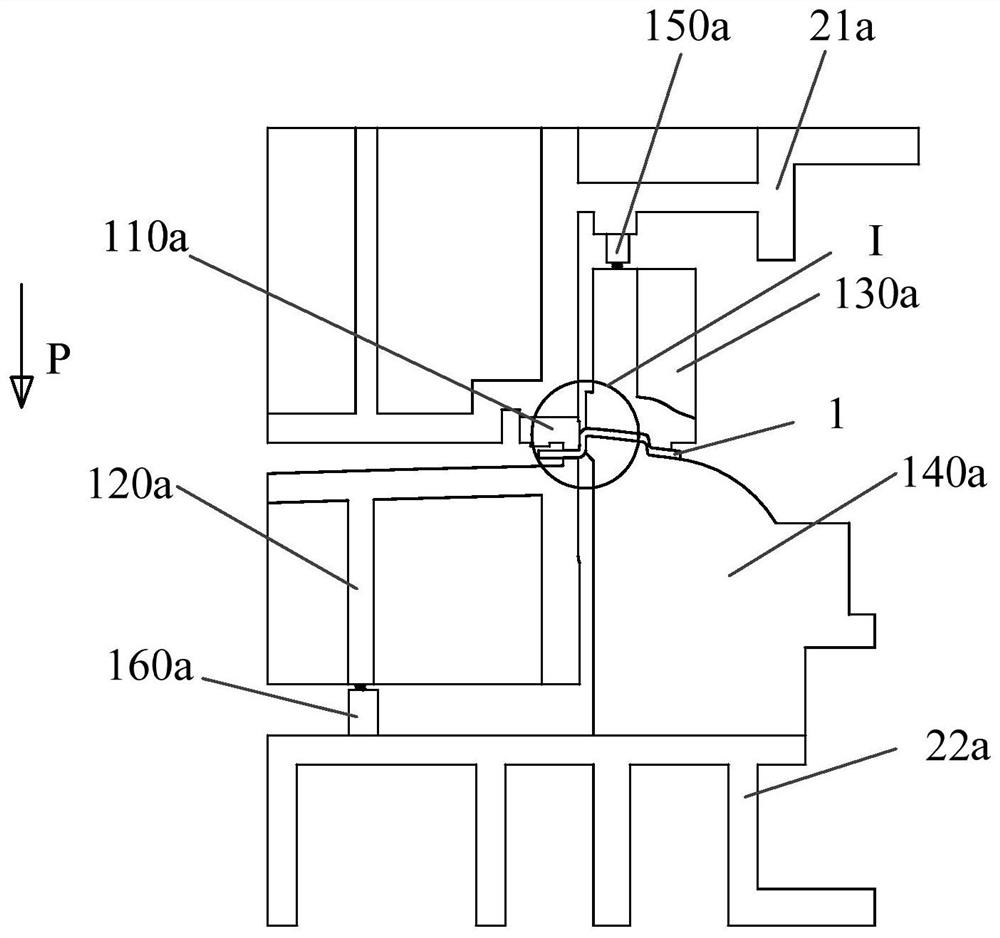

Out-of-cavity flow channel rapid dismounting type piezoelectric injection device and injection method

PendingCN111940235AImprove work performance consistencyQuick disassembly and replacementLiquid surface applicatorsCoatingsStructural engineeringMechanical engineering

The invention discloses an out-of-cavity flow channel rapid dismounting type piezoelectric injection device and an injection method. The device comprises a cavity, a fixed seat, a fluid seat, a piezoelectric driving mechanism, an impact mechanism, an injection mechanism and a displacement sensor. The cavity is detachably fixed on the fixed seat, the fluid seat is detachably connected with the fixed seat, a flow channel is arranged in the fluid seat. The flow channel is connected with the injection mechanism through a pipeline, the piezoelectric driving mechanism comprises a piezoelectric driver and a lever, the piezoelectric driver is arranged in the cavity and perpendicularly arranged at one end of the lever, the other end of the lever extends out of the cavity from the interior of the cavity and is detachably connected with the impact mechanism, and the displacement sensor is arranged in the cavity and located above the lever. The impact mechanism extends into the fluid seat from theoutside of the fluid seat, the impact direction of the impact mechanism is the direction of the injection mechanism, and the impact mechanism can move up and down along the pipeline. According to thedevice, the flow channel can be quickly dismounted and replaced, glue is prevented from overflowing into the cavity, and the impact mechanism does not need to be corrected after dismounting and maintenance.

