Stirring-sucking dredging robot suitable for multiple working conditions

A robotic and multi-working-condition technology, applied to mechanically driven excavators/dredgers, earth movers/shovelers, construction, etc., can solve the problems of low dredging efficiency and inability to adapt to dredging work, and achieve The video observation is stable, the convenience is improved, and it is not easy to block the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

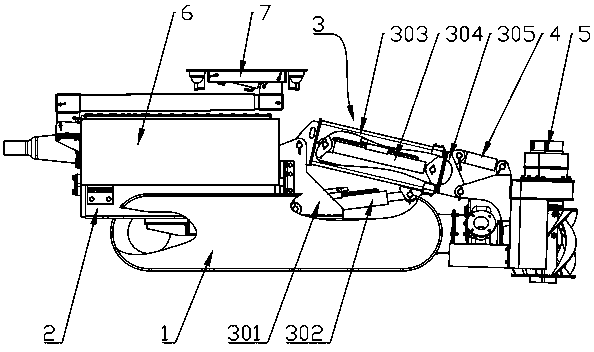

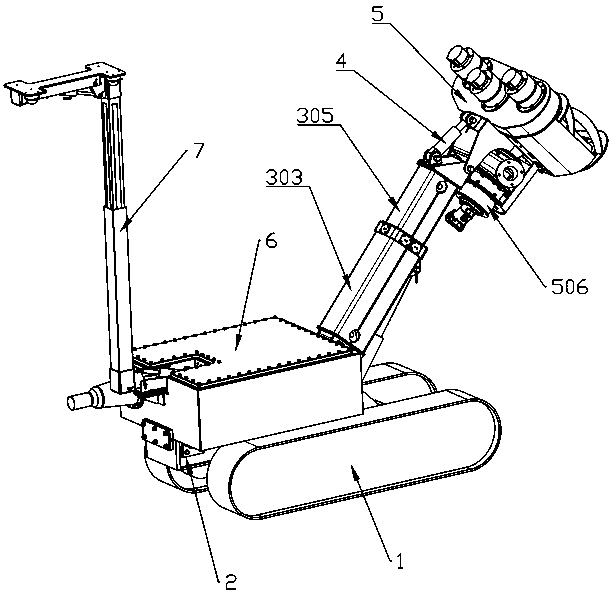

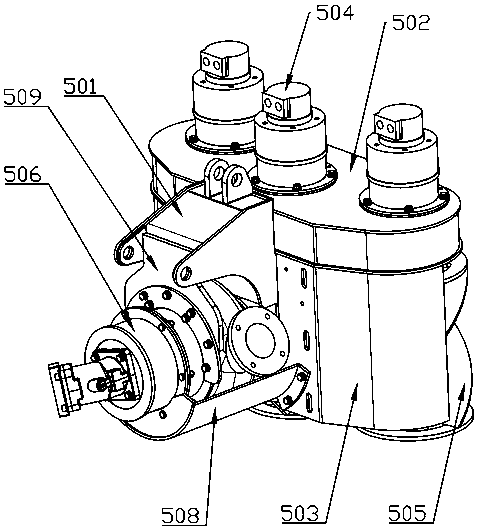

[0029] Such as figure 1 — Image 6 As shown, a stirring suction dredging robot suitable for multiple working conditions in this embodiment includes a crawler walking mechanism 1, a lifting mechanism 3 and a dredging actuator 5 are installed on the front of the crawler walking mechanism 1, and the crawler belt The rear part of the walking mechanism 1 is provided with a counterweight module 2 and a sealed box body 6. The sealed box body 6 is provided with hydraulic components, electric control components and signal feedback devices, and a video acquisition device 7 is installed above the sealed box body 6. .

[0030] The lifting mechanism 3 includes a boom se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com