Owner:DONGGUAN UNIV OF TECH

Special stack mold injection molding machine for template opposite-opening mold moving middle injection

The invention discloses a special stack mold injection molding machine for template opposite-opening mold moving middle injection. The special stack mold injection molding machine comprises a rack (1) and a mold (8) and further comprises a pressurizing oil cylinder set, a pressurizing template (3), a band-type brake template (5), a band-type brake mechanism (6), a mold moving oil cylinder (7), a mold base (9) and an injection mechanism (11). A pressurizing oil cylinder (2) achieves mold locking through the band-type brake mechanism (6). The mold moving oil cylinder (7) drives the pressurizing template (3) and the band-type brake template (5) to do the linear mold opening and closing movement on the rack (1), and a mold moving synchronous mechanism (10) is arranged between the pressurizing template (3) and the band-type brake template (5). The pressurizing template (3) and the band-type brake template (5) synchronously act through the mold moving synchronous mechanism (10). The special stack mold injection molding machine has the beneficial effects that material leakage risks happening during mold opening are avoided, an equipment structure is simplified, the equipment reliability is improved, and the equipment running stable degree is improved.

Owner:CHENGDU LIANYU PRECISION MACHINERY

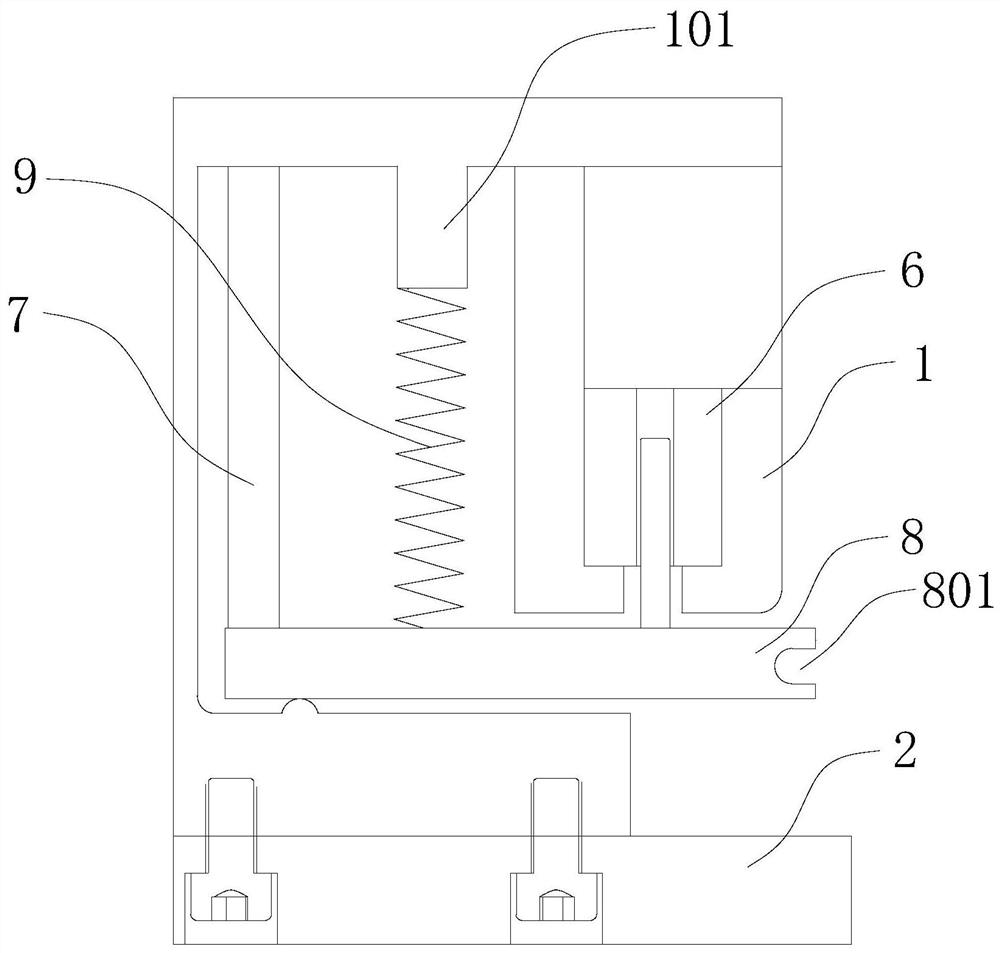

Tandem type brake master cylinder with adjustable pre-tightening force for electric control brake system

InactiveCN114537349ASame itineraryTravel impactBraking action transmissionDriver/operatorWheel cylinder

The pre-tightening force adjustable tandem type brake master cylinder comprises a shell, a first-stage piston and a second-stage piston are arranged in the shell, the first-stage piston and the second-stage piston are arranged in parallel, a first-stage spring and a second-stage spring are installed at the front end of the first-stage piston and the front end of the second-stage piston respectively, and the first-stage spring and the second-stage spring are arranged in parallel. The first-stage piston is sealed by the first sealing ring and the second sealing ring, a pedal feeling is simulated through the pedal simulator, and the electric master cylinder conducts braking action. When the electric master cylinder breaks down, when a driver steps on a pedal, the first-stage piston and the second-stage piston start to move, and liquid in a first cavity composed of the shell, the first-stage piston and the second-stage piston and liquid in a second cavity composed of the shell and the second-stage piston flow to the wheel cylinder through a liquid outlet and a liquid outlet for braking. And the springs connected with the two pistons have the same structure, so that the production is convenient, the occupied volume is small, and the cost increase caused by different adjustment structures of vehicle types is avoided.

Owner:BEIJING YINGCHUANG HUIZHI TECH

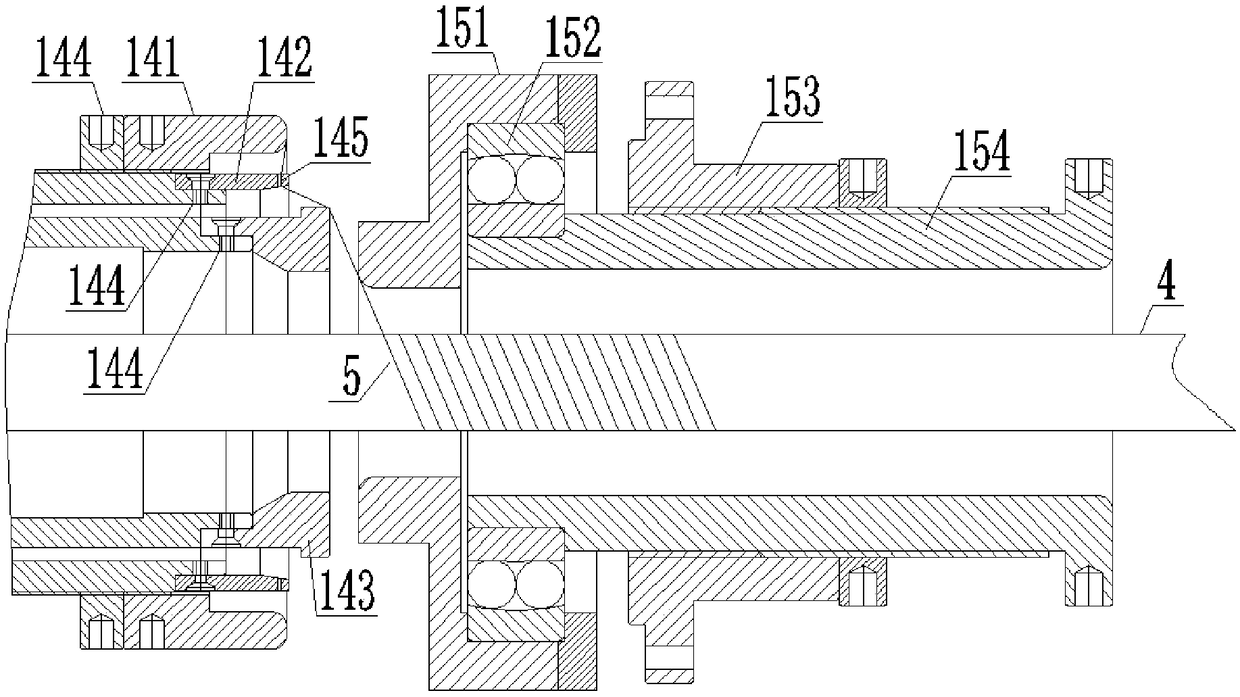

Continuous composite stamping die

InactiveCN103600011ARealize continuous stamping and formingShort tripPinsNailsPunchingStamping process

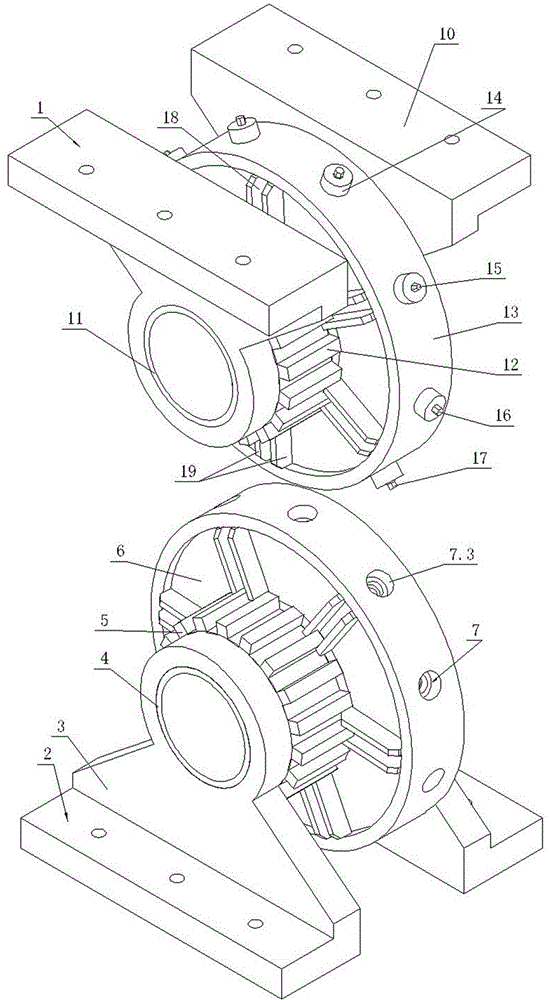

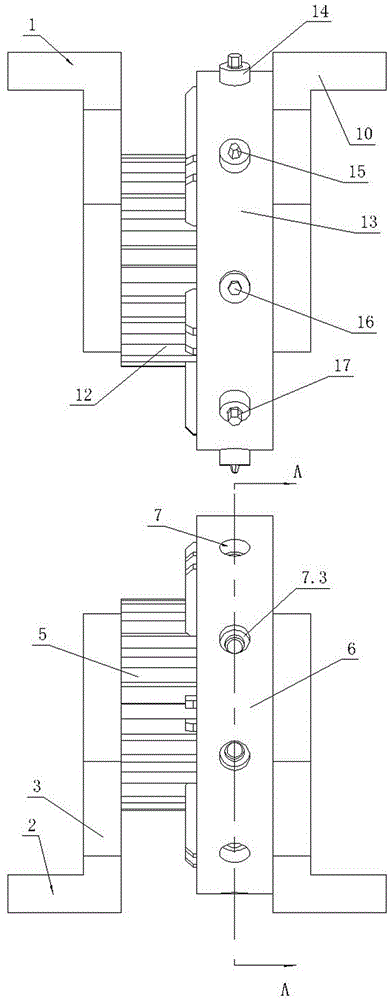

The invention discloses a continuous composite stamping die. The continuous composite stamping die comprises an upper die (1) and a lower die (2). Two ends of a lower spindle (4) are fixed with two lower supports (3) respectively, a lower transmission gear (5) and a lower rotation disc (6) are rotatably sleeved on the lower spindle (4), a plurality of radial through holes (7) are formed in the lower rotation disc (6), and a nozzle is arranged on the lower die (2). Two ends of an upper spindle (11) of the upper die (1) are fixed with two upper supports (7) respectively, and an upper transmission gear (12) and an upper rotation disc (13) are limited circumferentially and are ratatably sleeved on the upper spindle (11). Three stamping columns (14) are arranged on the upper rotation disc (13), and a hexagonal hole stamping punch (15), a hexagonal hole expansion punch (16) and a chamfering punch (17) are arranged successively on the three stamping columns (14). By means of the stamping die, the punching process is fast in speed, high in efficiency, safe and convenient.

Owner:广东顺德慎业丰五金电器有限公司

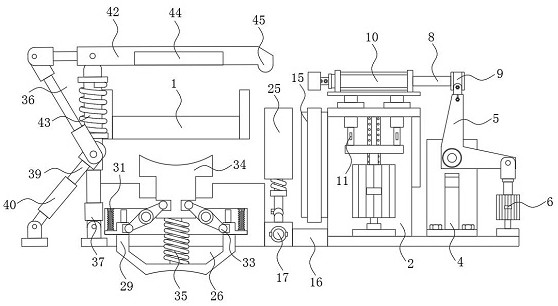

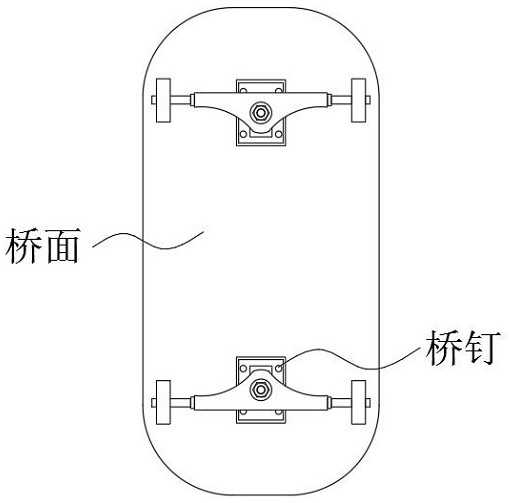

Board production equipment with height calibration function for bridge nail positioning and mounting

InactiveCN113290358AAvoid damageReduce detection lifeMeasurement devicesMetal working apparatusStructural engineeringMechanical engineering

The invention discloses board production equipment with a height calibration function for bridge nail positioning and mounting, and relates to the technical field of special-shaped component processing and detection. The equipment particularly relates to a first conveying belt, an intermittent feeding mechanism, an integrated mounting mechanism, a positioning and fixing mechanism and a horizontal calibration mechanism, and the intermittent feeding mechanism is arranged on one side of the bottom end of the first conveying belt. According to the board production equipment with the height calibration function for bridge nail positioning and mounting, the horizontal calibration mechanism is arranged, and a driving component drives a sliding sleeve through a first connecting rod, so that the sliding sleeve longitudinally slides at the surface end of a pen handle; on one hand, the pen handle rotates around a bottom end connecting pin to be close to the side end face of a to-be-detected board component, and on the other hand, a second connecting rod drives a telescopic pressing rod to rotate for locking; and the telescopic pressing rod is connected with the pen handle through a spring to form an elastic structure, so that the damage to a to-be-detected material or the reduction of the detection service life of a horizontal calibrator caused by overlarge extrusion force can be avoided, and the applicability is high.

Owner:东莞市鸿安自动化科技有限公司

stamping die

InactiveCN103599986BShort tripPut an end to the safety hazard of smashing and injuring people's handsShaping toolsNutsImpellerPunching

Owner:XINGHUA TIEXIN ELECTRONICS ENG

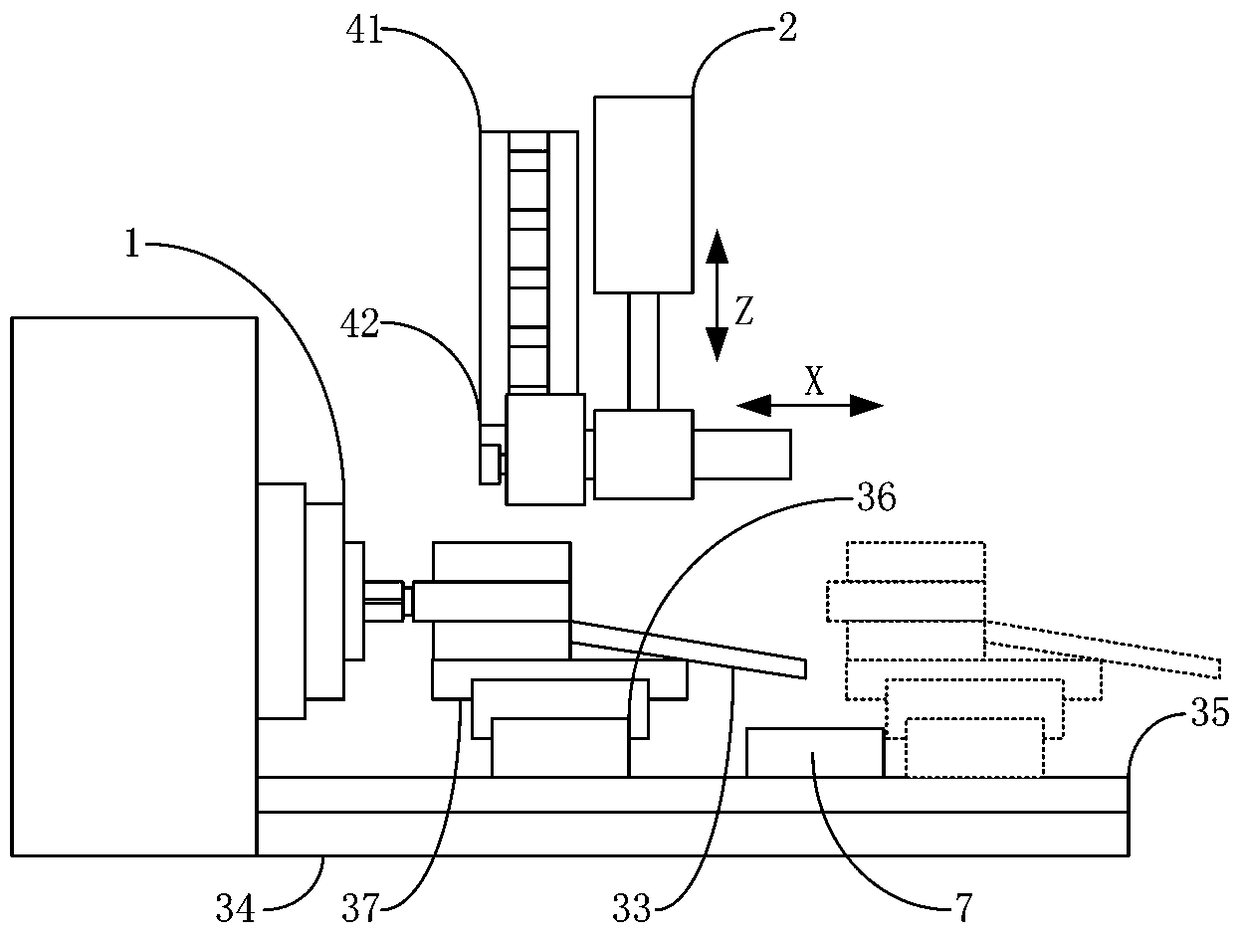

Automatic production equipment of round head pin

PendingCN108971523ARealize automated productionIncrease productivityAutomatic workpiece supply/removalTurning machinesEngineeringMechanical engineering

The invention discloses automatic production equipment of a round head pin. The equipment comprises a fixed rotating unit, an automatic feeding unit and a turning unit; the fixed rotating unit is usedfor reinforcing the round head pin to realize turning and rotating driving, and material claws of the automatic feeding unit at least comprise X-axis displacement and Z-axis displacement; and the turning unit comprises a first turning part, a second turning part and a discharging guide rail, wherein the first turning part is used for rough turning, the second turning part is used for finishing turning, the discharging guide rail is used for guiding out a turning finished product, and the first turning part, the second turning part and the round head pin are located on the same horizontal plane. According to the automatic production equipment of the round head pin, automatic production of the round head pins can be realized, and the production efficiency is high. Automatic feeding is realized by the cooperation of the two-shaft material claws and a feeding drawer, the discharging and turning parts are integrated, the automatic feeding and automatic discharging are reasonably allocated,the equipment design is ingenious, and the equipment cost is reduced. The turning unit is provided with two turning stations of the rough turning and the finish turning, the stroke of the two turningstations is consistent, the control is easy to realize, and the forming and machining precision is high.

Owner:斯塔比奥紧固件(昆山)有限公司

Stop device of bending machine

InactiveCN104475604ASimple structureGuaranteed accuracyMetal-working feeding devicesPositioning devicesEngineeringStops device

The invention relates to the technical field of stop devices, particularly to a stop device of a bending machine. The stop device comprises a base plate and a vertical plate perpendicular to the base plate. Each of lateral ends of the base plate is provided with a mounting hole. Fastening screws are arranged in the mounting holes and allow the same to be fixedly connected with stroke rods. The bottoms of the stroke rods are provided with slide blocks respectively. The slide blocks slide on a slide rail. According to the arrangement, stokes of the stroke rods are electrically controlled and consistent.

Owner:马宁

stamping die

InactiveCN103480732BShort tripPut an end to the safety hazard of smashing and injuring people's handsShaping toolsNutsPunchingGear wheel

The invention discloses a punching die, which comprises a punch (1) and a die shell (2), wherein the die shell (2) comprises two supports (3), a rotating shaft (4), a shifting gear and a rotating barrel (6), the two ends of the rotating shaft (4) are fixed with the two supports (3), the shifting gear and the rotating shaft (4) are registered, a ratchet gear is arranged between the shifting gear and the rotating shaft (4), the rotating barrel (6) is rotatably registered on the rotating shaft (4), a plurality of radial through holes (7) are formed in the rotating barrel (6), the outer openings of the radial through holes (7) are arrayed in the outer circumferential surface of the rotating barrel (6) in rows along the axial direction, the punch (1) is provided with a plurality of rams (8), all of the row of rams (8) are over against the row of radial through holes (7) on the highest position of the rotating barrel (6), and the rotating shaft (4) is also provided with a device for releasing a punching forming screw (10) from the radial through holes (7) in an ejecting manner. The punching die enables the speed of a punching process to be high, the efficiency is high, and safety and convenience are realized.

Owner:TAIZHOU XINGYU SPORTS TACKLE

Automobile glass lifting switch

The invention aims to provide an automobile glass lifting switch. The automobile glass lifting switch is good in compatibility and capable of being applicable to automobiles with various gears so that the cost for developing automobile glass lifting switches by automobile enterprises can be reduced. The automobile glass lifting switch comprises a base, a shell connected with the base, a circuit board installed on the base, a swing button arranged on the shell and a pair of ejector rods arranged below the two sides of the swing button and is characterized in that an input terminal and an output terminal are arranged on the circuit board and are connected through four branch circuits which are connected in parallel, each branch circuit is provided with a touch switch, and the values of resistance of the branch circuits are different; the four touch switches are divided into two groups, and each group of touch switches are located below the ejector rod on the corresponding side; when each ejector rod is pressed down under the action of the swing button, the corresponding two touch switches below the ejector rod are triggered simultaneously or sequentially.

Owner:CHERY AUTOMOBILE CO LTD

Blind flanging dies and presses

The invention discloses a pressing and flanging die, which relates to the field of mechanical processing. The pressing and flanging die comprises a flanging knife block, a lower supporting core, an upper pressing core, a punch, a first elastic component, a second elastic component and Stroke difference elimination device. After the flanging is completed, the flange is on the lower support core, and both the first elastic component and the second elastic component are in a compressed state. During the return process of the flanging knife block, the upper die seat drives the flanging knife block to rise. Under the elastic action of the second elastic component, the lower support core rises along with the flanging knife block. The first jacking block and the second jacking block are configured to abut during the return process of the flanging knife block. In order to transmit the lifting force of the lower support core to the upper support core through the first top block and the second top block, so that the upper support core and the lower support core move together along the return direction of the flanging knife block, and then the upper pressure core It moves synchronously with the bottom support core during the return process, and the stroke is consistent, so as to avoid flange deformation and improve the yield rate.

Owner:CHERY AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com